Abstract

Rafoxanide (RAF) is a poorly water-soluble drug that forms a complex with povidone K25 (PVP) in a cosolvent system containing acetone and an alkaline aqueous medium. This study aims to investigate the impact of RAF-PVP complexation on in vitro and in vivo release of RAF. We prepared two RAF amorphous solid dispersions (ASDs) spray-dried from these two cosolvents. The first is a complexation-based spray-drying using a 70% 0.1 N NaOH solution with 30% acetone. The second is a traditional spray-dried formulation containing 80% acetone and 20% ethanol. Evidence from multiple solid-state characterization techniques indicated that ASDs spray-dried using both methods were amorphous. However, RAF ASDs based on drug–polymer complexation in the feed solution demonstrated not only faster drug release during dissolution testing but also higher in vivo absorption in an animal model. The improved RAF release in the complexation-based ASD is due to (1) high energy state of RAF owing to the amorphous form, (2) high pH in the microenvironment due to the ionized state of RAF and residual sodium hydroxide, (3) increased apparent solubility of RAF results from RAF–PVP complexation in dissolution media and biological media, and (4) improved wettability.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Rafoxanide (RAF) is a salicylamide derivative used for veterinary parasite control. [1] It is poorly water-soluble weak acid with a pKa of 4.6. Its solubility in water is less than 0.1 μg/mL, and this solubility only increases to 11 μg/mL in a 0.1 N NaOH aqueous solution. Oral absorption of RAF is limited by its poor aqueous solubility.

Several formulation strategies have been reported to improve the aqueous solubility of RAF. [2] Shoa’a [3] invented injectable formulation containing RAF and a nonionic surfactant, and a micellar solution demonstrated improved RAF absorption. Lo et al. [4] reported that RAF forms a water-soluble complex with PVP in a cosolvent consisting of a NaOH aqueous solution and water-miscible organic solvents (e.g., acetone). The complex is formed in situ and remains in aqueous solution even after the removal of the organic solvent.

Because of its complexation with PVP, RAF in aqueous 0.1 N NaOH solution in water can reach a concentration of 75 mg/mL. This is nearly equivalent to a 7000-fold increase in solubility. This study aims to utilize this RAF–PVP complexation to develop a solid dosage form of RAF with improved oral bioavailability.

In the 1980s, Plaizier-Vercammen investigated the complexation of PVP with several aromatic compounds (e.g., salicylamide derivatives in various solvent systems). [5,6,7,8] As a salicylamide derivative, RAF has unique properties due to its long hydrophobic rigion that contains two ether-linked benzene rings. Due to this hydrophobic rigion, RAF was found to be surface active and was found to aggregate into micelles in an aqueous environment. [9]

Due to this self-association of RAF, we expect the complexation of RAF and PVP to be of a greater complexity. Our previous study characterized RAF–PVP complexation in different cosolvents. [10] It was found that RAF interacts with PVP in a mixture of 70% 0.1 N NaOH and 30% acetone, but it does not interact in a mixture of 80% acetone and 20% ethanol. This difference is due to the polarity of the solvent and the ionization state of RAF. In a 70% 0.1 N NaOH and 30% acetone mixture, we observed both the hydrophobic interaction (π–π stacking) between RAF molecules and the hydrophilic interaction (hydrogen bonding) between RAF and PVP. This hydrophobic interaction existed only in polar environments where RAF was ionized. Hence, we propose to spray dry concentrated RAF solutions, in which RAF–PVP complexation occurs in situ, to prepare an RAF amorphous solid dispersion (ASD).

ASDs have been widely employed technique in the pharmaceutical industry to improve the oral bioavailability of BCS Class II and Class IV compounds by improving their kinetic aqueous solubility. [11] In ASDs, the hydrophobic active pharmaceutical ingredient (API) is converted into a high-energy amorphous state and dispersed at the molecular level in polymeric matrix. [12] The polymer inhibits drug crystallization through weak physical interactions such as hydrogen bonds [13], van der Waals forces [14], and hydrophobic interactions. [15] This results in a physically stable (low risk of phase separation) system with sustained supersaturation. Because these interactions very weak, they can be detected only in the solid state.

In our previous study, we demonstrated a model system with strong drug–polymer complexation in solution state, which is often ignored in ASD systems. This manuscript mainly investigates the impact of solution state interaction on ASD prepared by spray-drying process.

In the spray-drying process, the feed solution containing the drug and polymer is atomized into fine droplets and sprayed along with a hot gas stream. As the solvent evaporates, the atomized droplets convert into a fine powder. [16] The choice of solvent for the feed solution preparation is critical in the spray-drying process.

Paudel and van den Mooter [17] reported that the solvent composition of the feed solution significantly affects the miscibility of spray-dried ASDs. They also found that ASDs prepared from solvent–antisolvent mixtures (a dichloromethane–acetone cosolvent) showed better miscibility than those prepared from mixtures of “good” solvents (a methanol–acetone cosolvent). Their explanation for this phenomenon was that the antisolvent has a favorable impact on the solubility of the drug in the polymer, and this increased solubility enables the drug molecules to reach the nearest interacting groups of the polymer in the right conformation. Similarly, Janssens et al. [18] showed that the use of various solvent mixtures affects the phase behavior of solid dispersions. However, the effect of solvent selection on the properties of ASDs has not been studied from the perspective of molecular interaction.

This study, for the first time, takes advantage of drug-polymer complexation in solution state to prepare ASD using spray-drying process. This study also compares the solid-state properties, in vitro dissolution, and in vivo absorption of both complexation-based ASDs and traditional ASDs. The outcomes of this study will help (a) explore complexation-based spray-drying process for preparation of ASD, (b) understand how molecular interactions in both solid-state and aqueous media affect the drug release of ASDs, and (c) understand the effect of feed solution solvent selection on the properties of ASDs.

In this study, rafoxanide (RAF) is the model compound and povidone K25 (PVP) serves as the polymer. Figure 1 shows the chemical structure of RAF and PVP, and Table 1 presents the physicochemical properties of RAF.

Materials and methods

Rafoxanide was purchased from ShenZhen Nexconn Pharmatechs Ltd. (ShenZhen, China). Kollidon® VA64 and Kollidon® 25 N.F. were kindly donated by the BASF Chemical Company (Florham Park, NJ, USA). HPLC–grade acetonitrile was purchased from Fisher Scientific (Pittsburgh, PA, USA). All other chemicals used in this study were ACS grade or higher.

Methods

Rafoxanide solubility as a function of PVP concentration

The thermodynamic equilibrium solubility of RAF was determined at ambient conditions (25 °C). Excess amount of RAF was added to vials that contained 10 mL of 0.1 N NaOH aqueous solution and various PVP concentrations (0%, 1%, 2%, 5%, and 10%). After constant mixing using a magnetic stir bar for 48 h with a stirring rate of 100 rpm, the solutions were centrifuged at 1400 G using a Microfuge 18 Centrifuge (Beckman Coulter, Brea, CA, USA) for 10 min. The supernatant was used either as is or diluted using acetonitrile before HPLC analysis. The crystalline form of the undissolved RAF was determined using X-ray powder diffraction (XRPD) to exclude the impact of potential crystalline form change on solubility.

Isothermal titration calorimetry

Isothermal titration calorimetry (ITC) was performed using a Nano ITC (TA Instruments, New Castle, DE, USA). The reaction cell (V = 1.34 mL) was filled with 20 mg/mL PVP solution in the specified cosolvent. The syringe (250 µL) was loaded with 50 mg/mL RAF solution in the same cosolvent. The two solutions were mixed by injecting 10-µl aliquots into the reaction cell at 25 °C. The injection-stirrer syringe was rotated at a constant speed (250 rpm) throughout the experiment. Data from the injection of 50 mg/mL RAF solution into pure cosolvent were acquired as reference.

Spray-drying conditions

Spray drying was performed using a Buchi mini B290 spray dryer coupled with an inert loop B-295 (Buchi, Flawil, Switzerland). ASDs were spray dried using two different feed solutions: (a) a solution consisting of 70% 0.1 N NaOH and 30% acetone (i.e., complexation-based spray drying) and (b) a solution consisting of 80% acetone and 20% ethanol (i.e., traditional spray drying). For both spray-drying processes, the total solid content of the feed solutions was 8% w/v, and the ratio of RAF to PVP was 1:1, 1:2, and 1:3 w/w. Due to the difference in boiling points between the two cosolvents, different processing parameters were used for the two spray-drying processes.

For complexation-based spray drying, the feed solution was processed at a spray rate of 0.3 kg/h with an inlet temperature of 102 °C to maintain a 78 °C outlet temperature. The atomization rate and the drying gas rate were set at 0.5 kg/h and 20 kg/h, respectively. The condenser temperature was set at 5 °C.

For traditional spray drying, the feed solution was processed at a spray rate of 0.4 kg/h with an inlet temperature of 76 °C to maintain a 45 °C outlet temperature. The atomization rate and the drying gas rate were set at 0.5 kg/h and 17 kg/h, respectively. The condenser temperature was set at − 5 °C.

These processing parameters were designed to maintain a heat-to-mass transfer ratio of 1.2 for both processes to minimize the effect of processing factors. After spray drying, the ASDs underwent secondary drying in a vacuum oven overnight at 30 in. Hg and 40 °C to remove residual solvent.

Contact angle of spray-dried formulations

The contact angle of compacted spray-dried tablet was measured with the sessile drop technique using a Drop Shape Analyzer instrument (FTA 1000, First Ten Angstrom, Virginia, USA). Compacts with a diameter of 12 mm and a mass of 500 mg were prepared using a Rimek mini PRESS-IISF (Karnavati Engineering, India). The compression force was 1000 N for 5 s. Water was dispensed from a syringe in predefined volumes onto the sample surface; then, video images were captured using an FTA image analyzer. This instrument calculated the contact angle by fitting a mathematical model to the shape of the drop, followed by calculating the slope of the tangent to the drop at the liquid–solid–vapor interface line. All measurements were performed under ambient conditions and in triplicate.

Differential scanning calorimetry

Differential scanning calorimetry (DSC) (Model DSC Q20, TA Instruments, New Castle, DE, USA) was used to investigate the thermal properties of the API and the formulations. The instrument was operated under a dry nitrogen purge (50 mL/min) with an RCS40 (TA Instruments, New Castle, DE, USA) refrigerated cooling system accessory. Before experiments were conducted, the instrument was calibrated using an indium standard. Samples of approximately 5 mg were weighted into standard DSC pans and crimped with a hermetic lid. The samples were heated from 25 to 200 °C with a temperature ramp of 10 °C/min. TA Universal Analysis 2000™ software was used for data analysis.

Non-sink dissolution testing

In vitro dissolution testing of RAF spray-dried ASDs was conducted using a USP dissolution apparatus II (Vankel dissolution apparatus, Model 7000, Palo Alto, CA, USA). A 50-mM phosphate buffer at pH 6.8 and 37 °C was used as the dissolution media. A 300-mg sample of spray-dried dispersion containing 75 mg rafoxanide was introduced into each vessel. The paddle speed was set at 50 rpm. About 1-ml dissolution samples at 5, 15, 30, 45, 60, 90, and 120 min were collected, and these samples were filtered through a 0.45-μm PTFE membrane filter. All dissolution testing was performed in triplicate, and all dissolution samples were analyzed using the HPLC method.

HPLC method for RAF concentration analysis

The concentration of RAF was determined using a reversed-phase HPLC method. Hypersil® Gold C18, 5 × 30 mm, 3 μm (Thermo Scientific, Waltham, MA, USA), was used for separation. A mixture of 85% water and 15% acetonitrile v/v containing 0.05% trifluoroacetic acid was used as the mobile phase. The injection volume was 10 μL, and the flow rate was set at 1.0 mL/min. A UV detector (Waters® 2998 PD detector, Milford, MA, USA) was used for quantification at 485 nm. The retention time of RAF was 4.5 min, and the quantitation limit of the instrument is 0.1 µg/mL.

Animal PK study

Animal experiments were performed in full compliance with related guidance, including UT Health Science Center guidelines in agreement with the Association for Assessment and Accreditation of Laboratory Animal Care (AAALAC), the Animal Welfare Act (AWA), and the Guide for the Care and Use of Laboratory Animals.

In vivo absorption was performed by oral administration of corn oil suspensions of ASDs to mice at 7.2 mg/kg (n = 4). Plasma samples were taken by cardiac puncture at the time points of 1, 2, 4, 8, 12, 24, and 48 h. Plasma samples were precipitated with ice-cold acetonitrile containing IS (internal standard) (i.e. Salicylanilide) and were vigorously vortexed for 2 min and sonicated on ice bath for 10 min. Samples were placed on ice for 5 min to allow RAF and IS transfer to the organic phase. Next, samples were centrifuged at 4 °C (20,000×g for 20 min). The supernatant was collected, followed by evaporation of organic solvent using air-dry evaporator. The samples were then reconstituted in the mobile phase (1:1 water: acetonitrile) and were analyzed using LC/MS. The data were analyzed for descriptive and inferential statistics using Prism 7 software (GraphPad). Results are presented as means ± s.d. (n = 4), except for Tmax (median values and range). A non-parametric test (Krushakal-Wallis test) was used to compare Tmax between groups, and analysis of one way ANOVA was used to test the differences in other parameters between the groups.

Results and discussion

This section is divided into four parts. First, we discuss the rationale of preparing RAF ASDs based on RAF–PVP complexation. Next, we discuss the spray-drying conditions for the preparation of RAF ASDs and the rationale of solvent selection. Then, we discuss the physical-state properties of RAF ASDs prepared under two different spray-drying conditions. Last, we discuss the in vitro dissolution and in vivo absorption of RAF ASDs prepared using two different spray-drying conditions.

Effect of solvent composition on RAF–PVP complexation

The chemical structure of RAF and its critical physicochemical properties are presented in Fig. 1 and Table 1, respectively. The drug substance RAF is a poorly water-soluble weak acid with a log D of 6.7 (pH 6.8). The aqueous solubility of RAF is less than 0.1 μg/mL at pH 7, and its solubility reaches only 11 μg/mL at pH 13 (in a 0.1 N NaOH solution). The low aqueous solubility of RAF is attributed mainly to three hydrophobic benzene rings and to intramolecular hydrogen bonding. [9]

Our previous study demonstrated that the presence of acetone significantly increases the apparent solubility of RAF. For example, an apparent solubility of 38,400 µg/mL can be reached in a solution consisting of 70% 0.1 N NaOH and 30% acetone. This occurs due to the self-association of RAF. [9] However, the micellar structure of RAF due to self-association decomposes after solvent removal; hence, it cannot be used to facilitate RAF release after oral administration.

Another study demonstrated that RAF interacts with PVP in a mixture of 70% 0.1 N NaOH and 30% acetone. [10] This complexation consists of both hydrophobic interactions (π–π stacking) between RAF molecules and hydrophilic interactions (hydrogen bonding) between RAF and PVP. This hydrophobic interaction exists only in polar environments where RAF is ionized. In other words, RAF does not interact with PVP in organic solvents (e.g., a mixture of 80% acetone and 20% ethanol).

However, RAF–PVP complexation in aqueous media is difficult to characterize due to the poor aqueous solubility of RAF. To understand the effect of aqueous media on RAF–PVP complexation, we investigated RAF–PVP complexation in mixtures of 0.1 N NaOH solution and acetone with four different 0.1 N NaOH solution concentrations (i.e., 60%, 70%, 80%, and 90%) using ITC.

ITC is an advanced technique used to detect the changes in enthalpy that result from the molecular interactions that occur during the titration of one ligand solution into another. ITC has been commonly applied to study a wide range of molecular interactions, including small polymer–polymer, molecule–protein, and drug–polymer interactions. [19,20,21,22] A complete set of thermodynamic parameters for these interactions, such as dissociation constants, enthalpy change, entropy change, and free energy change, can be derived from ITC experiments.

In this study, ITC could not detect RAF–PVP complexation in mixtures of 0.1 N NaOH solution and acetone containing 60% and 90% 0.1 N NaOH solution. In the mixture containing 60% 0.1 N NaOH, the signal was too weak due to weak interaction, while in the mixture with 90% 0.1 N NaOH, the signal was too weak due to low RAF solubility. Figure 2 presents the ITC thermogram of RAF–PVP complexation in the mixtures of 0.1 N NaOH solution and acetone with 70% and 80% 0.1 N NaOH solution. An average PVP molecular weight of 24,000 Da was used for the calculation.

It was concluded that the complexation in both mixtures was spontaneous, since the free energy change was negative. The dissociation constant (Kd) in the mixture of 70% NaOH solution and 30% acetone was determined to be 1.436 × 10−3 M, and the Kd in the mixture of 80% NaOH solution and 20% acetone was determined to be 2.1338 × 10−4 M. The lower value of Kd in the solvent mixture with a lower NaOH ratio indicates that the aqueous medium favors RAF–PVP complexation over acetone. Hence, we expected a stronger complexation in a 100% 0.1 N NaOH solution.

Contrary to this expectation, we observed a drastic increase in the apparent aqueous solubility of RAF in a 0.1 N NaOH solution in the presence of PVP. Figure 3 presents the apparent aqueous solubility of RAF in 0.1 N NaOH solutions (pH 13) at different PVP concentrations. The apparent solubility of RAF increased by 238-, 568-, 1,263-, and 2,019-fold in PVP concentrations of 1%, 2%, 5%, and 10%, respectively. However, no obvious change in RAF solubility can be observed in an aqueous PVP solution.

In the current study, we utilized the RAF–PVP complexation in the 0.1 N NaOH solution to prepare concentrated feed solutions in which RAF is ionized. This concentrated feed solution was then spray-dried to obtain an RAF ASD. We hypothesized that the high transient solubility of NaRAF was due to its amorphous form, and a high microenvironment pH facilitated RAF–PVP complexation in dissolution media. The complexation further improves the RAF dissolution rate and retains RAF supersaturation.

Spray-drying conditions for the preparation of ASDs

It should be noted that the stronger RAF–PVP complexation in solvent mixtures with lower acetone content does not necessarily result in a higher apparent solubility of RAF. The apparent solubility of RAF is also limited by intrinsic solubility of RAF. The solubilization of RAF based on RAF–PVP complexation is a slow process due to the low solubility of RAF. For example, it takes overnight to dissolve 2% RAF in 0.1 N NaOH in the presence of 6% PVP. Considering both the apparent solubility and solubilization rate of RAF, 30% acetone was added to prepare the concentrated feed solution.

In the current study, RAF ASDs were spray dried using the following two cosolvents: (1) 70% 0.1 N NaOH solution and 30% acetone (complexation-based spray drying) and (2) 80% acetone and 20% ethanol (traditional spray drying). RAF and PVP were spray-dried at various weight ratios (1:1, 1:2, and 1:3). The solid content of the feed solution was 8% w/v, and the RAF-to-PVP ratio was 1:3 w/w. A heat-to-mass transfer ratio of 1.2 was controlled for in both formulations to minimize effect of processing factors. Please refer to “Methods” for detailed information on the feed solution preparation and spray-drying conditions.

Physical state characterization of RAF ASDs

Thermal behavior of RAF ASDs

The thermal behavior of RAF ASDs was characterized using DSC. We could not prepare amorphous RAF due to its high crystallization tendency. As shown in Fig. 4, spray-dried RAF showed a melting peak at 166.8 °C, indicating its crystalline nature. However, all spray-dried RAF ASDs were amorphous, indicating high miscibility between RAF and PVP. The amorphous form of RAF in ASDs was confirmed using X-ray diffraction (XRD) and polarized microscopy (PLM). Please refer to the supplemental information for details. Traditional ASDs showed an increasing glass transition temperature (Tg) with increasing PVP concentration. In contrast, complexation-based ASDs showed a decreasing Tg with increasing PVP concentration. This is most likely due to difference in Tg between RAF free acid and RAF sodium salt (NaRAF). Namely, the Tg of RAF is lower than the Tg of PVP, while the Tg of NaRAF is higher than the Tg of PVP. This hypothesis is supported by the fact that the Tg of all RAF-PVP ASDs are lower than PVP and the Tg of all NaRAF-PVP ASDs are higher than PVP. Amorphous RAF cannot be prepared by spray-drying process due to its high crystallization tendency.

Solid-state interaction

Our previous study demonstrated that RAF interacts with PVP in a mixture of 70% 0.1 N NaOH and 30% acetone but not in a mixture of 70% acetone and 20% ethanol. In the mixture of 70% 0.1 N NaOH and 30% acetone, both hydrophobic interaction (π–π stacking) between RAF molecules and hydrophilic interaction (hydrogen bonds) between RAF and PVP were observed. [10] RAF–PVP complexation in the mixture of 70% 0.1 N NaOH and 30% acetone may lead to different interactions in the solid state, and this may further affect physical stability and dissolution behavior. In this study, solid-state NMR (ssNMR) was used to investigate RAF–PVP interaction after solvent removal.

ssNMR is a well-developed method for the characterization of drug–polymer interactions in ASD, due to its capability to demonstrate detailed information on the molecular structure, molecular dynamics, and domain morphology in both small-molecule and macromolecular systems. [23] Recently, 2D ssNMR has been developed as a more sensitive tool to probe interactions between amorphous materials and small molecules by measuring direct dipolar interactions, spin diffusion, and 1H spin–lattice (T1) relaxation times. [24].

For example, 2D 1H–1H heteronuclear correlation (HETCOR) experiments have conducted using strong magnetic fields to detect hydrogen bonding between a surfactant and nanoparticles of probucol, an enteric methacrylic acid–methyl methacrylate polymer. [25] This high-resolution experiment can detect the distance of interest between molecules in a range of 5–10 Å. [26] In this study, a 2D 13C–1H HETCOR experiment was conducted to investigate molecular interactions between RAF and PVP in spray-dried ASDs.

Figure 5 shows the 13C–1H HETCOR spectra of PVP, traditional RAF ASD, and complexation-based RAF ASD at the region of interest. In complexation-based RAF ASD (Fig. 5c), a cross-peak was observed between amide H in the RAF molecules (1H chemical shift at 10 ppm) and the carbonyl C in PVP (13C chemical shift at 176 ppm). This is strong evidence for the presence of hydrogen bonding between RAF and PVP in complexation-based ASDs. No cross-peak was observed for the traditional RAF ASD, indicating the absence of hydrogen bonding in traditional ASDs. No hydrophobic interaction was observed for both ASDs. This result was expected because the driving force of hydrophobic interaction is the increased system entropy due to free water molecules. [27] This driving force no longer exists after solvent removal.

Wettability of RAF ASDs

The contact angle of RAF ASDs at 1:3 w/w ratio was measured to investigate the difference in wettability between RAF ASDs prepared using two different spray-drying processes. During dissolution, higher wettability results in reduced particle aggregation and hence leads to increased surface area. [28] The influence of wettability on the dissolution rate of ASDs has been reported by Verma et al. [29] They reported that ASDs with higher wettability (Cilostazol ASDs) dissolves faster than other ASDs.

Contact angle measurement is widely used to determine material wettability. [29] The limits of the contact angle for a given material in contact with water are 0° for complete wetting and 180° for no wetting. In the current study, the contact angle was measured over a period of 1–5 s. Significant difference was observed between different groups (p ˂ 0.05). As shown in Table 2 the physical mixture, traditional ASD, and complexation-based ASD exhibited contact angles of 59.7°, 31.0°, and 19.7°, respectively. The contact angle for the complexation-based ASD was the smallest, which indicates that the in situ ionization of RAF improved the wettability of the ASD.

Physical stability of RAF ASDs

The physical stability of the RAF ASDs prepared using two different spray-drying process was investigated. For this purpose, each ASD were packaged in an induction-sealed HDPE bottle that was then placed in a stability chamber at 40 °C and 75% RH. Figure 6 presents the DSC thermograms of the stability samples. All the formulations were demonstrated to be in homogenous amorphous phase after one year of storage, indicating that all RAF ASDs remained physically stable during storage. The high physical stability of RAF ASDs also showed that PVP plays as an effective crystallization inhibitor for RAF. It should be noticed that the traditional RAF ASDs were physically stable over the 1-year period despite the fact that RAF does not interact with PVP in the formulation.

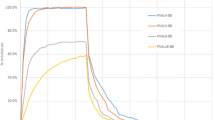

In vitro dissolution of RAF ASDs

Dissolution test under non-sink conditions is the most widely applied method to determine in vitro drug release kinetics in ASD systems [30, 31]. In this study, a 50-mM phosphate buffer at pH 6.8 was used as the dissolution medium. All ASDs were wetted well when introduced to the dissolution medium. The dissolution profiles of RAF ASDs are shown in Fig. 7. The dissolution of the API (RAF) and the physical mixtures was not presented, because the concentration was below the detection limit of the HPLC method (0.1 µg/mL) within the first hour. This concentration was undetectable due to the extremely poor aqueous solubility of crystalline RAF.

As shown in Fig. 7a, 100% drug release was achieved within 1 h for the complexation-based ASDs that had RAF-to-PVP weight ratios of 1:3 and 1:2. For these two ASDs, the dissolution samples remained supersaturated even after 24 h of storage at ambient conditions. At a 1:1 ratio, only 40% drug release was achieved within 2 h for the complexation-based ASDs.

In contrast, traditional ASDs (Fig. 7b) showed a much slower dissolution rate compared with complexation-based ASDs. ASDs with RAF-to-PVP weight ratios of 1:3, 1:2, and 1:1 achieved drug releases of only 31.2%, 17.1%, and 2.4%, respectively. The faster dissolution rate of complexation-based ASDs could be explained by (a) the preformed complex in the complexation-based ASD or (b) the high microenvironment pH created by RAF sodium salt.

To test the first hypothesis, an additional study (traditional spray drying II) was performed using RAF sodium salt instead of RAF free acid. A mixture of RAF sodium salt and PVP at a 1:3 weight ratio was dissolved in a mixture of 80% acetone and 20% ethanol. Then, this concentrated feed solution was spray-dried under the same conditions as in the traditional spray-drying process. In the ASD prepared using the traditional spray-drying II process, no preformed complexes were formed, and the RAF was ionized. As shown in Fig. 8, the RAF ASD prepared using traditional spray-drying II showed a dissolution profile similar to the ASD prepared using complexation-based spray drying. This result indicates that the faster dissolution rate of complexation-based RAF ASDs is due to the high microenvironment pH created by RAF sodium salt.

Furthermore, the feed solution complexation-based spray-drying process can be neutralized (from pH 13 to pH 7) without precipitation overnight using 0.1 HCl solution. It should be noted that the RAF remains in ionized state due to its pka (pka of RAF is 4.6). The dissolution profile of NaRAF ASD spray dried from the neutralized feed solution showed similar dissolution profile as compared with NaRAF ASD spray dried from complexation-based spray-drying process (Figure S3). This study also support that the high microenvironment pH created by RAF sodium salt plays a critical role in fast dissolution rate of NaRAF ASD.

In vivo absorption of RAF ASDs

A bioavailability study in mice was performed to compare the in vivo absorption kinetics of both complexation-based RAF ASDs and traditional RAF ASDs to RAF–PVP physical mixtures. Suspensions of the formulations in corn oil were administered to the mice at 7.2 mg/kg, and plasma samples were taken using cardiac puncture.

The results of the bioavailability study are shown in Fig. 9 and summarized in Table 3, where Cmax is the maximum observed concentration, Tmax is the time of occurrence of Cmax, and AUC is the area under the curve. After a single oral administration, RAF plasma concentrations were measurable up to 48-h post-dose in all test animals, indicating continuous systemic exposure to RAF over the entire blood-sampling period. The AUC (2866 μg h/mL) of complexation-based ASD showed significant difference (p ˂ 0.05) and was 1.3- and 3.7-fold greater than the AUC of traditional ASDs and the physical mixture, respectively. No significant difference in absorption rate was observed for complexation-based ASDs (Tmax = 15 h) compared with traditional ASDs (Tmax = 18 h) and the physical mixture (Tmax = 21 h). The Cmax (85.0 μg/mL) of complexation-based ASDs showed significantly difference (p ˂ 0.05) and was 1.3- and 3.7-fold greater as compared with the Cmax of the traditional ASDs and the physical mixture, respectively. The high Tmax for all RAF formulations is most likely due to adsorption of RAF on mucosal membranes and slow partitioning out of the mucosal tissues and into the systemic circulation [32]. Similarly, a Tmax of 50 h was reported for RAF oral formations in sheep [33]. The results of this study show that significant gains in bioavailability were achieved for both ASDs compared with the physical mixture, since the p < 0.05.

Conclusion

Drug–polymer complexation in solution state is often overlooked in traditional ASD. This is because solution state interactions are difficult to detect, for three reasons:(1) Solution state interactions in conventional ASD system are too weak to be detected (this is also solvent dependent), and (2) it is hard to achieve the detection limit of most techniques due to poor aqueous solubility of the drug (solution state interaction is detected by titrating ligand solution into drug solution). In the current study, we were able to detect RAF-PVP interaction in solution because (1) RAF forms strong interaction with PVP in the 0.1 N NaOH solution. (2) We used different levels of acetone during testing to aid solubilization RAF and observed a trend with decreasing acetone ratio. Taking advantage of RAF-PVP complexation in solution state, a novel RAF ASD based on RAF–PVP complexation was successfully developed. The complexation-based RAF ASD exhibited faster in vitro dissolution and higher in vivo absorption as compared with traditional RAF ASD. Complexation between RAF and PVP increased apparent solubility of RAF in alkaline media and hence allows for in situ salt formation. Four factors account for the fast release of RAF in complexation-based RAF ASD: (1) high energy state of RAF owing to the amorphous form, (2) high pH in the microenvironment due to the ionized state of RAF and residual sodium hydroxide, (3) increased apparent solubility of RAF results from RAF–PVP complexation in dissolution media and biological media, and (4) improved wettability. Even though no interaction was observed in traditional RAF ASD, it was as physically stable as complexation-based RAF ASD over 1-year period at 40 °C and 75% RH. This is because the low crystallization tendency of amorphous RAF. It should be noted that in ASD systems, especially where the drug is amphiphilic, the mucosal partitioning can be a rate-limiting factor that overrides solubilization efforts. This study also demonstrated that solvent selection of feed solution in spray-drying process can be critical to the performance of RAF ASDs.

References

El-Banna H, Goudah A, El-Zorba H, Abd-El-Rahman S. Comparative pharmacokinetics of ivermectin alone and a novel formulation of ivermectin and rafoxanide in calves and sheep. Parasitol Res. 2008;102(6):1337–42.

Bywater RJ, Dupe RJ. Veterinary compositions for the treatment of scours and dehydration. Google Patents: 1991.

Shoa'a AR. Veterinary compositions for the treatment of parasitic diseases. Google Patents: 2004.

Lo PKA, Williams JB. Solubilization of eafoxanide. Google Patents: 1978.

Plazier-Vercammen J, De Neve R. Interaction of Povidone with aromatic compounds I: evaluation of complex formation by factorial analysis. J Pharm Sci. 1980;69(12):1403–8.

Plaizier-Vercammen JA, De Nève RE. Interaction of povidone with aromatic compounds II: evaluation of ionic strength, buffer concentration, temperature, and pH by factorial analysis. J Pharm Sci. 1981;70(11):1252–6.

Plaizier-Vercammen JA, De Nève RE. Interaction of povidone with aromatic compounds III: thermodynamics of the binding equilibria and interaction forces in buffer solutions at varying pH values and varying dielectric constant. J Pharm Sci. 1982;71(5):552–6.

Plaizier-Vercammen JA. Interaction of povidone with aromatic compounds IV: effects of macromolecule molecular weight, solvent dielectric constant, and ligand solubility on complex formation. J Pharm Sci. 1983;72(9):1042–4.

Meng F, Liu T, Schneider E, Alzobaidi S, Gil M, Zhang F. Self-association of rafoxanide in aqueous media and its application in preparing amorphous solid dispersions. Mol Pharm. 2017;14(5):1790–9.

Meng F, Jing Z, Ferreira R, Ren P, Zhang F. Investigating the association mechanism between rafoxanide and povidone. Langmuir. 2018;34(46):13971–8.

Meng F, Gala U, Chauhan H. Classification of solid dispersions: correlation to (i) stability and solubility (ii) preparation and characterization techniques. Drug Dev Ind Pharm. 2015;41(9):1401–15.

Purohit HS, Taylor LS. Phase behavior of ritonavir amorphous solid dispersions during hydration and dissolution. Pharm Res. 2017;34(12):2842–61.

Frank DS, Matzger AJ. Probing the interplay between amorphous solid dispersion stability and polymer functionality. Mol Pharm. 2018;15(7):2714–20.

Nie H, Mo H, Zhang M, Song Y, Fang K, Taylor LS, Li T, Byrn SR. Investigating the interaction pattern and structural elements of a drug–polymer complex at the molecular level. Mol Pharm. 2015;12(7):2459–68.

Frank DS, Matzger AJ. Effect of polymer hydrophobicity on the stability of amorphous solid dispersions and supersaturated solutions of a hydrophobic pharmaceutical. Mol Pharm. 2019;16(2):682–8.

Paudel A, Worku ZA, Meeus J, Guns S, Van den Mooter G. Manufacturing of solid dispersions of poorly water soluble drugs by spray drying: formulation and process considerations. Int J Pharm. 2013;453(1):253–84.

Wu JX, Yang M, van den Berg F, Pajander J, Rades T, Rantanen J. Influence of solvent evaporation rate and formulation factors on solid dispersion physical stability. Eur J Pharm Sci. 2011;44(5):610–20.

Janssens S, Anné M, Rombaut P, Van den Mooter G. Spray drying from complex solvent systems broadens the applicability of Kollicoat IR as a carrier in the formulation of solid dispersions. Eur J Pharm Sci. 2009;37(3–4):241–8.

Termühlen F, Kuckling D, Schönhoff M. Isothermal titration calorimetry to probe the coil-to-globule transition of thermoresponsive polymers. J Phys Chem B. 2017;121(36):8611–8.

Pierce MM, Raman C, Nall BT. Isothermal titration calorimetry of protein–protein interactions. Methods. 1999;19(2):213–21.

Mealy JE, Rodell CB, Burdick JA. Sustained small molecule delivery from injectable hyaluronic acid hydrogels through host–guest mediated retention. Journal of Materials Chemistry B. 2015;3(40):8010–9.

Callies O, Daranas AH. Application of isothermal titration calorimetry as a tool to study natural product interactions. Natural product reports. 2016;33(7):881–904.

Schmidt-Rohr K, Spiess HW. Multidimensional solid-state NMR and polymers. Elsevier: 2012.

Pham TN, Watson SA, Edwards AJ, Chavda M, Clawson JS, Strohmeier M, Vogt FG. Analysis of amorphous solid dispersions using 2D solid-state NMR and 1H T 1 relaxation measurements. Mol Pharm. 2010;7(5):1667–91.

Io T, Fukami T, Yamamoto K, Suzuki T, Xu J, Tomono K, Ramamoorthy A. Homogeneous nanoparticles to enhance the efficiency of a hydrophobic drug, antihyperlipidemic probucol, characterized by solid-state NMR. Mol Pharm. 2009;7(1):299–305.

Lu X, Xu W, Hanada M, Jermain SV, Williams RO III, Su Y. Solid-state NMR analysis of crystalline and amorphous Indomethacin: An experimental protocol for full resonance assignments. J Pharm Biomed Anal. 2019;165:47–55.

Kozak JJ, Knight WS, Kauzmann W. Solute-solute interactions in aqueous solutions. J Chem Phys. 1968;48(2):675–90.

Craig DQ. The mechanisms of drug release from solid dispersions in water-soluble polymers. Int J Pharm. 2002;231(2):131–44.

Verma S, Rudraraju VS. Wetting kinetics: an alternative approach towards understanding the enhanced dissolution rate for amorphous solid dispersion of a poorly soluble drug. AAPS PharmSciTech. 2015;16(5):1079–90.

Sun DD, Wen H, Taylor LS. Non-sink dissolution conditions for predicting product quality and in vivo performance of supersaturating drug delivery systems. J Pharm Sci. 2016.

Fotaki N, Long CM, Tang K, Chokshi H. Dissolution of amorphous solid dispersions: theory and practice. In Amorphous Solid Dispersions: Springer; 2014. p. 487–514.

Bartlett JA, van der Voort Maarschalk K. Understanding the oral mucosal absorption and resulting clinical pharmacokinetics of asenapine. AAPS PharmSciTech. 2012;13(4):1110–5.

Swan G, Botha C, Taylor J, Mulders MS, Minnaar P, Kloeck A. Differences in the oral bioavailability of three rafoxanide formulations in sheep. J S Afr Vet Assoc. 1995;66(4):197–201.

Acknowledgments

We thank the University of Texas at Austin for the use of instruments in completing this project.

Funding

This project received financial support from the Hovione LLC.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Meng, F., Ferreira, R., Su, Y. et al. A novel amorphous solid dispersion based on drug–polymer complexation. Drug Deliv. and Transl. Res. 11, 2072–2084 (2021). https://doi.org/10.1007/s13346-020-00869-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13346-020-00869-3