Abstract

One isolate of Colletotrichum truncatum was found recently causing severe anthracnose symptoms and leading to the death of beggartick (Bidens pilosa L. and Bidens subalternans DC.), one of the major weeds of Brazilian agriculture. This isolate, namely UFU 280, was selected for development of a mycoherbicide against this weed. Associated of beggartick, one of the, Here, results of a preliminary attempt to develop a protocol for mass production of inoculum (conidia) and fungal biomass of C. truncatum was performed aimed at paving the way for greenhouse and field evaluations of this biocontrol candidate. Isolates of Colletotrichum spp. have been successfully produced in the past to serve as the active ingredients of mycoherbicides. The method of choice has been the production of propagules through liquid fermentation. We assessed the effect of several options of liquid media recipes, type of seeding of medium, pH levels, incubation lengths, incubation temperatures and agitation speeds on the shaking speed on the concentration of conidia obtained per volume of medium. Additionally, a possible effect of the kind of medium utilized over the virulence of the inoculum was also evaluated through an inoculation study. We found that an adequate amount of conidia of C. truncatum (isolate - UFU 280) can be obtained in ME liquid culture medium, adjusted to a pH of 9.0, seeded with a conidial suspension and incubated for 6 days, under a regime of orbital shaking of 150 rpm, at temperatures ranging from 20 to 25 °C. Mortality of beggartick plants using conidia produced in different liquid culture media was of 100%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Weeds are major limiting factors for agricultural productivity worldwide. They compete with crops for water, light, and mineral nutrients from the soil, interfere with harvesting, contaminate and increase the moisture content of the harvested product, which reduces the quality of the final product. In addition, weeds can serve as alternative hosts for pests and diseases of cultivated crops (Auld 1998).

Beggartick (Bidens pilosa L. and Bidens subalternans DC.) are among the worst weeds of tropical agriculture (Holm 1991), including in Brazil (Kissmann and Groth 1999). It is a very prolific species, reproducing three times a year and dense infestations of the plant are often observed in the field. Beggartick control in Brazil is hindered by the increasingly widespread occurrence of herbicide-resistant biotypes (Gelmini 2001; Hrac-BR 2017), especially to acetolactate synthase (ALS) inhibitor herbicides. The extensive and repetitive use of ALS herbicides in Brazil is behind the selection pressure on beggartick populations, which resulted in the predominance of herbicide-resistant biotypes in many important soybean-producing areas of the country (Rizzardi et al. 2002; Baio et al. 2013). In a scenario where herbicide resistant-weeds become widespread, combined with the lack of new herbicide molecules, new approaches to control beggartick are necessary and offer novel opportunities for a much neglected strategy: mycoherbicide development (Charudattan 2001). Mycoherbicides first appeared in the late 1970s and their history has been reviewed by many authors, including, more recently by Hallet 2005; Ghosheh 2005; Yandoc-Ables et al. 2006a, b; Barreto 2009; Barreto et al. 2012).

Results of a recent survey for fungal pathogens occurring on beggartick in Brazil were published recently (Guatimosim et al. 2015). This was aimed at subsidizing the classical approach of biocontrol through searches for fungi which might occur in the native range of invasive Bidens spp. Mexico and Central America (Guatimosim et al. 2015). The authors did not indicate any of the fungal species found and described in their publication as of having potential for use for mycoherbicide development. Based on this perspective and the current challenge caused by beggartick resistant biotypes in Brazil, we aimed to find potential fungi for biological control of this plant.

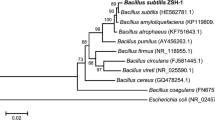

To identify fungi that could be developed as mycoherbicides for beggartick, we carried out a short-scale survey for pathogenic fungi associated with B. pilosa and B. subalternans during 2015 in the Alto Paranaíba region (state of Minas Gerais, Brazil). Of special interest was a group of B. pilosa individuals, bearing severe anthracnose symptoms which led to the death of numerous plants (Fig. 1). In the laboratory, we prepared slides under microscope and isolated the fungus in pure culture. The fungus was morphologically and molecularly identified as Colletotrichum truncatum. The pathogenicity of the fungus was confirmed after inoculations with conidial suspensions on healthy plants of beggartick (B. pilosa and B. subalternans).

Isolates belonging to Colletotrichum spp. have been exploited to develop mycoherbicides since the early days of mycoherbicide history, including the pioneering products (Collego®, later re-registered as Lockdown®) and Biomal® (Yandoc-Ables et al. 2006a, b). Field observations of extensive damage to beggartick caused by an anthracnose fungus encouraged further investigating C. truncatum isolate UFU 280 as a potential novel mycoherbicide active ingredient. This potential was further confirmed in preliminary inoculation assays and by host-specific pathogen of beggartick, being pathogenic only the B. pilosa and B. subalternans (unpublished data).

To further advance towards a mycoherbicide, it is critical to develop a preliminary method for producing larger amounts of viable and virulent inoculum for greenhouse and field tests. This is a critical issue to be considered for a commercial mycoherbicide to become viable (Bowers 1982; Silman et al. 1991; Shearer and Jackson 2006; Boyette et al. 2014). In general, submerged culture fermentation is considered the most cost-effective production method (Stowell 1991; Silman et al. 1991; Shearer and Jackson 2006; Boyette et al. 2014). During preliminary tests it was observed that virulent isolate of C. truncatum UFU 280 obtained from beggartick was capable of sporulating in liquid culture media. Here we report the results of investigation on some factors which are known to be of relevance for the mass production of inocula of biocontrol fungi to establish a preliminary protocol for in vitro production of infective propagules of C. truncatum UFU 280 in liquid culture media.

Methods

Culture and maintenance

The Colletotrichum truncatum UFU 280 isolate used in this study was obtained from B. pilosa individuals, collected near the municipality of Iraí de Minas (Minas Gerais – Brazil) with severe anthracnose symptoms. The isolate was encoded (C. truncatum UFU 280) and incorporated into the mycological collection of the Laboratory of Microbiology and Phytopathology (LAMIF) of the Federal University of Uberlândia – Campus Monte Carmelo. The isolate was stored on silica gel according to Dhingra and Sinclair (1995) and when necessary was cultivated on PDA medium.

Biomass and conidial production in selected media

Seven recipes of liquid culture media for cultivation of fungi were arbitrarily chosen and assessed in terms of the resulting amount of biomass and conidia of C. truncatum produced. These were: a) JP (Jenkins-Prior) – see recipe in Fargues et al. (2001); b) VB (Vegetable–Broth) – see recipe in Pereira et al. (2003) of VBA, but without agar; c) PD (Potato Dextrose) - Dhingra and Sinclair (1995); d) CD (Czapek Dox) - Dhingra and Sinclair (1995); e) CB (Carrot broth: carrot extract - 20 g/400 mL, 1 L of distilled water); f) ME (Malt Extract) – Bailey and Jeger (1992); g) SYEA (Sucrose yeast extract and asparagine) – see recipe in Zauza et al. (2007).

Three mycelial plugs (ø = 5 mm diam.) taken from the margin of 7-day-old C. truncatum cultures growing on PDA were aseptically transferred to each of five separate 250-mL flasks, each containing 100 mL of each of the above liquid culture media. The flasks were kept on an orbital shaker (Nova Instruments® - NT 714) at 180 rpm under room temperature (25 ± 2 °C) for 15 days. Fungal biomass was ground in a homogeniser (Marconi® – MA 099, Marconi Equipamentos para Laboratório Ltda, Piracicaba, SP, Brazil) for one minute and then were filtered with gauze to remove fungal biomass. 20 μL aliquots were withdrawn from each flask for evaluation of conidia concentration. The conidial concentration in each flask was assessed using a hemocytometer. Dry weight of fungal biomass was evaluated by vacuum filtering the contents of each flask in a Buchner funnel using Whatman No.1 filter, followed by drying the biomass at 70 °C for 24 h in an air circulation oven (SOLAB®). Then the resulting fungal biomass was weighed on a precision balance (accuracy = 0.001 g, Prix AS 310 R2).

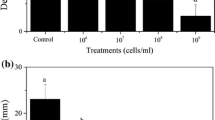

Pathogenicity of C. truncatum conidia produced in selected liquid culture media

Beggartick plants (B. pilosa) at the 2-leaf-pair stage were inoculated with conidial suspension at 1 × 105 conidia/mL. Conidia produced in VB, PD, CB, ME and SYEA were used for inoculations. The JP and CD culture media were excluded from this experiment because there was no sporulation in these media. The conidial suspensions were prepared as described in the previous experiment. As control, plants were sprayed with distilled water +0.05% Tween 20. The conidial suspensions were sprayed onto the foliage of beggartick plants using a hand atomizer until runoff. The inoculated plants were maintained in moist chamber for 48 h in greenhouse with temperatures in the range 25 °C to 30 °C. The moist chamber consisted of wrapping the inoculated plants with a plastic previously moistened internally. The percent control (mortality) was determined 7 days after treatment. The experimental design was completely randomized with five replicates, each replicate consisting of a pot (500 mL) with one plant.

Optimal duration of incubation for biomass and conidial production

This experiment was performed in two rounds aimed at determining the best length of incubation for optimal conidial harvest and the best between two forms of seeding the medium. In the first round 5250 mL flasks containing 100 mL of ME medium each, were seeded with culture disks (three disks per flask) obtained from the margin of 7-day-old actively growing cultures on PDA. The flasks were placed in rotary shakers adjusted to 180 rpm and kept at room temperature (25 ± 2 °C) for 18 days. The second round procedure was identical to that described above except that each flask was seeded with 5 mL aliquots of a conidial suspension of C. truncatum UFU 280 (1 × 105 conidia/mL). This suspension was prepared adding 10 mL of sterile water to the surface of 7-day-old actively growing cultures on PDA and gently sweeping the surface with a sterile spreader. The suspension was adjusted to the desired conidial concentration. The flasks were left on the orbital shaker under the conditions mentioned above for periods of incubation of 3, 6, 9, 12, 15 or 18 days, after which the entire content of each flask was removed from them separately. The mycelium was filtered, and the dry biomass retained was determined for each flask content as describe above. The conidial concentration in the filtrate was then evaluated as described above.

Agitation regimes during fermentation and effect on biomass and conidial production

Five 250 mL flasks containing 100 mL of ME medium each were seeded with three mycelial disks of C. truncatum UFU 280 as described above. Groups of five flasks were placed separately on an orbital shaker (Nova Instruments® - NT 714) with orbital speeds adjusted respectively to 100, 120, 150 and 180 rpm and temperature adjusted to 25 °C. A group of five flasks was similarly treated, except that flasks were kept stationary, serving as control. After 18 days of incubation, content of all flasks was individually evaluated for dry biomass and conidial concentration of filtrate as described above.

Optimal level of medium pH for biomass and conidial production

25 flasks containing 100 mL of ME divided in groups of five were supplemented either with 1 N lactic acid or with 1 N NaOH to reach a pH level of: 2.3; 3.98; 6.98; 8.78 and 10.08. All flasks were autoclaved (120 °C for 20 min) and the pH of the medium was verified to ensure that no changes in pH level occurred. Seeding of each flask was performed, after the flasks and their content cooled, with culture disks as described above, and the flasks were left on an orbital shaker at 150 rpm under 25 °C for 18 days. Evaluation of fungal biomass and conidial concentration was performed for each flask as described above.

Incubation temperatures and their influence on biomass and conidial production

Groups of five 250 mL flasks, containing 100 mL of ME medium each with their pH adjusted to 9.0, were seeded with C. truncatum UFU 280, as described above. The groups of flasks were left separately on orbital shakers at 150 rpm under the following incubation temperatures: 15, 20, 25, 30 or 35 °C. After a period of 18 days, fungal biomass production was evaluated, and conidial concentration measured as described above.

Experimental designs and data analysis

All experiments were a randomised design with five replications for each treatment. The data were subjected to the Shapiro-Wilks and Levene tests for normality and homogeneity of variances. Analysis of variance (ANOVA, F Test, P = 0.05) was performed and the treatments were compared by means of the Tukey test (P = 0.05), and the quantitative factors were evaluated after adjusting the regression eqs. (P = 0.05). All analyses were done using the statistical package R version 3.1.1 (R Development Core Team 2011).

Results

Conidial concentrations obtained in the liquid culture media are given in Table 1. They were higher for ME (mean of 4.4 × 106 conidia /mL) followed by SYEA, VB, CB and PD. Concentration ranged between 2.3 × 104 and 1.3 × 106 conidia/mL. C. truncatum UFU 280 did not sporulate in CB nor in JP (data not shown). Larger amounts of mycelial mass were produced in JP, with an average of 1.55 g/100 mL of medium (Table 2). Fungal biomass in PD, AS, ME ranged from 0.11 to 0.77 g/100 mL of medium, with no difference among them. Lowest biomass was observed when the fungus was grown in CB and VB (Table 2).

Application of inoculum of C. truncatum (UFU 280) obtained from colonies grown in either in ME, SYEA, PD, CB or VB killed 100% of plants 7 days after spraying (Table 2). Conidia were not produced in either JP or CB and hence were unavailable for including in the test.

The longest incubation period of all tested (18 days) yielded the highest conidial concentration either for flasks seeded with culture disks or with conidial suspension (Table 1). The highest final conidial concentration obtained was for flasks seeded with culture disks but seeding with conidial suspension already produced a conidial concentration of 105 conidia/mL within a period of incubation of just 6 days of incubation. A much smaller conidial concentration (103 conidia/mL) was obtained at the 6th day of incubation for flasks seeded with culture disks. An increase in mycelial biomass was observed with the increase of the incubation period when both mycelial discs and conidial suspension were used as the inoculum source (Table 2).

Different speeds of orbital agitation had a significant effect on conidial yields (Table 1). Conidiation was absent under stationary conditions but reached a maximum of 5.1 × 106 conidia /mL at a regime of 150 rpm (Table 1). Sporulation decreased dramatically when orbital speed was of 180 rpm. Nevertheless, for mycelial biomass the 180 rpm regime resulted in the maximum yield (Table 2). Therefore, incubating C. truncatum UFU 280 at shaking speed of 150 rpm ensures adequate conditions for sporulation.

Medium pH of 9.0 was ideal for both conidial production and biomass production (Table 1). Either higher or lower pH levels inhibited mycelial growth and conidiation.

The ideal temperature for incubation for both conidiation and biomass production was between 20 to 25 °C (Table 2). Temperatures above or below this range inhibited conidiation (Table 2) and biomass production (Table 2). No conidia were detected within the media either at 15 or 35 °C (Table 2).

Discussion

Some of the basic conditions for producing inoculum of C. truncatum UFU 280 under liquid fermentation were first assessed here and the results allows for a preliminary protocol to be utilized in greenhouse and field experiments and, after improved may be useful for a commercial production of a putative mycoherbicide. An adequate amount of conidia can be obtained in ME liquid culture medium, adjusted to a pH of 9.0, seeded with a conidial suspension and incubated for 6 days, under a regime of orbital shaking of 150 rpm, at temperatures ranging from 20 to 25 °C.

The development of effective and low-cost methods for mass production of inoculum is a critical step both for the first stages of the evaluation of a potential mycoherbicide and for its viability as a commercial product (Boyette et al. 1991; Zhang et al. 2001). Liquid fermentation is the best option for industrial production of mycoherbicides (Churchill 1982; Boyette et al. 1991; Zhang et al. 2001). At this stage of the research, C. truncatum isolate UFU 280 can be considered as a good potential biocontroller of beggartick, as indicated by the high mortality levels obtained under controlled conditions (reaching 100%) as observed in this study. Greenhouse experiments in microplots are being conducted to corroborate this potential. Additionally, the fungus appears easily amenable to mass inoculum production under a simple set of conditions. The ME is the adequate liquid culture medium for mass production of C. truncatum UFU 280. It allows high conidia yield and did not allow a high production of mycelial mass. According to Dhingra and Sinclair (1995), a suitable culture medium supports high sporulation and low mycelial growth, as the sporulation is usually favored by nutritional exhaustion. The ME (Malt extract) liquid culture medium is also simple to manufacture and cheap. Conversely, mass production of microsclerotia of C. truncatum NRRL 18434, a host-specific pathogen of the weed Sesbania exaltata, requires more expensive and complex conditions, such as incubation at 28 °C in highly aerated liquid medium with 80 g glucose, 13.2 g casamino acids L−1 and salts (Jackson and Schisler 1995).

The shortest time for the suitable production C. truncatum UFU 280 conidia is reached after 6 days of incubation when conidial suspension was used as inoculum source. Longer incubation periods make a biological product unfeasible commercially. Cost-efficient mass production of fungi requires the maximum yield of propagules within the shortest time possible (Butt et al. 2001). Maximum yield of biomass and chlamydospores of the weed biocontrol agent Plectosporium alismatis is also achieved after incubation in submerged culture for 6 days (Cliquet et al. 2004). In its turn, the production of melanized C. truncatum NRRL 18434C microesclerotia requires 9–10 days of incubation (Jackson and Schisler 1995).

Intensity of agitation of medium during incubation may be an important factor affecting propagule production. It can dramatically influence the amount of biomass and the kind of structures produced by the fungus in submerged culture (Calam 1986; Cliquet et al. 2004; Jackson and Schisler 2002). It is possible that the combination of the levels of oxygenation of the medium and mechanic disruption of the mycelium influences conidial production. The ideal intensity of agitation (in the case, rotatory speed) found for propagule production of C. truncatum UFU 280 was 150 rpm, such as reported for the weed biocontrol fungi P. alismatis (Cliquet et al. 2004) and Lewia chlamidosporiformans (Vieira and Barreto 2010); however, C. truncatum NRRL 18434C required a speed of 300 rpm for microesclerotia production (Jackson and Schisler 1995) and Pleospora papaveracea requires a speed of 125 rpm (Bailey et al. 2004).

Most of the studies involving liquid fermentation to produce biocontrol fungi have concluded that the ideal range of pH is between 5 and 7 (Garraway and Evans 1984; Griffin 1994; Deacon 2006; Schisler et al. 1991; Jackson and Schisler 1995; Van Winkelhoff and McCoy 1984; McQuilken et al. 1990; Gardner et al. 2000; Tan et al. 2002). The optimal pH for C. truncatum UFU 280 sporulation is 9.0. Higher and lower pH resulted in lower fungal biomass yields and conidia production. Similarly, Zhao and Shamoun (2006) observed that the pH range between 6.0 and 9.0 was ideal for the sporulation of Phoma exigua, a potential mycoherbicide for the control of Gautheria shallon. For C. truncatum NRRL 18434C, the pH 5.5 is more appropriate for conidia production (Jackson and Schisler 1995).

In general, the optimum temperature for vegetative growth and sporulation of a fungus under fermentation process is similar to the predominant temperature conditions where this organism occurs in nature, but different optimum temperatures can be found for different isolates of a single fungal species (Dhingra and Sinclair 1995). We found that maximum mycelial growth and sporulation of C. truncatum isolate UFU 280 occurs within the range of 20–25 °C. Other bioherbicide fungi are also known to have specific temperature requirements. Bipolaris euphorbiae is a potential biocontrol agent for wild poinsettia (Euphorbia heterophylla), and its optimal sporulation temperature is 22 °C (Moraes, 2009). C. truncatum NRRL 18434C produces more conidia at 28 °C (Jackson and Schisler 1995), while optimal temperature for Phytophthora parasitica is 18 °C (Gardner et al. 2000); for Fusarium sulphurum is 37 °C (Barran et al. 1977); and for Fusarium oxysporum isolate M12-4A is 32 °C (Diarra et al. 1996). Additionally, the conversion of macroconidia of Fusarium oxysporum fsp. Batatas and their conversion to chlamydospores occurs at 24–28 °C (French and Nielsen 1966).

The preliminary protocol for mass production of conidia of C. truncatum isolate UFU 280 at a laboratory scale presented herein, paves the way towards a series of tests on fungus-host interactions, formulation and application of the potential mycoherbicide and its test in the greenhouse, in mini-plots and in field situations. Some experiments are already being conducted now and others are planned, benefiting from the information generated here. Also, in case the potential of this novel mycoherbicide candidate is further confirmed, scale-up tests will be necessary to verify if the performance of the fungus remain consistent for inoculum produced in large capacity bioreactors as well as the choice of stabilizing and storage methods for the final mycoherbicide product. The challenge of managing beggartick remains a major stimulus for the effort towards the development of a novel mycoherbicide tool.

References

Auld BA (1998) On the social value of biological control of weeds. Int J Soc Econ 25(6/7/8):1199–1206

Bailey JA, Jeger MJ (1992) Colletotrichum: biology, pathology and control. CAB International, Kew

Bailey BA, Hebbar KP, Neil NRO, Lewis JA (2004) Production of Pleospora papaveracea biomass in liquid culture and its infectivity on opium poppy (Papaver somniferum). Weed Sci 52:91–97

Baio FHR, Pires LF, Tomquelski G (2013) Mapeamento de picão preto resistente aos herbicidas inibidores da ALS na região sul Mato-grossense. Biosci J 29(1):59–64

Barran LR, Schneider EF, Seaman WL (1977) Requirements for the rapid conversion of macroconidia of Fusarium sulphureum to chlamydospores. Can J Microbiol 23:148–151

Barreto RW (2009) Controle biológico de plantas daninhas com fitopatógenos. In: Bettiol W, Morandi MAB (eds) Biocontrole de doenças de planta: uso e perspectivas. Jaguariúna, Embrapa Meio Ambiente, pp 101–128

Barreto RW, Elisson CA, Sier MK, Evans HC (2012) Biological control of weeds with plant pathogens: four decades on. In: Abrol D, Kashmir S (eds.) Integrated pest management. CAB International, University of Agricultural Sciences and Technology, Jammu, pp. 299-350

Bowers RC (1982) Commercialization of microbial biological control agents. In: Charudattan R, Walker HL (eds) Biological control of weeds with plant pathogens, 2nd edn. John Wiley and Sons, New York, pp 157–173

Boyette CD, Quimby Júnior PC, Connick Júnior WJ, Daigle DJ, Fulgham FE (1991) Progress in the production, formulation, and application of mycoherbicides. In: Tebeest DO (ed) Microbial control of weeds, 3rd edn. Chapman and Hall, New York, pp 209–222

Boyette CD, Hamed KA, Johnson B, Hoagland RE, Weaver MA (2014) Biological control of the weed Sesbania exaltata using a microsclerotia formulation of the bioherbicide Colletotrichum truncatum. Am J Plant Sci 5:2672–2685

Butt TM, Jackson CW, Murugan W (2001) Fungi as biocontrol agents, progress, problems and potentials. CBBS Publshing Co, London, pp 240–242

Calam CT (1986) Shake-flask fermentation. In: Arnold LD, Nadine AS (eds.) Manual of industrial microbiology and biotechnology. American Society for Microbiology, Washington, DC, pp 59–63

Charudattan R (2001) Biological control of weeds by means of plant pathogens: significance for integrated weed, management in modern agro-ecology. BioControl 46:229–260

Churchill BW (1982) Mass production of microorganisms for biological control. In: Charudattan R, Walker HL (eds) Biological control of weeds with plant pathogens. John Willey & Sons, New York, pp 139–156

Cliquet S, Ash G, Cother E (2004) Production of chlamydospores and conidia in submerged culture by Rhynchosporium alismatis, a mycoherbicide of Alismataceae in rice crops. Biocontrol Sci Tech 14:801–810

Deacon J (2006) Fungal biology. Institute of Cell and Molecular Biology, 4th edn. Blackwell Publishing Ltd. University of Edinburgh, Edinburgh 380 p

Dhingra OD, Sinclair JB (1995) Basic methods in plant pathology, 2nd edn. Lewis Publishers, CRC Press, Boca Raton 434p

Diarra C, Ciotola M, Hallet SG, Hess DE, Watson AK (1996) Mass production of Fusarium oxysporum (M12-4ª), a biocontrol agent for Striga hermonthica. Proceedings of the IX International symposium on biological control of weeds; 1996 January 19-26; Stellenbosch. South África. University of Cape Town. pp 149-152

Fargues J, Smits N, Vidal C, Vey A, Vega F, Mercadier G, Quimby P (2001) Effect of liquid culture media on morphology, growth, propagule production, and pathogenic activity of the Hyphomycete, Metarhizium flavoviride. Mycopathologia 154:127–137

French ER, Nielsen LW (1966) Production of macroconidia of Fusarium oxysporum fsp. batatas and their conversion to chlamydospores. Phytopathology 56:1322

Gardner K, Wiebe MG, Gillespie AT, Trinci APJ (2000) Production of chlamydospores of the nematode-trapping Duddingtonia flagrans in shake flask culture. Mycol Res 104:205–209

Garraway MO, Evans RC (1984) Fungal nutrition and physiology. Wiley, New York

Gelmini GA (2001) Resistência de biótipos de Euphorbia heterophylla L., Bidens subalternans L. e Brachiaria plantaginea (Link) Hitchc. a herbicidas utilizados na cultura da soja (Glycine max (L.) Merril). Dissertação (Mestrado em Fitotecnia), Escola Superior de Agricultura “Luiz de Queiroz”, Piracicaba

Ghosheh HZ (2005) Constraints in implementing biological weed control: a review. Weed-Biol-Manag 5(3):83–92

Griffin D (1994) Fungal Physiology, 2nd edn. Wiley-Liss, New York

Guatimosim E, Pinto HJ, Pereira OL, Fuga CAG, Vieira BS, Barreto RW (2015) Pathogenic mycobiota of the weeds Bidens pilosa and Bidens subalternans. Trop Plant Pathol 40:64–83

Hallet SG (2005) Where are the bioherbicides? Weed-Science 53(3):404–415

Holm L (1991) The world’s worst weeds – distribution and biology. Krieger Publishing Company, Malabar

Hrac-BR - Associação brasileira de ação a resistência de plantas aos herbicidas. (2017) http://www.hrac-br.com.br/. Accessed 10 Oct 2017

Jackson MA, Schisler DA (1995) Liquid culture production of microsclerotia of Colletotrichum truncatum for use as bioherbicidal propagules. Mycol Res 99(7):879–884

Jackson MA, Schisler DA (2002) Selecting fungal biocontrol agents amenable to production by liquid culture fermentation. Proceedings of the 7th meeting of the IOBC OILB; 2002; Kusadasi. Turkey IOBC/WPRS bulletin. pp 387-390

Kissmann KG, Groth D (1999) Plantas infestantes e nocivas. Tomo II, São Paulo: BASF Brasileira. 978 p

McQuilken MP, Whipps JM, Cooke RC (1990) Oospores of the biocontrol agent Phytium oligandrum bulk-produced in liquid culture. Mycol Res 94:613–616. https://doi.org/10.1016/S0953-7562(09)80661-8

Moraes C (2009) Produção massal e influência de fatores físicos no cultivo e viabilidade de Bipolaris euphorbiae. Dissertação (Mestrado em Microbiologia Agropecuária), Faculdade de Ciências Agrárias e Veterinárias, Universidade Estadual Paulista, Jaboticabal

Pereira JM, Barreto RW, Ellison C, Maffia LA (2003) Corynespora cassiicola f. sp. lantanae: a potential biocontrol agent for Lantana camara from Brazil. Biol Control 26:21–31

R Development Core Team (2011) R: A language and environment for statistical computing. Vienna: R Foundation for Statistical Computing, 2011. Available in <http://R-project.org>

Rizzardi MA, Vidal RA, Fleck NG, Agostinetto D (2002) Resistência de plantas aos herbicidas inibidores da acetolactato sintase. Planta Daninha 20(1):149–158

Schisler DA, Jackson MA, Bothast RJ (1991) Influence of nutrition during conidiation of Colletotrichum truncatum on conidial germination and efficacy in inciting disease in Sesbania exaltata. Phytopathology 81:587–590

Shearer JF, Jackson MA (2006) Liquid culturing of Microsclerotia of Mycoleptodiscus terrestris, a potential biological control agent for the management of Hydrilla. Biol Control 38:298–306

Silman RW, Nelsen TC, Bothast RJ (1991) Comparison of culture methods for production of Colletotrichum truncatum spores for use as a mycoherbicide. FEMS Microbiol Lett 79:69–74

Stowell LJ (1991) Submerged fermentation of biological herbicides. In: TeBeest DO (ed) Microbial control of weeds, 3rd edn. Chapman and Hall, New York, pp 225–261

Tan WZ, Li QJ, Qing L (2002) Biological control of alligatorweed (Alternanthera philoxeroides) with a Fusarium sp. BioControl 47:463–479

Van Winkelhoff AJ, Mccoy CW (1984) Conidiation of Hirsutella thompsonii var. synnematosa in submerged culture. J Invertebr Pathol 43:59–68

Vieira BS, Barreto RW (2010) Liquid culture production of chlamydospores of Lewia chlamidosporiformans (Ascomycota: Pleosporales), a mycoherbicide candidate for wild poinsettia. Australas Plant Pathol 39:154–160

Yandoc-Ables CB, Rosskopf EN, Charudattan R (2006a) Plant pathogens at work: progress and possibilities for weed biocontrol. Part 1: classical vs. bioherbicidal approach http://www.apsnet.org/publications/apsnetfeatures/Pages/WeedBiocontrolPart1.aspx

Yandoc-Ables CB, Rosskopf EN, Charudattan R (2006b) Plant pathogens at work: progress and possibilities for weed biocontrol. Part 2: improving weed control efficiency http://www.apsnet.org/publications/apsnetfeatures/Pages/WeedBiocontrolPart2.aspx

Zauza EAV, Alfenas AC, Mafia GR (2007) Esterilização, preparo de meios de cultura e fatores associados ao cultivo de fitopatógenos. In: Alfenas CA, Mafia RG (eds) Métodos em Fitopatologia. UFV, Viçosa, p 42

Zhang W, Sulz M, Bailey KL (2001) Growth and spore production of Plectosporium tabacinum. Can J Bot 79:1297–1306

Zhao S, Shamoun SF (2006) Effects of culture media, temperature, pH, and light on growth, sporulation, germination, and bioherbicidal efficacy of Phoma exigua, a potential biological control agent for salal (Gaultheria shallon). Biocontrol Sci Tech 16(10):1043–1055

Acknowledgements

The authors wish to acknowledge The Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vieira, B.S., Dias, L.V.S.A., Langoni, V.D. et al. Liquid fermentation of Colletotrichum truncatum UFU 280, a potential mycoherbicide for beggartick. Australasian Plant Pathol. 47, 277–283 (2018). https://doi.org/10.1007/s13313-018-0555-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13313-018-0555-y