Abstract

The composite steel reinforced concrete (SRC) columns with the form of partial or full encasement of the steel section in the reinforced concrete (RC) have attracted pervasive attention due to their advantages compared to the conventional RC columns. This paper aims to summarize the representative publications regarding the SRC columns. Firstly, the analytical studies of the SRC columns, including comparative studies between available codes to address the philosophy of design and the limits in the available codes of design, bond slip behavior, analytical confinement material models, and finite element analysis, are addressed. In addition, the discussion and summary of the axial behavior of the SRC columns and the important parameters affecting the axial behavior of these types of columns were included. It also attempts to cover the parameters affecting the seismic behavior of the SRC columns. Important progress has been made by the previous studies in the SRC columns under the axial load and the combination of axial and seismic loads, but they fundamentally focused on the columns with the simple arrangement of steel section, and a few attention was paid to the new type of SRC columns with rotated cross-shaped steel section whose webs coincide with the diagonal lines of the columns’ section. Due to the lack of study and the brittle failure of the columns with lightweight and high strength concrete, more studies should still be made to know the behavior of the SRC columns. The paper concludes with suggestions for the future studies to enhance the effectiveness of the SRC columns.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The steel reinforced concrete (SRC) column (it is also called concrete encased steel (CES) column) consists of steel section partially or fully encased in reinforced concrete (Fig. 1). The presence of concrete improves the behavior of the structural steel sections by making them more effective and impervious to both overall and local buckling. The column has longitudinal bars, which have to be tied by the lateral horizontal stirrups at regular vertical spaces. The lateral stirrups bars are effective in improving the column capacity, confinement, and ductility. Furthermore, they restrain the longitudinal reinforcement bars from being moved during construction and resist bars buckling during the loading, which would cause spalling of the concrete cover even at small load levels, especially in the case of seismic or eccentrically loaded columns.

The cross-section of composite SRC columns (Davison and Owens 2011). a Fully encased SRC column with H-shaped steel. b Partially encased SRC column with H-shaped steel. c Partially encased SRC column with cross-shaped steel

Due to the composite actions between steel and reinforced concrete at this type of columns, the advantages of the applied materials may be used and their disadvantages may be averted, thus forming more reasonable structural members. Many benefits can be found from the SRC columns. The main advantages gained from using the SRC columns are as follows: significant saving in material and construction time; increasing the ductility, energy dissipation capacity, stiffness, and strength to dead weight ratio of the members; increasing the confined concrete zones by the steel section; providing enough rigidity, usable floor regions and economical cost for high-rise buildings; enhancing the fire resistance due to the concrete isolation and protection for the steel section; decreasing the cross-section of the columns compared to the RC columns; reducing the costs by using of high strength materials that reduce the cross-section areas; preventing the local buckling of steel by concrete, except for early stages of construction, where the concrete works as lateral support to the embedded steel element section; and providing a simple connection between steel beams and columns, and without extra effort to harden the column in the area of connection. Finally, the SRC columns can be useful in resisting the lateral loads.

However, the SRC columns have their disadvantages, such as: difficulties in casting the concrete in some cases due to large amounts of steel and small clear space between the steel; difficulties to repair the failed columns, as appeared in the failure pattern of the seismic loading tests conducted by Wang et al. (2016a) where the crushing of the concrete happen at the ends of the column followed by steel buckling, especially for columns with the high axial load; formwork is needed for constructing and casting the SRC column, but in the concrete filled steel tube (CFST) composite column, the steel tubes confine the concrete as a form and shoring system in construction for casting concrete; and shortages in the confinement of concrete by this kind of column than the achieved by CFST column.

Several studies have been completed on the composite members in the past years especially on SRC columns with cross-shaped steel section, which was usually made by welding two I- or H-shaped steel sections together. They studied the effects of confinement, concrete strength and other factors on the behavior of the SRC column. Some codes’ limitations and design methods were presented by (Viest et al. 1997; Jacobs and Goverdhan 2011; Soliman et al. 2013; El-Tawil and Deierlein 1999). The axial behavior of the SRC column elements was studied experimentally and analytically by Liang et al. (2014), Karimi et al. (2012), Morino et al. (1985), Soliman et al. (2013), Lelkes and Gramblička (2013), Weng et al. (2006) and by Chen and Wu (2017), Liang et al. (2014), de Sousa and Caldas (2005), El-Tawil and Deierlein (1999), Ellobody and Young (2011), Ellobody et al. (2011), Abdulhaq and Badaruzzaman (2011), Perea and Leon (2011), Lelkes and Gramblička (2013), respectively. In addition, the lateral seismic performance of the new and special types of composite SRC element sections has been studied by Fukuhara and Minami (2008), Wang et al. (2015, 2016a, b), Chen et al. (2015), Fang et al. (2015), Jiang et al. (2017), Weng et al. (2008a), Nishimura et al. (2004), Fauzan and Kuramoto (2011); as well as, the lateral seismic performance of the SRC elements with ordinary type sections has been studied by many scholars (Kitano et al. 2008; Kuramoto 2011; Naito et al. 2010; Zheng et al. 2012; Denavit 2013; Lu et al. 2014; Chen et al. 2014a, 2005; Chou and Uang 2007; Yan and Jia 2010; Ma et al. 2011, 2013; Zhang et al. 2012; Fei et al. 2006; Xiang and Wang 2016; Yan et al. 2017; Xu et al. 2016). The performance of the SRC elements after the fire was studied by Wang and Zhang (2017), Wang et al. (2017a), Zhang et al. (2014). Also, the effect of shear connectors welded to the steel section on the bond behavior of the SRC element has been investigated by Nguyen and Kim (2009), Kim et al. (2011), Zhang et al. (2014). Their outcomes demonstrated that the ordinary SRC columns with I or H-shaped steel section were predominantly used in the building practice.

This paper presents the experimental and analytical studies about SRC columns, including the advantages and disadvantages of the SRC columns, the new types of SRC columns, the analytical studies, the axial behavior of the SRC columns, the effect of different parameters on the seismic behavior of the SRC column, and the suggestions for the future studies.

2 New Types of SRC Columns

Several new and special types of the SRC columns with different arrangements of structural steel sections have been proposed to investigate the parameters that affect the behavior and performance of these types of the columns. The previous studies have investigated the role of various parameters affecting the behavior of the new types of SRC columns, including (1) type and shape of steel section, (2) steel section ratio, (3) materials strength, (4) axial load ratio, which is the ratio of the applied axial vertical concentric compression load (N) to the ultimate axial compression capacity of the column (Nu), (5) confinement effect of the concrete, and (6) fire resistance (Fukuhara and Minami 2008; Weng et al. 2008a; Fauzan and Kuramoto 2011; Chen et al. 2014a, 2015, 2018; Fang et al. 2015; Wang et al. 2015, 2016a, b; Xiang and Wang 2016; Jiang et al. 2017; Yang and Li 2012; Yang et al. 2018; Zhu et al. 2016; Nishimura et al. 2004; Fauzan et al. 2005; Minh 2017; Liang et al. 2014). The main finding is that the using of cross-shaped with two I steel section (+) instead of one I steel shape and using new kind of SRC columns instead of ordinary SRC columns could accomplish better seismic behavior.

Two improved cross-shaped SRC columns with normal weight concrete (NWC) confined by spiral stirrups embedded with new type section steel were developed by Wang et al. (2016a). Their results indicated that the behavior of the SRC columns has been obviously improved with new-type steel section. Fukuhara and Minami (2008) tested a new type of cross-shaped steel columns. They found that the concrete adhesion power is improved but the ultimate strength of specimens with the holes in the steel webs is decreased. However, the maximum strength and horizontal displacement (deformation angle) of specimens with cross-shaped steel section type were enhanced.

The cyclic behavior of joints between the SRC beams and the new type of SRC columns (Fig. 2) was experimentally investigated by Wang et al. (2015). From the results, they noted that the new-kind of joints exhibit shear failure. The deformation ability and energy dissipation capacity of the new-kind of SRC joints were better than the joints of ordinary SRC columns. The manufacturing of the specimen at Fig. 2a was easier to be cut and machined than Fig. 2b. In addition, Hsu et al. (2009) studied the effect of values of the bi-axial bending and the steel strength ratios on the SRC columns (Fig. 3). Their test results demonstrated that when the strength of steel section proportions in the weak-axis increased, the strength deterioration rates of the specimen increased. The ratio between the strong and weak axes steel strength was suggested to be 2.2 to improve the specimen’s performance under the earthquakes.

Two new kinds of connection between SRC beams and the new type of SRC columns (Wang et al. 2015). a Connection type-1. b Connection type-2

Specimen details (Hsu et al. 2009). a Cross-section and load directions. b 3-Dimensional sketch

The seismic resistance of steel reinforced high strength concrete (SRHC) column is affected by the structural steel form (Yang and Li 2012). The structural steel sections (Fig. 4) enhanced the positive impact of the stirrups and had more obvious benefit by increasing the effective confinement when the SRHC column exposed to a huge axial load ratio (Zhu et al. 2016). As shown in Fig. 5, the seismic behavior of the SRC cross-shaped columns was studied by Fang et al. (2015). They found that the ultimate horizontal load and the lateral displacement ductility increased seriously with increasing the amount of steel ratio, but the stiffness retraction was marginal. The ultimate lateral load at the case of the loading angle equals to 0° was smaller than that of at the loading angle equals to 45°, but the lateral displacement ductility at the loading angle equal to 0° was larger than that at the loading angle equal to 45°. This type of columns exhibits well energy dispersion and ductility deformation capacities. The cross-shaped SRC columns showed better seismic performance and greater lateral bearing capacity than the cross-shaped RC columns. Jiang et al. (2017) found that the steel ratio and the axial load ratio have huge impacts on the seismic behavior of mega SRC columns, but the effect of the steel cross-section shape was not significant.

The details of the SRHC column specimens (Zhu et al. 2016)

Cross-sections of the column specimens (Fang et al. 2015). a Specimen with loading angle equals to 0°. b Specimen with loading angle equals to 45°

3 The Analytical Studies

3.1 The Design Codes

The design and analysis of steel–concrete composite sections have been progressed for over four decades. The codes of practice contain various methods for the design of these columns. These methods are extrapolated from either steel column or reinforced concrete column design codes. The differences between prescriptions of these codes indicate that further studies research must be undertaken to gain an understanding of the structural behavior of these kinds of elements.

The capacity of a composite column is calculated as the summation of the strengths of all the components, reinforced concrete, and steel. The differences in the codes lie in the variety in the philosophy of the design; for example, the compatibility and strain distribution. This contradiction is regarding the differences in safety factors, the material properties, and limiting dimensions. The resistance factors and factors of safety in the available codes are equal to unity. This may compare fairly the capacities calculated by these methods (El-Tawil and Deierlein 1999; Shanmugam and Lakshmi 2001; Weng and Yen 2002).

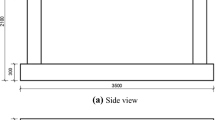

Table 1 shows the important descriptions and ranges in some available codes. In order to visualize the differences between these codes, a typical SRC column specimen (DH-T1-75) tested by Liang et al. (2014) is selected to calculate its capacity using each design code provision, and the calculated capacities are compared with the test capacity, as shown in Table 2. Figure 6 shows the details of the specimen DH-T1-75, and more details about the material properties of the specimen are available in Liang et al. (2014). From the calculation results, it can be found that all the three codes are on the conservative side, the BS.5400-5 gives the smallest capacity, and the EC4 gives the largest capacity.

The details of the specimen DH-T1-75 (Liang et al. (2014)

Figure 7 shows the interactions diagram (ID) and stress distributions of the SRC section. Where, b and h are the width and the height of the SRC column, respectively; Mpl,Rd is the plastic moment resistance of the SRC section; Mmax,Rd is the maximum design value of the moment resistance in the presence of an axial force; Npl,Rd is the plastic axial compressive force resistance; Npm,Rd is the design value of the concrete portion resistance to the axial load; fcd is the design compressive strength of concrete; fsd and fyd are the design value of the yield strength for the reinforcing steel bars and structural steel section, respectively; and hn is the position of the neutral axis.

Stress distributions for the SRC section and simplified interaction diagram (ID) (Eurocode4 2004)

3.2 The Bond Slip Behavior

The bond behavior between concrete and steel is an important issue in composite SRC members because of ensuring the interaction and cohesion of various components under different working conditions and implications, it has impacts on serviceability limit states, energy dissipation under cyclic loads, local stress distributions, and ultimate limit states design (LSD), etc. Connection enhancements in the form of embossments, ribs, and shear studs are used in composite slabs and beams, while such devices are not always added in composite columns.

Many scholars studied experimentally and analytically the bond slip behavior of SRC members in case of fire exposure or normal condition without fire effects (Zhang et al. 2014; Wang et al. 2017a; Ngo and Scordelis 1967; Spacone and El-Tawil 2004; Houde and Mirza 1974; Nguyen and Kim 2009; Wang and Zhong 1990; Kwak and Kim 2001; Khalfallah and Ouchenane 2007; Shafaei et al. 2009; Zheng et al. 2016). They found that the bond slip behavior is affected by several factors. The most significant and serious factor is the fire exposure where the bond cohesion becomes weak and the slip greatly increases. The simple model for simulating of bond considering different elements for the concrete and steel components is the concentrated springs. The springs could model either the action of the shear connectors or the friction effects between concrete and steel. The spring models are shown in Fig. 8. To take into account the bond slip of the reinforcing steel, different approaches are common in the finite element analysis. Ngo and Scordelis (1967) proposed an approach to utilize the bond-link element. This element links a node of the steel with a node of the adjacent concrete. As shown in Fig. 8c, the bond link spring element has no dimensions, and the two linked nodes (the linked nodes of concrete and steel) have the same coordinates. For each spring an appropriate stiffness and stress–strain relation should be defined.

To take the impact of slip into account, 3 spring elements were used to model the bond-slip behavior between concrete and steel reinforcement, which simulate the contacting behavior in the global 3 directions (Fig. 8b). For concrete and reinforcement, the transverse tangential and normal springs were used to represent the grip cohesion power, and the bond slip was represented by longitudinal spring. The bond stress between reinforcement and concrete was calculated according to Eq. (1) (Houde and Mirza 1974).

where τ is the bond stress (MPa); \({\text{f}}_{{\text{c}}}^{\prime}\) is the compression strength of concrete cylinder (MPa); and S is the slip displacement between reinforcement or steel section and concrete (mm).

For steel section and concrete, a large value was selected for the spring coefficient, and the model of the stress of bond and slip displacement for the transverse and longitudinal tangential spring is shown as Eq. (2) (Wang and Zhong 1990).

However, great efforts and long times are required to pick the points on concrete and steel one by one to put the springs on the points in this way, and the spring element cannot adequately represent the stiffness of the interface between the steel and concrete. Nguyen and Kim (2009) proposed a contact surface model (Fig. 9) by creating a thin surface to simulate the whole interface cohesion between the steel section and concrete.

Surfaces in tie constrain between steel section and cohesion layer, concrete slab and cohesion layer (Nguyen and Kim 2009)

3.3 The Analytical and Confinement Material Models

Extensive research has been done by Chen and Wu (2017), Liang et al. (2014), Spacone et al. (1996a, b), El-Tawil and Deierlein (2001a, b), Mander et al. (1988), Chen and Lin (2006), Ellobody and Young (2011), and Mirza and Skrabek (1992) to simulate the actual mechanism of the SRC columns by establishing analytical models that consider the effect of confinement and other factors.

The fiber section model was adopted to analyze the SRC members (Fig. 10). The section is divided into “n” fibers (not necessarily of equal area). To determine the straining actions such as moment or force, the stresses are integrated on the cross-section area. The material properties are assigned to each fiber of concrete, structural steel section, or steel reinforcing bar. Utilization of the ‘‘plane sections remain plane’’ theory and by relevant constitutive models, fiber stresses are determined from them. There are various formulas for finding the fiber’s strain with increasing the loads. Spacone et al. (1996a, b) defined the section axial strain and curvatures concerning a fixed reference system, and they did not need to trace the evolution of the position of the neutral axis (NA). Furthermore, El-Tawil and Deierlein (2001a, b) considered the moving of the NA with the loading (Fig. 10). Constitutive uni-axial models for steel and concrete are required to calculate the stresses of the fibers and modules of elasticity. As for the concrete models, the model of Kent and Park (1971), which was later enhanced by Scott et al. (1982), can be used to include the confinement effects. The SRC column was found to provide the initial strength against lateral shear during increasing the load. The major snag of the Kent and Park (1971) model formulas is that the initial stiffness of the concrete was not considered well. This problem was solved by Mander et al. (1988) model and other researcher’s models, like Tan et al. (2013), Fang et al. (2015), Chen and Wu (2017), and Liang et al. (2014). Mander et al. (1988) studied the confinement level required to achieve adequate ductility under seismic loading, the impact of flange shear studs for enhancing stiffness and bending strength, the concrete compressive strength, and the mechanism of shear resistance of the SRC section. Chen and Wu (2017) and Liang et al. (2014) modified the Mander’s model to consider the confinement effect on the SRC columns with cross-shaped steel and to predict the analytical axial load–displacement relationships of the columns.

Fiber-element discretization of encased composite section (El-Tawil and Deierlein 2001b)

The confining stress in the concrete region is enhanced by the structural steel section (Figs. 10 and 11). The confinement regions can be simplified, as adopted by Mirza and Skrabek (1992), by adjusting the parabolic regions into rectangular regions. By taking the impact of non-strengthened parts of the structural steel section on the confinement into account, half of the steel area is taken to determine the confining stress. In addition, Chen and Lin (2006) proposed the confinement factor (K) to study the confinement effect for highly and partially confined concrete. Figure 11 shows the lateral pressure due to the steel section. Where, bf and b are the flange’s total width and cantilevered length, respectively; tw and Aw’ are the web’s thickness and area, respectively; qu is the maximum lateral stress between highly confined concrete (HCC) and steel section; fst is the maximum tensile stress in the web; fy,f is the yield strength of the flange; fl’,s is the nominal confining stress on the highly confined concrete provided by the flange; and Mu is the ultimate moment at the base of the cantilevered flange.

Lateral confining pressure due to steel section (HCC) in partially encased SRC cross column (Chen and Wu 2017)

3.4 FE Analysis

Many scholars simulated the SRC structural members by using FE analysis to study this type of columns and to make a comparison between the experimental results and the FE results (Fang et al. 2015; Nguyen and Kim 2009; Kalfas et al. 1997; Spacone and El-Tawil 2004; Wang et al. 2016a; Ellobody and Young 2011; Ellobody et al. 2011). Fang et al. (2015) simulated the SRC cross-shaped column specimens by using FE analysis to investigate the behavior of the columns. They found that the FE analysis results and the test results were consistent. Wang et al. (2016a) established a FE model to predict the seismic performance of the developed SRC compression-bending members, and the FE results agreed well with the test results. Nguyen and Kim (2009) investigated analytically the behavior of large stud shear connectors using the non-linear FE models, the studied parameters were the ductility, the capacity of the connection, the load slip relationship and the failure mode. From the comparison of the ductility and capacity of shear connectors determined by the FE and those specified in EC4 and AASHTO LRFD, they found that the specifications of AASHTO LRFD overestimated the capacity of the large stud connectors; however, the design formulas presented in EC4 were conservative for small stud diameters (with the diameter of 22, 25 and 27 mm.), but not conservative for the diameter of 30 mm. The large stud ductility is better for utilizing in the composite bridges.

4 The Axial Behavior of SRC Columns

4.1 The Effect of the Axial Compressive Loading

Every column must experience the axial loads; which include live and dead loads. The RC columns have some limitations in high-rise buildings because the gravity of the building itself has a high axial load on the columns. To resist the axial loads, the dimensions of RC columns must be greatly increased, which increases the axial load in turn; the large dimensions are often rejected by the architectural engineers. The SRC column is one of the best solutions for this problem since the SRC column can increase the axial bearing capacity of the columns and enhanced the ductility without largely increasing the dimensions of the column.

The axial behavior of the SRC columns was studied by several scholars around the world, especially for researchers in countries with small or weak earthquakes (Chen and Lin 2006; Weng et al. 2006, 2008b; Yu et al. 2007; Zhang et al. 2014; Chen and Dai 2015; Wang et al. 2017a, b; Soliman et al. 2013; Ellobody and Young 2011; Rahman et al. 2016; Yang et al. 2018; Szmigiera 2007; Chen et al. 2014b; Zhu et al. 2013), this behavior includes the stress–strain curve, ductility, stiffness, and strength. The axial compression behavior is also important in simulating this type of columns under the lateral seismic loads. Soliman et al. (2013) investigated the impact of stirrups ratio on the axial behavior of the SRC column members. The ultimate axial load capacity and corresponding displacement of the specimens differ depending on both the stirrups ratio and the encased steel shape. In addition, Weng et al. (2008b) studied the SRC rectangular columns confined with double interconnected spiral under the monotonic axial compression loads. Excellent strength and ductility capacity of the columns were observed from the test results with significant cost savings.

The axial load-deformation behavior of the SRC column with considering the confinement effects was investigated by Chen and Lin (2006). They observed from the results that the steel sections improved the axial compression strength and post-ultimate strength. The cross-shaped structural steel section leads to the greatest confinement while the I-shaped has the lowest one. The axial load and long-term deformation behavior of the short SRC columns due to shrinkage and creep were investigated by Chen and Dai (2015). It was concluded from their results that the sustained axial load has small effects on the bearing capacity of the SRC columns, but the long-term deformations were large.

A comparison between the numerical and published experimental results was done by Rahman et al. (2016) to study the behavior of short fully encased composite SRC columns under (short-term) axial load. The results showed that the FE analysis predicted the experimental axial behavior of the columns with good agreement.

4.2 The Effect of Fire

The effect of fire is one of the most important parameters in the field of structural engineering. The presence of the steel section encased in the concrete of the SRC column member provides better fire resistance than the other types of columns. The fire resistance of the SRC column was affected by various factors, including the dimension and shape of the cross-section, slenderness ratio, the appearance of cracks, and eccentricity (Yu et al. 2007). Wang et al. (2017b) found that the fire resistance reduced for specimens that are influenced by big axial load ratio than the specimens that are affected by small axial compression loads.

The SRC columns with stud shear connectors under axial push out test after the fire were studied by Zhang et al. (2014) to investigate the force-slip relationship, the failure mode, and the shear transfer of the columns. They found that the shear transfer of the columns with shear connectors on the web of steel section was higher than the specimens with shear connectors on the flange of steel section. Yang et al. (2018) and Zhou and Han (2018) tested the SRC columns encased with CFST core under axial loads subjected to fire. They observed that the interior CFST core had a good effect on both the fire resistance and the behavior of the specimens after the fire. Wang et al. (2017a) studied the bond behavior of SRC columns subjected to fire. They found that the bond strength reduced by 54.2%, but the maximum corresponding slip increased from about 0.3 mm to 4 mm due to the impact of the fire.

From the previous literature, it can be found that the fire exposure has significant negative effects on the bond cohesion behavior of the SRC members, the large axial load reduces the fire resistance of the SRC column, and the presence of the shear connectors on the web provides better shear transfer after fire than the presence of them on the flange.

5 The Seismic Behavior of SRC Columns

There are a lot of parameters affecting the behavior of the SRC columns under seismic loading, including applied axial load ratio and confinement; some of the parameters are reviewed and addressed in this section.

5.1 The Effect of Applied Axial Load Ratio

The axial load ratio is one of the most important parameters on the cyclic behavior of the SRC columns. The impact of this parameter was studied by several researchers (Chen et al. 2005, 2014a, 2018; Zheng et al. 2012; Ma et al. 2013, 2015; Qian et al. 2016; Fang et al. 2015; Wang et al. 2016a; Kuramoto 2011; Yang and Li 2012; Zhu et al. 2016; Zhang et al. 2012; Nishimura et al. 2004; Fukuhara and Minami 2008; Minh 2017; Yan and Jia 2010; Ma and Jia 2017). The axial load ratio affects the capacity of the energy dissipation, ductility, carrying capacity, stiffness degradation, and distribution of the axial load on the column.

The hysteresis behavior was highly influenced by the ratio of the applied axial compressive load. When the applied axial load was 40% of the squash load, the columns appeared so less capacity of energy dissipation and displacement ductility compared with the columns with 20% of the axial squash load, because of a sensitive increase in the moment of secondary bending resulted by the axial loads (Chen et al. 2005). The axial load ratio affects the deformation ability, the damage pattern and the carrying capacity of the SRHC columns. The major influence parameter on the ductility of columns was the axial load ratio (Zheng et al. 2012). The seismic resistance behavior of SRC columns with high strength concrete is also affected by the axial compression ratio (Yang and Li 2012; Chen et al. 2014a), which had a negative effect on the deformation capacity and the capacity of energy dissipation (Zhu et al. 2016). The ductility of the short steel reinforced recycled concrete (SRRC) columns specimens decreased when the axial load ratio increased, but the capacity of the SRC columns gradually increased. Furthermore, the energy dissipation capacity of the specimens decreased when the axial load ratio increased (Ma et al. 2015). When the axial load ratio of cross-shaped SRC columns increased, the ultimate lateral loads increased, but the ductility and the stiffness decreased seriously (Fang et al. 2015).

The axial load ratio (with axial load ratio ≥ 0.42) had a small impact on the deformation behavior and ultimate capacity of the new-type of SRC column under seismic loads while the ductility of the columns decreased greatly by the higher axial compression ratio (Wang et al. 2016a). Qian et al. (2016) studied the seismic behavior of the concrete-encased with CFST core columns. The outcomes showed that the axial load ratio affected the distribution of the loads on the components of the column. The part of the axial load resisted by the external reinforced concrete increased at first and then decreased with the increase of the displacement at a small axial load ratio. Pam and Ho (2009) studied the critical zone length in high strength limited ductility RC columns (HSRC). From the results, it was observed that the critical zone length increased when increasing the axial compressive load.

5.2 The Effect of the Embedded Depth Ratio of Steel Sections

The embedded depth ratio of steel sections is the ratio of steel embedded depth to section height (ha) of the steel section, and it is used as a characterization factor. For the SRC columns, a suitable steel embedded depth is required to maintain their seismic behavior and strength capacity, which had been listed in the Hyogoken-Nanbu earthquake-1995 (Azizinamini and Ghosh 1997). According to the JGJ138-2001 (2001), the minimum ratio of the embedded depth for the ordinary SRC column is 3.0. The steel embedded depth ratio for the ordinary SRC column subjected to monotonic loading was investigated by Yamaguchi et al. (1998) and Nagata et al. (1999), and they noted that the steel embedded depth ratio of 1.67 was adequate for an ordinary SRC column. But to consider the safety reserve Chen et al. (2014a) suggested and recommended that the minimum steel embedded depth ratio for the ordinary SRC columns to be 2.5.

5.3 The Effect of Shear Connector

Extensive analytical and experimental studies have been conducted on the SRC composite specimens with steel shear connectors to study the performance of shear connectors subjected to axial load and combinations of axial and seismic loads (Baharom and Hossienpour 2015; Razaqpur and Nofal 1989; Oguejiofor and Hosain 1994; An and Cederwall 1996; Kalfas et al. 1997; Bursi and Gramola 1999; Roeder et al. 1999; Civjan and Singh 2003; Nakajima et al. 2003; Fei et al. 2006; Maleki and Bagheri 2008; Maleki and Mahoutian 2009; Nguyen and Kim 2009; Zhu et al. 2016; Pallarés and Hajjar 2009; Valente and Cruz 2009; Rodrigues and Laím 2011; Shariati et al. 2012a, b, 2013, 2014a, b; Kim et al. 2013; Zhang et al. 2014; Khorramian et al. 2015; Balasubramanian and Rajaram 2016; Tahmasbi et al. 2016; Ricles and Paboojian 1994). An overview of previous works in the area of shear connector performance and some other connectors are included. The results showed that the seismic loads lead to about 40% decreasing in the capacity of the shear stud compared to non-seismic shear capacities. This reduction occurs due to seismic fatigue of the weld/connector materials as well as concrete crushing causing the distribution of stress to migrate up the shank of the connector to the connector’s head, this increase bending stresses in the connector, causing earlier failures. The initial bending of the studs shear connectors did not have an impact on the shear stud capacity. The concrete strength affected on the seismic shear capacity of studs similarly to static capacities (Civjan and Singh 2003). The columns with studs (Fig. 4) showed a better capacity of deformation and energy dissipation with decreasing stiffness degradation but did not have a great impact on the performance of SRHC columns at the early loading steps (Zhu et al. 2016). Ricles and Paboojian (1994) found that the shear studs welded to the flange of steel sections (Fig. 12) not effective in improving the flexural resistance of the ordinary SRC columns under seismic loads. Two different types of shear connectors were studied by Valente and Cruz (2009). They found that the force capacity of the connection decreased when NWC was substituted by LWC.

The specimens detail (Ricles and Paboojian 1994)

5.4 The Effect of Slenderness Ratio and Shear Span Ratio

A lot of research has been conducted on the SRC columns with different slenderness ratio and shear span ratio (Chen et al. 2014a; Zheng et al. 2012; Ma et al. 2015; Mirza and Skrabek 1992; Dundar et al. 2008; Tokgoz and Dundar 2008; Ellobody and Young 2011; Denavit 2013; Campian et al. 2015; Keo et al. 2015; Ma and Jia 2017). It can be found from the result that the behavior of SRC columns is greatly affected by the slenderness ratio and the shear span ratio. When the ratio of shear span increased, the failure process becomes slow and the ductility increased (Zheng et al. 2012). With the increasing the ratio of the slenderness, the bearing capacity of the long columns reduced, but the likelihood of suddenly collapse increased (Yang and Li 2012). Ma et al. (2015) found that the area of the hysteresis curve of the SRRC columns with a large shear span ratio increased significantly, but the stiffness and bearing capacity of SRRC column decreased.

5.5 The Effect of Confinement of the Concrete

Extensive studies have been conducted to study the effect of confinement on the SRC columns (Weng et al. 2006; Chen and Lin 2006; Wang et al. 2016a; Yang and Li 2012; Zhu et al. 2016; Chen et al. 2014a; Zheng et al. 2012; Zhang et al. 2012; Ma et al. 2013, 2015; Ricles and Paboojian 1994; Pam and Ho 2009; Naito et al. 2010; Yan and Jia 2010); they found that the confinement by the stirrups can prevent the steel bar from buckling, resist shear failure, and produce a pressure of confinement for the core concrete, which greatly improves the capacity and the ductility. Moreover, the stirrups also fix the longitudinal bars from being moved at the construction time and resist the tendency to buckle outward under load, which would cause spalling of the outer concrete cover even at small load levels, remarkably in the case of columns under the eccentric loads.

The effect of the stirrup ratio was negligible on seismic resistance behavior of SRC columns with high strength concrete (Yang and Li 2012). The ductility of the new kinds of steel ordinary weight concrete columns with rotated cross-shaped steel sections decreased with the increasing of stirrup spacing (Wang et al. 2016a), but the ductility of the composite SRC columns with high strength concrete decreased with the increase of the stirrup amount ratio (Zheng et al. 2012).

Mander et al. (1988) proposed a formula, as shown in Eq. (3), for the strength of confined columns. Some researchers used the Mander’s equation to determine the impact of the confinement on the composite SRC columns with considering the lateral pressure (\({\text{f}}_{{\text{l}}}^{\prime}\)) due to both the steel sections and the stirrups.

where \({\text{f}}_{{\text{cc}}}^{\prime}\) is the confined concrete compressive strength (MPa); \({\text{f}}_{{\text{co}}}^{\prime}\) is the unconfined concrete compressive strength (MPa); and \({\text{f}}_{{\text{l}}}^{\prime}\) is the effective lateral confining stress (MPa).

The cyclic performance of ordinary short and long SRRC columns was evaluated by (Ma et al. 2015). It can be noted from their results that when the ratio of stirrups increased, the ductility and the capacity of energy dissipation of short columns increased as well. Ricles and Paboojian (1994) investigated experimentally the SRC columns subjected to seismic loads (Fig. 12). They found that the SRC columns had high horizontal ductility and strength if the buckling of the longitudinal reinforcement bars was prevented, and the structural steel section resisted the horizontal shear with the overloading.

The seismic resistance of spirally confined rectangular SRC columns with a new type of five interconnected spirals cage was studied by Weng et al. (2008a). This type of columns was able to resist a drift ratio up to 6% with significant cost savings of the steel. At the end of the test, the columns demonstrated tangible peel off the cover of concrete in the plastic zone near the column base, but the concrete in the confined regions of the five-spirals remained undamaged. Fauzan et al. (2005) studied a new composite system of engineering wood encased concrete-steel (EWECS) composite column. The shell of wood during construction acted as forming for the confining of the member; the result showed the utilization of the woody shell as confinement cover for this type of column gave economic and structural benefits, but it may have a negative impact on the fire resistance. Zhu et al. (2016) conducted experiments on the SRHC columns (Fig. 4) to investigate the seismic performance of the specimens. It can be concluded from their results that the stirrups and the used structural steel ratios were suitable for use in high rise buildings in seismic zones. The stirrups had a little impact on the lateral load and initial stiffness at the stage of cover spalling but had a useful impact on the deformation capacity and energy dissipation capacity.

The behavior and strength of cross-shaped SRC exterior and corner beam–column joints (Fig. 13) with applied forces from the single and double side were studied by Chen et al. (2009) and Chen and Lin (2009), respectively. As shown in Fig. 13; they studied different types of joins; including (a) corner steel joint with cross-shaped steel column; (b) corner joint consisted of SRC beam, SRC column with cross-shaped steel section, and corner stirrups; and (c) exterior joint consisted of SRC beam, SRC column with cross-shaped steel section, and corner stirrups. They found that the utilization of both the corner stirrups and cross-shaped steel sections was able to supersede the ordinary hoop stirrups, provide high lateral support to longitudinal reinforcement bars, and suitable concrete confinement in the joint. For the SRC column, increasing the depth of steel cross-section provides more concrete confinement and high shear strength in the beam–column joints region. In addition, Chen et al. (2005) found that the SRC beam–columns can provide a large capacity for energy absorption and good hysterical behavior by using cross tie stirrups and increase the numbers of lateral horizontal tie stirrups.

The beam column joint region (Chen et al. 2009). a Corner joint with steel beam and column. b Corner joint with SRC beam, SRC column, and corner stirrups. c Exterior joint with SRC beam, SRC column, and corner stirrups

5.6 The Effect of the Concrete Strength

In recent years, extensive research and composite buildings have been done with different types and strengths of concrete (Zheng et al. 2012; Szmigiera 2007; Tokgoz and Dundar 2008; Ellobody and Young 2011; Ricles and Paboojian 1994; Pam and Ho 2009; Ma and Jia 2017). The ordinary-strength concrete has a characteristic compressive strength \({\text{f}}_{{\text{c}}}^{\prime}\) up to 50 MPa; concrete with a compressive strength higher than 50 MPa is considered as high strength concrete (Warner et al. 1998), which may be made by using high-quality aggregates and superplasticizers, and the strength may exceed 100 MPa. When the concrete strength enhanced, the capacity of shear of the SRC columns increased but the deformation ability declined, the cyclic behavior of SRC columns with long webs of cross-shaped steel was more affected by the concrete strength (Wang et al. 2016a). Furthermore, the capacity of long SRC columns increased with the concrete strength increasing (Yang and Li 2012).

Several researchers used the high or very-high strength concrete to examine the behavior of SRC columns with these concrete materials (Zheng et al. 2012; Zhu et al. 2016; Pam and Ho 2009; Yan and Jia 2010; Yan et al. 2017). Zheng et al. (2012) found that the ductility of the SRC columns with high-strength concrete decreased with the increase of the stirrups amount ratio. Pam and Ho (2009) studied the critical zone length of the SRHC columns. They found that the column’s critical zone length increased when increasing the strength of the concrete. The cyclic behavior of the frames with SRC beams and steel reinforced ultrahigh strength concrete (SRUHC) columns were investigated by Yan and Jia (2010). Yan et al. (2017) established a numerical hysteretic model to study the seismic behavior of SRUHSC column and SRC beam joint. From their results, it was concluded that the proposed hysteretic model could simulate well the hysteretic curves properties by considering the damage effects.

5.7 The Effect of Lightweight Concrete (LWC)

The LWC usually consists of either lightweight sand or lightweight coarse aggregate. The LWC is lighter than the NWC by about 20% (Decker et al. 2015). The density of the LWC is about 1.44–1.84 t/m3 compared with the NWC with a density between 2.2 and 2.6 t/m3. Due to the advantages of the LWC, it attracts many researchers, and therefore it has a lot of applications in buildings. The applications of LWC in SRC elements effectively reduce the cost and seismic reaction due to decreasing the dead load. In structure design, this means reduced gravity loads and seismic masses, which allows the structural engineering designers to reduce the dimension of columns and other bearing members, thus reducing cost as well as construction time. The main advantages acquired from using the SRC columns including good behavior in durability, thermal and sound insulation, and frost resistance. Many researchers studied the performance of shear connectors and SRC members with LWC (Al-Shahari et al. 2003; Tan et al. 2013; Valente and Cruz 2009; Shariati et al. 2011; Yan et al. 2014). But the LWC exhibits obviously brittle behavior, it has a lower elastic modulus, and the capacity of shear connectors with LWC is smaller than the capacity of the shear connector with NWC, that makes it still needs more study. The behavior of the connection between the steel and LWC was studied by Valente and Cruz (2009). They found that the LWC was adequate to be used in the SRC composite members, it has a smaller load capacity than the NWC specimens, and it has a bigger capacity of deformation.

6 Discussion and Recommendations

This paper presents the experimental and analytical studies that are related to the SRC columns and what are the important things that had not studied, to assist next researchers to know what is unknown and to push forward this field, when these columns are used under the axial load and the combinations of axial and seismic loading conditions. It was found that the SRC columns were effective in resisting the vertical and horizontal loads. Table 3 summarizes the important conclusions and recommendations for future research.

On the basis of the overview of the SRC column that is presented in this review paper, the following discussion and recommendations can be found:

The previous researchers studied the effect of many parameters on the axial behavior of SRC columns, including the confinement, fire, kind of the axial load, and other influence factors; but they have not investigated the effects of fire and other parameters, such as concrete type, on the new types of these columns with rotated cross-shaped steel section. So, the future studies are advised to cover this point.

From the previous studies, the scholars have not studied the effect of bond slip behavior on the new types of SRC columns with rotated cross-shaped steel sections under the axial load and the combination of axial and seismic loads. So, the effect of bond slip behavior with the new types of SRC columns is suggested to study in the future. In addition, the future studies are suggested to study which embedded depth ratio of steel is appropriate and recommended for the new kinds of SRC columns under seismic loading with various kinds of concrete.

It is possible for the next researchers to study the effect of axial load ratio on the new types of the SRC columns specimen with rotated cross-shaped steel sections by using various kinds of concrete.

The scholars have not studied the effect of different types of shear connectors on the new kinds of SRC columns under the axial load and the combination of axial and seismic loads. The next researchers are suggested to study which types and positions of shear connectors are recommended to use with the new kinds of SRC columns with different kinds of concrete.

The previous researchers studied the impacts of slenderness and shear span ratio on the SRC columns, but they have not investigated their effects on the new kinds of SRC columns. So, the next researchers are advised to study the impact of slenderness and the ratio of the shear span on the new types of SRC columns.

The scholars have not studied the impact of confinement by stirrups and steel sections on the new types of SRC columns by using different kinds of concrete under the axial load and the combination of axial and seismic loads. The future studies are recommended to cover this point.

The SRHC and SRUHC columns are favorite due to its huge strength, small cross-section, and large unsupported spans in high-rise buildings, but it has a brittle failure behavior and there is a lack of study about the effect of the high and ultra-high strengths concrete on the behavior of new types of SRC columns. So, the next researchers may cover this point.

Despite the advantages of LWC mentioned in Sect. 5.7, but it has a brittle failure behavior. Extensive studies regarding the effect of LWC on the column and bearing members were found to reinforced concrete columns, CFST columns, walls, and ordinary type of SRC columns. However; limited studies available regarding the implementation of LWC in composite new types of the SRC members, but due to the benefits of the new type of SRC column, that found by Wang et al. (2016a). The next researchers are advised to study the effect of different strength grades of the LWC on the behavior of the new types of SRC columns.

7 Conclusions

The previous studies on the SRC columns fundamentally focused on the columns with a simple arrangement of structural steel section, with a few attention was paid to the new type of SRC columns. The SRC columns have proven to be efficient in resisting both vertical and horizontal loads. This makes them preferred in the high-rise building and the areas subjected to earthquakes. Increasing the depth of steel cross-section provides more concrete confinement and high shear strength. The new types of SRC columns need more analytical and theoretical studies to get new theoretical models for the design and to know the mechanism of the new kinds of these columns; in addition, to take into account the effect of confinement by stirrups and steel section in different design codes. The SRC column can increase the axial bearing capacity of the columns and enhanced the ductility with significant cost savings. But the fire resistance reduced for specimens that are influenced by large axial compression load ratio than the specimens that are affected by small axial compression loads.

The axial load ratio affects negatively on the seismic behavior of the SRC columns, especially on the ductility. For the ordinary types of the SRC columns, when the axial load ratio increased, the capacity of the columns increased, but the ductility, stiffness degradation, and the capacity of energy dissipation of columns decreased. While for the new-types of SRC columns with ordinary concrete the axial load ratio has no big effect on the ultimate deformation and capacity of specimens, but the ductility of the columns specimens decreased seriously by the high axial load ratio.

The SRC columns with studs connectors showed a better capacity of deformation and energy dissipation with decreasing the stiffness degradation but did not have a great impact on the performance of SRHC columns at the early loading steps. The seismic loads lead to about 40% decreasing in the capacity of the shear stud compared to non-seismic shear capacities. The suitable embedded depth of steel sections in the ordinary types of SRC columns with cross-shaped steel section subjected to monotonic loading was 2.5. And, when the ratio of shear span increased the deformation capacity of the SRC columns and the ductility increased but the failure process becomes slow.

The confinements by the stirrups and steel section enhanced the bearing capacity, the capacity of energy dissipation, and ductility of the SRC columns. But the impact of stirrup ratio on the behavior of seismic resistance of SRC columns with high strength concrete was small, where the ductility of the SRC columns with high strength concrete and new types of steel ordinary weight concrete columns with rotated cross-shaped steel sections columns decreased with the increasing of stirrup spacing. The utilization of both the corner stirrups and cross-shaped steel sections was able to supersede the ordinary hoop stirrups, provide high lateral support to the longitudinal reinforcement bars, and suitable concrete confinement in the joint. Using cross tie stirrups or increase the numbers of lateral horizontal tie stirrups also provide a large capacity for energy absorption and good hysterical behavior. The bond behavior between concrete and steel is an important issue in composite SRC members, especially in the case of fire exposure where the bond cohesion becomes weak and the slip greatly increases.

When the concrete strength enhanced, the capacity of shear of the SRC columns increased, but the deformation ability declined. The critical zone length of the SRHC column increased when increasing the strength of the concrete. The applications of LWC in SRC elements effectively reduce the cost and seismic reaction, so the LWC is adequate to be used in the SRC composite members. The LWC specimens have a smaller load capacity than the NWC specimens; they have a tendency to a bigger capacity of deformation. And the stud’s stiffness welded to SRC columns with LWC was lower than those in NWC.

References

Abdulhaq, A., & Badaruzzaman, W. H. W. (2011). Bearing capacity investigation of pin-ended composite columns with eccentricity loading using finite element simulation. Far East Journal of Psychology and Business,5(3), 34–46.

ACI318-8. (2008). Building code requirements for reinforced concrete. Cincinnati: American Concrete Institute.

Al-Shahari, A. M., Hunaiti, Y. M., & Ghazaleh, B. A. (2003). Behavior of lightweight aggregate concrete-encased composite columns. Steel and Composite Structures,3(2), 97–110.

An, L., & Cederwall, K. (1996). Push-out tests on studs in high strength and normal strength concrete. Journal of Constructional Steel Research,36(1), 15–29.

Azizinamini, A., & Ghosh, S. (1997). Steel reinforced concrete structures in 1995 Hyogoken-Nanbu earthquake. Journal of Structural Engineering,123(8), 986–992.

Baharom, S., & Hossienpour, E. (2015). Shear behaviour of innovative connectors in partially encased column. In Word congress on advances in structural engineering and mechanics.

Balasubramanian, R., & Rajaram, B. (2016). Study on behaviour of angle shear connector in steel–concrete composite structures. International Journal of Steel Structures,16(3), 807–811. https://doi.org/10.1007/s13296-015-0094-0.

BS.5400-5. (2002). Steel, concrete and composite bridges; Part 5: Code of practice for design of composite bridges, British Standards Institution Publications, London, UK.

Bursi, O. S., & Gramola, G. (1999). Behaviour of headed stud shear connectors under lowcycle high amplitude displacements. Materials and Structures,32(4), 290–297.

Campian, C., Nagy, Z., & Pop, M. (2015). Behavior of fully encased steel–concrete composite columns subjected to monotonic and cyclic loading. Procedia Engineering,117, 439–451.

Chen, C., Chen, C., & Shen, J. (2018). Effects of steel-to-member depth ratio and axial load on flexural ductility of concrete-encased steel composite columns. Engineering Structures,115, 157–166.

Chen, C., Li, J., & Weng, C. C. (2005). Experimental behaviour and strength of concrete-encased composite beam–columns with T-shaped steel section under cyclic loading. Journal of Constructional Steel Research,61(7), 863–881. https://doi.org/10.1016/j.jcsr.2005.01.002.

Chen, C., & Lin, N. (2006). Analytical model for predicting axial capacity and behavior of concrete encased steel composite stub columns. Journal of Constructional Steel Research,62(5), 424–433.

Chen, C., & Lin, K. (2009). Behavior and strength of steel reinforced concrete beam–column joints with two-side force inputs. Journal of Constructional Steel Research,65(3), 641–649.

Chen, C., Suswanto, B., & Lin, Y. (2009). Behavior and strength of steel reinforced concrete beam–column joints with single-side force inputs. Journal of Constructional Steel Research,65(8), 1569–1581.

Chen, C., Wang, C., & Sun, H. (2014a). Experimental study on seismic behavior of full encased steel–concrete composite columns. Journal of Structural Engineering,140(6), 1–10.

Chen, S., & Wu, P. (2017). Analytical model for predicting axial compressive behavior of steel reinforced concrete column. Journal of Constructional Steel Research,128, 649–660. https://doi.org/10.1016/j.jcsr.2016.10.001.

Chen, Z., & Dai, T. (2015). Effects of sustained axial loads on steel–reinforced concrete columns. HKIE Transactions,22(1), 16–22. https://doi.org/10.1080/1023697X.2015.1008590.

Chen, Z., Xu, J., & Xue, J. (2015). Hysteretic behavior of special shaped columns composed of steel and reinforced concrete (SRC). Earthquake Engineering and Engineering Vibration,14(2), 329–345.

Chen, Z. Y., Wang, Y., & Wu, J. Q. (2014b). Long-term deformations of steel–reinforced concrete columns under sustained axial loads. Applied Mechanics and Materials,351–352(2), 645–649.

Chou, C., & Uang, C. (2007). Effects of continuity plate and transverse reinforcement on cyclic behavior of SRC moment connections. Journal of Structural Engineering,133(1), 96–104.

Civjan, S. A., & Singh, P. (2003). Behavior of shear studs subjected to fully reversed cyclic loading. Journal of Structural Engineering,129(11), 1466–1474.

Davison, B., & Owens, G. W. (2011). Steel designers’ manual. New York: Wiley.

Decker, C. L., Issa, M. A., & Meyer, K. F. (2015). Seismic investigation of interior reinforced concrete sand-lightweight concrete beam–column joints. ACI Structural Journal,112(3), 287.

Denavit, M. D. (2013). Characterization of behavior of steel–concrete composite members and frames with applications for design, Ph.D. Thesis, University of Illinois at Urbana-Champaign, Civil & Environmental Eng Department. https://www.ideals.illinois.edu/handle/2142/42420.

de Sousa, J. B. M., Jr., & Caldas, R. B. (2005). Numerical analysis of composite steel–concrete column of arbitrary cross section. Journal of Structure Engineering,131(11), 1721–1730.

Dundar, C., Tokgoz, S., Tanrikulu, A. K., & Baran, T. (2008). Behaviour of reinforced and concrete-encased composite columns subjected to biaxial bending and axial load. Building and Environment,43(6), 1109–1120.

Ellobody, E., & Young, B. (2011). Numerical simulation of concrete encased steel composite columns. Journal of Constructional Steel Research,67(2), 211–222.

Ellobody, E., Young, B., & Lam, D. (2011). Eccentrically loaded concrete encased steel composite columns. Thin-Walled Structures,49(1), 53–65.

El-Tawil, S., & Deierlein, G. G. (1999). Strength and ductility of concrete encased composite columns. Journal of Structural Engineering,125(9), 1009–1019.

El-Tawil, S., & Deierlein, G. G. (2001a). Nonlinear analysis of mixed steel–concrete frames. I: Element formulation. Journal of Structural Engineering,127(6), 647–655.

El-Tawil, S., & Deierlein, G. G. (2001b). Nonlinear analysis of mixed steel–concrete frames. II: Implementation and verification. Journal of Structural Engineering,127(6), 656–665.

Eurocode4. (2004). Design of composite steel and concrete structures. Part 1.1: General rules and rules for buildings. London: British Standards Institution.

Fang, L., Zhang, B., Jin, G. F., Li, K. W., & Wang, Z. L. (2015). Seismic behavior of concrete-encased steel cross-shaped columns. Journal of Constructional Steel Research,109, 24–33.

Fauzan, F., & Kuramoto, H. (2011). Seismic performance of composite EWECS columns in new hybrid structural system. In Composite construction in steel and concrete VI (pp. 263–275). ASCE.

Fauzan, F., Kuramoto, H., & Kim, K. H. (2005). Seismic performance of composite EWECS columns using single H-steel. Proceedings of the Japan Concrete Institute, 27, 307–312.

Fei, D., Tao, C., & Congzhen, X. (2006). Performance and capacity of isolated steel reinforced concrete columns and design approaches. Beijing: China Academy of Beijing Research, Engineering Consulting and Design Institute: China Academy of Building Research (CABR) Technology Co., LTD.

Fukuhara, M., & Minami, K. (2008). Seismic performance of new type steel–concrete composite structures considering characteristic both SRC and CFT structures. Paper presented at the proceedings of 14th world conference on earthquake engineering, Beijing, China, paper no. 0017, 12–17 October 2008.

Houde, J., & Mirza, M. S. (1974). A finite element analysis of shear strength of reinforced concrete beams. Journal of ACI,42, 103–128.

Hsu, H. L., Jan, F. J., & Juang, J. L. (2009). Performance of composite members subjected to axial load and bi-axial bending. Journal of Constructional Steel Research,65(4), 869–878.

Jacobs, V. W. P., & Goverdhan, A. V. (2011). Review and comparison of encased composite steel–reinforced column detailing requirements. In Composite construction in steel and concrete VI (pp. 427–441).

JGJ138-2001. (2001). Technical specification for steel reinforced concrete. Beijing: Ministry of Construction of the People’s Republic of China, Beijing China Architecture and Building Press.

Jiang, H., Li, Y., & Zhu, J. (2017). Numerical simulation of mega steel reinforced concrete columns with different steel sections. The Structural Design of Tall and Special Buildings. https://doi.org/10.1002/tal.1304.

Kalfas, C., Pavlidis, P., & Galoussis, E. (1997). Inelastic behaviour of shear connection by a method based on FEM. Journal of Constructional Steel Research,44(1–2), 107–114.

Karimi, K., El-Dakhakhni, W. W., & Tait, M. J. (2012). Behavior of slender steel–concrete composite columns wrapped with FRP jackets. Journal of Performance of Constructed Facilities,26(5), 590–599.

Kent, D. C., & Park, R. (1971). Flexural members with confined concrete. Journal of the Structural Division,97, 1969–1990.

Keo, P., Somja, H., Nguyen, Q. H., & Hjiaj, M. (2015). Simplified design method for slender hybrid columns. Journal of Constructional Steel Research,110, 101–120.

Khalfallah, S., & Ouchenane, M. (2007). A numerical simulation of bond for pull-out tests: The direct problem. Asian Journal of Civil Engineering,5, 491–505.

Khorramian, K., Maleki, S., Shariati, M., & Sulong, N. H. R. (2015). Behavior of tilted angle shear connectors. PLoS ONE,10(12), e0144288.

Kim, S., Choi, K., Park, S., Park, S., & Jung, C. (2013). Experimental shear resistance evaluation of Y-type perfobond rib shear connector. Journal of Constructional Steel Research,82, 1–18. https://doi.org/10.1016/j.jcsr.2012.12.001.

Kim, S., Jung, C., & Ahn, J. (2011). Ultimate strength of composite structure with different degrees of shear connection. Steel and Composite Structures,11(5), 375–390. https://doi.org/10.12989/scs.2011.11.5.375.

Kitano, A., Goto, Y., & Joh, O. (2008). Experimental study on shear resistance of SRC column and steel beams frames constructed by simplified method. Paper presented at the proceedings of 14th world conference on earthquake engineering, Beijing, China, paper no. 0017, 12–17 October 2008.

Kuramoto, H. (2011). Behavior of columns in composite CES structural system. In Composite construction in steel and concrete VI (pp. 455–465).

Kwak, H. G., & Kim, S. P. (2001). Bond–slip behavior under monotonic uniaxial loads. Engineering Structures,23(3), 298–309.

Lelkes, A., & Gramblička, Š. (2013). Theoretical and experimental studies on composite steel–concrete columns. Procedia Engineering,65, 405–410.

Liang, C. Y., Chen, C., Weng, C., Yin, Y., & Wang, J. (2014). Axial compressive behavior of square composite columns confined by multiple spirals. Journal of Constructional Steel Research,103(103), 230–240.

Lu, X., Yin, X., & Jiang, H. (2014). Experimental study on hysteretic properties of SRC columns with high steel ratio. Steel and Composite Structures,17(3), 287–303.

Ma, H., Jiang, W., & Cho, C. (2011). Experimental study on two types of new beam-to-column connections. Steel and Composite Structures,11(4), 291–305.

Ma, H., Xue, J., Liu, Y., & Zhang, X. (2015). Cyclic loading tests and shear strength of steel reinforced recycled concrete short columns. Engineering Structures,92, 55–68.

Ma, H., Xue, J., Zhang, X., & Luo, D. (2013). Seismic performance of steel-reinforced recycled concrete columns under low cyclic loads. Construction and Building Materials,48(19), 229–237.

Ma, Y., & Jia, J. (2017). The influence of different parameter on the seismic behavior of SRUHSC frame. Advances in Materials Science and Engineering,2017(5), 1–14.

Maleki, S., & Bagheri, S. (2008). Behavior of channel shear connectors. Part I: Experimental study. Journal of Constructional Steel Research,64(12), 1333–1340.

Maleki, S., & Mahoutian, M. (2009). Experimental and analytical study on channel shear connectors in fiber-reinforced concrete. Journal of Constructional Steel Research,65(8), 1787–1793.

Mander, J. B., Priestley, M. J., & Park, R. (1988). Theoretical stress–strain model for confined concrete. Journal of Structural Engineering,114(8), 1804–1826.

Minh, T. N. (2017). Seismic behavior of concrete-encased steel column frames designed with proposed model of required transverse reinforcement. Ph.D. Thesis, National Taiwan University of Science and Technology, China.

Mirza, S. A., & Skrabek, B. (1992). Statistical analysis of slender composite beam–column strength. Journal of Structural Engineering,118(5), 1312–1332.

Morino, S., Matsui, C., & Watanabe, H. (1985). Strength of biaxially loaded SRC columns (pp. 185–194). New York: American Society of Civil Engineers.

Nagata, T., Fukuchi, Y., & Wakamatsu, S. (1999). Experimental study on embedded depth and effective bearing flange width of steel members as bending: Strength of embedded type of steel reinforced concrete column base. In Proceedings of the annual meeting Architectural Institute of Japan, Tokyo (pp. 1167–1168). Architectural Institute of Japan (AIJ).

Naito, H., Akiyama, M., & Suzuki, M. (2010). Ductility evaluation of concrete-encased steel bridge piers subjected to lateral cyclic loading. Journal of Bridge Engineering,16(1), 72–81.

Nakajima, A., Saiki, I., Kokai, M., Doi, K., Takabayashi, Y., & Ooe, H. (2003). Cyclic shear force–slip behavior of studs under alternating and pulsating load condition. Engineering Structures,25(5), 537–545.

Ngo, D., & Scordelis, A. C. (1967). Finite element analysis of reinforced concrete beams. Journal of ACI,64(3), 152–163.

Nguyen, H. T., & Kim, S. E. (2009). Finite element modeling of push-out tests for large stud shear connectors. Journal of Constructional Steel Research,65(10), 1909–1920.

Nishimura, Y., Tsutsui, S., & Baba, N. (2004). Flexural behavior of steel reinforced concrete columns with T-shaped steel. Paper presented at the 13th world conference on earthquake engineering, Vancouver, BC, Canada, 1–6 August 2004.

Oguejiofor, E. C., & Hosain, M. U. (1994). A parametric study of perfobond rib shear connectors. Canadian Journal of Civil Engineering,21(4), 614–625.

Pallarés, L., & Hajjar, J. F. (2009). Headed steel stud anchors in composite structures. Part I: Shear. Journal of Constructional Steel Research,66(2), 198–212.

Pam, H. J., & Ho, J. C. M. (2009). Length of critical region for confinement steel in limited ductility high-strength reinforced concrete columns. Engineering Structures,31(12), 2896–2908.

Perea, T., & Leon, R. (2011). Behavior of composite CFT beam–columns based on nonlinear fiber element analysis. In Composite construction in steel and concrete VI (pp. 237–251).

Qian, W., Li, W., Han, L., & Zhao, X. (2016). Analytical behavior of concrete-encased CFST columns under cyclic lateral loading. Journal of Constructional Steel Research,120, 206–220.

Rahman, M. S., Begum, M., & Ahsan, R. (2016). Comparison between experimental and numerical studies of fully encased composite columns. Paper presented at the World Academy of Science Engineering and Technology (WASET).

Razaqpur, A., & Nofal, M. (1989). A finite element for modelling the nonlinear behavior of shear connectors in composite structures. Computers & Structures,32(1), 169–174.

Ricles, J. M., & Paboojian, S. D. (1994). Seismic performance of steel-encased composite columns. Journal of Structural Engineering,120(8), 2474–2494.

Rodrigues, J. P. C., & Laím, L. (2011). Behaviour of perfobond shear connectors at high temperatures. Engineering Structures,33(10), 2744–2753.

Roeder, C. W., Chmielowski, R., & Brown, C. B. (1999). Shear connector requirements for embedded steel sections. Journal of Structural Engineering,125(2), 142–151.

Scott, B., Park, R., & Priestley, M. (1982). Stress-strain behavior of concrete confined by overlapping hoops at low and high strain rates. ACI Structural Journal,79(1), 13–27.

Shafaei, J., Hosseini, A., & Marefat, M. S. (2009). 3D finite element modelling of bond-slip between rebar and concrete in pull-out test. In International conference on concrete and development.

Shanmugam, N. E., & Lakshmi, B. (2001). State of the art report on steel–concrete composite columns. Journal of Constructional Steel Research,57(10), 1041–1080.

Shariati, A., Shariati, M., Sulong, N. H. R., Suhatril, M., Khanouki, M. M. A., & Mahoutian, M. (2014a). Experimental assessment of angle shear connectors under monotonic and fully reversed cyclic loading in high strength concrete. Construction and Building Materials,52, 276–283.

Shariati, M., Shariati, A., Sulong, N. H. R., Suhatril, M., & Khanouki, M. A. (2014b). Fatigue energy dissipation and failure analysis of angle shear connectors embedded in high strength concrete. Engineering Failure Analysis,41, 124–134.

Shariati, M., Sulong, N. H. R., & Khanouki, M. M. A. (2012a). Experimental assessment of channel shear connectors under monotonic and fully reversed cyclic loading in high strength concrete. Materials and Design,34, 325–331.

Shariati, M., Sulong, N. H. R., Sinaei, H., Khanouki, A., Mehdi, M., & Shafigh P. (2011). Behavior of channel shear connectors in normal and light weight aggregate concrete (experimental and analytical study). In Advanced materials research (Vol. 168, pp. 2303–2307). Trans Tech Publ.

Shariati, M., Sulong, N. H. R., Suhatril, M., Shariati, A., Khanouki, M. M. A., & Sinaei, H. (2012b). Behaviour of C-shaped angle shear connectors under monotonic and fully reversed cyclic loading: An experimental study. Materials and Design,41, 67–73.

Shariati, M., Sulong, N. H. R., Suhatril, M., Shariati, A., Khanouki, M. M. A., & Sinaei, H. (2013). Comparison of behaviour between channel and angle shear connectors under monotonic and fully reversed cyclic loading. Construction and Building Materials,38, 582–593.

Soliman, K. Z., Arafa, A. I., & Elrakib, T. M. (2013). Review of design codes of concrete encased steel short columns under axial compression. HBRC Journal,9, 134–143.

Spacone, E., & El-Tawil, S. (2004). Nonlinear analysis of steel–concrete composite structures: State of the art. Journal of Structural Engineering,130(2), 159–168.

Spacone, E., Filippou, F. C., & Taucer, F. F. (1996a). Fiber beam–column model for non-linear analysis of R/C frames: Part I. Formulation. Earthquake Engineering and Structural Dynamics,25(7), 711–725.

Spacone, E., Filippou, F. C., & Taucer, F. F. (1996b). Fiber beam–column model for non-linear analysis of R/C frames: Part II. Applications. Earthquake Engineering and Structural Dynamics,25(7), 727–742.

Szmigiera, E. (2007). Influence of concrete and fibre concrete on the load-carrying capacity and deformability of composite steel–concrete columns. Journal of Civil Engineering and Management,13(1), 55–61.

Tahmasbi, F., Maleki, S., Shariati, M., Sulong, N. H. R., & Tahir, M. M. (2016). Shear capacity of C-shaped and L-shaped angle shear connectors. PLoS ONE,11(8), e0156989.

Tan, E. L., Thomas, C., & Siriviatnanon, V. (2013). Finite element modeling of nonlinear behaviour of headed stud shear connectors in foamed and lightweight aggregate concrete. In Proceedings of the fifth international conference on advances in experimental structural engineering (I) (Vols. 8, 9).

Tokgoz, S., & Dundar, C. (2008). Experimental tests on biaxially loaded concrete-encased composite columns. Steel and Composite Structures,8(5), 423–438.

Valente, I. B., & Cruz, P. J. S. (2009). Experimental analysis of shear connection between steel and lightweight concrete. Journal of Constructional Steel Research,65(10), 1954–1963.

Viest, I. M., Colaco, J. P., & Furlong, R. W. (1997). Composite construction design for buildings (1st ed.). New York: McGraw-Hill.

Wang, G., & Zhang, D. (2017). Experimental research on the post-fire seismic performance of steel reinforced concrete columns. Procedia Engineering,210, 456–463.

Wang, Q., Shi, Q., & Tao, Y. (2016a). Experimental and numerical studies on the seismic behavior of steel reinforced concrete compression-bending members with new-type section steel. Advances in Structural Engineering,19(2), 255–269.

Wang, Q., Shi, Q., & Tian, H. (2015). Seismic behavior of steel reinforced concrete (SRC) joints with new-type section steel under cyclic loading. Steel and Composite Structures,19(6), 1561–1580. https://doi.org/10.12989/scs.2015.19.6.1561.

Wang, Q., Shi, Q., & Tian, H. (2016b). Experimental study on shear capacity of SRC joints with different arrangement and sizes of cross-shaped steel in column. Steel and Composite Structures,21(2), 267–287.

Wang, W., Han, L., Tan, Q., & Tao, Z. (2017a). Tests on the steel–concrete bond strength in steel reinforced concrete (SRC) columns after fire exposure. Fire Technology,53(2), 917–945.

Wang, Y., Huang, Y., & Fu, C. (2017b). Performance of T-shaped steel reinforced concrete column under high temperature. Procedia Engineering,210, 565–573.

Wang, Z., & Zhong, S. (1990). Nonlinear finite element analysis on the steel reinforced concrete beams. Paper presented at the proceedings of 2nd symposium on theory and practice of concrete, Beijing, China, Tsinghua University Press, Beijing, China, 26–29 October 1990.

Warner, R., Rangan, B., Hall, A., & Faulkes, K. (1998). Concrete structures. Boston: Addison Wesley Longman.

Weng, C., Yin, Y., Wang, J., & Liang, C. (2008a). Seismic cyclic loading test of SRC columns confined with 5-spirals. Science in China Series E: Technological Sciences,51(5), 529. https://doi.org/10.1007/s11431-008-0067-z.

Weng, C. C., & Yen, S. I. (2002). Comparisons of concrete-encased composite column strength provisions of ACI code and AISC specification. Engineering Structures,24(1), 59–72.

Weng, C. C., Yin, Y. L., Wang, J. C., Liang, C. Y., & Huang, C. M. (2006). Experimental investigation on rectangular SRC columns with multi-spiral confinements. In Proceedings, 4th international conference on earthquake engineering, Taiwan.

Weng, C. C., Yin, Y. L., Wang, J. C., Shih, C. H., & Lu, C. R. (2008b). Axial strength and ductility of rectangular SRC columns with innovative double-spiral confinements. Paper presented at the 14th world conference on earthquake engineering, Beijing, China, 12–17 October 2008.

Xiang, P., & Wang, H. P. (2016). Structural performances of steel reinforced concrete special shaped column–beam joints under bidirectional low-cyclic reversed loading. American Journal of Civil Engineering,5(1), 16. https://doi.org/10.11648/j.ajce.20170501.13.

Xu, L., Pan, J., & Cai, J. (2016). Seismic behavior of steel reinforced ECC or ECC/concrete composite short columns. Paper presented at the 9th international conference on fracture mechanics of concrete and concrete structures.

Yamaguchi, T., Fukuchi, Y., & Wakamatsu, S. (1998). Experimental study on bending strength of embedded type of steel framed reinforced concrete column base. In Proceedings of the annual meeting Architectural Institute of Japan, Tokyo (pp. 1317–1318). Architectural Institute of Japan (AIJ).

Yan, C., & Jia, J. (2010). Seismic performance of steel reinforced ultra high-strength concrete composite frame joints. Earthquake Engineering and Engineering Vibration,9(3), 439–448.

Yan, C., Yang, D., Ma, Z. J., & Jia, J. (2017). Hysteretic model of SRUHSC column and SRC beam joints considering damage effects. Materials and Structures,50(1), 88.

Yan, J.-B., Liew, J. Y. R., Sohel, K. M. A., & Zhang, M. H. (2014). Push-out tests on J-hook connectors in steel–concrete–steel sandwich structure. Materials and Structures,47(10), 1693–1714.

Yang, B. S., & Li, Y. Y. (2012). Study on the behaviors of steel reinforced concrete cloumns. Advanced Materials Research,368–373, 248–252.

Yang, Y., Zhang, L., Xue, Y., Zhao, D., Deng, H., & Wu, B. (2018). Experimental research on the fire performance of a special cross-shaped composite column with a high-strength concrete-filled steel tubular core. Advances in Structural Engineering. https://doi.org/10.1177/1369433217753426.

Yu, J., Lu, Z., & Xie, Q. (2007). Nonlinear analysis of SRC columns subjected to fire. Fire Safety Journal,42(1), 1–10. https://doi.org/10.1016/j.firesaf.2006.06.006.

Zhang, S., Zhao, Z., & He, X. (2012). Flexural behavior of SRC columns under axial and bilateral loading. Applied Mechanics and Materials,166–169, 3383–3390.

Zhang, Z., Li, J., Zhang, L., & Yu, K. (2014). Study on the interfacial shear behavior of steel reinforced concrete (SRC) members with stud connectors after fire. Frontiers of Structural and Civil Engineering,8(2), 140–150.

Zheng, H., Chen, Z., & Xu, J. (2016). Bond behavior of H-shaped steel embedded in recycled aggregate concrete under push-out loads. International Journal of Steel Structures,16(2), 347–360.

Zheng, S., Lou, H., Wang, X., & Li, Z. (2012). Study on displacement ductility coefficient of steel reinforced high strength concrete column. Advanced Materials Research,368, 1097–1100.

Zhou, K., & Han, L. (2018). Experimental performance of concrete-encased CFST columns subjected to full-range fire including heating and cooling. Engineering Structures,165, 331–348. https://doi.org/10.1016/j.engstruct.2018.03.042.

Zhu, W., Jia, J., Gao, J., & Zhang, F. (2016). Experimental study on steel reinforced high-strength concrete columns under cyclic lateral force and constant axial load. Engineering Structures,125, 191–204. https://doi.org/10.1016/j.engstruct.2016.07.018.

Zhu, W. Q., Meng, G., & Jia, J. Q. (2013). Experimental studies on axial load performance of high-strength concrete short columns. Structures and Buildings,167(9), 509–519.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest regarding the publication of this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mostafa, M.M.A., Wu, T., Liu, X. et al. The Composite Steel Reinforced Concrete Column Under Axial and Seismic Loads: A Review. Int J Steel Struct 19, 1969–1987 (2019). https://doi.org/10.1007/s13296-019-00257-9

Received:

Accepted:

Published:

Issue Date: