Abstract

In this paper, a multi-disciplinary and multi-objective optimization (MDO–MOO) of a baseline over-wing-nacelle (OWN) concept design is presented. The present study extends the previous works, which considered only aerodynamic optimization, to include structural and mission design parameters. The competing objectives of minimum empty weight and minimum fuel weight for a design mission are considered in the multi-objective formulation as well as the single-objective problem of minimizing takeoff gross weight, one of many compromises possible for the multi-objective problem. An integrated computational environment has been implemented. High-fidelity analyses for the structural and aeroelastic assessment, together with middle-fidelity analyses for aerodynamic, mission, and performance analyses are performed. A complex multi-disciplinary analysis framework is proposed, to account for the interdisciplinary interaction and to provide a consistent computational framework. Optimization results with a Multi-objective Genetic Algorithm (MOGA) show Pareto frontiers accounting for structural, aeroelastic, and mission design constraints. The disciplines coupling is quantified, in terms of constraints, design variables influences, and possible trade-offs among the objectives.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Multi-disciplinary optimization (MDO) has been widely developed in engineering design, in particular in aerospace engineering [1]. This methodology allows designers to integrate simultaneously several disciplines in the design process and, therefore, to take into account the coupling interactions among all of them even during preliminary design phase. Indeed, a formal MDO approach can generally provide solutions more optimal than the ones obtained through standard sequential design.

Traditional design techniques solved the MDO problem sequentially. That is, each discipline designed for its own objective, with the aspects of other disciplines represented, at best, as constraints. The outcome of a disciplinary design was passed as input to the next discipline, finally returning to the first discipline. Since the advent of formal MDO 20–25 years ago, the sequential design process is being gradually replaced with MDO techniques, which generally consist of formulating the design problem as a nonlinear programming problem, possibly within a computational framework. Moreover, MDO techniques provide significant results when they are employed and addressed to explicit multi-objective optimization (MOO) [2]. In general, it might be helpful for the designer to take in consideration multiple objectives, for instance, one for each discipline. In fact, each discipline treated in isolation, as it follows its own objectives, typically leads to different and contrasting design solutions. Indeed, an essential issue that characterizes MDO and MOO analyses is the natural conflict that may arise among different objectives. Often, it might not be possible to determine a design solution that simultaneously optimizes all of the objectives, but it is possible to search the set of best compromise solutions, namely, the Pareto Frontier [3] to find another solution that improves at least one objective without worsening the others. The set of Pareto solutions in the objective space is known as the Pareto frontier. The Pareto frontier concept enhances MDO technique capabilities, as Pareto analyses provide a complete problem overview and enable a more aware final choice. In engineering fields, optimization based on the analysis of Pareto frontier is increasingly used during the design process.

Although there has been progress in implementing MDO in industry, a number of obstacles remain. In particular, formulating the problem, so that its contributing discipline analyses are at the right level of fidelity, yet maintain tractability, so that all the necessary objectives are accounted for in the design process, accounting for a range of variables, from continuous to discrete; all these features still present a problem in practice.

When multiple discipline solvers are required, the implementation of a best suited architecture for the MDA is a critical point that needs the designer to make significant choices about the right discipline coupling. Several architectures have been proposed over the time by the MDO community, depending on the specific problem to be solved [4].

The multi-objective nature of MDO presents a particularly difficult problem. Since the notion of optimality for many objectives generally involves infinitely many solutions along a Pareto frontier (Refs. [5, 6]) techniques that yield good multi-objective solutions and that can accurately explore the design space are needed. On one hand, often fast and accurate optimization algorithms (such as, gradient-based algorithms) are local and have difficulties when a complex design space has to be explored. On the other hand, robust and global numerical algorithms (such as stochastic multi-objective algorithms) are very expensive.

While improvements on traditional designs benefit from the accumulated experience enclosed in models, design of radically new systems cannot rely on such knowledge. Thus, MDO approaches for new systems must be particularly robust methodologically to allow for new configurations. In this context, appropriate handling of multi-objective optimization is particularly important (see Refs. [7, 8]).

The aim of the present paper is to show in a unified fashion the concepts and the results presented in Ref. [9] as well as some more recent developments. More specifically, the scope is to validate and optimize an unconventional baseline, the over the wing nacelle (OWN) proposed by NASA [10, 11]. A complex multi-disciplinary environment, including high-fidelity structural, aeroelastic, aerodynamic, mission, and control analyses in the optimization process, is utilized. This study case focuses on the handling of the MDO/MOO of complex multi-disciplinary systems. The aim is to find an efficient and effective strategy for implementing multi-disciplinary analysis and optimization, to accurately model the overall behavior with a low effort. Since the main goal of this work is to provide a global scenario for the multi-disciplinary and multi-objective problem, gradient-based methods have been excluded. Statistical analysis, together with Genetic Algorithms (GA), is chosen for the exploration of the design space. An interactive approach with the algorithm is proposed to reduce the numerical effort. A comparison of the performance of the traditional Single-Objective Optimization (SOO) and of the proposed explicit Multi-objective Optimization (MOO) approach will be done.

2 Background and application overview

The OWN is a concept from NASA Langley Research Center, which is promising to be a new solution for improving the aerodynamics in the transonic flight condition. This concept is a middle step between conventional transport aircraft and more unusual configurations. Figure 1 shows the baseline OWN configuration. The main differences between the OWN and a conventional aircraft are the location of the engine over the wing and the extension of the leading edge of the inboard section of the wing.

Several benefits due to the over-wing engine installation can be listed, such as the ground noise reduction due to the wing shielding of the engine, the possibility of installing engines of larger diameter (very high by-pass-ratio), and the possibility of creating thrust reversal spoilers simplifying the mechanism. The proposed configuration of the inboard section of the wing creates a flow tunnel between nacelle and fuselage, in which the shock locations can be controlled and the effect of the leading edge suction is enhanced, improving transonic drag performance.

In the previous publications, the work has focused on aerodynamic analysis of the configuration, with particular focus on the engine installation. The structural assessment was not performed, and therefore, the structural and aeroelastic analysis should be included in the optimization loop. Reference [10] discusses some earlier works and Ref. [12] shows some more recent results using a geometry modeling tool called Vehicle Sketch Pad (VSP) [13], and Cart3D (an inviscid, three-dimensional fluid flow toolset [14]).

Although such a concept has already been optimized from the aerodynamic and performance points of view, it should be validated by taking into account a more complete disciplinary scenario. Therefore, a multi-disciplinary environment will be presented, comprising, in addition to the mission performance and the aerodynamics (performed by FLOPS [15]), the structural and aerostructural assessment, carried out by the high-fidelity aerostructural tool FEMWING [16].

The purpose of this optimization analysis is to drive the preliminary design towards a set of better designs from a global point of view. Indeed, in this design phase, designers do not expect to obtain the exact answers about design parameters or response variables, but they look for the right direction to follow. Therefore, the analysis fidelity should reflect such requirements and include all the main analyses, even preferring approximated models over very detailed simulations. In this study case, the main design requirements, accordingly also with the international regulations, are verified, and thus, the necessary analyses for evaluating such response parameters need to be performed.

The computational effort of MDO/MOO processes is often quite high and the research/pursuit of a compromise between high-fidelity modeling and computational efficiency is mandatory. To include in the iterative process for the MDO of the OWN all the main analyses and keep the effort under control, approximations are addressed. The level of fidelity in this application aims to correctly evaluate the physical trend of the selected outputs when the design variables change. A certain error in the punctual values is admissible. A detailed description of the model fidelity is reported in Sects. 4.1 and 4.3.

The stochastic optimization algorithm MOGA II [19] has been employed to explore the design space and an interactive approach to optimization is proposed for a faster convergence to the Pareto frontier, as explained in Sect. 5.3.

3 Statement of the MDO/MOO problem

The MDO problem for the OWN accounts for the disciplinary behaviors which should be most critical for the overall design. Specifically, structures, aerodynamics, aeroelasticity, mission performance, stability, and control are the aerospace disciplines generally considered in the present framework.

Specifically, the optimization problem is intended to search for global optimum designs by optimizing the design variables that should affect all of the involved disciplines, so both structural and shape variables are used in this application. The optimization problem needs to be constrained to a reasonable and feasible design set, and therefore, it is important to introduce the main regulation constraints and check they are initially satisfied, so that the stresses, displacements, and main performance of all design guesses are checked.

3.1 Selected objectives for the optimization process

The choice of the objectives to be optimized is a key factor in the setup of the problem, because they represent the question the designer is asking to the optimizer. The choice of objectives should reflect the main goals of the involved disciplines, and at the same time parameters that significantly quantify the overall goodness of the design.

Traditionally, the Takeoff Gross Weight (TOGW) is used as optimization objective, because it correlates highly to the overall Lifecycle cost of the airplane. Indeed, the TOGW is an indirect measure of the total cost of the aircraft as it is operated over its lifetime. The TOGW results from the sum of the three main weight factors, which are the Empty Weight (EW), the Operating Weight (OW), and the Fuel Weight (FW). The EW is a measure of the airplane cost, while the FW is a measure of the operating cost. The OW does not change given the fixed performance requirements. The two components EW and FW are chosen as candidates for being objectives of the optimization, because they account for the monetary impact of the design and represent two contrasting behaviors. They are an indirect measure of structural performance, aerodynamic performance, and mission performance. Respectively, minimizing EW reduces structural weight and favors lower aspect ratio designs while minimizing FW increases flying efficiency and favors higher aspect ratio designs.

The minimum TOGW design is expected to be one of all the possible trade-off designs between the minimum FW design and the minimum EW one.

3.2 Design variables choice

The choice of the design variables and their ranges is made on the basis of two issues: (1) on one hand, the higher the number of the design variables the higher the computational effort; therefore, the number of design variables is keep as low as possible; (2) on the other hand, more design variables increase the freedom available to the optimizer to minimize the objectives while satisfying the constraints. In the present application, both structural and shape variables are used. The former are mainly addressed for the structural weight minimization and the latter for the aerodynamic optimization.

The most innovative component of OWN configuration is the wing because of the unusual position of the nacelle and the unconventional planform. Therefore, the number of wing design variables is high to allow the optimization to explore a wide design space.

Since the wing plant is unconventional, the wing is parametrically divided into four main sections having their own geometrical and structural variables to accurately model the design solutions in a more flexible way. To give more flexibility to the wing box design, the leading edge and trailing edge spars are allowed to move in chordwise direction. Moreover, as the thickness-to-chord ratio is optimized at each interface to give the optimization enough instruments for getting a good structural design for such a planform which may change.

Since the previous studies of this concept showed that the aerodynamic performance are improved when the leading edge of the inboard section is straight and advanced, the inboard section is allowed to change chord and span, but its sweep and taper ratio are, respectively, fixed to zero and one. In this way, the geometry can be optimized, but the main concept features are guaranteed to be preserved. edge sweep is a function of the current span and tip chord. The other sections have no rules to respect, except for the tip chord of the last one, which is fixed to a constant value. In fact, the involved disciplinary analyses would lead the tip chord to zero.

In order not to let the aerodynamic center move too much from its original position, the engine x-location is kept constant, while the wing leading edge is allowed to change within a small range. This degree of freedom allows the optimizer to better handle the combination chord length vs. chord flowwise location with respect to the wing box, which strongly affect the aeroelastic balance of the aircraft.

The fuselage geometry is kept constant during the optimization, while its structural design is optimized. The tail geometry is evaluated on the basis of the fuselage and the wing geometry, to reduce the design space and to guarantee a good sizing for each design guess. The tail is divided into two sections, and for each of them, the structural properties of the tail box are optimized.

The list of the design variables used in the analyses is reported in Table 1. The side constraints for the structural variables are evaluated through a preliminary structural optimization described in the following section.

3.3 Constraints

The design space is limited by applying the main airworthiness requirements. These include minimum landing climb gradient with all engines running, and minimum climb gradient with one-engine inoperative during three takeoff segments, an approach segment, and an enroute case. The second segment climb and, for two engine aircraft, the enroute climb are often critical design requirements affecting the required engine thrust and wing area.

The analysis is carried out for a fixed choice of the propulsion system. The propulsion system is a discrete variable. It has been chosen among the available engines used for similar vehicles. Preliminary simulations were conducted to chose the most appropriate propulsion system for such vehicle architecture and target mission. Finally, the Boeing 737–800 engine has been selected.

The majority of problems that occur in mission analysis are engine related, but aerodynamics and weights may contribute. Indeed, the primary deficiency may be due to an insufficient thrust-to-weight ratio, which results in the failure of most critical mission conditions (takeoff and landing). However, small wing area combined with low-aerodynamic performance may negatively affect such performance.

Specifically, the takeoff field length is heavily influenced by both the wing area and the thrust, while the landing field length is determined primarily by the approach velocity, which inversely depends on the wing area. These lengths should respect the limits defined in the regulations.

Moreover, the FAA requires that if an engine fails during approach for landing, the remaining engines must be able to maintain a specified climb gradient in the approach configuration. In addition, if an engine fails during second segment climb—after the obstacle has been cleared during takeoff, the remaining engines must be able to maintain a specified climb gradient in the takeoff configuration. These climb gradients are a function of the number of engines, and for bi-engines aircraft, it is equal to 2.1% for the missed approach, and equal to 2.4 for the second segment. During the MDA, a specific tool calculates the thrust required to maintain this gradient and subtracts it from the thrust available. The resulting thrust margin must be greater than or equal to zero. If this constraint is violated, since the thrust is fixed and cannot be increased, the optimizer is supposed to improve the lift/drag ratio or reduce the landing weight. If no feasible solutions were found, the propulsion system must be changed.

The stress assessment is conducted at ultimate load for a subset of extreme maneuver load cases, by applying a Safety Factor of 1.5 to the limit load stress margins. In addition, the wing displacement is checked for all the structural analyses.

The control action for performing these maneuvers is simulated, and the control angles are verified to be within reasonable limits. Finally, since the aerodynamic optimization would drive the solution towards high aspect ratio configurations, the aeroelastic modes are verified to be stable until an augmented drive velocity.

The detailed list of equality and inequality constraints is reported in the following:

-

Mission range = \(~2875~ {\text {miles}}\).

-

Cruise altitude = (15,000, 41,000) ft.

-

Stress (tensile, compression, Von Mises) \(< \sigma _{\text {u}} / 1.5\).

-

Displacement (wing tip vertical disp vs. wing span) \(< 5\%.\)

-

Angle of attack \(< 15^{\circ }\).

-

Elevator angle \(< 30^{\circ }\).

-

Aeroelastic damping \(> 2\%\).

-

Takeoff distance \(< 7700\,\,{\text {ft}}\).

-

Landing distance \(< 6200 \,\,{\text {ft}}\).

-

Missed approach climb gradient \(> 2.1\%\).

-

Second segment climb gradient \(> 2.4\%\).

4 Integrated environment for the multi-disciplinary optimization

The study case presented involves multiple disciplinary analyzers, to obtain as a complete as possible overview of the physical behavior of such a multi-disciplinary system.

Specific disciplinary tools are employed for evaluating each discipline performance when a certain design is analyzed during the optimization. On one hand, involving multiple specific evaluators allows to improve the fidelity of the multi-disciplinary analysis. On the other hand, it makes the complexity of the problem grow, because the architecture of the optimization process should guarantee the consistence of all of the disciplinary simulations with respect to the current design.

The approach used in the present application aims to guarantee the consistency of the MDA at each iteration, by implementing a systematic exchange of coupling variables within the same function evaluation, without introducing variable copies and consistency constraints. In fact, as the parallelization of the function evaluation in the MDA process makes the process easier to be implemented, it may increase the number of designs evaluated before the convergence is reached. Therefore, when, as in the present case, the function evaluation is quite expensive, it is worth to spend a bit longer time to implement a multi-disciplinary feasible (MDF) architecture.

4.1 Tools for the OWN optimization

Since this is a multi-disciplinary design, specific and proper disciplinary modelers and solvers are needed. The optimization computational environment is implemented in modeFRONTIER™ [17], which is an MDO and MOO platform and includes multiple optimization algorithms, beside gradient-based ones, to be applied.

The structural and aeroelastic high-fidelity analyses will be performed by FEMWING, a tool developed in the framework of the present research activity (see Sect. 4.2), able to be coupled with MSC.Nastran™solvers.

The FLight Optimization System (FLOPS) is used for performing the mission analysis and overall systems sizing. It is an aircraft performance and gradient-based optimization program for preliminary and conceptual design, which is originally based on empirical and analytical models. It has been enhanced by including more advanced models and the possibility to analyze unconventional configurations. It can perform the optimization of the design by defining objective and constraints to be respected, but this feature is not used in the present application.

Cart3D [14] is a high-fidelity inviscid analysis package for the aerodynamic analysis. It is able to simulate transonic flows and predict the shock locations. It has an adjoint feature able to perform an aerodynamic shape optimization. It will be used to improve the aerodynamic analysis in FLOPS.

4.2 The developed aerostructural tool: FEMWING

In the present work, the aerodynamic and structural finite-element models are generated for each design variable combination during the optimization, using FEMWING. FEMWING is a tool for the model generation and the simulation of structural and aerodynamic behaviors, intended to be used for the conceptual/preliminary design of aircraft.

Figure 2 shows an example of structural and aerodynamic models created by FEMWING for the OWN vehicle geometry once a set of design variables is assigned. It is able to account for the change of the aircraft geometry during the optimization process thanks to a re-meshing mechanism and then to automatically perform high-fidelity analyses for the current aircraft configuration without using surrogate models (Fig. 3). Indeed, FEMWING is able to entirely manage aerostructural analyses for aircraft-like vehicles and it is addressed to be coupled with commercial solvers (namely, MSC.Nastran) for the structural, aeroelastic, and aerodynamic simulations necessary in an MDO framework. FEMWING is intended to interact with an external optimization code as well, to be included in complex multi-disciplinary process together with other disciplinary tools. Therefore, the MDO–MOO procedure proposed in the present paper is able to account for significant changes in aircraft geometry during the optimization process.

4.3 Multi-disciplinary analysis

The MDO is carried out by combining all the discipline analyses, to sequentially evaluate the coupling variables necessary for the subsequent analyses. A small subset of load cases for the conceptual design optimization is selected, to satisfy the main requirements of FAR-25 (Airworthiness Standards: Transport Category Aircraft).

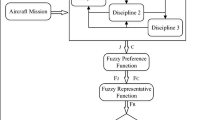

A multi-disciplinary feasible architecture for the MDA is developed. Figure 4 shows the MDO workflow, implemented in modeFRONTIER™environment. Four main function evaluation modules are executed in the order that they are presented in the following:

-

1.

Tail sizing: The sizing is based on a regression model, that is able to provide reasonable sizing for the vertical and horizontal tail, using the dimension of the fuselage and the wing, i.e., the geometrical design variables (common design variables \(x_0\)). The Generalized Tail Sizing Method (by J. Morris and D. M. Ashford of Douglas Aircraft [18]) is intended to give consistent and realistic tail sizes for conceptual design by calculating a volume ratio between wing and fuselage.

-

2.

Reduced femwing: It creates the structural FE model on the basis of the current design vector chosen by the optimizer (using the common design variables \(x_0,x_1\)) and the Tail Sizing module. It builds the primary structure mesh for the actual geometry and structural properties, but without including any non-structural mass. This module provides the structural weights of the wing, the fuselage and the horizontal tail (\(y_1\)), through a high-fidelity weight evaluation of the primary structure weights performed using MSC.Nastran. The material density is augmented by multiplying the real density for certain correction factors, which allow to take into account the additional weight due to secondary structural elements, rivets, joints, and so on.

-

3.

Flops in analysis mode: FLOPS module performs Takeoff Gross Weight, subsystem weights, aerodynamics and mission performance estimation (\(y_2,y_3\)) for the current structural weight and external geometry. It will simulates the most critical conditions, such as the landing and the takeoff with one inoperative engine. To make consistent the analysis, the actual structural weights evaluated in the reduced FEMWING module are used as input of the FLOPS analysis (using as input variables \(y_1,x_0,x_2,x_3\)). In detail, the mission analyses performed by FLOPS are:

-

Aerodynamic analysis: the aerodynamic performance of the current design is evaluated in terms of lift and drag in different flight conditions.

-

Mission profile: the entire mission cycle (takeoff, cruise, landing) is calculated for the required range and for the used propulsion system. The optimal altitude for the current design is evaluated and used for the cruise segment. All aerodynamics and mass properties are used for this analysis, and moreover, the mass breakdown due to the fuel burn is taken into account during the mission calculation.

-

Takeoff and landing: the takeoff and landing module computes the all-engine takeoff field length, the balanced field length including one-engine-out takeoff and aborted takeoff, and the landing field length. The approach speed is also calculated, and the second segment climb gradient and the missed approach climb gradient criteria are evaluated.

-

Fuel burn: the total fuel request for the entire mission cycle (takeoff, climb, cruise, landing) is evaluated for the current design.

-

Drag estimation: the drag is estimated during the entire mission cycle, taking into account the variation of the fuel weight during the mission. The drag estimation will be improved by an aerodynamic solver (Cart3D).

-

Subsystem sizing: all the subsystems and control systems are sized for the current design. Therefore, on the basis of the actual structural weight evaluated by FEMWING, the total Gross Weight of the current design is calculated.

-

-

4.

Femwing: The structural and aeroelastic analyses are performed by FEMWING, using all of the data previously evaluated (\(x_0,x_1,y_1,y_2,y_3\)). As previously done in REDUCED FEMWING module, the structural mesh is built on the basis of the structural and geometrical design variables picked by the optimizer, while to properly account for inertia effects and maneuver loads, system weights, control surface weights, vertical tail weight, payload, and fuel weight distributions (evaluated by FLOPS) are added to the structural model. Finally, the aeroelastic assessment is carried out (evaluating the \(y_0\)) through the following structural and aeroelastic high-fidelity analyses are performed by FEMWING module through MSC.Nastran™solvers:

-

Weight estimation: the primary structure weights of wing box, fuselage and tail box are evaluated for the current choice of geometry and structural properties.

-

Static taxi bump: gravity uniform load at 2g applied at landing gear grid points.

-

Static aeroelastic maneuvers: the longitudinal trim aeroelastic analysis at cruise flight condition for the following load factors:

2.5 g full payload and full fuel.

2.5 g full payload and zero fuel.

− 1.0 g full payload and full fuel.

− 1.0 g full payload and zero fuel.

-

Flutter: the dynamic aeroelastic stability analysis can be performed at 1.2 Vd. The aeroelastic damping ratio is verified to be more than 2%.

-

Along with these four disciplinary tools, the MDA analysis comprises other secondary calculation nodes, which allow to make consistent the input to the different modules, namely, to convert the variables into different unit of measure (for instance, feet from meters, or pound from kilograms and vice versa) and to convert the variables into different reference systems.

In addition, two fail criteria are added into the MDA to not waste time for performing the entire function evaluation if certain requirements, evaluated early in the analysis, are not satisfied. In detail, since the wing box is allowed to move chordwise and to change its size, a first fail condition checks whether the leading and trailing edges never have negative sweep. Moreover, if the mission analysis fails (i.e., the current design is not able to fly), the analysis stops and avoids to spend time for the next expensive function evaluation.

4.4 Multi-disciplinary process architecture

The mathematical formulation of the proposed MDA can be classified as a distributed MDF architecture, according to the categorization presented in the literature [4].

Figure 5 shows the conceptual workflow for the multi-disciplinary optimization of the OWN.

The disciplinary input and response variables are identified in Table 2.

4.4.1 Multi-objective optimization problem

It is possible to express the multi-objective optimization problem solved at the system level as in the following:

where \(\sigma\) is the stress level (comprising tensile, compression and von Mises), d is the wing displacement, \(\alpha\) is the angle of attack, \(\delta _{\text {e}}\) is the elevator deflection, FAROFF and FARLD are, respectively, the takeoff and landing distances, and AMFOR and SSFOR are, respectively, the missed approach and the second segment margins.

Sub-optimization modules are considered, but they are not allowed to alter the values of the design variables handled at the system level by modeFRONTIER [17]. In this way, variable copies and consistency constraints are not needed and the optimization process converges to an optimal design under the here described scheme.

Sub-optimizations at mission level and aerodynamic level are implemented and conducted separately by the specific mission and aero modulus of FLOPS and Cart3D.

In detail, the sub-optimization at the mission level is expressed as

where R is the mission range, T is the engine thrust, M is the Mach number, and h is the cruise altitude that can be optimized. This sub-optimization provides the optimum mission profile and the sizing of the subsystems for the current design, while the minimum total weight is the goal.

The optimization process is implemented for performing the aerodynamic sub-optimization as well, on the basis of an aerodynamic response surface provided by Cart3D analyses. Specifically, the problem that will be solved using an adjoint method at the aerodynamic sublevel is

where D is the aerodynamic drag. This local sub-optimization will efficiently find the optimal values of strictly aerodynamic shape variables, which the main optimization is less sensitive to.

4.4.2 Single-objective optimization problem

The single-objective optimization problem can be expressed as the MOO, except for the optimization problem solved at the system level. It is expressed as in the following:

5 Optimization strategy

This optimization analysis aims for analyzing the possible optimized design solutions for the OWN concept. Namely, once the main design preferences on the geometry are fixed through design variable rules (i.e., for instance, the position of the nacelle over the second section of the wing, the straight inboard section, non-swept trailing edge of the first two sections, tip chord fixed), the optimization is supposed to move within a design space around the baseline design. The purpose is the exploration of the feasible design space to select a set of optimal designs to be considered as starting point for the next design phases.

5.1 Optimization steps

When an optimization problem is studied, it is fundamental to choose an appropriate methodology. The adopted optimization analysis is carried out by following three main steps.

-

1.

Statistical analysis of the design space (DOE)

A preliminary statistical analysis for the optimization problem setting is performed. The entire design space is filled by 1000 designs, which are generated by applying the Uniform Latin Hypercube (ULH) technique. The statistical analysis is used to best initialize the algorithm: by identifying the most relevant input variables and proper side constraints. In addition, it allowed to select an efficient DOE as initial population of the optimization. In this work, the statistical analysis is also used for evaluating the correlation among candidate objectives (see Fig. 6) and their sensitivity to the different disciplinary behaviors. This supports the choice of the objectives, or the EW, as a measure of the structural performance, and the FW, as a measure of the aerodynamic lift-to-drag. The statistical analysis on the DOE set is also useful for estimating the sensitivity of the response variables with respect to the design variables. Moreover, it allowed to check whether the MDA is able to capture significant physical behaviors (such as those shown in Figs. 7 and 8).

As final result, the initial DOE for the optimization analyses is determined.

-

2.

Structural SOO (TOGW minimization)

The baseline of the OWN does not comprise an airframe design, because it has been optimized only from the aerodynamic and engine points of view.

Therefore, a first optimization process, to obtain a good starting guess of the airframe, has been done. In detail, the first structural optimization has been performed using only the structural variables, while the external geometry has been frozen by previous design activity [12]. Multi- objective Genetic Algorithm (MOGA II [19]) has been applied for this first optimization, because there is no initial data and a wide exploration of the design space should be done (history chart, as shown in Fig. 9).

All of the evaluated designs are divided into 11 clusters, namely, design families having common features. Each design cluster represents a certain type of designs. As a result, the structural design variable side constraints to be used for the next optimization steps are determined by observing the design variable values assumed by the selected clusters (for further details, see [16]).

-

3.

Multi-disciplinary MOO for the OWN

Once an initial guess of an acceptable airframe is obtained, the multi-disciplinary optimization of the whole model can be performed using all the design variables, both aerodynamic and structural variables, whose ranges are centered on their reference values. The multi-disciplinary optimization is performed by applying the multi-objective approach. The results are shown in Sect. 6.1.

-

4.

Multi-disciplinary SOO for the OWN

The multi-disciplinary optimization is performed by applying the single-objective approach, by optimizing a global target. The results are then compared to the previous ones in Sect. 6.2.

5.2 Optimization algorithm choice

In the literature, several optimization methods are being proposed for solving different kinds of optimization problems. Indeed, depending on the problem on hand, the method should be chosen on the basis of certain main requirements. In fact, it is not possible to define the ”best” optimization method for any kind of problem, but it is possible to find the best suited method for a certain problem.

The choice depends on several characteristics of the optimization problem, like, the dimension of the problem, the complexity/regularity of the functions, and the scope of the optimization.

When a new problem is faced, often, a high number of design variables and objectives are used to explore the design space. In this case, stochastic approaches are probably the best candidates for such problems, because in general, they can handle large problems and have the ability to deeply explore the design space.

However, if designers want to achieve advanced refinements and improvement of existing solutions, for example, when a sub-optimal solution has to be optimized in its neighbor and a reduction of the design space has already been done, deterministic approach may be more appropriate, due to their speed and accuracy in solving a local problem.

In explicit multi-objective optimization, the optimization strategy (1) should converge as closely to the true Pareto frontier as possible and (2) should maintain as diverse a solution set as possible. The first condition clearly ensures that the obtained solutions are near optimal, and the second condition ensures that a wide range of trade-off solutions is obtained.

Again, population-based methods can better handle multi-objective problems. In detail, the Multi-objective Genetic Algorithm (MOGA II [19]) will be employed in this optimization analysis, because it is robust and allows to easily solve MOO problems. The following optimization algorithm settings are used in the MOGA:

-

Mutation probability 10% with a DNA string mutation ratio of 5%: to introduce randomly new designs (more robust optimization).

-

Selection probability 5%.

-

Elitism operation active: it allows to keep the best designs over generations.

As general criteria, rich initial populations are created as starting condition. In fact, as previously discussed, the initial populations should give enough genetic information to the optimizer, because they determine the dimension of the design space that can be explored and they represent the instruments to be used for this purpose.

5.3 Interaction with the algorithm

To lead the optimization towards the Pareto frontier and speed up the convergence, an interactive approach is applied. Indeed, the genetic algorithm is able to converge to the global optimum solutions, but the convergence speed may be quite low when the asymptotic trend is reached.

The user interaction with the optimization process is based on three principles: (i) multi-step optimization; (ii) population size; and (iii) selection of analyses to be included.

- (i):

-

The multi-step approach is used when the optimization process reach an asymptotic phase. Specifically, the output variables trends are checked. When their improvement get slower, the run is first stopped, then a new starting population is defined on the basis of the temporary results. The best temporary designs and the best sub-optimal designs are selected to create the new starting population. Moreover, among them, only the designs that maximize the design distance in the design space are kept. Finally, the new starting population is enhanced by adding new random designs through a space filler technique, to maximize the chromosome diversity.

- (ii):

-

The population size is reduced during the optimization process. Specifically, initial generations having large populations (around 100 designs) are used in the first phase of the run, because in this phase it is important to widely explore the design space. Then a gradual decrease in population size until convergence is applied, up to ten designs when the Pareto frontier is refined.

- (iii):

-

The most computationally expensive analysis (in this case the flutter, which takes three times more than all of the other function evaluations) is not included from the start of the optimization process, because it is not worth to waste computational time for accurately evaluating numerous bad designs when the process is still far from the convergence. Therefore, a multilevel approach is applied, following the idea of allowing the optimizer to evaluate numerous designs at the beginning and then refine the sub-optimal solution by including all of the expensive analyses.

6 Results of the optimization

In this section, the results of the final multi-disciplinary optimization via an explicit MOO approach are presented. The Pareto frontier is evaluated for the objectives EW and FW to be minimized. The same optimization problem is then solved with a SOO, namely, by minimizing the TOGW. The results are then compared.

6.1 Multi-disciplinary MOO for the minimum empty and fuel weights

This multi-objective optimization problem is intended to solve explicitly the minimization of the two objective functions EW and FW, in the design space comprising structural and geometrical variables.

6.1.1 Two-step optimization

The initial population is generated starting from a 1000 design DOE through the space filler ULH, that comprises feasible, unfeasible (the flutter is not initially checked) and failed designs. This DOE is then reduced to 250 designs by excluding the failed designs and by selecting, among the feasible and unfeasible designs, the ones which maximize the distance in the design space (which was no longer guaranteed to be uniform when the failed are excluded).

The MOO and MDO problem is carried out by following the interactive strategy presented in the previous Sect. 5. In detail, since the aeroelastic stability check through the MSC.Nastran flutter analysis is much more expensive then the other function evaluations, this analysis is not performed for the initial generations. In the initial evolution of the solution, the number of the individuals of each generation is kept equal to 250. In this way, a wide exploration of the design space can be performed.

Figure 10a shows the evolution of the designs over generations in the objective space during the first step of the optimization, which fast moves towards lower values of both the objectives. During the optimization process, the run is monitored. Whenever designs do not uniformly fill the temporary Pareto frontier, or whenever the evolution speed gets slower, the process is restarted from a selection of good designs.

Together with such a design selection, random designs are added by optimizing the design space filling of the selected set, to introduce diversity in the population, and to avoid to artificially limit the evolution. When the process is stopped and restarted, the size of the populations is properly reduced and the flutter check is performed on a small sample of designs. This strategy allows one to speed up the process (as previously proved in Refs. [20, 21]).

Once a set of sub-optimum designs is obtained and the flutter check starts failing, the flutter analysis is introduced into the MDA and it is systematically performed for the evaluation of all of the design samples. In this second optimization phase, the population size is gradually reduced to 30 designs. Figure 10b shows the final generations of designs in the objective space. When the asymptotic trend is reached, and the unfeasible designs become more and more populated, the optimization is stopped.

6.1.2 The Pareto frontier

The advantage of the multi-objective approach is shown in Fig. 11a, b, where the final designs are classified on the basis of, respectively, their TOGW (Fig. 11a) and AR (Fig. 11b) through a color scale. The result of the MOO is the Pareto frontier, whose designs are highlighted by a green circle. The more optimal designs, belonging to or being next to the Pareto frontier, sweep a wide range of configurations, starting from designs having an AR less then 6 and ending to designs having an AR more than 14. All these very different designs have very close values of the TOGW; thus, they are all different compromises between structural and aerodynamic requirements for a quasi-constant value of TOGW.

This confirms that minimizing the two components of the TOGW provides the designer a numerous design set, from which it is possible to apply preferences a posteriori for picking the trade-off designs which better fit further additional requirements.

6.1.3 Significant Pareto designs

The Pareto designs are selected from all of the obtained designs, and the three designs having, respectively, the minimum value of EW, FW and TOGW are picked. Figures 12, 13, and 14 show the structural design together with the lifting surface planform of the three designs with a color scale representing the variation of the structural thickness. Figure 15 shows the location of these three Pareto designs on the Pareto frontier.

As previously hypothesized, the minimum EW design and the minimum FW design represent the extreme solutions of the Pareto frontier, while the minimum TOGW design is one of the compromises between them. This is confirmed by the design data, as listed in Table 3. Indeed, the minimum FW design has the highest value of the aspect ratio, and, therefore, of the total span, while its root chord of the outboard section is the lowest one. Its mean thickness-to-chord ratio is the lower than the one of the other designs, but the total variation is not very high (only 0.67%). As a consequence, to guarantee a proper bending stiffness, the spar caps and webs increase their area and thickness and the wing box (the spar positions) moves forward. The minimum EW design has the opposite trends, while the minimum TOGW design is always a trade-off between the other two.

The aspect ratio of the Pareto designs sweeps between around 12.5 and 9.85, with a total variation of 26%, while the L/D of the minimum FW design is 9.41% higher than the minimum EW design one.

In addition, it is interesting to notice that the ranges of EW, FW and TOGW of the Pareto designs are not very wide; indeed, the FW can be at maximum decreased by the 6.24% against an EW increase by 3.68%. Whereas, the TOGW range is very small, namely, its variation is around 0.68%. This confirms that all of the Pareto designs are optimal when ranked on the basis of the minimum TOGW preference.

6.1.4 Effect of constraints

The most limiting structural load cases for the wing box are the 2.5 g and the − 1.0 g maneuver load cases. The wing box is mainly sized by the 2.5 g maneuver load condition.

The flutter constraint mainly impacts on the aspect ratio of the wing, which is limited to a maximum value of 13.5. The aerelastic stability is imposed in a conservative way, by monitoring that all of the flow-interactive mode roots do not get close to the imaginary axes for a \(1.2V_d\) speed with a sufficient aeroelastic damping ratio. The not-aeroelastic roots (i.e., the ones that do not move in the complex plane when the velocity increases) are verified to have a damping ratio greater than \(0.1\%\), even if those modes should be theoretically flutter safe.

The AR is in addition limited by the stress constraints, due to the increase in bending load when the AR is high. Indeed, the flutter constraint limits the feasible design space by excluding very high AR designs (more than 14), namely, designs in the bottom area of the feasible objective space (low FW and middle values of EW). The stress constraints limit the solutions having a very low Empty Weight (full stressed designs), i.e., mainly excluding the designs lying next to the middle portion of the Pareto frontier. A graphical location of the active constraints in the objective space is shown in Fig. 16.

The flutter constraint is quite always covered by the stress constraint, but not when the structural design is heavier than necessary. In this case, higher masses of the structure causes lower aeroelastic frequencies which more probably may go towards the aeroelastic instability.

The mission constraints are no longer active when the designs have generally a low TOGW, while they are very often critical in the first phase of the optimization. These constraints limit the feasible objective space diagonally, excluding heavy designs and low-aerodynamic performance designs, because the thrust cannot be increased by the optimizer.

6.2 Multi-disciplinary SOO for the minimum gross weight

The same problem is solved by optimizing only one objective, namely, the Takeoff Gross Weight, to compare the two approaches. The same strategy proposed for the MOO problem is applied until convergence is reached.

In this case, the optimization evolves in the straight direction towards lower TOGW designs, but does not explore a wide set of designs, because it is not driven to do that (see Fig. 17). All of the optimum and sub-optimum designs are very similar each other. Specifically, their TOGW value is enclosed in a small range (see Fig. 18a), as well as their Aspect Ratio (see Fig. 18b). Considering these results, the designer do not have the possibility to analyze different compromises.

The best design, namely, the one having the minimum TOGW, lies in the Pareto frontier area resulting from the MOO analysis. In Table 4, the weight performance of the optimum design obtained through this analysis is compared to the ones of the Pareto designs calculated through the MOO in Sect. 6.1. Comparing the SOO minimum design to the design selected from the Pareto frontier by applying a posteriori the minimum TOGW preference, the SOO optimum design is equally performing than the MOO minimum TOGW design. In fact, the percentage difference between the TOGW value of two optimum designs is equal to 0.4%. Such value is comparable with the uncertainty of the Pareto frontier evaluation, which could be exactly represented in the objective space only when infinite iterations are performed.

The computational time saving, when only one objective instead of two is optimized, is negligible. On the contrary, the design overview obtained through the SOO is very limited when compared to the wide set of compromise designs that the MOO analysis has been able to provide (see the ranges of the EW, FW, and TOGW in the third column of Table 4).

7 Concluding remarks

A multi-disciplinary and multi-objective computational environment has been developed for the design optimization of an unconventional configuration known as OWN. The approach has allowed, in relation with the adopted levels of physical fidelity for all the considered disciplines, to describe the most relevant physical behaviors of the considered configuration. When unconventional designs are proposed, this approach represents a useful instrument for evaluating the effectiveness of the main features characterizing the concept and, therefore, to critical review them to further develop the design.

As concerning the scenario of the obtained design results, the MOO approach has shown to be generally much more complete and rich when compared to the SOO approach. Indeed, the results obtained by simply optimizing a single-objective function, which describes the overall designer preferences, are significantly more restrictive for next design optimization phases. In fact, it has been shown that the information that designers can get from SOO analysis are much poorer than the ones they can get from MOO analysis.

Moreover, the TOGW values of the Pareto designs obtained through explicit MOO are comprised in a very small range. Thus, the preference on minimum TOGW has not been an effective selection criterion in this application. Indeed, all Pareto designs are actually optimal according to such preference, and therefore, it does not help in ranking the Pareto designs. In this case, additional designer preferences should be stated to decide which designs will be the best candidates for the following design phases. Additional and more detailed preferences should be decided on the basis of these preliminary results.

Several optimum designs could be picked from the Pareto frontier to go to the next phase of design process. Specifically, further discipline analyses should be included into the MDA to refine the evaluation of candidate designs. For instance, higher fidelity aerodynamic analyses are required to better optimize the shape of the wing together with the nacelle. Moreover, it is important to verify that all the main concept features are suitable modeled. For instance, the current aerodynamic analysis is not able to account for the positive effect of the increase of the inboard wing section, which enlarges the flow tunnel size between the fuselage and the nacelle. it is mainly driven by the structural assessment.

This is a typical example of the issue that may arise when one of the involved disciplinary model is not sufficiently homogeneous with the others. However, the use of more detailed models, which may make the computational time less affordable, is not the only solution. Indeed, it is important to find the strategy for allowing the MDA to account for hierarchically equivalent disciplinary behaviors, for instance, by tuning the level of details of reduced models. For this specific case, the aerodynamic analysis should be enhanced by calculating a response surface through CFD codes, which will be able to evaluate with more details the aerodynamic forces for a certain number of flight conditions, comprising the shock locations, and, therefore, to better optimize the shape of the design.

Abbreviations

- AR:

-

Wing aspect ratio

- d :

-

Displacement

- E :

-

L/D

- h :

-

Cruise altitude

- x :

-

Design variable

- y :

-

Response variable

- \(\mathbf{X}\) :

-

Design space

- AMFOR:

-

Missed approach margin

- DOE:

-

Design of experiments

- EW:

-

Aircraft empty weight

- FARLD:

-

Landing distance

- FAROFF:

-

Takeoff distance

- FEM:

-

Finite-element model

- FW:

-

Aircraft mission fuel weight

- MDA:

-

Multi-disciplinary analysis

- MDF:

-

Multi-disciplinary feasible

- MDO:

-

Multi-disciplinary optimization

- MOGA:

-

Multi-objective genetic algorithm

- MOO:

-

Multi-objective optimization

- OW:

-

aircraft operative weight

- OWN:

-

Over-the-wing-nacelle

- SOO:

-

Single-objective optimization

- SSFOR:

-

Second segment margin

- TOGW:

-

Aircraft takeoff gross weight

- ULH:

-

Uniform latin hypercube

- \(\alpha\) :

-

Angle of attack

- \(\delta _{\text {e}}\) :

-

Elevator angle

- \(\sigma\) :

-

Stress

References

De Weck, O., Agte, J., Sobieszczanski-Sobieski, J., Arendsen, P., Morris, A., Spieck, M.: State of the Art and Future Trends in MDO. (2007). In: 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, Hawaii

Marler, R.T., Arora, J.S.: Survey of multi-objective optimization methods for engineering. Struct. Multidiscip. Optim. 26, 369–395 (2004)

Pareto, V.: Manuale di economia politica con una introduzione alla scienza sociale, Piccola biblioteca scientifica, Milano (1906)

Martins, Joaquim R.R.A., Lambe, Andrew B.: MDO: a survey of architectures. AIAA J. 51(9), 2049–2075 (2013). https://doi.org/10.2514/1.J051895

Osyckza, A.: Evolutionary algorithms for single and multicriteria design optimization. Physica, Berlin (2002)

Arora, J.: Introduction to Optimum Design, 2nd edn. Elsevier, Amsterdam (2004)

Mastroddi, F., Gemma, S.: Analysis of Pareto-Frontier for Multidisciplinary Design Optimization of aircraft Proceedings of the CEAS 2011 3-rd CEAS Air and Space Conference, 21st AIDAA Congress (2011)

Mastroddi, F., Gemma, S.: Analysis of Pareto frontiers for multidisciplinary design optimization of aircraft. Aerosp. Sci. Technol. 28, 40–55 (2013)

Gemma, S., Mastroddi, F.: Multi-disciplinary and multi-objective optimization of an unconventional aircraft concept. In: 16th AIAA/ISSMO Multidisciplinary Analysis and Optimization Conference, AIAA 2015–2327, 22–26 June, Dallas, Texas (2015)

Hill, G.A., Kandil, O.A.: Aerodynamic investigations of an advanced over-the-wing nacelle transport aircraft configuration. In: 45th AIAA Aerospace Sciences Meeting and Exhibit, 8–11 January, Reno, Nevada (2007)

Kinney, D.J., Hahn, A.S., Gelhausen, P.A.: Comparison of low and high nacelle subsonic transport AIAA-1997-2318, AIAA, Reston, VA (1997)

Hahn, A.S.: Application of Cart3D to complex propulsion-airframe integration with vehicle sketch pad. In: 50th AIAA Aerospace Sciences Meeting including the New Horizons Forum and Aerospace Exposition, 09–12 January, Nashville, Tennessee (2012)

Hahn, A.S.: Vehicle sketch pad: a parametric geometry modeler for conceptual aircraft design. AIAA-2010-657, AIAA, Reston, VA (2010)

Cart3D, Inviscid Aerodynamics Analysis, Software Package, Ver. 1.4, NASA Ames Research Center, Moffett Field, CA. http://people.nas.NASA.gov/~aftosmis/cart3d/ (2011)

McCullers, L.A.: Aircraft configuration optimization including optimized flight profiles. NASA CP-2327 Part 1, Number 87N11743 (1984)

Gemma, S. : Multi- and single-objective multidisciplinary optimization for the preliminary design of aircraft. Ph.D. dissertation, Dept. of Mechanical and Aerospace Engineering, University of Rome La Sapienza (2015)

modeFRONTIER User Manual, 4.0 Release Notes, Esteco (2009)

Morris, J., Ashford, D.M.: Aircraft fuselage configuration studies point to use of multideck fuselages. Society of Automotive Engineers, SAE 670370, Warrendale, PA

Poles, S.: MOGA-II, An improved Multi-Objective Genetic Algorithm. Technical report 2003-006, ESTECO, Trieste. http://www.esteco.com (2003)

Gemma, S., Mastroddi, F.: Nonlinear modelling for multi-disciplinary and multi-objective optimization of a complete aircraft, Aerotecnica Missili e Spazio. J. Aerosp. Sci. Technol. Syst. 92(1–2), 61–68 (2013)

Gemma, S., Mastroddi, F.: Nonlinear modelling for multi-disciplinary and multi-objective optimization of a complete aircraft. In: Proceedings XXII AIDAA National Conference, Napoli 9–12 Settembre (2013)

Acknowledgements

This paper has been supported by a Sapienza University of Rome project, year 2014, entitled “Advanced Multi-Disciplinary and Multi-Objective Optimization for the design of innovative very light aircraft”. This work has been carried out during a 9-months research period for Stefania Gemma as PhD student at the Analysis Systems Aeronautics branch at NASA LaRC under the Environmental Responsible Aviation (ERA) program. The authors thank Craig Nickol, Andrew Hahn, and Dr. Natalia Alexandrov from NASA LaRC for their helpful suggestions and support in the progress of the present work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gemma, S., Mastroddi, F. Multi-disciplinary and multi-objective optimization of an over-wing-nacelle aircraft concept. CEAS Aeronaut J 10, 771–793 (2019). https://doi.org/10.1007/s13272-018-0347-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13272-018-0347-7