Abstract

Pichia pastoris is a successful expression system that is frequently preferred in the secretion of proteins for both basic research and industrial purposes. In this study, recombinant Rhizomucor miehei (RmASNase) L-asparaginase was produced in Pichia pastoris. The impact of gene copy number on increasing protein production was examined with six clones harboring various gene copy numbers (1–5 and 5 +). The results demonstrated that the clone with three copies of the expression cassette integrated had the highest production level. Also, biochemical characterization of the enzyme was performed. It was determined that the optimum pH and temperature values of the purified enzyme were pH 7.0 and 50 °C, respectively. Stability analyses of the enzyme showed that it maintains its activity of 80% in the pH range of 5–9 and 67% in the temperature range of 20–50 °C. Ca+2 and Mn+2 ions increased the enzyme activity to 121% and 138%, respectively. In future studies, it is also possible to improve the activity and stability values of the enzyme with advanced molecular techniques and to increase production efficiency by producing at fermenter scale and under optimum conditions.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

L-Asparaginase or ASNase (EC 3.5.1.1, L-asparagine amidohydrolase) is the enzyme that hydrolyzes L-asparagine to aspartic acid and ammonia. The main application areas of this enzyme include the food industry as the acrylamide mitigation agent, and the pharmaceutical industry as a drug to treat acute lymphoblastic leukemia (Cachumba et al. 2016; Chi et al. 2021).

L-asparaginase is presented in various sources in nature, such as plants, animals and microorganisms. However, due to the ease of upstream and downstream processes that facilitate adaptation to large scale productions, microbial sources stand out as more advantageous than others (Jia et al. 2021). To date, recombinant asparaginase productions have been carried out using a variety of gene sources like Escherichia coli MTCC 739 (Vidya et al. 2011; Upadhyay et al. 2014), Erwinia carotovora (Pourhossein and Korbekandi 2014), Saccharomyces cerevisiae (Lopes et al. 2019), Pseudomonas aeruginosa (Izadpanah Qeshmi et al. 2022), Streptomyces griseus (Meena et al. 2015) and Zymomonas mobilis (Einsfeldt et al. 2016).

There are only a few microorganisms used in the industry to produce asparaginases. Currently, the pharmaceutical industry has used L-asparaginases prepared from E. coli and E. chrysanthemi (E. carotovora). However, these bacterial sources may cause immunological sensitization (da Cunha et al. 2019). In the food industry, Aspergillus niger and A. oryzae, which are considered as GRAS (generally recognized as safe) by the US Food and Drug Administration (FDA), are used (Xu et al. 2016). The search for new enzyme sources is necessary to obtain options with different biochemical properties and expand application areas. Therefore, recent studies focused on fungal L-asparaginases offering advantages such as better compatibility with the human system and suitable biochemical characteristics for food processing (Cachumba et al. 2016; da Cunha et al. 2019). Recombinant DNA technology is a promising strategy providing different approaches for the more efficient production of these proteins (Nordén et al. 2011; Hu et al. 2013; Ahmad et al. 2014; Castro et al. 2021; Zhu et al. 2021).

The methylotropic yeast Pichia pastoris is a widely used expression system for the secretion of heterologous proteins for both basic research and industrial processes. The features that make this system popular include (i) its ability to grow to high cell densities on simple and inexpensive media, (ii) its ability to secrete high levels of heterologous proteins under tightly regulated promoters, and (iii) to perform post-translational modifications such as glycosylation and disulfide bridge formation (Cereghino and Cregg 2000; Macauley-Patrick et al. 2005). L-asparaginase from Rhizomucor miehei has been successfully expressed in Pichia pastoris expression system in this study. Furthermore, the integrated expression cassette copy number effect was examined to improve production. The clone providing the highest production level was determined and the biochemical properties of the recombinant enzyme were characterized.

Materials and methods

Asparaginase gene source, vectors and strains

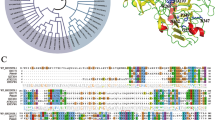

R. miehei L-asparaginase was synthesized as codon-optimized based on P. pastoris codon usage preference. The sequence alignment analysis of the DNA sequence used in this study with the native gene sequence is given in Fig. 1.

The RmASNase gene was cloned and expressed using the pPICZαA expression vector. E. coli XL1-Blue was used for subcloning and P. pastoris KM71H was used as the host expression system.

Cloning of the R. miehei L-asparaginase gene in P. pastoris

The RmASNase gene was cloned under the AOX1 promoter in the pPICZαA expression vector and extracellular expression was performed with S. cerevisiae α-mating factor. The schematic representation of the obtained vector pPICZαA-RmASNase was given in Fig. 2.

The obtained expression vector pPICZαA-ASNase was linearized with the PmeI and transferred into electro-competent P. pastoris KM71H cells by electroporation (Bio-rad electroporator). Transformant cells were spread on YPD agar plates containing 100–1000 μg/ml zeocin and incubated at 30 °C for 2–3 days.

Determination of the integrated expression cassette copy number by Southern blot

Selected transformants were transferred to YPD broth and copy numbers of the integrated expression cassettes in clones were determined by Southern blot analysis according to Karaoglan and Erden-Karaoglan (2020). Genomic DNA isolation was done using Yeast DNA Extraction Kit (Epicentre) according to the manufacturer’s protocol. For each clone, 1 µg of genomic DNA was digested with BstEII and separated on 0.8% TAE agarose gel. The DNA fragments in the gel were transferred to the positively charged nylon membrane. DIG-labeled AOX1 promoter probe was used for the hybridization. The imaging process was carried out using X-ray film in a dark room and the copy numbers of the integrated expression cassettes of the clones were determined according to the band size.

Recombinant L-asparaginase production in shake-flasks

The clones harboring different gene copy numbers were first inoculated into 5 ml of YPD medium. After the incubation at 28 °C and 250 rpm for 24 h, the cultures were used as inoculum as an initial density of OD600nm = 0.1 for 50 ml of BMGY medium and incubated for 24 h for cell accumulation. Then the cells were harvested and resuspended in BMMY medium for protein production. The induction phase continued for 72 h and supernatant samples were collected every 12 h during fermentation. Production levels of the clones were compared according to the enzyme activities determined.

SDS-PAGE analysis of the proteins

SDS–Polyacrylamide Gel Electrophoresis (SDS-PAGE) was carried out in 5% polyacrylamide loading gel and 10% polyacrylamide separation gel. The supernatant samples were mixed with 4 × SDS gel loading buffer in 25 µL and denatured for 10 min at 70 °C and the prepared samples were loaded onto the gel. Electrophoresis was performed in 1 × TGS (0.025 M Tris base/0.192 M Glycine/0.1% SDS, pH 8.3) buffer at 150 V for 60 min. After electrophoresis, the gels were stained with Coomassie Brilliant Blue G-250 for detection of the proteins.

Purification of the recombinant L-asparaginase

The produced 6 × His labeled enzyme was purified using Nickel resin. The resin was washed using 1 × PBS solution containing 25 mM imidazole. Elution of the his-tagged proteins was done using different concentrations of imidazole solutions (100, 200 and 400 mM) in 1 × PBS buffer. Protein samples in different fractions of the purification process were analyzed by SDS-PAGE. The resulting elution fraction was dialyzed against 1 × PBS buffer (10 mM potassium phosphate pH 7.4/300 mM NaCl/5% glycerol). The total protein amount was determined using the Coomassie Bradford Plus Protein Assay Kit according to the kit protocol.

Asparaginase enzyme activity

L-Asparaginase enzyme activity was determined spectrophotometrically by measuring the amount of ammonia released from asparagine (Wade and Phillips 1971). A reaction mixture was prepared with 100 µL of diluted enzyme solution, 500 µL of 50 mM Tris–HCl buffer (pH 7.3), 350 µL of ultrapure water and 50 µL of 40 mM L-asparagine solution. The enzyme reaction was carried out at 45 °C for 30 min. At the end of the period, 50 µL of 1.5 M TCA (trichloroacetic acid) solution was added to the reaction mixture to stop the reaction. Then, 80 µL of the reaction mixture was added in 1720 µL ultrapure water and mixed with 200 µL of Nessler’s reagent. After 5 min, absorbances at a wavelength of 436 nm were determined. One unit of asparaginase activity was defined as the amount of enzyme required to release 1μmoL of ammonia in 1 min under experimental conditions (45 °C pH 7.3).

Characterization of the recombinant L-asparaginase

The pH value at which the enzyme shows optimum activity was analyzed by using buffer solutions in the pH range of 3–10. Sodium citrate buffer for pH 3.0–6.0, MES (morpholinoethanesulfonic acid) buffer for pH 5.5–6.5, phosphate buffer for pH 6.0–8.0, Tris–HCl buffer solutions for pH 8.0–9.0 were used. All buffer solutions were prepared at a concentration of 50 mM and the reaction was continued at 45 °C for each buffer and enzyme activity was determined. In order to determine the pH stability of the enzyme, the enzyme was incubated in different pH buffers for 1 h at room temperature and the enzyme activity was determined (Huang et al. 2014).

The temperature value at which the enzyme exhibiting optimum activity was analyzed at optimum pH determined and different temperature values between 20 and 90 °C. The thermostability analysis of the enzyme was performed by measuring the residual enzyme activity after its 1-h incubation at different temperatures and optimum pH (Huang et al. 2014).

The enzyme activity was analyzed under optimum pH and temperature conditions in the presence of different metal ions and EDTA prepared at 1 mM and 5 mM concentrations (Karaoglan and Erden-Karaoglan 2020).

Kinetic parameters of the recombinant asparaginase was determined at optimum working conditions with different substrate concentrations (10–80 mM asparagine). Michaelis–Menten constant (Km) and maximum velocity (Vmax) values were calculated using Lineweaver–Burk double plot (Karaoğlan and Erden-Karaoğlan 2020).

Results and discussion

Cloning of the R. miehei asparaginase gene in P. pastoris

In the study, L-asparaginase (GenBank Accession No. KF290772.1) from R. miehei was supplied in the commercial pCC1 cloning vector. After triple enzyme digestion of the plasmid with XhoI-XbaI and ScaI, the gene was separated in the gel. DNA fragment with a length of approximately 2100 bp was isolated from the gel using the Gel Extraction Kit according to the manufacturer’s instructions. The obtained gene was digested with XhoI-XbaI enzymes and ligated to the pPICZαA plasmid from the XhoI-XbaI enzyme recognition site. The generated expression vector was named pPICZαA-ASNase.

Selection of the transformants with different gene copy numbers

In transformant cells, confirmation of expression cassette integration into the cell genome and determination of integrated expression cassette copy numbers were performed by Southern blot analysis. The probe used in Southern blot analysis was prepared by labeling the PCR product (approximately 500 bp) amplified from the AOX1 promoter with the primers AOX1pbF (5′-AGTCCAAGAACCGTGAGCAA) and AOX1pbR (5′-TTCTAGCGGTTTCTCTAGAC).

Genomic DNA was isolated from transformant cells selected from plates containing different concentrations of zeocin antibiotic. Genomic DNA (1 μg) samples were digested with the enzyme KpnI. P. pastoris KM71H genomic DNA was used as a control sample.

As a result of Southern blot analysis, the theoretically expected bands according to the DNAMAN 7.0 program were 4230 bp in the control sample, while 10,053 bp for single copy expression cassette, 15,638 for 2 copies, 21,223 for 3 copies, 26,808 bp for 4 copies and the bands were evaluated as 5 + copies. X-ray film image showing Southern blot analysis of clones determined to contain different copy numbers was given in Fig. 3. Recombinant protein productions were carried out with six clones containing 1, 2, 3, 4, 5 and 5 + gene copy numbers.

Southern blot analysis of the clones harboring different copy numbers of the expression cassettes integrated. The probe was prepared by labeling the PCR product amplified from the AOX1 promoter. DIG: DNA Molecular Weight Marker II, DIG-Labeled; C: untransformed KM71H strain; 1–12: clone numbers of transformants

Recombinant asparaginase production in shake flasks

Recombinant asparaginase production studies were carried out with the clones containing different expression cassette copy numbers. The cells cultured in YPD medium were used to inoculate 50 ml of BMGY medium with an initial density of OD600nm = 0.1. After cell accumulation in this medium, the induction phase was started in BMMY medium. The incubation was continued at 28 °C and 250 rpm for 72 h by adding methanol at a final concentration of 1% every 12 h.

In order to determine the gene copy number with the best production level for the expression of the recombinant asparaginase enzyme in P. pastoris, the clones were compared by measuring the asparaginase enzyme activity in the samples taken at regular intervals (Every 12 h).

As seen in Fig. 4, the highest production level was reached with the clone containing three copies of expression cassettes.

Comparison of asparaginase production levels versus time of the clones containing different numbers of expression cassettes. Samples were taken at regular intervals (12 h). Induction was continued for 72 h by adding methanol at a final concentration of 1% every 12 h. The activity value obtained from the clone harboring three copy numbers with the highest production was taken as 100% (103.90 U/mL)

Gene expression cassettes can be integrated into the genome in multiple copies in P. pastoris. However, the effect of gene copy number on protein production level shows a protein-specific effect, and the optimum copy numbers that provide the highest expression level differ in studies with different proteins. Clare et al. (1991) generated clones harboring multiple copies (4, 9, 13 and 19 copies) of mouse epidermal growth factor (mEGF) gene to increase the secretion level of the protein in the P. pastoris expression system. The authors reported a linear increase in protein production with an increasing copy number. Vassileva et al. (2001) tested hepatitis B surface Antigen (HBsAg) expression with the multi-copy strains (1, 4 and 8 copies) and observed the highest production level in the clone with eight-copy integrated expression cassettes integrated. Zhu et al. (2009) screened multi-copy strains (1, 3, 6, 12, 18, 29, 52 copies) for porcine insulin precursor expression and achieved the highest yield with 12 copies. To enhance protein production in multi-copy strains, Chen et al. (2017) investigated the mixed-feed strategy. The authors reported 42.6, 34.7 and 80.9% increase in protein expression with 6-, 12-, 18-copy strains. Sun et al. (2019) improved the protein expression in multi-copy strain by overexpressing the transcription factor Hac1p and α-signal peptide-cutting protease Kex2p. It can be seen from previous studies and our study that multi-copy strain development is one of the effective approaches to improve protein expression and must be optimized for each protein.

Purification of the recombinant asparaginase

The recombinant enzyme was purified for use in characterization analyzes. The purification process was carried out in two steps. First, ammonium sulfate precipitation (with 90% saturated solution) was applied to collect proteins in supernatant samples and then his-tagged proteins were purified using nickel resin. Analysis of the protein samples collected from the purification fractions was done by SDS-PAGE (Fig. 5).

SDS-PAGE analysis of the samples taken during the purification of the asparaginase (M: Marker; S: Supernatant; C: Sample obtained after ammonium sulfate precipitation; D: Sample of dialysis with 1 × PBS pH 7.4; W1-W4: Samples of washing steps with 25 mM imidazole; E1-E3: Samples of elution steps with 100, 200 and 400 mM imidazole, respectively. Supernatant samples were prepared in a total volume of 25 µL

Sample shown as S in Fig. 5 shows the supernatant sample, C is obtained after protein precipitation with ammonium sulfate, and D is obtained after dialysis. Samples taken from the washing and elution stages of the resin are shown in W1-3 and E1-3, respectively. The protein band expected to be 78 kDa representing the purified asparaginase protein was observed in E1 and E2 fractions of the elution samples obtained.

In previous studies, the most used agent for the precipitation of the enzyme in L-asparaginase purification is ammonium sulfate, which is applied in combination with other methods (da Cunha et al. 2019). A two-step purification process, ammonium sulfate precipitation and Ni–NTA chromatography was carried out in this study. A total of 500 mL supernatant sample was collected and the enzyme activity was determined as 114.76 U/mL. The purification fold was calculated as 5.37 and the purification efficiency was 67.75%. The specific activity of the purified sample was 1706.54 U/mg. The purification steps of the enzyme are summarized in Table 1. Huang et al. (2014) produced RmASNase intracellularly in E. coli BL21 and purified by Ni-IDA chromatography. The authors reported that the enzyme was purified 2.6-fold with a yield of 48.8% and a specific activity of 1985 U/mg. It is seen that purification efficiency is higher in the combined method with ammonium sulfate. However, it is thought that the specific activity may differ due to the activity determined in the crude enzyme.

Characterization of the recombinant asparaginase

The pH value at which the enzyme showed optimum activity was analyzed with buffers in the pH range of 3–10. The pH stability of the enzyme was determined by determining the remaining enzyme activity after 1-h incubation of the enzyme in different pH buffers at 45 °C. The results showing the pH value at which the enzyme exhibits optimum activity and pH stability are given in Fig. 6A.

Characterization of the recombinant asparaginase A enzyme activity and stability at different pH values (pH 3–10) B enzyme activity and stability at different temperature values (20–90 °C). pH stability of the enzyme was analyzed after incubation in different pH buffers for 1 h at room temperature. The thermostability analysis of the enzyme was performed by measuring the residual enzyme activity after its 1-h incubation at different temperatures and optimum pH

As seen in Fig. 6A, the pH value at which the asparaginase enzyme showed optimum activity was determined as pH 7, and the enzyme was active above 80% between pH 5 and pH 9 values. As seen in Fig. 6B, the temperature value at which the recombinant asparaginase enzyme showed optimum activity was determined as 50 °C, and the enzyme could maintain its activity above 67% at the end of 1-h incubation at temperatures between 20 and 50 °C.

The biochemical characteristics of enzymes isolated from different sources differ and the optimum working conditions of the enzyme generally vary between 30 and 60 °C and pH 6–9 (Cachumba et al. 2016; da Cunha et al. 2019; Jia et al. 2021). The optimum working conditions of the commercial enzymes used in the food industry obtained from Aspergillus oryzae (Acrylaway®, Novozymes) and A. niger (PreventASe®, DSM) are pH 6–7, 60 °C and pH 4–5, 50 °C, respectively (da Cunha et al. 2019). Activity and stability properties of the recombinant enzyme produced in this study was observed to be similar to those of the enzyme (RmASNase) previously expressed in E. coli conducted by Huang et al. (2014). In addition, its use in food safety and leukemia treatment applications was investigated in the study, and the findings reveal its remarkable potential (Huang et al. 2014).

Kinetic parameters of the recombinant L-asparaginase was analyzed for L-asparagine. Km and Vmax values of the enzyme were determined to be 45.30 mM and 2127.66 µmol/min/mg, respectively. In previous studies, Km values for fungal asparaginases have been reported in the range of 1 × 10–5 -0.1 M and Vmax values in the range of 4.44–3380 µmol/min/mg (Shrivastava et al. 2022; Mohan Kumar and Manonmani 2013; Huang et al. 2014; da Cunha et al. 2019). High catalytic activity results in less enzyme requirement in the processes. Therefore, the kinetic parameters that define the catalytic activity of the enzyme constitute one of the criteria used in the selection of enzymes for industrial purposes (Siedentop et al. 2021).

The effect of metal ions (Ca2+, Co2+, Cu2+, Fe2+, Mg2+, Mn2+, Zn2+, K+, Li+, Na+) and EDTA on asparaginase enzyme activity was analyzed (Table 2). The results showed that Ca2+ and Mn2+ ions increased the asparaginase enzyme activity, while Co2+, Cu2+, Fe2+ and Mg2+ ions partially inhibited. Enzyme activity was significantly maintained in the presence of Zn2+, K+, Li+, Na+ compared to the control as 86, 98, 101 and 94%, respectively. The negative effect of EDTA on enzyme activity suggests the dependence of enzyme activity on metal ions. Chi et al. (2021) have characterized L-asparaginase from Mycobacterium gordonae and reported a significant increase with Mn2+, Ni2+ and Mg2+ and a decrease with Cu2+ and Fe2+. Huang et al. (2014) observed a significant enhancement in asparaginase enzyme activity with Ca2+ (144%) and Mn2+ (183%). K+ and Na+ ions gave similar results in different studies with a slight effect on enzyme activity (Huang et al. 2014; Chi et al. 2021). The inhibitory effect of EDTA, recorded at different levels in previous studies, was also similar. It can be concluded from the previous studies that the impact of metal ions can vary both on other enzymes and in different sources of an enzyme (Hassan et al. 2018; Huang et al. 2014; Han et al. 2014; Chi et al. 2021; Karaoglan and Erden-Karaoglan 2020).

L-asparaginase from Rhizomucor miehei (RmASNase) was successfully expressed in P. pastoris in this study. Biochemical characterization showed that the enzyme exhibited activity above 80% between pH 5–9 and 67% after 1-h incubation at temperatures between 20 and 50 °C. The enzyme characteristics are observed to be conducive to acrylamide mitigation in potato chips and bakery products in the food industry.

In comparison to bacterial proteins, fungal proteins like RmASNase are predicted to have better compatibility with the human system and cause less immunogenicity (Shrivastava et al. 2022). Also, P. pastoris performs post-translational modifications, such as glycosylation, that have an impact on the pharmacokinetics and immunogenicity of the protein, making it superior to prokaryotic systems (Tran et al. 2017). However, further analyses are required to determine the potential of the RmASNase produced in this study for therapeutic use.

In future studies, it is also possible to improve the activity and stability values of the enzyme with advanced molecular techniques and to increase production efficiency by producing at fermenter scale and under optimum conditions.

Conclusion

Extracellular production of the L-Asparaginase enzyme from R. miehei was successfully performed in P. pastoris. The effect of gene copy number was investigated to realize more efficient production in this expression system. Six clones with varying DNA copy numbers (1, 2, 3, 4, 5, and 5 +) were used to produce recombinant proteins. The clone with three copies of the expression cassettes was found to have the highest protein production. The clone with the best activity was used for recombinant asparaginase production for subsequent analyses of the study. The enzyme was purified, and characterization analyzes were carried out to determine the optimum working conditions. The optimum pH and temperature for the purified enzyme were determined to be 7.0 and 50 °C, respectively. In summary, this study was the first to examine the impact of gene copy number on enhancing the production of the asparaginase enzyme in a eukaryotic expression system, P. pastoris and the best clone providing optimum expression was revealed. In future studies, higher production levels can be achieved by making large-scale protein productions and optimizing production conditions.

Data availability

The authors confirm that the datasets supporting the findings and conclusions of this study are available within the article.

References

Ahmad M, Hirz M, Pichler H, Schwab H (2014) Protein expression in Pichia pastoris: recent achievements and perspectives for heterologous protein production. Appl Microbiol Biotechnol 98:5301–5317. https://doi.org/10.1007/s00253-014-5732-5

Cachumba JJ, Antunes FA, Peres GF, Brumano LP, Santos JC, Da Silva SS (2016) Current applications and different approaches for microbial l-asparaginase production. Braz J Microbiol 47:77–85. https://doi.org/10.1016/j.bjm.2016.10.004

Castro D, Marques ASC, Almeida MR, de Paiva GB, Bento HBS, Pedrolli DB, Freire MG, Tavares APM, Santos-Ebinuma VC (2021) L-asparaginase production review: bioprocess design and biochemical characteristics. Appl Microbiol Biotechnol 105(11):4515–4534. https://doi.org/10.1007/s00253-021-11359-y

Cereghino JL, Cregg JM (2000) Heterologous protein expression in the methylotrophic yeast Pichia pastoris. FEMS Microbiol Rev 24(1):45–66. https://doi.org/10.1111/j.1574-6976.2000.tb00532.x

Che Z, Cao X, Chen G, Liang Z (2020) An effective combination of codon optimization, gene dosage, and process optimization for high-level production of fibrinolytic enzyme in Komagataella phaffii (Pichia pastoris). BMC Biotechnol 20:63. https://doi.org/10.1186/s12896-020-00654-7

Chen L, Mohsin A, Chu J, Zhuang Y, Liu Y, Guo M (2017) Enhanced protein production by sorbitol co-feeding with methanol in recombinant Pichia pastoris strains. Biotechnol Bioproc E 22:767–773. https://doi.org/10.1007/s12257-017-0011-9

Chi H, Chen M, Jiao L, Lu Z, Bie X, Zhao H, Lu F (2021) Characterization of a novel L-asparaginase from Mycobacterium gordonae with acrylamide mitigation potential. Foods 10(11):2819. https://doi.org/10.3390/foods10112819

Clare JJ, Romanos MA, Rayment FB, Rowedder JE, Smith MA, Payne MM, Sreekrishna K, Henwood CA (1991) Production of mouse epidermal growth factor in yeast: high-level secretion using Pichia pastoris strains containing multiple gene copies. Gene 105:205–212. https://doi.org/10.1016/0378-1119(91)90152-2

da Cunha MC, Dos Santos Aguilar JG, de Melo RR, Nagamatsu ST, Ali F, de Castro RJS, Sato HH (2019) Fungal L-asparaginase: Strategies for production and food applications. Food Res Int 126:108658. https://doi.org/10.1016/j.foodres.2019.108658

Einsfeldt K, Baptista IC, Pereira JCCV, Bruno RE, Mello FV, Costa-Amaral IC, Costa ES, Ribeiro MCM, Land MGP, Alves TLM, Larentis AL, Almeida RV (2016) Recombinant L-Asparaginase from Zymomonas mobilis: A Potential New Antileukemic Agent Produced in Escherichia coli. PLoS ONE 11(9):e0163203. https://doi.org/10.1371/journal.pone.0163203

Han S, Jung J, Park W (2014) Biochemical characterization of L-asparaginase in NaCl-tolerant Staphylococcus sp. OJ82 isolated from fermented seafood. J Microbiol Biotechnol. 24(8):1096–104. https://doi.org/10.4014/jmb.1405.05021

Hassan SWM, Farag AM, Beltagy EA (2018) Purification, characterization and anticancer activity of L-asparaginase produced by marine Aspergillus terreus. J Pure Appl Microbiol 12(4):1845–1854. https://doi.org/10.22207/JPAM.12.4.19

Hu H, Gao J, He J, Yu B, Zheng P, Huang Z, Mao X, Yu J, Han G, Chen D (2013) Codon optimization significantly improves the expression level of a keratinase gene in Pichia pastoris. PloS One 8(3):e58393. https://doi.org/10.1371/journal.pone.0058393

Huang L, Liu Y, Sun Y, Yan Q, Jiang Z (2014) Biochemical characterization of a novel L-Asparaginase with low glutaminase activity from Rhizomucor miehei and its application in food safety and leukemia treatment. Appl Environ Microbiol 80(5):1561–1569. https://doi.org/10.1128/AEM.03523-13

Izadpanah Qeshmi F, Homaei A, Khajeh K, Kamrani E, Fernandes P (2022) Production of a Novel Marine Pseudomonas aeruginosa Recombinant L-Asparaginase: Insight on the Structure and Biochemical Characterization. Mar Biotechnol. https://doi.org/10.1007/s10126-022-10129-9

Jia R, Wan X, Geng X, Xue D, Xie Z, Chen C (2021) Microbial L-asparaginase for application in acrylamide mitigation from food: current research status and future perspectives. Microorganisms 9(8):1659. https://doi.org/10.3390/microorganisms9081659

Karaoğlan M, Erden-Karaoğlan F (2020) Effect of codon optimization and promoter choice on recombinant endo-polygalacturonase production in Pichia pastoris. Enzyme Microb Technol 139:109589. https://doi.org/10.1016/j.enzmictec.2020.109589

Lopes W, Santos BAFD, Sampaio ALF, Gregório Alves Fontão AP, Nascimento HJ, Jurgilas PB, Torres FAG, Bon EPDS, Almeida RV, Ferrara MA (2019) Expression, purification, and characterization of asparaginase II from Saccharomyces cerevisiae in Escherichia coli. Protein Expr Purif 159:21–26. https://doi.org/10.1016/j.pep.2019.02.012

Macauley-Patrick S, Fazenda ML, McNeil B, Harvey LM (2005) Heterologous protein production using the Pichia pastoris expression system. Yeast 22(4):249–270. https://doi.org/10.1002/yea.1208

Meena B, Anburajan L, Sathish T, Vijaya Raghavan R, Dharani G, Vinithkumar NV, Kirubagaran R (2015) L-Asparaginase from Streptomyces griseus NIOT-VKMA29: optimization of process variables using factorial designs and molecular characterization of L-asparaginase gene. Sci Rep 24(5):12404. https://doi.org/10.1038/srep12404

Mohan Kumar NS, Manonmani HK (2013) Purification, characterization and kinetic properties of extracellular L-asparaginase produced by Cladosporium sp. World J Microbiol Biotechnol 29(4):577–587. https://doi.org/10.1007/s11274-012-1213-0

Nordén K, Agemark M, Danielson JÅ, Alexandersson E, Kjellbom P, Johanson U (2011) Increasing gene dosage greatly enhances recombinant expression of aquaporins in Pichia pastoris. BMC Biotechnol 11:47. https://doi.org/10.1186/1472-6750-11-4723

Pourhossein M, Korbekandi H (2014) Cloning, expression, purification and characterisation of Erwinia carotovora L-asparaginase in Escherichia coli. Adv Biomed Res 3:82. https://doi.org/10.4103/2277-9175.127995

Shrivastava A, Khan AA, Shrivastav A, Jain SK, Singhal PK (2022) Kinetic studies of L-asparaginase from Penicillium digitatum. Prep Biochem Biotechnol 42(6):574–581. https://doi.org/10.1080/10826068.2012.672943

Siedentop R, Claaßen C, Rother D, Lütz S, Rosenthal K (2021) Getting the most out of enzyme cascades: strategies to optimize In Vitro multi-enzymatic reactions. Catalysts 11:1183. https://doi.org/10.3390/catal11101183

Sun J, Jiang J, Zhai X, Zhu S, Qu Z, Yuan W (2019) Coexpression of Kex2 endoproteinase and Hac1 transcription factor to improve the secretory expression of Bovine Lactoferrin in Pichia pastoris. Biotechnol Bioproc E 24:934–941. https://doi.org/10.1007/s12257-019-0176-5

Tran AM, Nguyen TT, Nguyen CT, Huynh-Thi XM, Nguyen CT, Trinh MT, Tran LT, Cartwright SP, Bill RM, Tran-Van H (2017) Pichia pastoris versus Saccharomyces cerevisiae: a case study on the recombinant production of human granulocyte-macrophage colony-stimulating factor. BMC Res Notes. 4;10(1):148. https://doi.org/10.1186/s13104-017-2471-6

Upadhyay AK, Singh A, Mukherjee KJ, Panda AK (2014) Refolding and purification of recombinant L-asparaginase from inclusion bodies of E. coli into active tetrameric protein. Front Microbiol 15(5):486. https://doi.org/10.3389/fmicb.2014.00486

Vassileva A, Chugh DA, Swaminathan S, Khanna N (2001) Effect of copy number on the expression levels of hepatitis B surface antigen in the methylotrophic yeast Pichia pastoris. Protein Expr Purif 21:71–80

Vidya J, Vasudevan UM, Soccol CR, Pandey A (2011) Cloning, functional expression and characterization of l-asparaginase II from E. coli MTCC739. Food Technol Biotechnol 49(3):286–290

Wade HE, Phillips BP (1971) Automated determination of bacterial asparaginase and glutaminase. Anal Biochem 44:189–199. https://doi.org/10.1016/0003-2697(71)90360-5

Xu F, Oruna-Concha MJ, Elmore JS (2016) The use of asparaginase to reduce acrylamide levels in cooked food. Food Chem 1(210):163–171. https://doi.org/10.1016/j.foodchem.2016.04.105

Zhu T, Guo M, Tang Z, Zhang M, Zhuang Y, Chu J, Zhang S (2009) Efficient generation of multi-copy strains for optimizing secretory expression of porcine insulin precursor in yeast Pichia pastoris. J Appl Microbiol 107:954–963. https://doi.org/10.1111/j.1365-2672.2009.04279.x

Zhu W, Xu R, Gong G, Xu L, Hu Y, Xie L (2021) Medium optimization for high yield production of human serum albumin in Pichia pastoris and its efficient purification. Protein Expr Purif 181:105831. https://doi.org/10.1016/j.pep.2021.105831

Acknowledgements

This study was financially supported by the Erzincan Binali Yıldırım University Scientific Research Projects Coordination Unit with the project number FBA-2017-509.

Author information

Authors and Affiliations

Contributions

The authors FEK and MK have contributed to this study equally.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Ethics declarations

This article does not contain any studies with human participants or animals.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Erden-Karaoğlan, F., Karaoğlan, M. Improvement of recombinant L-Asparaginase production in Pichia pastoris. 3 Biotech 13, 164 (2023). https://doi.org/10.1007/s13205-023-03600-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-023-03600-4