Abstract

A strain CGT-1 producing β-cyclodextrin glucanotranferase (β-CGTase) was identified as Paenibacillus campinasensis by morphological analysis and 16s rDNA analysis. The gene coding for β-CGTase was cloned, sequenced, and expressed in Escherichia coli BL21(DE3). Recombinant β-CGTase was purified and its purity evaluated by SDS-PAGE, showing it encodes a mature protein with a molecular mass of 74 kDa. The β-CGTase was most active at pH 7.0 and 65 °C, respectively. More than 80% activity was retained after incubation at 55 °C for 5 h. The stability of the enzyme was in a pH range from 5.5 to 10.0. The Km and Vmax for the enzyme activity on CGTase were 3.75 mg/mL and 290.75 μmol/min, respectively. The recombinant plasmid pET28a-DacD-cgt-his, pET28a-OmpA-cgt-his, pET28a-OmpT-cgt-his, and pET28a-CGTase-cgt-his were constructed by cloning the signal peptide genes DacD, OmpA, OmpT, and signal peptide derived from cgtase gene into pET28a-cgt-his, respectively. The production of the recombinant β-CGTase with pET28a-DacD-cgt-his reached 60.89 U/mL after 72 h of culture, which produced an approximately 1.98, 2.93, 4.15 to 9.74-fold higher activity than those containing OmpA, CGTase, OmpT, and the control without signal peptide, respectively. The culture conditions for extracellular production of the recombinant β-CGTase in E. coli BL21(DE3) were optimized. The CGTase activity reached the highest level (37.67 U/mL) under the induction of 0.03 mM IPTG at OD600 of 0.8 at 30 °C after 48 h of culture. Optimization of the extracellular secretion of the β-CGTase from Paenibacillus campinasensis in recombinant E. coli laid the foundation for further industrial production and application of β-CGTase.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Cyclodextrins (CDs) are industrially produced by a biotransformation step utilizing the enzyme cyclodextrin glycosyltransferase (CGTase) (Biwer et al. 2002). CGTase is an important member of the α-amylase family of glycosyl hydrolase (family 13) (Szente and Szejtli 2004), which can catalyze the starch or starch matrix to cause intramolecular transglycosylation reaction to form CD (Li et al. 2007). α-amylases generally consist of three structural domains (A, B and C domain), while CGTases have five domains (A, B, C, D and E domain) (Tesfai 2012; Van der Veen et al. 2000): the A domain has an active site located at the bottom of (β/α)8-barrel; the B domain is a ring region that binds to the substrate; the C domain is β-sandwich structure with the function of binding maltose or native starch; the D domain has β-sheet-like structure whose function is unknown; the E domain is used to bind starch (Janeček et al. 2014; Van der Veen et al. 2000). CGTases have been detected in many strains of Bacillus, Thermoanaerobacter, Brevibacterium and Thermoanaerobacter bacilli, and most of CGTase are naturally produced by Bacillus (Ong et al. 2008).

CGTase catalyzes the cylclization of linear glucans into macrocycles, which are known as CDs. In most cases, CGTase predominantly forms mixtures of CDs with 6, 7 or 8 glucose units, which are also designated as α-, β- and γ-CD (Qi and Zimmermann 2004; Tesfai et al. 2012), CGTases are accordingly classified into α-, β- and γ-CGTase (Takada et al. 2003). CDs can form inclusion complexes with many guest molecules, and the physical and chemical properties of the guest molecules can be modified (Ong et al. 2008). It has been widely used in many industrial fields such as food, cosmetics, medical, health, and agriculture in capturing flavors and odors, stabilizing volatile compounds, improving hydrophobic substance solubility, and protecting substances against undesirable modifications (Del Valle 2004; Szejtli 1997, 1998). Therefore, the demand for CDs is growing at a high rate in many industrial areas (Szejtli 2004).

In previous studies, production of CDs was restricted due to the lack of suitable strains that can efficiently produce CGTase. High yield and the specificity of CGTase is also one of the main focuses in production. Escherichia coli has been used as one of the most common hosts for the production of recombinant proteins (Gordon et al. 2008) because of its clear genetic background, simple operation, culture conditions, and large-scale high-density fermentation (Baneyx 1999). The extracellular secretion of CGTase has been investigated in E. coli (Kim et al. 1999). Generally, the type I, II, III, IV, and V protein secretion pathways have been described in Gram-negative bacteria (Mergulhão et al. 2005), with the type II (SecB) pathway being the most widely used (Choi and Lee 2004), and CGTase is secreted to the medium via the SecB pathway. SecB is a two-step process consisting of crossing and folding of the pre-protein from the inner membrane to the periplasm and the protein secretion by nonspecific periplasmic leakage to the medium (Su et al. 2012). The pre-protein contains a signal peptide of 15–30 amino acids to assist folding of nascent peptide chain and extracellular localization (Choi and Lee 2004). Signal peptides such as DacD (Sonnendecker et al. 2017), PelB (Sonnendecker et al. 2017), OmpA (Cheng et al. 2011), OmpT (Negahdaripour et al. 2017), endoxylanase (Jeong et al. 1998), etc. have been used in efficient secretory production of recombinant proteins in E. coli (Lee et al. 2012). However, due to the formation of inclusion bodies in the process of protein expression, and low purification productivity, high-level extracellular secretion is not suitable for the expression of all biomolecules (Tsai et al. 2017). Therefore, it is essential to optimize induction time, induction temperature, and inducer concentration to obtain soluble and active recombinant proteins, rather than denatured recombinant proteins formed in inclusion bodies. It has been reported that the over expression of CGTase can increase the yield, decrease the expression time, and enhance the stability of the enzyme (Ramli et al. 2013).

The β-cyclodextrin has the lowest solubility in water (Zhu et al. 2016) among the three types of CDs and can be crystallized easily. Because of these unique structural features, it is easy to produce and has been widely used in industry (Fernandes et al. 2014). In this study, we describe the isolation of a potentially useful thermophilic bacterial strain from wine yeast mud and the optimization of high-level secretory expression of the recombinant β-CGTase in E. coli by using the signal peptide mentioned above.

Materials and methods

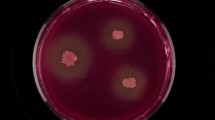

Isolation and identification of Paenibacillus campinasensis Hhj-1

The thermophilic bacterial strain Paenibacillus campinasensis Hhj-1 was isolated from the yeast mud of ZhiJiang liquor (Hubei, China) as a potential β-CGTase producer. Diluted wine yeast mud samples were spread on the screening medium plates (soluble starch (10 g/L), peptone (5 g/L), yeast extract (5 g/L), K2HPO4 (1 g/L), MgSO4 (0.098 g/L), Na2CO3 (5 g/L), agar (15 g/L), phenolphthalein (0.3 g/L), methyl orange (0.1 g/L), and fermentation medium: soluble starch (10 g/L), peptone (5 g/L), yeast extract (5 g/L), K2HPO4 (1 g/L), MgSO4 (0.098 g/L), and Na2CO3 (5 g/L). The formation of halo zones around the colonies after incubation at 37 °C for 2–3 days, resulted from the production of phenolphthalein–cyclodextrin inclusion complexes, was considered as an initial indication of CGTase activity (Kuo et al. 2009). Fermentation medium (LB medium) was then used to select potential CGTase-producing bacteria by the evaluation of CGTase activity. The selected strain was identified by morphological and 16S rRNA sequencing.

Total DNA was extracted using Bacterial Genomic DNA Extraction Kit (Omega Bio-tek, America), according to the manufacturer’s instructions. Bacterial primers: 27F (5′-AGAGTTTGATCCTGGCTCAG-3′) and 1492R (5′-GGTTACCTTGTTACGACTT -3′) were used to amplify 16S rRNA gene. The PCR products were purified and cloned into pMD-18T (Takara, Dalian). The 16S rRNA gene sequences of bacteria showing high degree of similarity with strain Hhj-1 were obtained using BLASTN (Hao et al. 2017) and were analyzed with MEGA 5.1 (Kumar et al. 2018). The phylogenetic tree of strain Hhj-1 was established using neighbor-joining method (Hao et al. 2017; John et al. 2003).

Cloning and expression of the CGTase gene

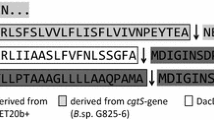

E. coli JM109, BL21 (DE3) and Trans5α (TransGen Biotech, Beijing) were used as hosts for gene cloning and protein expression. E. coli cells were incubated in LB medium containing 50 μg/ml kanamycin at 37 °C. The nucleotide and amino acid sequence of the five CGTase genes was obtained from National Center for Biotechnology Information (NCBI), and the four highly conserved amino acid regions of the CGTase were analyzed by DNAMAN. The homologous gene was analyzed from Bacillus sp. N-227 using BLAST; the CGT-cgtase gene was amplified from the genomic DNA by PCR using primers PCA cgt-N: 5′-ATGAAAAGATTTATGAAACTAAC-3′ and PCA cgt-C: 5′-TTAAGGCTGCCAGTTCACATTCA-3′, cloned into pMD18-T, and the recombinant plasmid pMD-cgt was obtained.

Signal peptide of CGTase was analyzed by SignalP-5.0 server (http://www.cbs.dtu.dk/services/SignalP). The CGTase had a signal peptide of 27 amino acids at N-terminal. After removal of signal peptide of the cgt gene, pMD-cgt was used as template to perform PCR amplification using primers cgt-N (5′-TAACCATGGCTGCCCCGGATACCTCGGTATCC-3′) and cgt-C-his (5′-CCACTCGAGAGGCTGCCAGTTCACATTCAC-3′). The cgt gene was cloned into pET28a (Takara, Dalian) to obtain the recombinant plasmid pET28a-cgt-his which was then transformed into E. coli BL21 (DE3) for expression.

pET28a-cgt-his was used as template to perform Inverse PCR amplification using primers listed in Table 1.The Inverse PCR products were purified, cyclized, and transformed into E.coli Trans5α for sequencing. The recombinant plasmid containing different signal peptide genes (DacD, OmpA, OmpT, and signal peptide derived from cgtase gene) was constructed.

Purification of the recombinant CGTase

The recombinant cells were collected (4 °C, 5000 g, 5 min), washed three times with deionized water, and then re-suspended in imidazole buffer (5 mM imidazole, 0.5 M NaCl, and 20 mM Tris–HCl buffer, pH 7.9). The cells were disrupted by sonication, centrifuged at 12,000g for 20 min, and the supernatant was kept at 65 °C for 1 h to denature all the thermolabile proteins, before centrifugation again at 20,000g (4 °C, 20 min) to remove denatured proteins. The resulting partially purified enzyme was further purified by Ni–NTA resin (7sea biotech, Shanghai). The active fractions were collected by gradient elution with the elution buffer (0.5 M NaCl, and 20 mM Tris–HCl buffer, 0.2, 0.4, 0.6, 0.8, 1.0 M imidazole, pH 7.9). The purity and molecular weight of the protein were analyzed by discontinuous SDS-PAGE (Sigma, America). Protein concentration was determined by the Bradford method using bovine serum albumin as standard.

Characterization of the purified β-CGTase

The activity of CGTase was determined at different pH using Na2HPO4-citric acid buffer (pH 4.0–7.0), Tris–HCl buffer (pH 7.0–8.5) or glycine–NaOH buffer (pH 8.5–11.0). For determination of optimal pH, soluble starch (4%, 100 μL), buffer (90 μL), and the enzyme (10 μL) were incubated at 55 °C for 10 min followed by activity measurements. Optimal pH was the pH where the enzyme displayed its maximal activity. The optimal temperature for CGTase was determined at 30–90 °C in Tris–HCl buffer (pH 7.0). Optimal temperature was the temperature where the enzyme displayed its maximal activity. The activity of the enzyme without pre-incubation was defined as 100%.

To determine the pH stability of CGTase, the residual activity was assayed under standard conditions (55 °C, 10 min) after a pre-incubation of the diluted enzyme solution at room temperature for 2 h in the pH 4.0–10.0 buffer. Thermal stability of CGTase was determined by assaying the residual enzyme with a pre-incubation for 1, 2, 3, 4, and 5 h at 55, 65, and 75 °C without the substrate. The activity of the enzyme without pre-incubation was defined as 100%.

The effects of metal ions and reagents on the activity of the purified enzyme were determined by adding 0.1 M BaCl2, CaCl2, CoCl2, HgCl2, NaCl, MgCl2, MnCl2, EDTA, and SDS into the reaction mixture at final concentration of 1, 5 and 10 mM, respectively. Each metal ion and reagent was incubated with enzyme for 10 min under standard conditions (pH 7.5, 55 °C) before adding soluble starch (4%, w/v). Activity was expressed as a percentage of the activity obtained in the absence of the metal ions or chemical agents.

Kinetic studies were performed by measuring the CGTase activity at various concentrations of soluble starch ranging from 0.8 to 7.0 mg/mL. The values of Km and Vmax were determined using Michaelis–Menten equation and double reciprocal plot (Lineweaver–Burk plot).

Optimization of the extracellular expression of CGTase in E. coli BL21(DE3)

A single colony of E. coli BL21 (DE3) harboring the recombinant plasmid pET28a- cgt-his, pET28a-DacD-cgt-his, pET28a-OmpA-cgt-his, pET28a-OmpT-cgt-his, and pET28a-CGTase-cgt-his was inoculated into 50 mL LB medium with 50 μg/mL kanamycin and grown at 37 °C overnight. Then, the 5% bacterium solution was inoculated into 100 mL LB medium containing 50 μg/mL kanamycin and cultured in a shaker (200 rpm) at 37 °C. When the optical density at 600 nm (OD600) reached 0.8, 0.5 mM isopropyl β-d-1-thiogalactopyranoside (IPTG) was added into the culture. The growth of recombinant E. coli BL21 (DE3) and the enzyme activities of the samples (1 mL) were determined after induction for 0, 4, 8, 20, 26, 32, 48, 55, 67, and 72 h at 30 °C.

In order to study the effect of induction time (OD600 = 0.4, 0.6, 0.8, 1.0, 1.3), induction temperature (20 °C, 25 °C, 30 °C, 37 °C) and IPTG concentration (0, 0.01, 0.03, 0.05, 0.1, 0.3, 0.5, 0.7 mM) on the cell growth and extracellular production of the recombinant β-CGTase using the signal peptide DacD, the growth of recombinant E. coli BL21 (DE3) and the enzyme activities were analyzed during the 48-h shaking induction.

Cellular fractionation

Cell fractionation was performed as described previously (Li et al. 2012).

Assay of CGTase

α-CGTase activity (Li et al. 2009) was determined by methylorange method with some modifications. 450 μL of 4% (w/v) soluble starch in phosphate buffer (50 mM, pH 8.0) was pre-incubated at 55 °C for 1 min, and then 50 μl diluted enzyme was added. After being incubated at 55 °C for 10 min, the reaction was terminated by the addition of 500 μL 1.0 M HCl. Subsequently, 500 μL 0.1 mM methyl orange in 50 mM phosphate buffer (pH 8.0) was added, and, after centrifugation at 10,000g for 3 min, the optical density was measured at 505 nm. One unit of α-CGTase activity was defined as the amount of enzyme that produced 1 µmol of α-CD per min.

β-CGTase activity (Kuo et al. 2009) was measured by phenolphthalein method with slight modifications. 200 μL of 4% (w/v) soluble starch in Tris–HCl buffer (0.1 M, pH 7.5) was pre-incubated at 55 °C for 1 min, and then 20 μL diluted enzyme was added. After being incubated at 55 °C for 10 min, the reaction was terminated by the addition of 700 μL Na2CO3–NaHCO3 buffer (0.5 M, pH 10.0). Subsequently, 100 μL 0.02% (w/v) phenolphthalein prepared in 5 mM Na2CO3 was added, and, after centrifugation at 10,000g for 3 min, optical density was measured at 550 nm. One unit of β-CGTase activity was defined as the amount of enzyme that produced 1 µmol of β-CD per min.

γ-CGTase activity (Tesfai 2012) was measured by BCG method with some modifications. 500 μL of 4% (w/v) soluble starch in phosphate buffer (pH 6.0) was pre-incubated at 55 °C for 1 min, and then 100 μL diluted enzyme was added. After being incubated at 55 °C for 10 min, it was terminated by the addition of 250 μL 0.2 M HCl. Subsequently, 100 μL 0.05% (w/v) bromocresol green in 20% ethanol was added and left at room temperature for 20 min. 2 mL of 1 M acetate buffer containing 30 mM citric acid (pH 4.2) was added; after centrifuging at 10,000g for 3 min, optical density was measured at 505 nm. One unit of γ-CGTase activity was defined as the amount of enzyme that produced 1 µmol of γ-CD per min.

Results

Identification of the P. campinasensis Hhj-1

Eleven strains of CGTase-producing bacteria were isolated from the yeast mud; strain Hhj-1, which has strong CGTase activity, was identified by morphological analysis and molecular identification. The partial sequence of 16S rRNA gene revealed 99% homology with that of P. campinasensis strain BL11. The strain was classified as P. campinasensis Hhj-1. The 16S rRNA sequence has been deposited in the GeneBank database under the accession number KF143743. Activity of α-CGTase, β-CGTase and γ-CGTase was also studied and only β-CGTase activity could be detected in strain Hhj-1. Therefore, we could ensure that the produced CGTase was a β-CGTase. The deduced nucleotide sequence of P. campinasensis Hhj-1 was compared with the other 16 strains, and the phylogenetic tree was also constructed (Fig. 1).

Phylogenetic tree of P. campinasensis strain Hhj-1 based on 16s rDNA sequence homology (the scale bar represents 0.01 substitutions per site, and the bootstrap values are based on 1000 resamplings. The number at each node is the bootstrap probability. The number after the species name is the GenBank accession number)

Purification of the recombinant CGTase and characterization of the recombinant CGTase

Intracellular expressed CGTase was purified by heat treatment (65 °C, 2 h) and Ni–NTA resin affinity. A single protein band was observed by SDS-PAGE with an estimated size of 74 kDa (Fig. 2).

CGTase was characterized using the purified recombinant enzyme. The recombinant CGTase was more than 90% active at pH 5.0–10.0 with an optimum at 7.0 in buffers (Fig. 3a), and more than 70% of the activity was retained after 2 h of incubation in buffers at pH 5.5‒10.0 at room temperature (Fig. 3b). The optimum temperature for the enzyme was 65 °C at pH 7.0. At temperature above 65 °C, the enzyme activity decreased significantly (Fig. 3c). Thermostability assays indicated that its residual activity was more than 95% after being incubated at 55 °C for 5 h and the activity was lost rapidly at 75 °C (Fig. 3d).

The effects of metal ions, EDTA, and SDS on the recombinant CGTase activity are shown in Table 2. CGTase was slightly inhibited by Ba2+, Co2+, EDTA, and Mn2+, while Hg2+ and SDS can inhibit CGTase significantly, especially at 10 mM concentration. CGTase activity was slightly increased by 1 mM Ca2+ and 1 mM Ba2+.

The kinetic analysis was performed by a colorimetric assay, measuring the β-CD concentration. The Lineweaver–Burk plot indicated that Km value of CGTase was 3.75 mg/mL and Vmax value of CGTase was 290.75 μmol/min (Fig. 4), when using soluble starch as substrate. A Kcat value of 3392/s was calculated from the data.

Optimization of extracellular expression in E. coli BL21 (DE3)

The recombinant plasmids pET28a-DacD-cgt-his, pET28a-OmpA-cgt-his, pET28a-OmpT-cgt-his, and pET28a-CGTase-cgt-his were constructed by cloning the signal peptide genes DacD, OmpA, OmpT, and the signal peptide derived from cgtase gene into pET28a-cgt-his, respectively. The plasmid pET28a-cgt-his was set as control.

The five different plasmids were induced to express for 72 h. OD600 and β-CGTase activity were determined in extracellular fraction at different times (Fig. 5). Except for a relative higher OD600 value of cells harboring pET28a-DacD-cgt-his, the recombinant plasmids pET28a-cgt-his, pET28a-OmpA-cgt-his, pET28a-OmpT-cgt-his, and pET28a-CGTase-cgt-his had no significant effect on the growth of the cells, and the growth trend of the cells was similar. Extracellular enzymatic activity of β-CGTase for the plasmid containing the DacD signal peptide was significantly higher than that for the other signal peptides and the control. It has been demonstrated that the extracellular β-CGTase activity with pET28a-DacD-cgt-his reached 60.89 U/mL after 72 h of culture, which produced an approximately 1.98, 2.93, 4.15, and 9.74-fold higher activity than those containing OmpA, CGTase, OmpT, and the control, respectively. The extracellular β-CGTase activity with pET28a-DacD-cgt-his reached 12.51 U/mL after 26 h of culture, which produced approximately 3.34, 3.56, 5.13, and 11.48-fold higher activity than pET28a-OmpA-cgt-his, pET28a-CGTase-cgt-his, pET28a-OmpT-cgt-his, and pET28a-cgt-his, respectively. After 48 h, the extracellular, periplasmic, intracellular, and insoluble inclusion bodies of the recombinant CGTase of the five different plasmids were analyzed by SDS-PAGE (Fig. 6).

Cell growth of E. coli (DE3) and β-CGTase activity in extracellular fraction at different times. [a DacD; b OmpA; c the signal peptide of cgt gene; d OmpT; e no signal peptide (each value represents the mean of three independent experiments, and error bars represent the standard deviation based on three independent experiments)]

SDS-PAGE analysis of cellular localization of —CGTase in the cells grown for 48 h. a Extracellular soluble fraction; b periplasmic fraction; c intracellular soluble fraction; d intracellular insoluble fraction. (M: molecular marker; 1, 6, 11, 16: DacD; 2, 7, 12, 17: OmpA; 3, 8, 13, 18: the signal peptide of cgtase; 4, 9, 14, 19: OmpT; 5, 10, 15, 20: pET28a-cgt-his)

The recombinant plasmid pET28a-DacD-cgt-his was taken as target plasmid to study different expression level under different induction time, induction temperature and inducer concentration. The results are shown in Fig. 7; since long-term induction enhances the hydrolysis reactions of CGTase and leads to the autolysis of bacteria, the induction period was shortened to 48 h (Carneiro et al. 2013). CGTase activity reached the highest level under the induction of 0.03 mM IPTG at OD600 of 0.8 at 30 °C, and with the bacterial growth, CGTase activity began to decline (Fig. 7a, b). The extracellular β-CGTase activity reached 37.67 U/mL at 30 °C, when it was approximately 5.55, 1.33, and 1.31-fold higher than at 20 °C, 25 °C, and 37 °C (Fig. 7c, d), respectively. The extracellular β-CGTase activity decreased with increasing IPTG concentration. When 0.03 mM IPTG was added, the activity was approximately 11.71, 1.14, 1,22, 1,71, 1,83, 1,92, and 1.93-fold higher than in the absence of IPTG and with 0.01 mM, 0.05 mM, 0.1 mM, 0.3 mM, 0.5 mM, 0.7 mM IPTG (Fig. 7e, f).

Effect of different induction time, induction temperature, and inducer concentration on recombinant protein. [a, b Induction time; c, d induction temperature; e, f inducer concentration (each value represents the mean of three independent experiments, and error bars represent the standard deviation based on three independent experiments)]

Discussion

In this paper, a β-CGTase producing strain Paenibacillus campinasensis Hhj-1 has been isolated and identified. This is the first report on the cloning and the high-level extracellular secretion of the β-CGTase from Paenibacillus campinasensis. The purification and characterization of CGTase from Paenibacillus campinasensis have been reported previously (Alves-Prado et al. 2007). The optimal pH for the recombinant β-CGTase was determined as 7.0 and the enzyme was stable from pH 5.0 to 10.0 in this study. However, Alves-Prado et al. (2007) reported that the purified CGTase could be stable from pH 6.0 to 11.0 after 24 h of incubation at 25 °C. The β-CGTase from Bacillus sp. G1 was stable in a wide pH range of 6.0–10.0 (Ong et al. 2008). A narrow pH stability (pH 6.0–9.0) was observed for the β-CGTase from Paenibacillus illinoisensis ZY-08 (Lee et al. 2012). The optimum reaction temperature was determined to be 65 °C and the recombinant enzyme retained about 80% activity when kept at 55 °C for 5 h. Therefore, the recombinant enzyme can show endurance in acid and alkali, which is consistent with the enzymatic properties of the CGTase derived from the original strain. The CGTase activity was inhibited strongly by 10 mM Mg2+, Cu2+ and Hg2+, Ni2+, whereas weakly affected by Na+. Lee et al. (2012) once reported a CGTase which could not be inhibited by EDTA, and it was not a metalloenzyme. However, the β-CGTase in this study was a metalloenzyme, and 1 mM Ca2+ played a key role in the catalysis of the enzyme. The enzymatic reaction kinetics of the purified recombinant enzyme showed Kcat value was 3392/s, Km value was 3.75 mg/mL, and Vmax value was 290.75 μmol/min. The Km of CGTase from Paenibacillus campinasensis Hhj-1 was higher than P. campinasensis strain H69-3 (1.69 ± 0.39 mg/mL) (Alves-Prado et al. 2007) and smaller than CGTase from Bacillus agaradhaerens (21.2 mg/mL) (Martins and Hatti-Kaul 2002). The Vmax of this CGTase was higher than Geobacillus thermoglucosidans CHB1 (23.7 μmol/min) (Jia et al. 2017). However, Km values ranging from 1.77 to 5.7 mg/mL and Vmax from 43 to 1027 μmol/min have been previously reported for various CGTases (Ibrahim et al. 2012).

In the expression experiment, DacD was proved to be the most efficient signal peptide, the extracellular β-CGTase produced an approximately 11.48-fold higher activity than that without a signal peptide after 26 h of culture, while lowest with the signal peptide OmpT. Sonnendecker et al. (2017) reported that the DacD signal peptide strongly promoted the extracellular production of CGTase in E. coli and the activity of the extracellular CGTase (Bacillus) was 2.7- to 4.6-fold higher than those containing PelB, CgtS signal peptide. As reported, insoluble inclusion bodies formed in E. coli under overexpression (Sørensen and Mortensen 2005), the recombinant CGTase accumulated near the inner membrane, the insoluble inclusion bodies blocked the translocation channels and hindered further protein secretion (Li et al. 2014). In this paper, induction temperature and IPTG concentration were reduced to enhance the production of the soluble protein. β-CGTase activity reached the highest level under the induction of 0.03 mM IPTG at OD600 of 0.8 at 30 °C. It has been previously reported that induction at lower temperatures (25 °C) increases the extracellular secretion of the recombinant proteins (Wang et al. 2018).

The study in this paper revealed the potential of β-CGTase from P. campinasensis Hhj-1 in application of β-cyclodextrin production in pharmaceutical, food, chemical and other related industries. The thermostable and wide PH reaction range of the enzyme will certainly make CGTase a promising candidate in food additives and pharmaceutical excipient.

References

Alves-Prado HF, Gomes E, Silva RD (2007) Purification and characterization of a cyclomaltodextrin glucanotransferase from Paenibacillus campinasensis strain H69-3. Appl Biochem Biotechnol 137–140:41–45

Baneyx F (1999) Recombinant protein expression in Escherichia coli. Curr Opin Biotechnol 10:411–421

Biwer A, Antranikian G, Heinzle E (2002) Enzymatic production of cyclodextrins. Appl Microbiol Biotechnol 59:609–617

Carneiro S, Ferreira EC, Rocha I (2013) Metabolic responses to recombinant bioprocesses in Escherichia coli. J Biotechnol 164:396–408

Cheng J, Wu D, Chen S, Chen J, Wu J (2011) High-level extracellular production of α-cyclodextrin glycosyltransferase with recombinant Escherichia coli BL21 (DE3). J Agric Food Chem 59:3797–3802

Choi JH, Lee SY (2004) Secretory and extracellular production of recombinant proteins using Escherichia coli. Appl Microbiol Biotechnol 64:625–635

Del Valle EMM (2004) Cyclodextrins and their uses: a review. Process Biochem 39:1033–1046

Fernandes A, Ivanova G, Brás NF, Mateus N, Ramos MJ, Rangel M, de Freitas V (2014) Structural characterization of inclusion complexes between cyanidin-3-O-glucoside and β-cyclodextrin. Carbohyd Polym 102:269–277

Gordon E, Horsefield R, Swarts HGP, de Pont JJHHM, Neutze R, Snijder A (2008) Effective high-throughput overproduction of membrane proteins in Escherichia coli. Protein Expr Purif 62:1–8

Hao JH, Huang LP, Chen X, Sun JJ, Liu JZ, Wang W, Sun M (2017) Identification, cloning and expression analysis of an alpha-CGTase produced by stain Y112. Protein Expr Purif 140:8–15

Ibrahim ASS, Al-Salamah AA, El-Tayeb MA, El-Badawi YB, Antranikian G (2012) A novel cyclodextrin glycosyltransferase from alkaliphilic Amphibacillus sp. NPST-10: purification and properties. Int J Mol Sci 13:10505–10522

Janeček Š, Svensson B, MacGregor EA (2014) α-Amylase: an enzyme specificity found in various families of glycoside hydrolases. Cell Mol Life Sci 71:1149–1170

Jeong KJ, Lee PC, Park IY, Kim MS, Kim SC (1998) Molecular cloning and characterization of an endoxylanase gene of Bacillus sp. in Escherichia coli. Enzyme Microb Technol 22:599–605

Jia XB, Ye XJ, Chen JC, Lin XJ, Vasseur L, You MS (2017) Purification and biochemical characterization of a cyclodextrin glycosyltransferase from Geobacillus thermoglucosidans CHB1. Starch. https://doi.org/10.1002/star.201700016

John KS, Warnow T, Moret BME, Vawter L (2003) Performance study of phylogenetic methods: (unweighted) quartet methods and neighbor-joining. J Algorithms 48:173–193

Kim MH, Lee JK, Kim HK, Sohn CB, Oh TK (1999) Overexpression of cyclodextrin glycosyltransferase gene from Brevibacillus brevis in Escherichia coli by control of temperature and mannitol concentration. Biotechnol Tech 13:765–770

Kumar S, Stecher G, Li M, Knyaz C, Tamura K (2018) MEGA X: molecular evolutionary genetics analysis across computing platforms. Mol Biol Evol 35:1547–1549

Kuo CC, Lin CA, Chen JY, Lin MT, Duan KJ (2009) Production of cyclodextrin glucanotransferase from an alkalophilic Bacillus sp. by pH-stat fed-batch fermentation. Biotech Lett 31:1723–1727

Lee YS, Zhou Y, Park DJ, Chang J, Choi YL (2012) β-Cyclodextrin production by the cyclodextrin glucanotransferase from Paenibacillus illinoisensis ZY-08: cloning, purification, and properties. World J Microbiol Biotechnol 29:865–873

Li ZF, Wang M, Wang F, Gu ZB, Du GC, Wu J, Chen J (2007) γ-Cyclodextrin: a review on enzymatic production and applications. Appl Microbiol Biotechnol 77:245–255

Li ZF, Li B, Liu ZG, Wang M, Gu ZB, Du GC, Chen J (2009) Calcium leads to further increase in glycine-enhanced extracellular secretion of recombinant α-cyclodextrin glycosyltransferase in Escherichia coli. J Agric Food Chem 57:6231–6237

Li B, Wang L, Su LQ, Chen S, Li ZF, Chen J, Wu J (2012) Glycine and triton X-100 enhanced secretion of recombinant α-CGTase mediated by OmpA signal peptide in Escherichia coli. Biotechnol Bioprocess Eng 17:1128–1134

Li ZF, Su LQ, Wang L, Liu ZG, Gu ZB, Chen J, Wu J (2014) Novel insight into the secretory expression of recombinant enzymes in Escherichia coli. Process Biochem 49:599–603

Martins RF, Hatti-Kaul R (2002) A new cyclodextrin glycosyltransferase from an alkaliphilic bacillus agaradhaerens isolate: purification and characterisation. Enzyme Microb Technol 30:116–124

Mergulhão FJM, Summers DK, Monteiro GA (2005) Recombinant protein secretion in Escherichia coli. Biotechnol Adv 23:177–202

Negahdaripour M, Nezafat N, Hajighahramani N, Rahmatabadi SS, Morowvat MH, Ghasemi Y (2017) In silico study of different signal peptides for secretory production of interleukin-11 in Escherichia coli. Curr Proteom 14:112

Ong RM, Goh KM, Mahadi NM, Hassan O, Rahman RNZRA, Illias RM (2008) Cloning, extracellular expression and characterization of a predominant β-CGTase from Bacillus sp. G1 in E. coli. J Ind Microbiol Biotechnol 35:1705–1714

Qi QS, Zimmermann W (2004) Cyclodextrin glucanotransferase: from gene to applications. Appl Microbiol Biotechnol 66:475–485

Ramli N, Abd-Aziz S, Alitheen NB, Hassan MA, Maeda T (2013) Improvement of cyclodextrin glycosyltransferase gene expression in Escherichia coli by insertion of regulatory sequences Involved in the promotion of RNA transcription. Mol Biotechnol 54:961–968

Sonnendecker C, Wei R, Kurze E, Wang J, Oeser T, Zimmermann W (2017) Efficient extracellular recombinant production and purification of a Bacillus cyclodextrin glucanotransferase in Escherichia coli. Microb Cell Fact 16:87

Sørensen HP, Mortensen KK (2005) Advanced genetic strategies for recombinant protein expression in Escherichia coli. J Biotechnol 115:113–128

Su LQ, Chen S, Yi L, Woodard RW, Chen J, Wu J (2012) Extracellular overexpression of recombinant Thermobifida fusca cutinase by alpha-hemolysin secretion system in E. coli BL21 (DE3). Microb Cell Fact 11:8

Szejtli J (1997) Utilization of cyclodextrins in industrial products and processes. J Mater Chem 7:575–587

Szejtli J (1998) Introduction and general overview of cyclodextrin chemistry. Chem Rev 98:1743–1754

Szejtli J (2004) Past, present, and future of cyclodextrin research. ChemInform 36:1825–1845

Szente L, Szejtli J (2004) Cyclodextrins as food ingredients. Trends Food Sci Technol 15:137–142

Takada M, Nakagawa Y, Yamamoto M (2003) Biochemical and genetic analyses of a novel gamma-cyclodextrin glucanotransferase from an alkalophilic Bacillus clarkii 7364. J Biochem 133:317–324

Tesfai BT (2012) Optimum extracellular production of recombinant cyclodextrin glucanotransferase from Anawrbranca gottschalkii and its cyclodextrin products. Jiangnan University, Wuxi

Tesfai BT, Wu D, Chen S, Chen J, Wu J (2012) Strategies for enhancing extracellular secretion of recombinant cyclodextrin glucanotransferase in E. coli. Appl Biochem Biotechnol 167:897–908

Tsai WC, Wu TC, Chiang BL, Wen HW (2017) Cloning, expression, and purification of recombinant major mango allergen Man i 1 in Escherichia coli. Protein Expr Purif 130:35–43

Van der Veen BA, Uitdehaag JC, Dijkstra BW, Dijkhuizen L (2000) Engineering of cyclodextrin glycosyltransferase reaction and product specificity. Biochim Biophys Acta Biomembr 1543:336–360

Wang L, Chen S, Wu J (2018) Cyclodextrin enhanced the soluble expression of Bacillus clarkii γ-CGTase in Escherichia coli. BMC Biotechnol 18:72

Zhu GY, Xiao ZB, Zhou RJ, Zhu GX, Niu YW (2016) Kinetics and release characteristics of menthyl acetate from its β-cyclodextrin inclusion complex by thermogravimetric analysis. J Incl Phenom Macrocycl Chem 84:219–224

Acknowledgements

This work was supported by grants from the Jiangsu Provincial Key Construction Laboratory of Probiotics Preparation (JSYSZJ2017001).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Rights and permissions

About this article

Cite this article

Zheng, J., Li, X. & Wu, H. High-level extracellular secretion and characterization of the thermophilic β-cyclodextrin glucanotranferase from Paenibacillus campinasensis in Escherichia coli. 3 Biotech 9, 372 (2019). https://doi.org/10.1007/s13205-019-1909-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-019-1909-z