Abstract

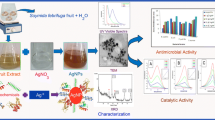

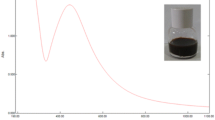

The silver nanoparticles (AgNPs) were prepared via a green synthesis method using guava fruit extract (Gfe) as a reducing agent and stabilizer. Factors affecting the synthesis such as temperature and Gfe volume were studied. The interactions between the synthesized AgNPs and Gfe were confirmed by the Fourier-transform infrared (FT–IR) measurement. The formation of AgNPs, for which the maximum surface plasmon absorption was observed at the wavelength of about 410 nm, was determined by the Ultraviolet–Visible (UV–Vis) spectroscopy. The transmission electron microscopy (TEM) analysis showed that the AgNPs had a spherical shape with an average diameter of 6.19 ± 2.44 nm at room temperature. In addition, the antibacterial properties of AgNPs against the Escherichia coli (E. coli) bacteria investigated using the disc diffusion and colony counting methods indicated that the synthesized AgNPs-Gfe inhibited the growth of E. coli with an excellent antibacterial activity of 99.99% at 5.6 × 106 CFU/ml of the initial E. coli concentration. This antibacterial activity of AgNPs-Gfe is much better than those of AgNPs–AA, and AgNPs–G (AA: Ascorbic Acid and G: Glucose). The AgNPs covered by organic compounds (tannin and flavonoid) have a high antioxidant activity and are good for health. These AgNPs-Gfe are, therefore, good candidates for biomedical applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, silver nanoparticles (AgNPs) have attracted many studies due to their wide applications in optics (Ajitha et al. 2016; Fahmy et al. 2019), selective coatings for solar energy absorption (Asmussen and Vallo 2018), catalysts (Veisi and Mohammadi 2018), and antibacterial agents (Das et al. 2020; Barabadi et al. 2021). In particular, the AgNPs have been popularly applied to antibacterial treatment owing to their nontoxicity towards human as compared to other materials (Priya et al. 2020). Numerous strains of bacteria including Gram-positive ( +) and negative (-) bacteria have been eliminated using the AgNPs (Pazos-Ortiz et al. 2017; Farjadian et al. 2020). Regarding the synthesis of AgNPs, many physical and chemical methods have been used to synthesize the AgNPs, such as chemical reduction (Garcia et al. 2020), sol–gel (Maharjan et al. 2020), microwave irradiation (Kaur et al. 2020), etc. among which chemical method has been widely applied because of its simplicity, rapidity, and convenience (Yaqoob et al. 2020). However, the usage of chemicals as reducing agents and stabilizers like ascorbic acid in the presence of chitosan, polyvinyl pyrrolidone (PVP), trisodium citrate (Na3C6H5O7), and citric acid (H3C6H5O7) (Gola et al. 2021) leads to the existence of a small number of absorbed toxic reagents/precursors and catalysts that are harmful to human beings and the environment (Rolim et al. 2019; Singh et al. 2020; Thakur et al. 2022). To overcome these challenges, it is important to produce the AgNPs by eco-friendly ways, which can easily yield large quantities of AgNPs without using more energy, high temperature, toxic substances, etc. (Bapat et al. 2022; Kamaruzaman et al. 2022). Due to the presence of a variety of active compounds, many plant extracts including Annona reticulata leaf (Parthiban et al. 2018), Boerhaavia diffusa leaf (Akintelu et al. 2019), Stevia leaf (Laguta et al. 2019), Azadirachta indica and Ocimum sanctum leaves (Priyadarshini et al. 2019), Ziziphus joazeiro leaf (Guimarães et al. 2020), Carica Papaya fruit (Firdaus et al. 2017), and orange peel (Skiba and Vorobyova 2019) have been used as bio-reducing agents in the green synthesis of AgNPs and the obtained results showed that the plant extracts not only reduced the metal cations but also stabilized the produced AgNPs.

Guava, one of the common tropical fruits planted in various tropical and subtropical areas, whose ascorbic-acid content (~ 80–300 mg/100 gr) is higher than that of orange, lemon, apple, pineapple, etc. (Naseer et al. 2018). Moreover, guava fruit contains a large number of polyphenol compounds (tannin and flavonoid), which have high natural antioxidant activity and are good for health (Cuadrado-Silva et al. 2017; Naseer et al. 2018). Recently, many reports have been related to the use of extract from guava to synthesize silver nanoparticles. For example, Lokina et al. used polyphenols in guava extract act as a reducing as well as a stabilizing agent to produce AgNPs (Lokina et al. 2015); or Bose and Chatterjee used guava (Psidium guajava) leaf extract as the reducing as well as a capping agent to synthesize AgNPs (Bose and Chatterjee 2016); or Sougandhi and Ramanaiah used Psidium guajava leaf extract for the synthesis of AgNPs without any external addition of reducing agents (Sougandhi and Ramanaiah 2020); or Nguyen et al. also synthesized AgNPs using Psidium guajava (P. guajava) leaf extract (Nguyen et al. 2021). Obtained results showed that guava extract containing much polyphenols can be used as reducing as well as stabilizing agent in the synthesis of AgNPs. Notwithstanding, these researches were limited on the guava leaf extract, while the application of guava fruit extract (Gfe) as a novel reducing agent and stabilizer for preparing the AgNPs has not been reported so far.

In this work, we report a new reducing agent extracted from guava fruit with eco-friendly and non-toxic properties. The effects of reaction temperature and volume of the Gfe on the preparation of AgNPs are examined in detail. Characterizations of AgNPs are determined using UV–Vis and FT-IR spectroscopies together with scanning electron microscopy (SEM) and transmission electron microscopy (TEM) images. Furthermore, antibacterial activities, which are performed on E. coli bacteria, are investigated using the colony counting and disc diffusion methods.

Materials and methods

Materials

All the information regarded to the materials as well as analytical instruments are described in the Supporting Information (SI).

Preparation of guava fruit extract

The extraction of guava fruit is illustrated in Fig. 1. Herein, 15 g of guava fruit (focusing on the fruit skin) were collected and cut into small pieces, prior to being thoroughly washed by tap water (Fig. 1a, b). Guava was then crushed in 15 mL of deionized water (Fig. 1c). The extraction was performed at the room temperature for 10 min (Fig. 1c). In the next step, the mixture was centrifuged (Fig. 1d) before the filtration to collect the guava extract (Fig. 1e, f). The obtained liquid was contained in a glass bottle grabbed with the black plastic bag to prevent the oxidation of ascorbic acid and was stored at 4 ℃ for further studies.

Determination of ascorbic acid and other organic compounds in guava fruit extract

The content of ascorbic acid was calculated following the redox titration method. Organic compounds such as tannin and flavonoid were determined according to the reported procedures with a slight modification. All the information related to the experiments are described in the SI.

Green synthesis of silver nanoparticles and comparative materials

The AgNPs were prepared by the green synthesis method using Gfe as a reducing agent and a stabilizer under moderate time of reaction at different temperatures (5–90 °C) and volumes (1–5 mL). Briefly, 2.0 mL of NaOH 1 M was slowly added to 100 mL of aqueous solution AgNO3 10−3 M and stirred at 200 rpm for 5 min in the dark at room temperature. A 0.21 mL of NH3 2.5% was then dropped gradually to the mixture within 5 min to form [Ag(NH3)2(OH)] complex (colorless solution, pH = 12.95). Finally, the prepared extract was added to the above solution, prior to stirring within approximately 2 h at room temperature to produce AgNPs–Gfe (pH = 12.13). The reduction of Ag+ to Ag0 by Gfe was followed by the change of solution color from colorless and yellow to orange. For the comparison, AgNPs were prepared in the same condition, but ascorbic acid (AA, C6H8O6) and glucose (G, C6H12O6) were used as chemical reducing agents. Full details of the experiments can be found in the SI. The flowchart for green synthesis of silver nanoparticles solution is shown in Diagram 1 .

Studies for antibacterial properties of synthesized silver nanoparticles

Antibacterial properties of the synthesized AgNPs-Gfe were investigated on E. coli bacterium using the disc diffusion method (Ekwealor et al. 2016). First, the mixture of peptone (5 gr), NaCl (5 gr), and agar (20 gr) were dissolved in 1000 mL of double distilled water, prior to being heated under stirring conditions to create a homogeneous solution. This solution was then transferred into conical flasks and aseptic for further studies. The next step was to prepare the suspension, which consists of the investigated bacterial culture (E. coli). To obtain the confluent growth, the bacterial suspension was roughly equally distributed across the whole agar area. The dishes were incubated in 24 h at 37 °C and then AgNPs-Gfe (10 µL) were added to a small circle at their center. These dishes were stored in 12 h at 10 °C before studying antibacterial properties of AgNPs-Gfe. The antibacterial activity was determined using the formula: D-d, where D (mm) is the diameter of the zone containing the inhibitory and the chemical, while d (mm) is the diameter of the zone containing the chemical only. The antibacterial capability of AgNPs-Gfe was also performed using the colony counting method on the E. coli bacteria (5.6 × 106 CFU/mL) and certified by the Pasteur Institute, Ho Chi Minh City, Viet Nam.

Results and discussion

Guava fruit extract analyses

Tannin, flavonoid, and ascorbic acid (AA), which are common reducing components, were found in Gfe. As shown in Fig. 2a–b, the green/white precipitate confirms the reaction between Fe3+/Pb2+ ions and Gfe. This reveals the presence of hydrolysis-tannin groups in the fruit extract (Ejikeme et al. 2014). In addition, the precipitation was not formed in the reaction between formaldehyde and Gfe as seen in Fig. 2c, indicating that tannin in Gfe was hydrolyzed (Fraga-Corral et al. 2020; Aristri et al. 2021). In Fig. 2d, the color of Gfe changes from colorless to dark yellow when NH3 reacts with Gfe, suggesting that Gfe might contain the flavonoid group. These results are consistent with those reported previously (Ejikeme et al. 2014). Furthermore, the formation of the blue complex of Fe4[Fe(CN)6]3/H+ (Fe2+) and colorless solutions after the sequent reactions between Gfe and [K3Fe(CN)6] (Fe3+), I2/KI 0.001 N, methylene blue 0.01%, and KMnO4 0.01 M (Fig. 2e–f) indicates the existence of AA in Gfe (Guntarti and Hutami 2019). Based on titration procedure, the content of AA is 102.7 mg/100 gr guava, which is in good agreement with the previous result (Santos et al. 2017).

Factors affecting the green synthesis of AgNPs

Effect of oxalic acid (OA) and PVA. Figure 3 shows the influence of OA on the synthesis of AgNPs in the presence of PVA as a stabilizer and without using PVA. Briefly, when OA 2% was used as the reducing agent, the samples 1.1S and 1.2S are colorless, demonstrating that the AgNPs were not formed. At the same time, the samples 2.1S and 2.2S are orange, revealing the successful synthesis of AgNPs. The samples 3.1S and 3.2S without OA are also orange, indicating the formation of AgNPs (Fig. 3a–b). These results clearly indicate that the effect of OA on the AgNPs synthesis was negligible. The successful synthesis of AgNPs was reconfirmed by the UV–Vis spectroscopy, which exhibits the maximum absorption peak around the wavelength of 400–420 nm causing by the surface plasmon resonance (SPR). The latter is originated from the oscillation of free electrons in the metal nanoparticles at the frequency resonated with that of the visible light (Behravan et al. 2018; Taghizadeh et al. 2019; Guimarães et al. 2020). As can be seen in Fig. 3c–d, the UV–Vis spectra of 3.1S and 3.2S samples show a good indication towards their absorbance as compared to the 1.1S, 1.2S, 2.1S and 2.2S samples. Obviously, the AgNPs were formed via the reactions between Gfe and AgNO3 without OA and PVA. Based on this observation, we can conclude that the Gfe can be used as a reducing agent and stabilizer for the green synthesis of AgNPs.

The morphologies of synthesized AgNPs-Gfe with PVA as a stabilizer and without PVA shown in Fig. 4a–b exhibit that the AgNPs-Gfe include nanospheres with diameter ranging from 20 to 35 nm and nanotriangles with a sharp edge of 30 nm. A remarkable result is that the AgNPs-Gfe were clustered when PVA was used as a stabilizer (Fig. 4a), but the AgNPs-Gfe without PVA were evenly distributed in the samples (Fig. 4b). These can be explained that although organic compounds in Gfe can play as protecting agents that inhibit the agglomeration of AgNPs-Gfe, adding PVA will make an increase in the concentration of protecting agents, which leads to the formation of AgNPs-Gfe clusters.

The FT-IR spectra of Gfe and AgNPs-Gfe obtained from the green synthesis are presented in Fig. 4c. Evidently, the absorption peaks at 3330, 1750 and 1252 cm−1 are related to stretching bonds of O‒H, C=O, and C‒OH groups in polyphenol compounds (Grasel et al. 2015; Ramesh et al. 2015). The stretching vibrations of C=C bonds in the aromatic ring of polyphenol compounds are recorded at the wavenumbers of 1685 and 1596 cm−1 (Grasel et al. 2015), whereas the wavenumbers of 1502 and 1450 cm−1 are associated with the stretching vibrations of C–C bonds in the aromatic ring (Grasel et al. 2015). Although the FT-IR spectrum of AgNPs-Gfe is similar to that of Gfe, there is a significant decrease in the intensities of the above characteristic peaks. In particular, the specific peak of C=O stretching vibration is shifted from 1750 to 1700 cm−1. These results confirmed that the AgNPs can interact with Gfe via the COO− group in polyphenol compounds owing to the electrostatic attraction (Ibrahim et al. 2019; Zhang and Jiang 2020). The proposed mechanism for the green synthesis of AgNPs using Gfe as reducing agent and stabilizer is presented in Fig. 5.

It is notable that the Gfe could be oxidized by air, leading to the formation of a brown solution, similar to the characteristic color of AgNPs. A control sample including a mixture of Gfe and double distilled water was prepared as presented in Fig. 4d. It is clear to see that both the control sample (3.2.0) and AgNPs-Gfe (3.2) have the same orange color, but there is no typical absorption peak of AgNPs recorded in the UV–Vis curve of the control sample. On the contrary, the maximum absorption peak of AgNPs was observed at 410 nm in the UV–Vis spectrum of AgNPs-Gfe. These results reveal that the colors of Gfe and AgNPs are completely independent.

Effect of volume of fruit extract. The AgNPs-Gfe samples with different Gfe volumes were labeled by Dc1, Dc2, Dc3, Dc4, and Dc5, which correspond to the Gfe volumes in the range of 1–5 mL, respectively. The UV–Vis spectra of these samples and their absorption intensities are shown in Fig. 6a–b. As can be seen in Fig. 6a, the wavelengths of the maximum absorption peak of all samples were recorded at 400 nm, confirming the successful synthesis of AgNPs-Gfe. However, the formation pathway of AgNPs-Gfe was not consistent with the increase of Gfe volume, because there was a fluctuation of the absorption intensities seen in Fig. 6b. For instance, the number of AgNPs-Gfe was increased with increasing the Gfe volume from 1 to 2 mL, whereas it was significantly decreased when the Gfe volume is changed from 3 to 5 mL. This can be explained that adding more Gfe could lead to a decrease in the solution pH, resulting in an increase in the reduction potential of C6H6O6/C6H8O6. As a result, the reducing ability of AA in Gfe is weaken, which leads consequently to a decrease in the rate of the reaction (Sajid et al. 2016).

The effects of the media pH on the stability of the colloidal AgNPs-Gfe were also examined in the present study. It was observed that the AgNPs-Gfe were immediately agglomerated after being synthesized during 10 min in the acid media (Fig. S2), whereas they were stable at least 2 weeks in the base media (Figs. S3–S4). The main reason is that the size of AgNPs in the base media is smaller than that in the acid one, resulting in the difficult agglomerations. These results are consistent with some previous reports (Makwana et al. 2015; Fernando and Zhou 2019).

Temperature effect. Figure 6c, d presents the effects of temperature on the UV–Vis spectra and absorption intensities of AgNPs-Gfe. It is clear that the maximum absorbances of all samples were varied around the wavelength of 400 nm. Nevertheless, the absorption intensities were increased with increasing the reaction temperatures. This means that the more temperature we added, the bigger size the AgNPs were obtained. This finding is consistent with the SEM images of AgNPs-Gfe synthesized at 70 °C and 90 °C (Fig. S5), in which the diameter of AgNPs-Gfe is within a range of 7–15 nm at the room temperature, while their particle sizes are increased from 30 to 60 nm at 70 °C and agglomerated into small clusters at 90 °C.

Antibacterial properties

Figure 7 shows a comparison of the UV–Vis spectra, TEM images, and particle-size distributions of AgNPs-Gfe with AgNPs-AA and AgNPs-G. As can be seen in Fig. 7a, d, g, the maximum absorption wavelengths of AgNPs-Gfe, AgNPs-AA, and AgNPs-G are 405, 415, and 420 nm, respectively, implying that the sizes of AgNPs-Gfe are smaller than those of AgNPs-AA and AgNPs-G. These results are consistent with the TEM images and particle-size distributions in Fig. 7b–c, 7e–f, h–i. Obviously, the AgNPs–AA and AgNPs–G are uniformly dispersed and have spherical shapes with an average size of roughly 25–35 nm. At the same time, the AgNPs–Gfe consist of nanospheres with 6.19 nm in diameter, which are smaller than 10 nm and are, thus, good for antimicrobial applications (Kumar et al. 2018; Tang and Zheng 2018). Furthermore, the reduction of Ag+ cations into the AgNPs-Gfe was occurred in a short time and the obtained AgNPs-Gfe nanospheres had a small size as compared to that of AgNPs synthesized using different plant sources (Table 1). For instance, the size of AgNPs obtained within the present study was 6.19 nm, which was suitable for the antibacterial applications, while that obtained using other plant sources varied from 10 to 100 nm. In addition, our AgNPs were synthesized at a low temperature (room temperature) and in a short reaction period (2 h), which are ideal criteria for the current green-chemistry technology.

The antibacterial capabilities of AgNPs were determined using the disc diffusion method. As compared to the AgNPs-AA and AgNPs-G samples, the AgNPs-Gfe had a better antibacterial potential. Indeed, the size of exhibition zone was gradually reduced from 16 mm (strong antibacterial substance) to 11 mm and 6 mm (medium antibacterial substance) for AgNPs-Gfe, AgNPs-G, and AgNPs-AA, respectively (Fig. 8). This finding agrees with the description of synthesized nanoparticles as great bacteria (such as E. coli) inhibitors in a large number of previous publications (Bhagat et al. 2019; Priyadarshini et al. 2019; Guimarães et al. 2020). However, the antibacterial properties of AgNPs depend on the concentration of bacteria and also AgNPs (Salleh et al. 2020). Therefore, the antibacterial activity of the synthesized AgNPs was also tested on the E. coli ATCC 25,922 using the colony counting method. The sample was carried out and certified by the Pasteur Institute, Ho Chi Minh City, Viet Nam. It is clear that the AgNPs-Gfe, AgNPs-AA and AgNPs-G can eliminate E. coli bacteria with an excellent efficiency of 99.99% (Table 2). However, the AgNPs–Gfe have smaller sizes than that of AgNPs–G or AgNPs–AA and thus, Ag particles are covered by phytochemicals having natural antioxidants. Therefore, the AgNPs-Gfe prepared by the green synthesis method are more advantageous than the AgNPs synthesized via common chemical reduction methods.

Conclusion

Within the present work, the silver nanoparticles (AgNPs) had been successfully produced via an eco-friendly, cost-effective, simple, and green approach based on the guava fruit extract (Gfe). The FT-IR and UV–Vis analyses showed that the Gfe contains polyphenol compounds with high antioxidant properties, which are good for health and can be used as a reducing agent as well as a stabilizer. The obtained AgNPs-Gfe nanospheres with 6.19 ± 2.44 nm in diameter have the maximum absorbance at the wavelength around 410 nm. The antibacterial studies using the colony counting and disc diffusion methods indicated that the AgNPs-Gfe can inhibit the Escherichia coli growth and multiplication with an excellent efficiency of 99.99%. This result strongly supports the recommendation for the use of Gfe as a reducing agent to produce AgNPs via the green method as compared to other chemical reducing agents, which have certain disadvantages due to their usages of toxic substances and high temperature.

Data availability

Not applicable.

References

Ajitha B, Kumar Reddy YA, Reddy PS, Jeon H-J, Ahn CW (2016) Role of capping agents in controlling silver nanoparticles size, antibacterial activity and potential application as optical hydrogen peroxide sensor. 6: 36171–36179. https://doi.org/10.1039/C6RA03766F

Akintelu S, Folorunso A, Oyebamiji A, Erazua E (2019) Antibacterial potency of silver nanoparticles synthesized using Boerhaavia diffusa leaf extract as reductive and stabilizing agent. Inter J Pharm Sci Res 10:374–380

Alrasheid A, Eltilib S, Ahmed S, Mohamed A, Widatalla H, Yassin L, Ali M, Widdatallh M (2020) Green synthesis and antibacterial properties of silver nanoparticles using Sudanese Azadirachta indica leaves extract. Sci Res 8:14–19. https://doi.org/10.11648/j.sr.20200801.13

Aristri MA, Lubis MA, Iswanto AH, Fatriasari W, Sari RK, Antov P, Gajtanska M, Papadopoulos AN, Pizzi A (2021) Bio-based polyurethane resins derived from tannin: source, synthesis, characterisation, and application. 12. https://doi.org/10.3390/f12111516

Asmussen SV, Vallo CI (2018) Absorber materials based on polymer nanocomposites containing silver nanoparticles for solar thermal collectors. 174: 640-647. https://doi.org/10.1016/j.solener.2018.09.062

Bapat MS, Singh H, Shukla SK, Singh PP, Vo D-VN, Yadav A, Goyal A, Sharma A, Kumar D (2022) Evaluating green silver nanoparticles as prospective biopesticides: an environmental standpoint. 286: 131761. https://doi.org/10.1016/j.chemosphere.2021.131761

Barabadi H, Mojab F, Vahidi H, Marashi B, Talank N, Hosseini O, Saravanan M (2021) Green synthesis, characterization, antibacterial and biofilm inhibitory activity of silver nanoparticles compared to commercial silver nanoparticles. 129: 108647. https://doi.org/10.1016/j.inoche.2021.108647

Behravan M, Hossein PA, Naghizadeh A, Ziaee M, Mahdavi R, Mirzapour A (2018) Facile green synthesis of silver nanoparticles using Berberis vulgaris leaf and root aqueous extract and its antibacterial activity. Int J Biol Macromol 124:148–154. https://doi.org/10.1016/j.ijbiomac.2018.11.101

Bhagat M, Anand R, Datt R, Gupta V, Arya S (2019) Green synthesis of silver nanoparticles using aqueous extract of Rosa brunonii Lindl and their morphological, biological and photocatalytic characterizations. J Inorg Organomet Polym Mater 29:1039–1047. https://doi.org/10.1007/s10904-018-0994-5

Bose D, Chatterjee S (2016) Biogenic synthesis of silver nanoparticles using guava (Psidium guajava) leaf extract and its antibacterial activity against Pseudomonas aeruginosa. 6: 895–901. https://doi.org/10.1007/s13204-015-0496-5

Cuadrado-Silva CT, Pozo-Bayón MÁ, Osorio C (2017) Targeted Metabolomic Analysis of Polyphenols with Antioxidant Activity in Sour Guava (Psidium friedrichsthalianum Nied.) Fruit. 22: 11.

Das CGA, Kumar VG, Dhas TS, Karthick V, Govindaraju K, Joselin JM, Baalamurugan J (2020) Antibacterial activity of silver nanoparticles (biosynthesis): a short review on recent advances. 27: 101593. https://doi.org/10.1016/j.bcab.2020.101593

Ejikeme C, Stephen E, Eboatu A (2014) Determination of physical and phytochemical constituents of some tropical timbers indigenous to nigerdelta area of Nigeria. Euro Sci J 10:1857–7881

Ekwealor PA, Ugwu MC, Ezeobi I, Amalukwe G, Ugwu BC, Okezie U, Stanley C, Esimone C (2016) Antimicrobial evaluation of bacterial isolates from urine specimen of patients with complaints of urinary tract infections in Awka. Nigeria 2016:9740273. https://doi.org/10.1155/2016/9740273

Fahmy HM, Mosleh AM, Elghany AA, Shams-Eldin E, Abu Serea ES, Ali SA, Shalan AE (2019) Coated silver nanoparticles: synthesis, cytotoxicity, and optical properties. 9: 20118–20136. https://doi.org/10.1039/C9RA02907A

Farjadian F, Akbarizadeh AR, Tayebi L (2020) Synthesis of novel reducing agent for formation of metronidazole-capped silver nanoparticle and evaluating antibacterial efficiency in gram-positive and gram-negative bacteria. 6: e04747. https://doi.org/10.1016/j.heliyon.2020.e04747

Fernando I, Zhou Y (2019) Impact of pH on the stability, dissolution and aggregation kinetics of silver nanoparticles. 216: 297–305. https://doi.org/10.1016/j.chemosphere.2018.10.122

Firdaus M, Andriana S, Elvinawati AW, Swistoro E, Ruyani A, Sundaryono A (2017) Green synthesis of silver nanoparticles using Carica Papaya fruit extract under sunlight irradiation and their colorimetric detection of mercury ions. J Phys Conf Ser 817:012029. https://doi.org/10.1088/1742-6596/817/1/012029

Fraga-Corral M, García-Oliveira P, Pereira AG, Lourenço-Lopes C, Jimenez-Lopez C, Prieto MA, Simal-Gandara J (2020) Technological application of tannin-based extracts. 25. https://doi.org/10.3390/molecules25030614

Garcia PRAF, Prymak O, Grasmik V, Pappert K, Wlysses W, Otubo L, Epple M, Oliveira CLP (2020) An in situ SAXS investigation of the formation of silver nanoparticles and bimetallic silver–gold nanoparticles in controlled wet-chemical reduction synthesis. 2: 225–238. https://doi.org/10.1039/C9NA00569B

Gola D, kriti A, Bhatt N, Bajpai M, Singh A, Arya A, Chauhan N, Srivastava SK, Tyagi PK, Agrawal Y (2021) Silver nanoparticles for enhanced dye degradation. 4: 100132. https://doi.org/10.1016/j.crgsc.2021.100132

Gomathi M, Annamalai P, Rajkumar PV, Shanmugam R, Chandrasekaran R, Anbarasan P (2019) Green synthesis of silver nanoparticles using Gymnema sylvestre leaf extract and evaluation of its antibacterial activity. S Afr J Chem Eng 32:1–4. https://doi.org/10.1016/j.sajce.2019.11.005

Grasel F, Ferrao M, Wolf C (2015) Development of methodology for identification the nature of the polyphenolic extracts by FTIR associated with multivariate analysis. Spectrochim Acta A Mol Biomol Spectrosc. 153:94–101. https://doi.org/10.1016/j.saa.2015.08.020

Guimarães M, Silva F, Costa M, Oliveira H (2020) Green synthesis of silver nanoparticles using Ziziphus joazeiro leaf extract for production of antibacterial agents. Appl Nanosci 10:1073–1081. https://doi.org/10.1007/s13204-019-01181-4

Guntarti A, Hutami EN (2019) Validation and vitamin C testing in crystal guava (Psidium guajava L.) with variations of origin with the HPLC method (High Performance Liquid Chromatography). 11: 52–59.

Ibrahim EH, Kilany M, Ghramh HA, Khan KA, ul Islam S. (2019) Cellular proliferation/cytotoxicity and antimicrobial potentials of green synthesized silver nanoparticles (AgNPs) using Juniperus procera. 26: 1689–1694. https://doi.org/10.1016/j.sjbs.2018.08.014

Jebril S, Jenana R, Dridi C (2020) Green synthesis of silver nanoparticles using Melia azedarach leaf extract and their antifungal activities: In vitro and in vivo. Mater Chem Phys 248:122898. https://doi.org/10.1016/j.matchemphys.2020.122898

Kamaruzaman NH, Mohd Noor NN, Radin Mohamed RMS, Al-Gheethi A, Ponnusamy SK, Sharma A, Vo D-VN (2022) Applicability of bio-synthesized nanoparticles in fungal secondary metabolites products and plant extracts for eliminating antibiotic-resistant bacteria risks in non-clinical environments. 209: 112831. https://doi.org/10.1016/j.envres.2022.112831

Kannan B, Qing W, Wang Y, Liu X-H, Thayumanavan P, Wang Y, Ma F, Zhanga Y (2016) Antidiabetic activity of silver nanoparticles from green synthesis using Lonicera japonica leaf extract. RSC Adv 6:40162–40168. https://doi.org/10.1039/c5ra24391b

Kaur G, Kalia A, Sodhi HS (2020) Size controlled, time-efficient biosynthesis of silver nanoparticles from Pleurotus florida using ultra-violet, visible range, and microwave radiations. 50: 35–41. https://doi.org/10.1080/24701556.2019.1661466

Kumar B, Smita K, Cumbal L, Debut A (2017) Green synthesis of silver nanoparticles using Andean blackberry fruit extract. Saudi J Biol Sci. 24:45–50. https://doi.org/10.1016/j.sjbs.2015.09.006

Kumar SV, Bafana AP, Pawar P, Rahman A, Dahoumane SA, Jeffryes CS (2018) High conversion synthesis of <10 nm starch-stabilized silver nanoparticles using microwave technology. 8: 5106. https://doi.org/10.1038/s41598-018-23480-6

Laguta I, Stavinskaya O, Kazakova O, Fesenko T, Brychka S (2019) Green synthesis of silver nanoparticles using Stevia leaves extracts. Appl Nanosci 9:755–765. https://doi.org/10.1007/s13204-018-0680-5

Lokina S, Stephen A, Kaviyarasan V, Arulvasu C, Narayanan V (2015) Cytotoxicity and antimicrobial studies of silver nanoparticles synthesized using Psidium guajava L. Extract 45:426–432. https://doi.org/10.1080/15533174.2013.831881

Maharjan S, Liao K-S, Wang AJ, Zhu Z, McElhenny BP, Bao J, Curran SA (2020) Sol-gel synthesis of stabilized silver nanoparticles in an organosiloxane matrix and its optical nonlinearity. 532: 110610. https://doi.org/10.1016/j.chemphys.2019.110610

Makwana BA, Vyas DJ, Bhatt KD, Jain VK, Agrawal YK (2015) Highly stable antibacterial silver nanoparticles as selective fluorescent sensor for Fe3+ ions. 134: 73–80. https://doi.org/10.1016/j.saa.2014.05.044

Naseer S, Hussain S, Naeem N, Bhatti MP, Rahman M (2018) The phytochemistry and medicinal value of Psidium guajava (guava). Clin Phytoscience 4:1–8. https://doi.org/10.1186/s40816-018-0093-8

Nguyen TD, Nguyen DP, Hoang YH, Nguyen TT, Nguyen HT (2021) Rapid synthesis of silver nanoparticles using the extract of Psidium guajava leaf based on light-emitting diodes irradiation. 75: 5623-5631. https://doi.org/10.1007/s11696-021-01747-z

Parthiban E, Manivannan N, Ravichandran RNM (2018) Green synthesis of silver-nanoparticles from Annona reticulata leaves aqueous extract and its mosquito larvicidal and anti-microbial activity on human pathogens. Biotechnol Rep 21:e00297. https://doi.org/10.1016/j.btre.2018.e00297

Pazos-Ortiz E, Roque-Ruiz JH, Hinojos-Márquez EA, López-Esparza J, Donohué-Cornejo A, Cuevas-González JC, Espinosa-Cristóbal LF, Reyes-López SY (2017) Dose-dependent antimicrobial activity of silver nanoparticles on polycaprolactone fibers against gram-positive and gram-negative bacteria. 2017: 4752314. https://doi.org/10.1155/2017/4752314

Priya K, Vijayakumar M, Janani B (2020) Chitosan-mediated synthesis of biogenic silver nanoparticles (AgNPs), nanoparticle characterisation and in vitro assessment of anticancer activity in human hepatocellular carcinoma HepG2 cells. 149: 844–852. https://doi.org/10.1016/j.ijbiomac.2020.02.007

Priyadarshini S, Sulava S, Bhol R, Jena S (2019) Green synthesis of silver nanoparticles using Azadirachta Indica and Ocimum Sanctum leaf extract. Curr Sci 117: 1300–1307. https://doi.org/10.18520/cs/v117/i8/1300-1307

Ramesh PS, Kokila T, Geetha D (2015) Plant mediated green synthesis and antibacterial activity of silver nanoparticles using Emblica officinalis fruit extract. 142: 339-343. https://doi.org/10.1016/j.saa.2015.01.062

Rolim W, Pelegrino M, de Araujo Lima B, Ferraz L, Costa F, Bernardes J, Rodigues T, Brocchi M, Seabra A (2019) Green tea extract mediated biogenic synthesis of silver nanoparticles: characterization, cytotoxicity evaluation and antibacterial activity. Appl Surf Sci 463:66–74. https://doi.org/10.1016/j.apsusc.2018.08.203

Roy P, Das B, Mohanty A, Mohapatra S (2017) Green synthesis of silver nanoparticles using Azadirachta indica leaf extract and its antimicrobial study. Appl Nanosci.: 843–850. https://doi.org/10.1007/s13204-017-0621-8

Sajid PA, Chetty SS, Praneetha S, Murugan AV, Kumar Y, Periyasamy L (2016) One-pot microwave-assisted in situ reduction of Ag+ and Au3+ ions by Citrus limon extract and their carbon-dots based nanohybrids: a potential nano-bioprobe for cancer cellular imaging. 6: 103482–103490. https://doi.org/10.1039/C6RA24033J

Salleh A, Naomi R, Utami ND, Mohammad AW, Mahmoudi E, Mustafa N, Fauzi MB (2020) The potential of silver nanoparticles for antiviral and antibacterial applications: a mechanism of action. 10. https://doi.org/10.3390/nano10081566

Santos WNLd, da Silva Sauthier MC, dos Santos AMP, de Andrade Santana D, Almeida Azevedo RS, da Cruz Caldas J (2017) Simultaneous determination of 13 phenolic bioactive compounds in guava (Psidium guajava L.) by HPLC-PAD with evaluation using PCA and Neural Network Analysis (NNA). 133: 583–592. https://doi.org/10.1016/j.microc.2017.04.029

Singh H, Kumar A, Thakur A, Kumar P, Nguyen V-H, Vo D-VN, Sharma A, Kumar D (2020) One-pot synthesis of magnetite-ZnO nanocomposite and its photocatalytic activity. 63: 1097–1108. https://doi.org/10.1007/s11244-020-01278-z

Skiba M, Vorobyova V (2019) Synthesis of silver nanoparticles using orange peel extract prepared by plasmochemical extraction method and degradation of methylene blue under solar irradiation. Adv Mater Sci Eng 2019:1–8. https://doi.org/10.1155/2019/8306015

Sougandhi PR, Ramanaiah S (2020) Green synthesis and spectral characterization of silver nanoparticles from Psidium guajava leaf extract. 50: 1290-1294. https://doi.org/10.1080/24701556.2020.1745839

Taghizadeh S, Alimardani V, Lohrasbi P, Younes G, Kaviani E (2019) Gold nanoparticles application in liver cancer. Photodiagnosis Photodyn Ther 25:389–400. https://doi.org/10.1016/j.pdpdt.2019.01.027

Tang S, Zheng J (2018) Antibacterial activity of silver nanoparticles: structural effects. 7: 1701503. https://doi.org/10.1002/adhm.201701503

Thakur A, Kumar A, Kaya S, Vo D-VN, Sharma A (2022) Suppressing inhibitory compounds by nanomaterials for highly efficient biofuel production: a review. 312: 122934. https://doi.org/10.1016/j.fuel.2021.122934

Veerasamy R, Sethu V, Sivadasan S, Shah SA, Haris R (2016) Green synthesis of silver nanoparticles using Atrocarpus altilis leaf extract and the study of their antimicrobial and antioxidant activity. Mater Lett 180:264–267. https://doi.org/10.1016/j.matlet.2016.05.172

Veisi H, Mohammadi P (2018) Green synthesis of the silver nanoparticles mediated by Thymbra spicata extract and its application as a heterogeneous and recyclable nanocatalyst for catalytic reduction of a variety of dyes in water. J Clean Prod 170:1536–1543. https://doi.org/10.1016/j.jclepro.2017.09.265

Yaqoob AA, Umar K, Ibrahim MNM (2020) Silver nanoparticles: various methods of synthesis, size affecting factors and their potential applications–a review. 10: 1369–1378. https://doi.org/10.1007/s13204-020-01318-w

Zhang W, Jiang W (2020) Antioxidant and antibacterial chitosan film with tea polyphenols-mediated green synthesis silver nanoparticle via a novel one-pot method. 155: 1252-1261. https://doi.org/10.1016/j.ijbiomac.2019.11.093

Funding

The authors did not receive support from any organization for the submitted work.

Author information

Authors and Affiliations

Contributions

Conceptualization: Van-Phuc Dinh, Duy-Khoi Nguyen; data curation: Duy-Khoi Nguyen; formal analysis and investigation: Duy-Khoi Nguyen, Van-Phuc Dinh, N.Quang Hung; methodology: Van-Phuc Dinh, N.Quang Hung; supervision: Van-Phuc Dinh; writing—original draft: Duy-Khoi Nguyen, N.Quang Hung, Van-Phuc Dinh.

Corresponding author

Ethics declarations

Conflict of interests

There are no conflicts to declare.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

We declare that the information in this manuscript has not been published elsewhere nor is it under consideration by any other journal. Furthermore, it is the consensus of all authors to submit this manuscript for possible publication in ABAB.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nguyen, DK., Hung, N.Q. & Dinh, VP. Antibacterial properties of silver nanoparticles greenly synthesized using guava fruit extract as a reducing agent and stabilizer. Appl Nanosci 13, 3709–3720 (2023). https://doi.org/10.1007/s13204-022-02506-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-022-02506-6