Abstract

Experimental fabrication and investigation of unique properties of two-dimensional monoatomic layers of carbon, silicon, germanium, and tin on different surfaces have opened bright perspectives for development of devices of new generation. Wide opportunities to control their exotic electronic and optical properties via appropriate choice of substrate, content and geometry of two-dimensional layer, combined with elastic strain engineering, made them the central theme of research in the field of nanotechnology and materials science. In this work we review epitaxial methods of synthesis of two-dimensional materials of group IV elements: silicene, germanene, and stanene. General structural properties of these materials are also briefly considered. Special attention is paid to the technological growth modes, providing fabrication of high-quality large-area two-dimensional structures necessary for emerging device application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Background

Two-dimensional materials (two-dimensional crystals, 2D materials) are the structures with the thickness of one or few atomic layers (Li et al. 2017; Molle et al. 2017; Matusalem et al. 2017; Gao et al. 2016; Ezawa and Le Lay 2015). They became one of the central themes of research after fabrication of graphene (monoatomic layer of carbon) in 2004 (Novoselov et al. (2004)). Graphene is carbon allotrope with sp2 hybridized atoms arranged in a planar honeycomb lattice. The fabrication of stable free-standing layer of atoms was quite unexpected result, since it was believed that a two-dimensional crystal cannot exhibit long-range order at any finite temperature (Acun et al. 2015). In the contrast with volumetric materials 2D crystals have extremely high ratio of surface area to their volume. Therefore, energetic structure, the majority of electrical and optical parameters of two-dimensional materials are determined by their surface properties and very sensitive to external effects.

The experimental synthesis and study of the unique properties of two-dimensional monoatomic carbon layers has opened up great opportunities for the study of other graphene-like 2D materials. At present, two-dimensional crystals are considered as one of the most promising materials for electronics and optoelectronics of the next generation of the technological development. The study of the possibilities of creation of the devices based on 2D materials allows a deeper study of the physical properties of these new materials and provides a starting point for the development of a huge number of practically important areas: starting from nanoelectronics and photonics to energy and telecommunication technologies.

In this case, such characteristics of the resulting structures as the number of layers, their composition, the value and distribution of elastic strains, the presence or absence of defects and impurities are critical. These structural characteristics directly affect the properties of 2D materials and, therefore, determine the parameters of devices based on them.

The discovery of graphene prompted investigators to search for other 2D materials, especially single-element ones. Graphene-like materials of group IV elements (transgraphenes or 2D-Xenes) such as silicene, germanene, and stanene, with a two-dimensional hexagonal lattice have attracted increased attention of researchers in the last few years due to their exotic electronic and optical properties due to the practically zero band gap, small effective masses, and the same symmetry as of graphene (Matusalem et al. 2017). All these factors lead, for example, to very high mobility of charge carriers. As a result, a fast-speed silicene-based field-effect transistor operating at room temperature has already been implemented (Tao et al. 2015), while stanene is considered as one of the main contenders for the creation of ultra-efficient cheap interconnections of integrated circuits (Houssa et al. 2016). In addition, under certain conditions, the quantum spin Hall effect is observed in these materials at temperatures significantly higher than the temperature of liquid nitrogen and they perform as topological insulators and high-temperature superconductors. The unique properties of graphene-like 2D materials make it possible to create completely new types of devices: topological transistors, highly sensitive gas sensors, energy-intensive power supplies, thermoelectric generators, quantum computers (Ezawa and Le Lay 2015; Mortazavi et al. 2016; Garg et al. 2017; Liao et al. 2018). Another important advantage of silicene and germanene is its direct compatibility with the existing highly developed silicon technology.

Among three basic technologies of synthesis of 2D materials (mechanical exfoliation, chemical vapor deposition, and physical vapor deposition) the main method for the creation of heterostructures with 2D crystals of silicene, germanene and stanene is molecular beam epitaxy. For all kinds of applications in modern nano- and optoelectronics, it is necessary to fabricate heterostructures with two-dimensional layers with different properties. In the case of the formation of two-dimensional crystals, the material layer thickness, surface roughness, distribution of elastic stresses, the presence or absence of defects are of decisive importance. In this situation, it is the quantity and quality of the deposited monolayers that are critical, since they determine, for example, the possibility of realization of superconductivity and topological properties in such materials (Liao et al. 2018). Due to the spontaneous nature of the growth of two-dimensional structures, among the most important parameters that determine the characteristics of the entire growth process and the properties of the formed 2D layers are the growth rate and substrate temperature, the amount of deposited material and surface conditions. So, the parameters of the formed structures can only be controlled indirectly by changing the conditions of the synthesis.

A rather significant amount of experimental works has already accumulated on growing two-dimensional layers of group IV elements on various substrates, since this system is very promising from the point of view of all kinds of applications in the future 2D nanoelectronics, optoelectronics, and photonics. However, even a small part of all possible advantages has not been implemented yet. There are practically no theoretical studies on modeling the formation of two-dimensional materials on various substrates and capable of predicting the morphological properties of the resulting heterostructures, as well as, for example, the critical thickness of the undesirable transition from two-dimensional to three-dimensional growth in these systems (when a 2D crystal turns into usual bulk material, losing its unique physical properties). In the case of growth of two-dimensional layers of silicene, germanene, and stanene, this problem is especially actual, since these materials were obtained only relatively recently (in 2012, 2014, and 2015, respectively), and the direct growth of such samples requires a lot of time and material costs (Cahangirov 2016).

The aim of this review is to conduct comprehensive overview of epitaxial methods of synthesis of two-dimensional materials of group IV elements: silicene, germanene, and stanene, as well as outline general structural properties of these materials. Special attention is paid to the technological growth modes, providing fabrication of high-quality large-area two-dimensional structures necessary for emerging device application.

Epitaxial synthesis of silicene, germanene, and stanene

Silicene

The idea of silicon equivalent of graphene was asserted in 1994 by Takeda and Shiraishi (1994). Then, in 2007 the believed new material was investigated theoretically in more details by Guzman-Verri and Lew Yan Voon (2007), who gave it the current name “silicene”. Unlike graphene, the structure of silicene (as well as germanene and stanene) is not completely flat, with buckled rings. This leads to the ordered distortions on the surface and increased flexibility, compared with graphene, and also increases the spectrum of its application in electronics (Jose and Datta 2011; Houssa et al. 2015; Lay 2015). Moreover, mixed sp2–sp3 hybridization is typical for graphene-like 2D materials of group IV elements (Fig. 1a) (Molle et al. 2018). The distance between neighbor silicon atoms in hexagonal lattice of silicene lx-x amounts to approximately 0.23 nm, the lattice constant ax is about 3.9 nm, and higher atoms in the layer are altered with respect to the lower atoms by the height δ of approximately 0.075 nm (Fig. 1b) (Molle et al. 2017; Vogt et al. 2012; Lin et al. 2012; Ezawa 2015; Balendhran et al. 2015). Such geometric structure is energetically more favorable and provides the stability of the whole structure.

At present, the preparation of silicene in experiments is extremely complicated. It is well known, that due to the weak interlayer interactions in graphite, a single flat layer of carbon atoms with sp2 hybridization can be easily exfoliated. At the same time, due to sp3 bonding in the bulk silicon, the same method of exfoliation could not be used for silicene synthesis. Therefore, the main method for manufacturing silicene sheets is the epitaxial growth of silicon on appropriate surfaces (Meng et al. 2013).

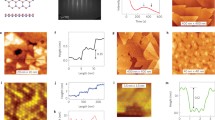

For the first time silicene was experimentally obtained by epitaxial methods in 2012 on the Ag(111) substrate by Vogt et al. (2012) and, independently, by Lin et al. (2012). In the former group clean and well-ordered Ag(111) surfaces were prepared by Ar+ ion bombardment (with the energy of 1.5 keV) and subsequent annealing at 530 °C for 30 min of (111)-oriented Ag single crystals under ultrahigh vacuum conditions (5 × 10–5 Torr). Silicon was deposited by evaporation from a Si source consisting of a directly heated Si-wafer piece, while the Ag sample was kept at temperatures between 220–260 °C (Fig. 2). The growth mode of the Si adlayer was determined by measuring the area ratio between Si and Ag as a function of Si deposition time. Si/Ag area ratio changed linearly, indicating an initial 2D growth behavior with a corresponding deposition rate of 0.017 ML/min (monolayers per minute). The honeycomb appearance of Si adlayer was prepared reproducibly for different Si deposition amounts. For smaller amounts of Si (less than 1 ML), the formation of smaller two-dimensional Si islands was observed, which grown bigger with increasing deposition and finally covered the Ag(111) terraces completely (Vogt et al. 2012).

Deposition of epitaxial silicene on Ag(111) (Molle et al. 2018)

In the latter work by Lin et al. the experiments were carried out inside an ultrahigh vacuum chamber with the base pressure of 5 × 10–11 Torr. Ag(111) substrate was cleaned via several cycles of Ar+ sputtering and annealing at 870 K. Si was in situ deposited by directly heating a small piece of Si wafer at the rate below 0.03 ML/min, which was estimated from dividing the Si covered areas by deposition time. The Ag(111) substrate was kept at various temperatures below 300 °C during the deposition. Two types of atomic arrangement were observed with slightly different displacements and distances between Si atoms (Lin et al. 2012).

Soon, Jamgotchian et al. (2012) have also synthesized silicene on Ag(111) substrate in wide range of growth temperatures. The experiments were performed in an ultrahigh vacuum system with the pressure 5 × 10–5 Torr. The Ag(111) sample was cleaned by several cycles of sputtering (600 eV Ar+ ions), followed by annealing at 480 °C for few hours. Silicon was evaporated by direct current heating of a pure silicon chip onto the Ag(111) maintained at constant temperature during the growth. The substrate temperature was controlled by a thermocouple located close to the sample. Deposition of about one silicon monolayer was performed in the temperature range from 150 to 350 °C with the steps of 30 °C. The evaporation rates were 0.01 ML/min and 0.05 ML/min. At higher deposition rates and for temperatures above 330 °C no superstructure was observed. Below this temperature a continuous evolution was observed between various superstructures. The number of structural defects in honeycomb hexagonal lattice also increased with growth temperature and with time at room temperature. So, the important role of the temperature in the growth of silicene was established (Jamgotchian et al. 2012).

After these pioneer works a race has begun for synthesizing silicene on various substrates. First, silicene was successfully synthesized by Fleurence et al. on the surface of ZrB2(0001) thin film grown by ultrahigh vacuum chemical vapor deposition on Si(111) wafer (Fleurence et al. 2012). The results of this work confirmed that silicene has more flexible crystal structure than graphene which allows an engineering of the band structure through the change in conditions of epitaxy.

Then, graphene-like silicon was also fabricated on Ir(111) substrate by Meng et al. (2013). Experiments were performed in an ultrahigh vacuum system with a base pressure of about 2 × 10−10 Torr. The Ir(111) substrate was cleaned by several cycles of sputtering and annealing. Silicon was deposited on Ir(111) at room temperature from a piece of silicon heated by a direct current. After deposition, the sample was annealed at 670 K for 30 min, whereupon a distinct well-ordered structure appeared. Such structure was characterized as a (√7 × √7) superstructure with respect to the substrate by means of low energy electron diffraction and scanning tunneling microscopy. The buckling of the silicon adlayer on the Ir(111) surface was revealed. The silicon atoms were located at two different heights with respect to the substrate: the distance between the top silicon atoms and the iridium substrate was about 2.83 Å, and the distance between the other silicon atoms and the substrate was around 2 Å. This height difference (0.83 Å) is consistent with the reported results on silicene on Ag(111) surface, where the height difference is 0.75 Å (Fig. 3).

Model of buckled silicene layer on Ir(111) surface (two colors are used for silicon atoms at different height positions) (Meng et al. 2013)

Later on, silicene sheets were fabricated on MoS2 surface (Chiappe et al. 2014), ZrC surface (Aizawa et al. 2014), Ru substrate (Huang et al. 2017), and graphite (Crescenzi et al. 2016).

Germanene

Germanene is in many aspects very similar to graphene and silicene, but in contrast to the planar graphene lattice, the germanene honeycomb lattice is buckled as for silicene and composed of two vertically displaced sublattices. The distance between germanium atoms in germanene lx-x is equal to 2.5 Å, lattice parameter ax is about 3.8 Å, and the value of the displacement of upper and lower layers δ is approximately 0.06–0.09 nm depending on the substrate (Molle et al. 2017; Ezawa 2015; Balendhran et al. 2015; Derivaz et al. 2015; Zhang et al. 2016; Davila and Le Lay 2016).

In 2009 Cahangirov et al. (Cahangirov et al. 2009) proposed the existence of free-standing germanene and demonstrated its structural stability with respect to atomic vibrations. Since this theoretical prediction, electronic and structural properties of germanene have been increasingly explored by theoreticians. The spin–orbit gap in germanene was estimated to be much larger than in graphene, which makes germanene the possible candidate to exhibit the quantum spin Hall effect at high temperatures (Acun et al. 2015).

Attempts to synthesize germanene on the same Ag(111) substrate as silicene failed, as the proper mismatch between lattice constants of silicene and Ag(111) is not fulfilled for germanene (Davila et al. 2014). Moreover, germanium and silver form solid solution Ag2Ge on the surface of the substrate, where Ge atoms, up to a coverage of 1/3 ML, substitute Ag ones (Cahangirov 2016).

Instead of this, in 2014 germanene was successfully grown on Au(111) substrate by Davila et al. (2014). However, its formation has shown great similarity to the growth of silicene sheets on the Ag(111) surface. The methodology of growth experiment was very similar to the one used for the synthesis of silicene on Ag(111). The clean Au(111) surface was prepared in a standard manner by Ar+ ion bombardment and annealing. Germanium was deposited at the temperature of 200 °C to the adlayer thickness of about 1 ML. Two-dimensional layer with honeycomb structure and corrugation of about 0.01 nm was obtained at the area larger than 50 × 50 nm2.

In the same year, the growth of germanene on Pt(111) was reported by Li et al. (2014). Experiments were performed in an ultrahigh vacuum system with a base pressure of about 2 × 10−10 Torr. The Pt(111) substrate was cleaned by several cycles of sputtering and annealing. The germanium was deposited on Pt(111) at room temperature from a germanium rod mounted in an electron-beam evaporator. After deposition, the sample was annealed at the temperature range of 600–750 K for 30 min. Using low energy electron diffraction and scanning tunneling microscopy a (√19 × √19) periodicity with respect to the Pt(111) substrate was found. Scanning tunneling microscopy data revealed the presence of a continuous and well-ordered (√19 × √19) superstructure, which was interpreted as a germanene adlayer on the Pt(111) substrate.

And already in 2015 germanene was fabricated epitaxially on Al(111) substrate by Derivaz et al. (2015). Al(111) has hexagonal symmetry with a lattice parameter close to that expected for the growth of germanene. Moreover, the Al(111) lattice parameter (0.405 nm) lays between that of Au(111) (0.408 nm) and that of Pt(111) (0.392 nm), which were successfully used as a substrate for germanene growth. Experiments were performed in an ultrahigh vacuum system with a base pressure of about 3 × 10−11 Torr. The Al(111) substrate was cleaned by numerous cycles of sputtering and annealing at 500 °C. The germanium was deposited on the Al(111) substrate maintained at about 87 °C with a very low flux of about 0.005 nm/min from the Ge evaporation cell. The deposited amount corresponded to one germanene monolayer. The authors found that a (3 × 3) (with respect to the Al(111) surface) germanene reconstruction formed a continuous layer that covered the Al(111) and had domain sizes larger than 100 nm (Fig. 4) (Derivaz et al. 2015).

Model of buckled germanene layer (green balls) on Al(111) surface (brown balls): a top view and b side view of the area outlined in a (Derivaz et al. 2015)

However, the synthesis of germanene on metallic surfaces is unsuitable for electronic devices, while the exploiting of 2D insulator as a substrate for germanene is highly desirable for the realization of functional field-effect electronic devices (Acapito et al. 2016). Further studies showed that germanene growth is also possible on non-metallic substrates. Thus, in various studies, surfaces of MoS2 (Zhang et al. 2016) and hexagonal AlN (Acapito et al. 2016) were used for the epitaxial synthesis of germanene.

Besides that, a possible candidate on the role of wide band gap material for the substrate for germanene growth is hexagonal boron nitride (h-BN). h-BN has a band gap of about 6 eV and its lattice constant (2.5 Å) is almost identical to the nearest neighbor distance of germanene (Fig. 5) (Acun et al. 2015).

Model of the germanene layer (red lines) on the surface of hexagonal boron nitride (blue balls) (Acun et al. 2015)

Stanene

In addition, just few years ago, reports began to appear on the fabrication by the method of molecular beam epitaxy of the following graphene-like group IV material, namely stanene. It has lattice constant ax of about 4.7 nm, the nearest neighbor distance for tin atoms lx-x is equal to 2.8 nm, and buckling parameter δ for stanene is of order of 0.1 nm (Molle et al. 2017; Ezawa 2015; Balendhran et al. 2015; Webb 2014; Gross 2014; Sahoo and Wei 2019).

For the first time, stanene was synthesized on the Bi2Te3(111) surface in 2015 by Zhu et al. (Zhu et al. 2015). In this study Bi2Te3(111) films with the thickness up to 40 nm were grown by molecular beam epitaxy on the Si(111) wafer. High-purity Sn (99.999%) was evaporated from the effusion cells with the deposition rate of about 0.4 ML/min to the substrate kept at room temperature (Fig. 6a).

After this, series of works reported on the growth of stanene at various surfaces. Gou et al. obtained high-quality monolayer epitaxial stanene films on Sb(111) surface (Gou et al. 2017). They used single crystal Sb(111) surface cleaned by a standard Ar+ ion sputtering and annealing process. During the deposition of Sn, the Sb(111) substrate was kept at about 400 K in the chamber with the pressure less than 2 × 10−10 Torr.

Then, using the similar techniques, stanene films were obtained on InSb(111) surface by Xu et al. (2018). The InSb(111) substrates were again cleaned by repeated cycles of Ar+ ion sputtering and subsequent annealing at 400 °C. Tin was evaporated from the Knudsen cell with the rate of 0.3 ML/min onto the substrate maintained at room temperature. The strained stanene sheets fabricated in this work are promising from the point of view of possible room temperature device applications, as they demonstrated large strain-induced band gap.

Recently, large area stanene with low buckling was synthesized on Ag(111) substrate with intermediate layer of Ag2Sn by Yuhara et al. (2018). The experiments were performed using ultrahigh vacuum systems with the base pressure below 5 × 10−10 Torr. Clean Ag(111) surfaces were prepared by 2 keV Ar+ ion sputtering at room temperature, followed by annealing of the sample at the temperatures up to 600 °C. Tin was deposited onto the Ag(111) surface at various temperatures up to 300 °C with the growth rate of 0.05 ML/min. The amount of deposited Sn reached 1.5 ML. After deposition of 1/3 ML of Sn on Ag(111) large area Ag2Sn surface alloy was formed. After successive Sn deposition on the surface of Ag2Sn alloy nearly perfect planar layer of stanene was formed in a 2D island growth mode (Yuhara et al. 2018).

And one of the latest works by Liao et al. reports on successful fabrication of high-quality stanene sheets on PbTe(111) surface (Liao et al. 2018) by molecular beam epitaxy (pressure 1 × 10−10 Torr). To ensure lattice matching, five layers of Bi2Te3 were first grown on top of Si(111) substrates, followed by the growth of PbTe layers. Finally, Sn was deposited at the substrate temperature of 120 K. The subsequent annealing at temperatures up to 400 K was performed to improve the film quality. A layer-by-layer growth was maintained from the first up to the fifth layer. Above five monolayers, islands tend to form. The lattice constant of stanene expanded as the number of PbTe layers increased (Fig. 6b) (Liao et al. 2018). This work also showed for the first time the superconducting properties of a few-monolayer stanene, which will undoubtedly inspire researchers to further comprehensive studies of the methods for the synthesis of graphene-like materials of group IV elements and their fundamental properties, as well as the development of new generation devices based on them.

Perspectives

To date, works on the creation of a new generation devices based on two-dimensional crystals of silicene, germanene, and stanene are at the stage of refining the technology for producing such 2D structures, selecting a substrate, surfactants, and the sequence of deposition of layers. The first laboratory samples of devices based on these materials are created. Theoretical and practical studies of the energy and electronic structure of these two-dimensional materials, their mechanical, electrophysical, and optical properties are carried out (Mortazavi et al. 2016; John and Merlin 2017; Mukhopadhyay et al. 2017; Shi and Singh 2017; Shubham 2018; Lew Voon et al. 2018). Experimental studies are actively being conducted with the goal of creating 2D crystals of proper quality, that will allow researchers to observe all the expected topological and superconducting properties of these materials (Liao et al. 2018; Kort-Kamp 2017; Yu and Wu 2018; Zhai et al. 2019) and their chemically functionalized derivatives (Molle et al. 2017, 2018; Nakano et al. 2018). Some new technological approaches and structure configurations are also constantly proposed, for example, for enhanced passivation methods for 2D materials (Shahid et al. 2018) or creation of graphene-based flexible 2D-layered material junctions (Balabai and Solomenko 2019).

The studies considered in this review provide methods of producing high-quality silicene, germanene and stanene on solid surfaces, allowing exploration of their unique physical properties and potential applications in future functional nanodevices. In all cases, the manufacture of 2D materials of the required quality demands strict selection of the substrate for the synthesis (in accordance with the crystal structure and lattice parameters of the growing material), careful preparation of the growth surface via several cycles of ion sputtering and annealing for obtaining atomically flat layer without foreign atoms and defects, precise control of growth temperature (usually less than 500 °C) and low growth rates (about 0.1 ML/min or less).

The results of the conducted review allow one to begin to build kinetic models of the epitaxial formation of two-dimensional materials that take into account the thermodynamic parameters of the systems under consideration, as well as the processes of atom migration on the surface and their incorporation into a growing monolayer of a 2D material. Such models should be able to describe the various stages of the formation of a two-dimensional layer with a thickness of one to several monolayers, as well as the appearance of two-dimensional islands. With the help of these models it will be possible to establish methods for overcoming the nucleation of islands and preventing an undesirable transition from two-dimensional to three-dimensional growth (Izhnin et al. 2018, 2019; Lozovoy et al. 2018, 2019, 2020). Kinetic growth models will also help to evaluate the boundaries of technological parameters in the method of molecular beam epitaxy required for creation of high-quality 2D crystals of silicene, germanene and stanene, as well as other two-dimensional materials.

These new discoveries are expected to have a huge impact on the development of related science and technology because of the predicted high carrier mobilities, topological and superconducting properties up to room temperature, as well as potential applications for photonics. However, the further comprehensive studies of silicene, germanene, and stanene growth are required, including the search of new substrates and refining their physical properties, to realize all their possible advantages.

Thus, the development of epitaxial technology of synthesis of 2D materials of group IV elements should allow one to control the thickness of material layer, surface roughness, the presence or absence of defects, which determines, for example, the possibility of using such materials to create high-speed field effect transistors, super-efficient low-cost interconnections for integrated circuits, topological transistors, high-sensitive gas sensors, thermoelectric generators, energy sources, quantum computers and other emerging devices.

References

Acapito F, Torrengo S, Xenogiannopoulou E, Tsipas P, Marquez Velasco J, Tsoutsou D, Dimoulas A (2016) Evidence for germanene growth on epitaxial hexagonal (h)-AlN on Ag(111). J Phys Cond Matt 28:045002

Acun A, Zhang L, Bampoulis P, Farmanbar M, van Houselt A, Rudenko AN, Lingenfelder M, Brocks G, Poelsema B, Katsnelson MI, Zandvliet HJW (2015) Germanene: the germanium analogue of graphene. J Phys Condens Matter 27:443002

Aizawa T, Suehara S, Otani S (2014) Silicene on zirconium carbide (111). J Phys Chem C 118:23049–23057

Balabai R, Solomenko A (2019) Flexible 2D layered material junctions. Appl Nanosci 9:1011–1016

Balendhran S, Walia S, Nili H, Sriram S, Bhaskaran M (2015) Elemental analogues of graphene: silicene, germanene, stanene, and phosphorene. Small 11:640–652

Cahangirov S (2016) Introduction to the physics of silicene and other 2D materials. Springer, Berlin, p 96

Cahangirov S, Topsakal M, Akturk E, Sahin H, Ciraci S (2009) Two- and one-dimensional honeycomb structures of silicon and germanium. Phys Rev Lett 102:236804

Chiappe D, Scalise E, Cinquanta E, Grazianetti C, van der Broek B, Fanciulli M, Molle A (2014) Two-dimensional Si nanosheets with local hexagonal structure on MoS2 surface. Adv Mater 26:2096–2101

De Crescenzi M, Berbezier I, Scarselli M, Castrucci P, Abbarchi M, Ronda A, Jardali F, Park J, Vach H (2016) Formation of silicene nanosheets on graphite. ACS Nano 10:11163–11171

Davila ME, Le Lay G (2016) Few layer epitaxial germanene: a novel two-dimensional Dirac material. Sci Rep 6:20714

Davila ME, Xian L, Cahangirov S, Rubio A, Le Lay G (2014) Germanene: a novel two-dimensional germanium allotrope akin to gralhene and silicene. New J Phys 16:095002

Derivaz M, Dentel D, Stephan R, Hanf M-C, Mehdaoui A, Sonnet P, Pirri C (2015) Continuous germanene layer on Al(111). Nano Lett 15:2510–2516

Ezawa M (2015) Monolayer topological insulators: silicene, germanene, and stanene. J Phys Soc Jpn 84:121003

Ezawa M, Le Lay G (2015) Focus on silicene and other 2D materials. New J Phys 17:090201

Fleurence A, Friedlein R, Ozaki T, Kawai H, Wang Y, Yamada-Takamura Y (2012) Experimental evidence for epitaxial silicene on diboride thin films. Phys Rev Lett 108:245501

Gao J, Zhang G, Zhang Y-W (2016) Exploring Ag(111) substrate for epitaxially growing monolayer stanene: a first-principles study. Sci Rep 6:29107

Garg P, Choudhuri I, Pathak B (2017) Stanene based gas sensors: effect of spin-orbit coupling. Phys Chem Chem Phys 19:31325–31334

Gou J, Kong L, Li H, Zhong Q, Li W, Cheng P, Chen L, Wu K (2017) Strain-induced band engineering in monolayer stanene on Sb(111). Phys Rev Mater 1:054004

Gross M (2014) Stanene the next miracle material? Chem Ind 78:24–27

Guzman-Veri GG, Lew Yan Voon LC (2007) Electronic structure of silicon-based nanostructures. Phys Rev B 76:075131

Houssa M, Dimoulas A, Molle A (2015) Silicene: a review of recent experimental and theoretical investigations. J Phys Condens Matter 27:253002

Houssa M, van den Broek B, Iordanidou K, Lu AKA, Pourtois G, Locquet JP, Afanasev V, Stesmans A (2016) Topological to trivial insulating phase transition in stanene. Nano Res 9:774–778

Huang L, Zhang Y, Zhang Y-Y, Xu W, Que Y, Li E, Pan J, Wang Y, Liu Y, Du S, Pantelides ST, Gao H-J (2017) Sequence of silicon monolayer structures grown on a Ru surface: from a herringbone structure to silicene. Nano Lett 17:1161–1166

Izhnin II, Fitsych OI, Voitsekhovskii AV, Kokhanenko AP, Lozovoy KA, Dirko VV (2018) Nanostructures with Ge–Si quantum dots for infrared photodetectors. Opto-Electron Rev 26:195–200

Izhnin II, Fitsych OI, Voitsekhovskii AV, Kokhanenko AP, Lozovoy KA, Dirko VV (2019) Interaction between islands in kinetic models of epitaxial growth of quantum dots. Appl Nanosci. https://doi.org/10.1007/s13204-019-00965-y

Jamgotchian H, Colignon Y, Hamzaoui N, Ealet B, Hoarau JY, Aufray B, Biberian JP (2012) Growth of silicene layers on Ag(111): unexpected effect of the substrate temperature. J Phys Condens Matter 24:172001

John R, Merlin B (2017) Optical properties of graphene, silicene, germanene, and stanene from IR to far UV A first principles study. J Phys Chem Solids 110:307–315

Jose D, Datta A (2011) Structures and electronic properties of silicene clusters: a promising material for FET and hydrogen storage. Phys Chem Chem Phys 13:7304–7311

Kort-Kamp WJM (2017) Topological phase transitions in the photonic spin Hall effect. Phys Rev Lett 119:147401

Le Lay G (2015) Silicene transistors. Nat Nanotechnol 10:202–203

Lew Voon LC, Zhu J, Schwingenschlogl U (2018) Silicene: recent theoretical advances. Appl Phys Rev 3:040802

Li L, Lu S, Pan J, Qin Z, Wang Y, Wang Y, Cao G, Du S, Gao H-J (2014) Buckled germanene formation on Pt(111). Adv Mater 26:4820–4824

Li X, Tao L, Chen Z, Fang H, Li X, Wang X, Xu J-B, Zhu H (2017) Graphene and related two-dimensional materials: Structure-property relationships for electronics and optoelectronics. Appl Phys Rev 4:021306

Liao M, Zang Y, Guan Z, Li H, Gong Y, Zhu K, Hu X-P, Zhang D, Xu Y, Wang Y-Y, He K, Ma X-C, Zhang S-C, Xue Q-K (2018) Superconductivity in few-layer stanene. Nat Phys 14:344–348

Lin CL, Arafune R, Kawahara K, Tsukahara N, Minamitani E, Kim Y, Takagi N, Kawai M (2012) Structure of silicene grown on Ag(111). Appl Phys Express 5:045802

Lozovoy KA, Kokhanenko AP, Voitsekhovskii AV (2018) Comparative analysis of germanium–silicon quantum dots formation on Si(100), Si(111) and Sn/Si(100) surfaces. Nanotechnology 29:054002

Lozovoy KA, Kokhanenko AP, Dirko VV, Akimenko NYu, Voitsekhovskii AV (2019) Evolution of epitaxial quantum dots formed by Volmer−Weber growth mechanism. Cryst Growth Des 19(12):7015–7021. https://doi.org/10.1021/acs.cgd.9b00820

Lozovoy KA, Korotaev AG, Kokhanenko AP, Dirko VV, Voitsekhovskii AV (2020) Kinetics of epitaxial formation of nanostructures by Frank–van der Merwe, Volmer-Weber and Stranski-Krastanow growth modes. Surf Coat Technol 384:125289. https://doi.org/10.1016/j.surfcoat.2019.125289

Matusalem F, Koda DS, Bechstedt F, Marques M, Teles LK (2017) Deposition of topological silicene, germanene and stanene on graphene-covered SiC substratres. Sci Rep 7:15700

Meng L, Wang Y, Zhang L, Du S, Wu R, Li L, Zhang Y, Li G, Zhou H, Hofer WA, Gao H-J (2013) Buckled silicene formation on Ir(111). Nano Lett 13:685–690

Molle A, Goldberger J, Houssa M, Xu Y, Zhang S-C, Akinwande D (2017) Buckled two-dimensional Xene sheets. Nat Mater 16:163–169

Molle A, Grazianetti C, Tao L, Taneja D, Alam H, Akinwande D (2018) Silicene, silicene derivatives, and their device applications. Chem Soc Rev 47:6370–6387

Mortazavi B, Dianat A, Cuniberti G, Rabczuk T (2016) Application of silicene, germanene and stanene for Na or Li ion storage: a theoretical investigation. Electrochim Acta 213:865–870

Mukhopadhyay T, Mahata A, Adhikari S, Asle ZM (2017) Effective mechanical properties of multilayer nano-heterostructures. Sci Rep 7:15818

Nakano H, Tetsuka H, Spencer M, Morishita T (2018) Chemical modification of group IV graphene analogs. Sci Technol Adv Mater 19:76–100

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Sahoo SK, Wei K-H (2019) A perspective on recent advances in 2D stanene nanosheets. Adv Mater Interfaces 6:1900752

Shahid MU, Mohamed NM, Muhsan AS, Khatani M, Bashiri R, Zaine SNA, Shamsudin AE (2018) Dual functional passivating layer of graphene/TiO2 for improved performance of dye-synthesized solar cells. Appl Nanosci 8:1001–1013

Shi Z, Singh CV (2017) The ideal strength of two-dimensional stanene may reach or exceed the Griffith strength estimate. Nanoscale 9:7055–7062

Shubham SA (2018) Electrochemical properties of stanene as an efficient anode material for Na-ion batteries. Comput Condens Matter 14:84–88

Takeda K, Shiraishi K (1994) Theoretical possibility of stage corrugation in Si and Ge analogs of graphite. Phys Rev B 50:916–922

Tao L, Cinquanta E, Chiappe D, Grazianetti C, Fanciulli M, Dubey M, Molle A, Akinwande D (2015) Silicene field-effect transistors operating at room temperature. Nat Nanotechnol 10:227–231

Vogt P, De Padova P, Quaresima C, Avila J, Frantzeskakis E, Asensio MC, Resta A, Ealet B, Le Lay G (2012) Silicene: compelling experimental evidence for graphenelike two-dimensional silicon. Phys Rev Lett 108:155501

Webb R (2014) Future stuff: stanene. New Sci 224:38–39

Xu C-Z, Chan Y-H, Chen P, Wang X, Flototto D, Hlevyack JA, Bian G, Mo S-K, Chou M-Y, Chiang T-C (2018) Gapped electronic structure of epitaxial stanene on InSb(111). Phys Rev B 97:035122

Yu X-L, Wu J (2018) Evolution of the topological properties of 2D group IVA materials and device design. PCCP 20:2296–2307

Yuhara J, Fujii Y, Nishino K, Isobe N, Nakatake M, Xian L, Rubio A, Le Lay G (2018) Large area planar stanene epitaxially grown on Ag(111). 2D Mater 5:025002

Zhai X, Wen R, Zhou X, Chen W, Yan W, Gong L-Y, Pu Y, Li X (2019) Valley-mediated and electrically switched bipolar-unipolar transition of the spin-diode effect in heavy group-IV monolayers. Phys Rev Appl 11:064047

Zhang L, Bampoulis P, Rudenko AN, Yao Q, van Houselt A, Poelsema B, Katsnelson MI, Zandvliet HJW (2016) Structural and electronic properties of germanene on MoS2. Phys Rev Lett 116:256804

Zhu F, Chen W, Xu Y, Gao C, Guan D, Liu C, Qian D, Zhang S, Jia J (2015) Epitaxial growth of two-dimensional stanene. Nat Mater 14:1020–1025

Acknowledgements

The reported study was funded by Russian Science Foundation according to the research project № 19-72-00019.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Izhnin, I.I., Kurbanov, K.R., Lozovoy, K.A. et al. Epitaxial fabrication of 2D materials of group IV elements. Appl Nanosci 10, 4375–4383 (2020). https://doi.org/10.1007/s13204-020-01372-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-020-01372-4