Abstract

The structure and properties of silver-containing nanocomposites formed by the method of thermochemical reduction of Ag+ ions in polyelectrolyte-metal complexes pectin–Ag+–polyethyleneimine were studied using X-ray diffraction analysis, thermogravimetric analysis, pyrolysis mass spectrometry, transmission electron microscopy and antimicrobial test. The optimal parameters for the formation of nanocomposites based on interpolyelectrolyte complexes of pectin–polyethyleneimine and Ag nanoparticles (reduction temperature T = 150 °C, reduction time t = 30 min) have been found by X-ray diffraction analysis, in which the structural manifestation of the silver metal phase is fully realized. Using transmission electron microscopy, it was found that nanocomposite formed by thermochemical reduction of Ag+ ions at 150 °C for 30 min has an average nanoparticle size of 4.1 nm that less than for nanocomposite obtained at T = 120 °C during the same reduction time (average nanoparticle size is 5.8 nm). Ag nanoparticles obtained by using a typical reducing agent (NaBH4) have an average size equals 3.8 nm. It was revealed that nanocomposites obtained by thermochemical method have significantly higher antimicrobial activity compared with nanocomposites obtained by chemical reduction of Ag+ ions using NaBH4. A mechanism of thermochemical reduction of silver ions in IMC pectin–Ag+–polyethyleneimine, which is based on the transfer of electrons from the nitrogen atoms of amino groups PEI to Ag+ ions, has been investigated by destructive processes that occur at the same time.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Synthesis of silver-containing nanocomposites, involving macromolecular compounds is a current trend in the scientific searches because of their high-potential practical application. Silver-containing nanocomposites have potential applications in microelectronics (Glicksman 1984), optics (Gupta et al. 2008; Pankhurst et al. 2003), catalysis (Murugadoss and Chattopadhyay 2008), biodiagnostics (Rosi and Mirkin 2005), bactericide (Garamus et al. 2004). Nanocomposites based on the synthetic and natural polyelectrolytes containing silver nanoparticles demonstrate antibacterial and fungicidal properties and show a promise as materials for the medical applications (Prozorova et al. 2014; Banasiuk et al. 2016). The creation of such materials is impossible without conducting fundamental research aimed at elucidating the nature of the formed particles, the mechanisms and patterns of reactions occurring in the process of their formation.

The crucial problem to be solved, while synthesizing metal-containing nanocomposites, is in preparing of nanoparticles, having definite parameters, such as size, distribution in bulk and morphology. Stabilization of nanoparticles in the polyelectrolyte complexes enables them to be protected from aggregation processes (Zezin 2016).

Currently, the following methods of Ag-containing nanocomposites formation are widely used: chemical (Zezin 2016), chemical-radiation (Pergushov et al. 2014), thermochemical reduction of Ag+ ions in polymer-metal complexes (Liu et al. 2014; Geczi et al. 2018; Biao et al. 2017). The principal advantage of the radiation-chemical reduction of the metal ions is that there is no need to introduce the chemical reductants into reaction, thus it allowing for nanoparticles to be obtained without impurities (Pergushov et al. 2014; He et al. 2018). But this method requires the application of special equipment for radiation generating. At the chemical reduction such reductants as NaBH4 (Roto et al. 2018), dimethylformamide (Kaewvilai et al. 2015), hydrazine (Seo et al. 2004), etc., are used. Although such an approach is simple and effective enough for getting nanocomposites with controlled structure and properties, however, the biological toxicity and the environmental hazard of the residual reducing agents are considered as a problem.

For thermochemical reduction, polymers of natural and synthetic nature are used (Liu et al. 2014; Geczi et al. 2018; Biao et al. 2017; Nootsuwan et al. 2018; Ali 2013; Liang et al. 2011; Raghavendra et al. 2016), which serve as both reducing agents and stabilizers of nanoparticles.

Earlier, in ref (Demchenko et al. 2017), we have investigated the structure, morphology, and antimicrobial properties of copper-containing nanocomposites formed by thermochemical reduction of Cu2+ ions in pectin–Cu2+–PEI interpolyelectrolyte–metal complexes. It has been shown, that the optimal time for complete thermochemical reduction of Cu2+ ions to metallic copper at T = 170 °C is 30 min. The antimicrobial investigations of the elaborated nanocomposites revealed they possess a high antimicrobial activity against S. aureus and E. coli strains. In (Liu et al. 2014), PEI–Ag nanocomposites were synthesized by the method of thermochemical reduction of Ag+ at different temperatures, where PEI acted as a reducing agent and stabilizer of silver nanoparticles, while the authors did not consider in detail the mechanism of reduction.

Depending on the reduction temperature, nanoparticles of sufficiently large size were formed, from 25 to 80 nm. Authors (Geczi et al. 2018) prepared Ag-containing nanocomposites PLA–Ag–PEI for the medical application, using PEI as reducing agent at 140 °C, but the morphology and antimicrobial properties of the received nanocomposites were not investigated deeply. In (Biao et al. 2017), the silver nanoparticles with an average size of 10 nm were synthesized, where chitosan was used as a reducing agent and stabilizer. Literature analysis has shown that the method of thermochemical reduction of Ag+ ions is much faster, environmentally friendly, and cost-effective than the traditional methods. However, the individual polyelectrolytes (such as polyelectrolyte–Ag+) are usually used to reduction of Ag+ ions and stabilize Ag nanoparticles, which often leads to the formation of sufficiently large nanoparticles.

Thus, the aim of this work is to study the structure, morphology and antimicrobial properties of silver-containing nanocomposites, obtained by the thermochemical reduction of Ag+ ions in interpolyelectrolyte-metal complexes pectin–Ag+–PEI.

Experimental

Materials

To obtain the interpolyelectrolyte complexes (IPEC), pectin–polyethyleneimine; the interpolyelectrolyte–metal complexes (IMC), pectin–Ag+–polyethyleneimine; and nanocomposites of IPEC–Ag the following reagents were used: anionic polyelectrolyte citrus pectin (Cargill Deutschland GmbH, Germany) with M = 30,000, cationic polyelectrolyte anhydrous branched polyethyleneimine (PEI) (Aldrich) with Mn = 10,000 and Mw = 25,000 g/mol, silver (I) nitrate (AgNO3) (Aldrich) with M = 169.9.

Preparation of polymer systems

The samples of IPEC based on anionic and cationic polyelectrolyte were obtained by mixing of their 5% aqueous solutions taken at a molar ratio of 1:1, at T = 20 ± 2 °C. A mixture was casted on a Teflon plate and dried at room temperature to obtain IPEC as film. The water-insoluble IPEC films were macerated in distilled water three times to wash from the initial polyelectrolyte and dried at 20 ± 2 °C up to constant weight. The thickness of the resulting films was 100 μm.

To obtain a sample of the interpolyelectrolyte-metal complexes of silver, the IPEC films were immersed into an aqueous solution of silver nitrate at T = 20 ± 2 °C for 24 h. The colorless IPEC films became dark red.

The adsorption capacities of IPEC films, A (mmol/g), were calculated through the formula

where m is the weight of the film, V is the volume of silver nitrate solution, and cin and ceq are the initial (0.1 mol L−1) and the equilibrium concentrations of silver ions. For IMC films A = 5.0 mmol g−1.

Thermochemical reduction of Ag+ ions in the polymer films has been performed by keeping them at 100–160 °C within 30 min. The specimens were heated in an oven using precise thermal regulator VRT-3. Temperature regulation precision was ± 0.5 °C.

As a result of the reduction, IMC films changed their color from blue red to a metallic silver one that confirms the formation of the silver-containing nanocomposites.

Experimental methods

The structure of the IPEC (pectin–PEI); the IMC (pectin–Ag+–PEI); and nanocomposites of IPEC–Ag were studied by wide-angle X-ray scattering (WAXS) on a DRON-4-07 diffractometer, whose X-ray optical scheme was used to “pass” primary-beam radiation through samples. The heterogeneous structuring of these polymeric systems (at the nanometer level) was studied via small-angle X-ray scattering (SAXS) (Lysenkov et al. 2015) with a CRM-1 camera, having a slit collimator of the primary irradiation beam made via the Kratky method. All X-ray diffraction studies were performed at T = 20 ± 2 °C in CuКα radiation monochromated with a Ni filter. The size of the Ag nanoparticles and their morphology in the polymer matrix were examined with a JEM-1230 transmission electron microscope (JEOL, Japan) at a resolution of 0.2 nm.

The thermal stability and thermal oxidative degradation of nanocomposites were studied using the TGA Q50 device manufactured by TA Instruments (USA) in a dry air atmosphere in the temperature range from 20 to 700 °C with a linear heating rate of 20 °C min−1.

Volatile products released from the nanocomposites during thermochemical reduction were studied using the pyrolysis mass spectrometry (PMS), which allows evaluating chemical transformations in organic substances by the composition of their thermal degradation products. The research was carried out using the MX-1321 mass spectrometer, which provides the determination of the gas mixture components in the range of mass numbers 1–4000, in the temperature range from 20 to 400 °C with a linear heating rate of 6 °C min−1.

The antimicrobial activity of IPEC–Ag nanocomposites was studied using reference strains of opportunistic bacteria Staphylococcus aureus ATCC 6538 and Escherichia coli ATCC 35218 (as a model Gram-positive and Gram-negative bacteria) (Case and Johnson 1984).

Results and discussion

The features of structure formation of the of IPEC–Ag nanocomposites formed by thermochemical reduction of Ag+ ions in IMC

The analysis of wide-angle X-ray diffractograms has shown that IPEC formed of the oppositely charged polyelectrolytes of pectin and PEI is characterized by short-range ordering during a translation of the fragments of the oppositely charged polyelectrolyte macromolecular chains in space. This is indicated by one diffraction maximum of the diffuse type at 2θm~ 20.8° on the X-ray diffractogram of the IPEC sample (see Fig. 1, curve 1). Average distance (d) between macromolecular chains of pectin and PEI in the IPEC bulk, according to the Bragg equation:

where λ is the wavelength of the characteristic X-ray radiation, is 4.3 Å (λ = 1.54 Å for CuKα radiation).

The XRD patterns of (1) the IPEC; (2) the IMC; and (3–9) the nanocomposites obtained by the thermochemical reduction of Ag+ ions in IMC at the temperature (3) 100, (4) 110, (5) 120, (6) 130, (7) 140, (8) 150, and (9) 160 °C for 30 min; a standard diffractograms of nanocomposites, b increased diffraction maxima that characterize the structure of metallic silver nanocomposites

However, the sorption of AgNO3 by the IPEC film and formation of the IPEC–Ag+ sample is accompanied by a change in the diffractogram. This result is proved by the appearance of an intense diffuse diffraction maximum at 2θm ~ 11.2° (curve 2). This diffraction maximum, according to (Demchenko et al. 2017), characterizes the existence of polyelectrolyte–metal complexes between the central ions (Ag+) and ligands. Taking into account the angular position of this diffraction peak on the X-ray diffractogram of the IMC, Bragg distance d between the macromolecular chains of polyelectrolytes coordinated with Ag+ ions is found to be 7.9 Å. In its turn, the amorphous halo disappears at 2θm~ 20.8°, relating to the structural peculiarity of pectin–PEI IPEC. This indicates the full transfer of polyelectrolyte complexes into polyelectrolyte–metal complexes.

After thermochemical reduction of Ag+ ions in the IMC in the temperature range 100–160 °C, nanocomposites are formed based on the IPEC and Ag nanoparticles.

This is indicated by the manifestation of two diffraction maxima of the diffuse type at 2θm = 38.2° and 44.2, corresponding to the crystallographic plan of the face-centered cubic lattice of silver with (111) and (200) indexes, respectively, and confirming the presence of metallic silver in the polymeric system (curves 3–8). X-ray diffractograms of silver-containing nanocomposites formed by thermochemical reduction of Ag+ ions with a step-by-step increase in temperature from 100 to 150 °C show an increase in the intensity of the diffraction maxima at 2θm = 38.2° and 44.2°, which characterize the structure of silver nanoparticles, and a decrease in the intensity of the diffraction maximum at 2θm ~ 11.2°, which characterizes the structure of interpolyelectrolyte-metal complexes pectin–Ag+– polyethyleneimine.

At the further uprising of reduction temperature Ag+ in IMC (to T = 160 °C) the intensity of the diffraction maximums, characterizing the metal silver’s structure did not change (Fig. 1, curves 8–9). Therefore, according to the WAXS data we can conclude that the optimal temperature for Ag+ ions’ reduction in IMC with further formation of nanocomposite is to be 150 °C.

The effect of the reduction time of Ag+ ions in IMC at a constant temperature of 150 °C on the structure of silver-containing nanocomposites was also studied (Fig. 2).

The XRD patterns of (1) the IPEC; (2) the IMC; and (3–7) the nanocomposites obtained by the thermochemical reduction of Ag+ ions in IMC at the temperature 150 °C for (3) 5, (4) 10, (5) 20, (6) 30, and (7) 40 min; a standard diffractograms of nanocomposites, b increased diffraction maxima that characterize the structure of metallic silver nanocomposites

From the analysis of X-ray diffractograms, it can be seen that the intensity of the diffraction maxima at 2θm = 38.2° and 44.2°, which characterize the structure of silver nanoparticles, increases with a step-by-step increase in the reduction time from 5 to 30 min, and all samples do not have a diffraction maximum at 2θm ~ 11.2°, which characterizes the structure of interpolyelectrolyte-metal complexes pectin–Ag+–polyethyleneimine (curves 3–6). The intensity of the maxima that characterize the Ag structure increases especially sharply when the reduction time increases from 5 to 10 min (curves 3, 4). At the further uprising of reduction time Ag+ in IMC (up to 40 min) the intensity of the diffraction maximums, characterizing the metal silver’s structure did not change (Fig. 2, curves 6, 7). Therefore, according to the WAXS data we can conclude that the optimal time for Ag+ ions’ reduction in IMC with further formation of nanocomposite is to be 30 min.

The revealed features in the structural formation of the IPEC–Ag nanocomposites are forming the basis for the studying of heterogeneity of their structures.

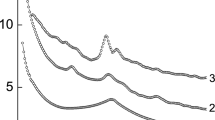

The analysis of small-angle X-ray scattering profiles of the IPEC–Ag nanocomposites, obtained by the thermochemical reduction of Ag+ ions in the interpolyelectrolyte–metal complexes at temperature 110, 130 and 150 °C and presented in accordance with (Ruland 1971; Perret and Ruland 1971) as dependences of Ĩ on q (Fig. 3a), where Ĩ is the intensity of scattering without the collimation correction and q = (4π/λ)sinθ = 2πs, shows that all mentioned systems have heterogeneous structuring—i.e., contrast electron densities Δρ (Δρ = ρ– < ρ>, where ρ and < ρ > are the local and average values of the electron density, respectively) are present in their volumes. This result means that in all the polymer–metal systems, there are no less than two types of region heterogeneity with different values of local electron density ρ. However, the absence of the interference peak from all the profiles of intensity indicates the stochastic nature of the location of various types of heterogeneity regions.

a Profiles of the intensity of SAXS of the nanocomposites obtained by the thermochemical reduction of Ag+ ions in IMC at the temperature (1) 110, (2) 130, and (3) 150 °C for 30 min. b Dependence of Q′ Porod invariant (1) and range of heterogeneity (2) nanocomposites on the temperature of the Ag+ ions reduction in the IMC

The values of their Porod invariants Q′ were compared to semiquantitatively evaluate the relative levels of the structural heterogeneity of these polymer systems (Porod 1982):

These values are invariant with respect to the shapes of the heterogeneity regions and are directly related to the rms values of fluctuations of electron density (< Δρ2>) in a two-phase system:

here, < Δρ2>=φ1φ2(ρ1–ρ2)2, where φ1 and φ2 are the volume ratios of heterogeneity domains in a two-phase system and ρ1 and ρ2 are the electron densities of heterogeneity domains (φ1 + φ2 = 1) in a two-phase system. Comparing values of invariant Q′ for the polymer systems investigated one can observe that relative level of structure heterogeneity nanocomposites grows up with increasing reduction temperature (Fig. 3b, curve 1 and Table 1). An evaluation of the effective sizes of the heterogeneity regions existing in these polymer-metal systems was performed through the method from (Ruland 1971; Perret and Ruland 1971) via calculation of structural parameters, such as the range of heterogeneity (range of inhomogeneity), lp, which is directly related to the average diameters of heterogeneity regions, < l1 > and < l2 > , in the two-phase system:

As the result of lp parameter’s calculation, we have revealed that increasing of temperature reduction for Ag+ ions in IMC and simultaneous formation of IPEC–Ag nanocomposite are accompanied by diminishing of heterogeneity areas’ effective size (Fig. 3b, curve 2 and Table 1).

Morphology of silver-containing nanocomposites

The conversion of interpolyelectrolyte–metal complexes pectin–Ag+–polyethyleneimine into nanocomposites containing Ag nanoparticles is confirmed by transmission electron microscopy (see Fig. 4a and b). Analysis of the micrographs of nanocomposites based on the polyelectrolyte complexes and Ag nanoparticles obtained at 120 and 150 °C for 30 min shows that the average size of nanoparticles formed at 120 °C is 5.8 nm and at 150 °C is 4.1 nm (see Fig. 4a and b). This effect, in our opinion, is due to the fact that primarily the reduction of Ag+ ions and the formation of Ag nucleation centers occur in the functional groups which required the least energy to transfer electrons to Ag+ ions. Higher temperatures promote the rapid formation of Ag nucleation centers throughout the polymer bulk.

a TEM images and histogram of the IPEC–Ag nanocomposite, obtained during thermochemical reduction of Ag+ ions in the IMC at the T = 120 °C for 30 min. b TEM images and histogram of the IPEC–Ag nanocomposite, obtained during thermochemical reduction of Ag+ ions in the IMC at the T = 150 °C for 30 min. c TEM images and histogram of the IPEC–Ag nanocomposite, obtained by chemical reduction of Ag+ ions in IMC was conducted with NaBH4 (a molar ratio of [BH4−]: [Ag+] = 2.0)

To compare the morphology of the studied silver-containing nanocomposites obtained by thermochemical reduction of Ag+ ions and the same nanocomposites were formed by reduction of Ag+ ions in IMC pectin–Ag+–polyethyleneimine using a typical NaBH4 reducing agent (a molar ratio of [BH4−]: [Ag+] = 2.0). Analysis of micrographs shows that nanocomposites formed by the chemical reduction of Ag+ ions have an average nanoparticle size of 3.8 nm (Fig. 4c). In this case, small aggregates of silver nanoparticles are formed in the bulk of the polymer.

Mechanism of formation of silver-containing nanocomposites in the process of thermochemical reduction of Ag+ ions in the interpolyelectrolyte-metal complexes

The mechanism of thermochemical reduction consists of the electrons transfer from the nitrogen atoms of amino groups of the polyethyleneimine to Ag+ ions during the process of IPEC-metal complexes destruction at T = 100 °C and higher temperature as well, according to Fig. 5a:

a Mechanism of thermochemical reduction of Ag+ ions in the IMC: pectin–Ag+–polyethyleneimine. b The XRD pattern of the PEI–Ag+, obtained at the temperature (1) 80, (2) 100, (3) 120 °C for 30 min. c The XRD pattern of the pectin–Ag+, obtained at the temperature (1) 120, (2) 160 °C for 30 min i (3) the original pectin sample

Such mechanism is also proved by the control experiment—similarly to the preparation of IMC films (pectin–Ag+–PEI), the polymer systems like pectin–Ag+ and PEI–Ag+ were obtained. Further, the samples were heated at elevated temperature to carry out silver ions reduction.

Analysis of X-ray diffractograms shows that intensive reduction of Ag+ ions to silver metal occurs only in the PEI–Ag+ polymer system at temperatures of 100 and 120 °C (Fig. 5b). This is indicated by the corresponding diffraction maxima which characterize the structure of the metallic silver (curves 2, 3).

Diffractograms of pectin–Ag+ samples obtained at temperatures of 120 and 160 °C show diffraction maxima of the diffuse type that characterize the crystal structure of pectin (Fig. 5c, curves 1–3). Also on the diffractogram of the pectin–Ag+ sample obtained at a temperature of T = 160 °C for 30 min, there is a low-intensity maximum at 2θm ~ 38.2°, which characterizes the structure of silver nanoparticles that can be formed during the oxidation of pectin hydroxyl groups, which is accompanied by the reduction of Ag+ ions. Therefore, one can make a conclusion the thermochemical reduction of Ag+ ions in the IMC films proceeds for the account of polyethyleneimine as mentioned above (Fig. 5a).

Thermogravimetric analysis and mass spectroscopic studies of nanocomposites

Thermogravimetric analysis and mass spectroscopy methods were used to figure out the mechanism of processes occurring during the thermochemical reduction of Ag+ ions in IMC.

Using thermogravimetric analysis, the experiments were performed in which a sample of pectin–Ag+–PEI was heated at a linear speed of 20 °C min−1 to a temperature of 150 °C and maintained for 30 min, after which the sample was continued to be heated at the specified speed until the complete destruction of the polymer nanocomposite. According to TGA data, when the pectin–Ag+–PEI sample was aged at 150 °C for 30 min, the weight loss is approx. ~ 3.7% (Fig. 6). With further heating, two peaks are observed on the DTGA curve (at T = 208.7 °C and 452.7 °C), associated with the destruction of pectin and PEI, respectively (Shankar et al. 2016; Ahn et al. 2017; Lawson et al. 2008; Zhao et al. 2012). The yield on the linear section of the TGA curve at a temperature above 500 °C (the remainder of the mass of the substance is 24.6%) is associated with the residue of the metallic silver. Mass spectroscopy was used to record volatile products released during the thermochemical reduction of Ag+ ions in IMC at a temperature of 150 °C for 5, 20, and 30 min (Fig. 7). As can be seen from the mass spectra, during the thermochemical reduction (5, 20, and 30 min), ion fragments (IF) with m/z 18 and 44 were allocated the highest intensity, which may be due to the desorption of H2O and CO2 at this temperature. The presence of fragments with m/z 28 and 30 is a confirmation of the previously proposed reduction mechanism due to the transition of an electron of a nitrogen atom to a metal ion with the formation of a cation radical in the PEI chain [R–CH2–CH2–N+H2] (Demchenko et al. 2017). That is, the formation of IF with m/z 28 and 30 can indicate a rearrangement and rupture of the C–C bond, which is located between the nitrogen atoms, which causes the release of fragments such as CH2 = N+H2 and CH2 = N+ (see Fig. 5a). It should be noted that IF with m/z = 30 can also correspond to the NO fragment, which is formed due to the destruction of the anion of the AgNO3 salt. It is noteworthy that the IF with m/z = 30 completely disappears up to 30 min, which may indicate a complete reduction of Ag+ ions in IMC, and this is fully correlated with the WAXS data.

In general, weight loss at a reduction temperature of 150 °C for 30 min, according to the fixed IF, may indicate an loss of the present water, anion, and only minor destruction of the matrix.

Antimicrobial properties of investigated nanocomposites

IPEC–Ag nanocomposites created by the thermochemical reduction of Ag+ ions in the IMC at T = 150 °C within 30 min demonstrate higher antimicrobial activity against S. aureus and E. coli strains compared to IPEC–Ag, synthesized at T = 120 °C within 30 min (Fig. 8 and Table 2). This effect is associated with smaller nanoparticle sizes.

Images of antimicrobial test results of agar plates containing IPEC–Ag nanocomposites, obtained via the thermochemical and chemical reduction of Ag+ ions in the IMC against S. aureus (a) and E. coli (b). Description of the samples is given in Table 2

To compare the antimicrobial activity of the silver-containing nanocomposites obtained by thermochemical reduction of Ag+ ions, same nanocomposites were formed by reduction of Ag+ ions in IMC pectin–Ag+–polyethyleneimine using a typical NaBH4 reducing agent (a molar ratio of [BH4−]: [Ag+] = 2.0).

After incubation proceeding for 24 h at 37 °C one can observe a clear zone around the films’ contours, thus confirming inhibition of bacteria growth.

The growth of the inhibition’s zone diameter for S. aureus was 27.6 mm for specimen prepared by thermochemical reduction (T = 150 °C, for 30 min), and 18.2 mm for those obtained by chemical reduction. For E. coli these values are 26.6 mm and 17.6 mm, correspondingly. The width of the test samples are 10 mm (Table 2). This effect is due to the fact that nanocomposites synthesized by thermochemical reduction are less strongly associated with the polymer matrix IPEC.

Active growth of the test bacteria and absence of growth inhibition have been observed in the test specimens (polymer film without nanoparticles) (Fig. 8, sample A0).

Conclusions

The peculiarities of structural organization of the developed polymer nanocomposites using method of the thermochemical reduction of the silver ions in the interpolyelectrolyte-metal complexes like “pectin–Ag+–polyethyleneimine” have been investigated by WAXS and SAXS methods at temperature interval from 100 to 160 °C. Optimal conditions for the formation of nanocomposites at which the structural manifestation of metallic silver is fully realized have been established (reduction temperature T = 150 °C and reduction time t = 30 min). Using the SAXS method, it was found that when the reduction temperature increases, the nanocomposites with a high level of heterogeneity of the structure and lower values of the lp heterogeneity range are formed.

Using transmission electron microscopy, it was revealed that at higher temperature (150 °C) of reducing the average particle size is smaller that correlates with the effective size of the heterogeneity regions of nanocomposites formed by the thermochemical reduction of Ag+ ions. In our opinion, such a result is due to the fact that higher temperatures lead to the rapid reduction and formation of Ag nucleation centers throughout the polymer.

It was found that nanocomposites IPEC–Ag created by thermochemical reduction of Ag+ ions in IMC at T = 150 °C within 30 min demonstrated higher antimicrobial activity against S. aureus and E. coli strains compared to IPEC–Ag, synthesized by at T = 120 °C within 30 min, that is a result of nanoparticles size of Ag. It was found that the nanocomposites obtained by this method have significantly higher antimicrobial activity compared to nanocomposites obtained by chemical reduction using NaBH4.

The mechanism of thermochemical reduction of silver ions in IMC pectin–Ag+–polyethyleneimine, which consists in the transfer of electrons from nitrogen atoms of PEI amino groups to Ag+ ions, is proposed.

References

Ahn S, Halake K, Lee J (2017) Antioxidant and ion-induced gelation functions of pectins enabled by polyphenol conjugation. Int J Biol Macromol 101:776–782

Ali IO (2013) Synthesis and characterization of Ag0/PVA nanoparticles viaphoto- and chemical reduction methods for antibacterial study. Colloids Surf A Physicochem Eng Aspects 436:922–929

Banasiuk R, Frackowiak JE, Krychowiak M, Matuszewska M, Kawiak A, Ziabka M, Lendzion-Bielun Z, Narajczyk M, Krolick A (2016) Synthesis of antimicrobial silver nanoparticles through a photomediated reaction in an aqueous environment. J Nanomed 11:315–324

Biao L, Tan S, Wang Y, Guo X, Fu Y, Xu F, Zu Y, Liu Z (2017) Synthesis, characterization and antibacterial study on the chitosan-functionalized Ag nanoparticles. Mater Sci Eng C 76:73–80

Case CL, Johnson TR (1984) Laboratory experiments in microbiology. Benjamin Cummings Pub Inc, California, pp 126–129

Demchenko V, Riabov S, Rybalchenko N, Goncharenko L, Kobylinskyi S, Shtompel’ V (2017) X-ray study of structural formation, thermomechanical and antimicrobial properties of copper-containing polymer nanocomposites obtained by the thermal reduction method. Eur Polym J 96:326–336

Garamus VM, Maksimova T, Richtering W, Aymonier C, Thomann R, Antonietti L, Mecking S (2004) Solution structure of metal particles prepared in unimolecular reactors of amphiphilic hyperbranched macromolecules. Macromolecules 37:7893–7900

Geczi Z, Hermann P, Kőhidai L, Lang O, Kőhidai Z, Meszaros T, Barocsi A, Lenk S, Zelles T (2018) Antimicrobial silver-polyethyleneimine-polylactic acid polymer composite film for coating methacrylate-based denture surfaces. J Nanomater 2018:1–9

Glicksman HD (1984) Metal handbook, 9th edn. American Society for Metals, Ohio

Gupta S, Uhlmann P, Agrawal M, Chapuis S, Oertel U, Stamm M (2008) Immobilization of silver nanoparticles on responsive polymer brushes. Macromolecules 41:2874–2879

He C, Chen Q, Yarmolenko MA, Rogachev AA, Piliptsou DG, Jiang X, Rogachev AV (2018) Structure and antibacterial activity of PLA-based biodegradable nanocomposite coatings by electron beam deposition from active gas phase. Prog Org Coat 123:282–291

Kaewvilai A, Wattanathana W, Jongrungruangchok S, Veranitisagul C, Koonsaeng N, Laobuthee A (2015) 3,4-Dihydro-1,3-2H-benzoxazines: novel reducing agents through one electron donation mechanism and their application as the formation of nano-metallic silver coating. Mater Chem Phys 167:9–13

Lawson G, Gonzaga F, Huang J, Silveira G, Brook MA, Adronov A (2008) Au–carbon nanotube composites from self-reduction of Au3+ upon poly(ethyleneimine) functionalized SWNT thin films. J Mater Chem 18:1694–1702

Liang S, Yang J, Zhang X, Bai Y (2011) The thermal-electrical properties of polyvinyl alcohol/AgNO3 films. J Appl Polym Sci 122:813–818

Liu Z, Wang Y, Zu Y, Fu Y, Li N, Guo N, Liu R, Zhang Y (2014) Synthesis of polyethylenimine (PEI) functionalized silver nanoparticles by a hydrothermal method and their antibacterial activity study. Mater Sci Eng C 42:31–37

Lysenkov EA, Gagolkina ZO, Lobko EV, Yakovlev YuV, Nesin SD, Klepko VV (2015) Structure-property relationships in polymer nanocomposites based on cross-linked polyurethanes and carbon nanotubes. Funct Mater 22:342–349

Murugadoss A, Chattopadhyay A (2008) A “green” chitosan-silver nanoparticle composite as a heterogeneous as well as microheterogeneous catalyst. Nanotechnology 19:015603

Nootsuwan N, Sukthavorn K, Wattanathana W, Jongrungruangchok S, Veranitisagul C, Koonsaeng N, Laobuthee A (2018) Development of antimicrobial hybrid materials from polylactic acid and nano-silver coated chitosan. Orient J Chem 34:683–692

Pankhurst QA, Connolly J, Jones SK, Dobson J (2003) Applications of magnetic nanoparticles in biomedicine. J Phys D Appl Phys 36:167–181

Pergushov DV, Zezin AA, Zezin AB, Müller AHE (2014) Advanced functional structures based on interpolyelectrolyte complexes. Adv Polym Sci 255:173–226

Perret R, Ruland W (1971) Eine verbesserte auswertungsmethode fur die rontgenkleinewin-kelstreuung von hochpolymeren. Koll Z Z Polym 247:835–843

Porod G (1982) Small-angle X-ray scattering. In: Glatter O, Kratky O (eds) Acad Press, London

Prozorova GF, Pozdnyakov AS, Kuznetsova NP, Korzhova SA, Emelyanov AI, Ermakova TG, Fadeeva TV, Sosedova LM (2014) Green synthesis of water-soluble nontoxic polymeric nanocomposites containing silver nanoparticles. Int J Nanomed 9:1883

Raghavendra GM, Jung J, Seo J (2016) Step-reduced synthesis of starch-silver nanoparticles. Int J Biol Macromol 86:126–128

Rosi NL, Mirkin CA (2005) Nanostructures in biodiagnostics. Chem Rev 105:1547–1562

Roto R, Rasydta HP, Suratman A, Aprilita NH (2018) Effect of reducing agents on physical and chemical properties of silver nanoparticles. Indones J Chem 18:614–620

Ruland W (1971) Small-angle scattering of two-phase systems: determination and significance of systematic deviations from Porod’s law. J Appl Cryst 4:70–73

Seo WS, Kim TH, Sung JS, Song KC (2004) Synthesis of silver nanoparticles by chemical reduction method. Korean Chem Eng Res 42:78–83

Shankar S, Tanomrod N, Rawdkuen S, Rhim JW (2016) Preparation of pectin/silver nanoparticles composite films with UV-light barrier and properties. Int J Biol Macromol 92:842–849

Zezin AA (2016) Synthesis of hybrid materials in polyelectrolyte matrixes: control over sizes and spatial organization of metallic nanostructures. Polym Sci C 58:118–130

Zhao J, Simeon F, Wang Y, Luo G, Hatton TA (2012) Polyethylenimine-impregnated siliceous mesocellular foam particles as high capacity CO2 adsorbents. RSC Adv 2:6509–6519

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Demchenko, V.L., Kobylinskyi, S.M., Riabov, S.V. et al. Novel approach to the formation of silver-containing nanocomposites by thermochemical reduction of Ag+ ions in interpolyelectrolyte-metal complexes. Appl Nanosci 10, 5409–5419 (2020). https://doi.org/10.1007/s13204-020-01368-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-020-01368-0