Abstract

The influence of the initial stress/strain state in FePt/Au/FePt thin films on the chemical L10-FePt formation after post-annealing is studied. It is shown that the level of stress/strain depends on the Au interlayer thickness revealing a correspondence in L10 ordering-onset temperature. Compressive strain present in the as-deposited films promotes lowering of the L10-FePt ordering temperature. A reduction of the onset temperature for ordering by 100 °C is observed in films having a 30-nm-thick intermediate Au layer compared to samples revealing lower compressive strain values. During annealing, the strain state caused by the difference in thermal expansion coefficients of FePt, Au, and substrate is relaxed during A1 → L10-FePt phase transformation. It is well known that the coercivity of FePt films rises with increasing fraction of the ordered L10-FePt phase. Furthermore, the insolubility of Au in the L10-FePt lattice results in Au diffusion predominantly along grain boundaries leading to magnetic FePt grain isolation, which in turn gives rise to enhanced coercivity. At an annealing temperature of 900 °C, coercivities as high as 27.5 kOe are achieved for FePt samples with an initial 30-nm-thick Au interlayer.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The ordered L10-FePt phase is a promising material for heat-assisted magnetic recording (HAMR) applications due to its high magnetocrystalline anisotropy (Weller et al. 2013; Weller et al. 2016; Lyubina et al. 2011). However, industrial application of thin FePt films requires L10 ordering at low temperatures, control of grain size, and orientation of easy magnetization axis (Hono et al. 2018; Kief and Victora 2018).

Alloying FePt film by third elements such as Au, Ag or Cu can considerably reduce the ordering temperature and enhance coercivity (Feng et al. 2008a, b; Yu et al. 2010; Brombacher et al. 2012; Maret et al. 2012; Maeda et al. 2002; Vladymyrskyi et al. 2014; Pavlova et al. 2013; Platt et al. 2002). For instance, in FePt/Au films, the ordering temperature of FePt films reduces to 350 °C. Moreover, during annealing, Au atoms diffuse along the FePt grain boundaries which results in a further increase in coercivity (Feng et al. 2008a, b).

The change in ordering kinetics of the L10-FePt phase was attained by controlling stress due to the lattice mismatch between buffer layer and FePt film (Hsu et al. 2003; Hsu et al. 2001; Zha et al. 2008). The initial stress state is associated with the ordering process and oriented grain growth in [001] direction of thin FePt films during annealing can be achieved, as reported in Hsiao et al. (2009) and Yuan et al. (2012). Furthermore, elastic stress and strain induced by rapid thermal annealing promote the oriented growth of L10-FePt grains in [001] direction even on amorphous substrates (Kim et al. 2006; Hsiao et al. 2011, 2012a, b; Albrecht and Brombacher 2013; Wang et al. 2012; Yano et al. 2008; Rasmussen et al. 2005). However, external stress can either assist or hinder the L10 phase transformation of FePt alloys (Hazen and Navrotsky 1996). In this regard, it was shown that large compressive stress increases the energy barrier of ordering reaction which results in volume expansion, while strong tensile stress blocks the formation of the L10 phase by preventing densification, a vital process prior to ordering (Yuan et al. 2012). Furthermore, the film thickness also has a strong effect on the interface reaction, and thus can be used to tune the L10 ordering process in FePt thin films (Li et al. 2008).

The aim of this work was to study the effect of initial stress/strain in FePt thin films employing intermediate Au layers in FePt/Au/FePt trilayers on the L10-FePt phase formation during post-annealing.

Experimental

Fe50Pt50(15 nm)/Au(x nm)/Fe50Pt50(15 nm) layer stacks with various Au interlayer thicknesses (x = 7.5; 15; 20 and 30 nm) were prepared by magnetron sputtering (Ar pressure 3.5 × 10−3 mbar) from individual Fe, Pt, and Au targets on thermally oxidized (100-nm-thick SiO2) single crystalline Si(001) substrates at room temperature.

The evaporation rates were monitored in situ by a quartz microbalance. The layer thicknesses of as-deposited films were determined by Rutherford backscattering spectrometry (RBS). Post-annealing of the samples was carried out in high vacuum (1.3 × 10−5 mbar) in the temperature range of 300–900 °C for 30 s with heating and cooling rates of about 5 °C/s and 0.25 °C/s in average, respectively.

The structural properties of the as-deposited and annealed films were characterized by X-ray diffraction (ULTIMA IV Rigaku diffractometer) using Cu Kα radiation. In-plane residual stress was obtained by the sin2ψ method (Yuan et al. 2012; Cullity and Stock 2014). The χ-axis is the horizontal axis in the diffraction plane by which the θ and 2θ angles are defined. The ψ angle is the angle of χ-axis rotation, tilting the film plane normal in the plane perpendicular to θ–2θ plane. Fundamental peaks of the FePt(111) plane were selected to study the angular dependence of planar spacing dψ=0 at ψ = 0° (sample plane perpendicular to θ–2θ plane), − 17.5°, − 15°, − 10°, − 5°, and 0°. The location of the diffraction peaks was obtained by smoothing the reflection profile using the Savitzky–Golay’s function. The dependence d(sin2ψ) was linearly fitted to extract the slope and dψ=0. Then, the residual stresses of the samples were calculated assuming a biaxial stress state in the layer (Cullity and Stock 2014; Gruber et al. 2011) using the following equation, \(\sigma_{\varphi } = \frac{E}{{d_{\psi = 0} \times (1 + \nu )}}tg\alpha\), where E is the elastic modulus, ν—Poisson’s ration, and tgα—the slope. As the film stack consists of two spatially separated FePt layers with different stress states, we can evaluate only the average stress value in the (111) plane. The residual strain ε⊥ along the surface normal was extracted using \(\varepsilon_{ \bot } = \frac{{d_{\psi = 0} - d_{\text{bulk}} }}{{d_{\text{bulk}} }}\), where dbulk is the stress-free lattice spacing of the A1 (dbulk = 2.235 Å (Menshikov et al. 1975)) or L10 (dbulk= 2.19023 Å (Cabri and Feather 1975)) bulk phase.

The magnetic properties were determined by superconductive quantum interference device–vibrating sample magnetometry (SQUID-VSM) and polar magneto-optical Kerr effect (MOKE) magnetometry.

Results

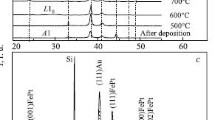

Figure 1 shows XRD patterns of the FePt/Au/FePt film samples. All as-deposited layer stacks reveal reflections of the chemically disordered A1-FePt phase and samples with Au interlayer in addition the (111) reflection which gets stronger with Au layer thickness (Fig. 1a). Post-annealing in the temperature range of 300–500 °C did not lead to a noticeable structural change in the films (not shown).

The L10 ordered phase in films without Au starts to form during annealing at 600 °C, which is indicated by the appearance of a weak superstructure FePt(001) reflection (Fig. 1b). In contrast, films with thin Au layers (< 20 nm) do not show chemical ordering at this annealing temperature, while films with thicker Au layer do. With increasing annealing temperature to 700 °C, basically, all films show signatures of L10 ordering (Fig. 1c).

We suggest that these changes in ordering temperature are connected with the initial stress/strain state present in films. Figure 2a, c shows the dependence of residual stress and strain of the FePt layer with different Au interlayer thickness in the as-deposited state, respectively. The stress/strain state varies with the Au interlayer thickness and at some critical thickness, the process of stress/strain relaxation can be accomplished by inelastic deformation (Gruber et al. 2011). This is visually reflected in the sign change of the stress shifting from compressive to tensile at an Au layer thickness of 15 nm (Fig. 2a), thereby reducing the strain (Fig. 2c). According to the rule of Le Chatelier–Braun, this should lead to an increase in ordering temperature as observed experimentally (Fig. 2b). Further increase of the Au interlayer thickness to 30 nm is accompanied by a rise in compressive stress and strain and, correspondingly, decrease in ordering temperature (Fig. 2). Thus, a clear correspondence between residual strain/stress state present in the as-deposited samples and the onset temperature of chemical ordering is observed.

The stress/strain state varies further during thermal annealing due to the difference in thermal expansion coefficient of FePt, Au and substrate. While the stress state does not change much with annealing temperature during L10 phase formation (Fig. 3a), a strong variation of the residual strain which becomes tensile upon L10 phase formation (Figs. 2c, 3b) is observed. The latter is due to the decrease in volume as the volume of the L10-FePt lattice is smaller than for A1. The difference between behavior of the stress with the annealing temperature compared to the change in deformations is due to the fact that the XRD registers only the elastic stress, while the deformation also reflects the plastic component.

Annealing in the temperature range of 700–900 °C strongly promotes the ordering processes in the FePt layers, as reflected by the splitting of the (200) and (002) reflections and the high intensities of the superlattice (001) reflection (Fig. 1c, d). However, no preferred (001) texture is obtained. After annealing, the position of the FePt(111) reflection does not change with Au layer thickness. This suggests that the Au atoms diffuse via grain boundary diffusion and are not incorporated into the FePt lattice, as expected (Feng et al. 2008a, b; Yu et al. 2010).

The ordering degree of the L10-FePt phase is expressed by the intensity ratio between the (001) and (002) reflections which increases with annealing temperature and gets more pronounced in film samples with Au interlayers (Fig. 4a). From the intensity ratio of the (001) and (111) reflections follows that the fraction of L10 grains with the c-axis perpendicular to the substrate plane get strongly reduced for samples with Au interlayer (Fig. 4b). Furthermore, the c/a lattice ratio indicating the tetragonality of the lattice remains more or less unchanged confirming again that Au is not incorporated in the FePt lattice (Fig. 4c). This is also confirmed by the increase of the Au(111) reflection with annealing temperature (Fig. 1).

The observed structural changes will also have a strong impact on the magnetic properties which were measured by SQUID-VSM and MOKE magnetometry. The coercivity HC of the films is strongly dependent on the amount of L10-FePt ordered phase and the fraction of Au at the grain boundaries (Fig. 4a, d). The latter results in magnetic exchange isolation of the FePt grains which will strongly increase the coercivity. As expected, the coercivity of the films extracted from M–H hysteresis loops increases strongly with Au layer thickness, reaching the highest value of 27.5 kOe for the film sample with the thickest Au interlayer of 30 nm after annealing at 900 °C (Fig. 4d). Moreover, the hysteresis loops regardless of the direction of the applied magnetic field are virtually identical in agreement with the polycrystalline growth of the L10-FePt thin films.

Conclusions

It was shown that the initial stress and strain state, which can be tailored by an Au interlayer in FePt/Au/FePt trilayers, affect the ordering process and, thus, the magnetic properties. More specific, large compressive strain in the as-deposited FePt layers promote the L10-FePt phase formation. Addition of 30-nm-thick Au interlayer leads to reduction of ordering temperature by 100 °C due to higher compressive strain values in FePt layers. It was observed that with increasing Au interlayer thickness and annealing temperature, the amount of ordered L10-FePt phase grows. This is accompanied by an increase in coercivity up to 27.5 kOe due to the high degree of L10 fraction and strong exchange isolation of magnetic FePt grains induced by grain boundary diffusion of Au.

References

Albrecht M, Brombacher C (2013) Rapid thermal annealing of FePt thin films. Phys Status Solidi A 210:1272

Brombacher C, Schletter H, Daniel M, Matthes P, Jöhrmann N, Maret M, Makarov D, Hietschold M, Albrecht M (2012) FePtCu alloy thin films: morphology, L10 chemical ordering, and perpendicular magnetic anisotropy. J Appl Phys 112:073912

Cabri LJ, Feather CE (1975) Platinum-iron alloys: a nomenclature based on a study of natural and synthetic alloys. Can Mineral 13:117 (PDF Card № 00-029-0717)

Cullity BD, Stock SR (2014) Elements of X-ray diffraction, vol 15, 3rd edn. Pearson, Harlow, p 466

Feng C, Zhan Q, Li B, Teng J, Li M, Jiang Y, Yu G (2008a) Magnetic properties and microstructure of FePt/Au multilayers with high perpendicular magnetocrystalline anisotropy. Appl Phys Lett 93:152513

Feng C, Li B-H, Liu Y, Teng J, Li M-H, Jiang Y, Ya G-H (2008b) Improvement of magnetic property of L10-FePt film by FePt/Au multilayer structure. J Appl Phys 103:023916

Gruber W, Chakravarty S, Baehtz C, Leitenberger W, Bruns M, Kobler A, Kübel C, Schmidt H (2011) Strain relaxation and vacancy creation in thin platinum films. Phys Rev Lett 107:265501

Hazen RM, Navrotsky A (1996) Effects of pressure on order-disorder reactions. Am Mineral 81:1021

Hono K, Takahashi Y, Ju G, Thiele J, Ajan A, Yang X, Ruiz R, Wan L (2018) Heat-assisted magnetic recording media materials. MRS Bull 43:93

Hsiao SN, Yuan FT, Chang HW, Huang HW, Chen SK, Lee HY (2009) Effect of initial stress/strain state on order-disorder transformation of FePt thin films. Appl Phys Lett 94:232505

Hsiao SN, Chen SK, Liu SH, Liao CJ, Yuan FT, Lee HY (2011) Effect of annealing process on residual strain/stress behaviors in FePt thin films. IEEE Trans Magn 47:3637

Hsiao SN, Liu SH, Chen SK, Yuan FT, Lee HY (2012a) Effect of intrinsic tensile stress on (001) orientation in L10 FePt thin films on glass substrates. J Appl Phys 111:07A702

Hsiao SN, Liu SH, Chen SK, Chin TS, Lee HY (2012b) Direct evidence for stress-induced (001) anisotropy of rapid-annealed FePt thin films. Appl Phys Lett 100:261909

Hsu Y-N, Jeong S, Laughlin DE, Lambeth DN (2001) Effects of Ag underlayers on the microstructure and magnetic properties of epitaxial FePt thin films. J Appl Phys 89:7068

Hsu Y-N, Jeong S, Laughlin DE, Lambeth DN (2003) The effects of Ag underlayer and Pt intermediate layers on the microstructure and magnetic properties of epitaxial FePt thin films. J Magn Magn Mater 260:282

Kief MT, Victora RH (2018) Materials for heat-assisted magnetic recording. MRS Bull 43:87

Kim J-S, Koo Y-M, Shin N (2006) The effect of residual strain on (001) texture evolution in FePt thin films. J Appl Phys 100:093909

Li X, Liu B, Sun H, Guo J, Wang F, Li W, Zhang X (2008) L10 phase transition in FePt thin films via direct interface reaction. J Phys D Appl Phys 41:235001

Lyubina J, Rellinghaus B, Gutfleisch O, Albrecht M (2011) Chapter Five - Structure and Magnetic Properties of L10-Ordered Fe–Pt Alloys and Nanoparticles. In: Buschow KHJ (ed) Handbook of magnetic materials, vol 19. Elsevier, Amsterdam, p 291

Maeda T, Kai T, Kikitsu A, Nagase T, Akiyama J (2002) Reduction of ordering temperature of a FePt-ordered alloy by addition of Cu. Appl Phys Lett 80:2147

Maret M, Brombacher C, Matthes P, Makarov D, Boudet N, Albrecht M (2012) Anomalous X-ray diffraction measurements of long-range order in (001)-textured L10 FePtCu thin films. Phys Rev B 86:024204

Menshikov A, Tarnóczi T, Krén E (1975) Magnetic structure of ordered FePt and Fe3Pt alloys. Phys Status Solidi A 28:K85 (PDF Card № 03-065-9121. (1975) Calculated from NIST using POWD-12++)

Pavlova OP, Verbitska TI, Vladymyrskyi IA, Sidorenko SI, Katona GL, Beke DL, Beddies G, Albrecht M, Makogon IM (2013) Structural and magnetic properties of annealed FePt/Ag/FePt thin films. Appl Surf Sci 266:100

Platt CL, Wierman KW, Svedberg EB, van de Veerdonk R, Howard JK, Roy AG, Laughlin DE (2002) L10 ordering and microstructure of FePt thin films with Cu, Ag and Au additive. J Appl Phys 92:6104

Rasmussen P, Rui X, Shield JE (2005) Texture formation in FePt thin films via thermal stress management. Appl Phys Lett 86:191915

Vladymyrskyi IA, Karpets MV, Katona GL, Beke DL, Sidorenko SI, Nagata T, Nabatame T, Chikyow T, Ganss F, Beddies G, Albrecht M, Makogon IM (2014) Influence of the substrate choice on the L10 phase formation of post-annealed Pt/Fe and Pt/Ag/Fe thin films. J Appl Phys 116:044310

Wang L-W, Shih W-C, Wu YC, Lai C-H (2012) Promotion of [001]-oriented L10-FePt by rapid thermal annealing with light absorption layer. Appl Phys Lett 101:252403

Weller D, Mosendz O, Parker G, Pisana S, Santos TS (2013) L10 FePtX–Y media for heat-assisted magnetic recording. Phys Status Solidi A 210:1245

Weller D, Parker G, Mosendz O, Lyberatos A, Mitin D, Safonova NY, Albrecht M (2016) FePt heat assisted magnetic recording media. J Vac Sci Technol B 34:60801

Yano K, Nandwana V, Poudyal N, Rong C-B, Ping Liu J (2008) Rapid thermal annealing of FePt nanoparticles. J Appl Phys 104:013918

Yu YS, Li H-B, Li WL, Liu M, Fei WD (2010) Structure and magnetic properties of magnetron sputtered [(Fe/Pt/Fe)/Au]n multilayer films. J Magn Magn Mater 322:1770

Yuan FT, Liu SH, Liao WM, Hsiao SN, Chen SK, Lee HY (2012) Ordering transformation of FePt thin films by initial stress/strain control. IEEE Trans Magn 48:1139

Zha CL, He SH, Ma B, Zhang ZZ, Gan FX, Jin QY (2008) Dependence of ordering kinetics of FePt thin films on different substrates. IEEE Trans Magn 44:3539

Acknowledgements

This work was financially supported by the German Academic Exchange Service (DAAD) in the frame of the Leonard Euler scholarship program (Grant ID 55576194 and ID 57042790).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Makushko, P.V., Verbytska, M.Y., Shamis, M.N. et al. Effect of initial stress/strain state on the L10 phase formation of FePt in FePt/Au/FePt trilayers. Appl Nanosci 10, 2775–2780 (2020). https://doi.org/10.1007/s13204-019-01066-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-019-01066-6