Abstract

The grape culture is quite affected by fungi. Among them is Glomerella cingulata, whose control is carried by synthetic fungicides such as mancozeb, which can cause damage to human and environmental health. An alternative is the use of natural fungicides, such as eugenol. It has already proven antifungal activity but has instability problems. In this context, nanoencapsulation would be a possibility to minimize the mancozeb toxicity and the eugenol instability. In this study, nanoemulsions containing eugenol and mancozeb, isolated and in association, were prepared by the spontaneous emulsification method. Afterwards, the antifungal activity, through the macrodilution technique in broth and the physicochemical stability of these formulations were evaluated. The nanoemulsions presented adequate nanometric characteristics with diameter between 180 and 210 nm, polydispersity index less than 0.3, negative zeta potential and acid pH. Besides good physicochemical stability. The compounds when nanoencapsulated presented an antifungal activity against G. cingulata with efficacy 103 and 3 times better for mancozeb and eugenol, respectively, compared to its free form. The study demonstrates the viability of obtaining nanoemulsions containing mancozeb and/or eugenol with antifungal activity against of G. cingulata, having these an innovative character for the treatment of vine-growing pests.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Grape and wine production is now a global multibillion dollar enterprise. This is related to factors such as increased international trade, and notable technological innovations in production, storage and transportation (Daane et al. 2018). In addition to consumer awareness of the health benefits of food, which creates a growing demand for natural and functional products, such as grapes that provide antioxidants (Wightman and Heuberger 2015).

Viticulture has a great importance on the Brazilian economy. In 2016, the cultivated area of grapes was about 78,000 ha, which generated a production around 984,000 tons (Mello 2017). However, viticulture in Brazil presents handling problems making its cultivation difficult and generating excess spending on planting. Fungal diseases are one of the main problems in all regions of grape production in Brazil. In areas, where the climatic conditions are favorable to the development of these pathogens, the control can reach 30% of the production cost of the grape (Sônego and Garrido 2005).

Among the fungi that attack the vines is the Glomerella cingulata (Stonem.) Spauld. & Schrenk. This fungus attacks the fruits of the ripe vines, and due to this fact, the disease took the name of ripe rot of grapes. This is one of the fungal disease most relevant postharvest and, as well as most fungal diseases, it causes losses both in quality and in the quantity of grape produced (Zaffari and Borba 2016).

The large-scale control of the disease caused by the G. Cingulata is carried out by synthetic fungicides, like mancozeb. One of the fungicides most used in agricultural practice, due to its broad spectrum of action; however, it can cause damage to the environment and the human health (Rozwalka et al. 2008). The toxicological classification of fungicides varies from I to IV, with I being the most toxic to humans and the environment (Garrido and Sônego 2004). Furthermore, studies have demonstrated embryotoxicity in non-target organisms, (Tilton et al. 2008) carcinogenic effects on laboratory animals exposed to mancozeb (Belpoggi et al. 2002) and neurotoxicity (Nordby et al. 2005).

The application of essential oils (EO) has been a very attractive method to control postharvest diseases (Aminifard and Mohammadi 2013). In nature, EO play an important role in protecting plants from bacteria, viruses, fungi, insects and attacks from herbivores (Roswalka 2010). Because of that, the antifungal property of these EO can be used, offering the possibility of replacing synthetic fungicides. This would be an alternative to obtaining more natural products, especially due to the problems that are attributed to countless synthetic products both for human health and for the environment (Bandoni and Czepak 2008).

Among the EO with antifungal activity already described in the scientific literature is the oil of clove, whose majority compound is eugenol (Abd-Elsalam and Khokhlov 2015). Eugenol (4-allyl-2-metoxifenol) is an aromatic compound that presents antimicrobial potential against a broad spectrum of microorganisms, such as: Salmonella enterica; Listeria monocytogenes (Mazzarrino et al. 2015); Botrytis cinerea (Aguilar-González et al. 2015); Glomerella cingulata (Rozwalka et al. 2008); Rhizoctonia solani, Fusarium solani, Fusarium oxysporum and Macrophomina phaseolina (Costa et al. 2011). However, this compound presents low stability due to the presence of the hydroxyl radical which is unstable in the presence of light, air, humidity and high temperatures, characteristics that can affect its efficacy (Karmakar et al. 2012). Besides that, it has low solubility in water, which reduces its bioavailability, hindering practical use (Salvia-Trujillo et al. 2015).

Therefore, an alternative to work around the toxicity limitations of the synthetic antifungals and/or the instability of active compounds like eugenol would be the nanoencapsulation. The nanostructured systems have advantages such as controlled release, dose decreased and increased stability of the encapsulated compound (Oliveira 2014). Among the different nanostructured systems are the nanoemulsions.

Nanoemulsions are heterogeneous systems, where a liquid (the internal phase) is dispersed in another (the outer phase), in the form of droplets, in the presence of an emulsifying agent (Hung et al. 2007). Due to their peculiarities, they present benefits to encapsulate lipophilic compounds (Solans et al. 2005).

Judging the need to obtain antifungal products with less toxicity and considering the properties already described for eugenol oil, allied with the advantages of nanoencapsulation and the nonexistence so far of studies of the effect of the nanoencapsulation on the properties of eugenol and mancozeb against an important grape pathogen, the purpose of this study was verify the viability to produce effective formulations, reducing the dose of the synthetic fungicide due to the co-encapsulation of the compound of a natural origin, and providing stable and effective formulations containing only the natural fungicide with potential antifungal activity against G. cingulata.

Materials and methods

Materials

Eugenol oil and mancozeb fungicide were acquired by the Sigma Aldrich (São Paulo, Brazil). The fungus G. Cingulata (CNPUV 380) was kindly donated by the EMBRAPA Uva e Vinho of Bento Gonçalves, RS, which was isolated from grape berries of the Cabernet Sauvignon variety and identified by optical microscopy.

Development of the nanoemulsions

The nanoemulsions were prepared in triplicate applying the method of spontaneous emulsification (Flores et al. 2011). The formulations were prepared containing two phases: an oily phase consisting of oil, synthetic fungicide, sorbitan monooleate (Span 80®) and acetone; and an aqueous phase, composed by polysorbate 80 (Tween 80®) and purified water, according to Table 1. Both phases were homogenized separately with the aid of a magnetic agitator, at room temperature, and after that, the reversal of oily phase was performed in the aqueous phase, under moderate and constant agitation, which was maintained for 10 min. Finally, the organic solvent and the water was evaporated with rotary evaporator (75 rpm at temperature 30 °C) and the final volume adjusted to 25 mL. For comparison purposes, the following formulations were made: nanoemulsion containing mancozeb and eugenol (NE-ME), nanoemulsion containing mancozeb (NE-M), nanoemulsion containing eugenol (NE-E) and blank nanoemulsion (NE-B), where eugenol was replaced by a mixture of medium-chain triglycerides (Crodamol™) and the presence of the mancozeb was omitted.

For the preparation of the formulations containing the mancozeb (NE-M and NE-M), the organic phases were subjected to magnetic agitation and to ultrasonic baths for about 15 min.

Characterization of the nanoemulsion

The formulations were characterized according to average droplet diameter, polydispersity index, zeta potential, pH, eugenol content and morphological analysis. The average droplet diameter and polydispersity index were determined by the dynamic light scattering technique in the Zetasizer equipment® Nano-ZS ZEN model 3600 (Malvern, England). The formulations were diluted 500 times (v/v) in ultrapure water and filtered with the use of a syringe and membrane with porosity diameter of 0.45 µm (Millipore®). The zeta potential was obtained through the electrophoretic mobility technique (Zetasizer® Nano-Zs ZEN model 3600, Malvern), after dilution of the formulations of 500 times (v/v) in an aqueous solution of sodium chloride (NaCl 10 mM) and filtered the same way described above. The pH was determined with the assistance of a potentiometer (DM-22, Digimed®) previously calibrated, directly in the formulations. All the analysis was made in triplicate and the results expressed as average and standard deviation.

The eugenol content in the formulations was carried out by HPLC using chromatograph Prominence® (Shimadzu, Japan), with pump model LC-20AT, ultraviolet detector PDA model SPD-M20A, with variable wavelength UV/VIS, based in the method previously described by Saran et al. (2013) with adaptations, where the mobile phase was composed of water and methanol (60:40); flow rate 1.0 mL/min; C18 column (150 mm × 4.6 × 5 m), detection at 270 nm; injection volume of 20 µL and column temperature 40 °C. The determination of the eugenol content has occurred by the co-validation method from the analytical parameters: linearity, limits of detection and quantification, specificity and precision, according to official validation guides (ICH 2005; ANVISA 2017).

For this quantification, was used a 25 mL flask containing methanol, where it was pipetted 45.4 µL of the formulation. The extraction method of eugenol from the nanoemulsions consisted in magnetic stirring without heating for 30 min, followed by centrifugation for 30 min (3500 rpm with refrigeration at 15 °C). After extraction, the contents were filtered through a 0.45 µm diameter porous membrane (Millipore®), with the aid of a syringe, directly for the vials and injected into the chromatographic system.

The morphology of the nanoemulsions was evaluated by Transmission Electron Microscopy (TEM). The samples were diluted 10× in ultrapure water and deposited in Formvar-carbon support films (electron microscopy sciences), negatively stained with uranyl acetate solution (2% w/v) and observed in different magnifications.(Ourique et al. 2008).

Stability study of the nanoemulsions

For the stability study, the nanoemulsions (n = 3) were stored under three different conditions: room temperature (25 °C), refrigeration (4 °C) and climate chamber (40 °C with 65% humidity). Subsequently, the average droplet diameter, polydispersity index, zeta potential and pH were evaluated at the times of 0, 7, 15, 30, 60 and 90 days after preparation, while the eugenol content was evaluated only at 0, 30, 60 and 90 days. With the data obtained was possible to evaluate the statistical significance of different storage times in relation with the zero time for each storage condition.

Evaluation of antifungal activity

The fungus G. Cingulata was grown in potato dextrose agar (PDA) and maintained under incubation of 25 °C from 7 to 10 days. The antifungal activity tests were carried out by the macrodilution technique in broth, following the reference method of the CLSI M38-A with modifications (NCCLS 2002). The culture medium used was RPMI 1640 buffered to pH 7 with MOPS 0.165 mol/L. Sterile test tubes were prepared containing 1 mL of the culture medium. 1 mL of the treatment (Table 2) was added in the first tube, and then performed the serial dilution. The inoculum of G. Cingulata was standardized according to the scale of 0.5 McFarland, and then were added 100 µL in all tubes. As treatments control, the blank nanoemulsion (without the active substances) was evaluated to demonstrate that the constituents of the formulation do not interfere in the activity. As control of the technique were made two tubes: a positive control composed by the culture medium and the inoculum, with the objective of evaluating the standard growth of the microorganism, without interference of treatments; and another negative control containing only medium of culture, to assess the presence of possible contamination in the technique. After 72 h of incubation at 25 °C a visual reading of the results was made, where the minimum inhibitory concentration (MIC) was defined as the lowest concentration of treatment that prevented the growth of the fungus.

Statistical analysis

The data were expressed through the average followed by the standard deviation (DP). The data obtained were submitted to the analysis of variance (ANOVA) followed from Dunnett. Values of P < 0.05 were considered as statistical significance, presenting a confidence of 95%. The analyses were performed with the aid of the Software Graphpad Prism 5.0 (Graphpad Software, INC).

Results and discussion

Characterization of the nanoemulsion

The nanoemulsions were analyzed right after the preparation by their physicochemical characteristics (Table 3). These presented an average diameter between 180 and 210 nm, polydispersity index (PDI) less than 0.3, negative zeta potential and acid pH. The systems sizes correspond to the already reported in the literature (160–220 nm) by the method of spontaneous emulsification (Flores et al. 2011). PDI less than 0.3 indicate uniformity of the size of the droplet in the formulation (Jaiswal et al. 2015). The zeta potential represents the surface load of the droplet and the negative load found in the formulations is attributed to the aqueous phase surfactant used, polysorbate 80. In addition to the values (in module) obtained are influenced by oily phase used in the preparation of the systems (Flores et al. 2011). It should be noted that formulations containing eugenol (NE-E and NE-ME) had a significantly more acidic pH when compared to NE-M, which may indicate that this characteristic is given by the oil used in the preparation of this formulation. These results showed that the formulations produced presented satisfactory nanometric characteristics.

The content of eugenol in the formulations was around of 13 mg/mL in the NE-E and 14 mg/mL in the NE-ME, which represents about 40% of the theoretical value (33.3 mg/mL). This value was attributed to losses during the evaporation route process, since eugenol extraction process of the formulations was previously tested, and the best condition employed in this study.

Microscopic analyzes of the nanoemulsions demonstrate morphologies with spherical shape, regular and well-defined edge, both for the formulations containing the mancozeb fungicide and eugenol, as for its association. No relevant changes were observed in the morphology, after the incorporation of the two compounds together, as shown in Fig. 1.

Stability study of the nanoemulsions

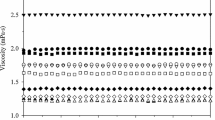

The stability study had as objective check the effect of time and different temperatures in the nanoemulsions formulations, to find the best storage conditions. For this, the changes of the diameter, polydispersity index, zeta potential and pH were determined in conditions of storage of: refrigeration (RE), room temperature (RT) and climatic chamber (CC) for 90 days.

As shown in Table 4, which demonstrates the mean droplet size, NE-ME presented some points of statistical difference, highlighting the condition of CC in 90 days, where there was a significant increase in the size. This contrasts with the other formulations (NE-M, NE-E and NE-B) that remained close to the initial size, not presenting statistical difference in stored time and condition. Showing lower system stability for that parameter when associated with the two active and stored in CC condition. The storage temperature may have a significant influence on the size of droplet, fact that has already been reported in other studies such as Eid et al. (2015) which reports the size increase in nanoemulsion formulations containing avocado oil exposed to the temperature of 40 °C after the third month of storage.

As noted in Table 5, the formulations NE-B and NE-M obtained the values for PDI close to 0.17, and the NE-E and NE-ME close to 0.25. Despite some variations in this parameter, the values remain less than 0.3, indicating the homogeneity of the system. According to Jaiswal et al. (2015), the PDI indicates the uniformity of the droplets size in the nanoemulsion, and emphasizes that the higher the value of the polydispersity, the lower the uniformity of the drop size of nanoemulsion.

The zeta potential is important for physicochemical stability of nanoemulsions, since repulsive forces tend to avoid possible internal phase aggregations (Roland et al. 2003). This parameter can be verified in Table 6. The formulation NE-E presented statistical difference in the time of 60 days in all storage conditions, NE-ME and NE-B presented a difference at the 90 days in condition of CC, whereas NE-M did not have a significant difference during the period and storage conditions evaluated. Even though there were variations in the zeta potential, the PDI and diameter parameters remained stable and there was no macroscopic evidence of destabilization such as aggregation or phase separation.

The pH values are set out in Table 7. NE-E and NE-B presented statistical difference from 7 days in almost all conditions. In the NE-M formulation there was statistical difference in the RT and CC conditions from 7 days, while the RE condition values remained unchanged up to 60 days. In NE-ME occurred statistical difference in the condition of CC from the 7 days and in the condition of RT from the 30 days. The RE condition kept the pH stable until the end of the 90 days. In general, can be observed a decrease in the pH as time passes and accentuated in the condition of CC. Masmoudi et al. (2005) highlight that the nanoemulsions may presents a decrease in pH due to hydrolysis of fatty acid esters in free fatty acids which is the product of degradation. Therefore, changes in pH may interfere with the stability of the active and preservation of the nanostructured form of nanoemulsions. Thus, the best form of storage for this parameter is RE, since this condition kept the pH of the formulations stable for longer.

Table 8 shows the results of eugenol content. It can be verified that both formulations NE-ME and NE-E had a slight loss of the content in the condition of CC in the time of 90 days, but still not demonstrating significant statistical.

After the stability study, the condition that best kept the parameters evaluated during the time periods proposed for all formulations was the condition of RE. These results corroborate with those of Eid et al., 2015, who mentioned that the best stability condition for nanoemulsions containing avocado oil was observed at 4 °C, which corresponds to the RE condition.

Evaluation of antifungal activity

The minimum inhibitory concentrations (MIC) to the different treatments are presented in the Table 9. As reported, the nanoencapsulated compounds presented better antifungal activity compared to the free compounds, since less concentration was needed for the inhibition of the fungus. It can be highlight that NE-M was the treatment with better antifungal activity.

With the nanoencapsulation of the mancozeb was necessary a concentration 103 times smaller than the free fungicide to ensure the same efficacy. This result can be explained by the fact that the mancozeb is a fungicide with contact action, which acts by inactivating the essential enzymes for the fungi growth. Knowing that the contact fungicides are poorly soluble in water or of slow solubility, whereas the conidia or spores of the fungus require water to germinate and which is already described in the literature that the nanoemulsification improves solubility of water-insoluble compounds (Ourique et al. 2008; Flores et al. 2011), together with the small droplet size of the nanoemulsified active. These characteristics facilitate the absorption and penetration of the active through biological surfaces (Kumari et al. 2018), mainly at the moment germination, thus inhibiting the fungal growth with greater efficiency.

As for the natural fungicide, it can be noticed that with the nanoencapsulation there was a reduction 3 times from the free form eugenol concentration required to achieve the same efficacy. This potentialization observed for NE-E may be related to the nanometric size of the droplets that provides a larger surface area (Jaiswal et al. 2015) and increased the active absorption (Kim et al. 2001) can be by passive cellular absorption, with reduced resistance to mass transfer; besides the sustained release, driven by the separation between the oil droplets and the aqueous phase, which prolong the oil activity (Lu et al. 2018).

The co-encapsulation of the compounds also demonstrated favorable results when compared to its free form, with an increase in the effect of the mancozeb. This can also be explained by the nanotechnology properties already described above.

According to the results, the formulations that presented the best performance were NE-M, followed by NE-ME and NE-E. In all cases demonstrating the ability of nanotechnology to enhance the antifungal activity of the active compounds, mancozeb and eugenol.

Conclusion

It was possible to demonstrate the viability of obtaining nanoemulsions containing mancozeb and/or eugenol, isolated or associated in the same nanodroplet, through the method of spontaneous emulsification, with appropriate physicochemical characteristics. The size, PDI and zeta potential parameters remained satisfactory during the 90 days of the stability study, emphasizing refrigeration as the best storage condition. The nanostructuring enhanced the antifungal activity of these compounds against to the fungus G. cingulata representing an innovative strategy for the treatment of viticulture pests. It also demonstrates a growing nanotech field and a perspective on the sustainable growth of agri-food production, presenting an effective and economically viable alternative for reducing the excessive use of synthetic pesticides and their negative impacts on human and environmental health.

References

Abd-Elsalam KA, Khokhlov AR (2015) Eugenol oil nanoemulsion: antifungal activity against Fusarium oxysporum f. sp. vasinfectum and phytotoxicity on cottonseeds. Appl Nanosci 5(2):255–265. https://doi.org/10.1007/s13204-014-0398-y

Aguilar-González AE, Palou E, López-Malo A (2015) Antifungal activity of essential oils of clove (Syzygium aromaticum) and/or mustard (Brassica nigra) in vapor phase against gray mold (Botrytis cinerea) in strawberries. Innov Food Sci Emerg Technol 32:181–185. https://doi.org/10.1016/j.ifset.2015.09.003

Aminifard MH, Mohammadi S (2013) Essential oils to control Botrytis cinerea in vitro and in vivo on plum fruits. J Sci Food Agric 93(2):348–353. https://doi.org/10.1002/jsfa.5765

ANVISA (2017) Ministério da Saúde (MS)—Agência Nacional de Vigilância Sanitária. RDC No. 166, de 24 de julho de 2017. Diário Oficial [da] República Federativa do Brasil 2017:22

Bandoni A, Czepak MP (2008) Os recursos vegetais aromáticos no Brasil, Edufes. Vitória

Belpoggi F et al (2002) Results of long-term experimental studies on the carcinogenicity of methyl tert-butyl ether. Ann N Y Acad Sci 837:77–95. https://doi.org/10.1111/j.1749-6632.1997.tb56865.x

Costa ART et al (2011) Ação do óleo essencial de Syzygium aromaticum (L.) Merr. & L.M.Perry sobre as hifas de alguns fungos fitopatogênicos. Rev Brasil Plantas Med 13(2):240–245. https://doi.org/10.1590/S1516-05722011000200018

Daane KM et al (2018) Entomological opportunities and challenges for sustainable viticulture in a global market. Annu Rev Entomol 63(1):193–214. https://doi.org/10.1146/annurev-ento-010715-023547

Eid AM et al (2015) Usage of sugar ester in the preparation of avocado oil nanoemulsion. Asian J Pharm Clin Res 8(4):66–69

Flores FC et al (2011) Nanostructured systems containing an essential oil: Protection against volatilization. Quim Nova 34(6):968–972. https://doi.org/10.1590/S0100-40422011000600010

Garrido LR, Sônego OR (2004) Podridão da Uva Madura ou Podridão de Glomerella - Biologia, Epidemiologia e Controle. Embrapa Uva e Vinho Circular Técnica 52:10

Hung CF et al (2007) The effect of oil components on the physicochemical properties and drug delivery of emulsions: Tocol emulsion versus lipid emulsion. Int J Pharm 335(1–2):193–202. https://doi.org/10.1016/j.ijpharm.2006.11.016

ICH (2005) ICH Topic Q2 (R1) validation of analytical procedures: text and methodology. In: International conference on harmonization (November 1996), p 17. http://www.ich.org/fileadmin/Public_Web_Site/ICH_Products/Guidelines/Quality/Q2_R1/Step4/Q2_R1__Guideline.pdf. Accessed 02 Jan 2018

Jaiswal M, Dudhe R, Sharma PK (2015) Nanoemulsion: an advanced mode of drug delivery system. 3 Biotech 5(2):123–127. https://doi.org/10.1007/s13205-014-0214-0

Karmakar S et al (2012) Clove (Syzygium aromaticum Linn) extract rich in eugenol and eugenol derivatives shows bone-preserving efficacy. Nat Prod Res 26(6):500–509. https://doi.org/10.1080/14786419.2010.511216

Kim CK, Cho YJ, Gao ZG (2001) Preparation and evaluation of biphenyl dimethyl dicarboxylate microemulsions for oral delivery. J Control Release 70(1–2):149–155. https://doi.org/10.1016/S0168-3659(00)00343-6

Kumari S et al (2018) Thymol nanoemulsion exhibits potential antibacterial activity against bacterial pustule disease and growth promotory effect on soybean. Sci Rep 8(1):1–12. https://doi.org/10.1038/s41598-018-24871-5

Lu WC et al (2018) Preparation, characterization, and antimicrobial activity of nanoemulsions incorporating citral essential oil. J Food Drug Anal 26(1):82–89. https://doi.org/10.1016/j.jfda.2016.12.018

Masmoudi H et al (2005) The evaluation of cosmetic and pharmaceutical emulsions aging process using classical techniques and a new method: FTIR. Int J Pharm 289(1–2):117–131. https://doi.org/10.1016/j.ijpharm.2004.10.020

Mazzarrino G et al (2015) Salmonella enterica and Listeria monocytogenes inactivation dynamics after treatment with selected essential oils. Food Control 50:794–803. https://doi.org/10.1016/j.foodcont.2014.10.029

Mello LMR (2017) ‘Panorama da produção de uvas e vinhos no Brasil’, Campo and Negócios, pp 54–56

NCCLS (2002) Método de Referência para Testes de Diluição em Caldo para a Determinação da Sensibilidade a Terapia Antifúngica dos Fungos Filamentosos: Norma Aprovada, NCCLS document M38-A. NCCLS

Nordby KC et al (2005) Indicators of mancozeb exposure in relation to thyroid cancer and neural tube defects in farmers’ families. Scand J Work Environ Health 31(2):89–96. https://doi.org/10.5271/sjweh.855

Oliveira CB (2014) Tratamento da Infecção por Trypanosoma evansi: testes in vitro e in vivo. Universidade Federal de Santa Maria, Santa Maria

Ourique AF et al (2008) Tretinoin-loaded nanocapsules: preparation, physicochemical characterization, and photostability study. Int J Pharm 352(1–2):1–4. https://doi.org/10.1016/j.ijpharm.2007.12.035

Roland I et al (2003) Systematic characterization of oil-in-water emulsions for formulation design. Int J Pharm 263(1–2):85–94. https://doi.org/10.1016/S0378-5173(03)00364-8

Roswalka LC (2010) Óleos essenciais: Ação sobre Colletotrichum gloeosporioides E Colletotrichum musae. Associados Ou Não à Película de Antracnose em Goiaba. Universidade Federal de Lavras

Rozwalka LC et al (2008) Extratos, decoctos e óleos essenciais de plantas medicinais e aromáticas na inibição de Glomerella cingulata e Colletotrichum gloeosporioides de frutos de goiaba. Ciência Rural 38(2):301–307. https://doi.org/10.1590/S0103-84782008000200001

Salvia-Trujillo L et al (2015) Physicochemical characterization and antimicrobial activity of food-grade emulsions and nanoemulsions incorporating essential oils. Food Hydrocolloids 43:547–556. https://doi.org/10.1016/j.foodhyd.2014.07.012

Saran S et al (2013) Validated RP-HPLC method to estimate eugenol from commercial formulations like Caturjata Churna, Lavangadi Vati, Jatiphaladi Churna, Sitopaladi Churna and clove oil. J Pharm Res 6(1):53–60. https://doi.org/10.1016/j.jopr.2012.11.013

Solans C et al (2005) Nano-emulsions. Curr Opin Colloid Interface Sci 10(3–4):102–110. https://doi.org/10.1016/j.cocis.2005.06.004

Sônego OR, Garrido L da R (2005) Principais doenças fúngicas da videira no Sul do Brasil, Embrapa Uva e Vinho, pp. 1–16

Tilton F, La Du JK, Tanguay RL (2008) Sulfhydryl systems are a critical factor in the zebrafish developmental toxicity of the dithiocarbamate sodium metam (NaM). Aquat Toxicol 90(2):121–127. https://doi.org/10.1016/j.aquatox.2008.08.008

Wightman JD, Heuberger RA (2015) Effect of grape and other berries on cardiovascular health. J Sci Food Agric 95(8):1584–1597. https://doi.org/10.1002/jsfa.6890

Zaffari EA, Borba RS (2016) Levantamento dos Principais Fungicidas e Inseticidas Comercializados pelas Agropecuárias de Bento Gonçalves para Utilização na Cultura da Videira. Sci Agrar Parana 15(4):385–390. https://doi.org/10.18188/1983-1471/sap.v15n4p385-390

Acknowledgements

The authors are grateful to Fundação de Amparo à Pesquisa do Estado do Rio Grande do Sul (FAPERGS), Universidade Franciscana and EMBRAPA Uva e Vinho de Bento Gonçalves, in particular to Dr. Lucas Da Ressurreição Garrido who kindly gave us the fungus.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Velho, M.C., de Oliveira, D.A., da Silva Gündel, S. et al. Nanoemulsions containing mancozeb and eugenol: development, characterization, and antifungal activity against Glomerella cingulata. Appl Nanosci 9, 233–241 (2019). https://doi.org/10.1007/s13204-018-0903-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-018-0903-9