Abstract

Nanomaterials have great impact on textile industry for multifunctional and smart clothing as per the need of present, and further, green nanotechnology is the current hotspot of research and industrial developments. Silver nanoparticles (AgNPs) are synthesized (in situ) by using natural compounds of plant extracts (naphthoquinones, phenolics/flavonoids, polyphenols) as reducing or stabilizing agents, and simultaneously deposited on wool fabric for coloration, UV protection and antioxidant properties. UV–visible spectroscopy is used to monitor the route of biosynthesis of nanoparticles and transmission electron microscopy for morphological characteristics of synthesized AgNPs. Spherical and almost oval-shaped AgNPs were synthesized by naphthoquinones, polyphenols and flavonoids, respectively. Scanning electron microscopy (SEM) coupled with energy dispersive X-ray (EDX) spectroscopy, X-ray diffraction pattern (XRD) and Fourier transform infrared spectroscopy were used for the AgNPs@Wool fabrics characterization. SEM–EDX analysis and XRD patterns confirmed the successful deposition of silver nanoparticles on wool. Coloration characteristics in terms of color strength (K/S) and CIEL*a*b*c*h° values, UV protection abilities in terms of UV transmittance and UV protection factor, and % antioxidant activity of AgNPs@Wool are suggestive of good-to-excellent results.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Nanomaterials are defined as materials which are in the size range of 1–100 nm. Their surface area and size ratio make them important for various applications in chemistry, physics and biology. Nanotechnology is an emerging technology, attracting the attention of scientists from various fields, for industrial developments in recent times for the development of materials with improved characteristics. Textile industry is one of the industries highly influenced by nanomaterials applications. Today modern textiles are equipped with nanoparticles for various functionalities such as UV protection, antioxidant activity, self-cleaning property and antimicrobial activity (Hebeish et al. 2011; Perelshtein et al. 2012; Wagener et al. 2016; Islam et al. 2017). Nowadays green and sustainable chemistry strongly interfered into the space of technological developments for the sake of increased awareness of human beings towards environmental issues. Utilization of ecofriendly, biodegradable and renewable resources for nano-technological developments are the important aspects of green chemistry. Preparative methods and stabilizing compounds provide specific characteristics to nanoparticles, other than the area–size ratio (El-Rafie et al. 2011).

Plant extracts-mediated synthesis of nanoparticles has been a greener approach in terms of biocompatibility and environment friendly. Organic compounds in plant sources are very well known to reduce metal ions into nanoparticles although the nature of reducing agents involved is not well understood. Characteristics of nanoparticles are highly influenced by the sources of plant extracts, various combinations of compounds and their concentrations (Li et al. 2007; Kumar and Yadav 2009; Song et al. 2009; Song and Kim 2009; Iravani 2011; Mittal et al. 2013). Silver nanoparticles are highly studied in previous years for their inhibitory effect towards bacterial strains and microorganisms. They are widely used for biomedical applications and now also in antimicrobial finished textiles for these characteristics (Shrivastava et al. 2007; Ravindra et al. 2010; Shahid et al. 2017a, b).

Plant extracts are considered as advantageous for nanomaterials synthesis in terms of resource availability, reaction rate and feasibility of large scale synthesis (Rao and Tang 2017). A number of plant resources have been used for nanomaterials synthesis previously (Chandran et al. 2006; Bar et al. 2009; Umadevi et al. 2012; Shah et al. 2015; Ahmed et al. 2016). Roots of Alkanna tinctoria plant, Boraginaceae family, are generally large in proportion of the size of plant. Naphthoquinones (Alkannin and Shikonin) are main class of active compounds in the roots (Rekaby et al. 2009). Delonix regia from Caesalpiniaceae family is widely distributed all over the world. Phenolic acid, flavonoids, and terpenoids are the chemical constituents of D. regia. Having various pharmaceutical effects, it had been also utilized for nanoparticles synthesis via reducing potential of polyols such as quercetin and gallic acid, etc. (Adjé et al. 2012; Azab et al. 2013; Dauthal and Mukhopadhyay 2013). Terminalia chebula of Combretaceae family is well known for natural dyeing and also utilized previously for nanoparticles synthesis. T. chebula is grown in Asian continent and popular in traditional medicine. Major chemical compounds in the fruits are polyphenolic compounds such as gallic acid, ellagic acid, chebulic acid, chebulic ellagitannins, and gallate esters (Pfundstein et al. 2010; Edison and Sethuraman 2012; Kumar et al. 2012; Shabbir et al. 2016a, b).

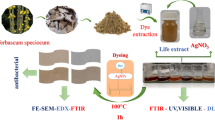

Ag nanoparticles are well known and highly studied for their antimicrobial properties (Vankar and Shukla 2012). In the present work, a simple and green protocol for Ag nanoparticles synthesis and simultaneous deposition on wool fabric via plant extracts is investigated for the extension of application range of silver nanoparticles other than antimicrobial properties, studied extensively in previous years. Effect of the various chemical compounds from plant extracts (Fig. 1) for reduction of Ag+ to Ag nanoparticles and functionalization of wool was studied. Different techniques were used for Ag nanoparticles characterization and their adsorption confirmation. Coloration, UV protection and antioxidant activities were evaluated with the effect of reducing and stabilizing compounds of different plant extracts.

Materials and methods

Materials used

Knitted 100% wool of thickness 0.54 mm, weight 316 g/m2, fabric count per inch 34 × 22, was used in this study. Silver nitrate (AgNO3) of 99.8% purity was purchased from HPLC, Mumbai–400002, Maharashtra, India. Powdered T. chebula fruits were obtained from Sir Biotech India Ltd. Kanpur, India, and used without any further purification in experiment. A. tinctoria roots in powder form were purchased from SAM Vegetables, Muradabad, UP, India. D. regia flowers were collected from Jamia Millia Islamia campus and dried in shade before extraction. 2,2′-Azino-bis (3-ethylbenzothiazoline-6-sulphonic acid) diammonium salt (ABTS) was bought from Shanghai D & B Chemicals Technology Co. Ltd., China. All other chemicals used were of laboratory grade.

Experimental

Extraction of reducing/stabilizing compounds

Aqueous extracts of A. tinctoria, D. regia and T. chebula were prepared of 1 mg/ml concentration each. 100 mg each of A. tinctoria roots, D. regia flowers and T. chebula fruits were transferred into extraction flasks with 100 ml distilled water, and extracted for 45 min at 70 °C temperature on heating mantle. Extracted solutions were filtered via Whatman filter paper and used in the experiments.

In situ synthesis of Ag nanoparticles

Simultaneous synthesis of silver nanoparticles and their deposition on wool surface was carried out. Three experimental setups of AgNO3 in combinations with reducing compounds from A. tinctoria, D. regia and T. chebula were taken. Wool samples of 1 g weight, after washing with non-ionic detergent, were dipped into 49 ml of AgNO3 solutions of 2 mM concentration with 1:50 of material to liquor (M:L) ratio at room temperature (25 °C). 1 ml of each aqueous extract of 1 mg/ml concentration was added dropwise to the respective experimental setups. Temperature of the setups was raised with constant rate up to 70 °C and was maintained at this temperature for 60 min with constant stirring. Visual color change observed after a few minutes due to surface plasmon resonance property of silver nanoparticles generated in solutions.

UV–visible spectral analysis

UV–visible spectra of silver nanoparticle solutions were measured in T80 + UV/Vis Spectrometer, PG Instruments Ltd.

Transmission electron microscopy (TEM)

Synthesized nanoparticles TEM images were taken on HT-700 transmission electron microscope operating at 120 kV. A drop of Ag nanoparticle solution was dripped on the carbon-coated copper grid and dried at room temperature for sample preparation for TEM images.

Scanning electron microscopy (SEM) and energy dispersive X-ray (EDX) spectroscopy

AgNPs treated wool fabric samples were observed for surface morphology using Hitachi TM3030 tabletop scanning electron microscope (Hitachi High Technologies America Inc., USA). Energy dispersion spectrum was also evaluated with the same instrument for Ag content or coating on wool surfaces.

X-ray diffraction (XRD) analysis

The XRD analysis of the naked wool and bio-synthesized Ag nanoparticles treated wool was performed on the X’Pert-Pro MPD X-ray diffractometer (PANalytical B.V., NL). Scattering angle range was taken 10°–80°.

Fourier transform infrared (FT-IR) spectral analysis

Deposition of silver nanoparticles and modification of wool fabric by deposition was studied in FT-IR spectral analysis. Spectra of naked and silver nanoparticles treated wool fabrics were taken on Perkin Elmer Spectrum RXI FT-IR System and compared for functional modifications or interactions via silver nanoparticles.

Color characteristics

Color characteristics of Ag nanoparticles treated wool in terms of color strength (K/S) and L* (lightness), a* (redness and greenness) and b* (yellowness and blueness) were recorded on HunterLab UltraScan PRO reflectance spectrophotometer at 10° standard observer; illuminant D65. Chroma (c*) and hue angle (h°) values were calculated by using equations:

UV protection activity

UV transmittance and ultraviolet protection factor (UPF) for treated wool samples were determined in Labsphere UV-1000F ultraviolet transmittance analyzer (Labsphere Inc., USA).

Antioxidant activity

ABTS (2,2′-azinobis-(3-ethylbenzothiazoline-6-sulfonic acid)) radical decolorization essay was applied to evaluate the antioxidant activity of treated wool fabric (Re et al. 1999; Shahid et al. 2017a, b). ABTS radical cations (ABTS·+) were produced by reaction of 7 mM ABTS stock solution with 2.45 mM potassium persulfate, and stored in dark at 25 °C for 14 h. Phosphate buffer was used to dilute the ABTS·+ solution up to absorbance of 0.700 ± 0.025 at 734 nm before measurements and then the sample was added to ABTS·+ solution (10 mg in 10 mL). Scavenging ability of ABTS·+ after 30 min at 734 nm was calculated by equation:

where \(A_{\text{control}}\) is initial absorbance of ABTS·+ and \(A_{\text{sample}}\) is absorbance of remaining ABTS·+.

Results and discussion

Natural compounds from plant extracts are well known for nanomaterials synthesis. Various metal nanoparticles were synthesized in past for different applications via reducing/stabilizing effect of biological compounds from plants (Rao and Tang 2017; Kumar et al. 2012; Khan et al. 2015; Shanmugam et al. 2016). Present study deals with in situ synthesis and simultaneous deposition of Ag nanoparticles on wool for functional properties (UV protection, antioxidant activity and coloration). In experimental setups, on addition of plant extract dropwise into the AgNO3 solution with wool fabric, color change observed after some time which gradually changed towards yellowish brown confirms the reduction of Ag+ to Ag0 nanoparticles. Surface plasmon resonance characteristic of Ag nanoparticles produces this color to the solution.

UV–Vis spectral characteristics

UV–visible spectra of the nanoparticle residual solutions (A-AgNPs, D-AgNPs and T-AgNPs) were taken and characteristic absorption peaks of Ag nanoparticles were observed at 435 nm, 448 nm, and 423 nm, respectively (Fig. 2). Brownish yellow colored wool fabric samples from experimental setups were tested for functionalities achieved and color characteristics (A-AgNPs = A. tinctoria assisted Ag nanoparticles, D-AgNPs = D. regia assisted Ag nanoparticles and T-AgNPs = T. chebula assisted Ag nanoparticles).

TEM images

Figure 3 illustrates the morphology of Ag nanoparticles synthesized via plant extracts. Naphthaquinone and polyphenolic compounds from A. tinctoria and T. chebula extracts reduced Ag+ ions into Ag nanoparticles of almost spherical shape of sizes mostly in the range of 15–30 nm and 3–5 nm, respectively, while D. regia produced nearly oval shaped of average size range of 10–25 nm as shown in particle size distribution plots (Fig. 3). It is also concluded from TEM images that the synthesized nanoparticles are highly stabilized as seen isolated, not aggregated. Chemical nature of the reducing and stabilizing compounds of plant extracts altered the mechanism of synthesis and resulted in different morphological results.

SEM and EDX analysis

Surface morphology of the naked and Ag nanoparticles treated wool fabrics is illustrated in Fig. 4 with their corresponding EDX spectrum. Surface of untreated wool fabrics was smooth while that of the treated ones was rough due to the deposition of Ag nanoparticles. When the roughness was compared of all treated wool fabrics, more roughness was found on A-AgNPs and D-AgNPs deposited wool fabrics owing to the bigger size of Ag nanoparticles, while it was less rough on T-AgNPs deposited wool surface due to small sized nanoparticles as discussed earlier. But the color yield (discussed later) was observed highest in case of T-AgNPs treated wool fabric which suggests more adsorption of them on wool surface. EDX spectral analysis of AgNPs treated wool shows peaks at 3 keV confirming the presence of Ag deposition on wool. Elemental analysis also supports the color yield results of T-AgNPs treated wool, having highest adsorbed Ag nanoparticles, i.e., the silver content was 3.96% in comparison to A-AgNPs and D-AgNPs treated wool with 3.10 and 2.63%, respectively. EDX elemental analysis also resulted in the conclusion that the spherical-shaped nanoparticles were deposited more as the higher silver content in case of A-AgNPs and T-AgNPs treated wool fabrics.

XRD analysis

XRD patterns of naked wool and AgNPs@Wool fabrics were comparatively analyzed (Fig. 5). Face centered cubic crystalline Ag nanoparticles deposition was confirmed by XRD analysis with the help of diffraction peaks at particular 2θ values with corresponding crystallographic planes (111), (200), (220) and (311). There were no Ag peaks observed in case of naked wool and prominent peaks were observed in case of T-AgNPs treated wool suggestive of higher deposition of Ag nanoparticles. From Fig. 5, it is concluded that the spherical-shaped nanoparticles were deposited more, so prominent peaks observed in XRD patterns also. All of the treated wool fabric samples showed Ag peaks in XRD pattern ascertaining the deposition of nanoparticles on wool surface.

FT-IR spectral analysis

FT-IR spectra of naked wool and Ag nanoparticles treated wool fabric are displayed in Fig. 6. Spectra of simple wool (black in Fig. 6) give characteristic peaks of wool; broad peak at 3280 cm−1 for N–H stretching, peaks in the region 3050–2900 cm−1 are assigned for C–H stretching along with peaks at 1440 and 1365 cm−1, peaks at 1740, 1635, 1520 and 1220 cm−1 are assigned for C=O, C=C and C–O–C functional groups in amino acid chains in wool structure (Shabbir et al. 2016b; Ebrahimi and Parvinzadeh Gashti 2015). A slight change or not at all, observed in the spectra of AgNPs@Wool fabrics suggests no change in the chemical structure of wool, although the color change of wool, SEM–EDX and XRD analysis confirmed the nanoparticles deposition on wool surface (Tang et al. 2012).

Colorimetric properties

Color characteristics of Ag nanoparticles treated wool fabrics were investigated in terms of color strength (K/S) and CIEL*a*b*c*h° values (Fig. 7 and Table 1). Color strength data plotted in Fig. 7a in the range of 350–700 nm, clearly show Ag nanoparticles deposition on wool surface in the order T-AgNPs > D-AgNPs > A-AgNPs, parallel to the color strength order. Spherical-shaped nanoparticles (A-AgNPs and T-AgNPs) produced color of yellow tone while D-AgNPs shifted color towards blue tone, as plotted in color space diagram (Fig. 7b). Small spherical sizes of T-AgNPs produced darkest shade on wool with shifted color coordinate towards red. Color fast shades which are durable against laundry and of varying tone depending on the morphology of the nanoparticles were produced.

UV protection activity

Ultraviolet radiations from sun are distributed in three regions: UV-C below 280 nm, UV-B in range of 280–315 nm, and UV-A in 315–400 nm range. UV-C radiations among them are absorbed by oxygen and ozone layer in stratosphere, but UV-B and UV-A radiations reaches up to earth via the depleted ozone layer. These radiations may lead to hazards for human and animal life on earth, so protection is needed in forms of creams/lotion and UV-protective clothing. UV protection abilities of textiles are calculated in terms of UV transmittance and UV protection factor (UPF) (Feng et al. 2007). Ag nanoparticles treated wool fabrics are investigated in this study for UV protection activity. Transmittance plot (Fig. 8) shows the transmittance values of treated samples below 5% in comparison to untreated wool in both UV-B and UV-A regions. Transmittance below 5% suggests good UV protection abilities of fabrics (Teng and Yu 2003; Mongkholrattanasit et al. 2011).

UV protection activities in terms of UPF of untreated/original and nanoparticles treated wool were comparatively studied and rated accordingly (Fig. 9, Table 2). UPF of D-AgNPs (> 39 UPF) treated wool fabric falls into excellent grade while A-AgNPs and T-AgNPs (25–39 UPF) treated in very good rating of UV protection in comparison to original wool (UPF=6.85) which falls in bad rating. UPF values in the range of 15–24, 25–39, and > 40 are classified as good, very good, and excellent ratings for UV protection, respectively, according to AS/NZS 4399:1996 (Sun and Tang 2011). From the results, it can be concluded that the non-spherical (D-AgNPs) and large-sized (A-AgNPs) nanoparticles are more appropriate for UV protection abilities in comparison to spherical and smaller-sized nanoparticles (T-AgNPs).

Antioxidant activity

Antioxidant activity is the important characteristic of biomedical textiles. Ag nanoparticles treated wool fabrics were tested for antioxidant activity by standard method (ABTS). Various functional agents were applied for antioxidant activity on textiles previously such as natural dyes and some polymeric compounds (Zemljič et al. 2014; Shahid et al. 2017a, b). Silver nanoparticles of various sizes were synthesized and deposited on the surface of wool fabrics for antioxidant functionalization. Quite satisfactory results were observed with D-AgNPs and T-AgNPs on wool, whereas A-AgNPs affected negatively the antioxidant results (Fig. 10). These results might be explained on the basis of anti-oxidative role of AgNPs and stabilizing extract compounds capped on AgNPs (Chandrasekhar and Vinay 2017). Deposition of Ag nanoparticles enhanced the antioxidant activity up to more than 50% in comparison to naked wool with ~ 27% in case of D-AgNPs and T-AgNPs. Phenolic compounds (D. regia and T. chebula) associated with Ag nanoparticles for their stabilization are expected to have ability of free radicals stabilization via delocalization in the chemical structure and Ag nanoparticles are expected to have ability of electron donation to the free radicals (or free radicals can accept electrons from Ag). Thus both elemental Ag and extract compounds capped on Ag nanoparticles might mutually contribute in this way towards antioxidant functionalization. In this study, it can be concluded from the results that the dominating effect of stabilizing compounds contribute primarily towards antioxidant functionalization of treated wool fabric.

Conclusion

One-pot biosynthesis of Ag nanoparticles and functionalization of wool fabrics via plant extracts have been studied for the effect of reducing and stabilizing compounds on nanoparticles synthesis, observed by shape and size in TEM images, and functionalities imparted on wool. SEM–EDX, XRD and FT-IR confirmed the nanoparticles deposition on wool surface, and relationship between Ag nanoparticles morphology and deposition factor on wool was established with the effect of reducing/stabilizing agents on Ag nanoparticles. UV protection abilities of wool were highly improved with the application of Ag nanoparticles. UV transmittance consistently below 5% and higher UPF values of treated wool fabrics justifies good UV-protective potential of Ag nanoparticles on wool. Large-sized Ag nanoparticles (A-AgNPs and D-AgNPs) were found having great influence on transmitted UV radiations. Antioxidant activity was mainly found to depend on reducing/stabilizing compounds on nanoparticles. High dependency of reducing/stabilizing compounds from plant extracts was observed on synthesized nanoparticles characteristics as well as on the functionalities on wool textiles.

References

Adjé FA, Lozano YF, Le Gernevé C, Lozano PR, Meudec E, Adima AA, Gaydou EM (2012) Phenolic acid and flavonol water extracts of Delonix regia red flowers. Ind Crops Prod 37:303–310

Ahmed S, Ahmad M, Swami BL, Ikram S (2016) A review on plants extract mediated synthesis of silver nanoparticles for antimicrobial applications: a green expertise. J Adv Res 7:17–28

Azab SS, Abdel-Daim M, Eldahshan OA (2013) Phytochemical, cytotoxic, hepatoprotective and antioxidant properties of Delonix regia leaves extract. Med Chem Res 22:4269–4277

Bar H, Bhui DK, Sahoo GP, Sarkar P, Pyne S, Misra A (2009) Green synthesis of silver nanoparticles using seed extract of Jatropha curcas. Colloids Surf A Physicochem Eng Asp 348:212–216

Chandran SP, Chaudhary M, Pasricha R, Ahmad A, Sastry M (2006) Synthesis of gold nanotriangles and silver nanoparticles using Aloevera plant extract. Biotechnol Prog 22:577–583

Chandrasekhar N, Vinay SP (2017) Yellow colored blooms of Argemone mexicana and Turnera ulmifolia mediated synthesis of silver nanoparticles and study of their antibacterial and antioxidant activity. Appl Nanosci. https://doi.org/10.1007/s13204-017-0624-5

Dauthal P, Mukhopadhyay M (2013) Biosynthesis of palladium nanoparticles using Delonix regia leaf extract and its catalytic activity for nitro-aromatics hydrogenation. Ind Eng Chem Res 52:18131–18139

Ebrahimi I, Parvinzadeh Gashti M (2015) Extraction of juglone from Pterocarya fraxinifolia leaves for dyeing, anti-fungal finishing, and solar UV protection of wool. Color Technol 131:451–457

Edison TJI, Sethuraman MG (2012) Instant green synthesis of silver nanoparticles using Terminalia chebula fruit extract and evaluation of their catalytic activity on reduction of methylene blue. Process Biochem 47:1351–1357

El-Rafie MH, El-Naggar ME, Ramadan MA, Fouda MM, Al-Deyab SS, Hebeish A (2011) Environmental synthesis of silver nanoparticles using hydroxypropyl starch and their characterization. Carbohydr Polym 86:630–635

Feng XX, Zhang LL, Chen JY, Zhang JC (2007) New insights into solar UV-protective properties of natural dye. J Clean Prod 15:366–372

Hebeish A, El-Naggar ME, Fouda MM, Ramadan MA, Al-Deyab SS, El-Rafie MH (2011) Highly effective antibacterial textiles containing green synthesized silver nanoparticles. Carbohydr Polym 86:936–940

Iravani S (2011) Green synthesis of metal nanoparticles using plants. Green Chem 13:2638–2650

Islam S, Shabbir M, Mohammad F (2017) Insights into the functional finishing of textile materials using nanotechnology. In: Muthu SS (ed) Textiles and clothing sustainability. Springer, Singapore, pp 97–115

Khan MN, Khan TA, Khan Z, Al-thabaiti SA (2015) Green synthesis of biogenic silver nanomaterials using Raphanus sativus extract, effects of stabilizers on the morphology, and their antimicrobial activities. Bioprocess Biosyst Eng 38:2397–2416

Kumar V, Yadav SK (2009) Plant-mediated synthesis of silver and gold nanoparticles and their applications. J Chem Technol Biotechnol 84:151–157

Kumar KM, Mandal BK, Sinha M, Krishnakumar V (2012) Terminalia chebula mediated green and rapid synthesis of gold nanoparticles. Spectrochim Acta Mol Biomol Spectrosc 86:490–494

Li S, Shen Y, Xie A, Yu X, Qiu L, Zhang L, Zhang Q (2007) Green synthesis of silver nanoparticles using Capsicum annuum L. extract. Green Chem 9:852–858

Mittal AK, Chisti Y, Banerjee UC (2013) Synthesis of metallic nanoparticles using plant extracts. Biotechnol Adv 31:346–356

Mongkholrattanasit R, Kryštůfek J, Wiener J, Viková M (2011) Dyeing, fastness, and UV protection properties of silk and wool fabrics dyed with eucalyptus leaf extract by the exhaustion process. Fibres Text East Eur 19:94–99

Perelshtein I, Applerot G, Perkas N, Grinblat J, Gedanken A (2012) A one-step process for the antimicrobial finishing of textiles with crystalline TiO2 nanoparticles. Chem A Eur J 18:4575–4582

Pfundstein B, El Desouky SK, Hull WE, Haubner R, Erben G, Owen RW (2010) Polyphenolic compounds in the fruits of Egyptian medicinal plants (Terminalia bellerica, Terminalia chebula and Terminalia horrida): characterization, quantitation and determination of antioxidant capacities. Phytochem 71:1132–1148

Rao B, Tang RC (2017) Green synthesis of silver nanoparticles with antibacterial activities using aqueous Eriobotrya japonica leaf extract. Adv Nat Sci Nanosci Nanotechnol 8:015014

Ravindra S, Mohan YM, Reddy NN, Raju KM (2010) Fabrication of antibacterial cotton fibres loaded with silver nanoparticles via “Green Approach”. Colloids Surf A Physicochem Eng Asp 367:31–40

Re R, Pellegrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237

Rekaby M, Salem AA, Nassar SH (2009) Eco-friendly printing of natural fabrics using natural dyes from alkanet and rhubarb. J Text I 100:486–495

Shabbir M, Islam S, Bukhari MN, Rather LJ, Khan MA, Mohammad F (2016a) Application of Terminalia chebula natural dye on wool fiber-evaluation of color and fastness properties. Text Cloth Sustain 2:1–9

Shabbir M, Rather LJ, Islam S, Bukhari MN, Shahid M, Khan MA, Mohammad F (2016b) An eco-friendly dyeing of woolen yarn by Terminalia chebula extract with evaluations of kinetic and adsorption characteristics. J Adv Res 7:473–482

Shah AT, Din MI, Bashir S, Qadir MA, Rashid F (2015) Green synthesis and characterization of silver nanoparticles using Ferocactus echidne extract as a reducing agent. Anal Lett 48:1180–1189

Shahid M, Cheng XW, Tang RC, Chen G (2017a) Silk functionalization by caffeic acid assisted in situ generation of silver nanoparticles. Dyes Pigm 137:277–283

Shahid M, Zhou Y, Tang RC, Chen G, Wani WA (2017b) Colourful and antioxidant silk with chlorogenic acid: process development and optimization by central composite design. Dyes Pigm 138:30–38

Shanmugam C, Sivasubramanian G, Parthasarathi B, Baskaran K, Balachander R, Parameswaran VR (2016) Antimicrobial, free radical scavenging activities and catalytic oxidation of benzyl alcohol by nano-silver synthesized from the leaf extract of Aristolochia indica. Appl Nanosci 6(5):711–723

Shrivastava S, Bera T, Roy A, Singh G, Ramachandrarao P, Dash D (2007) Characterization of enhanced antibacterial effects of novel silver nanoparticles. Nanotechnol 18:225103

Song JY, Kim BS (2009) Rapid biological synthesis of silver nanoparticles using plant leaf extracts. Bioprocess Biosyst Eng 32:79

Song JY, Jang HK, Kim BS (2009) Biological synthesis of gold nanoparticles using Magnolia kobus and Diopyros kaki leaf extracts. Process Biochem 44:1133–1138

Sun SS, Tang RC (2011) Adsorption and UV protection properties of the extract from honeysuckle onto wool. Ind Eng Chem Res 50:4217–4224

Tang B, Zhang M, Hou X, Li J, Sun L, Wang X (2012) Coloration of cotton fibers with anisotropic silver nanoparticles. Ind Eng Chem Res 51:12807–12813

Teng C, Yu M (2003) Preparation and property of poly (ethylene terephthalate) fibers providing ultraviolet radiation protection. J Appl Polym Sci 88:1180–1185

Umadevi M, Shalini S, Bindhu MR (2012) Synthesis of silver nanoparticle using D. carota extract. Adv Nat Sci Nanosci Nanotechnol 3:025008

Vankar PS, Shukla D (2012) Biosynthesis of silver nanoparticles using lemon leaves extract and its application for antimicrobial finish on fabric. Appl Nanosci 2(2):163–168

Wagener S, Dommershausen N, Jungnickel H, Laux P, Mitrano D, Nowack B, Schneider G, Luch A (2016) Textile functionalization and its effects on the release of silver nanoparticles into artificial sweat. Environ Sci Technol 50:5927–5934

Zemljič LF, Volmajer J, Ristić T, Bracic M, Sauperl O, Kreže T (2014) Antimicrobial and antioxidant functionalization of viscose fabric using chitosan–curcumin formulations. Text Res J 84:819–830

Acknowledgements

Mohd Shabbir is highly thankful to University Grants Commission, India, for financial support via BSR (Basic Scientific Research) Fellowship for meritorious students and to Prof. Ren-Cheng Tang, Soochow University, China, for extending testing facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shabbir, M., Mohammad, F. Multifunctional AgNPs@Wool: colored, UV-protective and antioxidant functional textiles. Appl Nanosci 8, 545–555 (2018). https://doi.org/10.1007/s13204-018-0668-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-018-0668-1