Abstract

The aim of the present work is to use the latest achievements of nanotechnology (atomic layer deposition, ALD) in the field of food packaging to prevent biofilm formation by food-associated bacteria. Some potential applications of nanotechnology in the food packaging industry are studied in the manuscript, in the field of antibacterial materials for food packaging. The ALD technique was used to synthesize vanadium (V)-doped TiO2 thin nanofilm on commercially available polypropylene (PP) food container to enhance an antibacterial activity for potential use in food packaging, to reduce spoilage, thereby, prolonging the food shelf- life. To better understand the ability and effectiveness of the antimicrobial packaging material of V-doped TiO2, to prevent the biofilm formation by dairy-associated pathogenic bacteria, the coated and uncoated PP containers with a fresh raw cow’s milk were tested. We have illustrated the effectiveness of ALD Al2O3 + TiVOx nanocoating against populations of milk-borne pathogenic bacteria.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

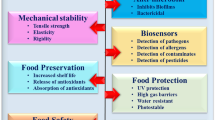

Preventing the growth of microorganisms on packaging material surfaces is one of the crucial applications of antibacterial nanocoatings. The nanomaterials science and biotechnology achievements are available to design surfaces with an enhanced antibacterial property (Barazi, et al., 2023). Nanotechnology improves the quality of life through the application of new antibacterial packaging materials in the food industry by improving the quality of food products (Fawzy et al. 2018; Sharma et al. 2019). Antibacterial nanomaterials are considerably reducing the risk of foods with pathogen contamination, extending the shelf-life of foods, minimizing the microbial growth on food container surfaces during storage, transportation and handling. Therefore, antibacterial nano- coating can be used for the production of a new packaging material that maintains fresh product for as long as to prevent its deterioration (Erkmen and Bozoglu, 2016). Antibacterial nanomaterials can be used for killing or reducing the activity of different types of microorganisms and the colonization of the microorganisms on the inner surface of the food container. There are various methods to estimate bacteria viability, each with unique advantages and disadvantages to determine the effectiveness of nano-coating as antimicrobial agents, avoiding biofilm formation (Meng et al. 2019; Jayaraj et al. 2018; Yonezawa et al. 2020). Thus, the need for new antibacterial packaging materials for food technology with low toxicity is continuously increasing.

Several review papers have been published by a number of authors (Barazi et al., 2023; Erkmen and Barazi, 2008; Duncan 2011, etc.) on antimicrobial materials for food packaging and food safety (effects on food quality). Titanium oxide-based nanomaterials have been extensively studied as an effective packaging material in food storage applications (Gumiero et al. 2013; Othman et al. 2014; and Tang et. al., 2018). Yemmireddy et al. (2017) showed that nanocoating of the surfaces of chopping boards and food packaging material with TiO2 significantly reduces the activity of microorganisms on the surfaces.

Various antimicrobial coating materials such as titanium, copper, zinc, and chitosan were used as antimicrobial agents (Norambuena et al. 2016; Chang Y-N et al., 2012; Mocanu et al. 2019; Gupta et al. 2013; Allahverdiyev et al. 2011; Jin and He 2011). As well-known, metal oxides are extensively studied due to their non-toxicity, stability, efficient biological properties, etc. to use as antibacterial agents. A variety of oxides such as ZnO (Chang Y-N et al., 2012; Mocanu et al. 2019), Fe2O3 (Chang Y-N et al., 2012), TiO2 (Gupta et al. 2013), Ag2O (Allahverdiyev et al. 2011), CaO (Allahverdiyev et al. 2011), MgO (Jin and He 2011) and CuO (Jin and He 2011) have been used previously as efficient antibacterial agents. The key advantages of inorganic antimicrobial agents (metal oxides) are improved safety and stability, as compared with organic antimicrobial agents. Among reported semiconducting materials TiO2 has been widely used as an effective antimicrobial agent for food and medical applications. As well known, TiO2 coated materials are nontoxic and have an antibacterial property due to its inert nature as compared with other metal oxides, cheap, and stable in water and air. When exposed to UV light it produces chemically active charged and radical species (see below) that do work leading to antibacterial effects. The mechanism behind the photocatalytic antimicrobial effect of TiO2 is well known. However, optical properties of TiO2 need to be modified in order to more efficiently utilize the visible region of a sun light spectra so material can be more efficient in ambient light (renewable energy source). TiO2 can be modified by using dopant to improve its antibacterial activity at ambient light. For that purpose, in the present work, we are using very special techniques called Atomic Layer Deposition (ALD, see below). Doping with transition metals is a promising approach to reducing the TiO2 absorption threshold and extending its optical absorption range from the UV light region to the visible (natural) light region (Zhang et al. 2011) (see Fig. 1). TiO2 doped with transition metal ions such as Cr, Fe, Pt, Pb, Sn, Zn, Ag, Cu, V, Mo (Norambuena et al. 2016), and N, C often used to elevate the antibacterial properties of TiO2. Nanoparticles, such as gold, silver, zinc oxide, titanium oxide etc. have been used for antibacterial coating materials for food containers. Norambuena et al. (2016) found that TiO2 doped with Cu considerably reducing the adhesion of S. aureus on the surface and can be used for food application.

In the present work, we have studied ALD vanadium (V)-doped TiO2 coating to improve the antibacterial properties of pure TiO2 under visible light irradiation for prevent formation of the food-borne pathogens microorganism thereby avoid food spoilage prolonging the food shelf-life. Previously V-doped TiO2 has been successfully used for medical application to prevent post-surgical complications of hernia PP meshes (Abdulagatov et al. 2022). Bahadur et al. (2016) and Abdulagatov et al. (2022) used the doped and undoped TiO2 for inactivation of bacteria on different substrates. Most of the previous publications are focused on nanoparticles of undoped or doped TiO2. Titanium dioxide doped with transition metals (Fe, Cr, Cu, Zn, Ag, etc.) is widely used for various biomedical applications as an antibacterial agent (see, also Refs. Norambuena et al. 2016; Meng et al. 2019). Although metals-doped TiO2 is inactivating of bacteria on the various materials surface, the most metals with an antibacterial property have cytotoxicity profile. Therefore, in order to commercially apply nanomaterials in food packaging, a careful understanding of the safety issues and the effects on human health is required. Vanadium doping sufficiently increases the carrier lifetime, therefore, concentrations of the ROS and antibacterial activity of TiO2 and extending the absorption range of TiO2 (Liu et al. 2009). The dopant such as vanadium is supposed to change the TiO2 band gap between conduction and valence bands to make it an efficient photocatalyst in visible region of spectra, i.e., band gap is too narrow to be effect at ambient light (see Fig. 1). The dip coating technique has been used by Klosek and Raffrey (2001) to deposit V on a TiO2, which is active in the visible light (396–450 nm). Zhou et al. (2010) also used the sol– gel method to synthesize a V doped TiO2 coating whose light absorption range of TiO2 is shifted from 380 nm to about 650 nm. A chemical vapor deposition (CVD) technique was applied by Chin et al. (2012) to synthesize V-doped TiO2 nanoparticles. The authors showed that V-doped TiO2 nanocoating exhibits the best absorption in the visible light range than bare TiO2. The magnetron sputtering technique was used by Silversmit et al. (2005) to synthesize V2O5/TiO2 thin film. The sol–gel method applied by Rodella and Mastelaro (2003) for V-doped TiO2 coating to enhance its antibacterial properties. Antibacterial properties of V2O5 have been studied by Jayaraj et al. (2018) against S. aureus bacteria under visible light range. They found that vanadium doping is considerably increasing the size of the inhibition zones for E. coli and S. aureus (19 mm and 23 mm, respectively). Mondal et al. (2020) also observed high antibacterial performance of V2O5–TiO2 materials for wastewater treatment.

The main mechanism which TiVOx nanocoating kills bacteria is the production of reactive oxygen species (ROS) such as superoxide anion \(\left( {{\text{O}}_{{ 2}}^{{ - }} } \right)\), hydroxyl radical \(\left( {{}^{ \bullet }{\text{OH}}} \right)\), phototoxic singlet oxygen \(\left( {{}^{{1}}{\text{O}}_{{2}} } \right)\), and hydrogen peroxide (H2O2) under light irradiation providing antibacterial properties (Wang et al. 2020). These decomposition products (high ROS quantum yield) can kill bacteria in the way that they destroy the outer membrane of bacteria cells, thus causing the cell death. The ROS formation can contribute to cell wall dysfunction and rupture due to membrane lipid oxidation. Thus, vanadium is a material which can be used for coating PP food containers as a way to prevent formation of the food-borne pathogens microorganisms.

The antibacterial activity of deposited nanomaterials essentially depends on the coating technique. There are various techniques to deposit V-doped TiO2 films, such as physical vapor deposition (PVD, Silversmit et al. 2005), sol–gel (Rodella and Mastelaro 2003), chemical vapor deposition (CVD) (Gupta and Kumar 2008), atomic layer deposition (ALD) (Abdulagatov, 2012), and electrospinning. The ALD process, in contrast to conventional coating techniques such as PVD and CVD, consists of sequential, self-limiting chemical reactions as alternating precursors are introduced, separated by a purge of an inert gas (see below). Self-limiting means that the material deposition will stop once all the sites on the surface are fully saturated, and the resultant layer is uniformly spread over the surface. This condition allows the formation of uniform and conformal thin nanofilms on the surface of PP food containers. An ALD cycle may then be repeated to increase the number of layers and thus the thickness and the composition of the thin film deposited, which are controlling the antibacterial activity of the coated material. Since microbial contamination of solid and liquid foods occurs at the surface of the container, we have made an attempt to improve safety and to delay spoilage by using antibacterial coating on the internal surface of the PP food containers using ALD coating technology from gas phase (see below). ALD has some of important advantages for the food and biomedical applications such as: (1) coating conformity (100%); (2) thickness and composition control; (3) low deposition temperatures (from room temperature to 200 °C), which is very important for food containers made from the various materials (metal, plastic, glass, wood, paper, etc.); and (4) excellent adhesion and barrier properties of the coatings (Jen S–H et al., 2011; Ashurbekova et al., 2021). Thus, the ALD technique is a way to deposit high-quality V-doped TiO2 (TiVxOy) nanomaterials for antibacterial coating of the food containers. The goal of the present work is to synthesize the antibacterial nanofilms (V-doped TiO2) generated by ALD as a proof-of-concept investigation for use doped TiO2 as a new antibacterial material to reduce food-borne pathogens microorganism.

Thus, the ability of the antibacterial coatings to protect food products from microbial contamination and subsequent spoilage remains an important research objective. Commercially available polypropylene (PP № 5) food containers are often used in the food industry due to their advantages such as durable strength, stability, and inexpensive. To protect the PP containers from microbial contamination, the inner surface of the container can be coated with antibacterial material. Thus, the main goals of the present work are developing an antimicrobial food packaging multilayer nanocoating material (vanadium-doped TiO2 nanocomposite with enhanced antibacterial activity) with highly antibacterial properties, based on ALD technology for potential use in food packaging to extend the transport and storage phase of food distribution while maintaining freshness, i.e., to reduce or inhibit microbial growth. In the present study we have developed multiple layers of nanocoating of (TiVxOy) on the PP food container surface to improve its antibacterial properties, thereby, prevent formation of the food-borne pathogens microorganism. We used V-doped TiO2 coating to enhance the antibacterial activity of TiO2, therefore, prevent biofilm formation by food-associated pathogens microorganism. This work describes for the first time the technology of applying antibacterial nanocoatings based on vanadium-doped titanium dioxide by ALD technique on a PP food container surface. Thus, in the present work we are providing a new food packaging nanomaterial (TiVxOy) based on ALD coating of commercial PP food containers, which is the elimination of pathogenic contamination. However, more additional studies are required to deeply understand antibacterial properties of materials for multipurpose use and the mechanisms which govern their antibacterial properties.

Materials and methods

Materials

Commercially available polypropylene (PP № 5) food containers with a volume of 80 cm3 (see Fig. 2) have been used in this work for ALD antibacterial coating. The main physical–chemical characteristics of PP are provided in our previous publication (Abdulagatov et al. 2021). The PP food container (Fig. 2 left) has been placed in an ALD chamber (reactor). The PP container was cleaned with deionized water, isopropanol and dried in a stream of high purity nitrogen before being placed in the ALD reactor. In the ALD process of Al2O3, the Trimethylaluminum (Al(CH3)3 precursor, CAS # 75–24-1, purity > 97.0%) and second precursor DI water have been used. V-doped TiO2 (TiVOx) nanofilms were deposited using the ALD process described below based on titanium tetrachloride (TiCl4, CAS # 7550–45-0, purity > 99.9%), vanadium oxytrichloride (VOCl3, CAS # 7727–18-6, purity 99.995%), and DI water precursors supplied by Sigma-Aldrich. Ultrahigh purity grade nitrogen (UHP N2, 99.9999% purity) was used as a carrier gas during deposition.

Methods: ALD experiment

The details of ALD technique and the physical–chemical bases have been widely described in our previous series publications (Abdulagatov et al. 2011; Abdulagatov, 2012; Ashurbekova et al., 2020; Abdulagatov et al. 2021; Ashurbekova et al., 2021). Thus, only a brief review will be given here. The schematic diagram of the experimental ALD apparatus for synthesizing vanadium (V)-doped TiO2 thin nanofilm on the PP food container is presented in Fig. 3. The main parts of the ALD apparatus consisted of (Fig. 3): (1) reactor (reaction zone); (2) dosing valves; (3) containers for precursors (chemicals); (4) flow meter for N2; (5) exhaust for chemical reaction byproducts; (6) temperature and pressure controlling units. The heart of the ALD apparatus consists of a reactor where the surface reactions are taking place. Experimental ALD apparatus under a computer-assisted control system makes it possible to significantly simplify the coating process and control the thicknesses and composition of the nanofilms. The experimental ALD coating process is fully automated. The Al2O3 thin films were deposited onto the internal surface of the PP container using Al(CH3)3 and H2O, then TiO2 and V2O5 were grew up on Al2O3 layer using TiCl4, VOCl3 and H2O as ALD precursors, and N2 served as a purging gas. The vanadium-doped TiO2 was layered on top of the Al2O3 thin film to improve the adhesion properties of the antibacterial layer (TiVxOy). In the present ALD experiment TiCl4 dosing time was a 1 s with a 30 s N2 purge, 1 s dosing of H2O, and a 30 s for N2 purge. The sequence of the precursor pulses and the consecutive inert gas (N2) purges form a so-called ALD supercycle which is consist of (1) precursor (TiCl4) pulse; (2) purge; (3) precursor (H2O) pulse; (4) purge; (5) precursor (VOCl3) pulse; (6) purge; (7) precursor (H2O) pulse; and (8) purge (see below Fig. 4). This cycle is repeated until the desired film thickness and composition is reached.

Sequence of reagent supply during the ALD TiVOx nanofilm deposition (see also our previous publication Abdulagatov et al. 2021)

The total flow rate of the N2 was 100 sccm. The vanadium-doped TiO2 thin films were grown at a temperature of (85 to 95) °C and 1 Torr. A total of 250 cycles (100 cycles for Al2O3 and 250 supercycles for TiVxOy films) corresponding to 38 nm of the (Al2O3 + TiVxOy) film were carried out. As will be shown below, the structures in which the TiVxOy was layered on top of the Al2O3 (Al2O3 + TiVxOy) has the highest antibacterial activity.

The ALD coating process is controlling by setting the main characteristics of the process, namely: dose and purge time of the precursors during one ALD cycle of Al2O3 which can be denoted as: t1/t2/t3/t4 where t1 is the TMA dose time; t2, t4 are the purge times; t3 is the H2O dose time. In order to deposit 10 nm of ALD Al2O3 100 cycles with the following timing characteristics has been used 2.5/35/2.5/35 s (i.e., t1 = 2.5/t2 = 35/t3 = 2.5/t4 = 35 s). In order to obtain an ALD TiVOx nanofilm 28 nm thick, 250 ALD supercycles were performed with process time parameters of 2.5/35/2.5/35/2.5/35/2.5/35 s. The precursors dose and purge times during one ALD deposition supercycle of TiVOx was denoted as: t1/t2/t3/t4/t5/t6/t7/t8, where t1 is the dose time of TiCl4; t2, t4, t6, t8 are the purge times; t5 is the dose time of VOCl3; t3, t7 are the H2O dose times.

Methods. PP food container surface characterization

The composition (elemental concentrations, atomic percentage) in the outermost layer of the PP container with TiVOx coatings and uncoated PP container was measured by Electron Microscope ASPEX Express with an energy -dispersed detector OmegaMax (EDX- detector OmegaMax, FEI, USA).

Methods. Antibacterial test of the TiVOx coated PP food container

There are different techniques to test the effectiveness of the antimicrobial activity of the nanomaterials (Meng et al. 2019; Jayaraj et al. 2018; Yonezawa et al. 2020). In order to test the ability of Al2O3 + TiVOx coated packaging material fresh raw cow’s milk was used as a test material. The test experiment of the effect of the antibacterial coating on the shelf- life of raw cow’s milk was carried out in the Republican Veterinary Laboratory (Dagestan, Russian Federation). To test the antibacterial activity of the TiVOx coating, we used the method of taking into account the level of contamination, namely, determining the number of Mesophilic Aerobic and Facultative Anaerobic Microorganisms (MAnFAM). MAnFAM is one of the key indicators of microbiological safety of food products, (Standard GOST 32901–2014s. 8.4.2.1 https://docs.cntd.ru/document/ 1,200,115,745: Interstate standard for dairy products. Methods of Microbiological Analysis). The Standard applies to dairy products and specifies method for microbiological analysis. Before culture inoculation, the acidity of milk was determined according to Standard 3624–92 (see, for example, https://docs.cntd.ru/document/1200021584). In accordance with Standard 32,901–2014, inoculation was done from the dilutions recommended for raw milk and cream. In the study of raw milk, its dilutions from (10–4 to 10–6) cm3 was inoculated in a nutrient medium. We used the average dilution, which corresponds to the recommendation. Fresh cow’s milk was placed in antibacterial coated (test) and uncoated (control) containers. The containers were stored at 4 °C and the contamination level of the product was determined after 3, 5 and 9 days of storage. The used method of accounting for product contamination is based on the ability of MAnFAM microorganisms to multiply on dense nutrient agar at a temperature of (30 ± 1) °C for 72 h. The amount of the inoculated product was determined taking into account the most probable microbial contamination. One milliliter of the raw milk test sample was inoculated into Petri dishes with a pre-marked lid and poured into 15 ml of melted and cooled to 40-45ºC nutrient medium for the MAFAnM determination. Immediately after pouring the agar, the contents of the Petri dish were thoroughly mixed by gently shaking to distribute the inoculum uniformly. After the agar solidified (cooling), the Petri dishes were turned upside down and placed at this position in a thermostat at a temperature of (30 ± 1) ºC for 72 h. The number of grown colonies was counted on each dish, placed upside down on a dark background, using a magnifying glass with a magnification of 5–10 times. The arithmetic mean obtained for all plates was taken as the final result of the analysis.

The primary inoculation of culture media with microorganism to determine the compliance of the initial fresh test raw cow’s milk sample with the standard indicators showed that the MAnFAM in the milk sample is within the normal range, CFU/g less than 5 × 105 CFU/ml (Fig. 5 A), i.e., whether the initial milk sample complied with the standard indicators for this product. The original sample was divided into 6 parts of 30 ml and poured into 6 food grade PP food containers: 3 antibacterial coated and 3 uncoated. Then they were placed in a refrigerator at temperature of + 4 °C for subsequent crops after 3, 5, and 9 days in order to identify the dependence of the level of contamination of milk on the residence time in the containers. To better understand the ability and effectiveness of the antimicrobial packaging material of V-doped TiO2 to prevent the biofilm formation by dairy-associated pathogenic bacteria (effectively reducing bacterial populations), the coated and uncoated PP food containers with a fresh raw cow’s milk were tested.

The level of contamination of raw cow’s milk. A initial contamination level of raw fresh cow’s milk (control container); B the level of contamination of raw cow’s milk after 3 days residence in the PP food container without coating; C after 3 days residence with Al2O3 + TiO2/V2O5 antibacterial coating (antibacterial container); D after 5 days without coating; E after 5 with Al2O3 + TiO2/V2O5 antibacterial coating (antibacterial container); F after 9 days without coating; G after 9 days with Al2O3 + TiO2/V2O5 antibacterial coating

Methods. Determination of titanium and vanadium in cow milk in PP container with antibacterial coating

The determination of titanium and vanadium (diffusion of the antibacterial agent into food) in cow milk kept in a PP container with antibacterial coating for 9 days was carried out using atomic emission spectrometer (AES) contrAA-700 (Analytik Jena AG, Germany).

Results and discussion

In this work, temperature-controlled ALD technique, described above, has been used for the first time to synthesize vanadium-doped TiO2 thin film on PP containers for long-term food storage. Multiple layers of (Al2O3 + TiVOx) with a thickness of 38 nm (10 nm of Al2O3 and 28 nm of TiO2 doped with V, TiVOx) was deposited on the internal surface of the PP food container using described above ALD technique (see Fig. 2) to improve its antibacterial activity, thereby, to improve safety and to delay spoilage. The coated thickness was calculated using the growth rate per supercycle (0.11 nm/supercycle (Abdulagatov et. al., 2021) and the number of supercycles (250). The coating is applied to the inner surface of a PP food container to improve its antibacterial activity. The sequence of reactants supply in the process of ALD TiVOx, which constituted one ALD supercycle, is shown in Fig. 4. According to this deposition scheme, after the TiCl4 purge, a monolayer of titanium oxochloride groups is formed on the surface, and the puffing of H2O vapor leads to the replacement of chlorine ions (Cl–) by hydroxyl groups ( OH)–, which further react with VOCl3. After that, a monolayer of vanadium oxochloride groups is formed on the surface, and the inlet of H2O vapor leads to the regeneration of surface hydroxyl groups. The described process is one supercycle. This supercycle is repeated 250 times to obtain a TiVOx coating with a thickness of 28 nm.

To improve the adhesion of the TiVOx coating to the PP container and create additional hydroxyl groups on the surface of polypropylene, preliminary ALD of Al2O3 was performed using TMA and H2O. The Al2O3 ALD process, consisting of repeated surface reactions between TMA and H2O, can be represented as follows:

\({\mathbf{Reaction}} \, {\mathbf{B}}:{] - }\left( {\text{O}} \right)_{x}^{{}} - {\text{Al}}\left( {{\text{CH}}_{{3}} } \right)_{3 - x}^{*} + {\text{H}}_{{2}} {\text{O}}\left( {\text{g}} \right) \to ]\left( { - {\text{O}}} \right)_{x} - {\text{Al}}\left( {{\text{OH}}} \right)_{x}^{*} + \left( {3 - x} \right){\text{CH}}_{{4 }} \left( {\text{g}} \right)\),

where “]” is the surface; * is the reactive group surface; x — ligands fractions remained after precursors dosing; CH4 is the gaseous reaction byproduct.The A-B reaction is one ALD cycle. We performed 100 Al2O3 ALD cycles to obtain a 10 nm thick film (growth rate ~ 0.1 nm/cycle (Abdulagatov, 2012). Thus, the ALD method makes it possible to produce a uniform coating of a vanadium-doped TiO2 nanofilm over the entire food PP container at a temperature of 85 °C, and the thickness and composition of the nanofilm can be controlled by changing the number of ALD cycles.

The composition (elemental concentrations, atomic percentage) in the outermost layer of the PP container with TiVOx coatings and uncoated PP container (wt %) are: uncoated PP container (C-76.7%; O-22.6%; Al-0.5%; Cl-0.1%; Ti-0.0%; V-0.0%) and coated PP container (C-78.1%; O-21.1%; Al-0.6%; Cl-0.1%; Ti-0.1%; V-0.2%). The content of titanium and vanadium atoms in the coated PP container indicates the successful implementation of the TiVOx antibacterial nanocoating into the structure of the polypropylene food container. A comparison of the ALD TiVOx coated (right) and uncoated (left) PP food container surfaces is shown Fig. 2 (see above). The color of the coated food container (Fig. 2, right) slightly changed.

The antibacterial activity test of a coated PP container has been compared with an uncoated PP container. The results are shown in Fig. 5. Figure 5 (B-G) shows the level of contamination of the test sample (raw cow’s milk), which was 3 (B and C), 5 (D and E), and 9 (F and G) days residence in the coated and uncoated PP food containers. Figures 5 (B) to 5 (G) show growth of MAnFAM in TiVOx—coated and uncoated PP food containers after 3, 5, and 9 days, respectively. Figure 5 (D and F) show the contamination level of raw cow’s milk after 5 days residence in the uncoated (D) and coated (F) containers, respectively. Figure 5 (F and G) show the results of the contamination level of raw cow’s milk after 9 days in the uncoated (F) and coated (G) containers, respectively.

Analysis of the results of the tests performed showed an increase in MAnFAM from (2.3 ± 0.02) × 105 CFU/ml to (5.3 ± 0.03) × 105 CFU/ml in the control (uncoated) containers (Fig. 5 B, D and F) during all periods of observation (after 3, 5 and 9 days residence). However, the test results for the coated containers (see Fig. 5 C, E and G) showed the growth of MAnFAM from (9.4 ± 0.12) × 104 to (1.0 ± 0.16) × 105) CFU/ml, which indicates reducing (inhibition) in the MAnFAM growth. Figure 6 shows the increase of the total contamination of the test milk on the time spent (residence time) in the food containers with and without antibacterial coating. This plot (Fig. 6) relates the number of bacterial colonies able to grow on plates incubated with coated and uncoated containers, as a function of time. Lack of growth in the coated centenaries may indicate inhibition. As one can see from Fig. 6, the level of total contamination in the control PP container (food container without antibacterial coating) gradually increases, while in the tested container (with antibacterial coating), the level of contamination growth is considerably reduced due to the effect of antibacterial coating. Thus, V-doped TiO2 (TiVOx) -coated PP food containers showed good antibacterial activity after 9 days, i.e., inhibits the growth of bacteria (see Fig. 5 G), therefore, slowing down the growth of spoilage bacteria. The sample of coated PP food container was analyzed in five replicates and analysis of variance was applied to the data to distinguish the treatments at p < 0.05. The PP container with TiVOx coating shows significantly higher (p < 0.05) antibacterial efficacy than the uncoated one. The statistical analyses were performed using the Data Analysis Software (SPSS). The antibacterial activity (efficacy) of the PP container with TiVOx coating compared to the uncoated PP container was ~ 60% in the first 3 days, ~ 75% within 5 days, ~ 80% within 9 days.

Comparison with previous works

The present results were compared with the studies reported previously by other authors. In the work by Othman et al. (2014), an antibacterial film of TiO2 nanoparticles was applied to food packaging and its properties were tested by storing a lettuce leaf under UV radiation. The maximum antibacterial activity of the packaging in relation to the strain of microorganisms E. Coli was ~ 37% (in the uncoated package, the value of Log CFU/g was 10.04 ± 0.12, and in the coated package—6.29 ± 0.17). In the work by Tang et. al. (2018), a hydrothermally synthesized sodium alginate film containing functional Au-TiO2 nanocomposites improved antimicrobial activity by 60% and 50% against S. aureus and E. coli, respectively, compared to a film containing TiO2 nanoparticles. According to Gumiero et al. (2013), the maximum antibacterial activity under UV light of a composite matrix of high-density polyethylene + CaCO3 + TiO2 for better preservation of the original structure of the cheese due to the inhibition of lactic acid bacteria and coliform bacteria was 65% in relation to Coliforms and E. Coli; 50% for Lactic acid bacteria and 20% for yeasts and molds. The main disadvantage of previous works in the development of antibacterial packages based on TiO2 is the need to use UV radiation to activate the photocatalytic (bactericidal) properties of TiO2, which exhibits low antibacterial efficiency in the visible region of the solar spectrum. Doping of TiO2 with vanadium ions, proposed in the present work, makes it possible to shift the antibacterial activation of TiO2 to the visible region of the spectrum and activate its antibacterial properties in sunlight. The ALD method proposed in the present work allows such doping to be carried out precisely with control over the thickness and composition of the coating, which significantly affects the antibacterial properties of the material. Also in previous works, TiO2 nanoparticles are used as antibacterial agents, which are manually applied to the surface of the package. This significantly limits the scope of such packages, since in the absence of adhesion to the package, nanoparticles diffuse into packaged food over time, which is unsafe. Also, the disadvantage of using nanoparticles as antibacterial agents for packages is the impossibility of repeated use of the package due to the gradual loss of nanoparticles (instability) during their repeated use. The ALD technology proposed in the present work, compared to existing ones, is applicable to any packaging made from various materials (metal, glass, plastic, wood, paper, etc.).

We tried to control the possibility of vanadium and titanium diffusion into food from nano-coatings. In this work, we checked the concentration of vanadium in the environment (in milk). The effect of vanadium and titanium on human health is dose-dependent. From the results of the analysis carried out by the AES method, it can be concluded that the content of titanium and vanadium in milk was below the sensitivity limit of the AES (up to 10–8—10–7 wt. %), which is much less than the MPC of vanadium in drinking water (10–5 wt. %). Al2O3 pre-deposition enhances adhesion between the coating surface and TiVOx (barrier properties of the coating). In general, the use of the ALD method makes it possible to avoid the diffusion of the antibacterial agent (titanium and vanadium) into food due to the fact that the coating is synthesized on the surface of the PP container by stepwise sequential chemical reactions (high adhesive properties of the coating).

Conclusion

Thus, developed antibacterial packaging material (Al2O3 + TiVOx) inhibits the growth of bacteria, i.e., prevents the formation of microbial colonies and may destroy microorganisms. We have illustrated the effectiveness of ALD (Al2O3 + TiVOx) nanocoating against populations of milk-borne pathogenic bacteria. The ALD Al2O3 coating, as a seed layer for TiVOx, enhances adhesion between coating surface and TiVOx (increases barrier properties). Therefore, the ALD method allows to improve the adhesion of the antibacterial material to the container’s wall due to the fact that it is based on the technology of staged film growth using surface chemical reactions, which provides such advantages as durability and high coating efficiency. This made the antibacterial coating more stable in comparison with conventional techniques. We found that the level of contamination of the microorganisms in the nanocoated PP food containers on the 3th, 5th, and 9th days, have been reduced by 2.5, 3.9, and 5.3 times, respectively, in comparison with uncoated ones. Thus, the present work shows a way to increase the shelf- life of food in packaging materials, which consists in the fact that a TiVOx nanofilm is applied to the food container by ALD technique that demonstrates excellent antibacterial properties. TiO2 doped with vanadium illustrated the strongest antibacterial effect, i.e., vanadium increases the bacterial activity of pure TiO2. The application of TiVOx -coated PP food container in an experiment on fresh cow’s milk is illustrated sufficient enhancement its antibacterial properties, namely, reduced milk-related microbial growth, prevent the growth of the pathogenic bacteria, thereby, avoid food spoilage and prolonging the food. This makes the food industry safer, improves food quality and thus protects human health.

A uniform V-doped TiO2 (TiVOx) nanofilm is formed on the surface of the packaging material, which does not degrade over time (stability) in compare with organic antibacterial agents, and the probability of diffusion of vanadium into the packaged material (food product) is almost zero. In future work other factors such as nanofilm thickness, concentration of vanadium, surface charge, and the chemical nature of antibacterial agents (dopants) for wide range of food processing equipment such as cutting boards, filler gaskets, conveyors, gloves, garments, dishcloths, personal hygiene equipment and other food contact surfaces where bacteria grow expected, etc., which influence nanocoating antimicrobial efficiency, will be studied. They will self-sanitize during use. The use of new antibacterial packing materials (nanotechnology) will help produce food free from preservative damage. The application of ALD nanotechnology can be successfully used to produce the packaging materials that maintain fresh products.

Data availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Code availability

Not applicable.

References

Abdulagatov AI, Yan Y, Cooper JR, Zhang Y, Gibbs ZM, Cavanagh AS, Yang RG, Lee YC, George SM (2011) Al2O3 and TiO2 atomic layer deposition on cooper for water corrosion resistance. ACS Appl Mater Interfaces 3:4593–4601

Abdulagatov AI, Maksumova AM, Palchaev DK, Rabadanov MKh, Abdulagatov IM (2021) Atomic layer deposition and thermal transformations of thin titanium–vanadium oxide films. Russ J Appl Chem 94:890–902

Abdulagatov IM, Ragimov RM, Khamidov MA, Maksumova AM, Abdullaeva NM (2022) ALD coated polypropylene hernia meshes for prevention of mesh-related post-surgery complications: an experimental study in animals. Biomed Mater 17:015006. https://doi.org/10.1088/1748-605X/ac361e

Abdulagatov AI. Growth, characterization and post-processing of inorganic and hybrid organic-inorganic thin films deposited using atomic and molecular layer deposition techniques, PhD Thesis (Dissertation), Boulder, CO: Chemical Department, University of Colorado, USA 2012

Allahverdiyev AM, Abamor ES, Bagirova M, Rafailovich M (2011) Antimicrobial effects of TiO2 and Ag2O nanoparticles against drug-resistant bacteria and leishmania parasites. Future Microbiol 6:933–940

Bahadur J, Agrawal Sh, Panwar V, Parveen A, Pal K (2016) Antibacterial properties of silver doped TiO2 nanoparticles synthesized via sol-gel technique. Macromol Res 24:488–493

Barazi AÖ, Mehmetoğlu A, Erkmen O (2023) A Novel edible coating produced from a wheat gluten, Pistacia vera L. resin, and essential oil blend: antimicrobial effects and sensory properties on chicken breast fillets. Foods 12:2276

Chang Y-N, Zhang M, Xia L, Zhang JG (2012) The toxic effects and mechanisms of CuO and ZnO nanoparticles. Materials (basel) 5:2850–2871

Chin S, Park E, Kim M, Bae GN, Jurng J (2012) Synthesis and visible light photocatalytic activity of transition metal oxide (V2O5) loading on TiO2 via a chemical vapor condensation method. Mater Lett 75:57–60

Duncan TV (2011) Applications of nanotechnology in food packaging and food safety: Barrier materials, antimicrobials and sensors. J Colloid Interface Sci 363:1–24

Erkmen O, Bozoglu TF. (2016) Food preservation by modified atmosphere. In: Erkmen O, Bozoglu TF, Food microbiology principles into practice. volume 2: Microorganisms in Food Preservation and Processing. John Wiley and Sons, Ltd., Chichester, 132–165

Erkmen O, Barazi A (2008) Modelling the effects of modified atmosphere on Salmonella typhimurium in packaged meat during storage in the refrigerator and at 12 °C. Ann Microbiol 58:73–81

Fawzy ZF, Li Y, Shedeed ShI, El-Bassiony AM (2018) Nanotechnology in agriculture-current and future situation. Res Rev: J Agri Allied Sci 7:73–76

Gumiero M, Peressini D, Pizzariello A, Sensidoni A, Iacumin L, Comi G (2013) Effect of TiO2 photocatalytic activity in a HDPE-based food packaging on the structural and microbiological stability of a short-ripened cheese. Food Chem 138:1633–1640

Gupta R, Kumar A (2008) Bioactive materials for biomedical applications using sol–gel technology. Biomed Mater 3:034005

Gupta K, Singh RP, Pandey A, Pandey A (2013) Photocatalytic antibacterial performance of TiO2 and Ag-doped TiO2 against S. Aureus. P. Aeruginosa and E. Coli. Beilstein J Nanotechnol. 4:345–351

Jayaraj SK, Sadishkumar V, Arun Th, Thangadurai P (2018) Enhanced photocatalytic activity of V2O5 nanorods for the photodegradation of organic dyes: A detailed understanding of the mechanism and their antibacterial activity. Mater Sci Semicond Process 85:122–133

Jen S-H, Bertrand JA, George SM (2011) Critical tensile and compressive strains for cracking of Al2O3 films grown by atomic layer deposition. J Appl Phys 109:084305

Jin T, He Y (2011) Antibacterial activities of magnesium oxide (MgO) nanoparticles against foodborne pathogens. J Nanopart Res 13:6877–6885

Klosek S, Raftery D (2001) Visible light driven V-doped TiO2 photocatalyst and its photooxidation of ethanol. J Phys Chem B 105:2815–2819

KrN A, Ashurbekova KN, Saric I, Gobbi M, Modin E, Chuvilin A, Petravic M, Abdulagatov IM, Knez M (2021) Ultrathin hybrid SiAlCOH dielectric films through ring-opening molecular layer deposition of cyclic tetrasiloxane. Chem Mater. 33:1022–1103

Liu S, Xie T, Chen Z, Wu J (2009) Highly active V-TiO2 for photocatalytic degradation of methyl orang. Appl Surf Sci 255:8587–8592

Meng D, Liu X, Xie Y, Du Y, Yang Y, Xiao Ch (2019) Antibacterial activity of visible light-activated TiO2 thin films with low level of Fe the doping. Adv Mater Sci Eng 10:1–8

Mocanu A, Isopencu G, Busuioc C, Popa OM, Dietrich P, Socaciu-Siebert L (2019) Bacterial cellulose films with ZnO nanoparticles and propolis extracts: Synergistic antimicrobial effect. Sci Rep 9:1–10

Mondal M, Dutta H, Pradhan SK (2020) Enhanced photocatalysis performance of mechano-synthesized V2O5–TiO2 nanocomposite for wastewater treatment: correlation of structure with photocatalytic performance. Mater Chem Phys 248:122947

Norambuena GA, Patel R, Karau M, Wyles CC, Jannetto PJ, Bennet KE, Hanssen AD, Sierra RJ (2016) Antibacterial and biocompatible titanium-copper oxide coating may be a potential strategy to reduce periprosthetic infection: an in vitro study. Clin Orthop Relat Res 475:722–732

Othman SH, Abd Salam NR, Zainal N, Kadir Basha R, Talib RA (2014) Antimicrobial activity of TiO2 nanoparticle-coated film for potential food packaging applications. Int J Photoenergy 2014:945930

Rodella CB, Mastelaro VR (2003) Structural characterization of the V2O5/TiO2 system obtained by the sol-gel method. J Phys Chem Solids 64:833–839

Sharma S, Jaiswal S, Duffy B, Jaiswal AK (2019) Nanostructured materials for food applications: spectroscopy, microscopy and physical properties. Bioengineering 6:26–33

Silversmit G, Poelman H, Depla D, Marin GB, Gryse RD (2005) A fully oxidized V2O5/TiO2 (001)-anatase system studied with in situ synchrotron photoelectron spectroscopy. Surf Sci 584:179–186

Tang S, Wang Z, Li P, Li W, Li C, Wang Y (2018) Degradable and photocatalytic antibacterial Au-TiO2/sodium alginate nanocomposite films for active food packaging. Nanomaterials 8:930–941

Wang X, Wang X, Zhong X, Li G, Yang Zh, Gong Y, Liu Zh, Cheng L (2020) V-TiO2 nanospindles with regulating tumor microenvironment performance for enhanced sonodynamic cancer therapy. Appl Phys Rev 7:041411

Yemmireddy VK, Hung YC (2017) Photocatalytic TiO2 coating of plastic cutting board to prevent microbial cross-contamination. Food Control 77:88–95

Yonezawa K, Kawaguchi M, Kaneuji A, Ichiseki T, Iinuma Y, Kawamura K, Shintani K, Oda S, Taki M, Kawahara N (2020) Evaluation of antibacterial and cytotoxic properties of a fluorinated diamond-like carbon coating for the development of antibacterial medical implants. Antibiotics 9:495

Zhang P, Liu X, Yin S, Sato T (2010) Enhanced visible-light photocatalytic activity in K0.81Ti1.73Li0.27O4/TiO2−xNy sandwich-like composite. Appl Catal B: Environ. 93:299–303

Zhang P, Yin S, Sato T (2011) The influence of synthesis method on the properties of iron contained N doped TiO2 photocatalysts. Appl Catal B 103:462–469

Zhou W, Liu Q, Zhu Z, Zhang J (2010) Preparation and properties of vanadium-doped TiO2 photocatalysts. J Phys D Appl Phys 43:1–6

Funding

The research was supported by the State Assignment of the Government of the Russian Federation FZNZ-2020–0002 (Abdulagatov I.M., Maksumova A.M.)

Author information

Authors and Affiliations

Contributions

IMA: writing—original draft preparation, project administration, AMM: Conceptualization, writing—review and editing, supervision, MZM: investigation, methodology, ROT: investigation, writing—review and editing, SMK: investigation, data curation and formal analysis, AMS: methodology.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Ethics approval

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Abdulagatov, I.M., Maksumova, A.M., Magomedov, M.Z. et al. Antibacterial Food Packaging Nanomaterial Based on Atomic Layer Deposition for Long-Term Food Storage. J Food Sci Technol 61, 596–606 (2024). https://doi.org/10.1007/s13197-023-05867-0

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-023-05867-0