Abstract

Nutrition-rich extruded snacks were developed from a mixture of cornflour, Bengal gram flour fortified by tree bean (TB) powder (0, 5, and 10%) using a twin-screw extruder. The nutritional, antioxidant, and amino acid profile and structural, functional, and sensory properties of the ready-to-eat (RTE) extruded snacks were evaluated. Ash, protein, and fiber content in TB-fortified extrudates were increased, whereas nitrogen-free extract was decreased. Total phenolics (2.34 mg g–1 FW), ascorbate (2.23 mg g–1 FW), total flavonoids (0.16 mg g–1 FW), and reduced glutathione (8.53 µM g–1 FW) were higher in the extrudates with 10% TB powder. Similarly, RTE extruded snacks fortified by 10% TB exhibited higher DPPH, FRAP, ABTS, hydroxyl radical activities, reducing power, and essential amino acids, such as lysine, leucine, isoleucine, cysteine, threonine, tyrosine, and methionine derived by HPLC. Extrudates fortified by 5% TB powder exhibited better microstructure through scanning electron microscopy. However, 10% TB powder possessed higher physicochemical properties and overall sensory attributes. This study reveals the tremendous industrial potential of nutrient-rich RTE extruded snacks fortified by underutilized TB (10%).

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Extruded snacks have emerging commercial value among processed food products with higher consumer preference worldwide. On the other hand, the high fat and calories coupled with low fiber and protein content in cereal-based extruded snacks have negative consequences and serious health concerns (Korkerd et al. 2016). Nutritional improvement in extruded products with pro-health components, such as soluble protein and fiber, is thus imperative to address the health benefits of consumers (Tobias–Espinoza et al. 2019). Usually, cereal grains, corns, and pulses are the least expensive and predominant sources of raw materials for making extruded products (Offiah et al. 2019). The quality of raw materials used in extruded products is directly proportionate to the end products' nutritional quality and functional properties (Guy 2015). Therefore, fortification with protein- and fiber-rich byproducts with enhanced nutritional profile need to pay more research attention to meet consumer demands.

Among the quality raw materials available, pulses and legumes are the first choices to improve the nutritional quality of industrially important extruded products. Several reports have focused on protein enhancement in extruded products fortified by legumes, such as lentil, green pea, yellow pea, soybean and chickpea (Patil et al. 2016). However, fortification of underutilized tree bean in nutrition enhancement of extruded snacks has not yet been attempted.

Tree bean (Parkia roxburghii G. Don), a nutritionally potential leguminous vegetable, is grown abundantly in the Northeast Indian subcontinent, Myanmar, Thailand, Indonesia, and Malaysia. Tender pods and seeds of tree bean are rich sources of protein, carbohydrates, vitamins, minerals, dietary fibers, and antioxidants (Singh et al. 2009). High–quality tree bean protein (> 32% in tender pods and mature seeds) may represent a potential substitute for animal protein intake in the increasing vegan food consumption trends. Fresh seasonal tree bean pods have a unique flavor and aroma, which are preferred by the indigenous people of the northeastern hill region of India. The freshly harvested pods are highly perishable and need suitable processing to imbue their nutritional factors with extended shelf life (Sathya and Siddhuraju 2015).

Extrusion technology has become an emerging processing technique that rapidly transforms the food industry in the developed world (Offiah et al. 2019). Fortified RTE extruded products enhance taste, palatability, digestibility, extended shelf life, and consumers' acceptability (Mercier et al. 2016). Reports have shown that extrusion retains valuable compounds available in the raw materials due to reduced processing duration (Akhtar et al. 2015). However, proportionate composition and suitable processing conditions influence nutritive values in novel processed products (Oniszczuk et al. 2019). Overall strategies in the food industry have focused on ensuring dietary energy reduction and incorporating dietary fiber and protein during extruded product development (Tobias-Espinoza et al. 2019). Nutritionally rich tree bean powder would be a suitable and inexpensive source of raw material for obtaining high-quality extruded snacks with balanced protein, fiber, and essential amino acids lacking in most cereals.

Enhancing nutrition through fortification adds immense value to potential industrially extruded products. Biofortification for protein and fiber improvement sometimes hinders product expansion and crispness/hardness during extrusion, affecting consumer preference. Thus, nutritional assessment in novel biofortified extruded snacks is essential to validate the processing technology or processed products for large-scale commercialization. In this study, a systematic approach was undertaken to develop a novel protein-rich extruded snack from the nutritionally potential tree bean powder and examine the nutritional profile, antioxidant properties, radical scavenging activities, enzymatic antioxidants, and amino acid profiles of the unique extruded products for further industrialization. Structural variations and organoleptic properties were evaluated through a scanning electron microscope (SEM) imaging and sensory analyses. Extruded snacks developed from this indigenous underutilized tree bean with an enhanced food matrix may draw commercial interest in the food processing industry.

Materials and methods

Material preparation

Fresh and healthy tree bean (TB) pods were collected from the Langol Hill Research Farm of the Indian Council of Agriculture Research (ICAR) Research Complex for North Eastern Hill Region (ICARRCNEHR), Manipur Center, Imphal, India. Harvested tree beans were immediately pre-cooled at 10 °C for 1 h to remove field heat and mechanically injured beans were sorted out. Tree beans were subsequently placed in a 150 × 225 cm low-density polyethylene bag with 80–100 mm headspace for packaging and were processed within 10 h at the Quality Control Laboratory, PJTSAU, Hyderabad, India. The outer fibrous portion (epidermis) was scraped and washed thoroughly under running tap water. Cleaned beans were sliced with a stainless steel knife into pieces of 15 mm × 15 mm and were subjected to blanching at 80 °C for 5 min. Excess moisture was removed from the blanched TB pieces using a dry muslin cloth followed by drying in a tray drier at 55–60 °C for 14 h. The dried TB pieces were then ground to powder in a laboratory pulverizer and sieved to ensure uniform particle size (300 µm).

Corn (Zea mays) grits and Bengal gram (Cicer arietinum) were obtained from the local market in Hyderabad, India. Corn grits and Bengal gram (BG) were dried at 55 °C for 2 h, then ground separately in a hammer mill and sieved (300 μm sieve) to obtain the flour. Individual flours were packed in closed airtight glass containers and stored under ambient conditions until further use.

Preparation of extruded products

Three composite flour mixes were formulated with corn flour, BG flour and TB powder at ratios of 70:30:00 (control), 70:25:05 (5% TB powder) and 70:20:10 (10% TB powder) and were extruded as per the procedures described by Reddy et al (2014), as shown in Supplementary Fig. 1. Supplementary Fig. 1 is a flow chart on processing of tree bean RTE extruded products.

All three composite flour mixes were extruded at 80 ± 5 °C (heater I) and 95–100 °C (heater II), 300–350 rpm screw speed, 100 ± 10 °C die temperature, and 15 ± 2 kg h−1 feed rate in a co-rotating twin-screw extruder (Scientech Technologies, Kolkata, India) with a barrel diameter and L/D ratio of 37 mm and 27:1, respectively. The exit diameter of the circular die was 3 mm. The RTE extruded snack samples were sprayed with hot (80 °C) refined rice bran oil (75 ml kg−1) and spice mix (3 g kg−1) in a rotary tumbler. Extrudates were dried for 20 min at 60 °C to improve the crispness of the final extruded product. Dried RTE extruded products were cooled to room temperature (33 °C) and packaged in metalized polyethylene terephthalate (MPET) with oxygen transmission rate (OTR) of 0.95 cc m−2 day−1 and water vapor transmission rate (WVTR) of 1.2 g m−2 day−1 and stored at room temperature, i.e., 33 ± 4 °C, for further analysis.

Proximate analyses

Proximate analyses, such as moisture, ash, crude fat, crude fiber, crude protein, and nitrogen-free extracts (NFE) of the extruded tree bean were determined according to official methods of the Association of Analytical Chemists (AOAC 2016).

Antioxidant properties

Proline content, total phenolics, ascorbic acid (AsA), total flavonoids, total carotenoids and reduced glutathione levels were estimated per the standard protocols as reported by Kuna et al (2018).

Radical scavenging activities (RSA)

DPPH (2,2–diphenyl–1–picrylhydrazyl), FRAP (ferric reducing antioxidant power), ABTS [2,2'–azino–bis (3–ethylbenzothiazoline–6–sulfonic acid)], HRS (Hydroxyl radical scavenging) activity and RP (reducing power) was estimated following standard methodologies as described by Kuna et al (2018). Ascorbic acid, gallic acid and trolox were used as positive controls to calculate the percent inhibition.

Amino acid profiling

Amino acid profiles in RTE extruded samples were determined using HPLC (Agilent 1260 Infinity HPLC system; Santa Clara, CA, equipped with diode array and multiple wavelength detector) after samples were hydrolyzed with 6 N HCl as reported by Udenigwe and Aluko (2011). Method validation was performed to ensure the precision and accuracy of the results as per the standard procedure (AOAC 2016). Hydrolyzed peptide samples were derivatized with OPA (o–phthalaldehyde for primary amino acids) and FMOC (9–fluorenylmethyl chloroformate for secondary amino acids). The same samples were analyzed for amino acid composition using a Zorbax Eclipse–AAA column (250 mm × 4.6 mm, L × ID, particle size 5 μm) [Agilent Technologies, Santa Clara, CA]. Amino acid composition was expressed as percent amino acid of the total protein content of each sample.

Scanning electron microscopy (SEM)

Microstructure examination of RTE extruded snacks was performed using a scanning electron microscope (SEM). The control and experimental samples were viewed and imaged on an SEM (JSM 5600, JOEL) using an automated sputter coater (JFC–1600, JOEL) for 3 min at a magnification of 70x. The external appearance of the samples related to expansion (texture and porosity), which are the characteristics of RTE extruded snacks (Reddy et al. 2014), were studied. In addition, texture features, such as contrast (CON), correlation (COR), energy (ASM), homogeneity (HOM), and entropy (ENT), were analyzed using MATLAB® 8.4 (MA, USA) at thirty regions of interest (ROIs) as described by Pieniazek and Messina (2017).

Sensory evaluation

Sensory analyses were conducted at PJTS Agricultural University, Hyderabad, India, and ICAR Research Complex for NEH Region, Imphal, India, separately by 25 trained panel members at each center. The trained panelists did not know the project objectives. All RTE extruded samples were coded using random three-digit numbers and served with the order of presentation counterbalanced for evaluating the products based on their color, flavor, texture, taste, and overall acceptability using a nine-point hedonic scale (0 = extremely dislike to 9 = extremely like). Data from both centers were pooled to obtain results for sensory acceptability.

Statistical analysis

All data were analyzed using analysis of variance (ANOVA) in a completely randomized design (CRD), and significance was tested at probability level P ≤ 0.0001 using GraphPad Prism 8. Significative analyses of variance (mean sum of squares) for the traits measured in ready–to–eat extruded snacks fortified with tree bean powder (Supplementary Table 1). Graphical representations are the mean of nine replicates under each treatment (n = 27).

Results and discussion

Proximate analyses

Proximate analyses, such as moisture, ash, crude fat, crude fiber, crude protein, and nitrogen-free extracts (NFE) of three different extruded products are shown in Fig. 1a-f. Extruded products fortified by TB powder exhibited higher ash, crude protein, and carbohydrate content than extrudates obtained from corn and BG flour, which are considered one of the most suitable base materials for extruded products (Reddy et al. 2014) and served as the controls in our study. Fortification of TB powder at different concentrations of 5–10% resulted in increased proximate values, except NFE (soluble carbohydrates), in the extruded products. Extruded snacks with 10% TB powder exhibited 11.7 g% crude protein, which was eventually higher than the commercial extruded cereals that contain 5–8 g% crude protein (Santos et al. 2020). Similarly, the mixture of 10% TB powder resulted in an increase in moisture content (55.2%), ash content (39.1%), crude fat content (74.7%), and crude fiber content (96.8%) in the fortified extruded snacks compared with those in control. Increased moisture content is directly proportionate to feed flow in extruders and texture instability (Jalgaonkar et al. 2019), which was lower in 10% TB extrudates than 5% TB. Moisture content was positively influenced by initial moisture and negatively by extrusion temperature (Basilio-Atencio et al. 2020), which affects the expansion ratio of the extrudates (Ding et al. 2005). Higher ash content is considered an indicator of higher nutritional value in extruded food products (Offiah et al. 2019). An increase in hardness and a decrease in the expansion are characteristic features of additional fiber content (Onwulata et al. 2001), which was evident in the 10% TB mixture. The ultimate aim of food extrusion is to incorporate high fiber and protein content with low fat and energy (Tobias–Espinoza et al. 2019). As per the desired extrusion standards, a low–fat product should contain < 5% fat. In our study, the novel TB extruded products incorporated with 5% and 10% TB contained only 2.0% and 2.4% fat, respectively, compared with control. Increased fat content in the TB-fortified extruded products was due to the higher fat content in TB pods (16%) and seeds (34%) (Singh et al. 2009). In contrast, NFE (soluble carbohydrates) was significantly decreased by 7.4% and 27.7%, respectively, in 10% TB-fortified snacks than those in controls, which is a considerable nutritional concern for consumers.

Antioxidant properties

Figure 2 represents the nonenzymatic antioxidant properties of the extruded samples. Proline and total carotenoids were decreased in TB-fortified products compared to controls. Usually, oxygen and light are attributed to carotenoid instability during the course of processing (Santos et al. 2020). In our study, the increased moisture content in TB extruded products probably resulted in carotenoid instability. Tender TB pods are rich in non–enzymatic antioxidants, such as proline (48–65 mg g–1 protein) in the form of thiazolidine-4-carboxylic acid (Singh et al. 2009). Despite the decrease in total carotenoids and proline content, 10% TB-fortified extrudates exhibited higher total phenolics (2.34 mg g–1 FW), ascorbate content (2.23 mg g–1 FW), total flavonoids (0.16 mg g–1 FW) and reduced glutathione (8.53 µM g–1 FW). Total phenolics increase reasonably during extrusion processing, as it allows easier release of phenolic compounds from the mixture to the end product (Gui and Ryu 2013). Ascorbic acid is one of the most important antioxidative vitamins desired in products for consumer health concerns. In our study, ascorbate content increased with increasing concentrations of TB powder. In general, enhanced ascorbic acid content was due to the stability of both ascorbyl monophosphate and ascorbyl polyphosphate at low expander temperatures and short residency times in the extruder (Riaz et al. 2009). Total flavonoids are key components that increase consumer preference for extruded snacks and have potential health benefits (Kumar and Pandey 2013). The 10% TB mixture exhibited higher flavonoids (0.16 mg g–1 FW) followed by TB 5% and control samples. Proteins and sugars, in combination with flavonoid pigments, encourage Maillard reactions and result in a darkening of the final product under high–pressure extrusion (Guy 2015). We also observed similar results of high flavonoids and darker extrudates with fortified TB powder (10%). The darker appearance is likely due to the higher levels of flavonoids and phenolics in the TB powder. Reduced glutathione was higher in extrudates with fortified TB powder (8.5 and 5.2 µM g–1 FW in 10% and 5% TB powder, respectively) compared to that in controls (4.5 µM g–1 FW). Higher reduced glutathione is also an indicator of better oxidative scavenging during extrusion processing. Therefore, the developed extruded product fortified by 10% TB powder might be considered an antioxidant–rich RTE snack.

Radical scavenging activities (RSAs)

Extrusion influences starch gelatinizing hydrophilic antioxidants and total antioxidant capacities (Yang et al. 2014). Our results revealed higher DPPH, ABTS, FRAP, RP and HRS activities in the extruded products fortified by 10% TB powder than in the control (Fig. 3). DPPH and ABTS contribute hydrogen ions and govern free radical scavenging activities, whereas FRAP determines the ability to reduce Fe3+ to Fe2+. An apparent increase in radical scavenging activities in different biofortified extrudates was previously reported (Valdez-Flores et al. 2016). RP of the extrudates increased significantly in TB powder-fortified RTE snacks. Phenolic compounds and flavonoids depleted into low molecular substances during extrusion at high temperatures reasonably associated with higher RP (Kaur et al. 2012). Similarly, HRS activity was also increased in TB powder-fortified extrudates in our study, which is in accordance with previous reports (Sami 2017).

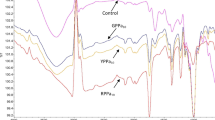

Amino acid profiling

Protein is an essential source for human nutrition, and underutilized TB pods constitute an excellent source of dietary protein. Amino acids are the organic compounds that combine to form proteins and are considered the building blocks of life, varying significantly during processing. In our study, significant variation was observed in the amino acid profiles among the fortified TB extrudates (Fig. 4). Protein content in the extrudates depends upon the quality and quantity of feed material used in the extrusion (Reddy et al. 2014). Figure 4b and c illustrate improved spectra, indicative of higher amino acid profiles in extrudates fortified by TB powder. Sathya and Siddhuraju (2015) reported an increase in essential amino acids in TB pods during processing. In our study, TB-fortified extrudates resulted in higher lysine, leucine, isoleucine, cysteine, threonine, tyrosine, and methionine in comparison to the control (Fig. 4d). Sulfur-containing amino acids, cysteine, and methionine, in particular, are inadequate in corn-based extrudates. Thus, alternate protein-rich fortification using TB powder increases essential amino acid content in the end products. Our study revealed a mere decrease in glutamate, serine, glycine, arginine, alanine, valine, and phenylalanine in the extrudates fortified by TB powder. Essential amino acids such as isoleucine, leucine, lysine, threonine, and valine were reportedly diminished in extruded products compared to those in raw flour (Paes and Maga 2004). Despite the adverse effect of thermal extrusion on essential amino acids, TB powder fortification maintained higher protein content in the extrudates, possibly due to its inherently high protein content.

Scanning electron microscopy (SEM)

Scanning electron microscope (SEM) illustration of the extrudates is represented in Fig. 5. The RTE extruded products fortified by TB powder exhibited both good expansion and diameter. Expansion in the extruded snack was higher in 5% TB powder and reduced in the 10% sample. Internal and external images demonstrated that extrudates fortified by 5% TB powder exhibited improved porosity (Fig. 5b) compared to 10% (Fig. 5c) and control samples (Fig. 5a). Larger pore sizes in the cross-sections were observed in controls without TB powder fortification. The degree of expansion determines the structure, consistency, and quality of the extruded snacks that depend on both processing conditions and raw material composition (Reddy et al. 2014). Figure 5a shows a symmetrical arrangement of carbohydrates and proteins with porous texture; however, Fig. 5a and b show a granular to sheared granular structure with a crispier network (fiber, protein, and starch). The absence of uniform starch granules in extrudates indicates proper gelatinization of the starch (Kaushal et al. 2019).

a–d Scanning electron micrographs of the ready–to–eat extruded snacks fortified by tree bean powder (A. TB 0%, B. TB 5%, and C. TB 10%). A1, B1 and C1 depict external images and A2, B2 and C2 represent internal images. D. Heat map represents the texture parameters of the extrudates fortified by tree bean powder using MATLAB® 8.4. Values are the mean of thirty replications under each treatments (n = 90)

There was a significant difference in ASM and ENT among the extrudates (Fig. 5d). However, extrudates with 10% TB powder possessed moderate ASM and COR values compared to 0% and 5% TB-fortified extrudates. Furthermore, 5% and 10% TB exhibited similar ENT, which was significantly lower than the control (TB 0%). CON and HOM represent differences in pixel and uniformity/hardness, respectively, whereas COR indicates linearity and ASM represents smoothness/roughness of the image. However, ENT exhibited low values for smooth images (Pieniazek and Messina 2017).

Sensory evaluation

Figure 6 depicts the sensory perception of TB-fortified extruded snacks. Samples with 10% TB powder derived better flavor, texture, taste, and overall consumer acceptability (8.2 out of 9 point scales). However, extruded snacks fortified by TB powder received < 8 points out of 9 for the color character, suggesting color improvement by adding permissible food colorants or seasoning agents as indicated by the sensory panels. Consumer preferences always focus on nutritional quality rather than on food color. However, in our study, flavor and nutritional components in the extrudates fortified by TB power were overrated than color indices. Generally, Maillard reactions during extrusion release flavor and aroma in protein-rich extrudates increase the taste and overall acceptability (Forsido et al. 2019). Fortification by starch and protein byproducts resulted in better sensory attributes due to enriched physicochemical and nutritional values (Reddy et al. 2014). Extruded snacks are less perishable, more durable, and more appealing than natural foods with indigenous TB flavor.

Conclusion

This study demonstrated that fortification of TB (5 and 10%) in corn and BG-based RTE extruded snacks significantly influenced the physicochemical, structural, and sensory properties. The novel extruded product fortified by 10% TB exhibited high protein (11.7 g%), dietary fiber (6.1 g%), and ash (12.8 g%) content, which was higher than those in cereal-based commercial extruded snacks. The extruded products contained healthy and balanced fat (< 3%) and NFE (< 70%) content. Sulfur-containing essential amino acids such as cysteine, and methionine, in particular, were increased by TB powder fortification in the extrudates. The 10% TB resulted in darker extrudates with rich flavonoids and antioxidants and an acceptable score for all sensory attributes. Thus, the novel extruded product fortified by 10% TB powder was adjudged as a nutrient-rich RTE extruded snack with future industrial potential.

Data availability

Data and materials will be available if required.

References

Akhtar JS, Malik MA, Alam MT (2015) Extrusion technology used for novel foods production. Int J Eng Dev Res 3:1–7

AOAC (2016) Official methods of analysis of AOAC international, 20th edn. Gaithersburg, Maryland, USA.

Basilio-Atencio J, Condezo-Hoyosa L, Repo-Carrasco-Valenciaa R (2020) Effect of extrusion cooking on the physical-chemical properties of whole kiwicha (Amaranthus caudatus L) flour variety cente5nario: process optimization. LWT–Food Sci Tech 128:109426. https://doi.org/10.1016/j.lwt.2020.109426

Ding QB, Ainsworth P, Tucker G, Marson H (2005) The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice–based expanded snacks. J Food Eng 66:283–289. https://doi.org/10.1016/j.jfoodeng.2004.03.019

Forsido SF, Duguma HT, Lema TB, Sturm B, Hensel O (2019) Nutritional and sensory quality of composite extruded complementary food. Food Sci Nutr 7:882–889. https://doi.org/10.1002/fsn3.940

Gui Y, Ryu GH (2013) The effect of extrusion conditions on the acidic polysaccharide, ginsenoside contents and antioxidant properties of extruded Korean red ginseng. J Ginseng Res 32(2):219–226. https://doi.org/10.5142/jgr.2013.37.219

Guy RCE (2015) Extrusion technologies. In: Encyclopedia of food grains, 2nd edn. 3:268–273. doi: https://doi.org/10.1016/B978-0-12-394437-5.00144-3

Jalgaonkar K, Jha SK, Mahawar MK, Yadav DN (2019) Pearl millet based pasta: optimization of extrusion process through response surface methodology. J Food Sci Technol 56:1134–1144. https://doi.org/10.1007/s13197-019-03574-3

Kaur G, Sharma S, Nagi HPS, Dar BN (2012) Functional properties of pasta enriched with variable cereal brans. J Food Sci Technol 49:467–474. https://doi.org/10.1007/s13197-011-0294-3

Kaushal P, Sharma HK, Singh AP (2019) Effect of extrusion processing on microstructural, physical, functional, antioxidant and textural properties of jackfruit flesh flour, rice flour and pigeon pea flour based extrudates. Int Food Res J 26(3):1045–1058

Korkerd S, Wanlapa S, Puttanlek C, Uttapap D, Rungsardthong V (2016) Expansion and functional properties of extruded snacks enriched with nutrition sources from food processing by–products. J Food Sci Technol 53:561–570. https://doi.org/10.1007/s13197-015-2039-1

Kumar S, Pandey AK (2013) Chemistry and biological activities of flavonoids: an overview. Sci World J. https://doi.org/10.1155/2013/162750

Kuna A, Sahoo MR, Sowmya M, Devi MP, Dasgupta M, Sreedhar M (2018) Nutrient and antioxidant composition in value added products made with underutilized Prunus (Prunus nepalensis) fruits. J Pharmaco Phytochem 7(4):1550–1556

Mercier S, Moresoli C, Mondor M, Villeneuve S, Marcos B (2016) A meta-analysis of enriched pasta: what are the effects of enrichment and process specifications on the quality attributes of pasta? Compr Rev Food Sci Food Saf 15:685–704. https://doi.org/10.1111/1541-4337.12207

Offiah V, Kontogiorgos V, Falade KO (2019) Extrusion processing of raw food materials and by–products: a review. Crit Rev Food Sci Nutr 59(18):2979–2998. https://doi.org/10.1080/10408398.2018.1480007

Oniszczuk A, Kasprzak K, Wójtowicz A, Oniszczuk T, Olech M (2019) The impact of processing parameters on the content of phenolic compounds in new gluten–free precooked buckwheat pasta. Molecules 24(7):1262. https://doi.org/10.3390/molecules24071262

Onwulata CI, Smith PW, Konstance RP, Holsinger VH (2001) Incorporation of whey products in extruded corn, potato or rice snacks. Food Res Int 34(8):679–687. https://doi.org/10.1016/S0963-9969(01)00088-6

Paes MCD, Maga J (2004) Effect of extrusion on essential amino acids profile and color of whole-grain flours of quality protein maize (qpm) and normal maize cultivars. Rev Bras Milho e Sorgo. https://doi.org/10.18512/1980-6477/rbms.v3n1p10-20

Patil H, Tiwari RV, Repka MA (2016) Hot-melt extrusion: from theory to application in pharmaceutical formulation. AAPS PharmSciTech 17(1):20–42. https://doi.org/10.1208/s12249-015-0360-7

Pieniazek F, Messina V (2017) Texture and color analysis of freeze-dried potato (cv. Spunta) using instrumental and image analysis techniques. Int J Food Prop. https://doi.org/10.1080/10942912.2016.1211143

Reddy MK, Kuna A, Devi NL, Krishnaiah N, Kaur C, Nagamalleswari Y (2014) Development of extruded ready–To–Eat (RTE) snacks using corn, black gram, roots and tuber flour blends. J Food Sci Technol 51:1929–1937. https://doi.org/10.1007/s13197-013-1251-0

Riaz MN, Asif M, Ali R (2009) Stability of vitamins during extrusion. Crit Rev Food Sci Nutr 49(4):361–368. https://doi.org/10.1080/10408390802067290

Sami R (2017) Antioxidant properties of peptides from soybean meal protein hydrolysates evaluated by electron spin resonance spectrometry. Adv Environ Biol 11(4):12–18

Santos IL, Schmiele M, Aguiar JPL, Steel CJ, Silva EP, Souza F, das C do A, (2020) Evaluation of extruded corn breakfast cereal enriched with whole peach palm (Bactris gasipaes, Kunth) flour. Food Sci Technol 40(2):458–464. https://doi.org/10.1590/fst.04019

Sathya A, Siddhuraju P (2015) Effect of processing methods on compositional evaluation of underutilized legume, Parkia roxburghii G. Don (yongchak) seeds. J Food Sci Technol 52(10):6157–6169. https://doi.org/10.1007/s13197-015-1732-4

Singh Salam J, Singh PK, Dutta BK, Sahoo UK (2009) Chemical composition and nutritive indices in Parkia roxburghii G. Don, a leguminous plant of India. Indian J Agric Biochem 22(2):87–93

Tobias-Espinoza JL, Amaya-Guerra CA, Quintero-Ramos A, Pérez-Carrillo E, Núñez-González MA, Martínez-Bustos F, Meléndez-Pizarro CO, Báez-González JG, Ortega-Gutiérrez JA (2019) Effects of the addition of flaxseed and amaranth on the physicochemical and functional properties of instant–extruded products. Foods 8(6):183. https://doi.org/10.3390/foods8060183

Udenigwe CC, Aluko RE (2011) Chemometric analysis of the amino acid requirements of antioxidant food protein hydrolysates. Int J Mol Sci 12(5):3148–3161. https://doi.org/10.3390/ijms12053148

Valdez-Flores M, Germán-Báez LJ, Gutiérrez-Dorado R, Medina-Godoy S, Norzagaray-Valenzuela C, Hernández-Verdugo S, Reyes-Moreno C, Valdez-Ortiz A (2016) Improving bioactivities of Jatropha curcas protein hydrolysates by optimizing with response surface methodology the extrusion cooking process. Ind Crops Prod 85(2016):353–360. https://doi.org/10.1016/j.indcrop.2015.12.084

Yang L, Zhang H, Cheng L, Gu Z, Hua D, Qi X, Qian H, Wang L (2014) Effect of extrusion on the hydrophilic antioxidant capacity of four whole grains. J Food Nutr Res 2(2):80–87. https://doi.org/10.12691/jfnr-2-2-4

Acknowledgements

This study was supported by the Department of Biotechnology (DBT), Govt. of India, under the DBT twinning project ‘Nutraceutical properties of underutilized fruits and vegetables in northeastern hill region of India’ (BT/336/NE/TBP/2012). The authors acknowledge the support of the RUSKA Laboratory, Hyderabad, India and MFPI - QC Lab, PJTSAU, Hyderabad for skillful assistance with SEM and amino acid profiling, respectively. The infrastructure facility provided by the Director and Joint Director, Indian Council of Agricultural Research (ICAR) Complex for NEH Region, Manipur Centre, India and the Vice-Chancellor and Director of Research, PJTSAU, Hyderabad, India, are gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

Manas Ranjan Sahoo: Conceptualization, Validation, Writing- original draft, Writing- review and editing, Funding acquisition, Supervision. Aparna Kuna: Conceptualization, Methodology, Validation, Writing- review and editing, Funding acquisition, Supervision. Mayengbam Premi Devi: Methodology, Investigation, Formal analysis. Mandarapu Sowmya: Methodology, Investigation, Product development and validation. Madhumita Dasgupta: Methodology, Investigation, Formal analysis, Validation, Writing- review and editing.

Corresponding author

Ethics declarations

Conflict of interest

We have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sahoo, M.R., Kuna, A., Devi, M.P. et al. Fortification of ready–to–eat extruded snacks with tree bean powder: nutritional, antioxidant, essential amino acids, and sensory properties. J Food Sci Technol 59, 2351–2360 (2022). https://doi.org/10.1007/s13197-021-05251-w

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-021-05251-w