Abstract

The effect of incorporating different proportions (5, 10, 15 and 20%) of cashew nut protein concentrate (CNPC) on the physicochemical properties, antioxidant activity and consumer acceptability of bread was investigated. Substitution of wheat flour with CNPC increased the water and oil absorption capacity, swelling capacity, peak and final viscosities. Substitution of CNPC in wheat bread significantly increased the protein (12.69–22.04 g/100 g), ash, crude fiber, calcium, magnesium, iron (2.09–3.36 mg/100 g), phosphorus and zinc (0.79–1.57 mg/100 g) content, while carbohydrate value decreased. Substitution of wheat flour with CNPC in bread increased the loaf weight while specific volume decreased (4.36–2.21 cm3/g). Acceptable bread was prepared with up to 15% CNPC; which contained the highest total phenolics (2.64 mg GAE/g), DPPH radical scavenging activity (71.22 µmol TE/100 g), ferric reducing antioxidant power (427.77 µmol TE/100 g) and ABTS radical scavenging activity (195.68 µmol TE/100 g) than the 100% wheat bread (1.28 mg GAE/g, 40.81 µmol TE/100 g, 375.62 µmol TE/100 g and 154.02 µmol TE/100 g).

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bread is an important stable food consumed by old and young people all over the world. Bread is prepared by baking the dough prepared with wheat flour, water, yeasts, salt, sugar and shortening ages (Mondal and Datta 2008). According to Haber et al. (2019), the most popular yeast-leavened bread is commonly prepared from wheat flour. Wheat flour is rich in gluten which is responsible for the viscoelastic properties of the dough. However, bread is mostly prepared from refined wheat flour deficient in essential amino acids, micronutrient and antioxidant.

There is an increasing demand for novel and healthy baked products by consumers who are now conscious of their well-being. This said, there are attempts to enrich wheat flour or other cereals with functional ingredients such as plant-derived protein in order to meet the health interest of the people’s diet. Enrichment of wheat flour with cashew protein in bread production is one of such sources.

Cashew (Anarcadium occidentale), a kidney or heart-shaped fruit is extensively grown in Africa and West Indies. In Nigeria, cashew nut is one of the major nuts of economic importance through exportation. Cashew nut is relatively rich in protein (~ 27.31%) with adequate amount of amino acids, fat (~ 34.95%), and dietary fiber, minerals (especially calcium, potassium, magnesium, sodium and zinc) (Vincent et al. 2009). Cashew nuts are highly nutritive which has made it to gain wide applications in the bakery and confectionary industry as dessert in cakes, pastries, cookies and cereal bars (Gadani et al. 2017; Emelike and Akusu 2019). The consumption of cashew nut has been attributed with reduced risk of cardio-vascular diseases, type II diabetes and colon cancer (Mukuddem-Petersen et al. 2005).

Plant-derived proteins have received increased attention as a dietary supplement because of consumer demand for healthy foods and their low cost (Henchion et al. 2017). Plant-derived proteins serve as functional ingredients in food products due to their nutritional, antioxidant and functional properties than flour (Aydemir and Yemenicioglu 2013). The inclusion of plant-derived protein concentrate in wheat-based bread has been studied to an extent (Chinma et al. 2015; Alzuwaid et al. 2021; Franco-Miranda et al. 2017; Coşkun et al. 2020). To the authors’ knowledge, information is scanty on the inclusion of cashew nut protein concentrate to enrich wheat bread. The purpose of this study was to determine the effect of incorporating of cashew nut protein concentrate on the physicochemical properties, antioxidant activity, and consumer acceptability of bread.

Materials and methods

Materials

Cashew kernels were obtained from Olam Nigeria Limited, Kwara State, Nigeria. Wheat flour (Dangote) and other baking ingredients (granulated sugar, salt, shortening, and food grade dry yeast (Saccharomyces cerevisiae) were purchased from Kure Market Minna, Nigeria. The reagents used in the study were of analytical grade.

Cashew nut powder (CNP) preparation

A standard method Sze-Tao and Sathe (2004) was employed for the preparation of CNP. The cashew nut was ground using a kitchen grinder. Cashew nut flakes were extracted with the use of n-hexane as solvent in ratio 1:10 (flakes to solvent). The extraction was done for 1 h with continuous magnetic stirring. Defatted cashew nut flakes were spread on aluminum foil and dried for 6 h in a fume cupboard to get rid of residual n-hexane. Dried defatted cashew flakes was then milled into a fine powder, pack in a plastic containers.

Preparation of cashew nut protein concentrate (CNPC)

The CNPC was prepared using alkaline isoelectric precipitation method as described in a standard procedure Wagner et al. (2000). Two different cashew powders were dispersed in distilled water at ratios 1:5 and 1:10, and the pH adjusted to 7.0 and 9.0, using NaOH (0.1 N). CNPC slurry was stirred continuously for 60 min at room temperature, and then centrifuged at 1000 × g for 30 min. Water was added to the cashew nut filtrate to make a slurry again and the pH adjusted as described above, and cold-centrifugation was repeated. The two supernatants were mixed together and divided into two different pHs (3.5 and 4.5) by adding HCl (0.1 N) and allowing it to stay for 2 h at 4 °C, after which it was cold-centrifuged as described above. The supernatant was discarded to obtain cashew nut protein slurry. The process of suspension and cold-centrifugation were repeated to cashew nut protein concentrate slurry, which was freeze-dried (Alpha 2–4, Martins Christ, Germany) for 12 h, blended and passed through a 100-mesh screen, packaged and stored under refrigeration condition.

Formulation of wheat flour (WF)-CNPC blends

The WF and CNPC were blended at different proportions (100: 0; 95: 5; 90:10; 85: 15 and 80: 20). The choice of the levels (5–20%) of inclusion of the protein concentrate was premised on a previous study where the inclusion of up to 20% protein concentrate did not significantly alter the sensory properties of bread and contributed to keeping the specific volume during 21 days of storage (Zorzi et al. 2020). A uniform blend of composite flours was achieved with aid of a Kenwood mixer (Speed 6 for 5 min).

Evaluation of functional properties

Water absorption capacity (WAC) and oil absorption capacity (OAC) of wheat flour and cashew nut protein concentrate blends were analyzed according to the AACC method 56–20 (AACC 2000). Two grams each sample (MO) was dispersed in 40 mL of deionised water or refined sunflower oil and vortexed for 10 min. The slurry was then centrifuged for 15 min at 1000 × g at 20 °C and the supernatant decanted. The centrifuge tubes were then inverted on a clean paper towel for 5 min and the residue weighed (M2). WAC and OAC were calculated as follows:

where Mo and M2 is the sample weight (db) and weight of wet or oily residue, respectively.

Swelling capacity (SC) of composite blends was according to Abu et al. (2005). The blends was first dispersed in deionised water to form a slurry (at ratio 1:20, w/v) which was then vortexed for 60 s. The slurry was then heated in a water bath at 90 °C for 30 min and mixed intermittent. The heated slurries were placed under running water to cool and in an ice bath for 10 min. The cooled slurries were centrifuged at 4500 × g for 10 min (20 °C), and the samples stood for 5 min at 24 °C. The residue was weighted after decanting the supernatant. SC (%) of the sample was calculated as: weight of the residue/initial sample weight × 100.

Pasting analysis

The pasting characteristics of the samples were analyzed using a rapid visco analyzer (RVA, Newport Scientific Pty Ltd., New South Wales 2102, Australia) as described by Chinma et al. (2016). A 2.5 g of each sample was used following standard pasting conditions described by the Author. The RVA parameters analyzed include: peak, final, break down and set back viscosities, pasting temperature and peak time were recorded.

Bread making

A standard procedure (straight dough method) previously described by Mohammed et al. (2012) was employed in bread making with slight modification in terms of the ingredients. The bread recipe: 5 g of sugar (Dangote Refinery Plc, Lagos, Nigeria) and 2 g of salt (Dangote Refinery Plc, Lagos, Nigeria), 5 g dry yeast (S. cerevisiae) (Angel Yeast Co., Yichang 140 Hubei, China), 10 g of margarine (Blue 138 Band, Unilever Plc., Lagos, Nigeria), and composite flour (200 g each). The ingredients and composite flour were thoroughly mixed in a bowl to make the dough. The prepared dough was allowed to rest for 30 min), weighed, cut into uniform sizes, kneaded and molded before placing in a greased pan; the dough was leave to proof at 35 °C for 36 min. The leavened dough was baked in an oven (Gallenkamp, UK) at 180 °C for 35 min. Bread samples were cooled under room temperature for 3 h before packaging in polyethylene bags for further analyses.

Proximate analysis

The moisture, ash, fat, protein and crude fiber was analyzed using standard method (AOAC 2005). Moisture value of breads was analyzed by drying at 105 °C in an oven (Gallenkamp 300 series, Widnes, Cheshire, UK) until constant weight (method No. 925.09B). Micro-Kjeldahl method was employed for protein analysis, after digestion, distillation and titration. The nitrogen value was corrected and multiplied by a factor of 6.25 to obtain the protein value (method No. 992.23). Ash content was analyzed by incinerating sample in a muffle furnace at 550 °C for 24 h (method No. 923.03). Fat content was determined by extracting the sample with petroleum ether using Soxhlet extraction apparatus (method No. 920.39C), while crude fiber was determined by digesting the sample with diluted acid and alkali (method No. 962.09E). Carbohydrate value was determined by the difference (AOAC 2005).

Mineral analysis

Mineral analysis of samples was determined using standard method (AOAC 2005). The minerals (calcium (Ca), magnesium (Mg), iron (Fe) and zinc (Zn)) were determined by atomic absorption spectrophotometry (Perkin–Elmer Model 2380, USA) while phosphorus (P) was determined using flame photometric method.

Total phenolic content (TPC) and antioxidant properties

Total phenolic content was determined using the Folin–Ciocalteau method previously described by Singleton and Rossi (1965), and results were expressed as milligrams of gallic acid equivalent (mg GAE) per 100 g of dried sample. Ferric reducing antioxidant power was determined following a standard procedure (Beta et al. 2005), and results expressed as mmol trolox equivalent (TE) per g sample. The DPPH (1,1-diphenyl-2-picryl-hydrazil) radical scavenging activity was determined according to Silva et al. (2005). The ABTS radical scavenging activity was determined using a standard method (Cai et al. 2004).

Sensory evaluation

The sensory properties (aroma, appearance, crust colour, taste, texture and overall acceptability) of the bread samples were evaluated using a 9-point Hedonic scale, where 1 and 9 represent ‘dislike extremely’ and ‘like extremely’, respectively. The bread samples were evaluated by a semi-trained panel consisting of 20 members who are regular consumers of bread. Bread samples were allowed to cool after baking and presented in coded plates. Portable water was provided to each participant to rinse their mouth before sensory testing and between samples.

Statistical analysis

Data generated from triplicate analyses were subjected to ANOVA (analysis of variance) using SPSS version 20 (IBM, Armonk, USA). The differences among the means were separated at 5% probability level (Turkey’s Test).

Results and discussion

Functional properties of wheat flour-cashew nut protein concentrate blends

Wheat flour-CNPC blends had higher WAC and OAC than the control (wheat flour) (Table 1). Higher WAC of wheat flour-CNPC blends than 100% wheat flour may be attributed partly to higher protein value of CNPC. Ability of flours to retain water has been attributed to higher protein content (Jideani and Jideani 2011). Higher OAC of the wheat-CNPC blends than 100% wheat flour may be attributed partly to the presence of non-polar amino acid residues dominate in cashew nut proteins. The mechanism of oil absorption in food materials involves capillarity interaction which allows the absorbed oil to be retained, (Du et al. 2014), which relatively depends on the amino acid composition, lipophilicity and surface polarity (Adebiyi et al. 2016). The interaction between flour and oil or water is one of the major factors in the use of flour as a food ingredient. The WAC of flour influences its hydration and gluten network development and subsequently affects bread quality (Millar et al. 2019). Good OAC of flour is an indication for the improvement of mouth-feel and retention of flavor in bakery products (Ahmed et al. 2019). The amount of water or oil absorbed by flour is very important in measuring dough quality, texture and subsequent taste of bread (Yadahally et al. 2012). Swelling capacity of the wheat flour-CNPC blends were significantly higher than the control and increased with increasing level of CNPC (except the blend containing 15% CNPC). Higher SC of the composite blends could suggest high water affinity indicating improved flour functionality (Olukomaiya et al. 2020).

Pasting characteristics is an important parameter that provides knowledge about the application of flour or starch in a food product. Pasting characteristics gives information about the behavior of about the changes in the paste viscosity of flour or starch as temperature changes. Substitution of wheat flour with CNPC increased the peak, breakdown, final, setback (except the blend containing 15% CNPC) viscosities of the blends compared to 100% wheat flour, while trough viscosity (except the blend containing 15% CNPC), peak time and peak temperature decreased (Table 1). Pasting behaviour has been reported to influence the distribution, size and structure of starch, lipid, protein and amylose contents, and water binding capacity (Wu et al. 2013). This put together, may account for the changes recorded in the pasting properties of wheat flour-CNPC blends. The blend containing 15% CNPC had the highest peak (178.80 RVU) and trough viscosity (121.54 RVU) than other samples. According to Morad et al. (1980) high peak and trough viscosity may enhance gel forming abilities of the flour. The developing and setting of the gas network during proofing and baking may be attributed to the increase in gel forming abilities which in turn improves the technological properties of the bread (Alvarez-Jubete et al. 2010).

Physicochemical properties of wheat flour-cashew nut protein concentrate breads

Substitution of wheat flour with cashew nut protein concentrate impacted on the chemical composition of the resulting breads (Table 2). The result trend of the chemical composition of wheat-cashew nut protein concentrate breads recorded is in line with previous reports on wheat-rice bran protein concentrate composite breads (Chinma et al. 2015) and wheat-apricot bread (Dhen et al. 2018). Moisture content of bread influences the physical, sensory and microbiological properties of the bread. Certain moisture level is required in bread to keep it fresh and moist to prevent drying out while on the shelf. Moisture value of 100% wheat bread was 28.45%, which decreased with increasing level of CNPC (up to 10% CNPC), and thereafter increased (p ≥ 0.05) from 29.13 to 29.40% (20% CNPC). Protein content of bread containing 5%, 10%, 15% and 20% CNPC significantly increased by 44.60%, 54.69%, 64.85% and 73.68%, respectively, compared to 100% wheat bread. The significant increase in protein value could be attributed to high content in cashew nut. Nuts are known to contain high quality proteins which are of health benefits especially to group of people with special caloric and glycemic requirements (Obese or diabetic patients). Similar trend was observed for ash, dietary fiber and fat contents of the wheat-CNPC breads which increased with increasing proportion of CNPC. Carbohydrate content of wheat-CNPC breads were significantly lower compared to the control. Carbohydrate content of breads containing 5%, 10%, 15% and 20% CNPC were reduced by 10.79%, 11.41%, 21.35% and 24.89%, respectively. The reduction in carbohydrate content could be attributable to the increase in other constituents (ash, fat and protein), since carbohydrate content was calculated by difference.

Addition of CNPC in bread significantly increased calcium, magnesium, iron, phosphorus and zinc contents from 44.50 to 49.26 mg/100 g, 76.27 to 84.61 mg/100 g, 2.09 to 3.36 mg/100 g, 240.41 to 255.74 mg/100 g, and 0.79 to 1.57 mg/100 g respectively. Higher contents of minerals recorded in wheat-CNPC breads than control may be attributed to high content of mineral elements present in cashew nut (Aremu et al. 2006; Vincent et al. 2009). The presence of minerals can be of nutritional benefits in helping to build the body, reduce nutritional deficiencies, maintaining regular heart rate and blood sugar regulation (Saris et al. 2000).

Physical and properties of bread

The 100% wheat bread had the lowest loaf weight (55.71 g), while bread containing 20% CNPC had the highest loaf weight (78.15 g) (Table 3). Loaf weight of the breads increased with the increasing level of CNPC, which may be attributed to the ability of the dough to less gas retention in the dough or the ability of the dough to retain a reasonable quantity of water. The higher protein content of the composite breads may also account for the increase in bread weight (Jideani and Jideani 2011). This is in accordance with the result of Dhen et al. (2018) for apricot kernel enriched bread.

Loaf volume (cm3) of breads decreased significantly from 242.29 cm3 (for control bread) to 172.71 cm3 (for bread containing 20% CNPC) with the addition of cashew nut protein concentrate. Similarly, the specific volume of breads decreased from 4.36 cm3/g (for control bread) to 2.21 cm3/g (for bread containing 20% CNPC). Bread volume and specific volume decreased with an increase in the proportion of CNPC. The decrease in bread volume and specific volume may be attributed partly to dilution of wheat dough gluten matrix due to addition of the non-gluten material, CNPC. The 100% bread crumb had a well packed gluten network outlook compared to the composite breads (especially the 15% and 20% CNPC while the 15% and 20% CNPC) with some pores or loose gluten network appearance on the crumbs (Fig. 1). The observed reductions in bread volume/ specific volume of the composite breads are in a good agreement with previous reports (Greene and Bovell-Benjamin 2004; Chinma et al. 2015).

Cross-section of bread samples a = 100% wheat bread (control); b = 95% wheat flour: 5% cashew nut protein concentrate bread; c = 90% wheat flour: 10% cashew nut protein concentrate bread; d = 85% wheat flour: 15% cashew nut protein concentrate bread; e = 80% wheat flour: 20% cashew nut protein concentrate bread

Sensory properties of wheat-CNPC breads

Results of the sensory properties of wheat-CNPC composite breads and control are presented in Table 3. Significant differences were recorded in aroma and appearance (except for breads containing 15% and 20% CNPC) of the wheat-CNPC breads when compared to the control. The 15% CNPC bread had the highest aroma and appearance scores. Statistically, no significant difference was recorded in the colour of wheat-CNPC breads when compared to the control, even though colour scores of breads decrease with increase in the proportion of CNPC. Taste scores of composite breads increase with increasing proportion of CNPC, which decreased upon substitution of 20% CNPC. Taste score of 100% wheat bread differed from other bread samples (except bread containing 20% CNPC), but there was no significant difference in taste between bread containing 10% CNPC and 15% CNPC. Bread containing 15% CNPC had the highest taste score (7.73) than other composite breads (6.95–7.40) as well as control (7.25). Texture of composite breads statistically did not differ from the control. The composite breads had higher texture scores than the control. The majority of the sensory panelists reported that the texture of the composite breads was softer than the 100% wheat bread, which may be due to the dilution of the gluten, and the high WAC recorded in the composite flours as mentioned earlier, which improved the texture of the composite bread. In terms of overall acceptability, bread containing 15% CNPC had the highest overall acceptability score (8.20) compared to other composite bread and the control.

Total phenolic content (TPC) and antioxidant property of most acceptable composite bread and 100% wheat bread

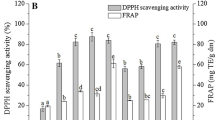

Total phenolic content and antioxidant activity of the most acceptable composite bread (bread containing 15% CNPC) and the control sample was evaluated, and results presented in Table 4. TPC, DPPH, FRAP and ABTS of breads ranged from 1.28 to 2.64 mg GAE/g sample, 40.81 to 71.22 µmol TE/100 g, 375.62 to 427.77 µmol TE/100 g and 154.02 to 195.68 µmol TE/100 g respectively (Table 4). The TPC, DPPH, FRAP and ABTS of bread containing 15% CNPC increased by 106.25%, 74.52%, 13.88% and 27.05% respectively, compared to 100% wheat bread may be due to high phenolic compounds present in CNPC. Phenolic compounds exert high antioxidant activity in food systems; and have beneficial health properties. Higher antioxidant activity of the most acceptable bread may also be attributed to the level of Maillard reaction components (amino acid in CNPC). Maillard reaction products have been reported to have free radical-scavenging activity (EL-Massry et al. 2003).

Conclusion

This study determined the effect of inclusion of cashew nut protein concentrate on the physicochemical characteristics, antioxidant activity, and consumer acceptability of bread. Incorporation of CNPC in wheat-based bread significantly increased the protein, ash, dietary fiber, and mineral contents and antioxidant activity of the composite breads compared to the control. Addition of cashew nut protein concentrate in wheat bread influenced physical characteristics of the bread. The 15% cashew nut protein concentrate bread was acceptable compared to the control. Future studies are recommended to determine the rheological and textural properties of the breads, and identify the phenolic compounds present in the product.

Abbreviations

- CNP:

-

Cashew nut Powder

- CNPC:

-

Cashew nut protein concentrate

- OAC:

-

Oil absorption capacity

- RVA:

-

Rapid visco analyzer

- SC:

-

Swelling capacity

- WAC:

-

Water absorption capacity

- WF:

-

Wheat flour

References

AACC (2000) Approved methods of the AACC international, methods 44–17, 76–13, 08–16, 32–40 and 35–05, 10th edn. The Association AACC, St. Paul, MN

Abu JO, Muller K, Duodu KG, Minnaar A (2005) Functional properties of cowpea (Vigna unguiculata L. Walp) flours and pastes as affected by γ-irradiation. Food Chem 93(1):103–111. https://doi.org/10.1016/j.foodchem.2004.09.010

Adebiyi JA, Obadina AO, Mulaba-Bafubiandi AF, Adebo OA, Kayitesi E (2016) Effect of fermentation and malting on the microstructure and selected physicochemical properties of pearl millet (Pennisetum glaucum) flour and biscuit. J Cereal Sci 70:132–139

Ahmed MI, Sulieman AA, Xu X, Na Y, Mahdi AA, Mohammed JK (2019) Effect of preprocessing methods on the physicochemical and functional properties of koreeb (Dactyloctenium aegyptium) seeds. J Cereal Sci 87:280–285

Alvarez-Jubete L, Arendt EK, Gallagher E (2010) Nutritive value of pseudocereals and their increasing use as functional gluten-free ingredients. Trends Food Sci Tech 21(2):106–113. https://doi.org/10.1016/j.tifs.2009.10.014

Alzuwaid NT, Pleming D, Fellows CM, Sissons M (2021) Fortification of durum wheat spaghetti and common wheat bread with wheat bran protein concentrate-impacts on nutrition and technological properties. Food Chem 334(1):127497. https://doi.org/10.1016/j.foodchem.2020.127497

AOAC (2005) Association of official analytical chemists. In W. Horwitz W, Latimer GW Jr. (Eds.), Official methods of analysis 18th ed, Gaithersburg, MD: AOAC International, pp 1e14

Aremu MO, Olonisakin A, Bako DA, Madu PC (2006) Compositional studies and physicochemical characteristics of cashew nut (Anarcadium occidentale) flour. Pak J Nutr 5:328–333

Aydemir LY, Yemenicioğlu A (2013) Potential of Turkish Kabuli type chickpea and gen and red lentil cultivars as source of soy and animal origin functional protein alternatives. LWT-Food Science and Technology 50:686–694

Beta T, Nam S, Dexter JE, Sapirstein HD (2005) Phenolic content and antioxidant activity of pearled wheat and roller-milled fractions. Cereal Chem 82:390–393

Cai Y, Luo Q, Sun M, Corke H (2004) Antioxidant activity and phenolic compounds of traditional Chinese medicinal plants associated with anticancer. Life Sci 74:2157–2184

Chinma CE, Anuonye JC, Ocheme OB, Abdullahi S, Oni S, Yakubu CM, Azeez SO (2016) Effect of acha and bambara nut sourdough flour addition on the quality of bread. LWT 70:223–228

Chinma CE, Ilowefah M, Shammugasamy B, Mohammed M, Muhammad K (2015) Effect of addition of protein concentrates from natural and yeast fermented rice bran on the rheological and technological properties of wheat bread. Int J Food Sci Technol 50:290–297

Coşkun Ö, Pehlivanoğlu H, Gülseren İ (2020) Pilot scale assessment for seed protein enrichment of gluten-free breads at varying water content levels and after protein modification treatments. J Food Process Preserv 44:e14512

Du SK, Jiang H, Yu X, Jane JL (2014) Physicochemical and functional properties of whole legume flour. LWT-Food Sci Technol 55:308–313

Dhen N, Rejeb IB, Boukhris H, Damergi C, Gargouri M (2018) Physicochemical and sensory properties of wheat-Apricot kernels composite bread. LWT 95:262–267

EL-massry K, Farouk A, EL-ghorab A, Volatile H (2003) Constituents of glutathione–ribose model system and its antioxidant activity. Amino Acid, 24:171–177.

Franco-Miranda H, Chel-Guerrero L, Gallegos-Tintoré S, Castellanos-Ruelas A, Betancur- Ancona D (2017) Physicochemical, rheological, bioactive and consumer acceptance analyses of concha-type Mexican sweet bread containing Lima bean or cowpea hydrolysates. LWT 80:250–256

Gadani BC, Miléski KML, Peixoto LS, Agostini JS (2017) Physical and chemical characteristics of cashew nut flour stored and packaged with different packages. Food Sci and Technol Campinas 37(4):657–662

Emelike NJT, Akusu MO (2019) Physicochemical, mineral and sensory characteristics of cashew nut milk. Int J Food Sci Biotechnol 4(1):1–6

Greene JL, Bovell-Benjamin AC (2004) Macroscopic and sensory evaluation of bread supplemented with sweet-potato flour. J Food Sci 69(4):167–173

Haber M, Mishyna M, Martinez JI, Benjamin O (2019) The influence of grasshopper (Schistocerca gregaria) powder enrichment on bread nutritional and sensorial properties. LWT 115:108395

Henchion M, Hayes M, Mullen AM, Fenelon M, Tiwari B (2017) Future protein supply and demand: strategies and factors influencing a sustainable equilibrium. Foods 6:53

Jideani IA, Jideani VA (2011) Developments on the cereal grains Digitaria exilis (acha) and Digitaria iburua (iburu). J Food Sci Technol 48:251–259

Millar KA, Barry-Ryan C, Burke R, McCarthy S, Gallagher E (2019) Dough properties and baking characteristics of white bread, as affected by addition of raw, germinated and toasted pea flour. Innov Food Sci Emerg Technol 56:102189

Mohammed I, Ahmed AR, Senge B (2012) Dough rheology and bread quality of wheat–chickpea flour blends. Ind Crops Prod 36(1):196–202

Mondal A, Datta A (2008) Bread baking–a review. J Food Eng 86:465–474

Morad M, Leung H, Hsu D, Finney P (1980) Effect of germination on physicochemical and bread-baking properties of yellow pea, lentil, and faba bean flours and starches. Cereal Chem 57:390–396

Mukuddem-Petersen J, Oosthuizen W, Jerling JC (2005) A systematic review of the effects of nuts on blood lipid profiles in humans. J Nutr 135:2082–2089

Olukomaiya OO, Adiamo OQ, Fernando WC, Mereddy R, Li X, Sultanbawa Y (2020) Effect of solid-state fermentation on proximate composition, anti-nutritional factor, microbiological and functional properties of lupin flour. Food Chem 315:126238

Saris NE, Mervaala E, Karppanen H, Khawaja JA, Lewenstam A (2000) Magnesium: an update on physiological, clinical, and analytical aspects. Clin Chim Acta 294:1–26

Silva BA, Ferreres F, Malva JO, Dias AC (2005) Phytochemical and antioxidant characterization of Hypericum perforatum alcoholic extracts. Food Chem 90:157–167

Singleton VL, Rossi JA (1965) Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am J Enol Vitic 16:144–158

Sze-Tao KWC, Sathe SK (2004) Functional properties and in-vitro digestibility of almond (Prunus dulcis L) protein isolate. Food Chem 69:153–160

Vincent OS, Adewale IT, Dare O, Rachael A, Bolanle JO (2009) Proximate and mineral composition of roasted and defatted cashew nut (Anarcadium occidentale) flour. Pakistán J Nutr 8:1649–1651

Wagner JR, Sorgentini DA, Anon MC (2000) Relationship between solubility and surface hydrophobicity as an indicator of modification during preparation processes of commercial and laboratory prepared soy-protein isolates. J of Agri Food Chem 48:3159–3165

Wu F, Chen H, Yang N, Wang J, Duan X, Jin Z, Xu X (2013) Effect of germination time on physicochemical properties of brown rice flour and starch from different rice cultivars. J Cereal Sci 58:263–271

Yadahally NS, Vadakkoot BS, Vishwas MP, Vasudeva S (2012) Nutrients and antinutrients in cowpea and horse gram flours in comparison to chickpea flour: evaluation of their flour functionality. Food Chem 131:462–468

Zorzi CZ, Garske RP, Flôres SH, Thys RCS (2020) Sunflower protein concentrate: a possible and beneficial ingredient for gluten-free bread. Innov Food Sci Emerg Technol 66:102539

Acknowledgements

The authors thank Mr Yohanna for his technical support.

Author information

Authors and Affiliations

Contributions

SA: Conceptualization, Data curation, Formal analysis, Writing-original draft and revision of reviewed manuscript. CC: Conceptualization, Reading of original draft of manuscript, reviewing and editing of original and reviewed manuscript. AM: Data curation, Formal analysis, analyses of data. RA: Data curation, Formal analysis, analyses of data. FK: Reading of original draft of manuscript, Review, editing and revision of reviewed manuscript. AY: Methodology, Formal analysis, analyses of data.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azeez, S., Chinma, C.E., Makanjuola, A.J. et al. Effect of cashew nut protein concentrate substitution on the physicochemical properties, antioxidant activity and consumer acceptability of wheat bread. J Food Sci Technol 59, 2200–2208 (2022). https://doi.org/10.1007/s13197-021-05233-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-021-05233-y