Abstract

Red-coloured fruit juices, due to their main bioactive components such as phenolic compounds and anthocyanins, have gained much attention. Present study was focused on the evaluation of pasteurization (at 90 °C for 30 s), mild heat treatment (at 60 °C for 8 min), sonication (at amplitude level of 42.7 μm and 25 °C for 8 min) and thermosonication (at amplitude level of 42.7 μm and 60 °C for 8 min) preservation techniques, on physico-chemical and safety attributes of red grape, pomegranate and sour cherry juices. The results indicated that all four treatment methods, had insignificant effects on brix, pH and titratable acidity of the treated fruit. Furthermore, while pasteurization had significant (p < 0.05) effects on the loss of vitamin C, total phenolic, total anthocyanin contents, and antioxidant activity of all juices, the sonication and mild heat treatment had minimum effects on the vitamin C and total anthocyanin contents of the juices. Among all four selected preservative methods, thermosonication significantly increased total phenolic content of three juices and reduced existed aerobic and coliform bacteria, moulds and yeasts population of the treated fruit juices as compared to that of the untreated, mild heat treated and sonicatioted samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fruits and vegetables are the main sources of bioactive compounds which have vital role in prevention of many diseases. Numerous epidemiological studies have indicated that daily consumption of fruits reduces risks of degenerative diseases such as cancer and coronary heart disease (Tiwari et al. 2010). The protective effects of fruits against these diseases are mainly attributed to their health promoting phytochemicals such as carotenoids, flavonoids, phenolic compounds, vitamins and various antioxidant phytonutrients (Ahdno and Jafarizadeh-Malmiri 2015; Rawson et al. 2011). Anthocyanins are plant pigments which present mainly in red coloured fruits such as pomegranate, sour cherry and red grape. Anthocyanins are known as antioxidant which has also high anti-inflammatory and platelet inhibitory activities (Tiwari et al. 2009).

The anthocyanin type and content of fruits varies largely with genotype and their variety. The most abundant anthocyanins in red grapes are the glucoside forms of cyanidin, malvidin, delphinidin, peonidin, petunidin and pelargonidin (Tiwari et al. 2010). The main anthocyanin compounds in sour cherry juice are cyanidin-3-glucosylrutinoside, cyanidin-3-glucosylrutinoside, cyanidin-3-rutinoside, cyanidin-3-sophoroside, cyanidin-3-glucoside and peonidin-3-rutinoside (Damar and Eksi 2012). Cyanidin-3-glucoside, cyanidin-3,5-diglucoside, and delphindin-3-glucoside are the main anthocyanins present in pomegranate (Çam et al. 2009).

Fruits are highly perishable and have short shelf life. Therefore, to ensure their year-round continuous supply, fruits mainly have to be processed into juices. Fruit juices are susceptible to chemical, physical and microbiological changes (Abdullah and Chin 2014). The main concern about raw fruit juices is microbial contamination with fungi (yeasts and moulds) and bacteria (acid-tolerant and pathogenic) which decreases nutritional and sensorial properties as well as safety aspects. On the other hand, fruit juices are thermally sensitive. Thermal processes such as pasteurization and sterilization are the main and commercial preservation methods as compared to other food preservation techniques, which have destructive effects on enzymes and microorganisms, and ensure food safety and long shelf life (Dubrovic et al. 2011). Colour is an important attribute related to the visual appeal and the quality of the fruit juices (Ahdno and Jafarizadeh-Malmiri 2017). Anthocyanins, as natural pigments presence in red coloured fruit juices, are highly unstable and very susceptible to degradation. Their stability is strongly influenced by two categories parameters namely; processing conditions (e.g. temperature, pH, light and oxygen) and presence of biological and other bioactive compounds (e.g. enzymes, flavonoids, proteins and metallic ions) (Tiwari et al. 2010).

Consumer demand for safe and nutritious fruit juices has led to the development of numerous non-thermal preservation techniques such as high pressure processing, irradiation, pulsed electric fields, power ultrasound, ozone and oscillating magnetic fields, which avoid unwanted effects of thermal processing techniques (Rawson et al. 2011; Tiwari et al. 2009). Several studies have been completed on utilizing non-thermal processing techniques on fruit juices treatment and the obtained results revealed that apart from ozone, the other mentioned techniques have minimal effect on anthocyanins content of fruit juices and potential to meet mandatory 5 log microbial reductions (Tiwari et al. 2009; Rawson et al. 2011; Awad et al. 2012; Zinoviadou et al. 2015). On the other hand, high capital cost, maintenance and energy consuming of these preservation methods, in addition to the resistance of some microorganisms and enzymes (e.g. polyphenol oxidase and β-glucosidase) against these techniques, are the main limitations for their commercially applications as an alternative to heat treatment (Tiwari et al. 2009).

As compared to other non-thermal preservation methods, utilizing of ultrasonication in fruit juice processing has been more attractive due to its capability to inactivate microorganisms without harsh effects on bioactive compounds and nutritional values of the juices (Mohideen et al. 2015). Several studies have been successfully done on application of ultrasonication, with absence of additives and preservatives, on microbial counts and bioactive content such as anthocyanins of blueberry, tomato, apple, red grape, sour cherry, pomegranate and strawberry juices (Adekunte et al. 2010; Dubrovic et al. 2011; Mohideen et al. 2015; Tiwari et al. 2010; Toydemir et al. 2013; Zhang et al. 2012).

While, heat treatments at temperature of more than 80 °C (e.g. pasteurization and sterilization) may cause undesirable changes in various properties of the fruit juices, thermosonication technology, which combines moderate heat of 37–75 °C with ultrasound treatment, is a much more suitable alternative processing technique to enhance inactivation of enzymes and microbial (Abdullah and Chin 2014).

Although the effects of ultrasonication and heat treatments on sour cherry, red grape and pomegranate juices have been reported separately in several studies, but, no comprehensive study has been done on application of thermosonications for mild processing of these juices. Therefore, the main objectives of this study was to investigate the effect of pasteurization, mild-heat treatment, sonication and thermosonication on functional properties (e.g. anthocyanins, total phenolic content and antioxidant capacity) and safety attributes (microbial count) of pomegranate, sour cherry and red grape juices.

Materials and methods

Materials

Sodium hydroxide, 2,6-dichloroindophenol, gallic acid, potassium chloride buffer, sodium acetate buffer, cyanidin-3-glucoside, 2,2-diphenyl-1-picrylhydrazyl, iodine solution, phenolphthalein, oxalic acid and methanol were purchased from Merck (Merck Co., Darmstadt, Germany).

Preparation of fruit juices

Same-sized red grape bunches were provided from Sardasht, a town in West Azarbaijan province of Iran, and grapes were split from bunches, washed with tap water, drained and kept in the refrigerator (10 °C) as was usual in fuit juice industries of Iran. Soursweet with red aril and peel, large and average sized pomegranate were purchased from local market (Saveh, Iran) washed and drained. After that, pomegranate peel was manually removed and the seed were separated by hand and stored in the refrigerator (10 °C). Sour cherry was also provided from local market (Maragheh, Iran) and the stems and stones were removed by hand and the remaining fruits washed in cold tap water, drained and stored in the refrigerator (10 °C). A mass of 1 kg of all three provided fruits were subjected into a domestic juice extractor (MJ-176NR, Nathional Co., Tokyo, Japan) and the obtained thick juices were then centrifuged using a laboratory centrifuge (D-7200, Hettich, Germany) adjusted at 2000 rpm for 20 min. The prepared thin fruit juices were then filtered using No. 1 Whatman filter paper and stored in refrigerator for further treatments and analysis.

Fruit juices treatments

Four different treatments were done on the provided pomegranate, red grape and sour cherry juices namely; pasteurization, mild heat treatment, sonication and thermosonication. In order to produce pasteurized fruit juices, 200 mL of the prepared fruit juices were added into 250 mL containers, sealed with aluminum foil and placed into a laboratory autoclave which was set at temperature of 90 °C for 30 s. For preparation of mild-heat treated of the provided three fruit juices, the prepared containers as already mentioned were placed in autoclave adjusted at 60 °C for 8 min. According to literature reviews, thermosonicated pomegranate, red grape and sour cherry juices were provided using a ultrasonic processor (Q125 Sonicator, Newtown, CT, USA) with 12 mm probe for 8 min at a constant frequency of 20 kHz and constant amplitude level of 42.7 μm (Tiwari et al. 2010). During the ultrasonication of the samples, their temperature was kept at two constant temperatures of 25 and 60 °C by circulation of the fruit juices which were known as sonication and thermosonication treatments, respectively. The probe was adjusted at 25 mm below of the juices surface in the containers.

Measurement of acidity, pH, brix and vitamin C content of the fruit juices

A digital refractometr (LR-01, Maselli, Parma, Italy) was used to measure the brix value of the raw and treated pomegranate, red grape and sour cherry juices, at 20 °C. The pH values of the fruit juices were measured using a laboratory digital pH meter (211, Hanna, Italy). Titratable acidity of the treated and untreated fruit juices was measured using described method by Alighourchi and Barzegar (2009). In fact, this method is based on titration using NaOH (0.1 N) and predominate organic acids which those are malic, tartaric and citric acids for sour cherry, red grape and pomegranate, respectively. Vitamin c content of the prepared juices was calculated using described method by Nerdy (2018). This method is also an titration technique based on utilizing 2,6-dichloroindophenol.

Measurement of total phenolic and total anthocyanin contents of the fruit juices

Total polyphenol content of the treated and untreated fruit juices was determined using the Folin and Ciocalteu assay as described by Çam et al. (2009). This method is based on measurement of the absorbance of the treated fruit juices with related chemicals and buffers using a spectrophotometer (8625 UV/VIS Unicam, England) at wavelength of 765 nm. The same procedure was applied for eight standard solutions of gallic acid (0, 25, 50, 75, 100, 150 and 200 mg/L). Final results were expressed as mg gallic acid equivalent per 1 L of the juices.

Total anthocyanin content of the prepared fruit juices was determined spectrophotometrically by pH differential method using two buffer systems: potassium chloride buffer, pH 1.0 (0.025 M) and sodium acetate buffer, pH 4.5 (0.4 M), described by Hasan et al. (2014). In this method, the amounts of anthocyanins were then calculated on the basis of cyanidin-3-glucoside and expressed as mg cyanidin-3-glucoside equivalent per 1 L of the juices.

Assessment of antioxidant activity of the fruit juices

The DPPH (2,2-diphenyl-1-picrylhydrazyl) radical scavenging assay was used to determine the antioxidant activity of the raw and treated pomegranate, red grape and sour cherry juices according to the method of Brownmiller et al. (2008). In this spectrophotometrically technique, absorbance of the treated juices with DPPH and methanol was measured at wavelength of 515 nm and antioxidant activity of the samples was calculated and expressed as inhibition percentage.

Assessment of the fruit juices safety

All the treated and untreated pomegranate, red grape and sour cherry juices were analyzed for aerobic plate count (APC), total coliforms (TC), yeasts and moulds following AOAC 990.12, 991.14 and 997.02 methods, respectively (AOAC 2005). The petri plates which inoculated with APC were incubated for 48 h at 35 °C and the red colonies were counted. For TC analysis, petri film plates (3 M Microbiology, St Paul, MN, USA) containing the juices were incubated for 24 h at 35 °C and the red colonies with formed gas were counted. Yeasts and moulds colonies were counted after an incubation period of 3–5 days at room temperature. In fact, yeast are typically indicated by small blue-green colonies with diffuse edges and center foci while molds are identified by large variably colored colonies with diffuse edges and center foci (Mohideen et al. 2015). The APC, TC and yeasts and molds colonies were counted and reported as the CFU/mL.

Experimental design and statistical analysis

A randomized full factorial design was used to evaluate the effects of independent variables including type of treatment, temperature, time and ultrasonication amplitude levels on the dependent variables of the treated and untreated pomegranate, red grape and sour cherry juices physico-chemical and microbial attributes. All of the treatments and analyses were conducted in triplicate the obtained results were given as mean ± standard deviation. One-way ANOVA followed by Duncan’s test at the 5% level of significance were used to data analysis using SPSS 16.0 statistical package (SPSS Inc., Chicago, USA).

Results and discussion

Characteristics of the untreated prepared fruit juices

Physico-chemical attributes of untreated red grape, pomegranate and sour cherry juices used for further processes including, pasteurization, sonication, mild heat treatment and thermosonication are presented in Table 1. As clearly observed in this Table, among all three provided fruit juices, the pomegranate juice has minimum pH value (3.9) with maximum acidity (0.8 g/100 g), vitamin C (12.90 mg/100 mL), total phenolic content (2322 mg/L) and antioxidant activity (53.67% inhibition). While, sour cherry and red grape juices, have maximum total anthocyanin contents of 553 and 443.9, respectively. The obtained results were indicated that during further processes on all these three juices, their acidity, pH and brix values did not show significant (p < 0.05) variation and those were nearly constant. Tiwari et al. (2010), have also found and reported that ultrasonic processing had insignificant effect on acidity, pH and brix value of red grape juice. Table 2 indicates microbial population of aerobic and coliform bacteria, yeasts and moulds presented in three prepared raw juices, as their safety attributes. As can be seen in this Table, among the studied juices, the untreated red grape juice containes minimum moulds population (3 cfu/mL) and maximum aerobic bacteria, coliforms and yeasts counts of 62, 22 and 19 cfu/mL, respectively.

Effect of different treatments on the vitamin C content of the prepared fruit juices

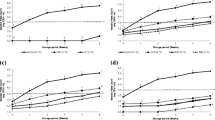

Vitamin C (ascorbic acid) is one the main water soluble vitamins which finds mainly in fruits, especially in citrus, and vegetables and has protecting effects against cancer and many infectious disease (Abdullah and Chin 2014). Figure 1a, shows the effects of different processing techniques on loss of vitamin C content of the red grape, pomegranate and sour cherry juices. As clearly observed in this figure, pasteurization, significantly (p < 0.05) degraded vitamin C content of all three provided juices as compared to their untreated samples. The obtained results can be explained by the fact that vitamin C is not stable component and it is simply oxidized under high temperature—long time processing methods (Abdullah and Chin 2014; Abid et al. 2013; Adekunte et al. 2010). Statistical analysis also indicated that for the red grape juice, there was insignificant difference between vitamin C content of mild heat treated juice (8.33 mg/100 mL) and that of its untreated. However, there was significant difference (p < 0.05) between vitamin C contents of untreated red grape juice, and that of sonicated (8.03 mg/100 mL) and thermosonicated (7.90 mg/100 mL) juices, there was insignificant difference between vitamin C content of mild heat treated and sonicated red grape juice. For the pomegranate juice, there was insignificant difference between vitamin C content of mild heat treated (12.27 mg/100 mL) and sonicated (11.93 mg/100 mL) juices. However, there was insignificant difference between vitamin C content of pomegranate juices treated by sonication and thermosonication (11.33 mg/100 mL) juices. For sour cherry juice, there were significant difference (p < 0.05) in the value of vitamin C content of all treated samples, as sour cherry juice under sonication, mild heat treatment and thermosonication had vitamin C content of 10.83, 10.57 and 9.73 mg/100 mL, respectively. The obtained results revealed that, in addition to the mild heat treatment, sonication and thermosonication could be easily remove dissolve oxygen during cavitation which it leads to less degradation of vitamin C content of the juices as compared to the fruit juices which were exposed to serious heating for long time (Abdullah and Chin 2014).

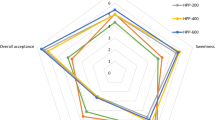

Effect of pasteurization, mild heat treatment, sonication ad thermosonication on vitamin C content (a) total phenolic content (b) and antioxidant activity (c) of red grape, pomegranate and sour cherry juices. Data are mean values of three replications. Mean values labeled with different letters for each fruit juices are significantly different (p < 0.05)

Effect of different treatments on the total phenolic and anthocyanin contents of the prepared fruit juices

Phenolic components such as anthocyanins are beneficial to human health as those optimize the immune system and prevent many diseases (Toydemir et al. 2013). Figure 1b, indicates the effects of different processing techniques on changes in total phenolic content of the red grape, pomegranate and sour cherry juices, as compared to that of their untreated. As can be seen in this figure, the pasteurization process decreased significantly (p < 0.05) total phenolic content of all three studied fruit juices. In fact, phenolic compounds are susceptible to degradation and their stability is mainly affected by temperature (Tiwari et al. 2010). The obtained results also revealed that total phenolic content of the sonicated pomegranate (2546 mg/L) and sour cherry (1995 mg/L) juices were significantly higher than that value for all treated and untreated samples, and in the case of red grape, there was insignificant difference between phenolic content of the sonicated (2257 mg/L) and untreated samples. This result can be explained by the fact that hydroxyl radicals generated by acoustic cavitation and food components, including phenolic compounds, can be attached to the aromatic ring of phenolic compounds and increased phenolic content (Abid et al. 2013). The obtained result was in line with findings of Abid et al. (2014). They also found that sonication process, increased total phenolic contents of the pomegranate and apple juices, respectively. The obtained results illustrated that there was insignificant difference between phenolic content of the untreated three fruit juices and that of those juices treated using mild heat and thermosonication.

Anthocyanins are bioactive compounds with desirable properties such as protecting effect against many diseases. They are the source of the reddish purple colour in the red-coloured fruits which can be increase organoleptic properties of their juices. Furthermore, several studies have revealed anthocyanins have antioxidant and antimicrobial activities (Damar and Eksi 2012; Mohideen et al. 2015; Tiwari et al. 2009; Toydemir et al. 2013). Table 3 indicates total anthocyanin content of the treated and untreated red grape, pomegranate and sour cherry juices. As clearly observed in this table, maximum anthocyanin degradation was obtained during pasteurization process for all three prepared fruit juices. However, for the red grape and pomegranate juices, minimum anthocyanin degradation was observed for all treated sample juices, and in the case of sour cherry juice, the total anthocyanin content of the sonicated juice was significantly (p < 0.05) higher than that of the untreated sour cherry juice. They also observed that total anthocyanin content of the sonicated pomegranate juice was increased (0.44–7.32%) as compared to that of the untreated sample, in some sonication amplitude levels and times. Abid et al. (2014) also observed that total anthocyanin content of red apple juice was constant under sonication process.

Effect of different treatments on the antioxidant activity of the prepared fruit juices

Carotenoids, anthocyanins, lycopens are the natural antioxidants which play important role in lowering the risk of many diseases such as neuronal and cardio vascular diseases, cancer and diabetes (Anarjan et al. 2017; Jabbar et al. 2014; Mohideen et al. 2015). Effects of different thermal and non-thermal processing techniques on the antioxidant activity of the red grape, pomegranate and sour cherry juices are shown in Fig. 1c. As same as other mentioned physico-chemical properties of the studied juices, pasteurization significantly (p < 0.05) decreased antioxidant activity of all three fruit juices as compared to that of the untreated samples. The obtained results revealed that antioxidant activity of the sonicated red grape, pomegranate and sour cherry juices were 49.50, 59.33 and 44.63% inhibition, and were significantly (p < 0.05) higher than that of the untreated sample juices. This result can be explained by the fact that the cavitation and disrupting properties of ultrasound waves causes release the bioactive components which those enhance antioxidant activity of the sonicated juices (Zinoviadou et al. 2015). Furthermore, the achieved results indicated that, there was insignificant difference between antioxidant activity of the untreated three juices and those treated with mild heat and thermosonication preservation techniques.

Effect of different treatments on the safety attributes of the prepared fruit juices

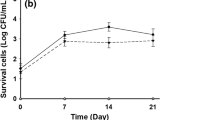

Effects of pasteurization, mild heat treatment, sonication and thermosonication, as preservative methods, on the microbial counts including aerobic plate counts, total coliforms, yeasts and mould counts are shown in Figs. 2 and 3. As clearly can be seen in Fig. 2a, for red grape juice, while, pasteurization killed all aerobic bacteria, thermosonication, sonication and mild heat treatment decreased significantly (p < 0.05) population of aerobic bacteria to 6.96, 23.70 and 37.50 cfu/mL, respectively. Same trend in reduction of aerobic bacteria population of pomegranate juices treated with thermosonication (1.73 cfu/mL), sonication (2.90 cfu/mL) and mild heat treatment (9.50 cfu/mL) was observed (Fig. 2a). The obtained results also revealed that all four treatments completely killed the aerobic bacteria of the sour cherry juices (Fig. 2a). As clearly observed in Fig. 2b, all four selected treatments, completely killed total coliforms existed in pomegranate and sour cherry. While, in the case of red grape juice, sonication (2.13 cfu/mL), thermosonication (3.20 cfu/mL) and mild heat treatment (11.93 cfu/mL) had strong bactericidal effects against coliforms after pasteurization. In fact, heating by denaturation of the proteins, can easily change the microorganism structure, especially cell membrane, and inactive enzymes which those cause microorganisms death (Abdullah and Chin 2014; Adekunte et al. 2010).

Effect of pasteurization, mild heat treatment, sonication ad thermosonication on aerobic total count (a) and total coliforms (b) of red grape, pomegranate and sour cherry juices. Data are mean values of three replications. Mean values labeled with different letters for each fruit juices are significantly different (p < 0.05)

Effect of pasteurization, mild heat treatment, sonication ad thermosonication on yeasts (a) and mould (b) population of red grape, pomegranate and sour cherry juices. Data are mean values of three replications. Mean values labeled with different letters for each fruit juices are significantly different (p < 0.05)

Figure 3a, indicates fungicidal effect of different four preservative methods against yeasts of the prepared red grape, pomegranate and sour cherry juices. As can be seen in this figure, pasteurization and thermosonication killed completely existed yeasts in the red grape juice and sonication and mild heat treatment significantly (p < 0.05) decreased yeasts population of the red grape juice to 1.9 and 6.4 cfu/mL, respectively. The mechanism of microbial killing is mainly caused by the thinning of cell membranes, localized heating and pressure increase and production of free radicals. The treatment with combination of heat and ultrasound could give extensive cell damage and breakage (Abdullah and Chin 2014). The obtained results were in line with findings of Jabbar et al. (2014). They reported that combination of sonication and other thermal processing methods could effectively reduce the microbial counts of the carrot juice. Adekunte et al. (2010) also revealed that sonication could be successfully utilized to inactive presented yeasts in tomato juices. The obtained results also revealed that for the prepared pomegranate and sour cherry juices, all the selected preservative methods did not show serious fungicidal effects (Fig. 3a).

Antifungal activities of the pasteurization, mild heat treatment, sonication and thermosonication against existed moulds in the prepared red grape, pomegranate and sour cherry juices are presented in Fig. 3b. As clearly observed in this figure, for all the prepared juices, pasteurization and thermosonication killed completely the moulds. However, for the red grape juice, mild heat treatment and sonication had the same fungicidal effects.

Conclusion

Demand for high quality fruit juices without additives and preservatives has encouraged utilizing of non-thermal techniques in juice processing. Thermosonication, as a novel and alternative technique for conventional heat treatment such as pasteurization and novel sonication alone, has potential in enhancing both quality and safety of the fruit juices, together. Furthermore, this preservative technique is more energy and cost effective. The obtained results in the present study indicated that as compared to the pasteurization, mild heat treatment and sonication alone, thermosonication did not affect negatively the values of most quality properties of the red grape, pomegranate and sour cherry juices. However, this techniques, could significantly increase phenolic compounds and decrease microbial counts of the prepared juices which accounts thermosonication for the practical application.

References

Abdullah N, Chin NL (2014) Application of thermosonication treatment in processing and production of high quality and safe-to-drink fruit juices. Agric Sci Procedia 2:320–327. https://doi.org/10.1016/j.aaspro.2014.11.045

Abid M, Jabbar S, Wu T, Hashim MM, Hu B, Zhang X, Zeng X (2013) Effect of ultrasound on different quality parameters of apple juice. Ultrason Sonochem 20:1182–1187. https://doi.org/10.1016/j.ultsonch.2013.02.010

Abid M, Jabbar S, Wu T, Hashim MM, Hu B, Zeng X (2014) Sonication enhances polyphenolic compounds, sugars, carotenoids and mineral elements of apple juice. Ultrason Sonochem 21:93–97. https://doi.org/10.1016/j.ultsonch.2013.06.002

Adekunte AO, Tiwari BK, Cullen PJ, Scannell AGM, O’Donnell CP (2010) Effect of sonication on colour, ascorbic acid and yeast inactivation in tomato juice. Food Chem 122:500–507. https://doi.org/10.1016/j.foodchem.2010.01.026

Ahdno H, Jafarizadeh-Malmiri H (2015) Clarification of date syrup by activated carbon: investigation on kinetics, equilibrium isotherm, and thermodynamics of interactions. Int J Food Eng 11:651–658. https://doi.org/10.1515/ijfe-2015-0093

Ahdno H, Jafarizadeh-Malmiri H (2017) Development of a sequenced enzymatically pre-treatment and filter pre-coating process to clarify date syrup. Food Bioprod Process 101:193–204. https://doi.org/10.1016/j.fbp.2016.11.008

Alighourchi H, Barzegar M (2009) Some physicochemical characteristics and degradation kinetic of anthocyanin of reconstituted pomegranate juice during storage. J Food Eng 90:179–185. https://doi.org/10.1016/j.jfoodeng.2008.06.019

Anarjan N, Fahimdanesh M, Jafarizadeh-Malmiri H (2017) β-Carotene nanodispersions synthesis by three-component stabilizer system using mixture design. J Food Sci Technol 54:3731–3736. https://doi.org/10.1007/s13197-017-2764-8

AOCS (2005) Official methods of analysis. Association of Official Analytical Chemists, Arlington

Awad TS, Moharram HA, Shaltout OE, Asker D, Youssef MM (2012) Applications of ultrasound in analysis, processing and quality control of food: a review. Food Res Int 48:410–427. https://doi.org/10.1016/j.foodres.2012.05.004

Brownmiller C, Howard L, Prior R (2008) Processing and storage effects on monomeric anthocyanins, percent polymeric color, and antioxidant capacity of processed blueberry products. J Food Sci 73:72–79. https://doi.org/10.1111/j.1750-3841.2008.00761.x

Çam M, Hisil Y, Durmaz G (2009) Classification of eight pomegranate juices based on antioxidant capacity measured by four methods. Food Chem 112:721–726. https://doi.org/10.1016/j.foodchem.2008.06.009

Damar I, Eksi A (2012) Antioxidant capacity and anthocyanin profile of sour cherry (Prunus cerasus L.) juice. Food Chem 135:2910–2914. https://doi.org/10.1016/j.foodchem.2012.07.032

Dubrovic I, Herceg Z, Jambrak AR, Badanjak M, Dragovic-Uzelac V (2011) Effect of high intensity ultrasound and pasteurization on anthocyanin content in strawberry juice. Food Technol Biotechnol 49:196–204. http://orcid.org/0000-0003-3967-6676

Hasan MM, Yun HK, Kwak EJ, Baek KH (2014) Preparation of resveratrol-enriched grape juice from ultrasonication treated grape fruits. Ultrason Sonochem 21:729–734. https://doi.org/10.1016/j.ultsonch.2013.08.008

Jabbar S, Abid M, Hu B, Wu T, Hashim MM, Lei S, Zhu X, Zeng X (2014) Quality of carrot juice as influenced by blanching and sonication treatments. LWT Food Sci Technol 55:16–21. https://doi.org/10.1016/j.lwt.2013.09.007

Mohideen FW, Solval KM, Li J, Zhang J, Chouljenko A, Chotiko A, Prudente AD, Bankston JD, Sathivel S (2015) Effect of continuous ultra-sonication on microbial counts and physico-chemical properties of blueberry (Vaccinium corymbosum) juice. LWT Food Sci Technol 60:563–570. https://doi.org/10.1016/j.lwt.2014.07.047

Nerdy N (2018) Determination of vitamin c in various colours of bell pepper (Capsicum annuum L.) by titration method. Alchemy J Pen Kim 14:164–177. https://doi.org/10.20961/alchemy.14.1.15738.164-178

Rawson A, Patras A, Tiwari BK, Noci F, Koutchma T, Brunton N (2011) Effect of thermal and non-thermal processing technologies on the bioactive content of exotic fruits and their products: review of recent advances. Food Res Int 44:1875–1887. https://doi.org/10.1016/j.foodres.2011.02.053

Tiwari BK, O’Donnell CP, Cullen PJ (2009) Effect of non thermal processing a technologies on the anthocyanin content of fruit juices. Trends Food Sci Technol 20:137–145. https://doi.org/10.1016/j.tifs.2009.01.058

Tiwari BK, Patras A, Brunton N, Cullen PJ, O’Donnell CP (2010) Effect of ultrasound processing on anthocyanins and color of red grape juice. Ultrason Sonochem 17:598–604. https://doi.org/10.1016/j.ultsonch.2009.10.009

Toydemir G, Capanoglu E, Roldan MVG, de Vos RCH, Boyacioglu D, Hall RD, Beekwilder J (2013) Industrial processing effects on phenolic compounds in sour cherry (Prunus cerasus L.) fruit. Food Res Int 53:218–225. https://doi.org/10.1016/j.foodres.2013.04.009

Zhang Y, Zhang Z, Chen F, Zhang H, Hu X (2012) Effect of sonication on eliminating of phorate in apple juice. Ultrason Sonochem 19:43–48. https://doi.org/10.1016/j.ultsonch.2011.05.014

Zinoviadou KG, Galanakis CM, Brncic M, Grimi N, Boussetta N, Mota MM, Saraiva JA, Patras A, Tiwari B, Barba FJ (2015) Fruit juice sonication: implications on food safety and physicochemical and nutritional properties. Food Res Int 77:743–752. https://doi.org/10.1016/j.foodres.2015.05.032

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hooshyar, L., Hesari, J. & Azadmard-Damirchi, S. Investigation of selected thermal and non-thermal preservative techniques to produce high quality and safe to drink sour cherry, red grape and pomegranate juices. J Food Sci Technol 57, 1689–1697 (2020). https://doi.org/10.1007/s13197-019-04202-w

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-019-04202-w