Abstract

Non-wheat grains, complementing the nutritional profile of wheat were utilized for the development of atta with multi-whole grains. Based on the dimensions, selected grains were segregated and the grinding techniques were applied for the production of multi whole grains flour. Multi whole grains flour was replaced with whole wheat flour to obtain five different formulations and further compared with control atta. With the increase in incorporation of the multi whole grain flours reduction in brightness (L*) from 79.73 to 78.47 and redness (a*) from 2.47 to 12.12 while the increase in yellowness (b*) was observed (12.10–12.70). Protein content increased from 13.44 to 14.83% while dietary fibre content was also found to be increased in all the formulations compared to control atta. Ash content, an indicator of mineral content showed an increasing trend with the increase in the level of non-wheat grains. Shear force required for tearing the chapatis at 0 h was observed to be in the range of 15.6 and 10.1 N and moisture content between 32.6 and 30.4%. Mineral analysis carried out for the 10% replacement showed an increase in the level of the estimated minerals. An overall eating quality of the chapatis was found to be acceptable up to 10% replacement compared to control atta chapati.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Whole-grain cereals and foods have been the focus of significant scientific, governmental and commercial interest during the past 10 years since epidemiological studies have increasingly shown their protective role against the risks of many chronic diseases, especially those related to metabolic syndrome, i.e. type 2 diabetes and cardiovascular diseases (Jacobs et al. 1998). Slavin (2004) has mentioned that most of the protective components are present in the germ and bran, which get reduced in the grain-refining process. He also indicated that based on epidemiological studies and biologically plausible mechanisms, the scientific evidence shows that the regular consumption of wholegrain foods provides health benefits in terms of reduced rates of coronary heart diseases and several forms of cancer. The beneficial effects associated with whole grain consumption are in part due to the existence of the unique phytochemicals of whole grains. The majority of phytochemicals of whole grains that are beneficial for health are present in the bran/germ fraction. In whole wheat flour, the bran/germ fraction contributed 83% of total phenolic content, 79% of total flavonoid content, 78% of total zeaxanthin, 51% of total lutein, and 42% of total β-cryptoxanthin. The bran/germ fraction of whole wheat may, therefore, impart greater health benefits when consumed as part of a diet, and help reduce the risk of chronic diseases (Liu 2007). Dietary fibre can have an impact on food by reducing the rate of glucose breakdown and absorption, hence avoiding an excess of glucose in the body and facilitating the steady breakdown of carbohydrates and release of glucose (Brennan 2005).

Chapatis are unleavened flat breads and a staple food made in Indian homes, shops and restaurants. Atta flour is widely used to make chapatis and is obtained by grinding wheat in stone chakkis. Supplementing atta with flours made from various legumes increases protein and mineral content and therefore increases the nutritional content of chapatis (Chakrabarti-Bell et al. 2013). However, a single whole grain will not provide wholesome nourishment. Grains differ in their nutritional composition; some are stronger in one nutrient and others in different nutrients. Different grains can be selected based on their protein, dietary fibre and mineral composition and combined to produce flours to get more wholesome and balanced food. Since atta is the staple food, chapatis from atta (whole wheat flour) with multi wholegrains can be a healthier option without changing the food habits and are also being eaten at least twice a day by a majority of the population in the sub-continent. With this background, an attempt is made in the present study to utilize the different grains rich in the nutritional components in which wheat is deficient, for the development of atta with multi whole grains with an objective to increase and balance nutritional quality of atta. Further, the developed atta is studied for the chapati making quality and its acceptability.

Materials and methods

Raw material selection

Grains selected for the study viz. wheat, maize, barley, sorghum, amaranthus, bengal gram, horse gram, soybean, finger millet, pearl millet and were purchased from the local market in Mysuru, India. The basis of grain selection was the nutritional profile (Gopalan et al. 1989), price and commercial availability.

Grain dimensions evaluation and processing for flour

Grains were cleaned using laboratory cleaner Labofix, Brabender, and stored in polyethylene bags until used. 50 kernels randomly picked from the sample of each grain were analysed. The three linear dimensions, namely, length, width and thickness of each of kernel was measured using digital Vernier calliper (Mitutoyo, Japan) and the values were averaged. The geometric mean diameter (Dg) of the seed was calculated by using the following equation:

Where; L is the length, W is the width and T is the thickness.

Based on the values for dimensions, grains were segregated in three sets- Maize, Soyabean and Bengal gram; Pearl millet, Sorghum, Horse gram, and Barley; Amaranthus and Finger millet for efficient grinding.

Grain processing for flour

Cleaned raw wheat was ground for the production of atta, using Chakki mill (CM), Indica, India, Mixer Jumbo Model. This flour was used as control flour. Other grains were ground in a Hammer mill (HM), Nataraj, India, Premium Model. The control flour and the multigrain flours were blended in a ratio of 95:5 (Formulation A); 90:10 (Formulation B); 85:15 (Formulation C); 80:20 (Formulation D) and 75:25 (Formulation E). Flours produced were packed in an airtight container and stored at room temperature for further use.

Atta chemical characterisation

Flours were tested as per methods approved American Association of Cereal Chemist (AACC 2000) for moisture (method 44–15), damaged starch (76–30A), ash (method 08–01), protein (method 46–13) and fat (method 30–10). Dietary fibre was estimated according to method 991.43 of AOAC, 1999.

Color measurement

The color of atta was measured using the Hunter Lab Color Measuring System (Color Measuring Labscan XE system, Reston, VA). A white board made from barium sulfate 100% reflectance was used as a standard. Samples were placed in the sample holder, and the reflectance was auto recorded for the wavelength ranging from 360 to 800 nm. In the color difference, L value indicated the degree of lightness or darkness (L = 0 indicates perfect black and L = 100 indicated perfect white); ‘a’ indicates the degree of redness (+) and greenness (−) whereas ‘b’ indicates the degree of yellowness (+) and blueness (−).

Dough mixing and pasting profile

Mixing profile of the dough from different flours were determined by Brabender Farinograph and pasting properties by using Micro-visco Amylograph according to American Association of Cereal Chemist Methods (AACC 2000).

Chapati preparation

The Dough was prepared using 200 gm flour and mixed in the Mixer (Spar Mixer, Spar Food Machine Mfg. Co. Ltd, Taiwan, Model 800B) for 3 min. Water was added according to the results obtained by Farinograph results less 3–4%, if required, for the flour from different grinders to get the consistency suitable for chapati sheeting. The dough was rested for 10 min before cutting into a piece of 40 gm each and was sheeted using a roller pin to a diameter of 15 cm. Electric hot plate was set at 225 °C, and the sheeted dough sheet was baked on the first side for 60 s and on the second side for 80 s. It was then transferred to tandoor grill and heated for 11 s where it puffs. It was allowed to cool to room temperature.

Moisture estimation of chapati at different time interval

Moisture of chapati was estimated by two stage method (AACC International, 2000, method 44–18) at 0, 4, 8 and 12 h from the time of its preparation. In the first stage, 20 g of the sample was taken in a clean dried petri plate and covered with a sieve and incubated at room temperature for overnight. The air dried samples are then powdered. From the powdered sample, 2 g is weighed into an aluminium dish and kept in an oven at 130 °C ± 1 for 1 h.

Sensory evaluation of chapatis

Chapatis were evaluated for appearance, tearing strength, pliability, aroma, eating quality and overall quality. Eight panellists were asked to give the scores between 0 and 20 for eating quality and between 0 and 10 for all the other parameters; desirable chapati characteristics being the one with the higher score.

Texture studies

Chapatis were packed in polypropylene pouches (two chapatis in each pouch for the study at different time interval), heat sealed and stored in an atmosphere maintained at temperature 25 °C and 45% RH throughout the texture study. Shear force was evaluated using Texture Analyzer (Lloyd Instruments Ltd, Fareham, Hampshire, UK, Model LR-5K) according to the method described by Hemalatha et al. (2014) with slight modifications. The load cell of 1 KN was used and set for 26.0 mm deflection, and Warner blade speed was set at 100 mm/min. Each chapati was cut into four pieces of 4 cm × 2 cm each, and the shear test was conducted for a total 16 pieces, and the average value of force in Newton was reported. Tests were carried out at intervals of every 1 h for first four hours and further after every 2 h up to 12 h.

Storage studies of atta

Storage studies of atta were conducted only for atta B which have shown acceptable chapati making qualities compared to control atta chapatis. 0.5 kg atta samples were packed in polypropylene pouches and stored at a temperature of 30 °C and relative humidity of 65%. Flours were tested for alcoholic acidity and moisture for a storage period of 120 days at an interval of every 30 days.

Mineral content of atta

Estimation of Calcium, Magnesium, Sodium, Potassium, Iron, Copper and Zinc content of the atta samples control and B was done by Atomic Absorption Spectrometry (Thermofisher Scientific AAS, iCE 3000 series, MA USA) using AOAC (2012) 19th edition method 985.35.

Results and discussions

Grain characteristics

Average values of the three principal dimensions of grains, namely, length, width and thickness determined in this study are presented in Table 1. The average length, width, and thickness of the grains varied among the different grains. Maize has shown the higher length i.e. (11.32 mm) followed by Bengal gram and wheat i.e. (7.2 mm) and (7.2 mm) respectively. Grains like ragi and amaranth have shown one value of dimension 1.57 and 0.84 mm respectively. It is because of the spherical shape of the grain. The sphericity of amaranth (112.32%) was much higher than soybean (82.39%), and jowar (76.73). However, it was lower for barley (53.17%). Moisture, protein and fat content of the grains varied, the values for the same are presented in Table 1. Soybean, Bengal gram, and Horse gram grains were higher in protein content with the values of 38.74, 23.03 and 21.44% respectively. Fat content was highest in Soybean (18.1%) and least in Horse gram grain (0.41%). Ash content, which is also an index of mineral content, was found to be higher in Soybean (4.61%), Amaranth (3.54%), Horse gram (3.20%) and Bengal gram (3.02%) compared to wheat (1.49%).

Composition of atta

Results of the analysis of various characteristics of atta and the different formulations are summarized in Table 2. The moisture content of different atta formulations is observed to be 9.35, 9.32, 9.25, 9.12, 9.08, and 9.02% respectively for control, formulation A, B, C, D, and E respectively. Initial moisture of all the non-wheat grains except finger millet was lower than wheat and has resulted in decreased moisture of the final atta as the proportion of them increased. Damaged starch produced by grinding with chakki for control atta was 18.03% and was found to be in the range of 17.48, and 15.62% for atta A to E. Inamdar et al. (2015) reported a higher damaged starch in chakki ground atta compared to hammer mill ground atta. Grinders imparting more compression along with shear forces as in chakki produced greater starch damage (Sharma et al. 2008). Atta samples were observed to be becoming less bright showing lesser L* value as the percentage of the non-wheat flour increased from 5 to 25% in the formulation. It was recorded as 79.73, 79.51, 79.26, 79.12, 79.00 and 78.74 for control, A, B, C, D, and E atta respectively. The redness value decreased (a* value 2.47–2.12) and the yellowness increased (y* value 12.1–12.7). Fenn et al. (2010) reported similar observations for colour in their studies on wheat-legume composite flour quality.

There was a significant difference in the protein content of the atta samples and was found to be 13.44, 14.52, 14.68, 14.74, 14.82 and 14.83% for control, A, B, C, D and E respectively. The results were as expected owing to the higher amount of protein content in Soybean (38.74%), Bengalgram (23.03%), Horsegram (21.44%) and Amaranthus (14.13%) compared to wheat. Gómez et al. (2008) reported an increase in protein content of cakes by incorporation of chickpea flour in wheat flour. Similar results were found for the values of Dietary fibre values in all the samples. Dietary fibre content of control atta was 17.68% and significantly increased for all the other formulations and ranged from 18.65 (A) to 22.55% (F). Ash content, which is a measure of mineral content in flour increased in in all the atta samples compared to the control atta. Fat content also increased with the amount of non-wheat flour substitution from 1.75 to 1.89% for control and atta F, the cause which being presence of higher fat than wheat in most of the grains used in the study (Table 1). Koletta et al. (2014) reported that incorporation of wholegrain non wheat flours from different cereals improved the nutritional quality of flour.

Rheological characteristics of atta

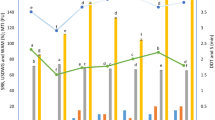

Water absorption of control atta was found to be 76.0% as indicated by Farinograph studies and it reduced to 75.7, 74.8, 73.2, 72.5 and 72.4 for atta A, B, C, D, and E respectively (Fig. 1). Water absorption of the flour increases with lower moisture content, higher protein and bran content and more damaged starch in the flour (Hallén et al. 2004). These results are in trend with the amount of damaged starch, protein and moisture content in the respective atta. Amir et al. (2015) in their studies on cookies making ability of composite flours from maize, sorghum, and wheat reported a decreasing pattern in farinograph water absorption of whole wheat flour with increase in replacing level of whole sorghum and whole maize flour. Ribotta et al. (2005) reported a decrease in dough water absorption by addition of full-fat soya flour in wheat flour. Dough development time and stability have shown a marginal increase among the atta samples compared to control. Singh et al. (1991) reported similar observations in wheat‐chickpea flour blends at 10–20% replacement with chickpea flour.

Pasting profile studies have indicated an increase in the gelatinization temperature from 61.3 °C for control to 61.5, 62.1, 62.4, 63.4 and 63.6 °C for atta A, B, C, D, and E respectively. The results indicate a delay in onset on pasting temperature. Tulse et al. (2014) observed the similar results in their studies on pasting profile of multigrain milled flour compared to wheat flour. Viscosity (PV), Hot Paste Viscosity (HPV) and Cold Pate Viscosity (CPV) of control atta was higher compared to all other atta (Fig. 1). The addition of non-wheat flours had a diluting effect on the starch and had resulted in the decreased PV. Pasting properties of flour are closely related to those of starch (Ohm and Chung 1999). The higher amount of starch results in greater swelling during gelatinization and is manifested as peak viscosity (McWatters et al. 2004). The decrease in the PV, HPV and CPV may be attributed to the higher NSP content in legumes as mentioned by Wood (2009). The results are in agreement with Rajiv et al. (2012, 2015).

Chapati characteristics

Chapatis prepared form different formulations of atta are shown in Fig. 2. Sensory characteristics evaluated by the panel of judges (Table 3) revealed that the appearance of the control atta chapati was better among all the chapatis, with the light brown spots which uniformly distributed on the surface. With the increase in the percentage of the other grains flour, the dark coloured spots become more, which may be attributed due to the lesser L value of the flours. The pliability gradually decreased from 8.0 to 7.0 for the chapatis form control atta to atta F. Tearing strength increased with increase in the percentage (5 and 10%), but at a higher percentage, it started to decrease and was lesser than control atta chapati. This may be attributed to the dilution of the gluten protein and their viscoelastic properties. Gujral and Pathak (2002) reported an increase in the extensibility of chapati with the incorporation of rice, corn, Bengal gram and millet flours up to a certain percentage before it started to decrease. Aroma of the control and atta B and C were similar but reduced for the chapati of atta D, E, and F. A typical wheaty aroma was desirable for chapati which was found in control atta chapati, but at a higher level of incorporation of non-wheat flour, it became bland. As expected, overall eating quality of the chapatis was found to be highest for control atta chapati. However, the chapatis with atta A (47) and B (46) were nearer to the overall quality scores of chapati form control atta. It was found to be 44.5, 39.5 and 36 for the chapatis from D, E and F atta respectively.

The estimated values of the moisture content of chapatis from different atta are given in Table 3. Moisture content of the chapatis at 0, 4, 8 and 12 h for control atta chapati was found to be 32.6, 31.9, 31.0 and 30.1% respectively. The moisture content of the chapatis from atta A, B, C, D and E at 0 h were found to be 31.7, 31.6, 31.0, 30.5 and 30.4% respectively. Control atta chapati has more moisture as the more water was absorbed while making the dough which is also attributed to the higher damaged starch of atta from chakki ground control atta compared to the other atta. Haridas Rao et al. (1989) observed that there was relatively less loss of moisture during the storage of chapatis from flours with high starch damage and reasoned it to the formation of more dextrin and sugars that have relatively greater water holding capacity compared to flours with lesser starch damage.

Results of the texture studies of chapatis conducted at various intervals are tabulated in Table 3. Shear force required to tear the chapatis from control, A, B, C, D, and E atta at 0 h was found to be 11.1, 11.2, 12.3, 14.4, 15.2, and 15.6 N respectively. Lower force to tear control atta chapati may be due to the presence of higher dough water absorption compared to the other atta. There was little decrease in the shear force at 4 h compared to fresh chapatis for chapatis from all the formulations. However, decrease in the shear force was more at the time interval of 8 h and 12 h. This is attributed to the brittleness due to staling of the chapatis. Similar results for Warner blade shear force values were observed by Inamdar et al. (2015) for the chapatis texture studies at different time intervals. Venkateswara Rao et al. (1986) had reported a decrease in the shear force required to tear the chapatis when they were packed polyethylene pouch and have attributed it to the staling of chapati and the chemical changes unrelated to moisture content.

Storage studies of atta

Flours when stored for long, undergoes various types of deterioration, which in turn gives high values for alcoholic acidity. Alcoholic acidity is an index of deterioration of flour during storage. Alcoholic acidity was found to be increased gradually during storage up to 90 days from 0.08 to 0.11% for atta B. However it increased to 0.25% at the end of 120 days. The moisture content of atta was 9.25% at 0 day and was found to be not significantly increased during storage period. It was found to be 9.54, 9.92, 10.4 and 10.93% at 30, 60, 90 and 120 day respectively. Kadam et al. (2012) have observed that moisture content of the composite whole wheat flours with chickpea and full-fat soya flour did not increase significantly during the storage period of 90 days compared to 0 day.

Mineral content of atta

Effect of the formulations on the mineral content of the atta samples is shown in Table 4. Control atta contained 20.6 mg of Calcium, 87.4 mg Magnesium, 5.99 mg Sodium, 253 mg Potassium, 3.06 mg Iron, 0.36 mg Copper and 2.69 mg of Zinc per 100 of sample. With the increase in the concentration of the other grains an increase in the content of all the analysed minerals was observed with the values 23.9, 92.3, 9.69, 285, 3.71, 0.38 and 2.71 mg/100 g for Calcium, Magnesium, Sodium, Potassium, Iron, Copper and Zinc respectively. This reflects the influence of the varying composition of the grains. The increase in mineral content is also evident from increase in the ash content of all the atta samples compare to control atta (“Composition of atta” section). Ragaee et al. (2006) analysed nutrient composition of selected cereals for food use and reported that barley and millet flours exhibit higher mineral content compared to commercial hard and soft wheat flours. Effect of soy flour supplementation on mineral and phytate contents of unleavened flat bread (chapatis) was studied by Khan et al. (2005), and they found that the soya supplemented flour contains higher amount of mineral (Fe, Zn, Mn, Cu, Ca and Mg) than wheat flour.

Conclusion

The present study describes the process for the production of atta with multi whole grains, its nutritional improvement and its utilization in chapati making. Colour of the atta, moisture and the damaged starch content of the produced atta varied. A significant increase in protein, dietary fibre and the mineral content of the atta is observed by addition of the different grains in whole wheat atta. The overall eating quality of the chapatis was found to be highest for control atta chapati. Studies indicate an improvement of the overall nutritional quality of the atta that offers diverse health benefits of different whole grains. This provides a scope for the utilization of the developed atta in foods like chapati and tortillas which are the staple food of a significant volume of the population. On the commercial retailing point of view, since packaged atta industry is also witnessing a growth of around 25% annually (Inamdar et al. 2015), the developed process for the atta with multi whole grains provides a healthier alternative to traditional wheat atta.

References

AACC (2000) Approved methods of the AACC, 10th edn. American Association of Cereal Chemists, St. Paul

Amir B, Mueen-ud-din G, Abrar M, Mahmood S, Nadeem M, Mehmood A (2015) Chemical composition, rheological properties and cookies making ability of composite flours from maize, sorghum and wheat. J Agroaliment Proc Technol 21:28–35

Brennan CS (2005) Dietary fibre, glycaemic response, and diabetes. Mol Nutr Food Res 49:560–570

Chakrabarti-Bell S, Wang S, Patel MJ, Weiss RM, Austin PJ (2013) Bubbles in chapatti doughs. J Cereal Sci 57:504–513

Fenn D, Lukow OM, Humphreys G, Fields PG, Boye JI (2010) Wheat-legume composite flour quality. Int J Food Prop 13:381–393

Gómez M, Oliete B, Rosell CM, Pando V, Fernández E (2008) Studies on cake quality made of wheat–chickpea flour blends. LWT Food Sci Technol 41:1701–1709

Gopalan C, Ramasastry BV, Balasubramanian SC (1989) Nutritive values of Indian foods (NVIF). National Institute of Nutrition, Hyderabad

Gujral HS, Pathak A (2002) Effect of composite flours and additives on the texture of chapati. J Food Eng 55:173–179

Hallén E, İbanoğlu Ş, Ainsworth P (2004) Effect of fermented/germinated cowpea flour addition on the rheological and baking properties of wheat flour. J Food Eng 63:177–184

Haridas Rao P, Leelavathi K, Shurpalekar SR (1989) Effect of damaged starch on chapati making quality of whole wheat flour. Cereal Chem 66:329–333

Hemalatha MS, Leelavathi K, Salimath PV, Rao UP (2014) Control of chapati staling upon treatment of dough with amylases and xylanase. Food Biosci 5:73–84

Inamdar AA, Sakhare SD, Prabhasankar P (2015) Chapati making quality of whole wheat flour (Atta) obtained by various processing techniques. J Food Process Preserv 39:3032–3039

Jacobs DR Jr, Marquart L, Slavin J, Kushi LH (1998) Whole-grain intake and cancer: an expanded review and meta-analysis. Nutr Cancer 30:85–96

Kadam ML, Salve RV, Mehrajfatema ZM, More SG (2012) Development and evaluation of composite flour for missi roti/chapatti. J Food Process Technol 3:134. doi:10.4172/2157-7110.1000134

Khan MI, Anjum FM, Hussain S, Tayyab Tariq M (2005) Effect of soy flour supplementation on mineral and phytate contents of unleavened flat bread (chapatis). Nutr Food Sci 35:163–168

Koletta P, Irakli M, Papageorgiou M, Skendi A (2014) Physicochemical and technological properties of highly enriched wheat breads with wholegrain non wheat flours. J Cereal Sci 60:561–568

Liu RH (2007) Whole grain phytochemicals and health. J Cereal Sci 46:207–219

McWatters KH, Phillips RD, Walker SL, Mccullough SE, Mensa-Wilmot Y, Saalia FK, Hung YC, Patterson SP (2004) Baking performance and consumer acceptability of raw and extruded cowpea flour breads. J Food Qual 27:337–351

Ohm JB, Chung OK (1999) Gluten, pasting, and mixograph parameters of hard winter wheat flours in relation to breadmaking. Cereal Chem 76:606–613

Ragaee S, Abdel-Aal ESM, Noaman M (2006) Antioxidant activity and nutrient composition of selected cereals for food use. Food Chem 98:32–38

Rajiv J, Lobo S, Jyothi Lakshmi A, Venkateswara Rao G (2012) Influence of green gram flour (Phaseolus aureus) on the rheology, microstructure and quality of cookies. J Texture Stud 43:350–360

Rajiv J, Inamdar AA, Sakhare S, Rao GV (2015) Roller milled black gram (Phaseolus mungo) semolina and its influence on the quality characteristics of high protein pasta. J Food Sci Technol 52:2464–2468

Ribotta PD, Arnulphi SA, León AE, Añón MC (2005) Effect of soybean addition on the rheological properties and breadmaking quality of wheat flour. J Sci Food Agric 85:1889–1896

Sharma P, Chakkaravarthi A, Singh Vasudeva, Subramanian R (2008) Grinding characteristics and batter quality of rice in different wet grinding systems. J Food Eng 88:499–506

Singh N, Harinder K, Sekhon KS, Kaur B (1991) Studies on the improvement of functional and baking properties of wheat-chickpea flour blends. J Food Process Preserv 15:391–402

Slavin J (2004) Whole grains and human health. Nutr Res Rev 17:99–110

Tulse SB, Reshma V, Inamdar AA, Sakhare SD (2014) Studies on multigrain milling and its effects on physical, chemical and rheology characteristics of milled streams. J Cereal Sci 60:361–367

Venkateswara Rao G, Leelavathi K, Haridas Rao P, Shurpalekar SR (1986) Changes in the quality characteristics of chapati during storage. Cereal Chem 63:131–135

Wood JA (2009) Texture, processing and organoleptic properties of chickpea-fortified spaghetti with insights to the underlying mechanisms of traditional durum pasta quality. J Cereal Sci 49:128–133

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pande, S., Sakhare, S., Bhosale, M. et al. Atta (whole wheat flour) with multi-wholegrains: flour characterization, nutritional profiling and evaluation of chapati making quality. J Food Sci Technol 54, 3451–3458 (2017). https://doi.org/10.1007/s13197-017-2801-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2801-7