Abstract

Combined use of soymilk–cow’s milk is a novel approach in food industry and has great potential to developed products with numerous health benefits. This study aimed to develop the enzyme-modified cheeses (EMCs) using soymilk–cow’s milk. The curd was hydrolysed using combination of proteinases/peptidase to produce a range of proteolysed products followed by lipolysis to create flavoured EMCs. Results showed that enzymes led to an increase in amino acids (AA), free fatty acids (FFA), complex volatiles, and improved sensory attributes. The EMCs showed higher mean values of AA, FFA and volatile compounds when prepared using Flavourzyme® in combination with Lipases AY30 and DF15. EMCs were less eggy, bitter, pungent, more buttery, saltier, nutty, and had sweet sensory characteristics. Overall, results demonstrated the potential of combined matrix to create a range of flavoured EMCs for a wider range of consumers.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Soymilk based products are consumed worldwide. Asians have been consuming soy products for more than 1000 years. Soymilk is widely used as a cheese analogue ingredient. It is gaining acceptance in the food industry as it provides a balance amino acids and fatty acids which is suitable for starter culture fermentation. It is relatively inexpensive and has protein characteristics similar to casein. It is also used as dairy substitutes in fermented products. Besides protein, it contains bioactive substances, such as hemagglutinins, saponins and isoflavones, which are purported to improve health by preventing various chronic diseases (Sacks 2006). Formulation of foods with ingredients that lower the health risks are challenging for food industry. Combined use of soymilk–cow’s milk is an innovative practice and has great potential to generate novel fermented products. For the formation of a curd substrate using starter culture and rennet, it is possible to make mixed soymilk–cow’s milk matrix in which both soy proteins and caseins are evenly dispersed (Grygorczyk et al. 2014). When soymilk is heated, the proteins dissociate, rearrange, aggregate, and become more susceptible to the gel matrix (Grygorczyk et al. 2013). Additionally gelation mechanism has an impact on the perception of fattiness in mixed soymilk–cow’s milk systems supplemented with anhydrous milkfat. When combined soymilk–cow’s milk is homogenized with milkfat, the soy protein and casein micelles become embedded in the fat globule surface. These acidified fat globules, referred to as interacting fillers of gel modulus and become an integral part of the gel network (Grygorczyk et al. 2014). In such a matrix, the size of the lipid droplets decrease and a higher amount of protein is adsorbed onto the newly formed interface (Grygorczyk et al. 2014). These soy proteins and caseins interact, resulting in an improved structure and texture (Grygorczyk et al. 2013, 2014). However, the beany off-flavours of soybean based products have limited their consumption (Li et al. 2014). To date, the published studies have only evaluated the effects on texture and structural characteristics of the products. One of the most used methodologies to overcome this problem is treatment of cheese curd with exogenous enzymes to generate flavoured potentiators, also known as enzyme-modified cheese (EMC), which has 15–30 fold higher flavour intensity (Wilkinson et al. 1992; Kilcawley et al. 1998, 2002, 2006). EMCs are developed using curd slurry techniques in powder or paste form, which deliver intense flavours, useful for the inclusion into a range of processed foods. Therefore, objectives of the present study were to evaluate a soymilk–cow’s milk based curd substrate recombined with anhydrous milkfat for the production of enzyme modified cheeses using exogenous enzymes. A two-stage process was applied in which mixed soymilk–cow’s milk curd was initially hydrolysis with proteinases/peptidase combinations to generate proteolysed products followed by lipolysis using different commercial lipases to yield a range of flavoured EMC products.

Materials and methods

Soymilk preparation

Dry food grade seed-lipoxygenase-free-soybeans (IA2032) with 36.3% protein, 18.4% fat and 26% carbohydrate were purchased from Stone bridge Ltd (Cedar Falls, IA). Soymilk was prepared according to the method of Grygorczyk et al. (2014). Briefly, each batch of about (240 g) soybean seeds were rinsed and soaked in Mili Q water overnight and hull was removed. Dehulled beans were washed and ground in Mili Q water (855 mL) using soymilk grinder (JYDZ-33B, Joyoung Co. Ltd, China) at a temperature of 95 °C and a rotation speed of 11,000 rpm for 4 min. The resultant slurry was passed twice through the cheese cloth to obtain soymilk, while the residues were discarded. Soymilk contained 4.94% protein. It was heated at 95 °C for 5 min and stored at 4 °C until further use.

Skimmed milk preparation

Pasteurized skimmed milk was obtained from Tianzi Dairy Company, Wuxi, Jiangsu, China. Low-heat skim milk powder (Fonterra dairy Ltd, New Zealand) was added to the liquid milk to increase protein contents up to 4%, stirred for 30 min, and stored overnight to hydrate proteins.

Homogenization

Skimmed milk (4% protein) and soy milk (4.9% protein) were mixed in a 1:1 ratio to make a final milk protein content of 4.5%, which is within the range of commercial yogurt protein concentration. Anhydrous milkfat (AMF; Punjab Milk Foods Inc., Canada) was added to the mixture to make fat content of 1.5%. Samples were heated at 40 °C and homogenized (31MR Laboratory Homogenizer, USA) with the first stage at 170 bars and the second stage at 35 bars.

Commercial enzymes

Five proteinases, one peptidase and three lipase preparations were selected for the production of targeted EMCs (Figs. 1a and 2b). Most of the enzymes were from widely used fungal sources. These enzymes significantly contribute to the bitterness and are responsible for high levels of carboxy and amino-peptidases activities (Kilcawley et al. 1998). The proteinases included Protease M “Amano” SD 100,000 μ/g, Protease P “Amano” 2 SD 300,000 μ/g, and ProteAX 1400 μ/g (Amano enzyme China, Ltd.) and they were derived from Aspergillus oryzae. Neutrase 0.5 L 1883 μ/g and Flavourzyme® 1000 L 1000 μ/g (Novozymes, Co, Ltd., China) were derived from Bacillussubtilis and A. oryzae, respectively. Peptidase R 420 μ/g (Amano enzyme China, Ltd.) was derived from Rhizopus oryzae and selected based on previously identified proline-specific peptidase activities. It has a significant role in the bitterness reduction and it induces glutaminase activity to generate the natural flavour enhancer glutamic acid from a glutamine substrate (Kilcawley et al. 2000; Sari et al. 2014). The lipase preparations used were Lipase AY “Amano” 30SD 30,000 μ/g, Lipase MER “Amano” 7500 μ/g and Lipase DF “Amano” 15 120,000 μ/g (Amano enzyme China, Ltd), derived from Candida cylindracea and R. oryzae. They were based on their hydrolytic differences in specificity towards esterase and lipase substrates (Kilcawley et al. 2000), and their products activities, as given by the supplier.

Curd substrate manufacture

The mixed soymilk–cow’s milk samples were pre-heated at 40 °C before addition of starter culture (YO-MIX™ 511 LYO 375 DCU, Danisco Shanghai, China) at the level of 0.2 DCU/L. 1 mM CaCl2 was added to ensure adequate calcium for the aggregation of micelles to obtain proper flocks. Simultaneous casein and soy proteins were aggregated by adding 0.18 IMCU/mL rennet with pH 6.4 at 37 °C, which was the gelation point of soy milk. The curd was cut crossways and allowed to settle for 5 min. It was then, agitated and poured onto a sieve covered with cheesecloth for wheying-off. Curd was pressed for 1 h (30 kg final curd) and mixed to a homogenous mixture for the preparation of substrate. Batches of substrate (13.2 kg) were formulated as follows: 7.5 kg curd, 1.7 kg anhydrous milkfat, 3.7 L deionised water, 30 g NaCl, 120 g disodium hydrogen phosphate, 60 g trisodium phosphate, 23.2 g potassium sorbate and 72.8 g trisodium citrate were blended to a homogeneous paste, and heated to 80 °C for 10 min. The mixture was cooled and stored at 4 °C until required.

Enzyme modified cheese manufacture

Each stage of the process was carried out in 2-L fermenter (Baoxing Co., Shanghai, China). 1.5 kg batches of proteolysed products 1–5 were produced by hydrolysis of curd substrate using proteinases in combination with peptidase preparations as described in Fig. 1a. The concentration of each proteinase preparation was selected in order to attain pH 4.6-WSN/NT% of ~64, as in the commercial bovine EMC under the process conditions for incubation (45 °C, 24 h, 500 rpm, no pH control). The peptidase dosage was identical for each treatment (Fig. 1a). Proteolysis was terminated by heat treatment at 80 °C for 20 min and each product was stored at −18 °C prior to analysis. One of these products was selected for further lipolysis based on ranked sensory preference analysis. Lipase dosage levels (Fig. 2a) were selected to attain an Acid Degree Value of ~24 deemed to the comparable bovine commercial EMC. Lipolysis was carried out at under following conditions: 45 °C, 24 h, 500 rpm, no pH control, and terminated at 80 °C for 20 min. Each lipolysed product was stored at −18 °C prior to the analysis. Dosage levels, incubation temperature, time, and agitation speed for the proteolysis and lipolysis phases were selected based on the literature (Kilcawley et al. 2000, 2006), as well as the supplier descriptions.

Compositional analysis

Products were analysed in triplicate for pH (BSI 1976), moisture (IDF 1958), NaCl (IDF 1979), fat (IDF 1986b), protein (IDF 1986a), Ash (Kindstedt and Kosikowski 1985), Phosphate (P) (IDF 1987) and Calcium (Ca) (IDF 1984). Results for P and Ca were expressed as mg g−1 protein. Results for moisture, fat, protein, NaCl, and ash were expressed as a percentage (%) on a dry weight basis.

Proteolysis analysis

The water-soluble extract (pH 4.6-WSE) was prepared as described by Hou et al. (2014). The total N content of each pH 4.6-WSE samples was determined in triplicate by the macro-Kjeldahl method (IDF 1986a) to obtain the levels of pH 4.6- soluble nitrogen (pH 4.6-SN). The peptide profile of each pH 4.6-WSE was determined by Reverse Phase HPLC (RP-HPLC) using a Nucleocil C8 column at the wavelength of (214 nm) following Kilcawley et al. (2000) and Kilcawley et al. (2006).

Degree of secondary proteolysis was measured by the levels of 5% phosphotungstic acid-soluble nitrogen (PTA-SN). A portion (30 mL) of each pH 4.6-SN sample extract was mixed with 18 mL of 9.2 N H2SO4, 9 mL of 33.3% dodeca-tungstophosphoric acid, and 3 mL of distilled water making a total volume of 5% phosphotungstic acid. The mixture was allowed to stand at room temperature for 18 h and filtered through Whatman filter paper No. 42. Each filtrate (5% PTA-SN) was analysed for N content by macro-Kjeldahl (IDF 1986a) and expressed as a percentage of the total N. The levels of individual free amino acids (FAA) were determined on 12% trichloroacetic acid filtrates prepared from the pH 4.6-WSE (Kilcawley et al. 2000, 2006). Filtrates were analysed using an amino acid analyzer (L-8800; Hitachi, Japan). Results for each product were expressed as μg g−1 on a dry weight basis. The effect of each enzyme preparation (proteinase and peptidase) and replicates were estimated for individual FAA. All analyses were performed in triplicates.

Ranked preference sensory analysis

The assessors (n = 16) were asked to rank the products based on preference for flavour using Spectrum Method™ (Meilgaard et al. 1999). Each proteolysed product was presented and instructed to use a score of 1 (most preferred) to 3 (least preferred) and report any descriptive observations on the sensory characteristics. Data from sensory analysis were computed for their statistical significance (p < 0.05) using Friedman’s test, Kendall’s coefficient and multiple comparison procedure to determine which products differed from each other. Ranked preference sensory analysis was performed on one batch of each product.

Lipolysis analysis

Lipid extraction and the composition of free fatty acids (FFAs) were accomplished as described by Erkaya et al. (2015). FFAs were analysed using a GC/MS system (Agilent 6980 N series, Agilent Tech. Inc., Santa Clara, CA, USA) equipped with an auto-sampler and flame ionization detector (Agilent Tech. Inc.) and a universal capillary injector with the following conditions: temperature of 200 °C; column was a DB-23 capillary column (60 m × 0.25 mm × 0.25 μm). The injector was held at 165 °C for 10 min; the temperature raised to 200 °C at 7.4 °C/min; this temperature was held for 22 min. The total run time was 47 min. The flame ionization detector was operated at 200 °C. The carrier gas was helium and was held at a constant flow of 1.2 mL/min. The acid degree (AD) values were determined as described by Kilcawley et al. (2006).

SPME–GC–MS analysis of volatile analysis

For volatile compounds, EMC samples were analysed by SPME–GC–MS using the method of Kurtovic et al. (2016). Each sample (3.0 g) was placed in a screw-capped headspace vial (20 mL) and sealed up with a Teflon cover. The vial was kept warm at 40 °C for 20 min with agitation, in order to reach equilibrium between adsorption and desorption. Extraction was achieved by using a 75 μm carboxen poly (dimethyl siloxane)-coated SPME fibre (Supelco, Bellefonte, PA, USA) into the vial and exposing it to the headspace for 20 min at 40 °C prior to adsorption. The desorbed volatiles were analysed by Thermo Scientific ISQ GC–MS (Trace GC Ultra gas chromatograph combined with ISQ, Thermo Scientific, USA) under the following conditions: injection temperature 280 °C; splitless mode; 5 min desorption time; Rtx-5Sil DB5-MS column 30 m × 0.25 mm ID × 0.25 μm film thickness (Restek, Bellefonte, PA, USA); programmed oven temperature: 35 °C start, 15 °C/min to 180 °C, then 20 °C/min to 260 °C and held 30 s; He carrier gas, flow rate 1.0 ml/min and detector temperature 280 °C. The peaks were identified by comparing with mass spectrum database library and their retention index (RI). The mass spectrometer operated in the electron impact (EI) ionization mode at 70 eV, and mass spectral data were acquired in the mass range of 33–300 amu at 0.7 scans/s.

Descriptive sensory analysis

All tests were conducted in a standard room with adequate illumination and controlled temperature. The session was conducted in the Sensory Analysis Laboratory of the School of Food Science and Technology, Jiangnan University (Jiangsu, Wuxi, China). The sensory profile of each EMC was determined by sixteen assessors (4 woman and 12 men aged 24–33 years), who were selected and initially trained for quantitative sensory descriptive analyses using Spectrum Method™ (Meilgaard et al. 1999). All of assessors had a prior experience of quantitative descriptive analysis and consumed cheese at least once a week. The panellist assessed the EMCs using the descriptors outlined in Table 4, with the defined list of descriptive terms Table S2 obtained from literature (Hulin-Bertaud et al. 2000). EMCs are usually used as a food flavour ingredient and do not affect colour and texture hence, these were not conducted. The assessors were given each sample (2 g) in a glass tumbler covered with a clock glass and were coded with random 4-digit number at the temperature 4 °C. Each assessor evaluated each product for flavour in triplicate. Still mineral water and plain crackers were provided as a palate cleanser to avoid error between the samples. A base cheese (Ba) was also prepared and evaluated into which EMC (3) product was selected and diluted to 10% (w/w) using the commercial EMC, as it was thought that their soy bitterness may negatively impact their sensory evaluation. Data were collected and scores were converted to values from 0–100 for required attributes.

Statistical analysis

SPSS statistical software (v.17.0, SPSS Inc., Chicago, IL, USA) was used to analyse data. Analysis of variance (ANOVA) and Duncan’s multiple range tests were used to determine the significant (p < 0.05) differences among results. All values reported were means of three independent replications.

Results and discussion

Composition

The compositional and proteolytic parameters of the substrate, their proteolysed products, targeted EMCs and comparable bovine commercial EMC are shown in Table 1. Overall differences in the products were low which reflected a higher degree of controlled process. The pH values decreased throughout the process as a result of increased FAAs and FFAs. The moisture contents showed a slight increase, which may be due to the hydrolysis of protein and lipids in the process. Levels of homogenous NaCl distribution in EMCs were recorded, which caused a salty flavour to the end point products. Protein contents of the proteolysed products ranged from 30.2 to 31.2%, while those in the lipolyzed products ranged from 28.6 to 29.3%, respectively. The level of calcium (Ca) ranged from 46.2 to 47.3% mg g−1, while the phosphate content varied from 55.8 to 56.2 mg g−1 on dry weight basis. In cheese development, deficient of Ca contents may disrupt the calcium-mediated protein interactions, thus weakening the protein matrix. However, a sufficient level of Ca in the EMCs was observed due to added CaCl2 and soymilk, which act as a strong promoter of protein-to-protein interactions (Noronha et al. 2008), and suggested homogenous conversion of proteins into the substrate via enhanced enzyme substrate interactions (Kilara 1985a).

Proteolysis

Water soluble nitrogen (pH 4.6-WSN/TN%) and 5% phosphotungstic acid soluble nitrogen (PTA-SN/TN%) were used as an index of proteolysis. For the proteinases/peptidase specificity towards substrate, the level of proteolysis was conducted separately, in which pH4.6-WSN/TN% of the products 1–5 increased at a linear rate of P-1 (r 2 = 0.98), P-2 (r 2 = 0.98), P-3 (r 2 = 0.99), P-4 (r 2 = 0.99), P-5 (r 2 = 0.99), over the incubation period of 24 h. The values of pH 4.6-WSN/TN% in the desired products P1–P5 increased from 49.66 to 57.24% and served as a close index of commercial EMC (Table 1). While, the level of PTA-SN% varied from 5.5 to 18.84%, respectively. The pH decreased during the production of proteolysed products P(1–5) and this could be associated with a higher level of proteolysis and free amino acids generation (Kilcawley et al. 2000, 2006). The differences among proteolytic indices (pH 4.6WSN-TN%/PTA-SN%) may be due to proteinases specificity or its substrate limitations. However, the targeted commercial EMC proteolytic indices levels could not be achieved, as the choice and variability in commercial EMCs are vast (Kilcawley et al. 2000). The RP-HPLC peptide profiles of the products (1–5) were apart from the early eluting peptides (RT ~50) (Fig. 1b) and indicated extensive secondary proteolysis, which was in good agreement with the indices of proteolysis (soluble N and FAA). However, similarities in the peptide pattern of the extensively proteolysed products may reflect residual peptides that cannot be further hydrolysed. The effect of different proteolytic treatments on mean concentration of individual FAAs (µg g−1) of the products (1–5) was evaluated statistically (Table 2). Throughout the process similar to WSN/TN% and PTA-SN/TN% indices, FAA levels were also significantly increased to various extents. Overall, the FAA contents were higher. Product 1 was similar to product 5, whereas it and differed from products 2, 3, and 4 respectively. Different proteolytic treatments had no effect on the release of aspartic acid, serine, threonine, leucine, and lysine amino acids. Predominant FAAs in the products were glutamic acid followed by aspartic acid, leucine, lysine, and proline, which are constituents of both soy cheese and cheddar cheese, and acts as precursors of flavouring compounds (Ahmad et al. 2008). Abundance of glutamic acid in the products suggested a link to the levels present in soy protein and casein and the higher levels of glutaminase activity in the enzyme preparation used in its products. Glutamic acid can be generated in combined soymilk–cow’s milk cheeses through the action of proteases in combination with peptidases, which was responsible for the diverse aroma profile (Kilcawley et al. 2006). This increased level of glutamic acid acted as a natural flavour potentiator to reduce bitterness and accentunate specific flavour notes in the products (Kilara 1985b; Kilcawley et al. 2006). Product-5 hydrolysed with Flavourzyme gained the highest levels of total FAAs, in which 20% alone was the free glutamic acid as flavour enhancer (Kilcawley et al. 2000). Increased glutaminase activity during the EMC production appeared to be beneficial. The levels of glutamic acid found in products (2 and 4) were higher and not significantly (p < 0.05) different from those in products 1, 3, and 5. The pH values of products 2 and 4 were also decreased (pH 5.62–5.44), which significantly contributed to high levels of glutaminase activity in the enzyme preparation (Peptidase R) during its production. Overall, higher levels of glutamic acid were observed in combined soy–cow’s EMC products than the commercial type EMCs (Kilcawley et al. 2000, 2006; Noronha et al. 2008). Product 2 and 4 differed (p < 0.05) in histidine, methionine, phenylalanine, and isoleucine contents. Product 2 was different from products 1, 3, 4, and 5 in the levels of most FAAs. The concentration of free proline was dominant in product 3 and may have resulted from the action of proline-specific peptidase activity in Protease AX and Peptidase R. The level of isoleucine was lower (p < 0.05) in product 2 than other products, which might be due to the lack of peptidase activity (ProteAX) used in its production. The Peptidase R, ProteAX, Protease M Amano SD, Flavourzyme 1000 L and Neutrase 0.5 L are known to contain peptidase activities (Kilcawley et al. 2002, 2006; Park and Lee 2015; Sari et al. 2014). Compared with the bovine commercial EMC, both primary and secondary proteolysis as indicated (pH 4.6WSN-TN/PTA-SN%) increased with good extent in the products 1–5, but their targeted commercial EMC levels could not be achieved, as the choice and variability in commercial EMCs are enormous (Kilcawley et al. 2000). Levels of FAA in the commercial EMC were 85.1, 2.5, 2.8, 2.8, 2.7, and 2.6 times higher than the base substrate and products 1–5, respectively. It was apparent from the results that extensive proteolysis was an integral process for the production of proteolysed products 1–5. The results highlighted that using combinations of proteinase and peptidase preparations are required to provide their sufficient levels. However, variations in the level of proteolysis between products were low, which supports the compositional data and indicates the use of a controlled process.

Ranked preference sensory attributes

Statistical analysis using Friedmans test and Kindall’s coefficient for the ranked preference of products 1–5 showed significant differences (p < 0.05) (Table-S1). However, multiple comparison analysis for ranked data indicated that only products 2 and 5 were significantly different from each other (p < 0.05). It was likely due to their differences in secondary proteolysis, which have a bigger impact on sensory perception. These results clearly highlighted that the variations in the proteolysis emerging from differences in the specificity of proteinases used in their production, also influence products flavour. Since, product-5 gained the highest score and was the most preferred, it was further chosen as the base substrate for lipolysis using commercial lipases preparations (Fig. 2) to produce a range of targeted EMCs.

Lipolysis

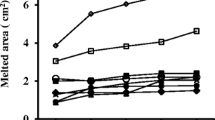

For the lipases specificity towards substrate, level of lipolysis assessed by acid degree value (ADV) in each EMC product (1–3) was separately conducted and increased at the linear rate of EMC-1 (r 2 = 0.99), EMC-2 (r 2 = 0.98), and EMC-3 (r 2 = 0.99), over the incubation period of 24 h. Slight variations in the composition and degree of pH 4.6-WSN between the base substrate product (5) and imitation EMCs (1–3) were observed (Table 1). The pH decreased, while moisture content increased throughout the production of EMCs (1–3), which generally favours enzymatic activity and likely related to an increase in the contents of FFAs. Microbial contamination was absent due to the heat treatment steps after proteolysis termination and the addition of potassium sorbate, which has major effects in controlling microbial contaminants (Kilcawley et al. 1998). Proteolysis did not increase in the lipolytic phase as the lipase lacks proteolytic side activities (Kilcawley et al. 2000). The extent of lipolysis as assessed by ADV was accomplished for all EMCs (1–3) and their levels were significantly (p < 0.05) increased and served closed to the commercial type EMC (Fig. 2b). These increased ADV contents may also have attributed to homogenisation of soymilk–cow’s milk as their slight difference can contributes to higher levels of FFAs contents (Kilcawley et al. 2006). Effects of different lipase preparations on mean concentration of individual FFAs (%) in the substrate (P-5), imitation EMCs (1–3) and comparable commercial type EMC are illustrated by (Fig. 2b). C4:0, C6:0, C16:0 and C18:1 were the most abundant FFAs in the substrate (P-5) as well as in the imitated EMCs (1–3). These higher levels were most likely due to FFAs from the microbial starter culture affinity and enzymes specificity towards substrates. Kurtovic et al. (2016) also found that salmon lipase showed higher contents and specificity towards C4:0, C6:0, and C18:1 during hydrolysis of milk lipids. The lipases also showed higher affinity towards C8:0, C10:0 C12:0, and C18:0 FFAs in imitated EMCs (Fig. 2) and were attractive from flavour viewpoint. However, C14:0 showed one of the lowest levels of FFAs. Similar trend was reported by Kilcawley et al. (2006), who studied imitation of Cheddar-type EMCs where a greater diversity of FFAs was achieved. Statistically significant differences (p < 0.05) for the levels of individual FFA (%) between EMCs (1–3) (Fig. 2) were due to the use of lipases of known differences in acyl and regio selectivity. Acyl migration is mainly associated with the movement of FFA from position Sn2 in di-glycerides and mono-glycerides to the position Sn1 or Sn3 in greater extent of lipolysis (Kilara 1985a). However, the addition or presence of calcium in the cheese matrix can also remove more FFAs from the interface and significantly influence the flavour perception altering their volatility (Kilcawley et al. 2006). It is worth noting that higher levels of Ca due to added CaCl2 and Ca from soymilk may also contribute to produce more FFAs. These results also showed the differences in ADV values corresponding to the significant differences in the levels of total FFAs. In a comparable commercial type EMC the levels of FFAs were slightly higher than the imitated EMCs 1–3 due to their enormous varieties, and they were in agreement with the ADV values too. In summary, from this process, we were able to produce important short and medium chain FFAs in the soymilk–cow’s milk based EMCs.

Volatile compounds of the targeted EMCs

Total fifty-six compounds: 8 ketones, 17 acids, 2 alkanes, 11 alcohol, 12 aldehydes, 1 benzene, 1 hydrocarbon, 1 ester, and 3 others, with varying reliability were found between retention time (RT) 3–27 min (Table 3). All of these compounds have previously been identified in different ratios in soymilk, soymilk cheeses (Moy et al. 2012; Li et al. 2014) as well as bovine milk cheeses with sensory characteristics. The most abundant compounds in EMCs (1–3) were butanoic acid, hexanoic acid, decanoic acid, dodecanoic acid, octanoic acid, phenol, heptanoic acid, pentanoic acid, 3-hydroxy-2-Butanone, 2-heptanone, and 2-pentanone which were also reported as flavour characteristics in numerous cheeses (Singh et al. 2003). Hexanoic acid and butanoic acid, which are mainly produced by lipolysis, were present in higher amounts as expected, as these are readily hydrolysed from mono-, di- and tri-acylglycerides (Omar et al. 2015; Kurtovic et al. 2016). These compounds are the major contributors of flavour in many dairy products. 2-furancarboxaldehyde and H-pyran-2-one also appeared as potential flavour compounds, which are quite unusual in dairy products but common in soy cheeses. Hexanal and 2-pentylfuran, which offer the typical beany and grassy soy off-flavours, were detected at very low levels (Li et al. 2014). However, some aldehydes, ketones, alcohols, and acids as aroma-active compounds, were also produced in higher contents through the catabolization or metabolization of FFAs and FAAs. Lipase AY 30SD was found to produce more 1-butanol, hexanoic acid, ethyl ester, styrene, 2-octanone, 2-nonanone, benzaldehyde, 2-furanmethanol, hexanoic acid, and heptanoic acid, which offered good smell of fragrance. Lipase MER was able to yield higher amount of 1-hexanol, E-2-nonenal, 1-hexanol, 2-ethyl, 2-methyl-propanoic acid, butanoic acid, decanoic acid, ethyl ester, 3-methyl-butanoic acid, pentanoic acid, octanoic acid, and decanoic acid in its product EMC-2, while higher levels of 3-methyl-butanal, 2-pentanone, methyl- benzene, 2-heptanone, 2-heptenal, hexadecane, 2(5H)-furanone, benzeneethanol, octanoic acid and dodecanoic acid were produced by Lipase DF 15 of EMC-3. In addition, the compounds which were absent in base substrate and originated in EMCs, may be related to enzymatic hydrolysis and acidic circumstances. Compared with the commercial EMC, some compounds contained higher amounts than the imitated EMCs, which may be due to their enormous varieties and this is in agreement with the FAA and FFAs contents too. There has been a general understanding that volatile flavour compounds of the cheeses are mainly originated from the degradation of milk constituents, particularly proteins and lipids, through the enzymatic interactions and maillard reaction of peptides and amino acids (Singh et al. 2003). These results showed that fermentation of mixed soymilk–cow’s milk using starter culture, and combination of enzyme preparations along with the flavour production, may not only contribute to soy flavour but also considerably reduce beany-grassy off-flavours.

Descriptive sensory properties

Sensory scores obtained for soy-cow’s mixed substrate (P-5), their imitated EMCs (1–3), cheese base (Ba), and commercial EMC are shown in Table 4. It is noteworthy that enzyme modified cheeses are unlikely to absolutely mimic their natural cheese flavours (Kilcawley et al. 2006). Base substrate showed the lowest scores of most of the attributes, particularly strength and dairy-sweetness. It exhibited milky, fruity, creamy, soy-sweet, salty, and buttery flavours, which appears to be important intrinsic characteristics flavour of the imitated EMCs. The intensities of flavour attributes (soy-sweet, buttery, creamy, brothy, and nutty) were relatively higher in all samples, which are typically inversely correlated with bitterness (Young et al. 2004; Kilcawley et al. 2006; Kilcawley et al. 2012). A suitable explanation for sweeter and creamier notes might be higher concentrations of aspartic acid, glutamic acid, lysine, proline, butanoic acid, and hexanoic acid, which significantly contributes to the sensory perceptions. It is worth noting that soymilk prepared from lipoxygenase-free soybeans have less cooked beany aroma than that made from normal soybeans (Torres-Penara et al. 1998), which also support the present results. EMCs (1–3) had the most intense fruity, dairy-sweet, soy-sweet, buttery, and salty flavour, whereas commercial EMC was not described with soy-sweet attribute. Among imitation products, EMC-3 was chosen as the best representative having close scores to commercial EMC. However, base cheese (Ba) obtained the balanced sensory scores for all attributes compared with commercial EMC, which could be due to the accessibility of the consumers. Overall, the sensory characteristics such as eggy, cooked, bitter, and pungent smell decreased in comparison to the substrate and commercial EMC, which may be likely due to the use of enzymes preparations and their higher levels of secondary proteolysis. This study revealed an expected effect of soy protein and anhydrous milkfat substitution on the sensory properties of EMCs. Kilcawley et al. (2000, 2006) also reported that inclusion of fat and protein significantly contributes to the proteolysis and lipolysis and influences sensory properties and the range of EMC products. However, overall results in this study demonstrated that products of mixed soymilk–cow’s milk recombined with milkfat and inclusion of enzyme preparations significantly enable greater diversity of sensory properties.

Conclusion

Soymilk in combination with bovine milk for the production of curd for enzyme modified cheeses (EMCs) manufacture is novel. In this study, the inclusion of enzyme preparations considerably impacted mixed soymilk–cow’s milk EMCs. Flavour development was clearly evident from enhanced ADV, increased FAAs, FFAs, and volatile contents as well as from the development of compositional and sensory attributes. However, little variations in FAA contents and peptide profiles were observed between the proteolysed products, suggesting that comparable known proteinase preparations should be further used in their production. The higher levels of a natural flavour enhancer, glutamic acid were appeared to have a significant impact on its sensory properties. Similarly, increased levels of acids, ketones, aldehydes, and alcohols resulted in higher intensity of EMCs flavours. This approach clearly demonstrated the ability of imitating EMCs from mixed soymilk–cow’s milk. Imitated cheeses are attributed to cost-effective of its manufacture and the replacement of milk ingredients. Therefore, with an economic standpoint, the present study will be useful in designing products with nutritional and soy flavour characteristics. The results will also be useful to test their suitability in future food researches.

References

Ahmad N, Li L, Yang XQ, Ning ZX, Randhawa MA (2008) Improvements in the flavour of soy cheese. Food Technol Biotech 46:252–261

BSI (1976) British standard method for chemical analysis of cheese, part 5. Determination of pH value. British Standards Institute, London

Erkaya T, Ürkek B, Doğru Ü, Çetin B, Şengül M (2015) Probiotic butter: stability, free fatty acid composition and some quality parameters during refrigerated storage. Int Dairy J 49:102–110

Grygorczyk A, Alexer M, Corredig M (2013) Combined acid- and rennet-induced gelation of a mixed soya milk–cow’s milk system. Int J Food Sci Tech 48:2306–2314

Grygorczyk A, Duizer L, Lesschaeve I, Corredig M (2014) Gelation of recombined soymilk and cow’s milk gels: effect of homogenization order and mode of gelation on microstructure and texture of the final matrix. Food Hydrocoll 35:69–77

Hou J, Hannon JA, Mcsweeney PL, Beresford TP, Guinee TP (2014) Effect of curd washing on cheese proteolysis, texture, volatile compounds, and sensory grading in full fat Cheddar cheese. Int Dairy J 34:190–198

Hulin-Bertaud S, Kilcawley KN, Wilkinson MG, Delahunty CM (2000) Sensory and compositional relationships between commercial cheddar-flavored enzyme-modified cheeses and natural cheddar. J Food Sci 65:1076–1082

IDF (1958) Determination of dry matter in cheese and processed cheese IDF Standard 4. Int Dairy F, Brussels

IDF (1979) Determination of chloride content: potentiometric titration method. Standard 88. In: Cheese and processed cheese. Int Dairy F, Brussels

IDF (1984) Determination of sodium, potassium and calcium contents: flame photometric method. Standard 119. Dried milk. Int Dairy F, Brussels

IDF (1986a) Determination of nitrogen content (Kjeldhal Method) and calculation of crude protein content. Standard 20A. Int Dairy F, Brussels

IDF (1986b) Determination of fat content (Gravimetric method). Standard 5B. Int Dairy F, Brussels

IDF (1987) Determination of the phosphorus content of natural and processed cheese (photometric method). Standard 33C. Int Dairy F, Brussels

Kilara A (1985a) Enzyme modified lipid food ingredients. Process Biochem 20:35–45

Kilara A (1985b) Enzyme modified protein food ingredients. Process Biochem 20:149–157

Kilcawley KN, Wilkinson MG, Fox PF (1998) Review: enzyme-modified cheese. Int Dairy J 8:1–10

Kilcawley KN, Wilkinson MG, Fox PF (2000) A survey of the composition and proteolytic indices of commercial enzyme modified Cheddar cheese. Int Dairy J 10:181–190

Kilcawley KN, Wilkinson MG, Fox PF (2002) Determination of key enzyme activities in commercial peptidase and lipase preparations from microbial or animal sources. Enzym Microb Tech 31:310–320

Kilcawley KN, Wilkinson MG, Fox PF (2006) A novel two-stage process for the production of enzyme-modified cheese. Food Res Int 39:619–627

Kilcawley K, Nongonierma A, Hannon J, Doolan I, Wilkinson M (2012) Evaluation of commercial enzyme systems to accelerate Cheddar cheese ripening. Int Dairy J 26:50–57

Kindstedt PS, Kosikowski FV (1985) Improved complexometric determination of calcium in cheese. J Dairy Sci 68:806–809

Kurtovic I, Marshall SN, Cleaver HL, Miller MR (2016) The use of immobilised digestive lipase from Chinook salmon (Oncorhynchus tshawytscha) to generate flavour compounds in milk. Food Chem 199:323–329

Li C, Li W, Chen X, Feng M, Rui X, Jiang M, Dong M (2014) Microbiological, physicochemical and rheological properties of fermented soymilk produced with exopolysaccharide (EPS) producing lactic acid bacteria strains. LWT—Food Sci Technol 57:477–485

Meilgaard M, Civille GV, Carr BT (1999) Sensory Evaluation Techniques, 3rd edn. CRC Press Inc., Boca Raton

Moy Y-S, Lu T-J, Chou Ch-Ch (2012) Volatile components of the enzyme-ripened sufu, a Chinese traditional fermented product of soy bean. J Biosci Bioeng 113:196–201

Noronha N, Cronin DA, O’Riordan ED, O’Sullivan M (2008) Flavouring of imitation cheese with enzyme modified cheeses (EMCs): sensory impact and measurement of aroma active short chain fatty acids (SCFAs). Food Chem 106:905–913

Omar KA, Gounga ME, Liu R, Mlyuka E, Wang X (2015) Effects of microbial lipases on hydrolyzed milk fat at different time intervals in flavour development and oxidative stability. J Food Sci Technol 53:1035–1046

Park MJ, Lee SY (2015) Quality characteristics of soy yogurt produced using proteases and mixed microbial consortia. J Korean Soc Appl Biol Chem 58:761–769

Sacks F (2006) Soy protein, isoflavones, and cardiovascular health: an American heart association science advisory for professionals from the nutrition committee. Circulation 113:1034–1044

Sari YW, Alting AC, Floris R, Sanders JP, Bruins ME (2014) Glutamic acid production from wheat by-products using enzymatic and acid hydrolysis. Biomass and Bioenergy 67:451–459

Singh T, Drake M, Cadwallader K (2003) Flavor of Cheddar cheese: a chemical and sensory perspective. Compr Rev Food Sci Food Saf 2:166–189

Torres-Penara AV, Reitmeier CA, Wilson LA, Fehr WR, Narvel JM (1998) Sensory characteristics of soymilk and tofu made from lipoxygenase-free and normal Soybeans. J Food Sci 63:1084–1108

Wilkinson MG, Guinee TP, O’Callaghan DM, Fox PF (1992) Effects of commercial enzymes on proteolysis and ripening in Cheddar cheese. Le Lait 72:449–459

Young ND, Drake M, Lopetcharat K, McDaniel MR (2004) Preference mapping of Cheddar cheese with varying maturity levels. J Dairy Sci 87:11–19

Acknowledgements

This work was supported by China Scholarship Council under Chinese Government Scholarship Programme.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ali, B., Khan, K.Y., Majeed, H. et al. Imitation of soymilk–cow’s milk mixed enzyme modified cheese: their composition, proteolysis, lipolysis and sensory properties. J Food Sci Technol 54, 1273–1285 (2017). https://doi.org/10.1007/s13197-017-2534-7

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-017-2534-7