Abstract

This study aimed to compare the effects of 1 % addition of four selected hydrocolloids (xanthan, guar, hypdroxypropylmethylcellulose and carrageenan) on quality characteristics of batter and of black waxy rice steamed cake compared to a control without hydrocolloids. Dynamic frequency sweeps of the batters at 25 °C indicated that all formulations exhibited gel-like behaviour with storage moduli (G′) higher than loss moduli (G″). Hydrocolloids increased the apparent viscosity and the thixotropic behaviour, depending on the type of hydrocolloids. Xanthan had the greatest effects on both moduli, whereas carrageenan had the smallest effects. During a storage period of 4 days the cakes with xanthan remained softer than control samples. The overall acceptability of cake with xanthan and guar were higher than control. This study is the first report on using black waxy rice flour as a main raw material in gluten free cake. The results of this study provided useful information for selection hydrocolloids as ingredients that can help to improve the physical properties of waxy rice steamed cake.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A variety of cereal foods are produced from wheat flour, such as bread, cake and pasta, all of which, contain gluten. However, many people suffer from gluten-related disorders. Celiac disease, also known as gluten intolerance to certain amino acid sequences found in the prolamin fraction of wheat (gliadin), rye (secalin) and barley (hordein), occurs in about 1 % of European people (Ciclitira et al. 2005). Gluten replacement is one of the most challenging issues for food science and technology, since finding high quality gluten-free foods is a major issue for celiac disease sufferers (Turabi et al. 2010).

The majority of bakery products are made of wheat flour or other cereal flours containing gluten. As alternatives to wheat flour, several other flours have been considered people requiring gluten-free products, both as coeliac and as non-coeliac persons intolerant or allergic to gluten. Rice flour is well-accepted and one of the most widely used cereal grain flours for the production of gluten-free baked products. Rice (Oryza sativa L.) is one of the leading food crops in Southeast Asia. It can be classified into two groups, non-waxy (also called non-sticky rice, non-glutinous rice) and waxy rice. This classification is based on the way the rice behaves during cooking, which is related to the amylose content in the rice grains (Usansa et al. 2011). The most common rice consumed by humans is white rice, followed by brown rice; however rice genotypes with either red, purple or black bran layer have been cultivated for a long time in Asia (Sutharut and Sudarat 2012). Among these coloured rice varieties, black rice (also known as purple rice or forbidden rice) is the most famous one because has a number of nutritional advantages, such as a higher content of natural anthocyanin compounds, protein, vitamins and minerals (Daiponmak et al. 2014).

Cake is one of the most loved bakery products, consumed worldwide by all ages in large quantities. The quality of cakes depends on many factors, such as the ingredients used for batter preparation, aeration of batter and process conditions. A number of studies are on the formulation of gluten-free baked cakes from non-waxy rice (Gularte et al. 2012; Matos et al. 2014; Ronda et al. 2009; Sumnu et al. 2010; Turabi et al. 2010) in traditional recipes. A limited number of studies used waxy rice as partial or 100 % substitution of wheat flour. Recently, Chueamchaitrakun et al. (2011) using mixed rice flour of waxy and non-waxy white rice in a ratio of 1:0, 3:1, 1:1 and 0;1, respectively in butter cake. They found that butter cake made from waxy rice flour were denser and flat. However literature reviews reveal that no studies have been made with 100 % of black waxy rice flour.

Hydrocolloids, also known as gums, are widely used in starch-based products mainly to improve stability, modify texture and facilitate processing (Kaur et al. 2015). Hydrocolloids are added in small quantities [<1 % (w/w) of flour] to bakery products mainly for retarding the staling and for improving the quality of fresh products. Because of these characteristics, several studies have been carried out showing the potential of hydrocolloids in the baking industry. Turabi et al. (2010) found that different types of gums including xanthan, guar, locust bean, carrageenan and xanthan–guar blends affected the pore area fraction and total number of pores in rice cakes. More porous cakes were obtained when xanthan and xanthan–guar gum blends were used in gluten-free cakes (Turabi et al. 2010). In the study of Breckon et al. (2003), xanthan gum appeared to enhance the quality of gluten-free cakes by increasing batter viscosity and cake height, resulting in a cake more similar to cakes made with wheat flour. It has also been reported that cakes formulated with xanthan gum displayed improved quality characteristics such as increased specific volume, enhanced texture in terms of decreased firmness, and delayed staling.

Our preliminary studies revealed that black waxy rice flour has a potential to be used as raw material to replace 100 % of wheat flour in cakes without adversely affecting the sensory acceptance. Most western-style cakes are intended for baking in an oven with dry heat between 160 and 200 °C. Under this conditions waxy rice cakes will be become dry, hard and dense, because of waxy rice has a greater amount of amylopectin and lack of gluten. Making cakes with steam at lower temperature, instead of oven dry heat, the moist air transfers heat more effectively and the rice cake can absorb more water, resulting in a light, tender and moist cake. However, due to its low gas retention capacity, black waxy rice steamed cake have some quality deficits such as low volume, poor texture, colour and crumb structure. In the literature a large number of various hydrocolloids have been widely used in gluten-free non waxy rice cake formulations to improve texture and appearance of gluten free cake products (Breckon et al. 2003; Preichardt et al. 2011; Sumnu et al. 2010; Turabi et al. 2008, 2010).

Thus the objective of this study was to characterise the influence of four hydrocolloids (Xanthan gum, Carrageenan, Guar and HPMC) on batter properties (rheological properties and specific gravity) and on steamed waxy rice cake properties (physical and sensory properties).

Materials and methods

Materials

Commercial black waxy rice (Khaw Niaw Dam) flour obtained from the local market in Thailand (Double bear brand, Burapa Proster Co., Ltd.). The composition of black waxy rice is as follows: 80.02 % carbohydrates, 7.05 % protein, 0.33 % fat, 1.32 % ash, 11.28 % moisture content, 0.75 % crude fiber and 4.28 % amylose content. Xanthan (XN; Grindsted type 200, KUK solution for pharma and food, Austria) guar gum (GR; Grindsted type 200, KUK solution for pharma and food, Austria) hydroxypropylmethylcellulose (HPMC; type K 4 M, VIVAPUR®, JRS, Germany), and carrageenan (Grindsted Carrageenan CX 102, KUK solution for pharma and food, Austria) were used in these studies. Sugar, butter (Milfina, Austria), evaporated milk (4.0 % fat, Milfina, Austria), fresh whole eggs were prepared by blending 32 % yolks with 68 % whites according to the whole egg composition (Edoura-Gaena et al. 2007), emulsifier (UFM SP, United Flour Mill Public Co., Ltd.) and baking powder (double acting type, Best Foods, Thailand).

Cake preparation

The basic black waxy rice cake recipe was chosen according to our preliminary study. The control cake formulation contained the following ingredients: 200 g black waxy rice flour, 200 g egg, 200 g powdered sugar, 100 g butter, 30 g milk and 1.7 g baking powder. Xanthan gum, guar gum, locust bean gum and k-carrageenan were added in 1 % of flour basis. The cakes were prepared using the following steps:

-

1.

Black waxy rice flour, baking powder and hydrocolloid were mixed and then sieved through a 100 mesh sifter.

-

2.

Eggs, sugar, salt and emulsifier were mixed with a cake mixer (Kitchen aids, 7 Quart bowl) at high speed for about 5 min until the colour turned white and the batter became fluffy.

-

3.

Flour, melted butter and milk were added and stirred at low speed for 1 min.

-

4.

After mixing, 30 g of cake batter were weighed into stainless cake cups (3.2 cm top radius, 2.3 cm bottom radius, 2.5 cm height).

-

5.

Then steamed in a steamer pot, 20 cm radius, at 100 °C for 20 min.

-

6.

The cake were removed from the cup and allowed to cool for 1 h before they were packed in plastic bags and finally stored room temperature for further testing.

Cakes were made in three replications for each experiment and all measurements were performed in triplicate.

Measurement of batter

Batter rheology

Rheological measurements were performed with a rheometer (Kinexus, Malvern Instruments, UK), equipped with a stainless steel parallel plate geometry (2.0 mm diameter) with a gap of 1 mm. Batters were prepared as previously described and after 30 min rest, the samples were loaded into the rheometer and the batters were allowed to rest for 5 min in order to allow relaxation of residual stresses. Frequency sweeps from 0.1 to 10 Hz were performed with a strain of 10−4 at 25 ± 0.5 °C. Preliminary tests indicated that this strain was well within the linear visco-elastic region. Three different batches were employed and each formulation was measured in triplicates.

The flow properties of the batters were investigated by measuring the dynamic viscosity η (in Pa s). At a constant temperature of 25 ± 0.5 °C the shear rate was increased from 0.1 to 100 s−1 within 2 min (ramp 1) and then decreased from 100 to 0.1 s−1 within another 2 min (ramp 2). Ramp1 was fitted to the power law model defined as η = m γ (n−1) where η represents the shear viscosity, m is the consistency coefficient, γ represents the shear rate and n is the flow behaviour index. Values of n = 1 indicate Newtonian behaviour while values of n < 1 are representative for shear-thinning. Values of n > 1 are found for shear-thickening fluids (Klang et al. 2011). In order to quantify the thixitropic behaviour, the difference of the apparent viscosity between ramp 1 and 2 was calculated at a shear rate of 16 s−1.

Batter specific gravity

Specific gravity of batter was determined as the ratio of the weight of a standard container filled with batter (W2) to that of the same container filled with water (W1) (Matos et al. 2014).

Measurement of cakes

Weight loss

The muffin cakes were weighted before steaming (W3) and after steaming and 1 h cooling (W4). The weight loss upon steaming was calculated as W3–W4 (Matos et al. 2014).

Central height

The standing height was measured in the center of the cake with a digital caliper from the highest point of the muffin to the bottom of the paper cup after cooling for 1 h at the room temperature.

Specific volume

The cake was weighed after 1 h cooling and the cake volume was measured by rapeseed displacement. The specific volume was also calculated as cake volume/cake weight.

Crust and crumb colour

Colour of the cakes were measured using a spectro-colour (HACH LANGE, Germany) Results were expressed in CIE L*a*b* values.

Cakes storage

Moisture content and texture profile analysis (TPA) were conducted at 0 and after 4 days storage. 3 g of cake samples were taken from the center, 1 cm under the crust. The moisture content was determined in triplicate in each replication by placing the samples in an oven at 105 °C for 4 h. The water content was calculated from the weight determined before and after oven drying.

Crumb texture was determined by a texture analyzer (Model: TA-XT Plus, Stable Micro Systems Ltd., Surrey, UK), equipped with a 50 kg load cell. The cake samples were cut horizontally at the height of the cup, the upper half was discarded and the 2.0 cm high lower halves were removed from the paper cup. The measurements were performed with a 100 mm diameter aluminum probe, 50 % deformation of their original height at a speed of 1 mm/s and 5 s waiting time before starting the second compression (Matos et al. 2014). The parameters obtained from the curves were hardness (kg), cohesiveness (no unit), springiness (no unit), chewiness (kg mm) and resilience (no unit). Hardness was defined as the maximum force during the first compression. Cohesiveness determined from the area of work during second compression divided by the area of work during the first compression. Springiness was defined as the distance to which the sample recovered in height during the time that elapsed between the end of the first compression cycle and the start of the second compression cycle. Gumminess was calculated by multiplying hardness and cohesiveness, whereas chewiness was obtained from the product of hardness, cohesiveness and springiness (Chaiya and Pongsawatmanit 2011). The results were represented as mean of at least five replicates for each formulation, which were prepared in tree batches on different days.

Sensory evaluation

Panels of twenty scientists had previous experience in evaluation of bakery products and were trained before the experiments. Qualitative descriptive analysis was exploited in order to evaluate cake crust colour, shape, crumb colour, moistness and firmness by scoring on 10 cm unstructured line scales. The overall acceptability of the product using a 9 point hedonic scales. The cakes were placed in plastic bags 24 h after steaming, sealed and stored at room temperature (25 °C) until subjected to sensory analysis.

Statistical analysis

Data were subjected to Analysis of Variance (ANOVA) using SPSS for Window version 21. In case of any differences in mean, multiple comparisons were performed using Duncan’s Multiple Range Test (DMRT) at 5 % level of significance (P < 0.05).

Result and discussion

Effect of hydrocolloid on batter properties

Flow behaviour of batter

The foremost reason behind the ample use of hydrocolloids in foods is their ability to modify the rheology of food system, namely, flow bahaviour (viscosity) and mechanical solid property (texture) (Saha and Bhattacharya 2010). Batters are complex mixtures of flour and various ingredients. The visco-elastic behaviour of the batter is important to retain air bubble into the batter and to create the cake structure.

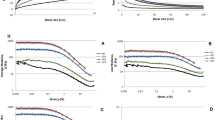

In order to understand the effect of hydrocolloid types on rheological properties of batters, the dynamic oscillatory as well as the flow behaviour of samples were analyzed. From the dynamic rheological measurements the elastic (or storage) modulus, G′, related to the elastic response of the system, and the viscous (or loss) modulus, G″, related to the viscous response of the system, were evaluated. It was found that all batters displayed elastic or gel-like behaviour because G′ was much higher than G″ along the frequency sweep (Fig. 1).

The samples were compared using G′ and G″ at a constant frequency of 1 Hz (Fig. 2). ANOVA indicated that the addition of the hydrocolloids had significant effects on batter properties. Xanthan gum had the greatest effect on G′ and G″ and gave values 4 times higher than the control. Higher values for G′ indicate higher gel strengths. Guar gum and HPMC showed the same effect with about 2 times higher values than the control. Carrageenan had no significant effect on G′ and G″. Similar observations on rheological studies have been reported previously by Rosell et al. (2011), HPMC, guar and xanthan gum in rice starch paste increased in G′ and G″.

The parameters of the power law model of the fitted flow curves m and n are summarized in Table 1. All the formulations containing different kinds of hydrocolloids showed shear-thining behaviour (n < 1), which means that apparent viscosity decreased with increasing shear rate which is consistent with results reported elsewhere for cake batters (Turabi et al. 2008). Figure 3 demonstrates the viscosity of the batters at a shear rate of 16 s−1.

All batter formulations, showed a hysteresis between ramp1 and ramp2 indicating different thixotropic bahaviour, which means that the mixing process is very important for the creation of a stable structure. The difference in viscosity between ramp1 and ramp2 at a shear rate of 16 s−1 increased with the addition of hydrocolloid as shown in Table 1. Xanthan obtained the highest value, followed by guar, HPMC, carrageenan and control respectively.

Batter specific gravity

Figure 4 shows that only xanthan gum increased the specific gravity significantly, which means that the batter with xanthan gum was heavier with lower aeration compared with others gum. Maybe this was due to the fact, that the batter with xanthan had the highest viscosity. This is in agreement with Ashwini et al. (2009), who found that hydrocolloids, namely, arabic gum, xanthan, guar, carrageenan and HPMC significantly increased also the specific gravity of cake batter with no eggs. Whereas Turabi et al. (2008) reported that non-waxy rice cakes with different gums without emulsifier, the formulation with guar gum, κ-carrageenan, HPMC, xanthan–guar blend and xanthan-κ-carrageenan blend had lower specific gravity than the control batter, and the addition of xanthan gum did not affect the specific gravity of batter significantly.

Effect of hydrocolloid on cakes quality properties

Central height, specific volume and weight loss

Addition of hydrocolloid affected the central height depending on the type. Formulations with xanthan were higher and more symmetric than cakes without and with others hydrocolloids. Cakes without hydrocolloids were flat and unleavened like a dome shape. These results are in agreement with Preichardt et al. (2011), who also found that cakes with xanthan displayed more uniform and greater volume, while rice cakes in the absence of xanthan exhibited an open and asymmetric pore structure.

Hydrocolloids increased the specific volume, especially cakes with xanthan and guar give the highest values (Table 2). Similar results were observed by Turabi et al. (2008), where the addition of xanthan improved the rice cake volume more than guar, locust, carrageenan, HPMC, xanthan–guar blend and xanthan–carrageenan blend. The results of this study are also supported by the study of Gómez et al. (2007), who observed that xanthan cakes had the highest central height and volume, with an increase of 12 % compared to the control, followed by locust bean gum (9 %) and carrageenan (7 %). Furthermore, Turabi et al. (2010) reported that cakes containing 1 % of xanthan significantly improved the cake volume. Whereas, in the study of Ashwini et al. (2009) only the addition of HPMC increased the volume of eggless cakes from 730 to 760 cm3/450 g and xanthan did not show any improvement in the volume while guar and carrageenan even decreased the volume.

A possible explanation could be that the final volume of the cakes with hydrocolloids was not mainly dependent on the initial air quantity in the batter but on its capacity of retaining it during baking and its effect on the starch gelatinization temperature (Gómez et al. 2007). Thus, rapidly rising bubbles in a low-viscosity cake batter may result in cake volume loss. Ashwini et al. (2009) stated that in less viscous batters, the produced carbon dioxide and water vapor might not be trapped in the air cells during baking, thus resulting in cakes with low volume. This was explained similar by Turabi et al. (2010), in low viscosity batters the air bubbles could easily rise to the surface and get lost into the atmosphere during baking. The air bubbles entrapped into the batter during mixing could not remain in the cake during baking because of the low apparent viscosity. Zhou et al. (2011) found that batter specific gravity decreases were associated with cake volume increases.

The weight loss of black waxy rice cakes is shown in Table 2 and ranged from 2.6 to 3.0/30 g batter, which was not statistically significant. Whereas, Gómez et al. (2007) studied the effect of several hydrocolloids (alginate, guar, HPMC, carrageenan, locust bean, pectin and xanthan) on the baking loss. All samples showed lower baking losses than the control cakes, except with HPMC. Sumnu et al. (2010) found that 1 % xanthan addition resulted in a significant decrease in the weight loss (%) as compared to control cakes.

Crust and crumb colour

The colour values for crust and crumb of all cakes are summarized in Table 2. ANOVA showed significantly differences in the L*, a*, and b* values for crusts and crumb made with different hydrocolloids. Hydrocolloids increases generally the L* (lightness) and b* (blue–yellow component) values. No differences were observed for the a* (redness) values of the crust. Addition of xanthan and guar resulted in cakes with the highest L* values, followed by HPMC and carrageenan. As expected, the L* values were correlated to the central height and to the specific volume: cakes with higher volume are also brighter.

Moisture content

Table 2 shows the moisture content of the cakes ranging between 30.65 and 31.35 % for fresh cakes. The moisture content of all cakes slightly decreased during storage 4 days. In the study of Gómez et al. (2007), several hydrocolloids namely guar, HPMC, carrageenan and xanthan were added to yellow layer cakes most of the formulation showed similar losses of weight and dehydration rate during storage of 3 days. This result could be related to the capacity to retain water and avoid its migration.

Texture characteristics

Table 3 depicts the effect of hydrocolloid addition on texture characteristics of black waxy rice cake, fresh and after 4 days storage. It was found that hydrocolloid addition affected texture parameters. For fresh cakes (0 day) xanthan reduced the hardness significantly by 25 % (control cake 3.22 kg; xanthan cake 2.39 kg). After 4 days storage the hardness increased for all cakes. HPMC had the highest hardness increase from 3.0 (fresh cake) to 4.4 (4 days storage) kg, while samples with xanthan remained softer than control samples. There are many possible factors involved in hardness change during storage, such as the molecular structure of hydrocolloids, the migration of water from the moist central crumb to the dry crust and the retrogradation of starch. These results are in agreement with those obtained by Preichardt et al. (2011) found that the addition of xanthan in gluten free cakes decreased the firmness. Gómez et al. (2007) observed that xanthan was able to maintain the firmness during 3 days storage. It was also stated by Sumnu et al. (2010), that the cake formulations containing 1.0 % guar gum and the control cake had significantly higher hardness values than the ones containing 1.0 % xanthan and xanthan–guar blend.

The addition of xanthan led to significantly increased cohesiveness in fresh cake. However, no difference in cohesiveness was found among the samples after 4 days storage. The springiness was not significantly different. Similar results were obtained by Preichardt et al. (2011), the springiness of the gluten free cake from rice and corn flour was not influenced by the addition of xanthan. Gumminess values in cakes with and without hydrocolloids exhibited a similar trend with the hardness values. Moreover, the result indicated that adding hydrocolloid may increase the resilience.

Sensory evaluation

The results are presented in Table 4. Cakes with xanthan were lighter in both crust and crumb colour than the other cakes. Xanthan cakes exhibited also the highest score for dome shape on the top of the cake. Similar results were obtained in Table 2. The lowest score of moistness was observed for HPMC and control. Cakes with xanthan, guar and carrageenan were most intense in moistness. The control cakes were more firm (P < 0.05) than other cakes. The overall acceptability of cake with xanthan and guar were higher than control, maybe affected by shape and moistness.

Conclusion

The addition of hydrocolloids significantly affected the rheological properties of the batter and some characteristics of the cake. Batters with high viscosity and high G′ gave cakes with higher volume. Hydrocolloids are capable to form a film around the gas bubbles which then could be better retained during baking. Xanthan had the highest effect on G′ and G″ and increased the apparent viscosity and the thixotropic bahaviour of the batter, followed by guar and HPMC, whereas carrageenan showed the smallest effect. The appearance and the specific volume of the cakes could be improved by addition of xanthan and guar. During a storage period of 4 days the cakes with xanthan remained softer than the others. The data obtained in this study will be useful for the baking industry.

References

Ashwini A, Jyotsna R, Indrani D (2009) Effect of hydrocolloids and emulsifiers on the rheological, microstructural and quality characteristics of eggless cake. Food Hydrocoll 23:700–707

Breckon DN, Garrison SJ, Gee DL (2003) A gluten-free flour mix is a successful substitute with the addition of xanthan gum in a yellow cake. J Am Diet Assoc 103:1

Chaiya B, Pongsawatmanit R (2011) Quality of batter and sponge cake prepared from wheat-tapioca flour blends. Kasetsart J (Nat Sci) 45:305–313

Chueamchaitrakun P, Chompreeda P, Haruthaithanasan V, Suwonsichon T, Kasemsamran S (2011) Physical properties of butter cake made from mixed Hom-Mali and glutinous rice flours. Kasetsart J (Nat Sci) 45:295–304

Ciclitira PJ, Johnson MW, Dewar DH, Ellis HJ (2005) The pathogenesis of coeliac disease. Mol Asp Med 26:421–458

Daiponmak W, Senakul C, Siriamornpun S (2014) Antiglycation capacity and antioxidant activities of different pigmented Thai rice. Int J Food Sci Technol 49:1805–1810

Edoura-Gaena RB, Allais I, Trystram G, Gros JB (2007) Influence of aeration conditions on physical and sensory properties of aerated cake batter and biscuits. J Food Eng 79:1020–1032

Gómez M, Ronda F, Caballero PA, Blanco CA, Rosell CM (2007) Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll 21:167–173

Gularte MA, de la Hera E, Gómez M, Rosell CM (2012) Effect of different fibers on batter and gluten-free layer cake properties. LWT Food Sci Technol 48:209–214

Kaur A, Shevkani K, Singh N, Sharma P, Kaur S (2015) Effect of guar gum and xanthan gum on pasting and noodle-making properties of potato, corn and mung bean starches. J Food Sci Technol 52:8113–8121

Klang V, Schwarz JC, Matsko N, Rezvani E, El-Hagin N, Wirth M, Valenta C (2011) Semi-solid sucrose stearate-based emulsions as dermal drug delivery systems. Pharmaceutics 3:275–306

Matos ME, Sanz T, Rosell CM (2014) Establishing the function of proteins on the rheological and quality properties of rice based gluten free muffins. Food Hydrocoll 35:150–158

Preichardt LD, Vendruscolo CT, Gularte MA, Moreira AdS (2011) The role of xanthan gum in the quality of gluten free cakes: improved bakery products for coeliac patients. Int J Food Sci Technol 46:2591–2597

Ronda F, Gómez M, Caballero PA, Oliete B, Blanco CA (2009) Improvement of quality of gluten-free layer cakes. Food Sci Technol Int 15:193–202

Rosell CM, Yokoyama W, Shoemaker C (2011) Rheology of different hydrocolloids–rice starch blends. Effect of successive heating–cooling cycles. Carbohydr Polym 84:373–382

Saha D, Bhattacharya S (2010) Hydrocolloids as thickening and gelling agents in food: a critical review. J Food Sci Technol 47:587–597

Sumnu G, Koksel F, Sahin S, Basman A, Meda V (2010) The effects of xanthan and guar gums on staling of gluten-free rice cakes baked in different ovens. Int J Food Sci Technol 45:87–93

Sutharut J, Sudarat J (2012) Total anthocyanin content and antioxidant activity of germinated coloured rice. Int Food Res J 19:215–221

Turabi E, Sumnu G, Sahin S (2008) Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocoll 22:305–312

Turabi E, Sumnu G, Sahin S (2010) Quantitative analysis of macro and micro-structure of gluten-free rice cakes containing different types of gums baked in different ovens. Food Hydrocoll 24:755–762

Usansa U, Burberg F, Geiger E, Back W, Wanapu C, Arendt EK, Kreisz S, Boonkerd N, Teaumroong N, Zarnkow M (2011) Optimization of malting conditions for two black rice varieties, black non-waxy rice and black waxy rice (Oryza sativa L. Indica). J Inst Brew 117:39–46

Zhou J, Faubion JM, Walker CE (2011) Evaluation of different types of fats for use in high-ratio layer cakes. LWT Food Sci Technol 44:1802–1808

Acknowledgments

The authors gratefully acknowledge the OeAD-Austrian Agency for International Cooperation in Education & Research, financed by Austrian Federal Ministry of Science and Research (BMWF) in the frame of the ASEA-Uninet. Thanks to the Department of Food Science and Technology of the University of Natural Resources and Life Sciences, Vienna (BOKU) for financial support in laboratory.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Itthivadhanapong, P., Jantathai, S. & Schleining, G. Improvement of physical properties of gluten-free steamed cake based on black waxy rice flour using different hydrocolloids. J Food Sci Technol 53, 2733–2741 (2016). https://doi.org/10.1007/s13197-016-2245-5

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-016-2245-5