Abstract

The effect of germination time on physicochemical characteristics of brown rice flour and its effect on gluten free bread qualities have been investigated. Germination was carried out at 28 °C and 100 % RH for 12, 24 and 48 h; brown rice and soaked brown rice was also analyzed. Significant changes on hydration and pasting properties of brown rice flour were found during germination. The starch degradation by enzyme activity could be evidenced with the decrease in viscosity and water binding capacity (WBC). No significant effect in specific volume, humidity and water activity of the gluten free bread was found as germination time increase, but a significant softness of the crumb was obtained. However, at 48 h of germination, the intense action of α amylase could result in excessive liquefaction and dextrinisation, causing inferior bread quality. Overall, germinated rice flour showed appropriate functionality for being used as raw ingredient in gluten free breadmaking.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Rice flour is one of the elected cereals for obtaining gluten free baked goods when those are addressed to gluten intolerant patients. Many studies have been focused on making rice flour based leavened baked gluten free products, and specifically bread (GFB) (Rosell and Gomez 2014). Rice flour is the side product of the rice milling industry but flour properties are definitive in the gluten free bread quality, as has been reported when assessing the impact of rice variety (Han et al. 2012), and particle size of the flour and length of rice grain (de la Hera et al. 2013). Having in mind gluten free bread quality, even treatments as extrusion has been proposed for improving rice flour breadmaking functionality (Martinez et al. 2014). In general, GFB are made from refined flours, which have lost very important nutritional compounds like fibers, vitamins and minerals. Nevertheless, endogenous constituents of the rice grain cannot be put back when using refined rice flour, resulting in a detrimental effect on the nutritional quality of the food.

Germinated brown rice flour (GBRF) and germinated glutinous brown rice flour have been used as functional food ingredients in breadmaking (Charoenthaikij et al. 2010a, b, 2012; Watanabe et al. 2004), due to its high content in bioactive compounds such as γ-aminobutiric acid and antioxidants such as phenolic compounds, γ-oryzanol and vitamin E (Cáceres et al. 2014). The benefits of these bioactive compounds include regulation of blood pressure and heart rate, alleviation of pain and anxiety, inhibition of cancer cell proliferation, and protection for oxidative stress (Oh and Oh 2004). Despite their nutritional benefits, germinated brown rice flour, pregerminated brown rice flour and germinated glutinous brown rice flour have been only used for partial substitution (10–30 %) of wheat flour in breadmaking (Charoenthaikij et al. 2010a, b, 2012; Watanabe et al. 2004). This practice produces changes in the rheological properties of the batter, modifying dough handling, besides an improvement of crumb texture, increase of gas production during fermentation and retard bread staling (Charoenthaikij et al. 2010b; Watanabe et al. 2004). The late benefit likely related to the alfa-amylase action forming low molecular weight dextrin that could inhibit amylopectin retrogradation (Gray and Bemiller 2003). In addition, germination could produce an excessive liquefaction and dextrinisation of starch granule, producing ‘wet sticky crumb’ (Hallen et al. 2004), because of that it is necessary to define the right germination time for optimizing flour breadmaking features. Nevertheless, no attempts have been made in using germinated rice brown flour for obtaining gluten free bread.

The aim of this study was to analyze the effect of germination time in physicochemical characteristics of the flour and the effect of use GBRF as primary ingredient of GFB on bread quality.

Material and methods

Commercial certified brown rice cultivar INIAP 15 was provided by the National Institute of Agricultural Research from Ecuador (INIAP). Seeds were harvest between May and December 2011. The gluten-free bread formulations also contained compressed yeast (LEVAPAN, Lessafre, Madrid, Spain) and hydroxypropylmethylcellulose Methocel K4M obtained from Dow Chemical Company (Michigan,USA).

Germination and flour preparation

Brown rice was sterilized with 0.1 % sodium hypochlorite solution (1:5 w/v) for 30 min, and then rinsed with distilled water. Afterwards, rice was soaked in distilled water (seed water ratio, 1/5, w/v) for 24 h at 28 ± 1 °C. Soaking water was drained and seeds were placed in plastic trays containing moist filter and were also covered with moist filter paper. The filter papers were kept wet by capillarity. Germination was carried out at 28 ± 1 °C and 100 % relative humidity under darkness for 12, 24 and 48 h. After germination, seeds were dried at 50 ± 1 °C for 24 h. Once dried, seeds were ground until a diameter inferior to 1 mm with a cyclone mill (UDY Corporation, USA). Five treatments were analyzed, brown rice flour as reference, soaked rice flour and germinated for 12, 24 and 48 h rice flour. Two sets of samples were prepared for each treatment.

Flour hydration properties

The water holding capacity (WHC) defined as the amount of water retained by the sample without being subjected to any stress was determined mixing 1.000 g ± 0.001 g of flour with distilled water (10 ml) and kept at room temperature for 24 h. WHC was expressed as grams of water retained per gram of solid. The swelling volume (SV) was determined following the method reported by Gularte and Rosell (2011) with slight modification. Samples (1 g ± 5 mg) were placed in a graduated cylinder and mixed with distilled water (10 ml), then kept at room temperature for 24 h. The swelling volume was calculated by dividing the total volume of the swollen sample by the original dry weight of the sample. The water binding capacity (WBC) defined as the amount of water retained by the sample under low-speed centrifugation was determined as described the standard method (AACC 2010). Samples (1.000 g ± 0.001 g) were mixed with distilled water (10 ml) and centrifuged at 2000×g for 10 min. WBC was expressed as grams of water retained per gram of solid. All the analyses were made in triplicate.

Flour Gel hydration properties

Water absorption index (WAI), water solubility index (WSI) and the swelling power (SP) of different rice flour fractions were determined following the method of Anderson et al. (1969) with slight modification. Briefly, flour (50.0 mg ± 0.1 mg) sample was dispersed in 1 ml of distilled water in an Eppendorf tube using a wire rod and cooked at 90 °C for 15 min in a water bath. The cooked paste was cooled with ice to room temperature, and then centrifuged at 3000×g at 4 °C for 10 min. The weight of dry solids was recovered by evaporating the supernatant overnight at 110 °C. Four replicates were made for each sample. WSI, WAI and SP were calculated by the Eqs. 1 to 3:

For the determination of oil absorption capacity (OAC), the method of Lin et al. (1974) was followed. Briefly, flour sample (100.0 mg ± 0.2 mg) was mixed with 1 ml of vegetable oil. The content was stirred for 1 min with a wire rod to disperse the sample in the oil. After a period of 30 min in the vortex mixer, tubes were centrifuged at 3000×g and at 4 °C for 10 min. The supernatant was carefully removed with a pipette and tubes were inverted for 25 min to drain the oil prior to re-weighing. The oil absorption capacity was expressed as grams of oil bound per gram of the sample on dry basis. Three replicates were made for each sample. OAC was calculated by the Eq. 4:

Determination of pasting properties of rice flours

Pasting properties of the rice flour were determined using a rapid viscoanalyser (RVA) (Newport Scientific model 4-SA, Warriewood, Australia) by following ICC standard method No 162 (ICC 1996). Sample (3 g based on 14 % moisture) was added to 25 mL of water. The suspension was heated at 50 °C for 1 min and then heated up to 95 °C at 12 °C/min. After holding at 95 °C for 2.5 min, the suspension was cooled to 50 °C at 12 °C/min. The rotational speed of the paddle was maintained at 160-rpm throughout the run, except during the first 10 s, when a 960-rpm speed was used. Peak viscosity, breakdown, final viscosity and setback (difference between final viscosity and peak viscosity) were evaluated.

Breadmaking and evaluation of bread quality

The dough was prepared using the formula of Marco and Rosell (2008). Half of the rice flour was mixed with boiling water (half of the water) in a Brabender Farinograph (Duisburg, Germany) for 5 min. The dough was left to rest until the temperature decreased to around 30 °C. Afterwards, the rest of the flour and water, besides the other solid ingredients, were added and mixed in a Brabender Farinograph (Duisburg, Germany) for 5 min. Then, dough was transferred (180 g) to pans and fermented for 40 min at 35 °C and 85 % RH. Finally, the fermented dough was baked 35 min at 175 °C. Loaves were cooled down at room temperature for 1 hour and then packed in polyethylene pouches. Further analysis was carried out after 24 h of baking.

Bread quality properties included specific loaf volume, height/width ratio of the slices, crumb color and its texture including hardness, springiness, resilience, chewiness and cohesiveness. The loaf volume was determined by rapeseed displacement, while the specific volume (mL g − 1) of the bread was calculated as the ratio of the volume (mL) to the weight (g) of the bread.

The crumb color was determined by the computer vision system (Yam and Papadakis 2004). The computer vision system station included a light source, a camera (canon SX500 IS, 16 mega pixel) and software (Adobe Photoshop CS5) for image processing and analysis. The texture profile analysis (TPA) of the breadcrumbs was performed by a Texture Analyzer CT3 (Brookfield, Middleboro, USA). A bread slice of 1-cm-thickness was compressed up to 50 % of its original height at a crosshead speed of 1 mm/s with a cylindrical acrylic probe (diameter 25.4 mm).

Statistical analysis

Standarized skewness and standarized kurtosis analyses were made to verify normal distribution of the data. Multiple sample comparison was conducted to evaluate significant differences among samples by analysis of variance (ANOVA) and multiple range tests. Fisher’s least significant differences (LSD) test was used to describe means with 95 % confidence (P < 0.05). Data was also evaluated using Pearson correlation coefficients to establish relationship among variables. Only correlation coefficients (in absolute value) equal or greater than 0.68 were considered meaningful. All statistical analyses were performed using Statgraphics Centurion 16 (Statistical Graphics Corporation, UK).

Results and discussions

Flour and flour gel hydration properties

The Table 1 shows the hydration properties of brown rice, soaked and germinated brown rice flour and their gels. It can be seen that there was a decreasing trend on the hydration properties of the flour (WBC, WHC and SV) as germination time increased, although that decrease was only significant in the case of WBC. During germination, enzyme activities like the α-amylase increases, which led to starch degradation and subsequent increase of small dextrins and fermentable sugar (Islam and Becerra 2012). The starch degradation might induce the release of the water entrapped within the starch granule, and that effect was even more dramatic as the starch hydrolysis proceeds and thus at extended germination, reducing the flour hydration properties. Additionally, the released sugars from starch hydrolysis during germination could form crosslinks between starch chains in the amorphous regions of a starch granule, which restricted starch swelling (Baek et al. 2004) also they could interact with water hindering the water available for starch hydration (Peroni-Okita et al. 2013). The water binding capacity (WBC) and water holding capacity (WHC) are important properties for bakery process, and become even more essential for making gluten free baked goods. Texture or consistency of dough depends on water absorption leading to body thickening and viscosity (Aguilera et al. 2011). High water absorption reduces stickiness and produces stiff dough (Han et al. 2012). At bread level, Han et al. (2012) found that rice lines with low water absorption produce fresh bread with a suitable volume and firmness. Presumably, that effect could explain texture improvement observed when partial replacement of wheat flour with germinated rice and pregerminated rice (Charoenthaikij et al. 2010b; Watanabe et al. 2004). It is interesting to notice that WHC of the soaked sample was significantly lower than that of samples germinated for 12 h and 24 h. Again, this result could be explained due to α amylase action that takes some time to degrade intact starch granules, changing its structure. Hydration properties of the flour gel (WAI and SP) were not significantly affected as germination time increases, with the exception of 48H germination. This could be also explained by the change produced in the starch structure and the presence of released sugars that will interact with the starch forming more compact gels. In contrast, water soluble index (WSI) increased as the germination time increases, which confirmed the action of enzymes during germination and thus the release of water soluble compounds. The oil absorption capacity (OAC) remained constant until 24 h of germination and only increased after 48 h germination.

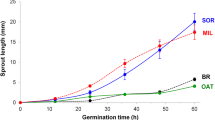

Flour pasting properties

The pasting plots and the recorded pasting properties of brown rice, soaked and germinated brown rice flour are shown in Fig. 1 and Table 2, respectively. A progressive reduction of the viscosity during heating and cooling was observed as the germination proceeded, which agree with previous reports (Charoenthaikij et al. 2012). Soaking induced a significant decrease of the viscosity after reaching the maximum viscosity during heating, which resulted in much lower viscosity after cooling. It seems that soaking process was enough to activate amylases and their activity became evident after starch gelatinization and during cooling where amylose recrystallization occurs. After 12 h germination (12H) only slight increase in the peak viscosity was detected, likely due hydrolysis products were washed out after soaking. Despite intact granules are less susceptible to amylase action, giving sufficient time starch can be degraded and sugars are released (Dura et al. 2014). At 48 h of germination the viscosity plot was drastically reduced during heating and cooling, owing to extensive degradation of starch granules. It might be expected that at this degree of degradation flour would not be suitable for breadmaking. Therefore, it seems that germination induced enzyme activation and that might respond to an exponential curve, as revealed the great action on the starch after 48H germination. The reduction of starch content with a simultaneous increase of reducing sugars content during germination have been previously reported (Charoenthaikij et al. 2012; Wu et al. 2013).

Peak viscosity, breakdown, setback and final viscosity decreased with germination due to degradation of the starch by the enzyme activity (Charoenthaikij et al. 2009, 2012; Mäkinen et al. 2013; Wu et al. 2013). The action of α amylase changes the structure of the starch molecule breaking down the polymers chains and reducing its ability to bind water and increase the viscosity. The setback value reflects the degree of retrogradation of amylose (Gani et al. 2013). Thus, germination reduces the ability of amylose to retrograde, which might be beneficial in breadmaking to reduce the gluten free bread tendency to stale during storage.

It is interesting to notice that breakdown, related to starch cooking stability (Rojas et al. 1999), increased until 12 h of germination. Previous studies about germination reported a breakdown decrease due to this process (Charoenthaikij et al. 2012; Mäkinen et al. 2013; Wu et al. 2013). However, those studies did not analyzed soaking and the first stage of germination (after 12 h of germination). A high breakdown demonstrates the ease of starch granules to be broken upon heating after the maximum swelling at the peak viscosity (Rojas et al. 1999). These results could demonstrate that during soaking and the first hours of germination starch granule was more susceptible to breaking, likely due to starch annealing or internal structure organization.

Evaluation of Bread Quality

Figure 2 displays cross section bread slices from brown, soaked and germinated rice flour. As germination time increased the crumb structure showed more elongated gas cells and of increasing size, which occurred up to 24 h germination (24H). Mäkinen et al. (2013) observed a reduction of batter viscosity with the use of malted cereal, which enhanced α amylase activity, and those batters led to breads with more open crumb. Intermediate or lower paste viscosities could favor expansion of batters during baking resulting in large specific volume and more open crumbs (Renzetti and Arendt 2009). Indeed, the increase in amylase activity and sugar content due to germination produced faster increase of the batter volume during fermentation allowing the formation of large holes in the center of the crumb. However, no significant correlation was found among specific volume and pasting properties. Actually, at 48 h of germination (48H GB) the crumb became deteriorated due to an excess of amylase activity, which, as it was discussed before in the pasting properties, induced complete degradation of starch. In fact, the presence of high level of α amylase could result in excessive liquefaction and dextrinisation, causing an inferior quality of bread described by the term ‘wet sticky crumb’ (Hallen et al. 2004). In addition, it can be observed that as germination time increased the surface became flattened; really at 24 h of germination it was more concave. This result suggests that as the germination time increased the fermentation time should be decreased because fermentable sugars released from α amylase action speed up the leavening. Fermentation was carried out at fixed time for comparing flours behavior, but even crumb structure revealed an over-fermentation in breads obtained from germinated flour.

Quality characteristics of gluten free bread from brown, soaked and germinated rice flour are shown in Table 3. No significant differences were found in the humidity, water activity and specific volume between samples, implying that germination does not produce significant changes in these bread characteristic. Although breads showed a significant higher specific volume than the bread obtained from non-germinated flour. A strong correlation was found between humidity and pasting properties such as peak viscosity (r = 0.92 P < 0.001), breakdown (r = 0.74 P < 0.01), final viscosity (r = 0.89 P < 0.01) and setback (r = 0.86 P < 0.01) as well as humidity and WHC (r = 0.73 P < 0.01), although those could not be related with bread quality properties. A negative correlation has been reported between dough consistency at cooling and specific volume of rice based gluten free breads (Matos and Rosell 2013) and a positive correlation between apparent viscosity and loaf volume (Sabanis et al. 2009), but no correlation was observed when germinated rice flour was used as raw material.

No significant effect was observed on the geometry (width/height) of the breads due to the time of germination, although a tendency to increase with the germination time was envisaged. A strong correlation was found between width/height and SV (r = 0.79 P < 0.001). The specific volume values of the samples ranged from 1.5 to 2.3 ml/g, these results are in agreement with the ones reported for rice GFB (de la Hera et al. 2013; Matos and Rosell 2012; Marco and Rosell 2008).

Generally rice gluten free breads are rather pale due to the refined flour use in their production, because of that crumb color becomes of importance when developing this type of baked products. CieL*a*b* scale was used to characterize crumb color. L* value showing the lightness of the crumb (Table 3) underwent a significant reduction as the germination time increased, which is desirable because GFB tends to have lighter color than wheat bread. The L* values ranged from 54.9 to 73.5, which are within the lower values reported in commercial gluten free rice breads (Matos and Rosell 2012). All the samples, except soaked flour, showed positive values for a*, which are associated with reddish color, also b* positive values were found, indicating yellowish tone. Indeed, a* and b* values increased as the germination time was extended. Those parameters showed higher values than the ones reported in commercial gluten free rice bread (Matos and Rosell 2012). All the samples showed a positive hue angle that reflected yellow-orange hue. Chroma values associated with the purity of color were higher than the ones obtained with commercial gluten free breads, which revealed its higher purity of color related to major intensity of the yellow component. In fact, Charoenthaikij et al (2010a) reported an increase of yellowness of bread with the addition of germinated brown rice flour to wheat flour. Hence, the increase of the chroma value could be due to the increase of reducing sugar during germination.

Significant differences were observed in the crumb texture properties among grain treatments (Table 4). The hardness values were lower than 10 N, that are inferior than those reported in commercial GFB (Matos and Rosell 2012), but still harder than wheat bread with hydroxypropylmethylcellulose (1.96 ± 0.19 N) reported by Bárcenas and Rosell (2005). Considering that GFB present high crumb hardness due to their complex formulation, these values are sought after (Matos and Rosell 2011). As the germination time increased the hardness of the crumb decreased, the degradation of starch during germination could cause a decrease of crumb hardness, probably due to the formation of thinner cell walls that led to softer crumbs. Also, Charoenthaikij et al. (2010a) found that a partial substitution with germinated brown rice flour reduces hardness of wheat bread compared to brown rice flour.

High springiness values are preferred because it is related to the freshness and elasticity of the bread. As the germination time increased, the springiness value decreased, indicating an increase in fragility and tendency to crumble when is sliced (McCarthy et al. 2005). Indeed, after 12 h of germination springiness values were lower than the ones reported before in gluten free rice bread (Marco and Rosell 2008; Matos and Rosell 2012). These low values can be a limiting factor for the use of germinated brown rice for GFB. The lowest value was found at 48 h of germination; actually the bread was too fragile that was difficult to cut. The intense action of α amylase after 48 h of germination could result in excessive liquefaction and dextrinisation, causing inferior bread quality (Hallen et al. 2004). Not only springiness but also resilience characterizes the loss of elasticity, because it indicates the ability of a material to return to its original shape after a stress (Onyango et al. 2011). Resilience and chewiness values decreased with the germination time. These values agree with those reported previously in commercial GFB (Matos and Rosell 2012).

The reduction of hardness and chewiness could be also related to the results found by Renzetti and Arendt (2009) when using protease treatment to improve the baking quality of brown rice bread. The formation of low molecular proteins and carbohydrates by germination yielded lower batter consistency and paste viscosity besides a decrease in WBC, overall they might improve texture as previously reported (Charoenthaikij et al. 2010b; Watanabe et al. 2004).

Thus, it is important to bear in mind a reformulation when a germinated brown rice is used as raw material, and it would be advisable to use brown rice up to 24 h of germination to develop GFB. Higher germination time could be used as a partial substitute for increasing nutritional value of GFB.

Conclusions

Germinated rice flour showed appropriate functionality for being used as raw ingredient in gluten free breadmaking. The germination time of the rice has a significant effect on flour properties and the resulting bread quality. Specifically, flours obtained after 24 h of germination led to an improvement in bread texture, which might be ascribed to the increase of amylase activities as well as starch degradation, which agrees with hydration and pasting results. Also bread color improved as a result of non-enzymatic browning reaction. However, excessive germination deteriorated the product as a result of extensive amylolysis. Germinated rice flour of more than 24 h of germination was not suitable for breadmaking.

References

Aguilera Y, Estrella I, Benitez V, Esteban R, Martín-Cabrejas M (2011) Bioactive phenolic compounds and functional properties of dehydrated bean flours. Food Res Int 44:774–780

Anderson R, Conway H, Pheiser V, Griffin E (1969) Gelatinization of corn grits by roll and extrusion cooking. Cereal Sci Today 14:4–12

Baek M, Yoo B, Lim S (2004) Effects of sugars and sugar alcohols on thermal transition and cold stability of corn starch gel. Food Hydrocoll 18:133–142

Bárcenas M, Rosell C (2005) Effect of HPMC addition on the microstructure, quality and aging of wheat bread. Food Hydrocoll 19:1037–1043

Cáceres P, Martinez-Villaluenga C, Amigo L, Frias J (2014) Maximizing the phytochemical content and antioxidant activity of Ecuadorian brown rice sprouts through optimal germination conditions. Food Chem 152:407–414

Charoenthaikij P, Jangchud K, Jangchud A, Piyachomkwan K, Tungtrakul P, Prinyawiwatkul W (2009) Germination conditions affect physicochemical properties of germinated brown rice flour. J Food Sci 74:C658–C665

Charoenthaikij P, Jangchud K, Jangchud A, Prinyawiwatkul W, Tungtrakul P (2010a) Germination conditions affect selected quality of composite wheat-germinated brown rice flour and bread formulations. J Food Sci 75:312–318

Charoenthaikij P, Jangchud K, Jangchud A, Prinyawiwatkul W, No H, King J (2010b) Physicochemical properties and consumer acceptance of wheat-germinated brown rice bread during storage time. J Food Sci 75:333–339

Charoenthaikij P, Jangchud K, Jangchud A, Prinyawiwatkul W, No H (2012) Composite wheat–germinated brown rice flours: selected physicochemical properties and bread application. Int J Food Sci Technol 47:75–82

De La Hera E, Martinez M, Gómez M (2013) Influence of flour particle size on quality of gluten-free rice bread. LWT-Food Sci Technol 54:199–206

Dura A, Blaszczak W, Rosell C (2014) Functionality of porous starch obtained by amylase or amyloglucosidase treatments. Carbohydr Polym 101:837–845

Gani A, Wani S, Masoodi F, Salim R (2013) Characterization of rice starches extracted from Indian cultivars. Food Sci Technol Int 19:143–152

Gray J, Bemiller J (2003) Bread staling: molecular basis and control. Compr Rev Food Sci 2:1–21

Gularte M, Rosell C (2011) Physicochemical properties and enzymatic hydrolysis of different starches in the presence of hydrocolloids. Carbohydr Polym 85:237–244

Hallen E, Ibanoglu S, Ainsworth P (2004) Effect of fermented ⁄ germinated cowpea flour addition on the rheological and baking properties of wheat flour. J Food Eng 63:177–184

Han H, Cho J, Kang H, Koh B (2012) Rice varieties in relation to rice bread quality. J Sci Food Agric 92:1462–1467

Islam M, Becerra J (2012) Analysis of chemical components involved in germination process of rice variety Jhapra. J Sci Res 4:251–262

Lin M, Humbert E, Sosulski F (1974) Certain functional properties of sunflower meal products. J Food Sci 39:368–370

Mäkinen O, Zannini E, Arendt E (2013) Germination of oat and quinoa and evaluation of the malts as gluten free baking ingredients. Plant Food Hum Nutr 68:90–95

Marco C, Rosell C (2008) Breadmaking performance of protein enriched, gluten-free breads. Eur Food Res Technol 227:1205–1213

Martinez M, Oliete B, Román L, Gómez M (2014) Influence of the addition of extruded flours on rice bread quality. J Food Qual 37:83–94

Matos M, Rosell C (2011) Chemical composition and starch digestibility of different gluten free breads. Plant Food Hum Nutr 66:224–230

Matos M, Rosell C (2012) Relationship between instrumental parameters and sensory characteristics in gluten-free breads. Eur Food Res Technol 235:107–117

Matos M, Rosell C (2013) Quality indicators of rice based gluten-free bread-like products: relationships between dough rheology and quality characteristics. Food Bioprocess Technol 6:2331–2341

Mccarthy D, Gallagher E, Gormley T, Schober T, Arendt E (2005) Application of response surface methodology in the development of gluten-free bread. Cereal Chem 82:609–615

Oh C, Oh S (2004) Effects of germinated brown rice extracts with enhanced levels of GABA on cancer cell proliferation and apoptosis. J Med Food 7:19–23

Onyango C, Mutungi C, Unbehend G, Lindhauer M (2011) Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT-Food Sci Technol 44:681–686

Peroni-Okita F, Cardoso M, Agopian R, Louro R, Nascimento J, Purgatto E, Tavares M, Lojolo F, Cordenunsi B (2013) The cold storage of green bananas affects the starch degradation during ripening at higher temperature. Carbohydr Polym 96:137–147

Renzetti S, Arendt E (2009) Effect of protease treatment on the baking quality of brown rice bread: from textural and rheological properties to biochemistry and microstructure. J Cereal Sci 50:22–28

Rojas J, Rosell C, Benedito C (1999) Pasting properties of different wheat flour-hydrocolloid systems. Food Hydrocoll 13:27–33

Rosell C, Gómez M (2014) Rice. In: Zhou W, Hui Y, DeLeyn I, Pagani M, Rosell C, Selman J, Therdthai P (eds) Bakery products: science and technology, 2nd edn. Wiley, Iowa, pp 89–106

Sabanis D, Lebesi D, Tzia C (2009) Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT-Food Sci Technol 42:1380–1389

Watanabe M, Maeda T, Tsukahara K, Kayahara H, Morita N (2004) Application of pregerminated brown rice for breadmaking. Cereal Chem 81:450–455

Wu F, Chen H, Yang N, Wang J, Duan X, Jin Z, Xu X (2013) Effect of germination time on physicochemical properties of brown rice flour and starch from different rice cultivars. J Cereal Sci 58:263–271

Yam K, Papadakis S (2004) A simple digital imaging method for measuring and analyzing color of food surfaces. J Food Eng 6:137–142

Acknowledgments

Authors acknowledge the financial support of Spanish Scientific Research Council (CSIC), the Spanish Ministry of Economy and Sustainability (Project AGL2011-23802), and the Generalitat Valenciana (Project Prometeo 2012/064). F. Cornejo acknowledges the financial support of Secretaría Nacional de Educación Superior, Ciencia, Tecnología e Innovación (SENESCYT, Ecuador). Instituto Nacional de Investigaciones Agropecuarias from Ecuador (INIAP) is thanked for providing the BR cultivars and Biotechnological Research Center of Ecuador (CIBE, Ecuador) for the laboratories facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Research Highlights

• A gluten free bread from germinated brown rice was developed

• Germination time of the rice affected flour properties and bread quality

• Flours obtained after 24 h of germination led to an improvement in bread texture

Rights and permissions

About this article

Cite this article

Cornejo, F., Rosell, C.M. Influence of germination time of brown rice in relation to flour and gluten free bread quality. J Food Sci Technol 52, 6591–6598 (2015). https://doi.org/10.1007/s13197-015-1720-8

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-015-1720-8