Abstract

The use of carbonate rocks is important worldwide due to their utility in various fields. However, their physical and mechanical characterization can determine their fields of application and their economic interest. The establishment of these properties allows the assessment of their economic importance and future use. Uniaxial compressive strength (UCS) is one of the most important mechanical properties used to test carbonate rocks. Los Angeles (L.A) and Micro-Deval (MDE) coefficients are essential properties used to verify the mechanical resistances of the aggregate to be used on roadways. Analyzing these mechanical parameters determine the economic interest of rocks. The purpose of this project is to explore additional carbonate resources in Tunisia, even when the determination of some parameters is not possible. For this purpose, 30 samples with different physical and mechanical properties were chosen from 8 different sites. Two of them are well known in Tunisia: one is exploited to extract aggregates of good mechanical resistance, and the other is exploited for marble stone mining. Laboratory test results show that many unexplored sites harbor rocks with good qualities which could be exploited in different applications. UCS, LA and MDE coefficient values show new good quality carbonate-rock resources. The results determined the physical properties of studied rocks to conclude the potential use of each rock and to estimate the parameters for which the measurements are not possible.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Various carbonate formations are of great economic interest and can constitute strategic reserves that play a key role in national development. The economic interest of carbonate rocks is not associated exclusively with the field of civil engineering (building materials: marble stones, cut stones, aggregates, hydraulic binders, etc.), but also with paper, plastics, rubber, polymer, paint, sealant, coating and adhesive industries as well as the conception of pharmaceutical and cosmetic products. Thus, the exploration of alternative mineral resources can be a solution for countries suffering from economic difficulties such as Tunisia (Elleuch et al. 2019). In west-central Tunisia, the Campanian–Maastrichtian Abiod Formation includes different types of carbonate rocks such as ’Thala’ Marble and other various carbonate rocks. The latter are present in several geological formations in the Mediterranean regions, producing a variety of building materials. Tunisia is among the countries that produce carbonate stones commonly used for construction and, thus, establishing an important industry nowadays (Calvo and Regueiro 2010; Abdelhedi et al. 2017). In recent years, several authors have studied the importance of carbonate rocks in Tunisia. Abdelhedi et al. (2020a) have elaborated models to predict the uniaxial compressive strength in carbonate rocks using artificial neural network and multiple linear regressions. Gouasmia et al. (2018) characterized carbonate aquifer using geophysical and geochemical approach in southern Tunisia. Jaballi et al. (2019) have studied the mineralogical and geochemical behavior of heated natural carbonate apatite of the Ypresian series in central Tunisia. More recently, Azaiez et al. (2020) studied the importance of carbonate rocks in hydrothermal water retention. The economic importance of carbonate rocks depends on their physical and mechanical properties. Therefore, performing laboratory tests to identify these characteristics is essential for the exploration of new natural resources (marbles, aggregates, etc.). Overall, executing laboratory tests is laborious, time consuming and expensive. In some cases, the determination of a particular parameter is not even possible (Abdelhedi et al. 2017).

Several authors have studied the relationships between different physical and mechanical properties in geomaterials (Mehrgini et al. 2019; Yalcinalp et al. 2018; Abdelhedi et al. 2018; Yasar and Erdogan 2004; Mahdiabadi and Khanlari 2019; Çelik 2019; Asheghi et al. 2019; El Sharawy and Gaafar 2019; Amri et al. 2019; Ceryan 2014; Yilmaz and Karasahin 2014; Zhang et al. 2019; Okogbue et al. 2020). However, only few authors have studied direct relationships between parameters determining the quality of aggregates (Abdelhedi et al. 2020b; Capik and Yilmaz 2017; Yu et al. 2019; Quintanilla et al. 2019).

Thus, the objective of this paper is to study carbonate formations in Tunisia and to explore new quarries by determining the qualities of rocks based on their physical and mechanical properties.

The second interest in this paper is to study the relationship between important rock properties to estimate their future use and their economic interests even if the determination of these parameters is not possible in the laboratory.

Geological setting

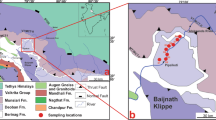

Rock samples with different physical and mechanical properties were taken from different locations of Tunisia (Fig. 1). The geographical location, the age of the formations from which the samples were taken and the geological description were presented in Tables (from 1 ,2, 3, 4, 5, 6, 7, 8). Dolomitic samples were collected from the following localities: the Nara Formation in Jebel Faied from which rocks are exploited as good-quality aggregate (five samples), the Gattar Formation in Jebel Matous inside the Sahara desert in Tunisia (two samples), the Zebbag Formation in Jebel Matleg localized in the extreme south of the north–south axis (two samples). Limestone samples were garnered from: Kef Eddour member, Metlaoui, located in the west of Tunisia (6 samples), the Gattar formation in Jebel Aziza from the east (two samples), EL Gariamembre of the Metloui Formation outcropping in Kabbara region (two samples), the Cherahil limestone Formation of Jebel Cherahil located in the extreme north of the north–south axis (three samples) and the Abiod Formation situated in the north west of Tunisia from which eight samples of fine grained limestone exploited as Thala marble were collected.

Materials and methods

To characterize the resistance of rock samples, several parameters can be determined. Good-quality aggregates are evaluated through the MDE and LA coefficients defining resistance to fragmentation and abrasion, respectively. The latter parameters measure the degradation of mineral aggregates of standard grading resulting from a combination of actions including abrasion or attrition, impact, and grinding in a rotating steel drum containing a specified charge of steel spheres (Ugur et al. 2010). Uniaxial compressive strength UCS is one of the key mechanical properties, while density and porosity are important physical parameters for the characterization of rocks (Abdelhedi et al. 2017). Accordingly, samples were shaped into 10 cm cubes for UCS testing and were crushed into granules of size between 10 and 14 mm to test resistance to fragmentation and abrasion. Additional experimental tests were carried out to determine the effective porosity and density.

Uniaxial compressive strength testing:

Compression is the most commonly used reference test for geomaterials (Harraden et al. 2019). The uniaxial compressive strength values were determined using the testing machine (Matest equipment Cyber-plus evolution, (Fig. 2). The steps done in this test were carried out according to the ASTM et al. (2012) standard. The tested specimen was placed on the lower bearing block of the machine. The axis of the specimen was carefully aligned with the center of thrust of the spherically seated block. Samples were subjected to incremental loading at a constant rate of 0.020 (MPa/s) (Abdelhedi et al. 2018). The load was applied until the specimen fails, and the maximum load carried by the specimen during the test was recorded (ASTM et al. 2012). The specimen’s UCS was calculated by dividing the compressive stress (Maximum load) by the loaded surface area (MPa).

Effective porosity:

To determine the effective porosity, samples were saturated with water. The effective porosity was determined as follows \(\left( P_e = \frac{V_{pi}}{V_t}\right)\): Where \(V_{pi}\): is the interconnected pore space. And \(V_t\): is the total volume of the sample (Peng and Zhang 2007; Anderson et al. 2019; Seifi et al. 2019).

Density:

The density is the mass of the specimens contained in a given unit volume (density \(= \frac{\rm {mass}}{\rm {volume}}\)). It is frequently expressed in g/cm3 (Salah et al. 2020; Johnson et al. 2019; Calvo and Regueiro 2017; Abdelhedi et al. 2018).

Los Angeles (L.A.) resistance to fragmentation

The Los Angeles test is used to determine the resistance of aggregates. The measurement of the mass percentage of the particles produced, having a size less than 1.6 mm, during the rotation of a closed drum containing the sample and the metal balls, leads to the determination of the Los Angeles coefficient (de Larrard 2002) (Fig. 3). The procedure of the standard P18-572 (1990) operates 5000 g of aggregates in the range of 10–14 mm. Afterwards, the prepared aggregate samples were placed in a steel drum and eleven steel spheres were loaded in it. Then, the drum was rotated for 500 revolutions with a speed of 30–33 rpm. The resistance to impact fragmentation is expressed by the equation:

where M is the dry mass of the fraction of the material passing through the 1.6 mm sieve after the test (g) (P18-573 1990).

Micro-Deval abrasion resistance (MDE)

The Micro-Deval test is used to measure the wear resistance of rocks. It is not the same when samples are tested in dry or wet conditions. The test results were obtained by combining grinding and abrasion of the wet material with steel balls in a rotating cylinder under well-defined conditions. The current test employs 500 g of material which was placed in the drum with the presence of 2500 ml of water.

For tests carried out on gravel between 4 and 14 mm, an abrasive load was used (Fig. 4). The Micro-Deval coefficient (MDE) is by definition the ratio:

where M is the dry mass of the test sample (500 or 10000g)and m is the dry mass of the fraction of the material passing through the 1.6 mm sieve after the test (g) (P18-573 1990).

Results

Characterization of carbonate rocks

The physical and mechanical properties determined in the laboratory are shown in Table 9.

Limestone Turonian from J. Matous:

In the south of Tunisia, this formation is not exploited because of its geographical location (very far from urban areas) and its physico-mechanical and geotechnical characteristics. It showed a low compressive strength (18–20 MPa), a low density which is around 2000 g/cm3 and high LA and MDE coefficients (LA = 42–45; MDE = 48–60).

Lower Lutetian Limestone from Kef Eddour

The samples are taken from the upper member. They are limestones of lower Lutetian age. Kef Eddour’s quarry is currently being exploited and offers yellowish brown dolomite with few coarse particles of flint. To exploit the phosphate series of the Chouabine Member, the mining industry stripped the carbonate member of Kef Eddour. The exploitation of this member is interesting, not only from an economic perspective but also from an environmental perspective. The geotechnical and mechanical characteristics of these rocks are very poor with a low UCS (UCS = 15.42–21.9 MPa), and very high LA and MDE coefficients (LA = 49–52; MDE= 63–87).

Dolomites Cenomanian–Turonian from Jebel Aziza

The dolomitic bar of Gattar is characterized by a brick-red colour due to the manganiferous mineralization. This formation is not currently being used. It is characterized by a relatively high compressive strength (41.13–45.64 MPa) which allows this bar to be used as a resistant stone for construction or as an aggregate due to its resistance to abrasion and wear (LA = 25 and MDE = 22–30).

Dolomites Cenomanian–Turonian from Jebel Matleg

These dolomites are not yet exploited in this region. The uniaxial compressive strength is between 36 and 37 MPa, the density is around 2400 g/cm3, the effective porosity varies from 6 to 10 %. LA and MDE coefficients ranges from 23 to 29 and 11 to 18, respectively

Ypresian limestone from Jebel Kabbara

These limestones are not yet exploited, they are characterized by: UCS values ranging from 61 to 66 MPa, densities from 2497 to 2750 g/cm3 and an effective porosity of 6%.The LA measure is equal to 25 and MDE varies from 23 to 29.

Lower and middle Lutetian limestone from Jebel Cherahil

The limestones of this formation are brittle and chalky limestones. This formation is not mined in this region, since it has relatively low geotechnical resistance (LA = 37–49, MDE = 41–59 and UCS = 30.72–33.32 MPa).

Jurassic dolomites from Jebel Faied:

The dolomites of the NARA Formation are affected by the tectonic impacts that occurred in the Faied region. Therefore, it was not possible to recover a sample of adequate size to perform the compression test. Various attempts to cut samples from this region have failed. The quarry is operating the two upper members, which have LA and MDE coefficients of around 19 and 10, respectively. This demonstrates the good mechanical resistance of these aggregates. The samples were taken from five superimposed layers (Fig. 5).

Table 10 illustrates the predicted UCS values using the correlations illustrated in Figs. 6 and 7. These correlations demonstrated that the sample number 1 had the lower UCS and the samples number 3, 4 and 5 had a good uniaxial compressive resistance. Those rocks are resistant and can be used as hard rock for building.

Campanian–Maastrichtian limestone from Thala (Thala Marbles)

It is necessary to define the characteristics of these blocks to preserve the brand image of this type of marble. Thala Marbles are marketed under several names, the best known are: Thala royal of golden beige colour, Thala imperial of beige to a whitish colour, Thala gray and Thala veined beige containing fine cracks filled with calcite. These rocks are exploded in the national market as marble. Their uniaxial compressive strength is higher than 50 MPa for 5 samples, the LA values are between 27 and 21, and the MDE coefficients range from 17 to 39.

Correlations between the different mechanical properties

Various types of relationships exist between several physical and mechanical parameters. The study of these relationships by producing correlations between different parameters allows not only to understand these different relations, but also to predict a number of parameters. Particularly when the execution of some test is not possible.

Correlation between resistance to fragmentation and uniaxial compressive strength UCS:

According to Fig. 6, the resistance to fragmentation determined by the L.A coefficient is greater when the UCS is lower. The correlation between the L.A coefficient and UCS measurements give a logarithmic relationship, with \(R^2=0.8\)

where L.A is the Los Angeles coefficient (Resistance to fragmentation) and UCS is the Uniaxial compressive strength measurement.

Correlation between Micro-Deval abrasion resistance (MDE) and uniaxial compressive strength UCS:

The Micro-Deval test is a measure of the abrasion resistance and the durability of rock aggregates (Gokalp et al. 2016). On the corresponding curve (Fig. 7), the highest MDE values are consistent with the lowest UCS values. A logarithmic trend was observed with a regression coefficient of \(R^2 = 0.73\). The equation of the curve is:

where UCS is the uniaxial compressive strength and MDE is the Micro-Deval abrasion resistance coefficient.

Correlation between resistance to fragmentation (L.A) and Micro-Deval abrasion resistance (MDE):

Figure 8 shows the correlation between the resistance to fragmentation measured using the L.A coefficient and the Micro-Deval abrasion resistance in carbonate samples collected from different geological formations in Tunisia. The curve showed a good linear relation with a correlation coefficient \(R^2= 0.92\) and exhibited the following equation:

Correlations between physical and mechanical properties

Correlations between density and mechanical properties within carbonate samples aggregates

The correlation established between the density values and the LA coefficients showed a linear relationship with a coefficient of determination equal to 0.8 (Fig. 9) and the following equation:

The relationship between the density and MDE coefficients also showed a linear relationship with a smaller coefficient of determination \((R^2=0.7)\) (Fig. 10). The established equation is:

Correlations between effective porosity and mechanical properties within carbonate samples aggregates

The Figs. 11 and 12 showed linear relationships between mechanical parameters measured through the LA and MDE coefficients and effective porosity with coefficients of determination equal to 0, 8 and 0, 7, respectively. The resulting equations are:

Discussion and analysis

Table 9 shows that 88% of rock samples with UCS values greater than 45 MPa displays LA coefficients ranging from 21 to 27 and MDE coefficients from 17 to 38. While samples with UCS values inferior to 35 MPa have LA and MDE coefficients higher than 37 and 41, respectively. The latter illustrates the predicted UCS values using the correlations illustrated in Figs. 7 and 8. These correlations demonstrated that the surface soil sample (number 1) had the lower UCS and the samples number 3, 4 and 5 had a good uniaxial compressive resistance. Those rocks are resistant and can be used as hard rock for building. The table 10 shows that both models used in the prediction of UCS values show the same trends: the sample S1 has a bad resistance while S3, S4 and S5 present higher UCS values. This signifies that the prediction of this mechanical parameter is correct. The Turonian limestone extracted from Jebel Matous shows poor mechanical properties. With such physical and geotechnical characteristics, these rocks cannot be considered as marble stones. Moreover, it cannot be used as road aggregates (of high resistance). However, this rock can be used as stones or aggregates in construction concrete. The dolomitic samples of Jebel Matleg have moderate abrasion and wear resistance (LA = 23 and MDE = 11). The mechanical properties of these rocks are similar to those from Jebel Faied, which has the best resistance of aggregates in Tunisia (good to medium) and which is destined for road construction. The Ypresian limestone of Jebel Kabbara has interesting mechanical and geotechnical characteristics. They are beige limestones with Nummulites having a rather important uniaxial compression resistance (66.37 MPa). They are, therefore, hard limestones. This carbonate member can be exploited as marble stone since its mechanical and physical characteristics are similar to those of Thala Marble. However the geotechnical parameters are not interesting (LA = 26 and MDE = 29). The limestone of Jebel Cherahil cannot be used as a good aggregate or marble given its physical and mechanical characteristics; however, it can be mined as stones or gravels for construction concrete (building materials). Figure 6 shows L.A coefficient is greater when the UCS is lower in logarithmic relationship. A power curve has also been established between the LA coefficient and the point load index determined by the Franklin test, and a linear relation was observed between Schmidt hammer values and resistance to fragmentation within metamorphic, sedimentary and igneous rocks (Kahraman and Gunaydin 2007). Tunc and Alyamac established a linear correlation between LA coefficients and the uniaxial compressive strength within concrete (Tunc and Alyamac 2019). Using regression analysis, an exponential correlation between LA coefficients and several physical and mechanical properties (hardness, UCS, porosity, point load strength, tensile strength) of rocks (igneous, metamorphic and sedimentary) was reported by Ozcelik (2011).

As mentioned above, the L.A. coefficient is one of the most required mechanical parameters to characterize the strength of the aggregates. The L.A. test is expensive, time-consuming, destructive and applicable only in a laboratory. Therefore, a simpler and more practical application to estimate the strength of the aggregates is provided throughout the established curve. Moreover, it was not possible to recover a sample of sufficient size to perform the uniaxial compression test of the Jurassic dolomitic rock from J. Faied. This correlation can, therefore, be useful, as an indirect method, to determine the UCS of the rocks from this formation. Figure 7 show a logarithmic relationship between MDE and UCS. Capik and Yilmaz in 2017 established a logarithmic correlation between Micro-Deval abrasion resistance (MDE) and uniaxial compressive strength with \(R^2=0.66\) in different rock types (Capik and Yilmaz 2017). Demei et al in 2019 studied the correlation between the MDE coefficient and polish value PV-10 in calcined bauxite aggregate (Yu et al. 2019). In 2019, Quintanilla et al studied the correlation between the MDE abrasion resistance coefficient and the cumulated mass loss of ballast grains (Quintanilla et al. 2019). In fact, the MDE abrasion test is laborious and time-consuming. Consequently, the established curve can be used as a simple method to estimate the abrasion resistance of the aggregates using the UCS values.

Figure 8 illustrate very good linear relationship with \(R^2=0.92\).

Cooley and James established a linear correlation between the resistance to fragmentation and Micro-Deval abrasion resistance (MDE) in 2003 (Cooley Jr and James 2003). Overall, the determination of some rock parameters can be used to estimate other non-available or laborious and time consuming measures through the indirect methods using the established correlation models. Figures 9 and 10 show linear relationships between Density and LA and MDE respectively. Kahraman and Toraman (2008) established an exponential relationship between LA measures and crushability index within metamorphic rock samples with a coefficient of determination equal to 0.8. Abdelhedi et al. (2020a, b) studied the relationship between MDE and ultrasonic velocity on carbonate rock samples and found a determination coefficient of 0.8. Several authors established many relationships between mechanical parameters within aggregates (M.D.E and LA) and different physical and mechanical parameters. However, the current study is the first correlation using the density of the rocks. Figures 11 and 12 show linear relationships between Effective Porosity and LA and MDE, respectively. We note that the relationships between the different physical and mechanical parameters correlated with LA coefficients are stronger than those correlated with MDE coefficients, according to their coefficients of determination (0.8 for LA and 0.7 for MDE). Consequently, the LA coefficient can be predicted more accurately than the MDE. However, the relationship between LA and MDE values is very strong (R = 0.9) which makes the prediction of one of these parameters from the other more accurate. To the best of our knowledge, this is the first report of a correlations established between the LA and MDE coefficients with the effective porosity.

We note that the relationships between the different physical and mechanical parameters correlated with LA coefficients are stronger than those correlated with MDE coefficients, according to their coefficients of determination (0,8 for LA and 0,7 for MDE).

Consequently, the LA coefficient can be predicted more accurately than the MDE. However, the relationship between LA and MDE values is very strong (\(R^2=0.9\)) which makes the prediction of one of these parameters from the other more accurate. To the best of our knowledge, this is the first report of the correlations established between the LA and MDE coefficients with the effective porosity.

Conclusion

The determination of the physical and mechanical parameters of the studied samples showed many important results. The first outcome of this study is the revelation of two new sites showing good carbonate rocks properties similar to those from the exploited sites.

-

Matleg carbonate rocks can be exploited as high-quality aggregates due to their abrasion resistance (MDE) and resistance to fragmentation (LA).

-

Kabbara rocks can be mined as marble stones since they have similar characteristics to Thala Marble stones (the UCS is more important for Kabbara limestones,which indicates a better resistance).

Some carbonate rocks can be used for building materials such as construction stones especially those of Jebel Cherahil, Jebel Matous and Jebel Aziza. In addition to the economic importance of exploiting these rocks, there is an environmental importance, mainly for the member of Kef Eddour which is being removed by the mining industry exploiting the Chouabine Member’s phosphate series. The established curves show strong relationships between physical and mechanical parameters especially for the relationship linking resistances to fragmentation and to abrasion determined through the MDE and the LA coefficients, respectively (\(R^2=0.92\)). The correlations performed in this study are very interesting and can be used when the determination of some parameters is not possible, such as the case of Jebel Faidh carbonate, where the stones are fragmented and consequently the uniaxial compression test cannot be performed. Hence, these correlations solved the problem and were applied to predict the UCS values. The elaborated correlations are interesting not only for the estimating of a parameter that cannot be determined in the laboratory, but also in the exploration of new resources. Moreover, this paper proved the utility of this approach for estimating the UCS of Jebel Faied samples from two models, one using LA and the other using MDE coefficients. The matching results approve the efficiency of these models. The current paper presents the first correlations between MDE and LA coefficients with the physical parameters: density and effective porosity.

References

Abdelhedi M, Aloui M, Mnif T, Abbes C (2017) Ultrasonic velocity as a tool for mechanical and physical parameters prediction within carbonate rocks. Geomech Eng 13(3):371–384

Abdelhedi M, Thameur M, Chedly A (2018) Ultrasonic velocity as a tool for physical and mechanical parameters prediction within geo-materials: application on cement mortar. Russ J Nondestruct Test 54(5):345–355

Abdelhedi M, Jabbar R, Mnif T, Abbes C (2020a) Prediction of uniaxial compressive strength of carbonate rocks and cement mortar using artificial neural network and multiple linear regressions. Acta Geodyn et Geromaterialia 17(3):367–378

Abdelhedi M, Jabbar R, Mnif T, Abbes C (2020b) Ultrasonic velocity as a tool for geotechnical parameters prediction within carbonate rocks aggregates. Arab J Geosci 13(4):180

Ammouri M, Bouaziz S, Ennifar S, Jallouli C, Tricart P (1991) Le gite manganézifère du Jebel Aziza (Chaine des Chotts): étude de la minéralisation dans son cadre morphostructural et paléogéographique. Note du service géologique de Tunisie 58:133–150

Amri S, Akchiche M, Bennabi A, Hamzaoui R (2019) Geotechnical and mineralogical properties of treated clayey soil with dune sand. J Afr Earth Sci 152:140–150

Anderson MO, Hannington MD, McConachy TF, Jamieson JW, Anders M, Wienkenjohann H, Strauss H, Hansteen T, Petersen S (2019) Mineralization and alteration of a modern seafloor massive sulfide deposit hosted in mafic volcaniclastic rocks. Econ Geol 114(5):857–896

Asheghi R, Shahri AA, Zak MK (2019) Prediction of uniaxial compressive strength of different quarried rocks using metaheuristic algorithm. Arab J Sci Eng 44(10):8645–8659

Astm C et al (2012) Standard test method for compressive strength of cylindrical concrete specimens. ASTM, West Conshohocken

Azaiez H, Gabtni H, Chabaane A, Sayem G, Bédir M (2020) Geophysical study of hammam sidi maamar geothermal site in central Tunisia for sustainable development. J Afr Earth Sci 170:103897

Belayouni H (1983) Etude de la matière organique dans la série phosphatée du bassin de Gafsa Metlaoui (Tunisie): Application à la compréhension des mécanismes de la phosphatogenèse. M.Sc. Thesis, The University of Tunis, Tunis, Tunisia (unpublished)

Burollet PF (1956) Contribution à l'étude stratigraphique de la Tunisie central. Ann Mines Geol 18:350

Burollet PF, Robaszynski F (1991) Les évènements de la limite Cénomanien-Turonien en Tunisie centrale: la formation Bahloul. Géologie alpine 67:3–42

Calvo JP, Regueiro M (2010) Carbonate rocks in the mediterranean region-from classical to innovative uses of building stone. Geol Soc Lond Spec Publ 331(1):27–35

Capik M, Yilmaz AO (2017) Modeling of micro deval abrasion loss based on some rock properties. J Afr Earth Sci 134:549–556

Çelik SB (2019) Prediction of uniaxial compressive strength of carbonate rocks from nondestructive tests using multivariate regression and ls-svm methods. Arab J Geosci 12(6):193

Ceryan N (2014) Application of support vector machines and relevance vector machines in predicting uniaxial compressive strength of volcanic rocks. J Afr Earth Sci 100:634–644

Chaâbani F (1995) Dynamique de la partie orientale du bassin de Gafsa au crétacé et au paléogène. Etude minéralogique et géochimique de la série phosphatée éocène (Tunisie méridionale). M.Sc. Thesis, The University of Tunis, Tunis, Tunisia (unpublished)

Cooley LA Jr, James RS (2003) Micro-deval testing of aggregates in the southeast. Transp Res Rec 1:73–79

de Larrard F (2002) Construire en béton: l’essentiel sur les matériaux. Presses des Ponts, Paris

El Sharawy MS, Gaafar GR (2019) Impacts of petrophysical properties of sandstone reservoirs on their irreducible water saturation: implication and prediction. J Afr Earth Sci 156:118–132

Elleuch MA, Elleuch L, Frikha A (2019) A hybrid approach for water resources management in Tunisia. Int J Water 13(1):80–99

Felhi M (2010) Les niveaux intercalaires de la série yprésienne du bassin Gafsa-Métlaoui: Apports de la minéralogie des argiles et de la géochimie de la matière organique résiduelle à la reconstitution paléoenvironnementale. M.Sc. Thesis, The University of Sfax, Sfax, Tunisia (unpublished)

Fournier D (1978) Nomenclature litho stratigraphique des séries de crétacé supérieur au Tertaire de la Tunisie. Bull Cent Rech Explor Prod Elf Aquitaine 2:97–148

Gaied ME, Ben Haj Ali M, Chaabani F, Taamallah MN (2000) Les potentialités en pierres marbrières et ornementales de Tunisie. Office nationale des mines, Tunis

Garnit H, Bouhlel S, Jarvis I (2017) Geochemistry and depositional environments of Paleocene-Eocene phosphorites: Metlaoui Group, Tunisia. J Afr Earth Sc 134:704–736

Ghedhoui R (2014) Apports de l’imagerie et des SIG pour une étude morphostructurale de la jeffara tunisienne: implications géodynamiques et intérêts pétroliers. M.Sc. Thesis, The University of Paris-Est, Paris, France (unpublished)

Gokalp I, Uz VE, Saltan M (2016) Testing the abrasion resistance of aggregates including by-products by using micro deval apparatus with different standard test methods. Constr Build Mater 123:1–7

Gouasmia M, Khorchani H, Mhamdi A, Dhahri F, Soussi M (2018) Hydrogeological characterization of a carbonate aquifer using geophysical and geochemical approach: case of the Krachoua formation in Tataouine area, southern Tunisia. Arab J Geosci 11(24):1–15

Gourmelen C, Rigane A, Broquet P, Truillet R, Aite MO (2000) Caracteres structuraux et dynamiques d’un bassin en transtension; la plate-forme tunisienne a l’Ypresien terminal. Bull Soc Geol Fr 171:559–568

Harraden CL, Cracknell MJ, Lett J, Berry RF, Carey R, Harris AC (2019) Automated core logging technology for geotechnical assessment: a study on core from the cadia east porphyry deposit. Econ Geol 114(8):1495–1511

Jaballi F, Felhi M, Khelifi M, Fattah N, Zayani K, Abbes N, Elouadi B, Tlili A (2019) Mineralogical and geochemical behavior of heated natural carbonate-apatite of the Ypresian series, Maknassy-Mezzouna basin, central Tunisia. Carbonates Evaporites 34(4):1689–1702

Johnson CL, Browning DA, Pendock NE (2019) Hyperspectral imaging applications to geometallurgy: utilizing blast hole mineralogy to predict au-cu recovery and throughput at the phoenix mine, nevada. Econ Geol 114(8):1481–1494

Kahraman S, Gunaydin O (2007) Empirical methods to predict the abrasion resistance of rock aggregates. Bull Eng Geol Environ 66(4):449–455

Kahraman S, Toraman O (2008) Predicting los angeles abrasion loss of rock aggregates from crushability index. Bull Mater Sci 31(2):173–177

Mahdiabadi N, Khanlari G (2019) Prediction of uniaxial compressive strength and modulus of elasticity in calcareous mudstones using neural networks, fuzzy systems, and regression analysis. Period Polytech Civil Eng 63(1):104–114

Mehrgini B, Izadi H, Memarian H (2019) Shear wave velocity prediction using elman artificial neural network. Carbonates Evaporites 34(4):1281–1291

Office nationale des mines ONM (2010) Les potentialités en substances utiles du gouvernorat de Kairouan. L’Office de Développement du Centre Ouest, Tunis, ONM

Okogbue CO, Aghamelu OP, Magaji S (2020) Assessment of quality of some laterites in northeastern Nigeria by multivariate analysis of their geotechnical index properties. Natl Resour Res. https://doi.org/10.1007/s11053-020-09632-4

Ozcelik Y (2011) Predicting Los Angeles abrasion of rocks from some physical and mechanical properties. Sci Res Essays 6(7):1612–1619

P18-572 (1990) Aggregates. Micro-deval attribution test. Association française de normalisation, Bureau de Normalisation Sols et Routes. Géotechnique-normes. Décembre 1990, Paris, France

P18-573 (1990) Aggregates. Los Angeles test–granulate. Los Angeles pruefung. Association française de normalisation, Bureau de Normalisation Sols et Routes. Géotechnique-normes. Décembre 1990, Paris, France

Peng S, Zhang J (2007) Engineering geology for underground rocks. Springer Science and Business Media, Berlin

Quintanilla ID, Combe G, Emeriault F, Voivret C, Ferellec JF (2019) X-ray ct analysis of the evolution of ballast grain morphology along a micro-deval test: key role of the asperity scale. Granul Matter 21(2):30

Rebai N, Achour H, Chaabouni R, Kheir RB, Bouaziz S (2013) DEM and GIS analysis of sub-watersheds to evaluate relative tectonic activity. A case study of the North–south axis (Central Tunisia). Earth Sci Inform 6:187–198

Rigane A (1991) Les calcaires de l’ypresien en tunisie centro-septentrionle: cartographie cinematique et dynamique des structures. M.Sc. Thesis, The University of Besançon, Besançon, France (unpublished)

Salah MK, Alqudah M, Monzer AJ, David C (2020) Petrophysical and acoustic characteristics of Jurassic and cretaceous rocks from central Lebanon. Carbonates Evaporites 35(1):12

Seifi H, Tokhmechi B, Moradzadeh A (2019) Improved estimation of shear-wave velocity by ordered weighted averaging of rock physics models in a carbonate reservoir. Natl Resour Res 29:2599–2617

Tlili A, Felhi M, Fattah N, Montacer M (2011) Mineralogical and geochemical studies of Ypresian marly clays and silica rocks of phosphatic series, Gafsa-Metlaoui basin, southwestern Tunisia: implication for depositional environment. Geosci J 15(1):53–64

Tunc ET, Alyamac KE (2019) A preliminary estimation method of los angeles abrasion value of concrete aggregates. Constr Build Mater 222:437–446

Ugur I, Demirdag S, Yavuz H (2010) Effect of rock properties on the Los Angeles abrasion and impact test characteristics of the aggregates. Mater Charact 61:90–96

Yalcinalp B, Aydin ZO, Ersoy H, Seren A (2018) Investigation of geological, geotechnical and geophysical properties of Kiratli (Bayburt, ne Turkey) travertine. Carbonates Evaporites 33(3):421–429

Yasar E, Erdogan Y (2004) Correlating sound velocity with the density, compressive strength and Young’s modulus of carbonate rocks. Int J Rock Mech Min Sci 41(5):871–875

Yilmaz A, Karasahin M (2014) Compressive strength of cement-bound base layers containing ferrochromium slag. Turk J Eng Environ Sci 37(3):247–258

Yu D, Xiong R, Li S, Cong P, Shah A, Jiang Y (2019) Laboratory evaluation of critical properties and attributes of calcined bauxite and steel slag aggregates for pavement friction surfacing. J Mater Civil Eng 31(8):04019155

Zargouni F (1985) Tectonique de l’Atlas méridional de Tunisie: evolution géométrique et cinematique des structures en zone decisaillement. M.Sc. Thesis, Louis Strasbourg University, Strasbourg, France (unpublished)

Zhang Y, Lebedev M, Smith G, Jing Y, Busch A, Iglauer S (2019) Nano-mechanical properties and pore-scale characterization of different rank coals. Natl Resour Res 28:1787–1800

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Abdelhedi, M., Abbes, C. Study of physical and mechanical properties of carbonate rocks and their applications on georesources exploration in Tunisia. Carbonates Evaporites 36, 35 (2021). https://doi.org/10.1007/s13146-021-00688-8

Accepted:

Published:

DOI: https://doi.org/10.1007/s13146-021-00688-8