Abstract

Preparation of polythiophene (PTh) and polyethylene oxide (PEO) polymer composites was done by in situ chemical oxidative polymerization method using FeCl3 as an oxidant. Thin films of PTh–PEO polymer composite were prepared for 1, 2, 3, 4, 5 and 6 wt% of lithium chloride (LiCl) as a dopant. Characterization of the sample were studied by Fourier transform infrared spectroscopy and scanning electron microscopy. DC conductivity as a function of temperature was measured in the temperature range 303–338 K by the two probe method. The temperature dependence of conductivity showed Arrhenius behaviour. PTh–PEO composite doped with 4 wt% LiCl showed the maximum value of DC conductivity.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Over the last two decades there is an explosive increase in the demand for composite materials, which are now available as materials with unique combination of properties. The electronic properties of conducting and insulating polymer matrices in combination with attractive mechanical properties have brought in a new set of opportunities to develop a wide range of application based conducting polymer composites. Besides, processing advantages of the polymers has now attained a level of maturity. Thus, the composites based on conducting polymers has been studied as materials for industrial products [1]. Polythiophene and its derivatives has been often considered as a model for the study of charge transport in conducting polymers and the high environmental stability of both their doped and undoped states [2]. There are many applications of the conductive polymers. The most exciting developments are the new class of semiconducting devices such as plastic batteries, sensors, conductive surface, magnetic recording [3–5]. Recently we have reported the electrical properties of Polythiophene–polyethylene oxide (PTh–PEO) polymer composites doped with Li2SO4. Here we report a detailed study of synthesis and characterization of PTh–PEO composites [6].

In the present study, the PTh–PEO composite doped with lithium chloride were prepared by in situ chemical oxidative polymerization method. DC conductivity of the polymer composite has been measured by two probe method. Interactions among the components were studied by FTIR. Scanning electron micrograph study has been carried out to observe the surface morphology of the polymer composite.

2 Experimental

2.1 Preparation of PTh–PEO Composite Doped with LiCl

Polythiophene polymer composites were prepared at ambient temperature (303 K) by in situ chemical oxidative polymerization method. Polyethylene oxide (PEO, MW = 100,000, Acros Organics) was used as a host polymer, and lithium chloride (LiCl) (Loba Chem) as the salt. Anhydrous FeCl3 was used as an oxidizing agent. A solution of PEO in methanol was first prepared by stirring for 6 h. and kept overnight. Appropriate amount of anhydrous FeCl3 and LiCl were then added and stirred for 15 min. When monomer thiophene was added drop by drop to the solution, a dark brown homogeneous solution was obtained. The solution was then poured on polypropylene dishes, to prepare the composite films. The wt% of LiCl was changed from 1 to 6. For each wt% of LiCl, quantity of thiophene was kept constant at 0.5 ml. The thiophene polymerization progresses because the evaporation of the solvent increases the oxidation potential of the cast solution. This evaporation results in the formation of polymer composite films. The digimatic micrometer was used to measure the film thickness and an average thickness of 220 μm was observed.

2.2 Fourier Transform Infrared Spectroscopy (FTIR)

The FTIR study of PTh–PEO polymer composites was studied on a SHIMADZU FTIR IR Affinity 1 spectrophotometer at room temperature. FTIR measurements were made in the range of 4000–500 cm−1 with resolution of 0.4 cm−1.

2.3 Scanning Electron Microscopy (SEM)

The morphology of the PTh–PEO polymer composites was observed by scanning electron microscopy (SEM) using JSM-7600F microscope, with resolution of 1.0 nm (15 kv).

2.4 DC Conductivity Measurement

DC electrical conductivity of the samples were measured in the temperature range of 303–338 K using Ohms law. Silver electrodes were used. A dc regulated power supply, a picoammeter having a resolution of 1 pA and a voltmeter having a resolution of 0.01 V were used for the measurement. The thickness of the films were measured with digimatic micrometer (Japan), having a least count of 0.001 mm.

3 Results and Discussion

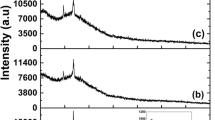

FTIR spectrum of PTh–PEO polymer composite doped with different wt% of lithium chloride is shown in Fig. 1. The spectral studies of the synthesised polymer composite films shows number of absorption peaks. From FTIR spectra of all synthesised films it is observed that the basic nature of the polymer composite is same. An attempt is made to explain the structure of PTh–PEO polymer composite films with the help of infrared spectra.

The major peaks at 1076.28 and 1643.35 cm−1 are due to the presence of C–S and C=C bonds in polythiophene respectively. The strong intensity of the 827.46 cm−1 band which is characteristic of 2,5—disubstituted thiophene rings indicates that the coupling of thiophene ring occurs preferentially at 2,5 positions which shift to 848.68, 846.30 and 860.25 cm−1 due to addition of lithium salt. The absorption band at the region of 650–600 cm−1 shows the ion–ion interactions in PEO–Li+ ions. Two medium peaks at 1475.07 and 1446.61 cm−1 are assigned to stretching vibrational modes of the thiophene ring [7]. The spectrum of PTh–PEO showed characteristic peaks in the range of 900–1200 cm−1 due to the C–O–C symmetric and asymmetric stretching and C–O–C deformation modes that confirmed the crystalline phase of PEO by the presence of triplet peak of C–O–C stretching [8, 9]. For PTh–PEO composite, it is observed that the triplet peak of PEO, C–O–C stretching slightly shifted to 1240, 1136 and 1066 cm−1. Besides, one of the split in the CH2 wagging mode band at 1352 cm−1 is observed in the composite.

Figure 2 shows the morphology of PTh–PEO composite doped with LiCl. The surface morphology changes severely from rough to smooth as shown in Figure. PTh–PEO composite doped with LiCl shows further drastic improvement of surface morphology as appears in figure, in which cluster of particles and voids are observed. The average size of the particles are 0.1 µm–50 nm, as shown in Fig. 2 From the PTh–PEO composites image, the crowd of particles resulting from the aggregation of the composite particles is seen. However, several aggregated phases and separate phase domains can be detected.

The smooth morphology is closely related to the reduction of PEO crystallinity in presence of the salt [10]. The reduction of PEO crystallinity arises from random distribution and dissociation of salt which may introduce the topological disorder in the composite. The reduction of crystallinity will produced more amorphous phase in the system. The amorphous phase makes the electrolyte more flexible and results in increase of segmental motion of the polymer.

The variation of ionic conductivity as a function of inverse temperature for PTh–PEO polymer composite doped with different wt% of LiCl is shown in Fig. 3. The range of temperature considered here is 303K to 338K. It can be observed that the ionic conductivity for all the compositions of PTh–PEO composite doped with different wt% LiCl increases with increasing temperature within the range.

The nature of the curves are consistent with Arrhenius type charge conduction in polymer composites and the conductivity relationship follows the equation,

where σ0 is the pre-exponential factor, Ea is the activation energy and k is the Boltzmann’s constant. The slope of each straight line gives the activation energy which lies between 0.14 and 0. 26 eV. The ionic conductivity increases with increasing lithium salt concentration due to the increase in carrier density. However, the formation of ion-pairs becomes more in the case of high salt concentration than in the case of low concentration, leading to a drop in the ionic conductivity. Many researchers [11, 12] reported a similar Arrhenius conductivity isotherm. A percolation behaviour [13, 14] was reported in case of PTh composites even for low concentration of PTh. This type of ionic conductivity behaviour follows Arrhenius model [15–17]. It can be seen that the Arrhenius plots for all the samples displays an identical behaviour. The ionic conductivity value increases with the different wt% of LiCl at different temperatures.

As the temperature increases, mobility of the ions increases, which results the rise in conductivity. Uppermost curve belong to 4 wt% of LiCl for which conductivity is maximum. The rate of increase of conductivity is linear for the composite; which may be due to the segmental motion of the ions in the polymer [18].

Plot of activation energy with different wt% of LiCl is illustrated in Fig. 4. Studies shows that activation energy is large for lower conductivity and small for higher conductivity [15]. Which shows that activation energy E a is found to be maximum for the 1 wt% of LiCl.

4 Conclusion

Polythiophene–Polyethylene oxide polymer composites were prepared successfully by insitu chemical oxidative polymerization of thiophene doped with LiCl. FTIR spectra confirm the successful polymerization of thiophene and formation of PTh–PEO composite doped with LiCl. SEM micrograph shows morphology of PTh–PEO composite doped with LiCl. Also the addition of LiCl shows further drastic improvement of surface morphology of polymer composite. The average size of the particles grain was found to be 0.1 µm–50 nm. The temperature dependence of conductivity showed Arrhenius behaviour. PTh–PEO composite doped with the 4 wt% LiCl shows the maximum value of ionic conductivity.

Refernces

Das N C, Shinchi Y, Masamichi H, Chaki T K, Khastgir D, and Chakraborty A, Polym Int, 54, (2005) 256.

Kanatzidis M, Chem Eng News 3 (1990) 36.

Gurunathan K, Murugan A V, and Amalnerkar D P, Mater Chem Phys 61 (1999) 173.

Pei J, Yu W L, Huang W A, and Heeger J, Eur Polym J 33 (2000) 2462.

Fahlman M, Birgesson J, Kaeriyama K, and Salaneck W R, Synth Met 75 (1995) 223.

Shirbhate P D, Yawale S P, and Pakade S V, IOSR J Appl Phys 1 (2014) 49.

Tnganas O, Liedberg B, Chang-Ru W, and Wynberg H, Synth Methods, 11 (1985) 239.

Jaipal Reddy M, and Chu P P, J Power Sources, 109 (2002) 340.

Chu PP, Jaipal Reddy M, and Tsai Joyce, Polym Sci Part B, 42 (2004) 3866.

Rout S K, and Hussian A, J Alloy Compd, 477 (2009) 706.

Barde W S, Pakade S V, and Yawale S P, J Non Cryst Solids, 353 (2007) 1460.

Bamford D, J Chem Phys 118 (2003) 9420.

Yin B, and Gu T, Eur Polym J, 34 (1998) 779.

Chakraborty M, Mukherjee D C, and Mandal B M, Synth Metals, 98 (1999) 193.

Prabu M, and Selvasekarapandian S, J Rare Earths, 28, (2010) 435.

Taunk M, Kapil A, and Chand S, Open Macromol J, 2 (2008) 74.

Jain P K, and Saxena N S, J Non-Oxide Photon Glasses, 1 (2009) 43.

Cohen M H, and Turnbull D, J Chem Phys, 31 (1959) 1164.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shirbhate, P.D., Pakade, S.V. & Yawale, S.P. Preparation and Characterization of Polythiophene Polymer Composite. Trans Indian Inst Met 69, 669–672 (2016). https://doi.org/10.1007/s12666-015-0537-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0537-5