Abstract

Due to the complexity of the geological conditions in the ecologically fragile mining area in western China, water and sand inrush disasters during the mining process are controlled by various factors. Based on the geographic information system (GIS) and analytic hierarchy process (AHP), a suitability analysis system was developed to assess the suitability of aquifer-protection mining in the study area. The system consists of models with 3 criteria and 10 sub-criteria to evaluate the suitability of coal mining. Then, the suitability assessment results are spatially visualized in thematic maps and color-coded maps. A case study of the Mahuang coalfield is conducted, and the geological and hydrogeological conditions are analyzed. An engineering application of the assessment of the suitability of aquifer-protection mining in the ecologically fragile mining area is proposed. Non-dimensional thematic maps for all the indices are constructed. According to the AHP, the weight vector of indices is calculated, which indicates that hydrogeological conditions have the highest weight. In particular, the specific capacity has the greatest influence. The suitability zoning map of the ecologically fragile mining area is obtained by the GIS. The results indicate that half of the study area has the highest suitability degree. The suitability analysis system can successfully enable the evaluation and prioritization of the applicability of aquifer-protection mining in ecologically fragile mining areas. Moreover, the system can provide a better understanding of the distribution of the suitability of aquifer-protection mining and accurately evaluate the suitability levels in ecologically fragile mining areas. Suitability assessment can be a useful decision-support tool for assessing the suitability of aquifer-protection mining in ecologically fragile mining areas.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water environment problems in the ecologically fragile mining areas in western China are currently the key issues in environmentally sustainable development. Mining activities not only cause overburden failure and surface subsidence but also affect the ecological environment, especially the overlying aquifers and the groundwater system, leading to groundwater loss and pollution (Singh et al. 1995; Zhang and Shen 2004; Woo et al. 2013). These severe conditions may intensify the deterioration of the environment in fragile ecological areas in China. Therefore, the concept and scientific connotation of aquifer-protection mining were proposed to protect aquifers and ecosystems in arid and semiarid mining areas, in addition to the construction of a framework for water conservation (Fan et al. 2015; Fan 2017). However, aquifer protection in longwall mining relies mainly on rapid advances with a severely weathered rock (SWR) layer and two key strata (KS) in the overlying strata (Zhang et al. 2010). Additionally, reducing the mining height and backfill mining can also be successfully applied in aquifer-protection mining techniques under suitable geological conditions (Zhang et al. 2011; Zhang et al. 2015; Zhang et al. 2016). Coordinated exploitation of both coal and water resources was proposed to provide a good example of wise environmental maintenance approach (Qiao et al. 2020). However, suitability evaluation and risk assessment of aquifer-protection mining depend on numerous influencing factors, such as the thickness and strength of the overlying strata and overburden failure rules.

Most geological objects, such as strata, coal seams and geological structures, encountered in coal seams in ecologically fragile mining areas are buried underground, resulting in notable concealment of mining activities (Ren et al. 2010; Ghasemi et al. 2012; Wang et al. 2016). Geological objects experience deformation, fracturing and displacement to different degrees during long-term geological processes, resulting in numerous factors impacting safe mining, and their spatial occurrence and distribution characteristics are complex (Yang et al. 2011; Meng et al. 2016; Ghabraie et al. 2017). To investigate mining disturbances, geological survey methods such as field geological survey methods, remote sensing methods, drilling methods, geophysical methods, and production and exploration methods in the mining production process can be implemented (Padmanaban et al. 2017; Pariseau et al. 2017; Zhang et al. 2018). By obtaining information on these factors, multifactor quantitative evaluation and analysis of safe coal seam mining have an important guiding significance for aquifer-protection mining. It is important for the prediction and evaluation of aquifer-protection mining to recognize and understand the spatial characteristics and distribution rules of these influencing factors and their impact on the safe mining of coal seams.

Risk assessment is an important tool to achieve aquifer-protection mining in ecologically fragile mining areas, which includes three steps: risk identification, risk analysis and risk assessment (Brown 2012; Mishra and Rinne 2014). Multicriteria evaluation methods are often applied in mining safety risk assessment, which enables the most appropriate choice to be made depending on different criteria (Wu et al. 2015a; Zeng et al. 2018). The multicriteria decision-making method of the analytic hierarchy process (AHP) can be used to investigate and analyze decisions that have multiple and even competing purposes, especially the prediction and assessment of water disasters in underground coal mining (Wu et al. 2013; Wu et al. 2015b). Multifactor analysis based on geographic information system (GIS) technology can be applied to predict and evaluate mine water hazards and overburden failure (Djamaluddin et al. 2011; Yang et al. 2018). The combination of GIS and AHP is a powerful tool to solve risk assessment problems, which are addressed in mining safety (Wu et al. 2011). A GIS-based AHP method combined with the vulnerability index method has been successfully applied in water burst assessments to implement necessary control measures to avoid water hazards (Zeng et al. 2016).

This study proposes a GIS-based AHP evaluation system for predicting and evaluating the suitability of aquifer-protecting mining in ecologically fragile mining areas. Ten factors that likely are important in suitability classification of aquifer-protection mining were identified. They were treated as criteria and sub-criteria in the decision-making process according to their nature and role in the evaluation process. A factor evaluation system can be constructed through field geological survey methods, remote sensing methods, drilling methods, geophysical exploration methods and other geological exploration methods, in addition to production exploration methods in the mine production process. According to the characteristics of these factors and their influence on the evaluation process, all identified factors were clustered into three groups: geological condition, hydrogeological environment and mining effect groups, as follows:

Lithology and thickness of the bedrock and fault structure (geological condition group).

Thickness of the aquifuge and aquifer, hydraulic conductivity and specific capacity of the aquifer (hydrogeological environment group).

Height of overburden failure, mining thickness and depth (mining effect group).

Thereafter, the spatial occurrence and distribution characteristics of these factors and their influences on safe mining in ecologically fragile mining areas are analyzed through the normalized mathematical model and GIS spatial analysis function, and various assessment factors are standardized. Thematic maps, which determine the weight vector of each evaluation factor, are primarily constructed with the ArcGIS method. Finally, a suitability classification diagram for aquifer-protection mining can be obtained by adopting the multifactor spatial fitting function of GIS. A suitability assessment system for aquifer-protection mining is constructed, which can quickly and accurately calculate the aquifer-protection risk areas in ecologically fragile mining areas. This study has an important guiding significance for the prediction and control of aquifer-protecting mining in ecologically fragile mining areas.

Materials and methods

Study area

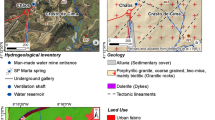

The Shanghaimiao coalfield is located at the southwestern edge of the Mu Us Desert in the Otog Front Banner, Inner Mongolia. The coalfield is situated at the junction of the three provinces of Mongolia, Shaanxi and Ningxia. Adjacent to the Ningxia Energy and Chemical Industry Base, the Mahuang coalfield lies on the east bank of the Yellow River and to the north of the ancient Great Wall, as shown in Fig. 1. This field is located in the eastern part of the Shanghaimiao coalfield, with an area of approximately 49.26 km2. The area experiences weak winds and little rainfall, and dust storms frequently occur up to 40 days per year. There are environmental problems such as a lack of water resources and land desertification.

The coal-bearing strata contain the Carboniferous Taiyuan Formation (C3t) and the Permian Shanxi Formation (P1s). A total of 60 drilling boreholes are involved in the evaluation of coal seams. The recoverable coal seams in this area are seam No. 1, No. 3, No. 3up, No. 5, No. 8, No. 9up, No. 9 and No. 10. Seam No. 1 is located in the upper part of the Shanxi Formation (P1s), which is penetrated by 52 boreholes, as shown in Fig. 2. The recoverable thickness of seam No. 1 ranges from 0.66 to 2.10 m, with an average thickness of 1.27 m.

The lower part of the Neogene is a sand–gravel aquifer, which is deposited in the lower part of the Neogene sandy clay. The thickness of the aquifer is approximately 3.20–105.50 m, with an average thickness of 23.53 m, as shown in Fig. 2. The specific capacity is between 0.198 and 0.271 L/(s·m), and the hydraulic conductivity ranges from 0.538 to 1.612 m/d, with a moderate water content. The aquifer in the Neogene system is the main aquifer that poses a risk to the working panel and roadway in future mining production. The upper part of the Neogene is an aquifuge with a thickness ranging from 96.80 to 180.20 m and an average thickness of 146.91 m. It is widely distributed throughout the area and has a very low permeability. The Permian Shihezi Formation gradually thins from east to west, and the formation is denuded in some of the boreholes in the west. The lithology is dominated by siltstone, sandy mudstone and mudstone. A small amount of gravel is contained in coarse sandstone layers, dispersed in the middle of these layers. The bottom is a layer of clay stone and clay mudstone, with an average thickness of 281.68 m, which is a relatively effective aquifuge. However, with increasing exploitation of the coal resources in the study area, the water resources have become severely damaged, which will eventually cause a series of environmental problems, such as land desertification.

Methodology

The AHP was first introduced by Saaty (1980) for the purpose of selecting priorities. It is an analytic tool to explicitly rank qualitative and quantitative criteria against each other and evaluate each criterion (Chang et al. 2008). Complicated problems that involve multiple interrelated objectives can be considered by the AHP, even though they are difficult to prioritize (Chuang, 2001). To rank their importance and suitability, the weights of each criterion are established. There are three general steps included in the AHP approach, which are described below.

The first step is to transform the decision-making problem into a hierarchy. To establish the hierarchy of a goal and identify criteria and sub-criteria relevant to aquifer-protection mining areas, three criteria are defined, as mentioned in the above three groups. These criteria are then divided into several sub-criteria. Assigned to each sub-criterion and criterion, alternative ratings of the reclassified spatial layers are defined from a very low suitability to the highest suitability.

In the second step, decision tables at each level of the hierarchical decomposition are established. Experts are invited to determine the importance of the criteria relevant to the mining area. Based on the discussion with experts, the basics of the AHP and the nine-point Saaty’s scale (1987) are introduced, as listed in Table 1. Comparison matrices at different hierarchical levels are created with the assigned rankings by experts. A square matrix captures a series of pairwise comparisons (PC matrices) of the selected criteria using relative data, where the diagonal elements of the matrix are equal to 1. A nine-point scale is adopted to conduct the comparison, which includes values of 1 to 9, where 1 indicates equal importance, 5 indicates strong importance and 9 indicates extreme importance (Table 1). By calculating the principal eigenvalue and the corresponding normalized right eigenvalue of the matrix, the relative preferences of the various criteria are obtained.

Then, the AHP computes the weights of the normalized eigenvector with respect to the criteria or sub-criteria and determines the local ratings to the alternatives. By evaluating the consistency of the matrix of order n, the consistency index (CI) is calculated by Eq. 1 to assess whether it reaches a certain threshold level. Otherwise, the comparison answers should be reexamined.

where λmax is the largest principal eigenvalue of the matrix. If CI = 0, the consistency reaches the level; otherwise, the larger CI is, the deviation of the consistency is more serious. Then, the consistency ratio (CR) values of comparisons are the ratios between CI and the random matrix (RI), as listed in Table 2. For a general rule, CR ≤ 0.1, means that the matrix is consistent. Then the eigenvector can be used as the weight vector. CR for this study is shown in Eq. 2.

The third step involves multiplying the weights of the sub-criteria and the rating of each alternative and then aggregating the products to determine the local ratings according to each criterion. Then, the global ratings are achieved by aggregating the products of the local ratings and weights of the criteria.

The constrained areas are marked according to the different assigned ratings on a scale of 1 (least suitable) to 5 (most suitable). The aquifer-protection mining suitability index (AMSI) is proposed, which is calculated to determine the suitability within the GIS environment.

The weighted linear combination method is commonly used in GIS environments to evaluate the risk and suitability of engineering applications. It contains two main parts of the criterion weight and the value function xi (Ai and Bi, respectively), which combines the evaluation results including the rankings and criterion weights. Therefore, the aquifer-protection mining suitability index (AMSI) is defined as Eq. 3.

where Aicwi and Aiscwi are the weight indices of criteria and sub-criteria, respectively.

A final suitability map is prepared via overlay analysis in GIS with the ten criterion layers according to the AMSI and the principle of information concentration. Higher AMSI values indicate areas more suitable for aquifer-protection mining. Therefore, the evaluation results can be classified into 5 grades using the Jenks method, which is G = (0.3, 0.45, 0.65, 0.80, 0.95) and is interpreted as G = (least suitable, low suitable, relative suitable, suitable, most suitable).

Criterion description and application

The AHP approach combined with the GIS was introduced to the key stakeholders in the risk assessment and suitability evaluation process as an appropriate method for solving this complex multicriteria issue in the mining safety region. Several criteria were calculated in assessing the suitability of aquifer-protection mining according to the questionnaire from the experts, as listed in Table 3. Figure 3 shows the methodology flowchart of using the hierarchical model. Ten criterion indices were selected for evaluating the suitability of aquifer-protection mining in this study. First, constraints were divided into three groups. Geological conditions were the first group, limiting the analysis to the lithology and thickness of the bedrock and the fractal dimensions of faults. The second group consisted of hydrological conditions, which included the thickness of the aquifer and aquifuge, specific capacity of the aquifer and hydraulic conductivity. The last group contained mining conditions, which mainly included the mining depth and thickness and height of overburden failure.

The change in the stress field and fracturing of the rock mass due to mining damage are the main reasons leading to water and sand inrush in coal mines. Water and sand inrush is a geological disaster induced by coal mining below aquifers and sand layers. The mining-induced fractures in the rock mass may become channels for water and sand flow that can burst through and flood the mining panel. In the ecologically fragile mining area in the west, the coal-bearing strata are shallow, and the thickness of the overlying bedrock is small. The water-conducting fractured zone formed by mining easily develops into overlying aquifers or surface water bodies, which may cause water and sand inrush disasters and further cause a significant reduction in shallow water resources. The thin aquifuge would be destroyed under the influence of mining, which causes the aquifuge to not completely or partially offset the damage caused by mining. The distribution of fractures generated in the aquifuge widely and rapidly changes in size, which will quickly lead to the formation of water-conducting channels, leading to the occurrence of water and sand inrush disasters. The surface of the ecologically fragile mining areas in the west is often covered by thick loose layers. The water abundance and size of the aquifer at the bottom of the loose layer have an important influence on the water inrush disasters in coal mines. In the process of mining, the height, distribution range and development characteristics of overburden failure affected by the fault structure will also greatly change, which will often lead to water and sand inrush disasters. Sometimes, even if advanced detection technology is utilized before mining or the hydraulic conductivity of the fault has been clearly determined, it is still impossible to avoid water loss. Suitability evaluation criteria may change from one area to another based on the hydrogeological and geological conditions and circumstances.

The types of factors are generally divided into benefit types and cost-based types. The benefit-type factor refers to the factor with the characteristic of the larger its value the better, such as the thickness of the overburden. The cost-based type factor refers to the factor with the characteristic of the smaller its value the better, such as the geological structure. To eliminate the effect of the different physical dimensions on the evaluation results, the factors can be standardized according to the following equations:

where rij is non-dimensional data and aij is the original data.

Each criterion was weighted by the AHP and mapped using ArcGIS techniques. Appendix Table 5 lists the normalized data of each criterion. The weight applies to a certain factor, which represents the relative importance of the factor in the overall suitability evaluation. The connotation of the weight is mainly manifested in the process of evaluation, which is a quantitative analysis of the different aspects of the objects and the degree of their importance. That is, the specific role of each influencing factor in the overall suitability evaluation is treated differently.

Results and analysis

Quantification of the evaluation index

Lithology and thickness of the bedrock

Figures 4 and 5 shows thematic layer maps of the lithology and thickness, respectively, of the bedrock of the No. 1 coal seam. The higher the index value is, the greater the contribution of the index is to safe mining. However, weak roofs may lead to overburden failure that is less than that induced by hard roofs, which is an advantage for safe mining. Then, the lithology of the bedrock is a cost-type factor for safe mining. Generally, thick bedrock may not be prone to conducting the upper aquifer when mining below water bodies, which indicates that the bedrock thickness is a benefit-type factor for safe mining. The normalized data are listed in Appendix Table 5.

The lithology of the coal roof is dominated by mudstone, followed by sandy mudstone, siltstone and medium sandstone. The uniaxial compressive strength of the bedrock is 15.00 MPa on average, lower than 30 MPa, which indicates that it is a weak rock. Figure 4 shows the irregular distribution of the lithology.

The local mudstone or carbonaceous mudstone has a thickness ranging from 0.43 to 0.9 m and is prone to caving, which is an unstable roof. Mudstone is visible in most parts of the region, with the thickness ranging from 0.43 to 16.08 m, and it is generally thicker in the west than in the east. Sandy mudstones are distributed in the northern and southern parts of the coalfield, with a thickness of 1.40 to 41.94 m, which generally become thinner toward the southern part. Siltstone is scattered and has a thickness ranging from 0.50 to 4.30 m. Medium sandstone is mainly distributed in the western part of the mine field near the coal seam denudation line, with a thickness of 0.95 o 19.45 m. Fine sandstone is only partially exposed in the boreholes of ZK1, ZK303 and ZK1102, and its thickness ranges from 3.59 to 9.55 m. The carbonaceous mudstone exposed in the boreholes of ZK103 and ZK302 has a thickness ranging from 0.34 to 0.79 m. In general, the bedrock in the western part is thicker than that in the eastern part, which indicates that the western part is safer when mining is conducted in the study area (see Fig. 5).

Fault structure

Faults are some of the geological structures that are more common in coal mine production. Quantitative evaluation of the complexity of faults is of great significance for safe production in coal mines. In recent years, many studies have demonstrated that fault networks are complex systems with fractal structures. Linear fractals are suitable for the study of fault structures due to their self-similarity. Fractals can only be generated in nonlinear systems. Fractal dimension numbers are constant quantities. Therefore, the fractal dimension is an important parameter for characterizing fractals. Since the traditional analysis method for faults is based on the density as the analysis index, it only contains information on the changes in the number of faults, fault extension length and fault cutoff distance. It can distinguish situations that cannot be analyzed with the density index. Therefore, it is more reasonable and accurate to evaluate the complexity of the fractures in a mine using fractal dimension indicators of faults instead of the traditional density indicator. In the study of faults, their fractal dimensions are mainly defined by the capacity dimension Dk, the information dimension Dl and the similarity dimension Ds.

where d is the diameter of the point set and N(d) is the minimum number that can be covered.

The similarity dimension and the information dimension are mainly adopted in the research of fault networks. Although the information dimension is more accurate than the similarity dimension, the measurement and calculation of the information dimension are very complicated. The similarity dimension and the information dimension have a positively correlated linear relationship. Therefore, the similarity dimension can be adopted as an evaluation index of fault structures.

The higher the fractal dimension is, the longer the length of the fracture is, the more small faults and branch faults there are and the more severe the cutting degree of the rock mass is. Otherwise, the cutting degree of the rock mass is low. Therefore, the fractal dimension is also a cost-type factor. Hence, the research area is first divided into 61 square grids with a side length of 1 km, which are marked one by one, as shown in Fig. 6. The similarity ratios are chosen as 1, 1/2, 1/4 and 1/8. N(r) is the number of grids, and the similarity dimension Ds of the fault network of each grid can be obtained by Eq. 5. Finally, the zone map of safe mining under the influence of the fault structure is obtained based on the GIS, as shown in Fig. 7. The western part is safer than the eastern part.

Thickness of the aquifer and aquifuge

Figure 8 shows a thematic map of the thickness of the aquifer, which is a cost-type factor for safe mining. The sand and gravel aquifer is a threat to the mining of the No. 1 coal seam, which exists in the lower part of the Neogene sandy clay, with a thickness between 3.20 and 105.50 m and an average value of 23.53 m. It gradually becomes thicker from northwest to southeast. The lithology is mainly composed of gravel with different compositions, such as mud-cemented sand, and the gravel diameter ranges from 2 to 5 cm, with a maximum diameter of 15 cm or larger, exhibiting a loose structure and poor development.

Figure 9 shows a thematic map of the thickness of the aquifuge, which is a benefit-type factor for safe mining. The upper Neogene sandy clay strata and the Permian Shihezi Formation are the main aquifuges in the Mahuang coalfield for mining the No. 1 coal seam. The clay layer in the Neogene system has a thickness ranging from 96.80 to 180.20 m and an average thickness of 146.91 m. It is widely distributed across the study area and substantially prevents precipitation from reaching the lower aquifer. The fine sandstone and mudstone in the Permian system gradually become thinner from east to west, which are dominated by siltstone, silty (sand) mudstone and mudstone, with much sandstone in the thin layer, and a clay rock layer and clayey mudstone occur at the bottom of the Permian Shihezi Formation. It has a thickness ranging from 7.99 to 924.95 m, which is a relatively effective aquifuge.

Specific capacity and hydraulic conductivity of the aquifer

Based on the hydrogeological conditions, the specific capacity and hydraulic conductivity of the aquifer are both cost-type factors for safe mining. Figures 10, 11 show thematic maps of the specific capacity and hydraulic conductivity, respectively, of the aquifer. Apparently, the southern part has safer mining conditions compared to the northern part. According to the ZK1102 and ZK703 boreholes in the Mahuang coalfield, the water level of the Neogene sand aquifer ranges from 13.23 to 34.20 m. When the depth is reduced from 30.35 to 37.90 m, the water inflow increases from 6.09 to 10.267 L/s, the specific capacity ranges from 0.198 to 0.271 L/(s·m), and the hydraulic conductivity varies between 0.538 and 1.612 m/d, which indicates that the aquifer has a moderate water abundance according to the “Detailed Rules for Coal Mine Water Prevention” (State Administration of Coal Mine Safety 2018), and waterproofing measures should be implemented in advance to realize safe mining.

In the vicinity of the southwestern part of the coalfield, the water-conducting fractured zone penetrates the aquifer in the lower part of the Neogene system due to the absence of or a thin overlying Permian Shihezi Formation. The aquifer in the gravel layer deposited on the coal-bearing stratum may cause the main discharge to the mining panel. Sufficient attention and effective measures should be taken in time for the prevention and control of mine disasters.

Mining depth and thickness

The mining depth of the No. 1 coal seam ranges from 168.34 to 1406.35 m. Generally, a larger mining depth may lead to a high and complex crustal stress, thus aggravating the degree of overburden failure, which seriously threatens safe mining. Therefore, the mining depth is a cost-type factor for safe mining, and the normalized data are summarized in Appendix Table 5. Figure 12 shows a thematic map of the mining depth according to the borehole data. The mining depth gradually increases from east to west, which indicates that the western part is safer than the eastern part considering only the mining depth.

The coal seam in the recoverable area has a thickness ranging from 0.66 to 2.10 m, with an average value of 1.27 m. According to mining experience and statistical analysis, a larger mining thickness may lead to a thicker water-conducting fractured zone and even induce water and sand inrush. Therefore, the mining thickness is a cost-type factor for safe mining. The normalized data based on the borehole information are listed in Appendix Table 5. Figure 13 shows a thematic map of the mining thickness in the Mahuang coalfield. The coal seam has a simple structure and is distributed relatively uniformly; the recovery coefficient is 85%, so most of the coal seam can be mined. The mining thickness in the northern part is advantageous to safe mining.

Height of overburden failure

Overburden failure is an important factor for mining conducted below water bodies and fragile ecological environments, which is a cost-type factor for safe mining. Appendix Table 5 summarizes the normalized data of the height of overburden failure. The overlying strata of the No. 1 coal seam mainly contain sandy mudstone and sandstone and exhibit a layered structure. For safety reasons, the height of overburden failure can be calculated by Eq. 6 on the basis of the moderate rock and the gentle dip angle of the strata.

Figure 14 shows a thematic map of the height of overburden failure. The overburden failure zone has significantly penetrated the Shihezi Formation in the Permian system, with a height ranging from 5.10 to 34.68 m. Within a certain distance between the threatened aquifer and the overburden failure zone, the southeast part is safer than the northern part.

Calculation of the weights by the AHP

According to the hierarchical layer, the evaluation matrix of criteria layer was firstly constructed according to the questionnaire results in Table 2 based on the expertise experience as follows.

The criteria of geological conditions contain the lithology and thickness of bedrock, and fractal dimension of faults. The evaluation matrix is shown as follows.

The thickness, specific capacity and hydraulic conductivity of aquifer, and the thickness of aquifuge are concluded in the criteria of hydrogeological conditions, and the evaluation matrix is shown as follows.

The mining effect contains mining thickness and depth, and height of overburden failure. The evaluation matrix is shown as follows.

According to the evaluation matrix, the weight of each criterion was calculated, as listed in Table 4. The hydrogeological condition has the highest weight among the three criterion factors, with a value of 0.5623, which indicates that the moderate aquifer seriously threatens safe mining. Due to the simple geological structure and the thick bedrock, the geological condition has a weight value of 0.2990, which is higher than that of the mining effect with a value of 0.1387. This indicates that the simple coal seam structure and thin mining thickness have little influence on safe mining. Moreover, the value of CR is 0.0047, which indicates that a suitable consistency occurs for verifying the results.

Specifically, the sub-criteria of the geological conditions mainly consist of the lithology and thickness of the bedrock and the fractal dimension of the faults. Among them, the thickness of the bedrock has the highest weight of 0.7217, followed by the lithology of the bedrock with a value of 0.2362 and the fractal dimension of the faults with a value of 0.0409. Among the criteria of the hydrogeological conditions, the specific capacity of the aquifer is the most important factor impacting the safety of coal mining. The hydraulic conductivity of the aquifer has the lowest influence due to the thick aquifuge. Because of the large mining depth and the simple coal seam structure, the height of overburden failure is the most serious threat to mining safety among the mining effect criteria. All of the sub-criteria have a CR value that is smaller than 0.02, which indicates that the results exhibit a good consistency relative to the application.

Evaluation of the criteria by the GIS and AHP

According to the analysis of the evaluation indices and weights, the evaluation of the sub-criteria and criteria was first carried out by the GIS. Figure 15 shows a thematic map of the criteria of the geological conditions. The maximum suitability index is 0.4061, and the relatively safe area is mainly distributed in the eastern–northern part. Most of the study area is unsuitable for coal mining considering only the geological conditions. Due to the uneven distribution of the lithology and thickness of the bedrock, the risk of water and sand inrush is intensified and seriously threatens the mining safety. Therefore, a clear understanding of the geological conditions is essential for safe mining.

Figure 16 shows a thematic map of the hydrogeological conditions. The suitability index ranges from 0.29657 to 0.8038. The western–southern part is the most suitable for coal mining considering the hydrogeological conditions. Especially in the west–north part, with the highest specific capacity, the risk of water and sand inrush is the most severe even though the aquifer is thin. This indicates that the specific capacity is the most important when coal mining is conducted below water bodies, and essential measures to reduce the specific capacity of aquifers should be taken in advance, such as drainage of the aquifer or backfill mining.

Figure 17 shows a thematic map of the mining effect. The suitability index varies between 0.3420 and 0.7572, which indicates that most of the study area is suitable to realize safe mining. The southeast part has the highest index of 0.7572. The western side has a fault with a throw of 700 m, which seriously threatens aquifer-protection mining. Moreover, the thin aquifer on the western side specifically increases the risk of water and sand inrush. Therefore, the suitability index changes less from southeast to northwest when only considering the mining effect criteria.

Final suitability map

Based on the thematic maps, the fitting process was implemented using the GIS, as shown in Fig. 18. Each criterion map was calculated using the GIS, while overlay analysis of the fitted maps was conducted according to the weights obtained with the AHP. The suitability of aquifer-protection mining was calculated by the AMSI. Then, suitability determination was achieved according to the evaluation process conducted based on the fitting results. Figure 18 also shows the zoning map of the suitability of aquifer-protection mining in the Mahuang coalfield. The AMSI ranges from 0.4555 to 1, which implies that the suitability degree changes from a low suitability to the highest suitability. Half of the research area has an AMSI higher than 0.65, which indicates a relatively suitable area to a highly suitable area for coal mining, especially the southern side, exhibiting the highest suitability degree. In the northwest part, because of the high fractal dimension of the faults, thin aquifuge and bedrock, high specific capacity of the aquifer and large mining thickness, the suitability index ranges from 0.4555 to 0.5111, which reveals a low to relatively suitable zone. According to the weights of the criteria, the hydrogeological conditions have the highest influence on safe mining, especially the specific capacity of the aquifer, which has the highest weight value of 0.3120 relative to safe mining. Therefore, the lower specific capacity in the southern part results in the highest suitability in the study area.

The suitability of aquifer-protection mining in the ecologically fragile area in western China was evaluated, and the suitability zones were determined by a new method combining the AHP and GIS to mitigate the risk of water and sand inrush threatening the water environment and human safety. A comprehensive evaluation index system was constructed, and the corresponding weight of each criterion was obtained. Yang et al. (2017) evaluated the risk of water inrush using the GIS and fuzzy set theory. The ultimate evaluation results were obtained based on the final evaluation vector (a number), which was improved in this study by the combined method, thus achieving results according to the information of the final suitability map, which were more accurate and distinct.

Conclusion

The aquifer-protection mining can preserve the water in the aquifer and control the surface subsidence before and after coal mining. A risk assessment system for aquifer-protection mining in ecologically fragile mining areas was constructed based on the AHP and GIS model. The suitability determination of aquifer-protection mining was evaluated based on a case study of the Mahuang coalfield according to the new system. The framework and evaluation method proposed in this manuscript can provide the guidance for the actual engineering, which can improve the economic benefit of the coal resources, protect the fragile ecosystem in western China and reduce the costs of environmental maintenance. The mathematical modeling is intended to supplement good structural and environmental engineering practices and provides the reference function and guidance for the actual engineering. And the results obtained from this study provided a safe zone for the aquifer-protection mining which is a helpful and significant guidance and reference for the actual mining and other similar cases in China and all over the world. The main conclusions are as follows.

The theory and method of coupling the GIS multifactor assessment model and AHP were proposed, which provided an effective method and approach for suitability analysis of aquifer-protection mining in ecologically fragile mining areas. The main control factors of aquifer-protection mining were first identified, including the lithology and thickness of the bedrock, the fractal dimension of faults, thickness of the aquifer and aquifuge, specific capacity and hydraulic conductivity of the aquifer, mining depth and thickness, and maximum height of overburden failure. Then, quantitative analysis of each factor was conducted with the AHP, and they were all standardized into dimensionless factors. Finally, GIS overlay analysis was conducted to evaluate the criteria for coal mining suitability, and a suitability map of aquifer-protection mining in the ecologically fragile mining area in western China was obtained in the GIS environment.

Nonlinear quantitative analysis was conducted to describe the structure of the fault instead of the traditional density evaluation method, which provided a more reasonable and accurate evaluation of the complexity of the mine fractures. The quantitative identification of fault structures can be realized based on the hydrogeology, engineering geology and mining technical conditions of the study area. Then, quantitative information on the various factors in the study area was obtained. An AHP model was established to quantify and analyze the relationship between all data points, and the importance degree of these various factors could be quantitatively analyzed. The results indicated that the hydrogeological conditions had the highest weight, especially the specific capacity of the aquifer, which has the greatest influence on aquifer-protection mining in the ecologically fragile mining area. Moreover, the thickness of the bedrock was also an important factor in aquifer-protection mining.

Based on the GIS, a suitability analysis system for aquifer-protection mining in ecologically fragile mining areas was constructed using the AHP. This method considered the complexity of the geological and hydrogeological conditions and mining effects in ecologically fragile mining areas and the suitability of aquifer-protection mining. The thematic map of each criterion appropriately evaluated the suitability and provided an independent AMSI for each criterion. Suitability determination of aquifer-protection mining in the Mahuang coalfield was realized using this GIS and AHP. The AMSI ranged from 0.4555 to 1 and indicated that half of the study area exhibited a relatively high to the highest suitability degree. The zone has a lower AMSI indicated a lower suitability degree. The results were successfully verified based on actual mining, which demonstrates that the method based on the GIS and AHP is rational and feasible in ecologically fragile mining areas.

References

Brown ET (2012) Risk assessment and management in underground rock engineering-an overview. J Rock Mech Geotech Eng 4(3):193–204. https://doi.org/10.3724/SP.J.1235.2012.00193

Chang NB, Parvathinathan G, Breeden JB (2008) Combining GIS with fuzzy multicriteria decision-making for landfill siting in a fast-growing urban region. J Environ Manag 87(1):139–153. https://doi.org/10.1016/j.jenvman.2007.01.011

Chuang PT (2001) Combining the analytic hierarchy process and quality function deployment for a location decision from a requirement perspective. Int J Adv Manuf Technol 18:842–849. https://doi.org/10.1007/s001700170010

Djamaluddin I, Mitani Y, Esaki T (2011) Evaluation of ground movement and damage to structures from Chinese coal mining using a new GIS coupling model. Int J Rock Mech Min Sci 48(3):380–393. https://doi.org/10.1016/j.ijrmms.2011.01.004

Fan L (2017) Scientific connotation of water-preserved mining. J China Coal Soc 42(1):27–35. https://doi.org/10.13225/j.cnki.jccs.2017.5066

Fan L, Ma X, Ji R (2015) Progress in engineering practice of water-preserved coal mining in western eco-environment frangible area. J China Coal Soc 40(8):1711–1717

Ghabraie B, Ren G, Smith JV (2017) Characterising the multi-seam subsidence due to varying mining configuration, insights from physical modelling. Int J Rock Mech Min Sci 93:269–279. https://doi.org/10.1016/j.ijrmms.2017.02.001

Ghasemi E, Ataei M, Shahriar K, Sereshki F, Jalali SE, Ramazanzadeh A (2012) Assessment of roof fall risk during retreat mining in room and pillar coal mines. Int J Rock Mech Min Sci 54(3):80–89. https://doi.org/10.1016/j.ijrmms.2012.05.025

Meng Z, Shi X, Li G (2016) Deformation, failure and permeability of coal-bearing strata during longwall mining. Eng Geol 208:69–80. https://doi.org/10.1016/j.enggeo.2016.04.029

Mishra RK, Rinne M (2014) Guidelines to design the scope of a geotechnical risk assessment for underground mines. J Min Sci 50(4):745–756. https://doi.org/10.1134/S1062739114040152

Padmanaban R, Bhowmik AK, Cabral PA (2017) Remote sensing approach to environmental monitoring in a reclaimed mine area. Int J Geo-Inform 6(12):1. https://doi.org/10.3390/ijgi6120401

Pariseau WG, Larson MK, Lawson HE et al (2017) User-friendly finite element design of main entries, barrier pillars, and bleeder entries. Int J Min Sci Technol. https://doi.org/10.1016/j.ijmst.2017.12.015

Qiao W, Howard KWF, Li W, Zhang S, Zhang X, Niu Y (2020) Coordinated exploitation of both coal and deep groundwater resources. Environ Earth Sci 79(5):120. https://doi.org/10.1007/s12665-020-8859-y

Ren W, Guo C, Peng Z, Wang Y (2010) Model experimental research on deformation and subsidence characteristics of ground and wall rock due to mining under thick overlying terrane. Int J Rock Mech Min Sci 47(4):614–624. https://doi.org/10.1016/j.ijrmms.2009.12.012

Saaty TL (1980) The analytic hierarchy process: Planning, priority setting, resource Allocation. McGraw-Hill,NY,USA[M]//The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation

Saaty RW (1987) The analytic hierarchy process—what it is and how it is used. Mathematical modelling 9(3–5):161–176

Singh RP, Yadav RN (1995) Prediction of subsidence due to coal mining in Raniganj coalfield, West Bengal, India. Eng Geol 39(1):103–111. https://doi.org/10.1016/0013-7952(94)00062-7

State Administration of Coal Mine Safety (2018) Detailed rules for coal mine water prevention. Coal industry press, Beijing (in Chinese)

Wang G, Wu M, Wang R, Xu H, Song X (2016) Height of the mining-induced fractured zone above a coal face. Eng Geol. https://doi.org/10.1016/j.enggeo.2016.11.024

Woo KS, Eberhardt E, Elmo D, Stead D (2013) Empirical investigation and characterization of surface subsidence related to block cave mining. Int J Rock Mech Min Sci 61(61):31–42. https://doi.org/10.1016/j.ijrmms.2013.01.015

Wu Q, Liu Y, Liu D, Zhou W (2011) Prediction of floor water inrush: the application of GIS-based AHP vulnerable index method to Donghuantuo Coal Mine, China. Rock Mech Rock Eng 44(5):591. https://doi.org/10.1007/s00603-011-0146-5

Wu Q, Fan S, Zhou W, Liu S (2013) Application of the analytic hierarchy process to assessment of water inrush: a case study for the NO 17 coal seam in the Sanhejian Coal Mine, China. Mine Water Environ 32(3):229–238. https://doi.org/10.1007/s10230-013-0228-6

Wu Q, Liu Y, Luo L, Liu S, Sun W, Zeng Y (2015a) Quantitative evaluation and prediction of water inrush vulnerability from aquifers overlying coal seams in Donghuantuo Coal Mine, China. Environ Earth Sci 74(2):1429–1437. https://doi.org/10.1007/s12665-015-4132-1

Wu Q, Liu Y, Zhou W, Li B, Zhao B et al (2015b) Evaluation of water inrush vulnerability from aquifers overlying coal seams in the Menkeqing Coal Mine, China. Mine Water Environ 34(3):258–269. https://doi.org/10.1007/s10230-014-0313-5

Yang W, Lin BQ, Qu YA, Li ZW, Zhai C, Jia LL et al (2011) Stress evolution with time and space during mining of a coal seam. Int J Rock Mech Min Sci 8(7):1145–1152. https://doi.org/10.1016/j.ijrmms.2011.07.006

Yang B, Sui W, Duan L (2017) Risk assessment of water inrush in an underground coal mine based on GIS and fuzzy set theory. Mine Water Environ 36:617–627. https://doi.org/10.1007/s10230-017-0457-1

Yang B, Yuan J, Duan L (2018) Development of a system to assess vulnerability of flooding from water in karst aquifers induced by mining. Environ Earth Sci 77(1):91–104. https://doi.org/10.1007/s12665-018-7275-z

Zeng Y, Wu Q, Liu S, Zhai Y, Zhang W, Liu Y (2016) Vulnerability assessment of water bursting from Ordovician limestone into coal mines of China. Environ Earth Sci 75(22):1431. https://doi.org/10.1007/s12665-016-6239-4

Zeng Y, Wu Q, Liu S, Zhai Y, Lian H et al (2018) Evaluation of a coal seam roof water inrush: case study in the Wangjialing Coal Mine, China. Mine Water Environ 37:174–184. https://doi.org/10.1007/s10230-017-0459-z

Zhang J, Shen B (2004) Coal mining under aquifers in China: a case study. Int J Rock Mech Min Sci 41(4):629–639. https://doi.org/10.1016/j.ijrmms.2003.01.005

Zhang D, Fan G, Liu Y, Ma L (2010) Field trials of aquifer protection in longwall mining of shallow coal seams in China. Int J Rock Mech Min Sci 47(6):908–914. https://doi.org/10.1016/j.ijrmms.2010.06.018

Zhang D, Fan G, Ma L, Wang X (2011) Aquifer protection during longwall mining of shallow coal seams: a case study in the shendong coalfield of China. Int J Coal Geol 86(2):190–196. https://doi.org/10.1016/j.coal.2011.01.006

Zhang J, Zhang Q, Sun Q, Gao R, Germain D, Abro S (2015) Surface subsidence control theory and application to backfill coal mining technology. Environ Earth Sci 74(2):1439–1448. https://doi.org/10.1007/s12665-015-4133-0

Zhang J, Li B, Zhou N, Zhang Q (2016) Application of solid backfilling to reduce hard-roof caving and longwall coal face burst potential.International Journal of Rock Mechanics & Mining Sciences 88: 197-205. https://doi.org/10.1016/j.ijrmms.2016.07.025

Zhang K, Yang T, Bai H et al (2018) Longwall mining–induced damage and fractures: field measurements and simulation using FDM and DEM coupled method. Int J Geomech 18(1):04017127. https://doi.org/10.1061/(ASCE)GM.1943-5622.0001040

Acknowledgements

The authors would like to acknowledge financial support from National Natural Science Foundation of China (Grant No. 41902292).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Rights and permissions

About this article

Cite this article

Liu, J., Zhang, D., Yang, B. et al. Suitability of aquifer-protection mining in ecologically fragile areas in western China. Environ Earth Sci 79, 356 (2020). https://doi.org/10.1007/s12665-020-09098-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12665-020-09098-w