Abstract

Smart manufacturing refers to integrating new generation information technologies and advanced manufacturing technologies to improve enterprise efficiency, increase customer satisfaction and enhance market competitiveness. Cloud manufacturing (CMfg) is a typical paradigm of smart manufacturing. With the rapid deployment and application of various CMfg systems, it is extremely urgent and significant to implement the standardized semantic description of manufacturing resources (MRs) characterized by geographical dispersion, high autonomy, and heterogeneity. In this paper, a metadata based manufacturing resource ontology modeling method is proposed to solve the consistency description problem of MRs in cloud. Firstly, the characteristic attributes of MRs in CMfg systems are analyzed, and a metadata-based manufacturing resource ontology-modeling framework is constructed. Then, a manufacturing resource domain ontology (MR_Onto) and a metadata model (MR_Meta) are designed, the mapping rules between them are discussed. Finally, a prototype tool describing manufacturing resources is developed, the feasibility and effectiveness of the proposed method and the developed tool are verified in an application case.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, the new generation information technologies (New-IT), such as cloud computing, big data, industrial internet of things, mobile internet, cyber physical systems, sensors and wireless technologies, are profoundly influencing the development of the manufacturing industry (Tao et al. 2018; Bordel et al. 2016; Boulekrouche et al. 2016; Sheltami et al. 2016). Through in-deep integrated application of New-IT and advanced manufacturing technologies (e.g. industrial robots), Manufacturing companies are gradually become more intelligent. Smart manufacturing (Kusiak 2017; Davani et al. 2017) has become a popular trend for manufacturing industries in the process of transformation and development. From the perspective of manufacturing strategies in various countries, based on powerful industrial cornerstone, Industrial 4.0 Strategy (Kagermann et al. 2013; Hermann et al. 2016) released by German in 2013 is designed to encourage enterprises to construct a smart manufacturing environment consisting of smart production and smart factory (Tao and Qi 2017). In such an environment, enterprises can more flexibly and reasonably configure various MRs to achieve the large-scale production of customized products, to agilely provide customers with creative manufacturing services, and eventually promote the improvement of the enterprises’ competitiveness. Industrial Internet strategy (Evans and Annunziata et al. 2012) released by U.S. aims to realize interconnection and interoperability among key business chains (e.g. design, production, management, and circulation), with the widespread application of Internet technologies. The implementation of the strategy will drive high-end manufacturing industries the return to the United States, and increase the intelligent level of manufacturing industries in U.S.. In response to the strategic challenges of developed countries, China issued Made in China 2025 in 2015 (Tang 2017). Smart manufacturing is listed as one of the five major projects in the strategy to promote manufacturing enterprises to innovate in the area of products, management, technologies, and services, and bring about the leap-forward development of traditional manufacturing enterprises in China. From the perspective of theoretical researches and industrialization applications, smart manufacturing has obtained extensive attention from academia and industry. Kusiak (2017) analyzed the five major technical bottlenecks in the implementation of smart manufacturing, and proposed three practical steps need to be taken to enable smart manufacturing, including the establishment of networks to discuss industrial issues, the development of platforms for modelling, sharing and innovation, enacting smart manufacturing policies. Tao et al. (2018) discussed the role of big data in supporting smart manufacturing, designed a conceptual framework of data-driven smart manufacturing, and outlined typical application scenarios of the proposed framework. Nilufer and Stephen (2018) discussed potential security challenges in smart manufacturing systems and proposed corresponding solutions. Stock et al. (2014) presented a three-level architecture of cloud based platform to facilitate convenient and low-cost integration and sharing of manufacturing IT. Yin et al. (2011a) presented CMfg service platform that can provide efficient, convenient, intelligent and low-cost manufacturing services for small and medium enterprises (SMEs). Chen et al. (2015) proposed a cloud based ERP platform with the service-oriented perspective to overcome low customization level and high implementation costs of traditional ERP systems. On the CloudERP platform, enterprise users can more inexpensively rent a customized ERP system to meet their specific business needs. In addition, the CloudERP providers can also simplify the installation and maintenance of released ERP systems and greatly improve their responsiveness to various personalized needs from enterprise users. Quirky is an industrial application version of smart manufacturing system, in which users can submit their product ideas online (Wu et al. 2015; Lin et al. 2011). Then Quirky will weekly select best one from all submitted creations to product and sell it over online. In the commercial mode, every user has an opportunity to become an inventor of the designed products and gain more benefits.

With the rapid deployment and application of various smart manufacturing systems, especially CMfg (Tao et al. 2011; Zhang et al. 2014), it is extremely urgent and significant to implement the standardized description of MRs, which are characterized by geographical dispersion, high autonomy, and heterogeneity. This technical bottleneck has attracted attentions from researchers. Zhang et al. (2010) analyzed attributes and features of different resource categories, and proposed an intelligent sensing and virtualization method of MRs in cloud. Ren et al. (2011) proposed a layered resource virtualization framework, then the related technologies including intelligent sensing, logical mapping and virtual accessing, were discussed. Li et al. (2012a) introduced fiber grating sensing technology for perception and access adaptation of manufacturing resrouces in the cloud environment. The proposed access technology is proved to be an effective method for real-time acquisition, processing and monitoring the running status of MRs by applying the ontology technology, Yen et al. (2011b) and Li et al. (2012b, 2014) respectively described outsourcing resources and machine tools as Web services. Goscinski and Brock (2010) proposed a framework named resources via web services (RVWS) for achieving higher abstraction of resources in cloud computing. Through the RVWS framework, all kinds of computing resources were published, discovered and selected based on the dynamic attributes of resources.

While the above researches provided some methods to solve the standardized description of MRs, they didn’t provide some metadata semantic support, making smart manufacturing systems less intelligent. To this end, this paper takes CMfg that is a typical paradigm of smart manufacturing as the application background, proposes a metadata based manufacturing resource ontology modeling method. Its main contributions are as follows:

-

1.

This paper systematically analyzed the characteristic attributes of MRs in CMfg systems.

-

2.

A metadata-based manufacturing resource ontology-modeling framework is constructed, and its key technologies are discussed, including MR_Onto, MR_Meta and metadata-ontology mapping rules.

-

3.

A prototype tool was developed, which provided a working environment for the metadata based semantic description of MRs in CMfg.

The remainder of the paper is organized as follows. In Sect. 2, we classify MRs and analyze their characteristic attributes in CMfg. On this basis, a metadata-based manufacturing resource ontology-modeling framework is constructed. Section 3 discusses key technologies of the proposed method, including MR_Onto, MR_Meta and the mapping conventions between manufacturing resource metadata and ontology. Section 4 gives a case for demonstrating the value of the proposed system. Eventually, Conclusions and future research hints are given in Sect. 5.

2 Manufacturing resource ontology-modeling framework

2.1 MRs in CMfg

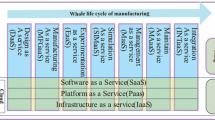

There are two types of MRs in CMfg: physical MRs and manufacturing capabilities (Zhang et al. 2010; Xu 2012). Physical MRs contains hard resources and soft resources (Fig. 1). The former refers to facilities needed for production and management, including machine tools, sensors, monitoring and control devices, network equipment and materials. The latter includes software systems and dominant or recessive manufacturing knowledge, e.g., manufacturing execution system (MES), cyber-physical system (CPS), patents and standards, process knowledge and maintenance experience, etc. Manufacturing capability refers to the dynamic virtual organization made up of human resources, hard MRs, and soft MRs, which can provide an overall solution for a specific production task, e.g., NC programming capability, networked collaborative production capability, and machine maintenance capability.

CMfg is a smart system that supports high integration and full sharing of MRs and services. Therefore, MRs published on CMfg have the characteristics of self-organization, self-evolution, interoperability, self-aggregation.

-

1.

Self-organization With the support of cloud computing, high performance computing, big data analysis, MRs in the platform can be automatically optimized and composed to construct reliable manufacturing cloud service, and meet the personalized needs from users.

-

2.

Self-evolution The more high-quality cloud services provided by MRs, the stronger their service capabilities, richer service experience and better service reputation. In other words, the MRs’ capability attributes will dynamically evolve with the operation of cloud services.

-

3.

Interoperability In CMfg, users can interact with MRs at any time during the manufacturing cloud service life cycle, this requires that MRs have good interoperability, enabling users to track the running status of MRs and service execution progress in real time.

-

4.

Self-aggregation While MRs in CMfg provide Web-based manufacturing cloud services for users, all kinds of manufacturing knowledge can be accumulated in the systems, such as numerical control programs, process parameter optimization proposals, and other experience knowledge, which will further enrich the service capabilities supported by MRs.

2.2 Metadata-based manufacturing resource ontology-modeling framework

Metadata is a kind of structured data with the advantages of consistency description, reducing redundant data, and eliminating heterogeneous information. Ontology (Orciuoli and Parente 2016) is an explicit formal specification for conceptual model, which can add semantic information to MRs so that MRs can be quickly discovered and applied in complex cloud environment. Based on the advantages of the above two aspects, we constructed a metadata-based manufacturing resource ontology-modeling framework. As shown in Fig. 2.

According to the meta object facility (MOF) defined by the object management organization, the proposed framework is composed of Meta–meta model layer (M0), Meta model layer (M1), Model layer (M2), and Instance layer (M3). M0 implements the highest abstraction of MRs and is used to define and construct MRs’ meta-model; M1 is an instance of M0, can finely describe the classes, attributes, relationships and operations related to MRs. Based on the relationship of the MRs’ attributes, M1 defines the conversion mechanism between metadata and ontology, and establish the ontology meta-model including concepts, attributes, relationships among concepts, and constraints between attributes and relationships; M2 supports to further decompose the above ontology meta-model, describes the specific manufacturing resource, through applying the conversion mechanism defined by M1. Finally, using ontology description tools, an ontology model instance of manufacturing resource is achieved.

3 MR_Onto and MR_Meta

3.1 MR-Onto

In order to semantically representing MRs in a structured form, MR-Onto is designed considering six main concepts (or thematic classes):

-

MResources represent various MRs in CMfg and their properties.

-

CServices represent cloud services supported by MRs and their properties.

-

Owners represent resource providers who add or modify information in the MR-Onto about their own resources.

-

Knowledge represents knowledge related to MRs and corresponding cloud services.

-

Transaction represents trading information of MRs.

-

Status represents operating status of MRs.

As shown in Fig. 3, these concepts are related to each other. For example, a manufacturing resource ownedby a provider can support a cloud manufacturing service. Besides, each class has its own properties. MResources has the “targeted_customer” property to be able to describe that a manufacturing resource can be used by individuals or enterprises. Transaction has a property to describe the trading way of cloud services supported by MResources, including online payment, pay-on-delivery and down payment.

Considering various kinds of MRs and various cloud services, MResources and CServices have a large number of subclasses. Some subclasses of MResources is illustrated in Fig. 4. Maintaining such a hierarchy aids not only explicit representation of cloud services supported by MRs, but also efficient reasoning about them. In addition to the these classes, Transaction is designed as a hierarchy of trading information about MRs, such as trading ways, price, evaluation, and trading records. Each transaction subclass has its own subclasses. The other classes, Owners, Knowledge and Status, don’t have hierarchy. Though, some information about them, such as the contact of owners, the version of knowledge, and the status of MRs, is maintained and updated.

3.2 MR_Meta

MR_Meta model is established in formula (1), that is:

In Eq. (1), M is the metadata model of manufacturing resource, namely MR_Meta. Mi is the i-th metadata in the MR_Meta, represents the i-th attribute of manufacturing resource, n represents the number of manufacturing resource attributes. Let A be an attribute collection of the same type of manufacturing resources in CMfg, there is:

In order to realize the transformation between MR_Onto and MR_Meta in the proposed framework, we define the metadata-ontology mapping rule, as shown in Table 1.

4 Prototype tool and application case

4.1 Prototype tool design

Based on the above theories and methods, a prototype tool describing manufacturing resources was designed, and then integrated into CMfg Service Platform that was developed by our research team. The functional architecture of the tool was shown in Fig. 5, which primarily consisted of four functional layers, including resource acquisition layer, meta modeling layer, ontology modeling layer, and application layer. In Resource acquisition layer, through the application of industrial internet of things and internet technologies, attribute information of MRs that should be released in CMfg was identified and collected, the semantic metadata of the information was stored. Meta modeling was the core function of the tool, which aimed to extract MRs’ characteristic attributes according to the collected information, and establish the MR_Meta. Then, following the conversion rules, MR_Meta was transformed into meta-ontology model. The main function of ontology modeling layer included the construction of ontology model, formal expression of ontology model, and XMLbased description. Application layer provides users with a visual application interface.

4.2 A case study

To demonstrate the feasibility and the effectiveness of the proposed method, we integrated the developed tool into the cloud manufacturing system that was designed by our team during the implementation of national high-tech project. Taking a five-axis vertical machining center (DMU-50) as an example, we verified in detail the effectiveness of the proposed method (Fig. 6). The specific steps of the experiment are as follows:

-

1.

Resource releasing Taking into account the characteristic of cloud manufacturing mode, we systematically analyzed the attributes of DMU-50, and these attribute information was registered and published on the CMfg system (Fig. 6a).

-

2.

Metadata extraction According to the resource classification rules mentioned above, DMU-50 is a hard manufacturing resource. Therefore, we first configured the computing parameters of the metadata extracting algorithm (Fig. 6b), and used the configured algorithm to refine the metadata information of DMU-50.

-

3.

Metadata-Ontology mapping The ontology model of DMU-50 was constructed by using the designed MR_Onto. According to the characteristics of cloud services supported by DMU-50, mapping rules between the DMU-50 meta-model and the DMU-50 ontology were configured, and Metadata-Ontology mapping of DMU-50 was implemented by using the mapping tool in CMfg (Fig. 6c).

-

4.

XML-based description Utilizing extensible markup language (XML) that was supported in CMfg, the standardized semantic description file of DMU-50 (Fig. 6d) was built, which was stored in the cloud database of CMfg system.

-

5.

Visual display With the support of industrial Internet of Things, CPS, manufacturing execution system (MES), The virtual model of DMU-50 in CMfg was connected with physical entity, and displayed and analyzed the production schedule, operation status, and processing quality of DMU-50 in real time, which improved the interaction experience between CMfg system and the users.

We analyzed the complexity trend of manufacturing resource models constructed by using metadata, ontology, and metadata-ontology respectively, as shown in Fig. 7. In CMfg environment, as the number of attributes of manufacturing resources increased, so did the complexity of manufacturing resource models which were constructed by the above three methods. From the overall trend, the metadata-ontology method is less affected by the change in the number of resource attributes, and the model constructed by it has the lowest model complexity, which proved the effectiveness of the proposed method.

5 Conclusion

Aiming at the description difficulty of various manufacturing resources in smart manufacturing systems, this paper proposed a metadata based manufacturing resource ontology modeling method. Based on metadata modeling theory, we established MR_Meta to achieve the standardized description of MRs. Defining the metadata-ontology mapping rule, we discussed MR_Onto that can mark the semantics for MRs in CMfg. At last, the application case proved the feasibility and effectiveness of the proposed method.

In the future, our research team will continue to conduct research around the key technologies involved in smart manufacturing, such as optimized deployment of wireless sensor networks, RFID-based logistics scheduling in the intelligent shop, and networked integration of heterogeneous machine tools.

References

Bordel B, Alcarria R, Martín D, Robles T, Rivera DSD (2016) Self-configuration in humanized cyber-physical systems. J Ambient Intell Humaniz Comput 8(4):1–12

Boulekrouche B, Jabeur N, Alimazighi Z (2016) Toward integrating grid and cloud-based concepts for an enhanced deployment of spatial data warehouses in cyber-physical system applications. J Ambient Intell Humaniz Comput 7(4):475–487

Chen CS, Liang WY, Hsu HY (2015) A cloud computing platform for erp applications. Appl Soft Comput J 27(C):127–136

Davani AM, Shirehjini AAN, Daraei S (2017) Towards interacting with smarter systems. J Ambient Intell Humaniz Comput 9(1):1–23

Evans PC, Annunziata M (2012) Industrial internet: pushing the boundaries of minds and machines. General Electric Company, Boston

Goscinski A, Brock M (2010) Toward dynamic and attribute based publication, discovery and selection for cloud computing. Future Gener Comput Syst 26(7):947–970

Hermann M, Pentek T, Otto B (2016) Design principles for Industrie 4.0 scenarios. In: Proceedings of 49th IEEE international conference on system science (HICSS), Koloa, HI, USA, 2016, pp 3928–3937

Kagermann H, Wahlster W, Helbig J (2013) Securing the future of German manufacturing industry recommendations for implementing the strategic initiative INDUSTRIE 4.0 final report of the industrial 4.0 working group. Federal Ministry Educ. Res., Bonn, Germany, Tech. Rep. http://www.acatech.de/fileadmin/user_upload/Baumstruktur_nach_Website/Acatech/root/de/Material_fuer_Sonderseiten/Industrie_4.0/Final_report__Industrie_4.0_accessible.pdf. Accessed 15 June 2018

Kusiak A (2017) Smart manufacturing must embrace big data. Nature 544(7648):23–25

Li RF, Liu Q, Xu WJ (2012a) Perception and access adaptation of equipment resources in cloud manufacturing. Comput Integr Manuf Syst 18(7):1547–1553

Li XB, Yin C, Gong XR, Yin S (2012b) Cloud manufacturing service platform for machine tool and processing operation. Comput Integr Manuf Syst 18(7):1604–1612

Li XB, Yin C, Yin S (2014) Semantic description and characteristics of machine tool resources in cloud manufacturing environment. Comput Integr Manuf Syst 20(09):2164–2171

Lin Z, Luo YL, Fan WH, Fei T, Lei R (2011) Analyses of cloud manufacturing and related advanced manufacturing models. Comput Integr Manuf Syst 17(3):458–468

Nilufer T, Stephen H (2018) Security of smart manufacturing systems. J Manuf Syst 47:93–106

Orciuoli F, Parente M (2016) An ontology-driven context-aware recommender system for indoor shopping based on cellular automata. J Ambient Intell Humaniz Comput 8(6):1–19

Ren L, Lin Z, Zhang YB, Fei T, Luo YL (2011) Resource virtualization in cloud manufacturing. Comput Integr Manuf Syst 17(3):511–518

Sheltami TR, Khan S, Shakshuki EM, Menshawi MK (2016) Continuous objects detection and tracking in wireless sensor networks. J Ambient Intell Humaniz Comput 7(4):489–508

Stock D, Stöhr M, Rauschecker U, Bauernhansl T (2014) Cloud-based platform to facilitate access to manufacturing it ☆. Proc CIRP 25:320–328

Tang J (2017) Made in China 2025. Integr Comer 3(1):204–215

Tao F, Qi Q (2017) New it driven service-oriented smart manufacturing: framework and characteristics. IEEE Trans Syst Man Cybern Syst 99:1–11

Tao F, Zhang L, Venkatesh VC, Luo Y, Cheng Y (2011) Cloud manufacturing: a computing and service- oriented manufacturing model. Proc Inst Mech Eng Part B J Eng Manuf 225(225):1969–1976

Tao F, Qi Q, Ang L, Kusiak A (2018) Data-driven smart manufacturing. J Manuf Syst. https://doi.org/10.1016/j.jmsy.2018.01.006

Wu D, Rosen DW, Wang L, Schaefer D (2015) Cloud-based design and manufacturing: a new paradigm in digital manufacturing and design innovation. Comput Aided Des 59(C):1–14

Xu X (2012) From cloud computing to cloud manufacturing. Robot Comput Integr Manuf 28(1):75–86

Yin C, Huang BQ, Liu F, Wen LJ, Wang ZK, Li XD et al (2011a) Common key technology system of cloud manufacturing service platform for small and medium enterprises. Comput Integr Manuf Syst 17(3):495–503

Yin S, Yin C, Liu F, Li XB (2011b) Outsourcing resources integration service mode and semantic description in cloud manufacturing environment. Comput Integr Manuf Syst 17(3):525–532

Zhang L, Luo YL, Tao F, Ren L, Guo H (2010) Key technologies for the construction of manufacturing cloud. Comput Integr Manuf Syst 16(11):2510–2520

Zhang L, Luo Y, Li BH, Li BH, Ren L, Zhang X et al (2014) Cloud manufacturing: a new manufacturing paradigm. Enterp Inf Syst 8(2):167–187

Acknowledgements

This work is supported in part by National Natural Science Foundation of China (Grant No. 51705049), in part by China Postdoctoral Science Foundation under Grant 2017M622975 and 2018T110947.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, X., Zhuang, P. & Yin, C. A metadata based manufacturing resource ontology modeling in cloud manufacturing systems. J Ambient Intell Human Comput 10, 1039–1047 (2019). https://doi.org/10.1007/s12652-018-0964-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12652-018-0964-3