Abstract

The co-culture approach has been discovered to be more efficient over isolated in carbon uptake, growth of bacteria and Poly(3-hydroxybutyrete) (P(3HB)) productivity. The current study focused on synthesis of P(3HB) from a co-culture of Alcaligenes sp. NCIM 5085 and Bacillus subtilis sand characterizing the recovered P(3HB) for better packaging applications. The enzymatic reactions mechanism possible was identified. The obtained P(3HB) was structurally analyzed using GCMS, FTIR, 1HNMR and 13CNMR. The peak observed at 1720.06 cm−1 on FTIR spectra indicates the existence of the C=O group, that is a defined marker of P(3HB). Subsequent NMR and GCMS investigation verified that the obtained polymer is P(3HB). The DSC analysis revealed the melting point (Tmelt), crystallization temperature (Tc) and glass transient temperature (Tg) of polymer 172.5 °C, 100 °C and − 6.8 °C, respectively, which are within the normal P(3HB) range. The TGA- DTG indicated the thermal degradation temperature (Tdegr) of synthesized P(3HB) was 254.5 °C and major weight loss was observed between 180 and 300 °C. As a result, it can be established that the synthesized P(3HB) seems to be more resistant to thermal degradation than the conventional P(3HB). The investigation imply that developing a bacteria co-culture technique seems to be a potential approach for such effective synthesis of valuable biopolymers from agricultural waste.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

The Co-culture of Alcaligenes sp. NCIM 5085 and Bacillus subtilis was implemented first time to synthesisze PHAs using molasses as substrate in the present work.

Introduction

India is one of the largest sugar producer and consumer as well as the second largest exporter according to the Press Information Bureau's Delhi 2022 study. During the sugar season 2021–22, India produced a milestone of over 5000 LMT sugarcane, of which around 3574 LMT has been pulverized by sugar factories to generate approximately 394 LMT of sugar. Each tonne of sugarcane yields 38 kg of cane molasses [1]. In light of the large amount of cane molasses produced each year, it is vital to use these low-cost byproducts to create value-added products. It can be used as a feedstock for producing Polyhydroxyalkanoates (PHAs), a biodegradable polymer [2].

PHAs are eco-friendly linear polyester and can be a substitute for the traditional plastic. PHAs are produced through microbial fermentation of sugar-rich substrate under nutrition-restricted circumstances [2,3,4]. Traditional plastics have been extremely helpful during last decades for a range of technologies and applications that have served humanity because of their durability, light weight, adaptability to geometry, dimension preferences, chemical inertness and relatively inexpensive. The widespread use of non-biodegradable plastic derived from non-renewable source imposes obstruction; retains in environment for a prolonged period of time and poses a hazard to living beings by disturbing the ecosystem. Furthermore, the production and combustion of petroleum-based polymers pollute the land, air, and water significantly. These concerns have encouraged researchers to do additional study into creative ways for the production and use of environment benign biodegradable biopolymers such as PHAs as alternative materials for traditional plastic. PHAs are biodegradable because the producing bacteria's genomic DNA contains an inbuilt depolymerase gene, phaZ. PHA has the same physical properties as polypropylene (PP) and can breakdown in composite soil mixtures under aerobic and anaerobic conditions in 45–60 days, eliminating the requirement for a treatment and disposal and preventing atmospheric pollution [5]. PHAs are an intriguing answer to the problems posed by petroleum plastic. Bacteria such as Pseudomonas sp., Bacillus sp., Cupriavidus necator, Rhodococcus sp., halotolerant can polymerize PHAs. There are around 150 different forms of PHA documented in the literature [6,7,8,9,10].

Poly(3-hydroxybutyretes) (P(3HB)s) are among the most basic types of short carbon length homopolymer of PHA and have gained a lot of attention due to their physical qualities that are similar to traditional plastics. P(3HB) owing biocompatible properties deteriorates slowly throughout the body and find an application in tissue engineering and drug carrier. P(3HB) which has superior gas barrier characteristics, water vapour permeability, melting temperature (Tmelt) and tensile strength than traditional plastics, is employed in food packaging. Since P(3HB)s have thermal and physicochemical properties similar to traditional plastics, they are employed in a range of other cutting-edge industries such as medical, nanotechnology and agriculture sector [11, 12].

P(3HB) is produced by fermentation of sugar by halophilic and a halotolerant bacterium, the former one does not require high osmotic pressure and salt concentration than other for P(3HB) synthesis [13]. Despite being biocompatible, biodegradable in nature and derived from renewable sources, P(3HB)'s commercialization is constrained due to its high manufacturing cost. The petroleum plastic cost is ten times cheaper than P(3HB) which is the biggest threat to replace traditional polymer. One of the most pressing concerns affecting PHA synthesis on a large scale is carbon source which has a direct impact on cell proliferation, productivity improvement, molecular weights, superiority and design [11]. The P(3HB) production cost involves 40%of feedstock and remaining in extraction and purification process. The commercially large scale P(3HB) production is done from expensive carbon sources like glucose, fructose and sucrose fermentation by pure culture. It is critical to find low-cost feedstock and nutrient sources for exploiting P(3HB) production. The cane molasses is an inexpensive by product of sugar factories and it contains nutrients that are required for P(3HB) production as well as it has potential to reduce production cost. Furthermore, several tactics for increasing P(3HB) accumulation have been widely investigated, such as the identification of novel adaptive and productive microbes, strain enhancement through genetically modified, feedstock optimization, fermentation methodology and bioreactor engineering. In literature a few pure culture microorganisms were reported for P(3HB) production. However, pure culture does not utilize all sugars (glucose, fructose and sucrose) present in cane molasses. In place of that employing co-culture or mixed culture strategy trigger to solve this problem. Co-culture system can enhance substrate consumption and PHA synthesis by synergistic metabolic activities that counterbalance internal and external stressors in co-culture. Additionally, one of the bacteria improves fermentation productivity and substrate assimilations while providing crucial monomeric subunits which is utilized by other bacteria for consumption and increased production can be achieved [3, 14].

The current study concentrates on using cane molasses from agricultural waste to produce P(3HB) by co-culture of Alcaligenes sp. NCIM 5085 and Bacillus subtilis with molasses as feedstock which is first of its kind. However, if sugars are not in monosaccharides, microorganism may not utilize or consume it efficiently, therefore an acid pretreatment was required to convert sucrose to monosaccharides. For effective assimilation of cane molasses a co-culture of Alcaligenes sp. NCIM 5085 and Bacillus subtilis for P(3HB) production was used which is reported first time here. The current investigation focused on optimization of P(3HB) production condition including the effect of initial cane molasses concentration, ammonium sulphate as nitrogen source, C/N ratio, disodium phosphate, monopotassium phosphate concentration and effect of physical parameters such as incubation time, inoculum volume and pH by developed co-culture. Possible mechanisms of enzymatic reactions are also proposed. Further, obtained P(3HB) was characterized by FTIR, NMR and GC–MS to understand the structure, bonds and compounds present in the P(3HB). The DSC analysis was employed to identify melting point (Tmelt), glass transition temperature (Tg) and crystallinity of P(3HB).TGA and DTG studies were employed to determine the degradation temperature (Tdegr) and rate of mass loss of P(3HB) with temperature. The properties of recovered P(3HB) were compared to those of conventional P(3HB).

Materials and methods

Development of Microbial Co-culture of Alcaligenes sp. NCIM 5085 and Bacillus subtilis and Cane Molasses Acid Pretreatment

The strain Alcaligenes sp. NCIM 5085was purchased from the National Chemical Laboratory Pune, India where as Bacillus subtilis was obtained from Enviro Tech limited, Ankleshwar, India. The microorganisms were kept alive on nutrient agar media at 4 °C which contained 20 g agar, 10 g peptone, 5 g NaCl, and 10 g beef extract per liter (Himedia, Mumbai, India). Later, 100 ml nutrient broth was added to a 250 ml Erlenmeyer flask to cultivate Alcaligenes sp. and B. subtilis, respectively. Both cultures were grown for 24 h at 35 °C in shaking conditions (180 rpm). Thereafter, 5 ml suspension of each pre-culture was aseptically transferred to the P(3HB) media and incubated for 24 h, where microbial co-culture of Alcaligenes sp. and B. subtilis was developed. This developed co-culture inoculum was transferred in P(3HB) production media in 10% (v/v). The cleared cane molasses was exposed to 33%, 1.5 N H2SO4 for acid pretreatment, and incubated at 90 °C for an hour on a water bath. The solution was centrifuged at 3000 rpm for 10 min; supernatant was neutralized with 2 M NaOH solution and used for P(3HB) synthesis. HPLC analysis was done to determine the chemical composition of the acid-pretreated cane molasses. HPLC analysis of acid-pretreated cane molasses revealed 17.59% of glucose, 16.67% of fructose and 0.197% of sucrose present in cane molasses.

P(3HB) Extraction and Quantification

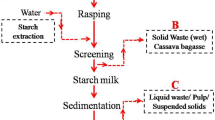

The co-culture was transferred in P(3HB) production media, incubated on a rotary shaker for 3 days at 35 °C. The biomass obtained in each run was centrifuged at 3000 rpm, 4 °C and dried for 24 h at 60 °C where cell dry weight (CDW) of biomass was obtained. P(3HB) was extracted using dispersion method, in which the cell pellet was treated with 50 ml 4–6% sodium hypochlorite for 15 min for cell lyses where 60 ml chloroform was added as solvent to dissolve P(3HB) and allowed to stir for 2.5 h at 30 °C. The mixture was then phase separated, where top layer contained: sodium hypochlorite, the middle layer: cell debris and bottom layer: P(3HB) dissolved in chloroform. Methanol at 2 °C was added as anti-solvent in the collected bottom layer and allowed to precipitate P(3HB) for 3 to 4 h. The solution was filtered through Whatman filter paper 41 and the P(3HB) retained on filter paper was allowed to air dry. To evaluate the concentration of P(3HB) in the precipitate, P(3HB) granules were treated with 10 ml concentrated H2SO4 on a water bath for 10 min at 100 °C; it was converted to P(3HB) granules to crotonic acid (CA) by dehydration process which shown in the reaction (1). The 3-Hydroxy butyrate(C4H8O3) which is a monomer of P(3HB) polymer released water molecules in the presence of concentrated H2SO4 and form crotonic acid (C4H6O2) (CA). The sample was analysed in UV spectrophotometer at 235 nm for crotonic acid. CA standard graph was prepared using H2SO4 as a blank. Figure 1 demonstrates the step by step process of P(3HB) extraction and determination.

P(3HB) content accounted by crotonic acid was evaluated as per following equations:

The supernatant was used to evaluate for total residual sugar of processed molasses. Sample was filtered prior to analysis using Sep-Pak classic alumina cartridges and Bioflow 0.22 m PES membrane cartridges. A HPLC of an Agilent model with a refractive index (Shodex) detector, both of which were set at 35 °C was used. A 5 ml sample was put into an amino column (250 mm × 4.6 mm, 5 m). Sucrose, fructose, and glucose standard solutions with concentrations of 5 mg/ml were used. A solution of acetonitrile and water (80:20) flowed at a rate of 1 ml min−1 as the mobile phase. Prior to analysis, mobile phase was also filtered for 15 min with a 0.22 m nylon filter.

Structural Analysis of P(3HB) Recovered

FT-IR analysis was carried out using BRUKER RFS 27 Multi RAM for extracted P(3HB) sample. A 5 mg sample was dissolved in 1 ml chloroform and collected on KBr plate and spectra were recorded at 4000–500 cm−1 range to identify probable functional group of the polymer. Furthermore, NMR analysis was used to identify the presence of proton and carbon atom of the polymer. Samples for13CNMR and 1H NMR were analyzed using AVANCE III 500 NMR with phase resolution > 0.1 degree frequency resolution > 0.1 Hz and spectrometer Windows XP based TOPSPIN 2.1 software. The spectra were recorded in CDCl3.

The Gas chromatography–mass spectrometry (GC–MS) analysis of recovered P(3HB) was carried out by Agilent Model 8890 GC System with Single Quadrupole MS (5977B MSD) equipped with Polar Columns (DB-WAX) & HP-5 MS UI. The mass spectra scan range was 1.6 − 1,050 amu where1 µl sample was injected for the analysis. The obtained mass spectra were compared with NIST library. The 4 mg of recovered P(3HB) treated with 1 ml of chloroform and 1 ml of acidified methanol (15% H2SO4) was kept for 140 min at 100 °C in a sealed tube, during the reactions the different methyl esters were formed; 0.5 ml distilled water was added as aqueous phase and organic layer of sample was extracted with 2 ml hexane for GC–MS analysis. Partial methanolysis of polymer sample was led to form different oligomers compounds. The method was followed as per Brandl et al. [15].

Thermal Properties of P(3HB) Recovered

TG-DSC and DTG were investigated utilizing NETZSCH STA 449 F3 Jupiter.TGA and DTG analyses were performed on7.2 mg of PHA sample in an alumina crucible and heated from ambient temperature to 500 °C at a heating rate of 10 K/min under a nitrogen gas flow rate of 20 ml/min. The extracted polymer was characterized using a NETZSCH DSC 204F1 Phoenix instrument in a N2 gas flow rate environment with a heating and cooling rate of 10 K/min with heating range of − 30 to 200 °C.

Molecular Weight Determination

Gel permeation chromatography (GPC) was used to determine the average molecular weight using a pump (Wayers 715), a differential refractometer detector at 30 °C and a styragel column with a linear range of molecular weight of 200–2,000,000 mol/g. Polymer was dissolved in chloroform and filtered through a 0.45 m PTFE membrane. At a flow rate of 1.0 ml/min, chloroform was utilized as a mobile phase.

Results and Discussion

Optimization of P(3HB) Synthesis

PHA Biosynthetic Genes

PHA synthesis is the enzyme that catalyses the ultimate polymerization of (R)-3-hydroxyacyl CoA into poly-(R)-3-hydroxyacyl CoA. The PHA production enzyme can be divided into four types depending on their subunit composition and substrate selectivity. The Class I and II PHA biosynthesis enzymes (C. necator and P. aeruginosa) PhaC have only single component with molecular weights ranging from 60 to 73 kDa. PhaC and PhaE subunits make up the Class III PHA biosynthesis enzymes (Allochromatium vinosum). PhaC possesses a molecular weight of 40 kDa and contains 21–28% amino acid sequence parallels with Class I and II PhaC, whereas PhaE has a comparable molecular weight and contains no amino acid sequences with PhaC. Class IV PHA synthesis (B.megaterium) contains PhaC and PhaR subunits where PhaR possesses a molecular weight of 22 kDa. Figure 2 depicts the P(3HB) production route of Alcaligenes sp. and Bacillus sp. [16, 17].

Effect of Carbon Sources Concentration

The concentration of the carbon source is a significant factor since it has a direct impact on metabolic process in which bacteria is engaged. To achieve optimum growth of cells and PHA production, carbon source optimization is therefore crucial. In light of this, the effects of varying cane molasses concentration with co-culture fermentation and P(3HB) formation were thoroughly studied. Figure 3a depicts when initial cane molasses concentration was increased; total sugar consumption was also increased and ranged 7.82 ± 0.08 to 9.74 ± 0.14 g/l. It may happen due to availability of more reducing sugar present in the medium. It can also be deduced from Fig. 3a that maximum growth was achieved at 30 g/l after 48 h of incubation at 35 °C. The findings suggest that co-culture may effectively assimilate sugars with increased biomass growth and PHA formation up to 30 g/l of cane molasses concentration and no significant biomass growth and PHA formation were seen beyond that. The higher content of sugar may inhibit further growth through increased osmotic pressure. The similar results were also observed by Saratale et al. [3], where maximum PHA (72.1 ± 2.15%)was obtained with 30 g/l sugarcane bagasse (SCB) hydrolysates which were evaluated for the impact of SCB concentration on PHA production by co-culture of Lysinibacillus sp. RGS and C. necator ATCC 17699. In another study, 69.90% P(3HB)V production was obtained with 3% (v/v) sucrose concentration in a batch fermentation of co-culture B. subtilis: C. necator by [18,19,20].

Optimized synthesis of P(3HB) from co-culture at different parameters a cane molasses concentration (20, 30, 40 g/l) and incubation time (24, 48, 72, 96 h). b C/N ratio (19, 29, 57, 114), c Na2HPO4 concentration (0.5, 1, 2, 3 g/l), d KH2PO4 concentration (0.5, 1, 2, 3 g/l), e Inoculum concentration (2, 5, 10%) and f pH (6, 7, 8)

Effect of C/N Ratio

Ano3her significant parameter that affects metabolism, cell biomass expansion and PHA buildup is the C/N ratio. C/N ratio was varied from 19 to 114 with varying ammonium sulphate and evaluated for the best growth condition of co-culture. Since elevated P(3HB) production was ordinarily retrieved under nitrogen starvation as reversed to cell growth. We can deduce that adequate nitrogen promotes cell growth and inhibits P(3HB) accumulation. This outcome is compatible with recent investigation, which found that too much nitrogen source concentration inhibits the formation of P(3HB), whereas limited nitrogen benefited P(3HB) biosynthesis, furthermore P(3HB) buildup would also be negatively impacted by excessive nitrogen limitations. Among all C/N ratios, 57 C/N ratio was found to indicate a maximum cell growth and P(3HB) production as shown in Fig. 3b. Zhou et al.[21] reported a maximum 35% PHA was accumulated at 10 C/N ratio which was varied between 1 to 100, this supports recent findings. Additionally, similar outcomes have been reported by other researchers [4, 22].

Effect of Phosphorus Nutrient

P(3HB) synthesis of crucial enzymes for microbial anabolism and catabolism is greatly influenced by the stress caused by ions Na+ and K+.Fig. 3c depicts that as the Na2HPO4concentration was increased from 0.5 to 1 g/l, maximum cell dry weight (CDW) was increased from 3.47 ± 0.01 to 5.48 ± 0.02 g/l; P(3HB) content 1.34 ± 0.00 to 2.88 ± 0.02 g/l and consumed total reducing sugar (TRS) 13.74 ± 0.16 to 21.75 ± 0.09 g/l. Beyond this concentration CDW was decreased to 1.20 ± 0.01 g/l; PHA content 0.3 ± 0.01 g/l and consumed TRS 11.66 ± 0.24 g/l for 48 h of incubation. The higher concentration of Na2HPO4 created an excessive stress in media which led to reduced biomass growth, P(3HB) production and TRS consumption.

The effect of increasing KH2PO4concentration from Fig. 3d reveals that KH2PO4concentration from 0.5 to 1 g/l increased the CDW from1.78 ± 0.04 to 5.48 ± 0.02 g/l; P(3HB) content 0.76 ± 0.01 to 2.88 ± 0.02 g/l and consumed TRS 10.51 ± 0.24 to 21.75 ± 0.0 g/l for 48 h of incubation. The increased stress in the media was caused by higher KH2PO4 concentration similar to Na2HPO4which resulted in decreased biomass growth and consumed TRS concentration for P(3HB) synthesis.

The cytoplasmic signaling and transport systems of bacteria were stimulated by the optimum concentration of Na+ in Na2HPO4 and K+ in KH2PO4, which raised P(3HB) biomass and improved P(3HB) synthesis. Higher concentration of both nutrients led to adverse effect on P(3HB) synthesis by co-culture in batch cultivation. Geethu et al. [23] reported the effect of KH2PO4 and Na2HPO4 on P(3HB) production when B. Endophyticus was grown on sucrose under batch fermentation and 46.57% P(3HB) production was obtained. Mohanrasu et al. [24] highlighted the significance of nitrogen, sodium and potassium content with in basal medium for cell proliferation for the PHA synthesis that limits the nutrients and enhances the synthesis. In another study where B. megaterium strain was used for glucose as a carbon source resulted in 2.74 g/l of PHA [25,26,27].

Effect of Incubation Time

Determining the harvesting time is crucial to achieve optimal PHA production since large amount of biomass is directly linked to P(3HB) yield [28]. As the incubation time was increased, a gradual increase in biomass, consumed TRS and P(3HB) production from co-culture was observed. During first 48 h of culture, P(3HB) production was attained a maximum value (0.48 ± 0.02 g/l) and started to decline with increasing time as shown in Fig. 2a. There may be several causes for reduction of P(3HB) with increasing time such as reduction in resources (carbon source), reduced enzyme affordability and energy of microbes. According to several researchers Saeed et al. [29], Zhu et al. [14], Narayan et al. [30], Dubey et al. [31], Javaid et al. [32] and Mohanrasu et al. [24]maximum biomass of P(3HB) batch fermentation was attained after 72, 56, 48, 48, 72 and 64 h, respectively.

Effect of Inoculum Concentration

The inoculum amount contributes to a shorter fermentation period with optimal productivity and a shorter lag time. For higher P(3HB) production, a lower inoculum concentration was insufficient, Fig. 2e. This observation suggests that a minimum certain numbers of bacteria are required to generate a particular volume of biomass in a specific time.

Effect of Initial pH

In addition to the nutritional characteristics, pH is a critical factor in determining P(3HB) yield. It was found that bacteria are extremely sensitive to the pH media; when it deviates from neutral pH, it affects both cell proliferation and P(3HB) production. Acidic and basic environment inhibit bacterial development. The effect of altering the initial pH on cell growth can be seen in Fig. 2e. It was also established from the results that bacteria's biosynthetic activities were at their peak at neutral pH, which facilitates P(3HB) production and similar results was obtained by Aslam et al. [33]. Maximum CDW 5.48 ± 0.02 g/l; P(3HB) content 2.88 ± 0.02 g/l; residual biomass content 2.6 ± 0.02 g/l, consumed TRS 21.75 ± 0.09 g/l, 53% P(3HB) accumulation, 0.048 g/l h P(3HB) productivity (qp), 0.53 Y(p/x) and 0.11 Y(p/s) were observed in the experiments. A 10% inoculum volume with neutral pH after 48 h of incubation was found optimum.

Structural Characterization of Recovered P(3HB)

FTIR

FTIR was used to examine the chemical structure of the extracted P(3HB). The FTIR spectra of P(3HB) recovered by co-culture are illustrated in Fig. 4. The occurrence of the C=O (carbonyl) group designated in literature for P(3HB) can be seen by a piercing peaks at 1720.06 cm−1.Similarly, Khan et al. [13]; Etxabide et al. [34]; Sirohi et al. [35] and Trakunjae al [36]. noted that peaks assigned at 1732, 1722, 1700 and 1721 cm−1are comparable to P(3HB) retrieved from co-culture of B. halotolerans 14SM & B. aryabhattai WK31,Cupriavidusnecator, Bacillus sp. NII2 and actinomycetes Rhodococcus sp. strain BSRT1,respectively.The distinctive peak at 1274.60, 3434.63, 2932.29 and 2975.58 cm−1are relevant to CH, terminal OH group, CH3(symmetric) and CH2 (asymmetric) groups, respectively. Stretching of the C–CH3, C–CH2 molecules, C–C bonds as well as the ester group's C–O link can also be seen in the series of bands between 500 and 1450 cm−1 which confirms the presence of butyrate polymer.

1HNMR and 13CNMR

In order to determine proton constituent present in recovered P(3HB), 1H NMR analysis was done, as depicted in the Fig. 5a.The doublet peak at δ = 1.26–1.28 ppm was assigned to proton of terminal CH3 (methyl) group; the doublet of quadruplet peak at δ = 2.45–2.63 ppm relevant to the CH2 (methylene) in the vicinity of an asymmetric carbon constitute and triplet peak at δ = 5.22–5.29 ppm reveals the CH (methyne) group of the P(3HB). The peak shown at δ = 7.27 ppm is of CDCl3 solvent. Present findings NMR is similar to those obtained by Sirohi [20, 35] and Munir & Jamil, [26] where P(3HB) was produced by Bacillus sp NII2 and co-culture of Pseudomonas sp. and Bacillus sp, respectively. The spectra obtained for 13C NMR analysis is demonstrated in Fig. 5b which disclose existence of four peaks. The peaks at δ = 19.77 ppm corresponds to CH3; δ = 40.78 ppm corresponds to CH2; δ = 67.62 ppm corresponds to CH and δ = 169.18 ppm corresponds to C = O group and the peak in between δ = 76.79–77.30 ppm is for CDCl3 solvent. The results appeared to be consistent with Sirohi et al. [20], Etxabide et al.[34] and Pradhan et al. [7], where P(3HB) production was carried out by Bacillus sp. NII2, C. necator, and B. megaterium & C. necator in a batch fermentation, respectively.The1HNMR and 13CNMR findings demonstrate that the polymers formed are linear homopolymer of P(3HB).

3GC-MS

Through GC–MS analysis, the moiety of any molecule can be identified and understood. The gas chromatogram is depicted in Fig. 6 where five major peaks at retention time 4.225 min, 9.114 min, 5.593 min, 7.332 min and 11.515 min were identified as octamethyl cyclotetrasiloxane. These oligomers compounds were formed due to partial methanolysis of polymer sample. The structure of P(3HB) formed from co-culture may be identified to fragmentation signals in the methyl esters which were created during methanolysis as shown in mechanism in Fig. 7.The following were the primary molecular fragmentations discovered: m/z 45 (C2H5O), m/z 55 (C3H5O+), m/z 59 (C2H3O2) (C3H7O+), m/z 61 (C2H3O2+), m/z 73 (C3H5O2+), m/z 87 (C4H7O2+), m/z 103 (C4H5O3+) and m/z 117 (C5H9O3+), Fig. 7.

A bench mark and distinctive fragment at m/z 103 (α-cleavage to the hydroxylated carbon) revealed the existence of a 3-hydroxy functional group. These findings were consistent with the P(3HB) isolated from P. plecoglossicida's, which showed the primary peak resembled for methyl 3-hydroxybutyrate and confirming the P(3HB) structure [37,38,39,40].The acylium ion molecules fragmented at 45, 73, and 85 m/z as a result of the ester's alkoxy group being removed by the α- cleavage reaction as shown in mechanism in Fig. 7. The removal of the alkyl group from the acyl part of the ester molecule resulted in the additional signals which were recorded at 59, 87, and 117 m/z. m/z 73 (M-1) and m/z 45 were another fragmentation ion observed in the Mc Lafferty rearrangement of the β-cleavage process to methyl esters.

The distinctive mass spectra peaks were allowed for the identification of the carbonyl and hydroxyl terminals of the associated hydroxyalkanoates. The study was supported by other studies as well [41, 42].

Thermal Properties of Recovered P(3HB)

DSC

The thermal transition of a recovered P(3HB) was studied using differential scanning colorimetry spectroscopy. Melting point, crystallization temperature and glass transition temperature are characteristics of a thermal transition. The DSC curve revealed a double melting point endothermic peak at 137 °C and 172.5 °C. However, because of the distinct crystalline structures in P(3HB), numerous melting patterns of P(3HB) during the DSC melting scan were recorded where double melting point is frequently reported in literature. During solvent evaporation a small crystallites was formed caused by a small endothermic peak. The observed result is consistent with Sivakumar et al. [43] who determined the double peak melting point of P(3HB) at 155 and 168 °C. In other study by Mourao et al.[44] the melting point at 164 °C was reported for P(3HB). A glass transition temperature (Tg) from the DSC thermogram was observed − 6.3 °C, (Fig. 8a) where as − 8 to + 15 °C range of Tg value is reported in literature, Etxabide et al. [32] and Mohanrasu et al. [24]. The glass transition temperatures indicate how the polymer chains are arranged within the polymer structure, whether crystalline or an amorphous P(3HB) structure owing low and high Tg value [7]. For example, Pradhan et al. [7] obtained Tg -8 °C for standard P(3HB), whereas, Chen et al. [45] observed − 7.34 °C. The 2nd cooling scan reveals the crystalline temperature (Tc) of P(3HB) is 100 °C, which is under range of 84 to 113 °C. Etxabide et al .[34] reported Tc value 97.8–102 °C for P(3HB) produced from C. necator whereas Sivakumar et al. [43] reported 105 °C.

The degree of crystallinity (XC), which is a significant feature of a polymer indicates the mechanical properties of the material, can be calculated using the melting enthalpy from the data collected in the DSC tests, which was obtained from the ratio between the melting enthalpy of the material (ΔHm) and the melting enthalpy of 100% crystalline P(3HB) (ΔH0m = 146 J/s) (Hosokawa et al. [46]; Oliveira, et al.[47]).

The data of enthalpy of fusion ΔH0m = 158.8 J/s, which was calculated by area under melting curve from DSC curve. % of crystallinity (% XC) of polymer was calculated and turned out to be 109% which was higher than standard P(3HB) value. However, the enthalpy of fusion for 100% crystalline P(3HB) was 146 J/s. The recovered P(3HB) was highly crystalline may be due to different P(3HB) synthesis genes contain by B. subtilis and Alcaligenes sp. shown in Fig. 2. In literature Pradhan et al. [7] obtained highly crystalline recovered P(3HB) (44%) by B. megaterium and compared it with P(3HB) recovered from C. necator (23%). The crystallinity of P(3HB) further can be reduced by adding plasticizer to it.

TGA and DTG

The TGA–DSC and DTG study allows differentiation between the deterioration and melting temperatures. The TGA and DTG thermogram illustrated in Fig. 8b show that the polymer mass loss occurred at a specific temperature and time as well as rapidly mass loss of polymer occurred with respect to temperature. The plot of % TG against temperature revealed that polymer disintegration occurred at 254.5°Cwhich was affirmed by the peak of DTG. TGA graph was illustrated for mass loss occurred after melting point temperature (172.5 °C) of P(3HB) due to chain scission and hydrolysis process. The cleavage of C=O and C–O links in ester groups via β-scission, dissolution of polymer caused the quick heat degradation of P(3HB) and crotonic acid formed led to raise the temperature. However, the very less amount which is 1.98% mass loss was occurred due to evaporation of physically absorbed solvent upto melting point temperature. The residual mass was 2.87% at 501.1 °C. The thermal degradation temperature (Tdegr) in the TGA thermogram was 254.5 °C which was greater than the standard P(3HB). It indicates that recovered P(3HB) has higher thermal stability than standard P(3HB). The NMR results confirmed the identification of the recovered polymer as P(3HB) and in line with the findings of Mourao et al.[44] (Tdegr = 254.20 °C) and Mohanrasu et al.[24] (Tdegr = 233 °C). The maximum mass loss rate of 49%/min was observed at 254.5 °C which is a maximum degradation temperature; indicates that polymer degrades quickly at this point. It can be concluded that the synthesized P(3HB) is more thermally stable or resistant to thermal deterioration than conventional P(3HB). Because there was a significant disparity between the Tdegr and Tmelt values of the P(3HB) and resultant biopolymer could be processed.

The recovered P(3HB) contains 132 kDa average molecular weight (Mn) and 326.4 kDa weight average molecular weight (Mw) with 2.47 PI. The P(3HB) recovered had slightly high molecular weight compared to standard P(3HB) (1.95 PI) and lower than Aremu et al. [48] who reported 3.90 PI of P(3HB) recovered from p. cepacia.

Conclusions

The aim of current investigation was to identify the potential of P(3HB) production by co-culture of Alcaligenes sp. NCIM 5085 and Bacillus subtilis which was grown on acid treated cane molasses. Microbe could assimilate the substrate more effectively when co-cultured than isolated one. A wide range of experiments were carried out to optimize P(3HB) synthesis parameters including substrate, C/N ratio, Na2HPO4&KH2PO4concentration, and physical factors such as incubation period, pH, and inoculum volume. The existence of functional groups, bonds, and components were identified by FTIR, NMR, and GCMS analysis. Thermal investigations revealed a melting point of 172.5 °C at a degradation temperature of 254.5 °C. A glass transition temperature of − 6.3 °C was detected by DSC. The recovered polymer acquired higher thermal stability than that of standard P(3HB) which extends its application range. The findings imply the co-culture for promising P(3HB) yielding bacteria with various metabolic activities might be a feasible alternative for increasing P(3HB) yield. Such strategy may provide new opportunities for improving the efficiency of biosynthesized P(3HB) in a viable biorefinery approach using several lignocelluloses feedstock.

Data availability

The data will be made available on request.

References

P. Delhi, India emerges as the world’s largest producer and consumer of sugar and world’s 2nd largest exporter of sugar, Ministry of Consumer Affairs, Food & Public Distribution, Food Public Distrib. (2022). https://www.pib.gov.in/PressReleseDetailm.aspx?PRID=1865320.

Kanzariya, R., Gautam, A., Parikh, S., Shah, M., Gautam, S.: Formation of polyhydroxyalkanoates using agro and industrial waste as a substrate–a review. Biotechnol. Genet. Eng. Rev. 00, 1–40 (2023). https://doi.org/10.1080/02648725.2023.2165222

Saratale, R.G., Cho, S., Kadam, A.A., Ghodake, G.S., Kumar, M., Bharagava, R.N., Varjani, S., Nair, S., Kim, D., Shin, H., Saratale, G.D.: Developing microbial co-culture system for enhanced polyhydroxyalkanoates (PHA) production using acid pretreated lignocellulosic biomass. Polymers (Basel). 4, 726 (2022). https://doi.org/10.3390/polym14040726

Mi, S., Lee, H., Hyun, S., Ju, M., Yeon, J., Ham, S., Jeon, J., Yoon, J., Kant, S., Gurav, R., Yeol, E., Yang, Y.: Screening of the strictly xylose-utilizing Bacillus sp SM01 for polyhydroxybutyrate and its co-culture with Cupriavidus necator NCIMB 11599 for enhanced production of PHB. Int. J. Biol. Macromol. 181, 410–417 (2021). https://doi.org/10.1016/j.ijbiomac.2021.03.149

Altaee, N., El Hiti, G.A., Fahdil, A., Sudesh, K., Yousif, E.: Biodegradation of different formulations of polyhydroxybutyrate films in soil. Springerplus 5, 1–12 (2016). https://doi.org/10.1186/s40064-016-2480-2

Abdelrahman, S.A., Barakat, O.S., Elsayed, T.R.: Biopolymer production by some marine bacterial strains isolated from Egypt. Egypt. J. Chem. 65, 513–523 (2022). https://doi.org/10.21608/EJCHEM.2021.105848.4875

Pradhan, S.: Production, ultrasonic extraction, and characterization of poly (3 - hydroxybutyrate ) ( PHB ) using Bacillus megaterium and Cupriavidus necator. Polym. Adv. Technol. 29, 1–9 (2018). https://doi.org/10.1002/pat.4351

Sen, K.Y., Hussin, M.H., Baidurah, S.: Biosynthesis of poly(3-hydroxybutyrate) (PHB) by Cupriavidus necator from various pretreated molasses as carbon source. Biocatal. Agric. Biotechnol. (2018). https://doi.org/10.1016/j.bcab.2018.11.006

Gahlawat, G., Soni, S.K.: Valorization of waste glycerol for the production of poly (3-hydroxybutyrate) and poly (3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer by Cupriavidus necator and extraction in a sustainable manner. Bioresour. Technol. 243, 492–501 (2017). https://doi.org/10.1016/j.biortech.2017.06.139

Naranjo, J.M., Posada, J.A., Higuita, J.C., Cardona, C.A.: Valorization of glycerol through the production of biopolymers: the PHB case using Bacillus megaterium. Bioresour. Technol. 133, 38–44 (2013). https://doi.org/10.1016/j.biortech.2013.01.129

Zulfiqar-Ali-Raza, S., Banat, I.M.: Polyhydroxyalkanoates : Characteristics, production, recent developments and applications. Int. Biodeterior. Biodegrad. 126, 45–56 (2018). https://doi.org/10.1016/j.ibiod.2017.10.001

Raza, Z.A., Tariq, M.R., Majeed, M.I., Banat, I.M.: Recent developments in bioreactor scale production of bacterial polyhydroxyalkanoates. Bioprocess Biosyst. Eng. 42, 901–919 (2019). https://doi.org/10.1007/s00449-019-02093-x

Khan, N., Ali, I., Mazhar, S., Munir, S., Batool, R.: Co-Culture of halotolerant bacteria to produce poly (3- hydroxybutyrate-co-3-hydroxyvalerate ) using sewage wastewater substrate. Polymers (Basel). 14, 4963 (2022). https://doi.org/10.3390/polym14224963

Zhu, Y., Ai, M., Jia, X.: Optimization of a two-species microbial consortium for improved Mcl-PHA production from glucose – xylose mixtures. Front. Bioeng. Biotechnol. 9, 1–15 (2022). https://doi.org/10.3389/fbioe.2021.794331

Brandl, H., Gross, R.A., Lenz, R.W., Fuller, R.C.: Pseudomonas oleovorans as a source of poly (β-hydroxyalkanoates) for potential applications as biodegradable polyesters. Appl. Environ. Microbiol. Environ. Microbiol. 54, 1977–1982 (1988). https://doi.org/10.1128/aem.54.8.1977-1982.1988

Rehm, B.H.A.: Polyester synthases: natural catalysts for plastics Bernd. Biochem. J. 376, 15–33 (2003). https://doi.org/10.1042/BJ20031254

Rehm, B.H.A.: Biogenesis of microbial polyhydroxyalkanoate granules: A platform technology for the production of tailor-made bioparticles. Curr. Issues Mol. Biol. 9, 41–62 (2007). https://doi.org/10.21775/cimb.009.041

Bhatia, S.K., Yoon, J.J., Kim, H.J., Hong, J.W., Gi Hong, Y., Song, H.S., Moon, Y.M., Jeon, J.M., Kim, Y.G., Yang, Y.H.: Engineering of artificial microbial consortia of Ralstonia eutropha and Bacillus subtilis for poly(3-hydroxybutyrate-co-3-hydroxyvalerate) copolymer production from sugarcane sugar without precursor feeding. Bioresour. Technol. 257, 92–101 (2018). https://doi.org/10.1016/j.biortech.2018.02.056

Tyagi, B., Takkar, S., Meena, R., Shekhar, I.: Production of polyhydroxybutyrate ( PHB ) by Parapedobacter sp. ISTM3 isolated from Mawsmai cave utilizing molasses as carbon source. Environ. Technol. Innov. 24, 101854 (2021). https://doi.org/10.1016/j.eti.2021.101854

Sirohi, R., Prakash, J., Tarafdar, A., Agarwal, A.: An environmentally sustainable green process for the utilization of damaged wheat grains for poly-3-hydroxybutyrate production. Environ. Technol. Innov. 21, 101271 (2021). https://doi.org/10.1016/j.eti.2020.101271

Zhou, Y., Han, L.R., He, H.W., Sang, B., Yu, D.L., Feng, J.T., Zhang, X.: Effects of agitation, aeration and temperature on production of a novel glycoprotein gp-1 by streptomyces kanasenisi zx01 and scale-up based on volumetric oxygen transfer coefficient. Molecules 23, 1–14 (2018). https://doi.org/10.3390/molecules23010125

Mathiyazhagan Narayanan, S., Kandasamy, V., Ashokkumar, O., Nasif, A., Pugazhendhi, G., Kandasamy, S., Kandasamy, V., Ashokkumar, O., Nasif, A.P.: Optimization and production of Polyhydroxybutyrate from sludge by Bacillus cereus categorized through FT-IR and NMR analyses. J. Enviromental Chem. Eng. 9, 104908 (2020). https://doi.org/10.1016/j.jece.2020.104908

Hariharapura, R.: Statistical optimisation of polyhydroxyalkanoate production in bacillus endophyticus using sucrose as sole source of carbon. Arch. Microbiol. 203, 5993–6005 (2021). https://doi.org/10.21203/rs.3.rs-713565/v1

Mohanrasu, K., Raj, R.G., Dinesh, G.H., Zhang, K., Prakash, G.S.: Optimization of media components and culture conditions for polyhydroxyalkanoates production by Bacillus megaterium. Fuel 271, 117522 (2020). https://doi.org/10.1016/j.fuel.2020.117522

Munir, S.: Polyhydroxyalkanoates (PHA) production in bacterial co-culture using glucose and volatile fatty acids as carbon source. J. Basic Microbiol. Basic Microbiol. 1, 8 (2018). https://doi.org/10.1002/jobm.201700276

Shalin, T., Sindhu, R., Pandey, A., Faraco, V., Binod, P.: Production of poly-3-hydroxybutyrate from mixed culture. Biologia (Bratisl). 71, 736–742 (2016). https://doi.org/10.1515/biolog-2016-0097

Suguna, P.P., Saranya, V.V., Abirami, P.P., Shenbagarathai, R.R.: Optimization and characterization of PHA (SCL-SCL) copolymer by indigenous bacillus thuringiensis A102 strain for biomedical applications. Curr. Microbiol. 77, 3978–3989 (2020). https://doi.org/10.1007/s00284-020-02221-x

Vrundha, M.G.R., Raghu, S.R.H., Divyashree, C.M.S.: Improvement of the production and characterisation of polyhydroxyalkanoate by bacillus endophyticus using inexpensive carbon feedstock. J. Polym. Environ. (2019). https://doi.org/10.1007/s10924-019-01397-z

Saeed, S., Firyal, S., Tayyab, M., Irfan, M., Mohyud-Din, A., Mehmood, T.: Bioconversion of apple peels (Malus domestica) to polyhydroxybutyrate using statistical design to optimize process parameters through Bacillus thuringiensis via solid-state fermentation. Biomass Convers. Biorefinery. 4, 89 (2022). https://doi.org/10.1007/s13399-022-02762-0

Narayanan, M., Kandasamy, S., Kumarasamy, S., Gnanavel, K., Ranganathan, M., Kandasamy, G.: Screening of polyhydroxybutyrate producing indigenous bacteria from polluted lake soil. Heliyon. 6, e05381 (2020). https://doi.org/10.1016/j.heliyon.2020.e05381

Dubey, S., Mishra, S.: Efficient production of polyhydroxyalkanoate through halophilic bacteria utilizing algal biodiesel waste residue. Front. Bioeng Biotechnol. 9, 1–11 (2021). https://doi.org/10.3389/fbioe.2021.624859

Javaid, H., Nawaz, A., Riaz, N., Mukhtar, H., Ullah, K., Manzoor, R., Kaleem, I., Murtaza, G.: Valorization of biomass and synthetic waste. Molecules 25, 5539 (2020)

Aslam, T., Saeed, S., Tayyab, M., Mujahid, H., Awan, A.R., Firyal, S., Hashmi, A.: Bioconversion of agricultural wastes to polyhydroxybutyrate by azotobacter vinelandii. Pak. J. Zool. 1, 5 (2020). https://doi.org/10.17582/journal.pjz/20170216050211

Etxabide, A., Kilmartin, P.A., Guerrero, P., de la Caba, K., Hooks, D., West, M., Singh, T.: Polyhydroxybutyrate (PHB) produced from red grape pomace: Effect of purification processes on structural, thermal and antioxidant properties. Int. J. Biol. Macromol. 217, 449–456 (2022). https://doi.org/10.1016/j.ijbiomac.2022.07.072

Sirohi, R.: Environmental Technology & Innovation Sustainable utilization of food waste : Production and characterization of polyhydroxybutyrate ( PHB ) from damaged wheat grains. Environ. Technol. Innov. 23, 101715 (2021). https://doi.org/10.1016/j.eti.2021.101715

Trakunjae, C., Boondaeng, A., Apiwatanapiwat, W., Kosugi, A., Arai, T., Sudesh, K., Vaithanomsat, P.: Enhanced polyhydroxybutyrate (PHB) production by newly isolated rare actinomycetes Rhodococcus sp. strain BSRT1–1 using response surface methodology. Sci. Rep. 11, 1–14 (2021). https://doi.org/10.1038/s41598-021-81386-2

Hamdy, S.M., Danial, A.W., Gad, S.M.F., Rab, E., Shoreit, A.A.M., El, A., Hesham, L.: Production and optimization of bioplastic ( Polyhydroxybutyrate ) from Bacillus cereus strain SH - 02 using response surface methodology. BMC Microbiol. 22, 1–16 (2022). https://doi.org/10.1186/s12866-022-02593-z

El-kadi, S.M., Elbagory, M., El-zawawy, H.A.H., El-shaer, H.F.A.: Biosynthesis of Poly-ß-Hydroxybutyrate ( PHB ) from Different. Polymers (Basel). 13, 1–20 (2021)

Andler, R., Pino, V., Moya, F., Soto, E., Valdés, C., Andreeßen, C., Pino, V., Moya, F., Soto, E., Valdés, C., Andreeßen, C.: Synthesis of poly-3-hydroxybutyrate ( PHB ) by Bacillus cereus using grape residues as sole carbon source. Int. J. Biobased Plast. 3, 98–111 (2021). https://doi.org/10.1080/24759651.2021.1882049

Silambarasan, S., Logeswari, P., Sivaramakrishnan, R., Pugazhendhi, A., Kamaraj, B., Ruiz, A., Ramadoss, G.: Bioresource technology polyhydroxybutyrate production from ultrasound-aided alkaline pretreated finger millet straw using Bacillus megaterium strain CAM12. Bioresour. Technol. 325, 124632 (2021). https://doi.org/10.1016/j.biortech.2020.124632

Mostafa, Y.S., Alrumman, S.A., Otaif, K.A., Alamri, S.A., Mostafa, M.S., Sahlabji, T.: Production and characterization of bioplastic by polyhydroxybutyrate accumulating Erythrobacter aquimaris isolated from mangrove rhizosphere. Molecules (2020). https://doi.org/10.3390/molecules25010179

Pillai, A.B., Kumar, A.J., Kumarapillai, H.: Biosynthesis of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) in Bacillus aryabhattai and cytotoxicity evaluation of PHBV/poly(ethylene glycol) blends. 3 Biotech. 10, 1–10 (2020). https://doi.org/10.1007/s13205-019-2017-9

Sivakumar, K., Shree, C.G., Ravishankar, K., Dhamodharan, R., Palani, P.: Statistical augmentation of polyhydroxybutyrate production by Isoptericola variabilis: Characterization, moulding, in vitro cytocompatibility and biodegradability evaluation. Int. J. Biol. Macromol. 166, 80–97 (2020). https://doi.org/10.1016/j.ijbiomac.2020.10.089

Mourao, M.M., Xavier, L.P., Urbatzka, R., Figueiroa, L.B., da Costa, C.E.F., Dias, C.G.B.T., Schneider, M.P.C., Vasconcelos, V., Santos, A.V.: Characterization and biotechnological potential of intracellular polyhydroxybutyrate by stigeoclonium sp B23 using cassava peel as carbon source. Polymers (Basel). 13, 1–21 (2021). https://doi.org/10.3390/polym13050687

Chen, Y., Chen, X., Du, H., Zhang, X., Ma, Y., Chen, J., Ye, J., Jiang, X., Chen, G.: Chromosome engineering of the TCA cycle in Halomonas bluephagenesis for production of copolymers of 3-hydroxybutyrate and 3-hydroxyvalerate. Metab. Eng. 54, 69–82 (2019). https://doi.org/10.1016/j.ymben.2019.03.006

Hosokawa, M.N., Darros, A.B., Moris, V.A.D.S., De Paiva, J.M.F.: Polyhydroxybutyrate composites with random mats of sisal and coconut fibers. Mater. Res. 20, 279–290 (2017). https://doi.org/10.1590/1980-5373-MR-2016-0254

Oliveira, F.C., Dias, M.L., Castilho, L.R., Freire, D.M.G.: Characterization of poly(3-hydroxybutyrate) produced by Cupriavidus necator in solid-state fermentation. Bioresour. Technol. 98, 633–638 (2007). https://doi.org/10.1016/j.biortech.2006.02.022

Aremu, L.: Solomon, Production of Poly (3-hydroxybutyrate) from cassava starch hydrolysate by Pseudomonas aeruginosa NCIB 950. Am. J. Sci. Ind. Res. 1, 421–426 (2010). https://doi.org/10.5251/ajsir.2010.1.3.421.426

Acknowledgements

Authors gratefully acknowledge their sincere thanks to Gujarat Institute of Desert Ecology, Bhuj, India to extend their facilities for conducting experiments. The authors acknowledge analytical services provided by Sophisticated Analytical Instruments Facility at I.I.T. Madras.

Funding

The authors would also like sincerely thanks to Department of Science and Technology, India for funding the project (DST/TDT/WM/2019/064) under the scheme Waste Management Technology. The research was carried out under the project.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

Authors have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kanzariya, R., Gautam, A., Parikh, S. et al. Thermally Stable P(3HB) Synthesis from Cane Molasses by Co-culture of Alcaligenes sp. NCIM 5085 and Bacillus subtilis. Waste Biomass Valor 15, 3535–3552 (2024). https://doi.org/10.1007/s12649-023-02396-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-023-02396-x