Abstract

The present study was conducted to investigate the decomposition of organic carbon (OC) and release of nitrate (NO3−), ammonium (NH4+), P, and K from 4 mixed treatments including T1 [85% poultry manure (PM) + 15% wheat straw (WS)], T2 (75% PM + 25% WS), T3 (75% PM + 15% WS + 10% zeolite), and T4 (65% PM + 25% WS + 10% zeolite) at specified intervals over 133 days. The results indicated that 38–43% of initial OC was decomposed at the end of the composting process. The amount of NO3− at the beginning of the process varied from 9.8 to 13.3 g kg−1 and finally ranged from 23.3 to 39.3 g kg−1. The amounts of NH4+ varied from 1.9 to 3.0 g kg−1 at the end of the composting process. The amount of P released at the beginning of the composting process ranged from 2.8 to 4.3 g kg−1, which reached 3.4–4.0 g kg−1 at the end of the process. The release of K occurred increasingly during the first two weeks and after a slight decrease in the third week, it showed a steady trend until the end of the composting process. The pseudo-second-order equation provided the best fit to the data. Treatment T4 was the best treatment in this study because the application of lower amounts of PM resulted in the production of compost with similar chemical properties to other treatments with higher PM participation.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

Different mixing ratios of poultry manure, wheat residues, and zeolite significantly influenced the release kinetics of C, N, P, and K during a 133-day co-composting process.

Introduction

Poultry farming is operating as an essential part of agriculture in many countries, and through this, a large amount of manure is regularly produced. Handling, storage, and disposal of poultry manure (PM) are among the main problems for poultry farmers [1]. The use of PM in agricultural lands is one of the ways to deal with the problem of disposal. PM increases soil fertility and improve plant nutrition due to its essential nutrients such N, P, and K. It also improves the chemical and physical properties of the soil by increasing the cation exchange capacity and aggregation and strengthening the soil structure. However, the direct use of PM in agriculture leads to adverse consequences such as the release of large amounts of greenhouse gases methane and nitrous oxide into the atmosphere, the loss of large amounts of N in the form of ammonia (NH3), and soil pollution with pathogens [2,3,4]. Therefore, it is necessary to find solutions that minimize these problems, both from an agricultural and environmental perspective.

Composting is one of the cost-effective and environmentally friendly ways that is widely used to stabilize nutrients and organic matter in organic solid wastes and its nutrient-rich product can be applied as an organic fertilizer or soil amendment [2, 5]. In this process, organic components are biodegraded by heterotrophic microorganisms, the bond of N with organic molecules is broken and it is transformed into available forms for plant uptake, i.e., ammonium (NH4+) and nitrate (NO3−), by chemotrophic microorganisms, pathogens and weed seeds are killed, the initial unpleasant odor is reduced, and the moisture content reaches a desirable level. Other benefits of composting include increased product value, reduced volume and easier transportation, and reduced environmental contamination [6, 7]. Furthermore, the use of compost in agricultural lands improves soil bio-physicochemical properties and thus increases soil quality [5].

It is well established that some characteristics of PM such as high humidity, low porosity, high N content and low C/N ratio, and sometimes high pH make it not suitable for composting alone. So, several solutions including the application of various types of organic bulking additives [8, 9], change of aeration intensity [10, 11], and addition of mineral compounds [12, 13] have been proposed to modulate these properties. Compared to factors such as temperature, moisture, and aeration, the type of additive has the greatest impact on the quality of compost produced, especially in terms of the content of nutrients such as nitrogen [14].

The selection of various organic additives such as straw and residues of crops, sawdust, etc., as carbon sources in co-composting PM is commonly based on the availability and abundance. However, some of these compounds are resistant to biodegradation due to their high lignin content. The use of compounds such as sawdust and wood chips, which are high in lignin, slows down the decomposition process in composting manures while reducing organic carbon (OC) loss [15]. As poultry farming and wheat production are among the most important agricultural sectors in many parts of the world, co-composting PM with wheat straw (WS) has been widely considered as one of the economic strategies for recycling these organic wastes. In addition, WS with contrasting properties modifies and balances the characteristics of PM.

Zeolite is a natural mineral that is widely used to reduce the emission of greenhouse gases, salinity, and N loss during the composting process [2, 16] due to some unique properties such as high cation exchange capacity, high water holding capacity, and porous network structure [17]. Composting food wastes with 10% zeolite has been reported to reduce NH3 volatilization and thus N loss [2]. Other studies showed that the combination of zeolite or lime and biochar reduced nutrient loss and improved compost quality [13, 18]. Although zeolite as a mineral additive is being studied in co-composting organic residues, all its effects on compost properties, especially nutritional properties, have not yet been fully elucidated.

One of the most important characteristics of composts is their nutrient content. Studies on co-composting PM with WS and zeolite have focused on parameters such as reducing NH3 emissions and increasing N storage, optimizing the C/N ratio, or reducing the moisture content. However, the release kinetics of essential macronutrients for plant growth during composting process has not received much attention, while it can be useful in the determination of the optimal time of application of organic fertilizers in agricultural fields. So, this study aimed to investigate the effect of different mixing ratios of PM and WS and the presence of zeolite on the decomposition rate of OC and release kinetics of NH4+, NO3−, P, and K during a 133-day co-composting process.

Materials and Methods

Preparation and Characterization of Raw Materials and Treatments

PM and WS were collected from the farm of the College of Agriculture of Razi University located in Kermanshah, western Iran, and natural zeolite was purchased from a factory located in Semnan, Iran. According to XRD analysis, zeolite was a type of clinoptilolite with a purity of 54% and also contained 23% quartz.

The raw materials were oven-dried at 70 °C and then passed through a 2-mm sieve for the following analyses. The pH and electrical conductivity (EC) were measured in 1:10 solid to water extract, OC of PM and WS was determined using dry oxidation in an electric furnace, while OC of zeolite was measured according to wet oxidation by potassium dichromate [19], total N was determined according to spectrophotometric method [20], and total P and K in the extract obtained by dissolving the ash from dry digestion of PM and WS and in the extract obtained from wet digestion of zeolite were measured using spectrophotometric molybdate-vanadate method [21] and flame photometer, respectively.

Four treatments were considered in the preparation of composts as follows: (T1) 85% PM + 15% WS, (T2) 75% PM + 25% WS, (T3) 75% PM + 15% WS + 10% zeolite, (T4) 65% PM + 25% WS + 10% zeolite based on dry weight. Twenty-liter plastic barrels with lids were used to prepare different compost treatments and each treatment was performed in three replications. In each barrel, raw materials were poured in the weight ratios considered for each treatment so that the total weight of dry matter per barrel was 10 kg, and then water was added up to 60% by weight. The barrels were covered with plastic nylon and placed in a greenhouse. On the lid of the barrels, five holes with the radius of 2 cm were created at intervals of 20 cm from each other. The treatments were kept moist during composting and stirred and aerated manually and regularly at weekly intervals.

Sampling to Analyze the Release of Nutrients from Composts

The samples were taken on days 1, 7, 14, 21, 35, 49, 77, 105, and 133 to investigate the release of nutrients during composting. From each treatment, several samples were taken from different points and mixed as a composite sample. Then, each composite sample was divided into two parts: one part was oven-dried at 70 °C to obtain the gravimetric moisture content. In oven-dried samples, pH and EC were measured in extracts with a ratio of 1:10 solid to distilled water, and OC was determined using dry oxidation. The other part with the initial moisture was used to extract N, P, and K released during composting. Extraction of NO3−, NH4+, and K was performed using a ratio of 1:20 solid to distilled water, and extraction of P was done using a ratio of 1:20 solid to 0.1 M H2SO4 after 30 min of shaking and 5 min of centrifugation [22]. Concentrations of nutrients released in extracts were measured using standard methods [23] and expressed per dry mass unit of different compost treatments based on the extraction ratio and gravimetric water content.

Investigation of Release Kinetics

In this study, kinetic equations including exponential, pseudo-second-order, parabolic diffusion, simple Elovich, and power function were used. The trend of changes in OC over time was fitted with exponential and pseudo-second-order equations and the changes of NH4+, NO3−, P, and K were fitted with pseudo-second-order, parabolic diffusion, simple Elovich, and power function equations. Equations that were better able to describe the trend of change of each parameter over time were selected based on the highest coefficient of determination (R2) and the lowest standard error (SE). These equations are defined as follows:

-

(1)

Exponential equation: \(q_{t} = q_{0} e^{ - kt}\) where qt is OC content (g kg−1) at time t, q0 is OC content (g kg−1) at time zero (initial OC), k is the rate of decomposition of OC, and t is time (day),

-

(2)

Pseudo-second-order equation: \(\frac{t}{{q_{t} }} = \frac{1}{{k_{2} q_{f}^{2} }} + \frac{t}{{q_{f} }}\) where qt is the amount of desired parameters including NH4+, NO3−, P, and K (g kg−1) at time t, qf is the amount of desired parameters at equilibrium or the end of process (final content), and k2 is the rate of release per unit time (kg g−1 day−1),

-

(3)

Parabolic equation: \(q_{t} = q_{0} + b_{1} t^{0.5}\)

-

(4)

Power function equation: \(Lnq_{t} = Lnq_{0} + b_{2} Lnt\)

-

(5)

Elovich equation: \(q_{t} = q_{0} + b_{3} Lnt\) where b1, b2, and b3 are the rates of release, and q0 is the initial content (g kg−1) of desired parameters.

The standard error of the estimate was calculated by following equation:

-

(6)

\({\text{SE}} = \left[ {\frac{{\sum (q - q*)^{2} }}{(n - 2)}} \right]^{\frac{1}{2}}\) where, q and q* represent the measured and predicted values of desired parameters, respectively, and n is the number of data points evaluated.

Statistical Analysis

One-way analysis of variance (ANOVA) with repeated measures and comparison of means based on Duncan's multiple-range test were performed using SAS software to compare measured parameters at each sampling time.

Results and Discussion

Properties of Raw Materials Used in Composting

Table 1 shows some chemical properties of the primary organic and inorganic compounds in the preparation of composts. The highest and lowest pH values were related to PM and WS, respectively, and the highest and lowest EC values were measured in zeolite and PM, respectively. The highest amount of N and P was observed in PM and the highest amounts of C and K were obtained for WS. Higher levels of N and P in PM than those in WS are related to protein and phosphate-rich diets in the poultry industry. A C/N ratio of less than 20 in PM may induce that a large amount of mineralized N enters the soil if this fertilizer is directly applied, which increases the potential for loss of this element in the form of NH3 volatilization or NO3− leaching, followed by environmental pollution. In contrast, a C/N value of more than 30 in WS indicates that N is not mineralized if it is directly added to the soil. The results indicated that C/N ratio in all treatments was below 20. Therefore, the combination of these two materials in the process of composting can lead to the production of a product with appropriate and balanced quality.

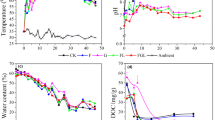

Changes in pH and EC During the Composting Process

The pH values were 5.8, 6.0, 5.7, and 6.3 at the first time (day 1) and increased to 7.1, 7.2, 6.9, and 7.4 at the end of incubation (day 133) in T1, T2, T3, and T4, respectively (Fig. 1a). The pH decreased on days 7 and 21, while it showed an upward trend at other times. The results of ANOVA showed that the effect of treatment (P < 0.05) and time (P < 0.01) on changing pH was significant but their interaction was not significant. Also, the final pH values of the composts were not significantly different from each other. The results of the composting of pig manure with different mixing ratios of biochar, zeolite, and wood vinegar indicated that the final pH of the composts increased compared to the initial values. Also, the final pH of different treatments did not differ significantly at the 5% level [24]. Increased pH is one of the indicators of good quality and maturity of compost so that in previous studies, the pH range of mature compost has been reported between 6 and 8.5 [25].

Variations of pH (a), EC (b), and OC (c) during the composting process in treatments T1 (85% poultry manure + 15% wheat straw), T2 (75% poultry manure + 25% wheat straw), T3 (75% poultry manure + 15% wheat straw + 10% zeolite), and T4 (65% poultry manure + 25% wheat straw + 10% zeolite). Error bars means standard deviation (n = 3)

The processes that reduce the pH during the decomposition of organic matter are: (1) production of carbon dioxide (CO2), its dissolution in water and dissociation and production of H+, (2) production of organic acids, their dissociation and production of H+ [26], and (3) nitrification in which by converting one mole of NH4+ to one mole of NO3−, 2 mol of H+ are produced. In contrast, reactions that lead to an increase in pH include ammonification and decarboxylation (degradation of dissociated organic acids) [3]. Therefore, increasing or decreasing the pH at each stage of composting depends on the dominance of each of these processes.

The evolution of EC during composting is shown in Fig. 1b. The trend of changes in EC in all treatments was initially upward and reached its highest value on day 21. This parameter then decreased and reached almost the initial value in all treatments at the end of incubation. The effect of treatment and time and their interaction was significant (P < 0.01) on changing EC. The final EC values in treatments T1, T2, T3, and T4 were 5.9, 6.4, 6.5, and 6.4 dS m−1, respectively which were not significantly different based on the results of ANOVA.

The increase in EC is related to the decomposition of organic compounds, resulting in the release of soluble substances. The decrease in EC can be due to the increase in the ionic activity product (IAP) relative to the solubility product constant (KSP), which results in a saturation index greater than one, in other words leading to the precipitation of some ions as insoluble compounds. It can also be due to NH3 volatilization and adsorption and/or absorption of soluble ions by surface functional groups during the process of humification and maturation of composts. During the first weeks, EC of treatments T3 and T4 containing zeolite were lower than treatments T1 and T2, possibly due to the adsorption of ions by zeolite. The peak of EC in all treatments was observed on day 21 and the highest value was related to T1 with the highest participation of PM. As reported in Table 1, PM is more easily affected by the decomposition process and the subsequent release of elements due to its lower C/N ratio compared to WS. However, the difference between EC of treatments decreased over time, so that at the end of incubation, there was no significant difference between EC of treatments due to the equilibrium in dissolution/precipitation and sorption/desorption processes.

Changes in OC During the Composting Process

The trend of changes in OC over time in different treatments is shown in Fig. 1c. Based on the slope of the curves, the rate of carbon decomposition was faster during the first few weeks and then slowed down. The results of ANOVA indicated that the effects of treatment, time, and their interaction on changing OC over time were significant (P < 0.01). However, the final OC contents of treatment were not significantly different. The initial values of OC in the treatments T1, T2, T3, and T4 were 519, 523, 473, and 490 g kg−1, respectively, which were reduced to 300, 297, 293, and 298 g kg−1 at the end of incubation. In other words, 42, 43, 38, and 39% of OC in these treatments were decomposed during 133 days of the composting process. The results of an investigation on three different mixing ratios for composting PM with WS indicated a range of 25–39% for the loss of OC at the end of the process [1].

In general, 60–70% of decomposed OC is converted to CO2 as a result of microbial respiration and 30–40% is for new synthesis of microorganisms [1, 27]. During the first weeks, the population of microorganisms and the rate of decomposition and microbial activity reach the highest level due to the increase in temperature of the composting organic materials (Fig. S1). At this stage, known as the thermophilic phase, simple and easily degradable organic components such as monosaccharides and disaccharides are used as a substrate by heterotrophs. In other words, the heating of organic compounds in the early stages of composting is due to the consumption of OC by aerobic bacteria and its conversion into heat energy. Afterward, the decomposition rate decreases because fewer microorganisms are able to obtain energy from complex and high molecular weight fractions of organic materials such as cellulose, hemicelluloses, and lignin [28]. At this stage, the temperature of the composting mass gradually decreases to eventually reach the ambient temperature. However, it should be noted that the porosity of the composting materials and constant aeration in the barrels can accelerate the cooling and lowering of the temperature, and as a result, easily degradable materials in the thermophilic phase may not be completely consumed by microorganisms [1].

The decomposition kinetics of OC over time was described using exponential and pseudo-second-order equations (Table 2 and Fig. S2). The rate of OC decomposition obtained from the exponential equation (k) was almost the same in all treatments. The negative sign of this parameter reflects the decrease in the amount of OC of the composting masses over time. The lowest value of constant k was obtained in treatment T4, which had the lowest incorporation percentages of PM. According to the pseudo-second-order equation, the rate of carbon decomposition (k2) varied over a narrow range among different treatments. Based on the values of R2 and SE, the pseudo-second-order equation had a better performance in describing the OC decomposition kinetics in different treatments.

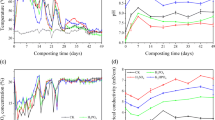

Changes in NO3 − Content During the Composting Process

The trend of changes in water-extractable NO3− content during composting of different treatments is shown in Fig. 2a. The NO3− content increased on days 7 and 21 and decreased at other times. The increase in NO3− content may be due to the increased rate of the nitrification process as a result of the increase in the population of nitrifying bacteria, e.g., Nitrosomonas and Nitrobacter that oxidize NH4+ and NO2− to NO3−. In the temperature range of 5 to 35 °C, the rate of biological processes doubles for every 10 °C increase in temperature. Therefore, increasing the temperature of the composting mass in the thermophilic stage increases the rate of the nitrification process. Increasing the amount of NH4+ also leads to increased nitrification. In contrast, decreased NO3− content can occur as a result of denitrification, microbial assimilation (NO3− uptake by microorganisms and conversion to microbial biomass N), and reduction in nitrification due to reduced NH4+ content. The results of ANOVA showed that the effect of treatment, time, and their interaction on changing NO3− during composting was significant (P < 0.01). The highest amount of NO3− at all times was extracted from T1 with the highest incorporation percentage of PM. The NO3− content increased from initial 13.3, 10.4, 10.3, and 9.8 g kg−1 to 39.3, 24.5, 23.9, and 23.3 g kg−1 at the end of composting process in T1, T2, T3, and T4, respectively. Furthermore, it was lower in zeolite-containing treatments which can be due to the sorption (adsorption + absorption) of NH4+ by zeolite and thus its non-participation in the nitrification process, as well as the lower incorporation rate of PM in these treatments. In addition, the porous lattice structure of the zeolite has the potential to trap NO3− ions [2, 13, 24].

Variations of NO3− (a), NH4+ (b), mineral N as (NH4+ + NO3−) (c), and mineral N as % of the total initial N content (d) during the composting process in treatments T1 (85% poultry manure + 15% wheat straw), T2 (75% poultry manure + 25% wheat straw), T3 (75% poultry manure + 15% wheat straw + 10% zeolite), and T4 (65% poultry manure + 25% wheat straw + 10% zeolite). Error bars means standard deviation (n = 3)

The parameters of the equations used to describe the release kinetics of NO3− over time are presented in Table 3 and Fig. S3. The parabolic, Elovich, and power function equations were fitted to the data from day 21 onwards (6 points) and the pseudo-second-order equation was fitted to all data. Among the first three equations, the power function equation was able to better describe NO3− release kinetics due to its higher R2 and lower SE. The parabolic, power function, and Elvich kinetic equations could not describe the trend of data from day 1 to day 14 because the process of releasing during the first two weeks was ascending and then descending. In other words, the release of NO3− was a two-step process and these three equations were fitted to the second part, which had a decreasing trend. So, the parameter q0 in the parabolic, Elovich, and power function equations does not indicate the amount of NO3− released on day 1. Since the data of days 1, 7, and 14 were omitted to fit these three equations, the q0 values represent the amount of NO3− released on day 21. As no data was eliminated to fit the pseudo-second-order equation, it was considered as the best equation to describe the release of NO3− during composting process. According to this equation, the lowest NO3− release rate was obtained for T4 with the lowest incorporation percentage of PM.

The results of this study in agreement with the results of previous studies showed that there is an inverse relationship between the release of NO3− from organic compounds and their C/N ratio. The higher the C/N ratio of the organic compounds, the lower the NO3− release. Researchers investigated the release of NO3− from leaf residues of several tree species and obtained the highest NO3− concentration on the first day and the last week of incubation, 15,000 and 25,000 mg kg−1, respectively, in the treatment with the highest total N equal to 14,600 mg kg−1 and the lowest amount of NO3− released at the same time, 12,000 and 22,000 mg kg−1, in the treatment with the lowest amount of total N equal to 1600 mg kg−1 [29].

Changes in NH4 + Content During the Composting Process

The trend of changes in NH4+ content in different compost treatments is shown in Fig. 2b. The amount of NH4+ at the beginning of the composting process ranged from 10.5 in T4 to 15.6 g kg−1 in T1. It reached a peak value on day 21 and then decreased in all treatments, similar to NO3−. The amounts of NH4+ at the end of the composting process were equal to 3.0, 2.8, 2.5, and 1.9 g kg−1 in treatments 1, 2, 3, and 4, respectively. Decreased amount of NH4+ can occur due to its absorption by microorganisms and conversion into microbial biomass (immobilization). The higher amount of NH4+ in T1 compared to other treatments is due to the presence of more PM with a low C/N ratio. In addition, the amounts of NH4+ in all treatments at the end of the composting process were more than the permissible level of 0.4 g kg−1 [14], which could be due to the high amount of N in PM used in composting. The results of ANOVA showed a significant effect of treatment type, time, and interaction on the release of NH4+ during composting process (P < 0.01).

Factors that increase or decrease the amount of NH4+ during the decomposition of organic compounds include (1) the content of the initial N content, (2) the intensity of the ammonification process, (3) the population of ammonifier microorganisms, and (4) the intensity of the nitrification process [30, 31].

Table 3 shows the parameters of the kinetic equations used in describing the release of NH4+ over time. Fitting these equations to the experimental data is also provided in Fig. S4. The lowest and highest NH4+ release rates obtained from fitting the parabolic, Elovich, and pseudo-second-order equations were obtained in treatments 4 and 1, respectively which had the lowest and highest incorporation percentage of PM, correspondingly. In addition, the presence of zeolite and its ability to absorb and/or adsorb NH4+ may lead to a decrease in the released NH4+ concentration in T4. Despite the higher values of R2 and SE of the power function equation compared to other kinetic equations, the pseudo-second-order equation was chosen as the best equation to describe the release of NH4+ due to its fit to all data.

The trend of changes in mineral N in the forms of NH4+ + NO3− in different compost treatments over time is shown in Fig. 2c. The amount of inorganic N at the beginning of the composting process ranged from 15.1 in T1 to 10.4 g kg−1 in T4 which corresponded to 11.2 and 6.7 g kg−1 in these treatments, respectively. The amounts of inorganic N in all treatments reached the peak values in the third week, which were equal to 42.3, 37.9, 32.4, and 25.6 g kg−1, in T1, T2, T3, and T4, respectively. Figure 2d represents the changes in the ratio of inorganic N to total initial N (in percentage) over time. This parameter ranged from 18.6 to 20.2% on the first day and from 11.6 to 15% at the end of the composting process. The highest percentages of mineral N of total initial N were observed on day 21, which varied from 46.2 to 56.8%. Nitrogen mineralization is a microbial process in which N in converted from organic forms such as nucleic acids and amino acids to mineral forms (NH4+ and NO3−). Nitrogen mineralization takes place in three successive stages of amminization, ammonification, and nitrification, and if factors such as pH, aeration, moisture, the population of microorganisms, and C/N ratio of organic compounds are not appropriate, this process will be reduced.

Changes in P Content Released During the Composting Process

The trend of changes in P released in different compost treatments is shown in Fig. 3a. The amount of released P in treatments 1, 2, 3, and 4 were equal to 3.5, 4.0, 3.4, and 3.8 g kg−1, respectively at the end of the process (after 133 days). During the decomposition process, the organic P in organic residues is converted to mineral P by the enzyme phosphatase produced by microorganisms. The higher amount of released P in T1 and T2 is related to the higher incorporation of PM in these treatments. Because poultry diets are rich in phosphate, PM is a rich source of P. Factors that increase P mineralization are: (1) temperature and moisture, (2) pH, (3) population of bacteria that are able to convert organic P into mineral P, 4) C/P ratio and the initial amount of P in organic residues. The results showed that the rate of P release gradually decreased due to the decrease in the amount of organic P and possibly the decrease in the population of P-mineralizing bacteria. Released P reached its maximum on day 14, which was equal to 12.5, 10.3, 7.5, and 5.8 g kg−1 in treatments 1, 2, 3, and 4, respectively. The lower amount of extractable P in T3 and T4 compared to T1 and T2 may be due to the lower participation rate of PM and also the adsorption of mineral P by zeolite. The results of analysis of ANOVA revealed that the effect of treatment, time, and their interaction on changing P released over time was significant (P < 0.01).

Variations of released P (a), P released as % of the total initial P content (b), released K (c), and K released as % of the total initial K content (d) during the composting process in treatments T1 (85% poultry manure + 15% wheat straw), T2 (75% poultry manure + 25% wheat straw), T3 (75% poultry manure + 15% wheat straw + 10% zeolite), and T4 (65% poultry manure + 25% wheat straw + 10% zeolite). Error bars means standard deviation (n = 3)

Figure 3b indicates the changes in the percentage of P released from the total initial P. The highest percentages of P released were: 44.1% (day 14), 42.0% (day 21), 29.2% (day 14), and 26.4% (day 21) in treatments 1, 2, 3, and 4, respectively. In other words, the release of P in composting treatments showed an increasing trend from the beginning of the process until the second or third week and after that, the amount of released P decreased. This decrease may be due to the decrease in the population of P-mineralizing microorganisms, immobilization of mineral P by microorganisms, sorption and complexation of P by surface functional groups, or precipitation of phosphate salts. The slow rate of P release has been attributed to the high C/P ratio of organic residues [22]. The release of P from eight types of plant residues and two types of organic fertilizers investigated and reported that the rate of P release from residues during the first 4 weeks of incubation was much higher than that occurred between 5 and 12th weeks. It was also found that the release of P from sunflower and wheat straw residues was higher than sheep manure, indicating that a high C/N ratio does not necessarily and exclusively delay the P release process [32].

Fitting the kinetic equations to the released P data over time showed that the P release rate in treatments 1 and 2 was higher than that in treatments 3 and 4. Also, the pseudo-second-order equation was more successful than other equations in describing the release of P during the composting process (Table 5 and Fig. S5). The results showed that the P release rate is inversely related to increasing the participation of PM in compost production and thus reducing the C/P ratio.

Changes in K Content Released During the Composting Process

Figure 3c shows that the release of K occurred increasingly during the first two weeks (14 days) and after a slight decrease in the third week, it showed a steady trend until the end of the composting process. Potassium released at the beginning of the composting process ranged from 12.1 in T4 to 18.3 g kg−1 in T2. The higher amount of K in T2 is due to the higher content of PM and WS in this treatment. Potassium is not involved in the structure of organic compounds and is a component of intracellular fluid and therefore more easily released than N and P. The amount of K released at the end of the composting process in treatments 1, 2, 3, and 4 were 20.6, 23.3, 17.3, and 18.1 g kg−1, respectively. Treatments 3 and 4 had less water-extractable K due to the adsorption of K by zeolite. In general, it can be said that by adsorbing and/or absorbing NH4+, NO3−, P, and K, zeolite can convert PM compost into a slow-release fertilizer that gradually releases these nutrients to the plant over time.

The results of ANOVA showed that the effect of treatment and time on K released during the composting process was significant (P < 0.01), but their interaction was not significant. The highest percentage of K released from the total initial K occurred on day 14, which was equal to 94.9, 97.0, 89.1, and 89.4% in treatments 1, 2, 3, and 4, respectively (Fig. 3d). The decrease in the amount of extractable K in the continuation of the composting process can be due to its uptake by microorganisms.

Fitting the kinetic equations showed that the rates of K release in treatments 1 and 2 were higher than those in treatments 3 and 4 (Table 4 and Fig. S6). This can be due to the higher participation of PM and WS in T1 and T2 and the presence of zeolite in T and T4. The pseudo-second-order equation was selected as the best equation to describe the release of K during the composting process.

Characteristics of Prepared Composts

The results of ANOVA showed that the effect of different treatments on the pH of the produced composts was not significant (Table 5). However, the pH value in T4 was higher than in other treatments. The pH of the four composts produced ranged from neutral to slightly alkaline. The results show that the pH of the composts is not much different from the pH of the raw materials and the composting process has not significantly changed the final value of this parameter.

The effect of the applied treatments on the EC of composts was not significant. The highest amount of EC was observed in T3. In addition, the application of 10% by weight of zeolite had no significant effect on the final values of EC and they were close to values of this parameter in the raw materials despite the release of solutes during the composting process. This could be due to the immobilization of these elements by microorganisms, adsorption by functional groups, and/or precipitation in the form of salt.

The highest and lowest amounts of C and N were obtained in treatments 1 and 3, respectively. However, based on the results of the comparison of means, no significant difference was observed between composts in terms of these properties. The range of the C/N ratio varied from 6.44 in treatment 1 to 6.81 in treatment 3. The highest amount of P was observed in treatment 1, which had the highest level of PM among treatments and the highest amount of K was measured in treatment 2.

Conclusions

The amount of organic carbon in different treatments varied in the range of 473–523 g kg−1 on day 1. It decreased by 38–43% and reached to 293–300 g kg−1 at the end of the 133-day composting process. The highest amounts of the release of ammonium, nitrate, phosphorus, and potassium occurred within the first three weeks and then their release decreased until the end of the composting process due to the microbial immobilization, precipitation, and/or adsorption. The percentage of inorganic nitrogen (ammonium + nitrate), phosphorus, and potassium released from their total initial contents varied respectively in the range of 11.6–15.0%, 12.1–15.5%, and 76.6–85.2% on day 133. The pseudo-second-order equation better described the trend of changes in the mentioned parameters over time than the parabolic, Elovich, and power function equations. The final values of pH, electrical conductivity, nitrogen, phosphorus, potassium, and carbon to nitrogen ratio of the prepared composts varied in the range of 6.9–7.4, 5.9–6.5 dS m−1, 43.0–46.6 g kg−1, 17.3–23.9 g kg−1, 17.6–26.0 g kg−1, and 6.4–6.8, respectively. Considering the electrical conductivity of the produced composts, this organic compound should be used with caution and in limited quantities in saline soils and salinity-sensitive crops. The use of zeolite in the poultry manure composting process did not significantly reduce the electrical conductivity, which could be because its solutes were not washed before use in the composting process. However, treatment T4 (65% poultry manure + 15% wheat straw + 10% zeolite) was the best treatment in this study because the application of lower amounts of poultry manure resulted in the production of compost with similar chemical properties to other treatments with higher poultry manure participation. Reducing the use of poultry manure declines the risk of nitrogen loss through processes such as nitrate leaching and ammonia volatilization. Also, further experiments should perform to investigate higher ratios of wheat straw and zeolite than the values used in this study.

Data Availability

The datasets analyzed during the current study can be available from the corresponding author on reasonable request.

References

Petric, I., Šestan, A., Šestan, I.: Influence of initial moisture content on the composting of poultry manure with wheat straw. Biosyst. Eng. 104, 125–134 (2009)

Chan, M.T., Selvam, A., Wong, J.W.C.: Reducing nitrogen loss and salinity during “struvite” food waste composting by zeolite amendment. Bioresour. Technol. 200, 838–844 (2016)

Liu, H., Ye, X., Chen, S., Sun, A., Duan, X., Zhang, Y., Zou, H., Zhang, Y.: Chitosan as additive affects the bacterial community, accelerates the removals of antibiotics and related resistance genes during chicken manure composting. Sci Total Environ. 792, 148381 (2021)

Younessi, N., Safari Sinegani, A.A., Khodakaramian, G.: Comparison of antibiotic resistance of coliforms and Escherichia coli strains in industrial and antimicrobial-free poultry manure. Arch. Agron. Soil Sci. 68, 257–272 (2020)

Liu, N., Liao, P., Zhang, J., Zhou, Y., Luo, L., Huang, H., Zhang, L.: Characteristics of denitrification genes and relevant enzyme activities in heavy-metal polluted soils remediated by biochar and compost. Sci. Total Environ. 739, 139987 (2020)

Bernal, M.P., Sommer, S.G., Chadwick, D., Qing, C., Guoxue, L., Michel, F.C.: Current approaches and future trends in compost quality criteria for agronomic, environmental, and human health benefits. Adv. Agron. 144, 143–233 (2017)

Wang, Q., Awasthi, M.K., Ren, X., Zhao, J., Wang, M., Chen, H., Zhang, Z.: Recent advances in composting of organic and hazardous waste: a road map to safer environment. In: Varjani, S., Parameswaran, B., Kumar, S., Khare, S. (eds.) Biosynthetic Technology and Environmental Challenges, pp. 307–329. Singapore, Springer (2018)

Chowdhury, M.A., de Neergaard, A., Jensen, L.S.: Composting of solids separated from anaerobically digested animal manure: effect of different bulking agents and mixing ratios on emissions of greenhouse gases and ammonia. Biosyst. Eng. 124, 63–77 (2014)

Hwang, H.Y., Kim, S.H., Kim, M.S., Park, S.J., Lee, C.H.: Co-composting of chicken manure with organic wastes: characterization of gases emissions and compost quality. Appl. Biol. Chem. 63, 3 (2020)

Tsutsui, H., Fujiwara, T., Matsukawa, K., Funamizu, N.: Nitrous oxide emission mechanisms during intermittently aerated composting of cattle manure. Bioresour. Technol. 141, 205–211 (2013)

Chowdhury, M.A., de Neergaard, A., Jensen, L.S.: Potential of aeration flow rate and bio-char addition to reduce greenhouse gas and ammonia emissions during manure composting. Chemosphere 97, 16–25 (2014)

Prasai, T.P., Walsh, K.B., Midmore, D.J., Jones, B.E.H., Bhatttarai, S.P.: Munure from biochar, bentonite and zeolite feed supplemented poultry: moisture retention and granulation properties. J. Environ. Manag. 216, 82–88 (2018)

Awasthi, M.K., Wang, Q., Huang, H., Ren, X., Lahori, A.H., Mahar, A., Ali, A., Shen, F., Li, R., Zhang, Z.: Influence of zeolite and lime as additives on greenhouse gas emissions and maturity evolution during sewage sludge composting. Bioresour. Technol. 216, 172–181 (2016)

Bernal, M.P., Alburquerque, J.A., Moral, R.: Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour. Technol. 100, 5444–5453 (2009)

Bohacz, J.: Changes in mineral forms of nitrogen and sulfur and enzymatic activities during composting of lignocellulosic waste and chicken feathers. Environ. Sci. Pollut. Res. 26, 10333–10342 (2019)

Zhang, L., Sun, X.: Effects of earthworm casts and zeolite on the two-stage composting of green waste. Waste Manag. 39, 119–129 (2015)

Waqas, M., Nizami, A.S., Aburiazaiza, A.S., Barakat, M.A., Rashid, M.I., Ismail, I.M.I.: Optimizing the process of food waste compost and valorizing its applications: a case study of Saudi Arabia. J. Clean. Prod. 176, 426–438 (2018)

Awasthi, M.K., Wang, Q., Ren, X., Zhao, J., Huang, H., Awasthi, S.K., Lahori, A.H., Li, R., Zhou, L., Zhang, Z.: Role of biochar amendment in mitigation of nitrogen loss and greenhouse gas emission during sewage sludge composting. Bioresour. Technol. 219, 270–280 (2016)

Walkley, A., Black, A.: An examination of the Degtjareff method for determining soil organic matter and a proposed modification of the chromic acid titration method. Soil Sci. 37, 29–38 (1934)

Baethgen, W.E., Alley, M.M.: A manual colorimetric procedure for measuring ammonium nitrogen in soil and plant Kjeldahl digests. Commun. Soil Sci. Plant Anal. 20, 961–969 (1989)

Phosphorus, K.S.: In: Sparks, R.L. (ed.) Methods of Soil Analysis, Part 3, Chemical Methods. SSSA Book Series Number 5, pp. 869–919. Soil Science Society of America, Madison (1996)

Baggie, I., Rowell, D.L., Robinson, J.S., Warren, G.P.: Decomposition and phosphorus release from organic residues as affected by residue quality and added inorganic phosphorus. Agrofor. Syst. 63, 125–131 (2004)

Jones, J.B.: Laboratory Guide for Conducting Soil Tests and Plant Analysis. CRC Press, Boca Raton (2001)

Wang, Q., Awasthi, M.K., Ren, X., Zhao, J., Li, R., Wang, Z., Wang, M., Chen, H., Zhang, Z.: Combining biochar, zeolite and wood vinegar for composting of pig manure: the effect on greenhouse gas emission and nitrogen conservation. Waste Manag. 74, 221–230 (2018)

Bargougui, L., Guergueb, Z., Chaieb, M., Mekki, A.: Co-composting of olive industry wastes with poultry manure and evaluation of the obtained compost maturity. Waste Biomass Valoriz. 11, 6235–6247 (2020)

Meng, X., Yan, J., Zuo, B., Wang, Y., Cui, Z.: Full-scale of composting process of biogas residues from corn stover anaerobic digestion: physical-chemical, biology parameters and maturity indexes during whole process. Bioresour. Technol. 302, 122742 (2020)

Barrington, S., Choinière, D., Trigui, M., Knight, W.: Effect of carbon source on compost nitrogen and carbon losses. Bioresour. Technol. 83(3), 189–194 (2002)

Sun, Y., Qu, J., Li, R., Li, W., Wang, Z., Chu, X.: Optimization of the enzyme production conditions of Bacillus licheniformis and its effect on the degradation of corn straw. J. Biobased Mater. Bioenergy 12(5), 432–440 (2018)

Han, M.Y., Zhang, L.X., Fan, C.H., Liu, L.H., Zhang, L.S., Li, B.Z., Alva, A.K.: Release of nitrogen, phosphorus, and potassium during the decomposition of apple (Malus domestica) leaf litter under different fertilization regimes in Loess Plateau, China. Soil Sci. Plant Nutr. 57, 549–557 (2011)

Zainudin, M.H., Mustapha, N.A., Maeda, T., Ramli, N., Hassan, M.: Biochar enhanced the nitrifying and denitrifying bacterial communities during the composting of poultry manure and rice straw. Waste Manag. 106, 240–249 (2020)

Zhou, S., Wen, X., Cao, Z., Cheng, R., Qian, Y., Mi, J., Wang, Y., Liao, X., Ma, B., Zou, Y.: Modified corn stalk biochar can reduce ammonia emissions from compost by increasing the number of ammonia-oxidizing bacteria and decreasing urease activity. Bioresour. Technol. 319, 124120 (2021)

Jalali, M., Ranjbar, F.: Rates of decomposition and phosphorus release from organic residues related to residue composition. J. Plant Nutr. Soil Sci. 172, 353–359 (2009)

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

SM: software, formal analysis, visualization, and interpretation of data, FR: conceptualization, methodology, validation, software, investigation, supervision, interpretation of data, and writing original draft, AB-A: conceptualization, methodology, validation, investigation, supervision, and project administration, RS: conceptualization, methodology, and validation. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interest

The authors declare they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Maleki, S., Ranjbar, F., Beheshti-Alagha, A. et al. Release Kinetics of Carbon, Nitrogen, Phosphorus, and Potassium During Co-composting of Poultry Manure Mixed with Different Ratios of Wheat Straw and Zeolite. Waste Biomass Valor 14, 57–68 (2023). https://doi.org/10.1007/s12649-022-01852-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01852-4