Abstract

In order to improve the efficiency of anaerobic digestion of long sludge retention time (SRT) sludge and seek a suitable disposal method for the massive plants harvested from constructed wetlands, we prepared Calamus-derived biochar (Calamus-BC) and added it to thermophilic anaerobic digestion (TAD) system of long SRT sludge. Moreover, the effect of Calamus-BC supplemental level (0, 5, 10, 15, 20 g/L) on TAD was explored through a series of batch experiments. Results showed that Calamus-BC addition can increase the conductivity and pH in TAD of long-SRT sludge obviously, thereby promoting methane production, reducing total VFAs accumulation and shortening the lag phases. When the Calamus-BC dosage was 15 g/L, the cumulative CH4 yield reached the highest 246.73 mL/g VS, which was 43.4% higher than the control group. Furthermore, it proved the modified Gompertz model was suitable for the actual evolution of CH4 production in TAD of long-SRT sludge. This study provided an alternative for efficient biomass stabilization and bioenergy recovery from long-SRT sludge and supplied a feasible resourceful approach for massive Calamus from constructed wetlands in water rehabilitation engineering.

Graphical Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

This study is the first time to propose an economical and efficient additive that can improve the efficiency and stability in TAD of long-SRT sludge. The results could supply useful information for treating long-SRT sludge from BNR process and massive Calamus from constructed wetlands.

Introduction

Biological nutrient removal (BNR) processes are widely used in wastewater treatment plants to meet the stringent limits of N and P discharges in China. However, compared with the conventional waste sludge, the waste sludge from BNR is an organic matter that is difficult to degrade and usually has a long sludge retention time (SRT) and high contents of N and P due to the long generation cycle of nitrifying bacteria [1]. In addition, the increased amount of municipal wastewater often leads to a gradual increase in the output of waste sludge from wastewater treatment plants. In brief, the properties of the waste activated sludge (WAS) from the BNR process are significantly different from those produced from the traditional activated sludge process, and the waste sludge output of BNR increases with the urban sewage quantity. Therefore, it is necessary to find a suitable treatment method for the WAS produced from BNR process.

Anaerobic digestion (AD) has been applied as an important technology globally for sludge reduction, stabilization, and resource utilization [2,3,4], which can be operated at mesophilic (35 °C) and thermophilic (55 °C) temperatures on the basis of methanogenic bacteria requirements [5]. Although mesophilic AD (MAD) of WAS is applied widely because of its good stability, the biogas production effect of MAD is not ideal due to the complex structure, strong rigidity and slow dissolution and hydrolysis process of sludge flocs [6]. Therefore, to facilitate the disintegration of WAS, a lot of pretreatment technologies have been widely studied such as alkaline, thermal, ultrasonic, enzymatic and their combinations [7]. Considering the huge energy consumption and economic cost, pretreatment is not always suitable in sludge anaerobic digestion. Compared with MAD, thermophilic AD (TAD) has higher energy consumption and poorer stability, but it is considered to have a great application prospect because of its rapid hydrolysis rate, high gas production potential and high pathogen removal rate [8]. However, the research and the application on the TAD of WAS are lacking at present [9]. Therefore, it is necessary to study the stability of TAD of WAS to promote the practical application.

Acidification is one of the major factors for the poor stability of TAD [10]. The fermentation rates enhanced by TAD usually cause the accumulation of volatile fatty acids (VFAs), which further leads to digester failure through inhibiting the methanogenic activity due to decreased pH [11]. For instance, Shi et al. [12] have found a fivefold higher accumulation of total VFAs in the TAD compared with those in the MAD. On the other side, ammonia nitrogen is another major factor for TAD. Total ammonia nitrogen (TAN) exists as ammonium ions and free ammonia nitrogen (FAN), and FAN is the main toxic form, which can diffuse passively into microbial cells and cause proton imbalance [13]. FAN concentration is affected by pH, T, and equilibrium reactions as Eq. 1 [14].

where T (K) refers to the Kelvin temperature. From the above formula, it is easy seen that higher pH would result in a higher concentration of FAN. In addition, the operation of digesters at elevated temperature would increases the negative effect of FAN. Therefore, the FAN concentration is another factor for the poor stability of the TAD [15, 16]. To resolve these problems, a variety of strategies that improve the stability of TAD are conducted, including domestication of resilient thermophilic microbiome, co-digestion with complementary substrates, microbial batteries, and application of conductive materials within TAD systems [17].

The direct interspecies electron transfer (DIET) is a recently discovered form of interspecies electron transfer, wherein the bacteria transfer electrons directly to methanogens without reliance on metabolites (e.g., H2) [18]. The addition of conductive materials, such as active carbon, can enhance methanogenesis by promoting the DIET among bacteria and methanogens [19]. Moreover, active carbon can adsorb the inhibitory compounds during the anaerobic digestion process, which leads to the enhanced stability of anaerobic digestion [20]. It is well known that TAD is more unstable and easily accumulates the inhibitory compounds compared with MAD. However, most of the studies on the conductive materials addition are focused on the MAD, whereas very limited information is available on the effects of conductive material addition on TAD [21,22,23].

As an economical and efficient carbon material, biochar has been reported that can improve microbial activities and the system biostability in the AD process due to the porous surface [24]. In addition, biochar was also proved to promote DIET by acting as an electronic conductor to metabolize ethanol during AD process [25]. Shen et al. [26] had observed that the biochar promoted the biostability of the AD process and enhanced the utilization of the digestion residues as soil amendment, which elevated the feasibility of biochar in AD processes. However, the effect of biochar made from waste Calamus in of constructed wetlands on sludge TAD is not clear. The constructed wetland is a cheap and widely applied facility in the rehabilitation of polluted water bodies, but it unavoidably produces a great deal of plants during water purification (such as Calamus and Phragmites communis etc.). These plants must be harvested to ensure the normal and stable operation of the constructed wetland when they are aged and withered regularly with the change of seasons. Thus, the produced plants cover a lot of land and increase the disposal costs of municipal solids [27]. Being the most popular plant in worldwide constructed wetlands, Calamus disposal becomes an important issue in the application of constructed wetlands.

This study aims to investigate the characterization of biochar derived from Calamus and explore the effects of Calamus-derived biochar (Calamus-BC) addition on the TAD of long-SRT sludge. Furthermore, the performance of the TAD reactor is evaluated in accordance with the production of CH4, TAN, and VFAs at various concentrations of Calamus-BC. This study could supply an important strategy for the stable operation of long-SRT sludge TAD system and offer a low-cost alternative for the resource utilization of wetland plants.

Materials and Methods

Substrates and Inoculum

The dewatered activated sludge (DWAS) used in this study was collected from the sludge dewatering workshop of the third wastewater treatment plant of Xi’an, China, which adopted an orbal oxidation ditch craft to treat municipal wastewater of 200 000 m3/day. The sludge is retented in the orbal oxidation ditch craft for 18–20 days, which led the waste sludge to be a typical long-SRT. The collected DWAS was stored at 4 °C before use, and its solid content was adjusted to 8% by using pure water when need to use as the substrate for this test. The inoculation sludge was collected from a laboratory-scale anaerobic reactor (35 °C) and domesticated for some time. The physicochemical properties of the DWAS and inoculation sludge are listed in Table 1.

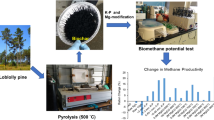

Preparation and Characterization of Calamus-BC

The Calamus stem collected from a constructed wetland of Xi’an was heated at 105 °C for 24 h to completely remove H2O, ground into a fine powder, and sieved using 100 mesh in this study. The biomass was filled in a porcelain crucible, compacted and covered tightly, then pyrolyzed in a muffle furnace at a heating rate of 20 °C/min to a final temperature of 600 °C for 2 h according to our optimum experiment previously. All biochar samples were stored in sealing bags before use.

The pH level of Calamus-BC was determined using a portable pH meter (PHS-3C) at a Calamus-BC to H2O ratio of 1:20. The surface morphology of the Calamus-BC was observed using a scanning electron microscope (SEM, JSM-6510LV). The total surface area, pore size distribution, and pore volume of Calamus-BC were measured using the BET surface analyzer (V-Sorb 2800P).

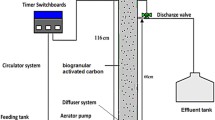

TAD of WAS

Batch experiments were conducted in a series of serum bottles, including the total volume of 100 mL with the working volume of 60 mL, and the total volume of 250 mL with the working volume of 200 mL. The serum bottles of 100 mL were used for the biogas sample collection, and the serum bottles of 250 mL were used to collect the liquid samples for hydrolysis analysis. The inoculum–DWAS ratio used in the test was set to 20% (based on volatile solid). The series of experiments were set as BC0, BC5, BC10, BC15, and BC20 (setting three replicates), where BC0 represented the control group, and BC5, BC10, BC15, and BC20 represented the Calamus-BC concentrations of 5.0, 10.0, 15.0, and 20.0 g/L, respectively. All bottles were flushed with N2 for 5 min to maintain anaerobic conditions and placed in a shaking water bath maintained at 52 °C and 140 r/min for TAD. Blank experiments with inoculum only were performed to remove the biogas produced from the inoculation sludge. The properties of each group of mixture at the beginning of the TAD are listed in Table 2.

Sample and Analytical Methods

The biogas production was determined daily by using a calibrated glass syringe. Biogas was collected once every five days, and its composition was analyzed by withdrawing a 300 μL sample using an Agilent syringe, then injecting it into a gas chromatograph (Agilent6890N, TCD) with a packed column (Agilent packed TDX-01). Argon was used as the carrier gas at a flow rate of 25 mL/min. The oven, column and detector temperature were 70, 100 and 170 °C, respectively. Liquid samples (10 mL) were collected from the serum bottle once every five days for determination. The pH was determined using a portable pH meter (PHS-3C). In addition, TS and VS were determined via the weight method. The TAN, soluble chemical oxygen demand (SCOD) and chemical oxygen demand (COD) were determined using standard methods (APHA, 1998). The samples were centrifuged at the relative centrifugal force of 8944 g for 10 min and passed through a cellulose acetate filter with pore size of 0.22 µm. The VFAs, including acetate, propionate, butyrate, and valerate, were analyzed using the GC (Agilent6890N, FID) equipped with a capillary column (PE WAX 30 m × 250 μm × 0.25 μm). Nitrogen was used as the carrier gas at a flow rate of 7.4 mL/min. The initial temperature for the oven, column and detector were 70, 220 and 300 °C and final temperature were 200, 220 and 300 °C, respectively.

Processing Parameters and Analysis

The modified Gompertz model (Eq. 2) was applied to determine the lag phase time (λ) and the maximum production potential (P0). The time to produce 90% of CH4 yield (T90) and the time for effective CH4 production (Tef) [28] could be using Eqs. 3 and 4, respectively. Equation 1 was used to calculate the concentration of the FAN in accordance with the actual pH and temperature.

where P (L/kgVSadded) is the cumulative CH4 yield at time t, e is exp (1) = 2.71828, Rmax (L/kgVSadded/day) is the maximum specific CH4 production rate, P0 (L/kgVSadded) is the CH4 production potential, and λ (day) is the lag phase time. The parameters in this equation (P0, Rmax, and λ) are estimated using the nonlinear fitting of Origin 2017.

Results and Discussion

Characterization of Calamus-BC

Figure 1 shows the SEM images of Calamus-BC, and Table S1 shows some parameters of Calamus-BC. Various micropores were connected to some narrow channels on the surface of Calamus-BC. The average pore size, total pore volume, and specific surface area (SBET) of Calamus-BC were 153.9 nm, 0.68 cm3/g, and 15.2 m2/g, respectively. Xiong et al. [29] have reported that the biochar made from rice straw and rice husk have an SBET of 61.681 and 41.512 m2/g, respectively; total pore volume of 0.025 and 0.019 cm3/g, respectively; and average pore size of 19.335 and 19.306 nm, respectively, under the same production conditions (pyrolysis at 600 °C for 2 h and sieving at 100 mesh). Thus, the Calamus-BC has smaller SBET and a larger average pore size and total pore volume than the biochar made from rice straw and rice husk. Luo et al. [30] have reported that the physical characteristics of biochar especially porous structure can enhance the microbial activity and improve the resistance to various inhibitors by promoting the biofilm formation. At the same time, the porous structure promoted the methanation process due to acceleration of the DIET between bacteria and methanogens [31]. Therefore, the Calamus-BC could promote the CH4 production process in TAD due to its porous structure.

Effects of Calamus-BC Dosage on the CH 4 Production in TAD

The batch experiment of 25 days was conducted. The daily biogas production rates of the test groups with Calamus-BC addition were evidently higher than that of the control group, and the biogas production rate increased with the increasing Calamus-BC dosage from day 1 to day 8 (Fig. S1). This finding might be ascribed to that the Calamus-BC increased the conductivity of the mixture (Table 2) and promoted the DIET process, thereby accelerating the biogas production rate. However, no significant difference was observed in the biogas production rate among the groups after eight days. The daily biogas production rate of BC15 was the highest among the four dosages and increased by 51.3% compared with the control group. Remarkably, the daily biogas production rate of the control group was higher than that of the test group on days 4, 8, and 11, which might be ascribed to that the test group had begun to decrease when the biogas production rate of the control group increased. These results indicated that the addition of Calamus-BC to TAD of long-SRT sludge led to an enhancement of CH4 production rate but also caused the fluctuations of the CH4 production in the initial stage of TAD.

The average contents of CH4, CO2, H2, and N2 in the total biogas volume during the whole experiment are shown in Table 3. The content of CH4 in the biogas of BC5, BC10, and BC15 was 64%, whereas those of the BC0 and BC20 were 61% and 67%, respectively. The contents of CO2 and N2 in the biogas were 31–36% and 2–3%, respectively, but H2 was not detected in all groups. Compared with that of the control group, the CH4 content in the biogas of the BC20 group increased from 61 to 67%, and the CO2 content decreased from 36 to 31%. There4fore, the addition of Calamus-BC increased the CH4 content but reduced the CO2 content, which might be attributed to the alkalinity of the biochar can convert CO2 to HCO3− or CO32−. This phenomenon increased the pH and promoted the CH4 production [32].

Biochemical Methane Potential (BMP) Analysis

Based on the test results and the modified Gompertz model, the CH4 production modeling was conducted (Fig. 2). The cumulative CH4 production of the test group with the Calamus-BC addition was significantly higher than that of the control group (Table 3).

The kinetic parameters obtained using the nonlinear curve fit through the Gompertz model are listed in Table 4. The test group had significantly higher Rmax (mLCH4/ gVS/day) and P0 (mLCH4/gVS) than the control group. Compared with those in the control, Rmax and P0 were enhanced by 29.92% and 22.9%, respectively, in the BC5; 44.56% and 25.12%, respectively, in BC10; 63.91% and 36.83%, respectively, in BC15; and 76.08% and 61.48%, respectively, in BC20. The λ of the test groups was significantly lower than that of the control group. In addition, the T90 and the Tef decreased with increasing Calamus-BC dosage, indicating that the high Calamus-BC dosage shortened the retention time of sludge digestion efficiently.

Therefore, adding Calamus-BC to TAD system of the long-SRT sludge increased P0 and Rmax and effectively shortened λ of TAD. Shen et al. have reported that the addition of biochar enhances Rmax and P0 [33]. Jang et al. [34] have also found that λ in MAD and TAD of animal manure decreases by 26.9% and 24.4%, respectively, when 10 g/L biochar is added. This study showed that the proper addition of Calamus-BC (15 g/L) increased the CH4 production. The excess addition of Calamus-BC might negatively affect the production of biogas and CH4 in TAD.

Effects of Calamus-BC on the stability of TAD

The changes in SCOD and TVFAs concentration in the liquid phase during TAD are shown in Fig. 3. The changes in SCOD concentration in all groups increased rapidly at the beginning and then gradually decreased until the final increase after 20 days. On day 10, the differences in SCOD concentration of each group were evident, and a negative correlation was observed between SCOD concentration and the Calamus-BC dosage (R2 = 0.9363). This result could be ascribed to that Calamus-BC promoted the CH4 production process and reduced the SCOD concentration, and these findings were consistent with the previous results of the daily biogas production rate. In addition, the Calamus-BC reduced the SCOD concentration through adsorption due to its porous structure and large SBET, as Siddique and Wahid [35] reported. Moreover, during days 10 to 20, the SCOD concentrations of BC10, BC15, and BC20 were significantly lower than those of BC0 and BC5, indicating that the adsorption and the degradation of SCOD were more evident when the Calamus-BC dosage reached a certain concentration.

As the important intermediates in TAD, the TVFA concentration represented the acidification stage of the sludge, which usually accounted for about 50% of the SCOD concentration [36]. Figure 3b shows that the TVFA concentration in the control group is higher than those of the Calamus-BC addition during the TAD process. The results showed that the substrate was difficult to digest without biochar and the addition of biochar could avoid acidification and improve the stability of TAD, which were consistent with the results of Shen et al. [37].

Figure 4 illustrates the evolution of different VFAs (i.e., acetate, propionate, butyrate, isobutyrate, valerate, and isovalerate) under different Calamus-BC dosages during TAD. The main components of VFAs were acetate, propionate, and isovalerate in the early stage of TAD (days 1–10) in all groups. However, the VFAs except for acetate and propionate were degraded almost completely after 20 days. Acetate is the main component of the VFAs and an important intermediate of the CH4 production process. The peak concentrations of acetate negatively correlated with the dosage of Calamus-BC (R2 = 0.9747), indicating that Calamus-BC promoted the degradation of acetate to produce CH4. The propionate is the most difficult intermediate to be degraded in the AD process. On the 15th day of TAD, the concentrations of propionate were 1417.94 (BC0), 547.28 (BC5), 48.08 (BC10), 0.00 (BC15), and 15.0 (BC20) mg/L. It is worth noting that the contents of acetate and propionate in BC0 and BC5 were higher than those in other groups. These results indicated that the long-SRT sludge is difficult to be digested, but the addition of a certain amount of Calamus-BC (≥ 10 g/L) can promote substrate degradation in a relatively short time. Similarly, Watanabe et al. [38] found that the propionate accumulation in the control group was earlier than that in the test group with biochar, and Giwa et al. [39] also believed that biochar accelerated the degradation of acetate and propionate during AD.

The changes in butyrate, isobutyrate, valerate, and isovalerate (Fig. 4c–f) in the test groups with Calamus-BC addition were reduced and degraded completely at the end of the TAD. The concentrations of butyrate and isobutyrate in the test groups were low throughout the AD process and significantly different from those in the control group, indicating that Calamus-BC evidently promoted the degradation of butyrate (> 93.47%) and isobutyrate (> 75.47%).

Figure 5 shows the changes in pH, TAN, and FAN in the liquid phase during the TAD process. The pH is affected by many factors, such as temperature, alkalinity, VFAs, and NH3 concentration [40]. After 5th days of AD, the pH value of each test group remained in the slightly alkaline range (8.10–8.40), which was significantly higher than that of the control group. because of the alkalinity of Calamus-BC. Wang et al. [32] reported that the alkalinity of biochar increased the pH of TAD systems by promoting the conversion of CO2 to HCO3−, or CO32−, reducing the VFA accumulation and improving the reactor stability.

Except for VFAs, TAN is another typical inhibitor to anaerobic digestion inhibitor, the inhibitory concentration of TAN ranges from 1500 to 7000 mg/L [41]. As shown in Fig. 5b, the change trends of TAN in all groups are similar. The final TAN concentrations were 2320.79 (BC0), 2309.79 (BC5), 2353.79 (BC10), 2548.28 (BC15), and 2430.78 (BC20) mg/L, indicating that the addition of Calamus-BC had no significant effect on TAN in TAD of the long-SRT sludge. Figure 5c shows the change trends of FAN concentration along the TAD process. The FAN concentrations in the test groups were significantly higher than those in the control group, which were 774.90 (BC0), 1022.60 (BC5), 936.52 (BC10), 1116.34 (BC15), and 1131.66 (BC20) mg/L at the end of the TAD, indicating that the decrease in the CH4 production in BC20 might be caused by the FAN inhibition (Fig. 2). This result showed that the CH4 production in TAD of sludge was inhibited by the accumulation of FAN especially the TAD with excess Calamus-BC.

Conclusion

Calamus-BC addition enhanced CH4 production and yield through the increased conductivity and pH in TAD of long-SRT sludge. The optimal dosage was 15 g Calamus-BC/L, which increased which increased 43.4% of cumulative CH4 production, while reduced 0.6 days of the lag phases compared with the control group. The control system was not capable of fully removing short VFA, which made WAS indigestible, but the addition of Calamus-BC effectively reduced the accumulation of VFA and promote DIET process in TAD. However, the synergistic reaction of long-SRT sludge and Calamus-BC addition might lead to a high FAN concentration, which may have a negative effect on the CH4 production process. Hence, the appropriate dosage of Calamus-BC is crucial. This study showed that biochar made from wetland plants represented by Calamus can effectively promote the anaerobic digestion of sludge and achieve the purpose of treating waste with waste.

Data Availability

Data for this study are available.

References

Liu, H., Leng, F., Chen, P., Kueppers, S.: Pollutant removal characteristics of a two-influent-line BNR process performing denitrifying phosphorus removal: role of sludge recycling ratios. Water Sci. Technol. 74(10), 2474–2482 (2016). (In Shanghai, China). https://doi.org/10.2166/wst.2016.438

Guang, Y., Guangming, Z., Hongchen, W.: Current state of sludge production, management, treatment and disposal in China. Water Res. 78, 60–73 (2015). https://doi.org/10.1016/j.watres.2015.04.002

Atelge, M.R., Krisa, D., Kumar, G., Eskicioglu, C., Nguyen, D.D., Chang, S.W., Atabani, A.E., Al-Muhtaseb, A.H., Unalan, S.: Biogas production from organic waste: recent progress and perspectives. Waste Biomass Valoriz. 11, 1019–1040 (2020). https://doi.org/10.1007/s12649-018-00546-0

Lafratta, M., Thorpe, R.B., Ouki, S.K., Shana, A., Germain, E., Willcocks, M., Jacquetta, L.: Demand-driven biogas production from anaerobic digestion of sewage sludge: application in demonstration scale. Waste Biomass Valoriz. 12, 6767–6780 (2021). https://doi.org/10.1007/s12649-021-01452-8

Bi, S., Qiao, W., Xiong, L., Ricci, M., Adani, F., Dong, R.: Effects of organic loading rate on anaerobic digestion of chicken manure under mesophilic and thermophilic conditions. Renew. Energy. 139, 242–250 (2019). https://doi.org/10.1016/j.renene.2019.02.083

Li, J., Hao, X., Loosdrecht, M.V., Luo, Y., Cao, D.: Effect of humic acids on batch anaerobic digestion of excess sludge. Water Res. 155, 431–443 (2019). https://doi.org/10.1016/j.watres.2018.12.009

Junior, I.V., Almeida, R.D., Cammarota, M.C.: A review of sludge pretreatment methods and co-digestion to boost biogas production and energy self-sufficiency in wastewater treatment plants. J. Water Process. Eng. 40, 101857 (2020). https://doi.org/10.1016/J.JWPE.2020.101857

Yang, L., Huang, Y., Zhao, M., Huang, Z., Miao, H., Xu, Z., Ruan, W.: Enhancing biogas generation performance from food wastes by high-solids thermophilic anaerobic digestion: effect of pH adjustment. Int. Biodeterior. Biodegrad. 105, 153–159 (2015). https://doi.org/10.1016/j.ibiod.2015.09.005

Mao, C., Feng, Y., Wang, X., Pinjing, H.: Review on research achievements of biogas from anaerobic digestion. Renew. Sust. Energ. Rev. 45, 540–555 (2015). https://doi.org/10.1016/j.rser.2015.02.032

Yeniguen, O., Demirel, B.: Ammonia inhibition in anaerobic digestion: a review. Process. Biochem. 48(5–6), 901–911 (2013). https://doi.org/10.1016/j.procbio.2013.04.012

Beevi, B.S., Madhu, G., Sahoo, D.K.: Performance and kinetic study of semi-dry thermophilic anaerobic digestion of organic fraction of municipal solid waste. Waste Manage. 36, 93–97 (2015). https://doi.org/10.1016/j.wasman.2014.09.024

Shi, J., Wang, Z., Stiverson, J.A., Zhongtang, Y., Yebo, L.: Reactor performance and microbial community dynamics during solid-state anaerobic digestion of corn stover at mesophilic and thermophilic conditions. Bioresour. Technol. 136, 574–581 (2013). https://doi.org/10.1016/j.biortech.2013.02.073

Altinbas, M., Cicek, O.A.: Anaerobic co-digestion of chicken and cattle manures: free ammonia inhibition. Energy Sources 41(7–12), 1097–1109 (2019). https://doi.org/10.1080/15567036.2018.1539143

Yang, Z., Wang, W., He, Y., Zhang, R., Liu, G.: Effect of ammonia on methane production, methanogenesis pathway, microbial community and reactor performance under mesophilic and thermophilic conditio-ns. Renew. Energy 125, 915–925 (2018). https://doi.org/10.1016/j.renene.2018.03.032

Nakashimada, Y., Ohshima, Y., Minami, H., Yabu, H., Nishio, N.N.: Ammonia–methane two-stage anaerobic digestion of dehydrated waste-activated sludge. Appl. Microbiol. Biotechnol. 79, 1061–1069 (2008). https://doi.org/10.1007/s00253-008-1501-7

Moestedt, J., Müller, B., Westerholm, M., Anna, S.: Ammonia threshold for inhibition of anaerobic digestion of thin stillage and the importance of organic loading rate. Microb. Biotechnol. 9(2), 180–194 (2016). https://doi.org/10.1111/1751-7915.12330

Ryue, J., Lin, L., Kakar, F.L., Elbeshbishy, E., Al-Mamun, A., Dhar, B.R.: A critical review of conventional and emerging methods for improving process stability in thermophilic anaerobic digestion. Energy. Sustain. Dev. 54, 72–84 (2020). https://doi.org/10.1016/j.esd.2019.11.001

Masahiko, M., Malvankar, N.S., Franks, A.E., Summers, Z.M., Lovley, D.R.: Potential for direct interspecies electron transfer in methanogenic wastewater digester aggregates. MBio 2(4), e00159 (2011). https://doi.org/10.1128/mBio.00159-11

Zhao, Z., Zhang, Y., Yu, Q., Dang, Y., Li, Y., Quan, X.: Communities stimulated with ethanol to perform direct interspecies electron transfer for syntrophic metabolism of propionate and butyrate. Water Res. 102, 475–484 (2016). https://doi.org/10.1016/j.watres.2016.07.005

Fagbohungbe, M.O., Herbert, B.M.J., Hurst, L., Ibeto, C.N., Semple, K.T.: The challenges of anaerobic digestion and the role of biochar in optimizing anaerobic digestion. Waste Manage. 61, 236–249 (2017). https://doi.org/10.1016/j.wasman.2016.11.028

Lei, Y., Wei, L., Liu, T., Xiao, Y., Dang, Y., Sun, D., Holmes, D.E.: Magnetite enhances anaerobic digestion and methanogenesis of fresh leachate from a municipal solid waste incineration plant. Chem. Eng. J. 348, 992–999 (2018). https://doi.org/10.1016/j.cej.2018.05.060

Zhao, Z., Zhang, Y., Li, Y., Dang, Y., Zhu, T., Quan, X.: Potentially shifting from interspecies hydrogen transfer to direct interspecies electron transfer for syntrophic metabolism to resist acidic impact with conductive carbon cloth. Chem. Eng. J. 313, 10–18 (2017). https://doi.org/10.1016/j.cej.2016.11.149

González, J., Sánchez, M., Gómez, X.: Enhancing anaerobic digestion: the effect of carbon conductive materials. C J. Carbon Res. 4(59), 1–19 (2018). https://doi.org/10.3390/c4040059

Fagbohungbe, M.O., Herbert, B.M.J., Hurst, L., Ibeto, C.N., Li, H., Usmani, S.Q., Semple, K.T.: The challenges of anaerobic digestion and the role of biochar in optimizing anaerobic digestion. Waste Manage. 61, 236–249 (2017). https://doi.org/10.1016/j.wasman.2016.11.028

Xu, H., Chang, J., Wang, H., Liu, Y., Zhang, X., Liang, Y., Huang, X.: Enhancing direct interspecies electron transfer in syntrophic-methanogenic associations with (semi) conductive iron oxides: effects and mechanisms. Sci. Total Environ. 695, 133876 (2019). https://doi.org/10.1016/j.scitotenv.2019.133876

Shen, Y., Linville, J.L., Leon, I.D., Schoene, R.P., Urgun-Demirtas, M.: Towards a sustainable paradigm of waste-to-energy process: enhanced anaerobic digestion of sludge with woody biochar. J. Clean. Prod. 135, 1054–1064 (2016). https://doi.org/10.1016/j.jclepro.2016.06.144

Zhang, H., Tang, W., Wang, W., Yin, W., Zha, J.: A review on China’s constructed wetlands in recent three decades: application and practice. J. Environ. Sci. 104(6), 53–68 (2020). https://doi.org/10.1016/j.jes.2020.11.032

Andriamanohiarisoamanana, F.J., Saikawa, A., Tarukawa, K., Qi, G., Pan, Z., Yamashiro, T., Iwasaki, M., Ihara, I., Nishida, T., Umetsu, K.: Anaerobic co-digestion of dairy manure, meat and bone meal, and crude glycerol under mesophilic conditions: synergistic effect and kinetic studies. Energy Sustain. Dev. 40, 11–18 (2017). https://doi.org/10.1016/j.esd.2017.05.008

Xiong, S., Deng, Y., Tang, R., Zhang, C., Zheng, J., Zhang, Y., Su, L., Yang, L., Liao, C., Gong, D.: Factors study for the removal of epoxiconazole in water by common biochars. Biochem. Eng. J. 161, 107690 (2020). https://doi.org/10.1016/j.bej.2020.107690

Luo, C., Lü, F., Shao, L., He, P.: Application of eco-compatible biochar in anaerobic digestion to relieve acid stress and promote the selective colonization of functional microbes. Water Res. 68, 710–718 (2015). https://doi.org/10.1016/j.watres.2014.10.052

Zhao, Z., Zhang, Y., Holmes, D.E., Dang, Y., Woodard, T.L., Nevin, K.P., Lovley, D.R.: Potential enhancement of direct interspecies electron transfer for syntrophic metabolism of propionate and butyrate with biochar in up-flow anaerobic sludge blanket reactors. Bioresour. Technol. 209, 148–156 (2016). https://doi.org/10.1016/j.biortech.2016.03.005

Wang, G., Li, Q., Gao, X., Wang, X.: Sawdust-derived biochar much mitigates VFAs accumulation and improves microbial activities to enhance methane production in thermophilic anaerobic digestion. ACS Sustain. Chem. Eng. 7, 2141–2150 (2018). https://doi.org/10.1021/acssuschemeng.8b04789

Shen, Y., Linville, J.L., Urgun-Demirtas, M., Schoene, R.P., Snyder, S.W.: Producing pipeline-quality biomethane via anaerobic digestion of sludge amended with corn stover biochar with in-situ CO2 removal. Appl. Energy 158, 300–309 (2015). https://doi.org/10.1016/j.apenergy.2015.08.016

Jang, H.M., Choi, Y.K., Kan, E.: Effects of dairy manure-derived biochar on psychrophilic, mesophilic and thermophilic anaerobic digestions of dairy manure. Bioresour. Technol. 250, 927–931 (2017). https://doi.org/10.1016/j.biortech.2017.11.074

Siddique, M.N.I., Wahi, Z.A.: Achievements and perspectives of anaerobic co-digestion: a review. J. Clean. Prod. 194, 359–371 (2018). https://doi.org/10.1016/j.jclepro.2018.05.155

Yu, L., Bian, C., Zhu, N., Shen, Y., Yuan, H.: Enhancement of methane production from anaerobic digestion of waste activated sludge with choline supplement. Energy 173, 1021–1029 (2019). https://doi.org/10.1016/j.energy.2019.02.076

Shen, Y., Yu, Y., Zhang, Y., Urgun-Demirtas, M., Yuan, H., Zhu, N., Dai, X.: Role of redoxactive biochar with distinctive electrochemical properties to promote methane production in anaerobic digestion of waste activated sludge—ScienceDirect. J. Clean. Prod. 278, 123212 (2021). https://doi.org/10.1016/j.jclepro.2020.123212

Watanabe, R., Tada, C., Baba, Y., Fukuda, Y., Nakai, Y.: Enhancing methane production during the anaerobic digestion of crude glycerol using Japanese cedar charcoal. Bioresour. Technol. 150, 387–397 (2013). https://doi.org/10.1016/j.biortech.2013.10.030

Giwa, A.S., Xu, H., Chang, F., Wu, J., Li, Y., Ali, N., Ding, S., Wang, K.: Effect of biochar on reactor performance and methane generation during the anaerobic digestion of food waste treatment at long-run operations. J. Environ. Chem. Eng. 7(4), 103067 (2019). https://doi.org/10.1016/j.jece.2019.103067

Ruffino, B., Campo, G., Cerutti, A., Zanetti, M., Lorenzi, E., Scibilia, G., Genon, G.: Preliminary technical and economic analysis of alkali and low temperature thermo-alkali pretreatments for the anaerobic digestion of waste activated sludge. Waste Biomass Valoriz. 7(4), 667–675 (2016). https://doi.org/10.1007/s12649-016-9537-x

Han, B., Butterly, C., Zhang, W., He, J.Z., Chen, D.: Adsorbent materials for ammonium and ammonia removal: a review. J. Clean. Prod. 283(12), 124611 (2020). https://doi.org/10.1016/j.jclepro.2020.124611

Acknowledgements

This work was supported by the science and technology innovation demonstration project of social development of Xi’an Science and Technology Bureau (Grant Number: 20SFSF0011) and Key Research and Development Program of Shaanxi Province (2021ZDLSF05-04)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wang, Y., Wang, Z., Wang, L. et al. Effects of Calamus-Derived Biochar on the Thermophilic Anaerobic Digestion of Long-SRT Waste Activated Sludge from the Municipal Wastewater Treatment Plant. Waste Biomass Valor 13, 2979–2989 (2022). https://doi.org/10.1007/s12649-022-01693-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-022-01693-1