Abstract

The inadequate management of municipal solid waste can cause environmental and health issues, however the predominance of municipal biowaste and food waste make anaerobic digestion (AD) an attractive option for the treatment and recovery of organic matter. From AD two by-products with high potential use are obtained, such as methane gas (present in biogas) and the digestate, whilst the process contributes to a mitigation of the problems generated by final disposal. Nevertheless, the AD process is affected by different factors associated with environmental conditions, the substrate, inoculum and reactor and experimental configuration. This paper presents an analysis and reflection on the effect of the variables associated with these factors from a technological surveillance over the period 2009–2019. Among the most studied variables, are temperature (in the thermophilic and mesophilic ranges), pH, and nutrients, while evaluation on psychrophilic temperature conditions and the head space effect, are less studied. In addition, few studies have evaluated the simultaneous performance of different variables, which is of interest, when considered that their interaction can elucidate elements that lead to a greater approximation between the theoretical and experimental production of methane.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

This article analyse, through a technological surveillance, the different factors and variables that affect anaerobic digestion of municipal biowaste and food waste, which was grouped, identifying the different optimal values for each variable, the most studied variables and those that have not yet had a wide development, and therefore are a research gap, and represent an opportunity for interested researchers in the subject. Likewise, it was identified that there are few studies that make a simultaneous evaluation of the variables, which leads to a lack of understanding of the interaction between them, which would lead to erroneous results.

Introduction

Aspects such as population growth, consumption habits, lifestyle and culture, have led to an increase in the production of municipal solid waste (MSW), a trend predicted to continue, with total production between the period 2014–2050 projected to rise from 1.3 to 3.4 billion tons. Worldwide, final disposal is the predominant form of MSW management, being landfill responsible for approximately 5% of all greenhouse gas (GHG) emissions [1, 2] and carrying to the generation of large quantities of leachates. Considering both the environmental and health problems associated with final disposal, the treatment of MSW is a problematic situation requiring urgent attention.

In economically developed countries (DCs), biowaste (BW) accounts for approximately 25–28% of total MSW, and in the least economically developed countries (LEDCs) 50–70% [3, 4], of which food waste (FW) represents 20–50% of BW worldwide [5] and 50–70% in LEDCs [6]. Furthermore, Slorach et al. [7] estimated that FW generates 6.7% of annual, global, anthropogenic GHG emissions. BW and FW come from domestic household activities, food processing industries, the hospitality sector, and public places such as cafeterias and restaurants. According to the Food and Agricultural Organization (FAO), approximately one-third of all food (1300 million tons) finishes up as waste each year. In DCs, this wastage mainly occurs at the consumption stage, whilst in LEDCs, FW results from economic and administrative limitations, inappropriate collection and storage techniques [8].

The National Planning Department [9] estimates that in Colombia, from the total food supply of 28.5 million tons per year, 9.76 million tons are wasted, with 64% of these losses attributable to the stages of production, post-harvest, storage and industrial processing. As for FW production per inhabitant, authors such as Magnet [10] point out that it is of the order of 361, 278, 157, 154, 74.7, 63, 51, and 44 kg/year in Australia, the United States, Japan, Germany, the United Kingdom, Colombia, India and China, respectively.

Given its predominantly organic composition, anaerobic digestion (AD) provides a promising treatment for BW and FW. AD is a multistage biological process developed in the absence of molecular oxygen [11, 12] that transforms organic substrates (i.e. carbohydrates, proteins and lipids) into digestate (with high potential for agricultural use [13]), and mainly biogas, with methane as the predominant gas [14]. With global dependence on fossil fuels estimated to exceed 80% of total requirement, the biogas produced from AD offers a versatile, renewable energy source which can be used for both electric power generation and as vehicular fuel [15, 16], thereby contributing to a reduction in the unsustainable reliance upon fossil fuels; particularly important given the depletion of reserves and atmospheric impacts [17, 18]. This is an aspect of great importance in the framework for concepts of the circular and green economies, which are aimed at reducing negative impacts, risks to the environment, GHG emissions and reintroducing waste into productive processes [5].

Hydrolysis is the first stage of the AD process, where extracellular enzymes are excreted by facultative and strict anaerobic microorganisms, in order to transform insoluble organic materials and compounds of high molecular mass into soluble organic materials [19, 20]. This is considered the limiting stage in the degradation of solid waste such as BW and FW, since the decomposition of long-chain carbohydrates such as cellulose, hemicellulose and lignine, predominantly present in these substrates, is slow. This limits the process because methane production does not develop rapidly [14]. Authors such as Li et al. [21], Parra-Orobio et al. [22], Morales-Polo et al. [23], Ohemeng-Ntiamoah and Datta [24] and Mirmohamadsadeghi et al. [5], indicate that variables such as temperature, pH, substrate composition and structure, particle size, substrate/inoculum (S/I) ratio, and the number of stages, among others, are of great influence at this stage.

One of the ways most widely used to evaluate the viability of AD substrates, is through a laboratory scale test known as biochemical methane potential (BMP), which allows quantification of maximum biogas production. The process and the test are both based on aspects specific to the substrate, the inoculum, the method of measurement, biogas composition, and the environmental and operational factors [25,26,27,28,29].

Researchers such as Donoso-Bravo et al. [30], Ariunbaatar et al. [31], Komilis et al. [32] and Tabatabaei et al. [33] have identified the need to further investigate aspects such as: (1) the improvement of substrate conditions, i.e. pH and nutrients; (2) inoculum quality improvement; (3) process kinetics; (4) reactor configuration, and (5) digestate quality, among others. Although there is no methodological consensus regarding the BMP test, papers by Angelidakii et al. [25], Raposo et al. [34], Holliger et al. [28] and Cárdenas-Cleves et al. [29] should be highlighted, because they contribute to establishing the main aspects for consideration, however in most cases only one variable is evaluated. The aim of this article is therefore to use technological surveillance to identify the main incident variables and those which have been the most and least studied, in order so that future work can be orientated in this regard.

Materials and Methods

Considering methodologies such as those used by Aleixandre-Benavent et al. [35] and Gómez-Luna et al. [36] a technological surveillance process consistent with the stages shown in Fig. 1 was carried out.

The observation window established was between 2009 and 2019 and bibliometric tools were used to identify the required information, to process the data by carrying out systematic searches in English and Spanish languages in order to consider both the international (Scopus) and Latin American (SciELO) contexts, and to identify both research, reflection and review articles on anaerobic digestion (AD) studies of BW and FW. The search equations were developed using a combination of keywords (anaerobic digestion, biochemical methane potential, kitchen waste, food waste, influential operating parameters, influencing factors, among others) and boolean operators that allowed the search to be restricted to the topic of interest.

The information found was collected, filtered, and processed using the free software Refviz® which also eliminates duplication. Clusters that grouped themes associated with AD and that presented proximity or similarity between them were formed. This methodology has been applied in other works such as Soto-Paz et al. [37] and Parra-Orobio et al. [38], demonstrating its validity. Due to the number of publications found, articles that had 20 or more citations were selected, and in the case of recent documents, the sections corresponding to the title, summary, keywords, and conclusions were reviewed. In this way, 15 articles were selected for each cluster and in the case of not achieving the required number, existing articles were read, and a complete mandatory reading was done to extract key aspects for the object of study.

Using the aforementioned methodology, the trends and countries which have done the greatest research around the AD substrates of interest (BW and FW) were identified. Once the conformation of the galaxies was completed, a grouping was carried out around the main factors involved in AD, which permitted the identification of thematic groups so that the different variables involved in each factor were established more clearly, their optimal or most commonly used values, and the main treatments applied to the substrate and inoculum to increase methane production, the results of which will be presented in “Trends in research and current status”, “Factors and variables influencing the AD process”.

Finally, a reflection was made with relation to the variables of greatest study and those that have not yet been widely investigated and therefore represent an opportunity for future work, in order to contribute not only to the progress and strengthening of this type of technology, but to also improve AD viability and to present opportunities to scale it for different contexts. Finally, some recommendations are made, with the objective of contributing to the identification of possible interactions between the incidence variables, and comparing the results with theoretical productions, with the aim of contributing to the standardization of the BMP test on which there are currently different experimental variations.

Results and Discussion

Trends in Research and Current Status

Anaerobic digestion is an alternative treatment for the recovery of substrates that seeks to transform waste, mainly into energy in the form of methane biogas. Figure 2 shows the geographical distribution of worldwide intellectual production in the 2009–2019 period, associated with the AD of BW and FW.

Figure 2 shows that DCs have developed and published more studies on the subject, related to the fact that these countries have subsidy policies and incentives which promote the development and acquisition of energy from renewable sources such as BW and FW [39]. It is therefore not surprising that these countries have biogas production plants [39]; in Europe for example, there are more than 120 full-scale plants to treat this type of organic waste and produce energy, with annual capacities exceeding 4 million tons [39]. Globally, the five countries with the highest rates of intellectual production on this subject are China (28.9%), the United States (9.8%), the United Kingdom (6.8%), Italy (5.8%) and India (5.0%). Whilst, in Latin America and the Caribbean, Brazil, Chile, Bolivia and Colombia stand out.

Figure 3 shows the temporal distribution in the percentage of intellectual production between 2009 and 2019, which in accordance with the results obtained by Lin et al. [40] shows that the study of AD with different substrates has been increasing in recent years, probably as a result of the possibility of obtaining not only biogas in the form of methane used as fuel or energy, but other forms of energy such as hydrogen. Furthermore, hydrogen production is also sometimes used as an indicator of reactor stability [41, 42] and the digestate, which is the semi-solid by-product can be used in agriculture to improve soil properties [43].

Another possible explanation for the increase in intellectual production related to AD, is the inclusion of concepts such as the circular economy and green economy, which are closely related to what is intended with this type of technology, specifically the inclusion of waste in value chains, thereby reducing generation and final disposal, contributing to people’s well-being and reducing negative environmental impacts [5]. In addition, laws issued at the local and national level in contexts of European, Asiatics and North America promote this type of technology by prohibiting food waste from being disposed of in landfills and/or incinerated. AD thus minimizes the negative effects of traditional BW management through final disposal; traditional BW management generates environmental and health problems, in addition to depleting and shortening the life of sanitary landfills [44].

It was also found that although there have been efforts to standardize methodologies such as the biochemical methane potential (BMP) is the most widely used test to evaluate the potential production of methane energy from any substrate, but these has not yet been standardized. It therefore presents different experimental and operational configurations, conditions that are subject in most cases to the availability of the economic resources and technological capacity of the research groups or centres where the study is carried out [25, 28, 29, 34].

Authors such as Mirmohamadsadeghi et al. [5], Esposito et al. [26], Lisboa et al. [27], Kondusamy and Kalamdhad [45], and Gallipoli at al. [46] highlight that applications of the BMP test allow: (1) to identify the potential for energy production of a substrate; (2) determine the degradation kinetics, which would allow simulation of the digestion processes and prediction of the behaviour of a scale digester; and (3) to identify and develop indicators to evaluate new substrates and inoculums. Among its limitations, slow degradation stands out, a problem which can be solved by performing strategies such as particle size reduction and substrate pre-treatment [21, 45, 47], in addition to the issue of slow start-up, which may be associated with conditions of lack of adaptation or acclimatization of the inoculum to the substrates [34, 48].

In the following section, the factors, and variables of incidence in the AD process are highlighted.

Factors and Variables Influencing the AD Process

Different factors affect biogas production and the removal efficiency of the AD process. According to classifications made by authors such as Angelidaki et al. [25], Cárdenas-Cleves et al. [29] and, Raposo et al. [34] who categorized the variables for each of the principal factors affecting the AD process, the main factors to include are (1) substrate and environmental, (2) inoculum and (3) reactor design and operation factors.

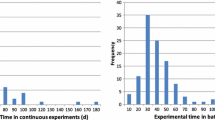

To make AD viable, and a consequence of the sensitivity of the biochemical methane production process, it is necessary to identify the points at which the different variables affect the process, either positively or negatively. Figure 4 shows the different clusters identified and the respective number of articles found for each variable; the clusters are grouped by factor in Fig. 5.

The most evaluated factor is related to experimental configuration, because it has the greatest number of associated variables, although most have not been widely investigated. The most studied aspects include the Organic Load Rate (OLR) and the number of stages involved in the process. Next was substrate and environmental factors, with pre-treatment being the most studied variable. Last is inoculum, which is mainly associated with variables such as the inoculum mixture, substrate inoculum ratio (S/I) and pre-treatment, with the latter being the most studied.

In contrast, among the aspects least studied are head space (2.16%) and retention time (3.03%); similarly, although temperature is a widely studied variable, most studies mainly reference to mesophilic and thermophilic regimes. Additionally, after reviewing the studies and the variables analysed in them, it was found that only 18% of the total studies simultaneously evaluated two or more variables, an analysis that is useful for establishing whether or not there are simultaneous interactions between the different variables [49, 50], determining the optimal points of each and the region in which the variable of interest is maximized. Given the information that can be extracted from them, studies of this type are scarce but nevertheless important.

Next, each of the AD influencing variables with FW is described, and some optimal process ranges are also mentioned. The current state of research on the variables with the highest influence in each of the factors is also analysed.

Substrate

Anaerobic digestion processes developed with BW and FW are prone to inhibition due to the accumulation of volatile fatty acids (VFAs) [18, 51] because one of the characteristics of BW and FW is acidic pH [37, 52]. This parameter, in addition to other variables such as total and bicarbonate alkalinity, which are closely related to pH, must be controlled and monitored, and in turn, this process depends on other aspects or strategies for optimizing the process, such as substrate pre-treatment and nutrient concentration [24]. In the following section, the main variables and aspects associated with this factor are presented.

pH, Alkalinity and Volatile Fatty Acids (VFAs)

These variables are of great importance because they can inhibit the AD process due to VFA accumulation [53]. Hydrolysis and acidogenesis usually develop under pH conditions between 5.5 and 6.5 units [54], while microbial methanogenesis consortia (methanogenic Archaea) require neutral conditions; otherwise, inhibitory processes can occur, generating a low methane yield [55]. Authors such as Mirmohamadsadeghi et al. [5], Cárdenas-Cleves et al. [29] and Yang et al. [53] claim that the optimal operating pH range for the AD process is between 6.0 and 8.0 units.

Alkalinity is closely related to pH and is one of the main control and monitoring variables that can indicate process state [29]. Therefore, Total Alkalinity (TA) and Bicarbonate Alkalinity (BA), and alkalinity indices such as α (BA/TA) and IA/PA (intermediate alkalinity/partial alkalinity) [56], must be adjusted according to the inoculum source and substrate characteristics. According to authors such as Sharma et al. [57], the recommended value for alkalinity is between 2000 and 4000 mg CaCO3/L for plant-based waste. In addition, the predominance of BA is important, because it neutralizes VFAs, which can inhibit processes such as hydrolysis [58] as a consequence of the high content of slow-degradation organic matter, thereby causing a decrease in pH [59].

Volatile fatty acids such as acetic, propionic and butyric acids are the main intermediates during the degradation of organic matter in the acidogenic stage and are transformed into acetate and then into methane and carbon dioxide through the action of methanogenic Archaea [60]. Authors such as Marchaim and Krause [61] and Buyukkamaci et al. [62] suggest that a propionic acid/acetic acid ratio of 1.4 or concentrations of acetic acid higher than 0.8 g/L can trigger a failure of AD, which could be used to warn of disequilibrium and serve as a monitoring variable to establish stability conditions. Other authors such as Giwa et al. [63] suggest that in general, an elevated concentration of propionic acid indicates acidification, leading to a decrease in pH and therefore an increase of CO2 in the biogas.

Although the natural buffer system for avoiding inhibition by VFAs is based on a balance between the phases or stages of production and the consumption of VFAs (carbonic, bicarbonate and carbonate acids prevent the pH value from drastically decreasing [5]), in the case of easily acidifiable substrates such as FW and BW, it is usually advisable to perform pH conditioning because the substrate and inoculum can lack TA and BA [25, 28].

Pre-treatment of the Substrate

Different types of substrate pre-treatment increase methane production; these include physical, thermal, chemical and biological methods [45]. The objective of physical methods is to separate FW from other waste flows, such as plastics [64], and to decrease particle size (crushing) in order to increase surface area to facilitate and accelerate degradation. This pre-treatment is highly related to VFA production and retention times, and ultimately results in lower operating costs [22]. Ultrasound, another type of physical pre-treatment, has been used by researchers such as Rasapoor et al. [47] to increase biogas production by up to 80% compared to a substrate without pre-treatment, both in laboratory and pilot-scale reactors, with a power of 0.2 W/mL.

Thermal pre-treatment is one of the most used methods, and it has even been successfully applied to a full-scale operation [21]. Authors such as Cesaro et al. [65] and Li et al. [21] mention that the effectiveness of this type of treatment is due to accelerated hydrolysis and the consequent decrease in hydraulic retention time given the greater solubility induced in both organic and inorganic compounds, in addition to lower viscosity values [66]. Conversely, studies such as those by Liu et al. [67] show that high temperatures (170 °C) and long exposure times (60 min) lead to a decrease in efficiency, which is consistent with the results of Li et al. [21], who stated that this type of process should not be carried out at temperatures above 120 °C or exceed 15 min of exposure.

Kondusamy et al. [45] indicated that alkaline chemical pre-treatments are also effective. Studies such as those of Wang et al. [68] and Wang et al. [69] have evaluated the effect of the addition of different low-cost buffer substances (i.e., NaOH, CaO, Ca (OH)2, KOH, K2HPO4, Na2CO3, NaOH) to optimize the process, and each substance has advantages and limitations that must be evaluated in each case. Neves et al. [70] indicated that care must be taken, because high concentrations of sodium or potassium can cause inhibition problems.

The main objective of biological pre-treatment is to simplify molecularly complex wastes, such as lipids or lignocellulosic components, so that the microorganisms involved in AD can assimilate them more easily. This type of pre-treatment includes enzymatic pre-treatment, which aims to reduce the duration of the hydrolysis step with a mixture of enzymes (e.g., hemicellulase, xylanase, araninase) [18], and the addition of fungi such as Trichoderma viride to boost methane production by increasing the availability of nutrients and organic acids. Given that certain species of fungi are more associated with particular materials, prior characterization of the substrate is essential [71].

Nutrients

Some elements, such as nitrogen, phosphorus, potassium, calcium, selenium, nickel, zinc, aluminium and iron, are necessary for good process performance because they are required for the growth of a large number of the microorganisms responsible for degrading the various compounds present in FW [72, 73].

One of the most important nutrients in biological processes is nitrogen and its form is directly related to pH. Compounds such as free ammonia (NH3) or ammonium ions (NH4+) are produced mainly through protein degradation. In high concentrations, NH3 can lead to inhibition, especially at high temperatures and high pH values. Authors such as Fernandes et al. [74] report that at a pH of 7 and a temperature of 35 °C, only 1% of NH3 is in its free form, while at a pH of 8 and at the same temperature, the concentration increases to 10%. Contrary to the behaviour of NH3, NH4+ will act as a buffer that contributes to VFA equilibrium [5].

Authors such as Parawira et al. [75] suggest that concentrations of NH4+ in the order of 1100 mg/L can create an adequate buffer capacity. However, authors such as Parra-Orobio et al. [76] report that only a third of this concentration (324 mg/L) is necessary to ensure enough BA is available to neutralize the VFA acidity in substrates such as BW and FW. It is therefore important to quantify NH4+ levels in the substrate and inoculum, in order to identify whether an external nutrient source should be added.

The traditional way to analyse the presence of adequate nutrient levels in the AD process is through the carbon/nitrogen (C/N) ratio, for which there is no established fixed value. However, authors such as Lee et al. [77] and Zhang et al. [60] claim that the most appropriate value is between 15 and 35. When the C/N is low, an increase in NH3 levels is favoured, making the AD process unfeasible [78]. Ariunbaatar et al. [33] reported a value of 3.8 g/L for the inhibitory concentration of NH3, while Hansen et al. [79] indicated a value of 1.1 gN/L. However, optimal conditions depend upon the characteristics of the substrate and the inoculum, as well as on pH and temperature conditions, so this behaviour should be investigated, and potentially inhibitory values should be identified for different scenarios [74].

Potassium concentrations lower than 400 mg/L lead to better production in the mesophilic and thermophilic ranges, whereas when concentrations are higher, the inhibitory effect is more pronounced in the thermophilic range; thus, bacterial groups that degrade acetate are more sensitive to the toxicity associated with high potassium concentrations [80].

Essential micronutrients include nickel (Ni), iron (Fe) and zinc (Zn) because for some microorganisms, these cations play an important role in maintaining enzymatic activity. Ni is required due to its relationship with coenzymes such as F430, because it serves as a central element [81], and the role of Fe is related to the transport of electrons and the conversion of carbon dioxide to methane. Zn concentrations have been found in methanogenic Archaea on the order of 50–630 mg/L [82], and thus, Zn is also expected to play an important role. However, it should be noted that depending on the concentration, pH and redox potential, these compounds can potentially produce inhibitory effects [60].

Some studies, such as those by Parra-Orobio et al. [51], Wei et al. [83] and Zhang et al. [84], discuss the addition of nutrients in the starting conditions of the AD process, leading to the successful development of the process.

Co-digestion

Co-digestion has emerged as an economic alternative to improve the AD process, because FW is an easily degradable substrate which tends to accumulate large amounts of VFAs, leading to a consumption of BA and therefore a decrease in pH, all of which are variables of interest because they affect the methanogenic Archaea, thereby compromising methane production [85]. This type of alternative seeks the simultaneous digestion of two or more substrates, generating synergistic effects induced by the introduction of co-substrates to the process, in order to provide the missing nutrient requirements and other aspects such as buffer capacity [86], so that biogas production can be increased. Co-digestion is considered a sustainable and beneficial strategy for the environment, and is a practice which originated in Europe, in countries such as Germany more than 20 years ago [87].

Among the co-substrates most commonly used in the AD of FW and BW, are sewage sludge from wastewater treatment plants (WWTP), and agro-industrial waste, such as green waste and pig slurry. The first is categorized as a good co-substrate based on its total organic carbon concentration, the contribution of alkalinity to the process and the presence of macro and micronutrients [40].

According to authors such as Hagos et al. [88] and Siddique and Wahid, [89] the nutrient requirement is one of the variables that affect the co-digestion process, this is closely related to the C/N ratio which in turn affects microorganisms, so it is important to take it into account when identifying a co-substrate. Lu et al. [90] in a study that used RA and co-substrates such as corn straw and cattle manure, identified that the best C/N ratio was found between 17 and 24 with this class of co-substrates. On the other hand, authors such as Ren et al. [91] point out that co-substrates of lignocellulosic origin are also useful for mixing with RA, an example of which are macro and micro algae, on which Cogan and Antizar-Ladislao [92] affirms that methane productions have increased using this type of materials.

Inoculum

The inoculum or seed is an important factor since it is the component that contributes the microorganisms to the reactor. Its quality, origin and acclimatization will largely depend on the development of the process; therefore it is important to choose an appropriate inoculum according to the characteristics of the substrate to be used. According to Holliger et al. [28], the inoculum should not provide more than 20% of the total methane production of the reactor and should ideally have a pH between 7 and 8.5 units. Next, the main variables and strategies that group this factor are described.

Source of Inoculum

The type and source of inoculum are important in the AD process because granular types are more beneficial for the process than flocculent ones, due to the greater settlement, microbial diversity and methanogenic activity of the former [34]. Similarly, depending on their origin, they can supply nutrients and provide the microorganisms that are necessary for the proper development of the process [48, 51]. The inoculum should ideally be physicochemically characterized, even with respect to its nutrient content, because this along with the characteristics of the substrate, will indicate the need for an external nutrient source [22]. The most commonly used inoculum types are (1) digester sludge from WWTPs, (2) sludge from agricultural waste treatment plants, (3) sludge from biological waste [93], (4) digester sludge from chicken excreta and (5) sludge from the degradation of pig and cattle manure [5].

Substrate/Inoculum (S/I) Ratio

The S/I ratio is important in the AD process because according to the characteristics of the substrate and the inoculum used, this ratio can vary [94]. Authors such as Raposo et al. [34] recommend employing ratios between 0.5 and 1.0 gVSsubstrate/gVSinoculum. This relationship is also expressed in terms of gCODsubstrate/gVSinoculum, and authors such as Liu et al. [67] and Parra-Orobio et al. [76] show that at a higher S/I ratio, there is less methane production, which according to authors such as Hansen et al. [95], may be due to the accumulation of VFAs and the low buffer capacity of the reactors, which facilitates the acidification of the system and thereby inhibits the AD process.

Inoculum Mixtures

To increase and improve the AD processes, strategies have been studied to increase biogas production, including the inoculum mixture. Studies such as Parra-Orobio et al. [51], focus on the biochemical methane potential (BMP) with different inoculum mixtures; using a granular inoculum from an anaerobic digester of a slaughterhouse and a flocculent sludge from a WWTP, they found that the optimal inoculum mixture was 25:75 V/V. Additionally, Cristancho et al. [96] mixed a flocculent inoculum from a UASB reactor and an inoculum with a tendency to form granules from a pig manure treatment process at 50:50 V/V, and compared their results to the yields obtained for each sludge separately; it was found that the inoculum mixture not only induced an increase in methane production but also showed better pH stability.

Pre-treatment of the Inoculum

Researchers have found that alternatives such as the addition of coagulants and nutrients or incubation of the inoculum, improve its characteristics. However, while the addition of coagulants improves the settlement of sludge, it can inhibit microorganisms, so the concentration to be added must be studied [51]. In addition, depending on the type of coagulant, the behaviour will vary, and therefore, each case should be evaluated. Romero-Güiza et al. [97] claimed that nutrients have a positive impact on the AD process, not only because of the stability that they provide to the process, but also because they facilitate their own reactions. In any case, the ideal is to show the shortcomings of the system and to supplement the missing nutrients with the objective of optimization [24]. Incubation consists in leaving the inoculum at the temperature at which the process is going to develop so that there is a period of temperature acclimation and a shorter latency or adaptive phase, thus avoiding low production once the reactor starts operating, which could potentially prevent the process from being classified as adequate [48, 68].

Experimental Design

The experimental design of the reactor is one of the main factors to be taken into account in AD, because different production values will be obtained for the same substrate and inoculum used [5]. More attention should be paid at certain stages of the process due to the sensitivity, and in some cases, operating costs will be higher [98]. Some variables and strategies considered in this factor are presented below.

Temperature

Temperature is one of the variables that most affects the AD process, because according to the temperature range, there are differences in the latency phase, microbial communities and stability, among others [64, 99]. Biogas production in wastewater has been identified in both the Arctic (< 0 °C) and at very high temperatures (100 °C) [12]. In general, three temperature ranges and optimal points are established; for example, the psychrophilic range is less than 20 °C, the mesophilic range is between 20 and 45 °C and the thermophilic range is between 45 and 65 °C, with 15, 35 and 55 °C being the optimal temperatures, respectively [14, 100].

Authors such as Deepanraj et al. [101], have conducted different studies with temperatures ranging between 30 and 60 °C in both the mesophilic and thermophilic ranges [102], and found greater yields at higher temperatures. Although high temperatures (thermophilic range) have a positive effect on biogas production as a consequence of the higher degradation rate of the substrate (approximately 50%) compared to the mesophilic range, and digestate with a lower amount of pathogens is obtained, i.e., a more adequate material in terms of safety for agricultural use [5, 103], more energy is required to maintain these temperatures [59], and in addition, in this condition the AD process is more sensitive to small changes and prone to the accumulation of propionic acid [18, 104]. Due to the stability of the process and the high organic loadings of FW, authors such as Guo et al. [11] indicate that mesophilic AD (i.e., 35–37 °C) is the most suitable for this type of substrate.

There are zones that due to their climatic and topographic characteristics are considered cold, and as a consequence of the energy expenditure required, some alternatives that enable viable AD in the psychrophilic range have been studied. Authors such as Rajagopal et al. [58] have showed that the co-digestion of FW with substrates such as dairy cattle manure favours methane gas production under psychrophilic conditions. Similarly, [105] carried out pilot-scale application studies at 16.8 °C for the AD of fruit and vegetable waste without particle size conditioning; the digester was constructed with a black geomembrane of different thicknesses (1.5 and 2.0 mm), and expanded polyethylene was used as insulation to prevent heat loss, the design did not involve the heating or mixing of substrates to obtain biogas. In European countries, FW-AD has become an emerging and applied technology due to the subsidies granted [31].

Number of Stages

The design of reactors by stages has emerged as a solution for the rapid transformation of FW into VFAs, because the processes that occur in the first stage of AD trigger a drastic drop in pH and therefore an inhibition of the process, mainly of methanogenic Archaea [106]. When compared to a single-stage digestion, AD that has been developed in two or three stages presents advantages, such as (1) an improvement of the hydrolysis phase, (2) process stability, (3) an increase in methane production, i.e., a decrease in the hydraulic retention time, (4) the use of high organic loads and (5) a greater microbial diversity [107, 108]. A disadvantages of the two stages includes the higher costs attributable to the needs and operation of another reactor [98].

In staged systems, a slightly acidic pH (5.5–6.5) is maintained in the first reactor with a short hydraulic retention time (HRT) (2–3 days), while in the second reactor, a pH close to neutrality (6–8) is maintained with a HRT of 20–30 days, to promote a favourable growth environment for the methanogenic Archaea [109]. Additionally, the temperature can vary between the stages; for example, the first stage can be maintained in thermophilic conditions, while the second is maintained in mesophilic conditions. In addition, according to authors such as Xu et al. [106], the recirculation of the leachate from the second to the first stage, can improve the process.

In the treatment of FW through AD, authors such as Nathao et al. [110] and Shen et al. [111] have increased methane gas production by 7.0–15.8% compared to single-stage reactors. Zhang et al. [109] demonstrated that a three-stage system (hydrolytic, acidogenic and methanogenic) is also favourable for AD degradation with a co-substrate, increasing production up to 22.7% when compared to a conventional system that used the same co-substrate. They also identified significant differences in the microbial population present and favoured the trophic group of interest corresponding to each stage.

Head Space

Another variable that affects the process and is related to pH is head space, which is especially important when biogas measurements are performed using the manometric method, which consists of introducing the needle of a manometer through a rubber plug and converting the measured pressure into the volume of the biogas produced by means of a series of equations [29, 104, 112]. According to Holliger et al. [113] and a study from 32 laboratories using different substrates, this method of quantifying methane yields inferior results when compared with measurements made by automated volumetric methods.

In agreement with authors such as Angelidaki et al. [25], Holliger et al. [28] and Valero et al. [114], head space can inhibit the process due to alterations in pH because with a greater partial pressure of CO2 in the head space, there is a greater presence of organic carbon dissolved in solution, and consequently, a lower concentration of CO2 in the biogas, for which low head space conditions favour the increase in partial pressure and the solubilization of CO2. In addition, because organic carbon is a buffer component (i.e., it contributes to pH equilibrium by preventing declines as a consequence of the VFAs produced from decomposing organic matter), it prevents inhibition of the process caused by the death of microorganisms such as methanogenic Archaea, which are responsible for methane production and are highly sensitive to changes in pH [24, 115, 116]. This also avoids the need for additional alkalizing agents which represents a cost saving.

Despite the importance of this variable on the efficiency of the AD process, it is observed that there is no consensus regarding the recommended range of values, and in this review values between 20 and 50% of the useful volume of the reactors were found [82, 84, 117]. In addition, no studies on the influence of this parameter with FW were found, only publications suggesting it should be evaluated [114, 116].

Use of Traditional Kinetic Models and Dynamics

Kinetic models enable the design, operation and control of biological systems [118]. Within these models, some models, such as the first-order model, consider environmental or operational influencing variables. Taking into account that overall in the AD of solid waste, the limiting stage of the process is hydrolysis, kinetic models can establish the influence of different factors [22, 46, 119]. In this sense, other models have been developed that enable the biomass-by-product ratio to be predicted in order to prioritize methane production. Furthermore, some of these models can be used to evaluate variables such as the latency phase, which is related to two stages of anaerobic degradation (acidogenesis and acetogenesis).

These models also include the logistical function, transfer function and modified Gompertz models: the first model assumes that the methane obtained is proportional to the microorganisms present and the substrate under biodegradation; the transfer model considers the reactor to be a fixed process, and thus, as a system of inputs and outputs; the Gompertz model assumes that production is proportional to microbial activity and decreases with the solid retention time [21, 30]. It should be noted that the latter is one of the most widely used models in AD processes using an FW substrate, even though some authors claim that production can sometimes be overestimated [120]. For this reason, in general, the use of several models is recommended in order to identify the one that best fits production trends. Furthermore, given that some models also provide information that others do not (i.e., the Gompertz model yields the latency phase, while the first-order model order can determine the hydrolysis constant); it is advisable to use them in a complementary manner, not for comparison purposes, but rather to obtain more information about the AD process.

Another model used to predict methane production is the Anaerobic Digestion Model No. 1 (ADM1) model, which was developed by the International Water Association (IWA). The model is based on mass and load balances, represents both biological and physicochemical reactions [121] and is divided into five steps: disintegration, hydrolysis, acidogenesis, acetogenesis and methanogenesis. The first step is a process in which organic and inorganic matter is transformed into carbohydrates, proteins and lipids; the model also considers the effects of inhibition by variables such as pH and hydrogen and consists of 32 dynamic state variables [122]. Furthermore, authors such as Hagos et al. [88] point out that this model together with its modified version are tools that contribute to the optimization of DA and Co-digestion.

Organic Load

Organic load is another variable of incidence in the AD process which affects the performance of the methanogenic Archaeas and therefore biogas production. Although higher organic load is expected to increase methane production, in practice it is not entirely true, since it can cause inhibition problems [123]. Some authors such as Kumar et al. [49] jointly evaluated the effect of organic load and temperature (mesophilic and thermophilic regime) on FW-AD; in their study organic loads between 1.0 and 6.1 kg COD/m3 * day were used. Kumar et al. [49] found that an increase in organic load increased methane production in both temperature regimes, and under thermophilic conditions, the acceleration of the hydrolysis of the process is favoured.

Solids Content

The total solids (TS) and volatile solids (VS) content of FW is generally between 18.1–30.9 and 17.1–26.3 respectively [60], so the moisture content is high (70–80%), and given the high VS/TS ratio which indicates the organic predominance of the substrate [5], it is an easily degradable substrate [99]. From the point of view of the TS content, AD can be classified in two types: when TS < 16%, it is a wet process and when 16% < TS < 40%, it is a dry process [93]; while according to other classifications, there is the conventional modality (≤ 20% TS), semi-dry (10% < TS < 20%) and dry (TS > 20%). The main advantage of wet AD is the greater contact between the substrate and the inoculum, which is why it is attributed greater efficiency, but its greatest limitation is the requirement of greater area due to the volume of liquid necessary to guarantee moisture [50, 93].

Experiences such as that of Yi et al., [124] conclude that as the content of TS increases and moves in the range of 10–20%, higher yields are obtained, likewise there is a decrease in the VS, which is reflected in increased biogas production.

Retention Time (RT)

RT is considered as the time it takes organic matter to decompose completely or the average time that organic matter remains in a reactor or digester [14]. Mao et al. [104], pointed out that temperature is an important variable, since it is closely related to bacterial growth and retention time. According to Kothari et al., [12], a time of 10–40 days is enough to treat organic waste at temperatures in the mesophilic range, but in the thermophilic range, this period is shorter. For example, a reactor operated in this range has a RT of approximately 14 days.

There are two kinds of RT, the first is the Solid Retention Time (TRS) and refers to the time in which the microorganisms are in the digester, and the second is the Hydraulic Retention Time (more related to liquid substrates), which is defined as the time in which the liquid passes through the digester [101]. Therefore, prolonged TRS and HRT are recommended in order to facilitate biological acclimatization to toxic compounds and greater degradation, therefore enhancing biogas production.

Research and Reflection Trends

According to this technological surveillance, factors such as the substrate, inoculum and reactor are observed to be of great importance in the AD process. Variables such as pH, alkalinity and VFAs, the solids content and nutrients, as well as an evaluation of the process under temperature conditions in the mesophilic and thermophilic ranges, have been extensively investigated. Among the strategies for improving the AD process of BW and FW, co-digestion with other substrates and both substrate and inoculum pre-treatments stand out.

Although it is observed that in general there are ranges considered optimal for the majority of variables identified for each factor, with some being more studied than others, it is necessary to evaluate each particular variable depending on local conditions (characteristics of available substrates and inoculums, temperature modification possibilities, nutrient addition, mode of operation, etc.), in order to first evaluate the conditions that sustainably favour the highest methane yield, thereby minimizing resource consumption and always obtaining the greatest possible amount of renewable energy.

In contrast, among the less evaluated aspects, there is the evaluation of the process performance in conditions of psychrophilic temperatures and head space is also known to have an important impact on the process, being another aspect that requires more research. Another interesting aspect of this study is the identification of the increasing importance that digestate or biosolid has taken, which is the solid material that in most cases is stabilized as a result of the degradation of the AD process itself. This material is rich in nutrients such as nitrogen, phosphorus and potassium and is of great interest for its potential use as a soil improver or partial replacement of chemical fertilizers. Variables such as pH, nutrient content, organic matter content and pathogens should be measured in the digestate once the process is finished, with the aim of assessing its potential use [125], since according to these characteristics, it can increase microbial activity and therefore the flow of CO2, in addition to generating nitrogen losses and may even have a phytotoxic effect [43].

In addition to the economic and environmental benefits associated with a decrease in the levels of biosolids or digestates, their return to the production chain can also contribute to a reduction of costs associated with the use of chemical fertilizers. For example, in 2009 in the United Kingdom, it was decreed that the digestate must comply with the protocol (The Quality Protocol for Anaerobic Digestate) established by the Environmental Agency, which issues a certificate, without which the material cannot be applied to the ground. In the Colombian case, Decree 1284 [126] was approved in 2014, which establishes criteria for the use of the biosolids generated in WWTP.

The above shows the opportunity for future work along these lines, in order to increase the closing of cycles in this kind of process and favour technologies that point both to a decrease in the generation of waste, and to a minimization in the final disposal of materials of high exploitation potential. Techniques such as Anaerobic Digestion, allow us to obtain materials with both energetic and agricultural potential, while reducing problems such as the generation of GHG and leachate, among other aspects. In this way, the AD is related with circular economy and green economy, promoting the incorporation of waste to other processes and reducing the quantity which finishes up in landfill [5].

Another aspect observed is that, in general, there are still few studies that jointly or simultaneously evaluate several of the related aspects, therefore future studies which jointly evaluate different variables should be developed, so that their effect upon methane production and the interaction between the different variables is documented.

Finally, it is recommended that the results obtained in different experimental conditions should be contrasted with expected theoretical production values from elementary analysis (C, H2, O2, N, S) or from the organic load (COD) of the substrate [127], to identify the variables that most contribute to this aspect, so that cost-effective analyses and multi-criteria techniques can be carried out for the application of improvement strategies.

Conclusions

-

The anaerobic digestion of biowaste and food waste is an increasingly relevant biological technology, because it contributes to extending the useful life of landfills, decreases the generation of leachates and greenhouse gases through both treatment and recovery, thereby helping to close production cycles.

-

While temperature (thermophilic and mesophilic) is one of the variables that has been widely studied, a limited number of studies have been conducted under psychrophilic conditions, which is important to study, especially in places where resources to provide the mesophilic temperature are scarce; a condition that has been reported within the optimum range due to its stability. Another variable for which there is not yet sufficient information is head space, although several articles suggest evaluating it due to its relationship with the carbonaceous system that influences the balance of bicarbonate alkalinity and volatile fatty acids.

-

The majority of studies present evaluations focused on a single parameter and ignore the interactions that may exist between two or more variables, so it is recommended to evaluate variables together to determine whether or not there is an interaction between them and to identify the optimal values for each variable.

References

Hoornweg, D., Bhada-Tata, P.: What a waste: a global review of solid waste management. http://siteresources.worldbank.org/INTURBANDEVELOPMENT/Resources/336387-1334852610766/What_a_Waste2012_Final.pdf (2012). Accessed 3 Aug 2018

Silpa, K., Yao, L., Bhada-Tata, P., Van Woerden, F.: What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. Urban Development Series. World Bank, Washington, DC (2018)

Thi, N.B.D., Kumar, G., Lin, C.-Y.: An overview of food waste management in developing countries: current status and future perspective. J. Environ. Manag. 157, 220–229 (2015)

Kaza, S., Yao, L., Bhada-Tata, P., Van Woerden, F.: What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050. World Bank, Washington, DC (2018)

Mirmohamadsadeghi, S., Karimi, K., Tabatabaei, M., Aghbashlo, M.: Biogas production from food wastes: a review on recent developments and future perspectives. Bioresour. Technol. Rep. 7, 100202 (2019)

Oviedo-Ocaña, E.R., Torres-Lozada, P., Marmolejo-Rebellon, L.F., Hoyos, L.V., Gonzales, S., Barrena, R., Sanchez, A.: Stability and maturity of biowaste composts derived by small municipalities: correlation among physical, chemical and biological indices. Waste Manag. 44, 63–71 (2015)

Slorach, P.C., Jeswani, H.K., Cuéllar-Franca, R., Azapagic, A.: Environmental sustainability of anaerobic digestion of household food waste. J. Environ. Manag. 236, 798–814 (2019)

FAO: http://www.fao.org/3/an894e/an894e00.pdf (2012). Accessed 14 Feb 2020

DNP: Pérdida y desperdicio de alimentos en Colombia. Disponible en: https://mrv.dnp.gov.co/Documentos%20de%20Interes/Perdida_y_Desperdicio_de_Alimentos_en_colombia.pdf (2016). Accessed 20 Feb 2020

Magnet: Food waste around the world. https://www.magnet.co.uk/adviceinspiration/blog/2018/February/food-waste-around-the-world/ (2018). Accessed 10 Jan 2020

Guo, J., Peng, Y., Ni, B.J., Han, X., Fan, L., Yuan, Z.: Dissecting microbial community structure and methane-producing pathways of a full-scale anaerobic reactor digesting activated sludge from wastewater treatment by metagenomic sequencing. Microb. Cell Fact. 14(1), 33 (2015)

Kothari, R., Pandey, A.K., Kumar, S., Tyagi, V.V., Tyagi, S.K.: Different aspects of dry anaerobic digestion for bio-energy: an overview. Renew. Sustain. Energy Rev. 39, 174–195 (2014)

Braun, R.: Anaerobic digestion: a multi-faceted process for energy, environmental management and rural development. In: Improvement of Crop Plants for Industrial End Uses (pp. 335–416). (2007)

Pramanik, S.K., Suja, F.B., Zain, S.M., Pramanik, B.K.: The anaerobic digestion process of biogas production from food waste: prospects and constraints. Bioresour. Technol. Rep. 8, 100310 (2019)

Enitan, A.M., Adeyemo, J., Swalaha, F.M., Kumari, S., Bux, F.: Optimization of biogas generation using anaerobic digestion models and computational intelligence approaches. Rev. Chem. Eng. 33(3), 309–335 (2017)

Grando, R.L., de Souza Antune, A.M., Da Fonseca, F.V., Sánchez, A., Barrena, R., Font, X.: Technology overview of biogas production in anaerobic digestion plants: a European evaluation of research and development. Renew. Sustain. Energy Rev. 80, 44–53 (2017)

Aghbashlo, M., Tabatabaei, M., Hosseini, S.S., Dashti, B.B., Soufiyan, M.M.: Performance assessment of a wind power plant using standard exergy and extended exergy accounting (EEA) approaches. J. Clean. Prod 171, 127–136 (2018)

Panigrahi, S., Dubey, B.K.: A critical review on operating parameters and strategies to improve the biogas yield from anaerobic digestion of organic fraction of municipal solid waste. Renew. Energy 143, 779–797 (2019)

Schnurer, A., Jarvis, A.: Microbiological handbook for biogas plants. Swed. Waste Manag. U 2009, 1–74 (2010)

Adekunle, K.F., Okolie, J.A.: A review of biochemical process of anaerobic digestion. Adv. Biosci. Biotechnol. 6(03), 205 (2015)

Li, Y., Liu, H., Su, D., Yan, F.: Characterization and thermophilic anaerobic digestion of organic fraction of municipal solid waste. Waste Biomass Valorization 7, 325–330 (2016)

Parra-Orobio, B.A., Donoso-Bravo, A., Torres-Lozada, P.: Anaerobic digestion of food waste. Predicting of methane production by comparing kinetic models. Ingeniería y Competitividad 19(1), 219–227 (2017)

Morales-Polo, C., Cledera-Castro, M.D.M., Moratilla Soria, B.Y.: Reviewing the anaerobic digestion of food waste: from waste generation and anaerobic process to its perspectives. Appl. Sci. 8(10), 1804 (2018)

Ohemeng-Ntiamoah, J., Datta, T.: Perspectives on variabilities in biomethane potential test parameters and outcomes: a review of studies published between 2007 and 2018. Sci. Total Environ. 664, 1052–1062 (2019)

Angelidaki, I., Alves, M., Bolzonella, D., Borzacconi, L., Campos, J., Guwy, A., Kalyuzhnyi, S., Jenicek, P., Van Lier, J.: Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci. Technol. 59, 927–934 (2009)

Esposito, G., Frunzo, L., Liotta, F., Panico, A., Pirozzi, F.: Bio-methane potential tests to measure the biogas production from the digestion and co-digestion of complex organic substrates. The Open Environ. Eng. J. 5(1), 1–8 (2012)

Lisboa, M.S., Lansing, S.: Characterizing food waste substrates for co-digestion through biochemical methane potential (BMP) experiments. Waste Manag. 33(12), 2664–2669 (2013)

Holliger, C., Alves, M., Andrade, D., Angelidaki, I., Astals, S., Baier, U., Bougrier, C., Buffière, P., Carballa, M., de Wilde, V., Ebertseder, F., Fernández, B., Ficara, E., Fotidis, I., Frigon, J., de Laclos, H., Ghasimi, D., Hack, G., Hartel, M., Heerenklage, J., Horvath, I., Jenicek, P., Koch, K., Krautwald, J., Lizasoain, J., Liu, J., Mosberger, L., Nistor, M., Oechsner, H., Oliveira, J., Paterson, M., Pauss, A., Pommier, S., Porqueddu, I., Raposo, F., Ribeiro, T., Rüsch Pfund, F., Strömberg, S., Torrijos, M., van Eekert, M., van Lier, J., Wedwitschka, H., Wierinck, I.: Towards a standardization of biomethane potential tests. Water Sci. Technol. 74(11), 2515–2522 (2016)

Cárdenas-Cleves, L.M., Parra-Orobio, B.A., Torres-Lozada, P., Vásquez-Franco, C.H.: Perspectives of biochemical methane potential-BMP test for control the anaerobic digestion process of wastes. Rev. Ion 29(1), 95–108 (2016)

Donoso-Bravo, A., Pérez-Elvira, S.I., Fdz-Polanco, F.: Application of simplified models for anaerobic biodegradability tests. Evaluation of pre-treatment processes. Chem. Eng. J. 160(2), 607–614 (2010)

Ariunbaatar, J., Di Perta, E.S., Panico, A., Frunzo, L., Esposito, G., Lens, P.N., Pirozzi, F.: Efecto del nitrógeno amoniacal en la digestión anaeróbica de una y dos etapas del desperdicio de alimentos. Gestión de Residuos 38, 388–398 (2015)

Komilis, D., Barrena, R., Grando, R.L., Vogiatzi, V., Sánchez, A., Font, X.: A state of the art literature review on anaerobic digestion of food waste: influential operating parameters on methane yield. Rev. Environ. Sci. Bio/Technol. 16(2), 347–360 (2017)

Tabatabaei, M., Aghbashlo, M., Valijanian, E., Panahi, H.K.S., Nizami, A.S., Ghanavati, H., Karimi, K.: A comprehensive review on recent biological innovations to improve biogas production, part 2: mainstream and downstream strategies. Renew. Energy 146, 1204–1220 (2019)

Raposo, F., De la Rubia, M.A., Fernández-Cegrí, V., Borja, R.: Anaerobic digestion of solid organic substrates in batch mode: an overview relating to methane yields and experimental procedures. Renew. Sustain. Energy Rev. 16(1), 861–877 (2012)

Aleixandre-Benavent, R., González Alcaide, G., González De Dios, J., Alonso-Arroyo, A.: Fuente de información bibliográfica (I). Fundamentos para la realización de búsquedas bibliográficas. Acta Pediátrica Esp. 69(3), 131–136 (2011)

Gómez-Luna, E., Fernando-Navas, D., Aponte-Mayor, G., Betancourt-Buitrago, L.A.: Literature review methodology for scientific and information management, through its structuring and systematization. Dyna 81(184), 158–163 (2014)

Soto-Paz, J., Oviedo-Ocaña, R., Torres-Lozada, P., Marmolejo-Rebellón, L.F., Manyoma-Velásquez, P.C.: Compostaje de biorresiduos: tendencias de investigación y pertinencia en países en desarrollo. Dyna 84(203), 334–342 (2017)

Parra-Orobio, B., Mendoza, M.N., Henao, D.R., Vélasquez, P.C.M., Torres-lozada, P.: Selection of inocula conditioning methodologies for the anaerobic digestion of food waste. Revista Facultad de Ingeniería 92, 9–18 (2019)

Shahriari, H., Warith, M., Hamoda, M., Kennedy, K.J.: Anaerobic digestion of organic fraction of municipal solid waste combining two pretreatment modalities, high temperature microwave and hydrogen peroxide. Waste Manag. 32(1), 41–52 (2012)

Lin, L., Xu, F., Ge, X., Li, Y.: Improving the sustainability of organic waste management practices in the food-energy-water nexus: a comparative review of anaerobic digestion and composting. Renew. Sustain. Energy Rev. 89, 151–167 (2018)

Ramos, C., Buitrón, G., Moreno-Andrade, I., Chamy, R.: Effect of the initial total solids concentration and initial pH on the bio-hydrogen production from cafeteria food waste. Int. J. Hydrog. Energy 37(18), 13288–13295 (2012)

Giovannini, G., Sbarciog, M., Steyer, J.P., Chamy, R., Wouwer, A.V.: On the derivation of a simple dynamic model of anaerobic digestion including the evolution of hydrogen. Water Res. 134, 209–225 (2018)

Nkoa, R.: Agricultural benefits and environmental risks of soil fertilization with anaerobic digestates: a review. Agron. Sustain. Dev. 34(2), 473–492 (2014)

Manyoma, P., Orejuela, J.P., Torres, P., Marmolejo, L.F., Vidal, C.J.: Landfill location with expansion possibilities in developing countries. Int. J. Ind. Eng. 22(2), 292–300 (2015)

Kondusamy, D., Kalamdhad, A.S.: Pre-treatment and anaerobic digestion of food waste for high rate methane production—a review. J. Environ. Chem. Eng. 2(3), 1821–1830 (2014)

Gallipoli, A., Braguglia, C.M., Gianico, A., Montecchio, D., Pagliaccia, P.: Kitchen waste valorization through a mild-temperature pretreatment to enhance biogas production and fermentability: kinetics study in mesophilic and thermophilic regimen. J. Environ. Sci. 89, 167–179 (2020)

Rasapoor, M., Adl, M., Baroutian, S., Iranshahi, Z., Pazouki, M.: Energy performance evaluation of ultrasonic pretreatment of organic solid waste in a pilot-scale digester. Ultrason. Sonochem. 51, 517–525 (2019)

Rajput, A.A., Sheikh, Z.: Effect of inoculum type and organic loading on biogas production of sunflower meal and wheat straw. Sustain. Environ. Res. 29(1), 4 (2019)

Kumar, G., Sivagurunathan, P., Park, J.H., Kim, S.H.: Anaerobic digestion of food waste to methane at various organic loading rates (OLRs) and hydraulic retention times (HRTs): thermophilic vs. mesophilic regimes. Environ. Eng. Res. 21(1), 69–73 (2015)

Pati, A.R., Saroha, S., Behera, A.P., Mohapatra, S.S., Mahanand, S.S.: The anaerobic digestion of waste food materials by using cow dung: a new methodology to produce biogas. J. Inst. Eng. (India) Ser. E 100(1), 111–120 (2019)

Parra-Orobio, B.A., Donoso-Bravo, A., Ruiz-Sánchez, J.C., Valencia-Molina, K.J., Torres-Lozada, P.: Effect of inoculum on the anaerobic digestion of food waste accounting for the concentration of trace elements. Waste Manag. 71, 342–349 (2018)

Götze, R., Boldrin, A., Scheutz, C., Astrup, T.F.: Physico-chemical characterisation of material fractions in household waste: overview of data in literature. Waste Manag. 49, 3–14 (2016)

Yang, L., Huang, Y., Zhao, M., Huang, Z., Miao, H., Xu, Z., Ruan, W.: Enhancing biogas generation performance from food wastes by high-solids thermophilic anaerobic digestion: effect of pH adjustment. Int. Biodeterior. Biodegrad. 105, 153–159 (2015)

Ward, A.J., Hobbs, P.J., Holliman, P.J., Jones, D.L.: Optimisation of the anaerobic digestion of agricultural resources. Bioresour. Technol. 99(17), 7928–7940 (2008)

Jankowska, E., Chwiałkowska, J., Stodolny, M., Oleskowicz-Popiel, P.: Effect of pH and retention time on volatile fatty acids production during mixed culture fermentation. Bioresour. Technol. 190, 274–280 (2015)

Ripley, L.E., Boyle, W.C., Converse, J.C.: Improved alkalimetric monitoring for anaerobic digestion of high-strength wastes. J. (Water Pollut. Control Fed.) 58(5), 406–411 (1986)

Sharma, V.K., Testa, C., Cornacchia, G., Lastella, G., Tarina, C.: Anaerobic digestion of semi-solid organic waste available from orthofruit market: preliminary experimental results. Energy Convers Manag 40, 287–304 (1999)

Rajagopal, R., Bellavance, D., Rahaman, M.S.: Psychrophilic anaerobic digestion of semi-dry mixed municipal food waste: for North American context. Process Saf. Environ. Prot. 105, 101–108 (2017)

Wang, K., Yin, J., Shen, D., Li, N.: Anaerobic digestion of food waste for volatile fatty acids (VFAs) production with different types of inoculum: effect of pH. Bioresour. Technol. 161, 395–401 (2014)

Zhang, C., Su, H., Baeyens, J., Tan, T.: Reviewing the anaerobic digestion of food waste for biogas production. Renew. Sustain. Energy Rev. 38, 383–392 (2014)

Marchaim, U., Krause, C.: Propionic to acetic acid ratios in overloaded anaerobic digestion. Bioresour. Technol. 43(3), 195–203 (1993)

Buyukkamaci, N., Filibeli, A.: Volatile fatty acid formation in an anaerobic hybrid reactor. Process Biochem. 39(11), 1491–1494 (2004)

Giwa, A.S., Xu, H., Chang, F., Zhang, X., Ali, N., Yuan, J., Wang, K.: Pyrolysis coupled anaerobic digestion process for food waste and recalcitrant residues: fundamentals, challenges, and considerations. Energy Sci. Eng. 7(6), 2250–2264 (2019)

Bernstad, A., Malmquist, L., Truedsson, C., la Cour Jansen, J.: Need for improvements in physical pretreatment of source-separated household food waste. Waste Manag. 33(3), 746–754 (2013)

Cesaro, A., Belgiorno, V.: Pretreatment methods to improve anaerobic biodegradability of organic municipal solid waste fractions. Chem. Eng. J. 240, 24–37 (2014)

Jin, Y., Li, Y., Li, J.: Influence of thermal pretreatment on physical and chemical properties of kitchen waste and the efficiency of anaerobic digestion. J. Environ. Manag. 180, 291–300 (2016)

Liu, X., Wang, W., Gao, X., Zhou, Y., Shen, R.: Effect of thermal pretreatment on the physical and chemical properties of municipal biomass waste. Waste Manag. 32(2), 249–255 (2012)

Wang, B., Strömberg, S., Nges, I.A., Nistor, M., Liu, J.: Impacts of inoculum pre-treatments on enzyme activity and biochemical methane potential. J. Biosci. Bioeng. 121(5), 557–560 (2016)

Wang, Y., Zang, B., Gong, X., Liu, Y., Li, G.: Effects of pH buffering agents on the anaerobic hydrolysis acidification stage of kitchen waste. Waste Manag. 68, 603–609 (2017)

Neves, L., Ribeiro, R., Oliveira, R., Alves, M.M.: Enhancement of methane production from barley waste. Biomass Bioenergy 30(6), 599–603 (2006)

Wagner, A.O., Schwarzenauer, T., Illmer, P.: Improvement of methane generation capacity by aerobic pre-treatment of organic waste with a cellulolytic Trichoderma viride culture. J. Environ. Manag. 129, 357–360 (2013)

Banks, C.J., Zhang, Y., Jiang, Y., Heaven, S.: Trace element requirements for stable food waste digestion at elevated ammonia concentrations. Bioresour. Technol. 104, 127–135 (2012)

Walker, M., Theaker, H., Yaman, R., Poggio, D., Nimmo, W., Bywater, A., Pourkashanian, M.: Assessment of micro-scale anaerobic digestion for management of urban organic waste: a case study in London, UK. Waste Manag. 61, 258–268 (2017)

Fernandes, T.V., Keesman, K.J., Zeeman, G., van Lier, J.B.: Effect of ammonia on the anaerobic hydrolysis of cellulose and tributyrin. Biomass Bioenergy 47, 316–323 (2012)

Parawira, W., Murto, M., Zvauya, R., Mattiasson, B.: Anaerobic batch digestion of solid potato waste alone and in combination with sugar beet leaves. Renew. Energy 29(11), 1811–1823 (2004)

Parra, O.B.A., Torres, L.P., Marmolejo, L.F., Cárdenas, C.L.M., Vásquez, F.C., Torres, L.W.A., Ordoñez, A.J.A.: Efecto de la Relación Sustrato-Inóculo sobre el Potencial Bioquímico de Metano de Biorresiduos de Origen MunicipaI. Ingeniería Investigación y Tecnología 16(4), 515–526 (2015)

Lee, J.T., Ee, A.W.L., Tong, Y.W.: Environmental impact comparison of four options to treat the cellulosic fraction of municipal solid waste (CF-MSW) in green megacities. Waste Manag. 78, 677–685 (2018)

Xiyu, C., Qiang, L., Jing, W., Cheng, Z.: Effect of carbon/nitrogen ratio on anaerobic co-digestion of swine manure with model stalk wastes. Renew. Energy Resour. 32(6), 848–853 (2014)

Hansen, K.H., Angelidaki, I., Ahring, B.K.: Anaerobic digestion of swine manure: inhibition by ammonia. Water Res. 32(1), 5–12 (1998)

Chen, Y., Cheng, J.J., Creamer, K.S.: Inhibition of anaerobic digestion process: a review. Bioresour. Technol. 99(10), 4044–4064 (2008)

Almeida, A., Nafarrate, R.E., Alvarado, A., Cervantes, O.A., Luevanos, M.P.E., Oropeza, R., Balagurusamy, N.: Expresión genética en la digestión anaerobia: un paso adelante en la comprensión de las interacciones tróficas de esta biotecnología. Acta Quím. Mex. 3(6), 14–34 (2011)

Myszograj, S., Stadnik, A., Płuciennik-Koropczuk, E.: The influence of trace elements on anaerobic digestion process. Civ. Environ. Eng. Rep. 28(4), 105–115 (2018)

Wei, Q., Zhang, W., Guo, J., Wu, S., Tan, T., Wang, F., Dong, R.: Performance and kinetic evaluation of a semi-continuously fed anaerobic digester treating food waste: effect of trace elements on the digester recovery and stability. Chemosphere 117, 477–485 (2014)

Zhang, L., Jahng, D.: Long-term anaerobic digestion of food waste stabilized by trace elements. Waste Manag. 32(8), 1509–1515 (2012)

Bouallagui, H., Touhami, Y., Cheikh, R.B., Hamdi, M.: Bioreactor performance in anaerobic digestion of fruit and vegetable wastes. Process Biochem. 40(3–4), 989–995 (2005)

Cárdenas-Cleves, L.M., Marmolejo-Rebellón, L.F., Torres-Lozada, P.: Anaerobic codigestion of sugarcane press mud with food waste: effects on hydrolysis stage, methane yield, and synergistic effects. Int. J. Chem. Eng. (2018). https://doi.org/10.1155/2018/9351848

Lacovidou, E., Ohandja, D.G., Voulvoulis, N.: Food waste co-digestion with sewage sludge–realising its potential in the UK. J. Environ. Manag. 112, 267–274 (2012)

Hagos, K., Zong, J., Li, D., Liu, C., Lu, X.: Anaerobic co-digestion process for biogas production: progress, challenges and perspectives. Renew. Sustain. Energy Rev. 76, 1485–1496 (2017)

Siddique, M.N.I., Wahid, Z.A.: Achievements and perspectives of anaerobic co-digestion: a review. J. Clean. Prod. 194, 359–371 (2018)

Lu, X., Jin, W., Xue, S., Wang, X.: Effects of waste sources on performance of anaerobic co-digestion of complex organic wastes: taking food waste as an example. Sci. Rep. 7(1), 1–9 (2017)

Ren, Y., Yu, M., Wu, C., Wang, Q., Gao, M., Huang, Q., Liu, Y.: A comprehensive review on food waste anaerobic digestion: research updates and tendencies. Bioresour. Technol. 247, 1069–1076 (2018)

Cogan, M., Antizar-Ladislao, B.: The ability of macroalgae to stabilise and optimise the anaerobic digestion of household food waste. Biomass Bioenergy 86, 146–155 (2016)

Koch, K., Lippert, T., Drewes, J.E.: The role of inoculum’s origin on the methane yield of different substrates in biochemical methane potential (BMP) tests. Bioresour. Technol. 243, 457–463 (2017)

Lesteur, M., Bellon-Maurel, V., Gonzalez, C., Latrille, E., Roger, J.M., Junqua, G., Steyer, J.P.: Alternative methods for determining anaerobic biodegradability: a review. Process Biochem. 45, 431–440 (2010)

Hansen, T.L., Schmidt, J.E., Angelidaki, I., Marca, E., Jansen, J.L.C., Mosbaek, H., Christensen, T.H.: Method for determination of methane potentials of solid organic waste. Waste Manag. 24(4), 393–400 (2004)

Cristancho, D.E., Arellano, A.V.: Study of the operational conditions for anaerobic digestion of urban solid wastes. Waste Manag. 26(5), 546–556 (2006)

Romero-Güiza, M.S., Vila, J., Mata-Alvarez, J., Chimenos, J.M., Astals, S.: The role of additives on anaerobic digestion: a review. Renew. Sustain. Energy Rev. 58, 1486–1499 (2016)

Vögeli, Y., Lohri, C.R., Gallardo, A., Diener, S., Zurbrügg, C.: Anaerobic Digestion of Biowaste in Developing Countries: Practical Information and Case Studies. Swiss Federal Institute of Aquatic Science and Technology (Eawag), Dübendorf (2014)

Duan, N., Zhang, D., Lin, C., Zhang, Y., Zhao, L., Liu, H., Liu, Z.: Effect of organic loading rate on anaerobic digestion of pig manure: methane production, mass flow, reactor scale and heating scenarios. J. Environ. Manag. 231, 646–652 (2019)

Connaughton, S., Collins, G., O’Flaherty, V.: Psychrophilic and mesophilic anaerobic digestion of brewery effluent: a comparative study. Water Res. 40(13), 2503–2510 (2006)

Deepanraj, B., Sivasubramanian, V., Jayaraj, S.: Kinetic study on the effect of temperature on biogas production using a lab scale batch reactor. Ecotoxicol. Environ. Saf. 121, 100–104 (2015). https://doi.org/10.1016/j.ecoenv.2015.04.051

Náthia-Neves, G., Berni, M., Dragone, G., Mussatto, S.I., Forster-Carneiro, T.: Anaerobic digestion process: technological aspects and recent developments. Int. J. Environ. Sci. Technol. 15(9), 2033–2046 (2018)

Ferrer, I., Vazquez, F., Font, X.: Long term operation of a thermophilic anaerobic reactor: process stability and efficiency at decreasing sludge retention time. Bioresour. Technol. 101, 2972–2980 (2010)

Mao, C., Feng, Y., Wang, X., Ren, G.: Review on research achievements of biogas from anaerobic digestion. Renew. Sustain. Energy Rev. 45, 540–555 (2015)

Martí-Herrero, J., Soria-Castellón, G., Diaz-de-Basurto, A., Alvarez, R., Chemisana, D.: Biogas from a full scale digester operated in psychrophilic conditions and fed only with fruit and vegetable waste. Renew. Energy 133, 676–684 (2019)

Xu, F., Li, Y., Ge, X., Yang, L., Li, Y.: Anaerobic digestion of food waste–challenges and opportunities. Bioresour. Technol. 247, 1047–1058 (2018)

Ventura, J.R.S., Lee, J., Jahng, D.: A comparative study on the alternating mesophilic and thermophilic two-stage anaerobic digestion of food waste. J. Environ. Sci. 26(6), 1274–1283 (2014)

Xiao, B., Qin, Y., Zhang, W., Wu, J., Qiang, H., Liu, J., Li, Y.Y.: Temperature-phased anaerobic digestion of food waste: a comparison with single-stage digestions based on performance and energy balance. Bioresour. Technol. 249, 826–834 (2018)

Zhang, J., Loh, K.C., Lee, J., Wang, C.H., Dai, Y., Tong, Y.W.: Three-stage anaerobic co-digestion of food waste and horse manure. Sci. Rep. 7(1), 1269 (2017)

Nathao, C., Sirisukpoka, U., Pisutpaisal, N.: Production of hydrogen and methane by one and two stage fermentation of food waste. Int. J. Hydrog. Energy 38(35), 15764–15769 (2013)

Shen, F., Yuan, H., Pang, Y., Chen, S., Zhu, B., Zou, D.: Performances of anaerobic co-digestion of fruit & vegetable waste(FVW) and food waste (FW): single-phase vs. two-phase. Bioresour. Technol. 144, 80–85 (2013)

Aquino, S.F., Stuckey, D.C.: Bioavailability and toxicity of metal nutrients during anaerobic digestion. J. Environ. Eng. 133(1), 28–35 (2007)

Holliger, C., Fruteau de Laclos, H., & Hafner, S.: A new protocol and software tool for standardizing biomethane potential tests: results of an inter-laboratory study. In: Presented at the 15th IWA World Conference on Anaerobic Digestion, Beijing, China (2017)

Valero, D., Montes, J.A., Rico, J.L., Rico, C.: Influence of headspace pressure on methane production in Biochemical Methane Potential (BMP) tests. Waste Manag. 48, 193–198 (2016)

Budzianowski, W.M.: A review of potential innovations for production, conditioning and utilization of biogas with multiple-criteria assessment. Renew. Sustain. Energy Rev. 54, 1148–1171 (2016)

Hafner, S.D., Astals, S.: Systematic error in manometric measurement of biochemical methane potential: sources and solutions. Waste Manag. 91, 147–155 (2019)

Zamanzadeh, M., Hagen, L.H., Svensson, K., Linjordet, R., Horn, S.J.: Anaerobic digestion of food waste–effect of recirculation and temperature on performance and microbiology. Water Res. 96, 246–254 (2016)

Lübken, M., Wichern, M., Schlattmann, M., Gronauer, A., Horn, H.: Modelling the energy balance of an anaerobic digester fed with cattle manure and renewable energy crops. Water Res. 41(18), 4085–4096 (2007)

Donoso-Bravo, A., Retamal, C., Carballa, M., Ruiz-Filippi, G., Chamy, R.: Influence of temperature on the hydrolysis, acidogenesis and methanogenesis in mesophilic anaerobic digestion: parameter identification and modeling application. Water Sci. Technol. 60(1), 9–17 (2009)

Fang, L.X., Nair, J., Ho, G.: Influence of food waste composition and volumetric water dilution on methane generation kinetics. Int. J. Environ. Prot. 2(9), 22–29 (2012)

Zhao, J., Li, Y., Pan, S., Tu, Q., Zhu, H.: Performance of a forward osmotic membrane bioreactor for anaerobic digestion of waste sludge with increasing solid concentration. J. Environ. Manag. 246, 239–246 (2019)

Hernández, M.S., Delgadillo, L.R.M.: Aplicación del modelo ADM1 en la digestión anaerobia de aguas residuales y desechos sólidos. Tumbaga 1(6), 29–42 (2011)

Nayak, A., Bhushan, B.: An overview of the recent trends on the waste valorization techniques for food wastes. J. Environ. Manag. 233, 352–370 (2019)

Yi, J., Dong, B., Jin, J., Dai, X.: Effect of increasing total solids contents on anaerobic digestion of food waste under mesophilic conditions: performance and microbial characteristics analysis. PloS One 9(7), e102548 (2014)

Ortiz, D.L.P., Botero-Londoño, M.A., Botero-Londoño, J.M.: Biomasa residual pecuaria: revisión sobre la digestión anaerobia como método de producción de energía y otros subproductos. Rev. UIS Ing. 18(1), 149–160 (2019)

MVCT: Decreto 1287 de julio 19 de 2014 “Por el cual se establecen criterios para el uso de los biosólidos generados en plantas de tratamiento de aguas residuales municipales” (2014)

Nielfa, A., Cano, R., Fdz-Polanco, M.: Theoretical methane production generated by the co-digestion of organic fraction municipal solid waste and biological sludge. Biotechnol. Rep. 5, 14–21 (2015)

Acknowledgements

The authors thank Universidad del Valle for financing the Research Project—CI 21071 “Evaluation of incidence parameters on the improvement of the biochemical methane potential from food waste”. Miguel R. Casallas-Ojeda also thanks to Coomeva for the financing through public education scholarships.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article