Abstract

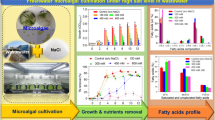

In the present work, effect of two carbon sources, namely, sodium bicarbonate and sodium acetate, on the growth of Spirulina platensis, raw swine wastewater (RSW) nutrients removal, and lipid production efficiency was thoroughly investigated. Experimental results showed that maximum biomass concentration and total nitrogen (TN), total phosphorous (TP), and ammonium removal percentage of 1.70 g L−1, 91.24%, 87.44%, 100% were achieved, respectively, when sodium bicarbonate was supplemented to the RSW, which were significantly (p < 0.05) higher than that of the control. With regard to sodium acetate as extra carbon source, maximum biomass concentration and TN, TP, and ammonium removal percentage reached 2.18 g L−1, 85.72%, 87.02%, and 100%, respectively, which were notably enhanced compared to that of the control. Furthermore, saturated fatty acids and unsaturated fatty acids content in the obtained biomass ranged from 68.01–69.44% to 30.56–31.99%, respectively, and hexadecanoic acid, palmitoleic acid, octadecenoic acid and linoleic acid were found to be the major fatty acid components in the algal lipids. Thus, sodium bicarbonate and sodium acetate supplementation to RSW are technically feasible strategies to enhance Spirulina platensis growth for simultaneously nutrients removal and biodiesel production.

Graphic Abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Statement of Novelty

In this work, Spirulina platensis was employed as microalgae specie for raw swine wastewater treatment. Spirulina platensis is more facilitated to be harvested compared to the commonly used microalgae species, such as Chlorella and Scenedesmus. In addition, extra carbon source supplementation to raw swine wastewater was proposed to enhance Spirulina platensis growth and nutrients removal, which can avoid the limitations of low CO2 mass transfer efficiency in open raceway ponds for microalgae cultivation.

Introduction

The demand for meats has been soaring in the past decades. In order to fill the gap between demand and supply on meats, great change has taken place in the feeding mode of livestock in the world, namely, from household to intense industrial mode [1]. This dramatic variation has contributed to the booming production of meats. Currently, the world population of hogs is 769.05 million hog heads and global pork production for 2018 was around 118.8 million metric tons [2]. In China, according to the data from the National Bureau of Statistics of China (NBSC), though the pig population dropped rapidly after 2014, the number of pigs being raised at the end of 2018 was still as high as 42.8 million heads (http://data.stats.gov.cn/easyquery.htm?cn=C01). Huge number of pigs, on the other hand, can result in corresponding dramatic increase in swine wastes generation. These wastes mainly consist of wastewater, organic solid wastes and exhausts from pig husbandry. Livestock wastes generally contain high concentration of carbon, nitrogen, phosphorous, and trace amount of heavy metals, antibiotics and hormones [3, 4], which have raised great concerns on environmental pollution and ecological security [3,4,5,6].

Spirulina platensis is a kind of eukaryotic microalgae, which is generally recognized as the Earth's oldest living plant originated approximately 3.6 billion years ago [7]. Spirulina platensis is also recognized as a promising alternative feedstock to edible and non-edible feedstocks for biodiesel production due to their efficient conversion of solar energy into chemical energy and commercial availability in large quantities [8, 9]. Furthermore, Spirulina platensis can grow tenaciously in nutritive wastewater and have strong nutrients uptake ability [10,11,12]. Considering abundant nutrients available in RSW and requirement of large quantities of carbon, nitrogen and phosphorous for Spirulina platensis growth, coupling Spirulina platensis cultivation and wastewater nutrient bioremediation show great potential in lowering the production cost of Spirulina platensis biomass and offset part of wastewater treatment expense. Therefore, a great number of studies had focused on the feasibility and scalability of integrating wastewater nutrient removal and Spirulina platensis cultivation for biofuels or bioproducts production, resource recovery and wastewater treatment [13]. For example, Lu et al. [14] had reported cultivating Spirulina platensis in pretreated brewery effluent could produce 1.562 mg L−1 biomass and reduced concentrations of nutrients to reach the allowable discharge limits. However, the small cell size of microalgae (< 30 µm), low biomass concentration and productivity (normally lower than 25 g m−2 day−1) make the microalgae biomass harvesting process energy intensive. Intensive energy consumption in microalgae biomass harvesting, however, significantly hinders the scale-up of the coupling process for algal-based biodiesel production and wastewater treatment. Additionally, open raceway pond is the widely used bioreactor system in large-scale microalgae cultivation [15], however, CO2 mass transfer efficiency in open raceway ponds is low due to low solubility of CO2 in water and shallow design of open raceway ponds. Insufficient carbon sources supply can limit microalgae growth and lipid production. In this context, increase of the microalgae growth during microalgae cultivation using nutrient rich wastewater is of great significance to make the microalgal biodiesel production and nutrients recovery more economical feasible. To achieve the above aims, a number of strategies had been tested, for example, Srinuanpan et al. [16] used starvation of phosphorous or ferrous to increase lipid contents and manipulate fatty acid compositions of two microalgae species. However, the microalgae growth was severely affected by nutrient limitation. Dao [17] used two auxins namely indole-3-acetic acid (IAA) and 2,4-dichlorophenoxyacetic acid (2,4-D) to enhance the growth and fatty acid methyl esters (FAMEs) production of Scenedesmus sp. LX1. Though the auxins could increase the microalgae growth and FAMEs production, the massive availableness, cost-effectiveness and bio-safety of them are still unclear.

Therefore, the current work aims to explore an easy scale-up and economical method to increase Spirulina platensis growth and RSW nutrients removal efficiency. The specific goals are to: (1) evaluate the effect of two different carbon sources (NaHCO3 and CH3COONa) on the growth of Spirulina platensis; (2) verify the effect of the two carbon sources on the nutrient removal capacity; and (3) determine the lipids productivity and fatty acid composition of the obtained Spirulina platensis biomass with various carbon source supplementation for biodiesel production potential evaluation.

Materials and Methods

Materials

RSW was collected from the floor flushing wastewater discharge point of a family-run small-scale pig farm. RSW was subjected to gravity sedimentation overnight followed by filtration with Whattman filter papers (pore size of 0.45 µm) for water quality analysis and Spirulina platensis cultivation substrate. The physicochemical properties of the RSW are listed in Table 1. Spirulina platensis strain was obtained from microalgae laboratory of Guangzhou Institute of Energy Conversion (GIEC), Chinese Academy of Sciences (CAS). The chemicals used in the experiment were all analytical grade and used without further purification.

Methods

Cultivation of Spirulina platensis with RSW

Pre-culture of Spirulina platensis using Zarrouk’s medium was carried out prior to the experiment. The pre-cultured Spirulina platensis cells were harvested at their logarithm growth phase. The obtained Spirulina platensis cells was then inoculated to RSW (with 50% dilution) with initial biomass concentration of 0.15 g L−1. Subsequently, the inoculums were illuminated with two florescent lights (1.2 m in length and power of 16W, Foshan Lighting Co. Ltd, China) fixed 30 cm above the mouths of the flat bottom flasks. The illumination intensity and time were set to be 3000 ± 100 lux and 24 h per day, respectively, based on our previous results [18]. All the treatments were provided with air as basic carbon source for Spirulina platensis growth and agitation to avoid cells sedimentation. The incubation time lasted continuously for 15 days. During cultivation, the growth of Spirulina platensis and variations of pH (determined using an acid meter equipped with a probe, model PH3C, Shanghai Jingke Instrument Co. Ltd, China) of culture medium were monitored every day, respectively. Variations of COD, ammonium, TN and TP concentration in RSW during Spirulina platensis growth were analyzed every other 2 days. The simplified schematic of the experiment setup is demonstrated in Fig. 1.

Experimental Design

In this work, 50% RSW supplemented with 1 g L−1 NaHCO3 or CH3COONa (designated as NaHCO3 and CH3COONa, respectively), was employed as cultivation substrate to evaluate their effect on Spirulina platensis growth, nutrient removal capacity and biodiesel production potential. For comparison, two controls namely control 1 (without Spirulina platensis inoculation or carbon sources supplementation), and control 2 (with Spirulina platensis inoculation but without carbon source supplementation) were designed to testify the effect of Spirulina platensis on removal rate of nutrients from RSW and carbon source supplementation on the growth of Spirulina platensis, nutrients removal ability, lipids content and fatty acid profiles of the obtained biomass, respectively.

Determination Spirulina platensis Growth

Biomass concentration is an indirect indicator to characterize microalgae growth. In this work, in order to determine the variation of Spirulina platensis growth, 5 mL culture was taken from each flask and filtered through a dried and pre-weighed Whatman filter paper (0.42 µm) (w1, g). The filter residue was rinsed twice with deionized water, dried at 105 °C to constant weight (w2, g). The biomass concentration could be calculated by Eq. (1):

The biomass productivity and specific growth rate of Spirulina platensis were obtained Eqs. (2) and (3), respectively:

where X0 and Xf are biomass concentration at the beginning and at the end of the cultivation (t), respectively.

RSW Quality and Biomass Lipid Analysis

Physicochemical parameters of RSW, including COD, TN, TP and ammonium concentration, were analyzed according to the “water and wastewater monitoring and analytical methods”, approved by the Ministry of Ecological and Environmental of China (MEE). The removal percentage and removal rate were calculated by Eqs. (4) and (5), respectively:

where C0 and Cf are the concentration at the beginning and at the end of the cultivation, respectively.

After 15-day cultivation, the biomass was harvested by gravity sedimentation (5 h) followed by centrifugation (5000 rpm, 10 min). Biomass pellets were freeze-dried at − 80 °C for lipid content and fatty acid profiles analysis. Total lipids content and fatty acid profiles of the obtained biomass were determined as described in our previous work [19].

Statistics Analysis

All the experiments were conducted in duplicates and average values with standard deviations were reported. One-way ANOVA using SPSS software (version 11.0) with p < 0.05 was carried out for data validation.

Results and Discussion

Biomass Concentration and Chlorophyll Content Variation

Biomass concentration is a useful indicator to evaluate microalgae growth and biomass productivity. Figure 2 illustrated the variations of biomass concentration during Spirulina platensis growth. From Fig. 2, steadily increase of biomass concentration in all treatments could be observed after Spirulina platensis being inoculated into the RSW, suggesting no significant inhibitory effect of the RSW to the growth of Spirulina platensis. After 15 days cultivation, maximum biomass concentration of 1.70 g L−1 and 2.18 g L−1 were achieved in NaHCO3 and CH3COONa treatments, respectively, which were significantly (p < 0.05) higher than that of the control 2 (1.27 g L−1). The better growth performance of Spirulina platensis in treatments with extra carbon sources supplementation indicated NaHCO3 and CH3COONa could be served as effective carbon source candidates for Spirulina platensis. The maximum biomass concentration obtained in CH3COONa supplemented RSW was quite closed to that in fresh Zarrouk’s medium (2.30 g L−1) [20], however, was higher than that in synthetic human urine supplemented with 200 mg L−1 CH3COONa reported by Chang [21], in which a maximum biomass concentration of 1.75 g L−1 was recorded. The better Spirulina platensis growth performance in the current study could possibly due to the different initial inoculation and five times higher CH3COONa concentration employed in the present work [22]. Higher maximum biomass concentration was achieved by Andrade and Costa [23], who achieved a maximum biomass concentration of 2.94 g L−1 with sugar wastewater as external carbon source, which could mainly attributed to the reduction of inhibitory effect by ammonium ion in wastewater as well as organic carbon in the sugar wastewater are readily easier to be assimilated by Spirulina platensis [21].

Specific growth rate and biomass productivity are another two important parameters to evaluate the microalgae biomass production efficiency. In this study, a specific growth of 0.14, 0.16, and 0.18 day−1 was achieved for Control 2, NaHCO3, and CH3COONa, respectively. The biomass productivity obtained for Control 2, NaHCO3, and CH3COONa was 74.67, 103.33, and 135.33 mg L−1 day−1, respectively, which agreed well with the results reported by Arana [24], who proved NaHCO3 could enhance the growth of Chlorella vulgaris. The enhanced Spirulina platensis specific growth rates and biomass productivities indicated NaHCO3 or CH3COONa supplementation could increase Spirulina platensis growth, which could possibly due to the utilization carbon sources by Spirulina platensis to synthesis carbohydrates, such as starch and lipids [25].

Organic Matter and Nutrients Removal

COD

Microalgae can grow in mixotrophic mode, in which both inorganic carbon and organic substances can be served as carbon sources for microalgae growth [26]. COD is a comprehensive indicator of organic compounds concentration in wastewater and is a key index in the livestock wastewater discharge standards. The changes of COD concentration in RSW vs cultivation time were depicted in Fig. 3. According to Fig. 3, treatments with Spirulina platensis inoculation had no significant effect on COD removal compared to that of control 1, demonstrating indigenous bacteria contributed to the principle organic substances degradation, whereas effect of Spirulina platensis assimilation could be neglected. This can probably be attributed to the weak bioavailability of organic compounds in the RSW to Spirulina platensis. After 6–9 days, however, the COD concentration in treatments with Spirulina platensis inoculation considerably increased, though a slight reduction appeared after 12 days (except control 2). This phenomenon is possibly due to the fast growth of Spirulina platensis, which could synthesize and release large amounts of water-soluble extracellular polysaccharides (EPS) [27]. Similar results were also reported by Xie who used microalgae-bacteria for anaerobic digestion effluents treatment [28]. Consequently, it is necessary to balance the Spirulina platensis cultivation time and biomass productivity as well as COD removal efficiency in the coupled process.

TP

Microalgae contain about 1% phosphorous element by weight, and phosphorous is an essential macronutrient for microalgae metabolism. The changes of TP concentrations in RSW during Spirulina platensis cultivation were presented in Fig. 4. Sharp decrease of TP concentration in RSW was observed during Spirulina platensis growth, which resulted from both the assimilation of Spirulina platensis cells and chemical precipitation since biomass concentration buildup in the RSW and the high alkalinity of the RSW during Spirulina platensis cultivation (as shown in Fig. 5). By the end of cultivation, there was no significant difference between treatments with Spirulina platensis inoculation and carbon sources addition, but dramatic higher TP removal amount compared to that of the control 1 (without Spirulina platensis inoculation), indicating that Spirulina platensis could assist recovering phosphorous from RSW.

Ammonium and TN

A general molecular formula of microalgae is C106H181O45N16P, indicating for every 1 kg of dried microalgae biomass produced approximately 0.11 Kg of nitrogen will be consumed. Therefore nitrogen supply is an important consideration of sustainable microalgae biomass production [29]. RSW is characterized of high nitrogen concentration. Free ammonia, ammonium salt and organic nitrogen are the principle chemical forms of nitrogen available in RSW. The distribution of inorganic nitrogen is strongly dependent on the pH value of wastewater. If not being managed properly, excess nitrogen discharge can easily lead to eutrophication of natural water body. In the present work, the variations of ammonium and total nitrogen (TN) concentration in the RSW during Spirulina platensis growth were determined and illustrated in Figs. 6 and 7, respectively. According to Fig. 6, compared to ammonium concentration reduced only from 37.83 to 26.83 mg L−1 in RSW in Control 1, the ammonium concentration in the RSW with Spirulina platensis inoculation or carbon sources supplementation decreased from 50–60 mg L−1 to 0 within 3 days, suggesting Spirulina platensis can enhance ammonium removal, since microalgae prefer ammonium as the nitrogen source than other chemical forms of nitrogen [30]. In addition, part of ammonium in RSW could volatilize as the pH values of RSW in all treatments during Spirulina platensis cultivation were 9.28–9.87 (as demonstrated in Fig. 5).

While for TN, it can be observed from Fig. 7 that a steadily decrease of TN concentrations during the 15-day cultivation of Spirulina platensis. The decline of TN concentration could attributed to combined effect of Spirulina platensis assimilation and volatilation due to continuous aeration and high alkalinity of RSW (as indicated in Fig. 5) during microalgae cultivation. Compared with variation trend of TN concentration in RSW, TN removal percentage and TN removal rate are more precise parameters to evaluate the nitrogen removal efficiency. Therefore, in the current study, TN removal percentage and removal rate were calculated and presented in Fig. 8. Accordingly, TN removal percentage of 74.44–91.24% and TN removal rate of 6.43 mg L−1 day−1–9.87 mg L−1 day−1 were achieved in all the treatments by the end of the experiment. In addition, dramatically higher TN removal percentage and removal rate were recorded in Control 2 compared to that of Control 1, suggesting Spirulina platensis greatly assisted in nitrogen removal. However, no significant enhancement of TN removal was observed between treatments with extra carbon source addition, which might due to insufficient bioavailable nitrogen in the RSW for further uptake by Spirulina platensis, though higher biomass production was recorded in treatments with extra carbon source supplementation.

Lipids Content and Fatty Acid Profiles of Biomass

Lipids content, especially neutral lipids abundancy is a significant prerequisite determining the potential of microalgae biomass for commercial biofuel production. Commonly, there are three types of lipids available in microalgae cells, namely, neutral lipids, glycolipid and phospholipid [31]. In this study, lipid contents of 10.97%, 8.52%, and 8.63% were detected in the biomass recovered from Control 2, NaHCO3, and CH3COONa (as presented in Table 2). Lower lipid content in the RSW supplemented with extra carbon sources possibly resulted from the “dilution effect” caused by much higher biomass production in these runs. Lipid contents achieved in the present work were relatively lower compared to the results reported by Andrade et al. [20] who used Zarrouk’s medium for Spirulina platensis cultivation. However, considering dual effect of RSW treatment and Spirulina platensis biomass production in the coupling process, the cost of lipid production can be reduced theoretically.

Besides lipids content, the fatty acid profiles of lipids in microalgae also dramatically affect the quality of biodiesel produced from microalgae [32]. In brief, both the length of carbon chain of fatty acid and number of unsaturated carbon-carbon bonds in fatty acids play a critical role on the properties of biodiesel. As illustrated in Table 3, hexadecanoic acid (C16:0), palmitoleic acid (C16:1), octadecenoic acid (C18:1) and linoleic acid (C18:2) were the major fatty acid components in the biomass obtained from all the treatments. These results were similar with that reported by Dehaghani [33]. According to the statement by Liu [34], the quality of biodiesel strongly depends on the content of oleic and palmitic acids. High oleic acid content in microalgae lipids facilitates balance of biodiesel properties including combustion heat, oxidative stability, lubricity, viscosity, cold filter plugging point (CFPP), and ignition quality, while palmitic acid imparts a higher oxidative stability and cetane number as well as lower NOX emissions [35]. Regarding the distribution of saturated fatty acids and unsaturated fatty acids, no obvious differences were observed between treatments with extra carbon sources supplementation and control 2 (ranging from 68.01–69.44% to 30.56–31.99% for saturated fatty acids and unsaturated fatty acids, respectively). Therefore, the lipids obtained by cultivating Spirulina platensis in RSW have great potential to be served as alternative feedstock for biodiesel production.

Conclusions

Coupling of nutrient removal and algal biomass production through microalgae cultivation in wastewater is widely considered to be a promising approach for microalgae biodiesel production. However, the coupled process is still not competitive due to extremely high microalgae biomass and lipid production cost. This study tested the effect of sodium bicarbonate and sodium acetate supplementation on the key indicators of the coupled process and found that both of which could significantly enhance Spirulina platensis growth and the RSW nutrients removal efficiency. Furthermore, the obtained biomass is also a suitable alternative to conventional feedstocks for biodiesel production based on the fatty acid profiles and productivity. Therefore, supplementation of sodium bicarbonate and sodium acetate are effective strategies to increase the Spirulina platensis productivity and nutrients removal efficiency of the integrated process of RSW treatment and biodiesel production. However, the optimal supplementation quantity of extra carbon sources and their effect on the distribution of indigenous microorganisms in RSW in long term cultivation still required to be addressed in further study. In addition, further research on the effectiveness of sodium bicarbonate and sodium acetate on other microalgae species are also required to be conducted.

References

Hu, Y.A., Cheng, H.F., Tao, S.: Environmental and human health challenges of industrial livestock and poultry farming in China and their mitigation. Environ. Int. 107, 111–130 (2017)

Nagarajan, D., Kusmayadi, A., Yen, H.W., Dong, C.D., Lee, D.J., Chang, J.S.: Current advances in biological swine wastewater treatment using microalgae-based processes. Bioresour. Technol. 289, 121718 (2019). https://doi.org/10.1016/j.biortech.2019.121718

Qian, Y., Song, K.H., Hu, T., Ying, T.Y.: Environmental status of livestock and poultry sectors in China under current transformation stage. Sci. Total Environ. 622, 702–709 (2018)

Cheng, D.L., Ngo, H.H., Guo, W.S., Liu, Y.W., Zhou, J.L., Chang, S.W., Nguyen, D.D., Bui, X.T., Zhang, X.B.: Bioprocessing for elimination antibiotics and hormones from swine wastewater. Sci. Total Environ. 621, 1664–1682 (2018)

Bai, Z.H., Li, X.X., Lu, J., Wang, X., Velthof, G.L., Chadwick, D., Luo, J.F., Ledgard, S., Wu, Z.G., Jin, S.Q., Oenema, O., Ma, L., Hu, C.S.: Livestock housing and manure storage need to be improved in China. Environ. Sci. Technol. 51, 8212–8214 (2017)

Gan, L., Hu, X.S.: The pollutants from livestock and poultry farming in China-geographic distribution and drivers. Environ. Sci. Pollut. Res. 23, 8470–8483 (2016)

Soni, R.A., Sudhakar, K., Rana, R.S.: Spirulina-from growth to nutritional product: a review. Trends Food Sci. Tech. 69, 157–171 (2017)

Sumprasit, N., Wagle, N., Glanpracha, N., Annachhatre, A.P.: Biodiesel and and biogas recovery from Spirulina platensis. Int. Biodeterior. Biodegrad. 119, 196–204 (2017)

Turkkul, B., Deliismail, O., Seker, E.: Ethyl esters biodiesel production from Spirulina sp. and Nannochloropsis oculata microalgal lipids over alumina-calcium oxide catalyst. Renew. Energy 145, 1014–1019 (2020)

Ghosh, U.K.: An approach for phycoremediation of different wastewaters and biodiesel production using microalgae. Environ. Sci. Pollut. Res. 25, 18673–18681 (2018)

Zhou, W., Li, Y., Gao, Y., Zhao, H.: Nutrients removal and recovery from saline wastewater by Spirulina platensis. Bioresour. Technol. 245, 10–17 (2017)

Liu, R., Yu, Q.Q., Guo, Q.Q., Zheng, W., Wang, G.R., Chen, L.J.: Raceway pond cultivation of a new Arthrospira sp ZJWST-S1 in digested piggery wastewater treated by MBR and ozonation. Int. J. Agric. Biol. Eng. 10, 115–124 (2017)

Javed, F., Aslam, M., Rashid, N., Shamair, Z., Khan, A.L., Yasin, M., Fazal, T., Hafeez, A., Rehman, F., Rehman, M.S.U., Khan, Z., Iqbal, J., Bazmi, A.A.: Microalgae-based biofuels, resource recovery and wastewater treatment: a pathway towards sustainable biorefinery. Fuel 255, 115826 (2019). https://doi.org/10.1016/j.fuel.2019.115826

Lu, Q., Liu, H., Liu, W., Zhong, Y.M., Ming, C.B., Qian, W., Wang, Q., Liu, J.L.: Pretreatment of brewery effluent to cultivate Spirulina sp for nutrients removal and biomass production. Water Sci. Technol. 76, 1852–1866 (2017)

Pankratz, S., Oyedun, A.O., Zhang, X., Kumar, A.: Algae production platforms for Canada's northern climate. Renew. Sust. Energy Rev. 80, 109–120 (2017)

Srinuanpan, S., Cheirsilp, B., Prasertsan, P., Kato, Y., Asano, Y.: Strategies to increase the potential use of oleaginous microalgae as biodiesel feedstocks: nutrient starvations and cost-effective harvesting process. Renew. Energy 122, 507–516 (2018)

Dao, G.H., Wu, G.X., Wang, X.X., Zhuang, L.L., Zhang, T.Y., Hu, H.Y.: Enhanced growth and fatty acid accumulation of microalgae Scenedesmus sp. LX1 by two types of auxin. Bioresour. Technol. 247, 561–567 (2018)

Lu, W., Alam, M.A., Luo, W., Asmatulu, E.: Integrating Spirulina platensis cultivation and aerobic composting exhaust for carbon mitigation and biomass production. Bioresour. Technol. 271, 59–65 (2019)

Lu, W., Wang, Z., Yuan, Z.: Characteristics of lipid extraction from Chlorella sp. cultivated in outdoor raceway ponds with mixture of ethyl acetate and ethanol for biodiesel production. Bioresour. Technol. 191, 433–437 (2015)

Andrade, B.B., Cardoso, L.G., Assis, D.J., Costa, J.A.V., Druzian, J.I., da Cunha Lima, S.T.: Production and characterization of Spirulina sp. LEB 18 cultured in reused Zarrouk's medium in a raceway-type bioreactor. Bioresour. Technol. 284, 340–348 (2019)

Chang, Y., Wu, Z., Bian, L., Feng, D., Leung, D.Y.C: Cultivation of Spirulina platensis for biomass production and nutrient removal from synthetic human urine. Appl. Energy 102, 427–431 (2013)

Lu, W., Wang, Z., Wang, X., Yuan, Z.: Cultivation of Chlorella sp. using raw dairy wastewater for nutrient removal and biodiesel production: Characteristics comparison of indoor bench-scale and outdoor pilot-scale cultures. Bioresour. Technol. 192, 382–388 (2015)

Andrade, M.R., Costa, J.A.V.: Mixotrophic cultivation of microalga Spirulina platensis using molasses as organic substrate. Aquaculture 264, 130–134 (2007)

Arana, T.J., Gude, V.G.: A microbial desalination process with microalgae biocathode using sodium bicarbonate as an inorganic carbon source. Int. Biodeterior. Biodegrad. 130, 91–97 (2018)

Zhang, W., Zhang, P., Sun, H., Chen, M., Lu, S., Li, P.: Effects of various organic carbon sources on the growth and biochemical composition of Chlorella pyrenoidosa. Bioresour. Technol. 173, 52–58 (2014)

Lowrey, J., Brooks, M.S., McGinn, P.J.: Heterotrophic and mixotrophic cultivation of microalgae for biodiesel production in agricultural wastewaters and associated challenges—a critical review. J. Appl. Phycol. 27, 1485–1498 (2015)

de Jesus, C.S., Assis, D.D., Rodriguez, M.B., Menezes, J.A., Costa, J.A.V., Ferreira, E.D., Druzian, J.I.: Pilot-scale isolation and characterization of extracellular polymeric substances (EPS) from cell-free medium of Spirulina sp. LEB-18 cultures under outdoor conditions. Int. J. Biol. Macromol. 124, 1106–1114 (2019)

Xie, B., Gong, W., Tian, Y., Qu, F., Luo, Y., Du, X., Tang, X., Xu, D., Lin, D., Li, G., Liang, H.: Biodiesel production with the simultaneous removal of nitrogen, phosphorus and COD in microalgal-bacterial communities for the treatment of anaerobic digestion effluent in photobioreactors. Chem. Eng. J. 350, 1092–1102 (2018)

Zhao, X.C., Tan, X.B., Yang, L.B., Liao, J.Y., Li, X.Y.: Cultivation of Chlorella pyrenoidosa in anaerobic wastewater: the coupled effects of ammonium, temperature and pH conditions on lipids compositions. Bioresour. Technol. 284, 90–97 (2019)

Podevin, M., De Francisci, D., Holdt, S.L., Angelidaki, I.: Effect of nitrogen source and acclimatization on specific growth rates of microalgae determined by a high-throughput in vivo microplate autofluorescence method. J. Appl. Phycol. 27, 1415–1423 (2014)

Sati, H., Mitra, M., Mishra, S., Baredar, P.: Microalgal lipid extraction strategies for biodiesel production: a review. Algal Res. 38, 101413 (2019). https://doi.org/10.1016/j.algal.2019.101413

Liu, S.H., Abu Hajar, H.A., Riefler, G., Stuart, B.J.: Lipid extraction from Spirulina sp. and Schizochytrium sp. using supercritical CO2 with methanol. Biomed. Res. Int. 4, 1–12 (2018)

Dehaghani, A.H.S., Pirouzfar, V.: Investigation on the effect of microalgae Chlorella sp. and Spirulina on biodiesel production. Pet. Chem. 58, 702–708 (2018)

Liu, J., Huang, J., Sun, Z., Zhong, Y., Jiang, Y., Chen, F.: Differential lipid and fatty acid profiles of photoautotrophic and heterotrophic Chlorella zofingiensis: assessment of algal oils for biodiesel production. Bioresour. Technol. 102, 106–110 (2011)

Yang, I.S., Salama, E.S., Kim, J.O., Govindwar, S.P., Kurade, M.B., Lee, M., Roh, H.S., Jeon, B.H.: Cultivation and harvesting of microalgae in photobioreactor for biodiesel production and simultaneous nutrient removal. Energy Convers. Manag. 117, 54–62 (2016)

Acknowledgements

This research was supported by Shaoguan University key research project (SZ2016KJ02) and China Scholarship Council (201708440546). The authors are also thankful for the valuable comments make by the anonymous reviewers, which greatly help in improving the quality of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, W., Liu, S., Lin, Z. et al. Enhanced Microalgae Growth for Biodiesel Production and Nutrients Removal in Raw Swine Wastewater by Carbon Sources Supplementation. Waste Biomass Valor 12, 1991–1999 (2021). https://doi.org/10.1007/s12649-020-01135-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-020-01135-w