Abstract

The complex structure and biochemical composition of the cell wall of microalgae impede their anaerobic digestion. To enhance the microalgae anaerobic biodegradability, various pretreatment approaches have been utilized. In this study, the enzyme and hydrothermal pretreatment methods were evaluated for microalgal biomass pretreatment and biogas yield. The optical and scanning electron microscopy along with Fourier transform infrared spectroscopy analysis confirmed the efficient action of both the pretreatment methods. The hydrothermal pretreatment resulted in more structural changes, though the increase in enzymatic concentration was also found to have a pronounced effect on both structural and chemical changes. The FTIR spectra determined that mostly the protein and carbohydrate structures of the microalgal cells were affected. Further upon quantitative analysis, it was observed that 10% dose (w/w) for 24 h of exposure time released significantly more soluble chemical oxygen demand compared to others. The multi-enzyme 10% dose for 24 h resulted in significantly higher biogas production potential (P) of 768.92 mL g−1 VS at a maximum biogas production rate (Rm) of 32.16 mL g−1 d−1 with a very short lag phase (λ) of 0.09 days at the end of 30 days, in comparison to untreated and other pretretment conditions in this study. Both the pretreatment approaches in the present study enhanced the microalgal biomass disintegration, digestibility and biogas production. However, more research is required to optimize the process parameters of these pretreatment approaches to make them more reasonable and applicable.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Statement of Novelty

The research to investigate the biofuel potential of microalgae biomass have lured special global attention as algal biofuels hold promising alternates to conventional fuels. This study was undertaken to determine the biogas potential of the salt-tolerant microalgal strain isolated from the waterlogged area of Punjab, India. The effect of pretreatments (enzyme and hydrothermal) on solubilization of algal biomass have been studied both qualitatively and quantitatively. It further assesses their effect on biogas yield. Although a lot of research has been conducted on freshwater algal species, this is of its first kind of study from Indian Punjab as it involves the salt tolerant strain isolated from this unexplored area in terms of microalgal diversity.

Introduction

The incessant rise in energy demand over the last few decades has made the researchers to look for the alternative of fossil fuels and produce the innovative technologies. Among the various renewable sources available, organic wastes and biomass are potential feedstocks to be utilized as renewable sources for biofuel generation [1]. Various kinds of available biomass like edible oil, sugarcane etc. have been used traditionally to produce biofuels. However, compared to these, microalgae prove to be a desirable substrate for biofuel production because of the various benefits as: (i) high productivity due to higher photosynthetic efficiency; (ii) requires less water for growth compared to terrestrial crops and can be grown in wastewater, brackish water and saline; (iii) can be cultivated in non-arable lands thus limited competition with food crops for arable land; (iv) can help in carbon dioxide mitigation as microalgae uses it for its growth [2,3,4,5]. Thus it has lured the attention of scientists and entrepreneurs as an alternative energy source to conventional fossil fuels during the last decade.

Microalgae are being vastly explored for biodiesel production, still, the production of biodiesel at full scale has various constraints like the requirement of considerable cultivation and harvesting technologies for efficient biomass production, harvesting and processing. Also in comparison to fossil fuels, the biodiesel production from microalgae has not been still optimized and reached competitive prices [6]. In comparison to this, anaerobic digestion of microalgal biomass or algal residues for biogas production is a potential alternative [3]. It has been reported that algal biomass with low lipid content or lipid extracted algal residue produce significantly more energy through anaerobic digestion (AD) compared to biodiesel production [7, 8]. Also, for AD wet biomass can be used and, therefore, no extensive drying methods are required.

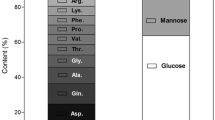

In addition to this, microalgae have proven to be a promising AD substrate as reported by various recent studies [9,10,11]. Microalgae biomass composition (proteins, carbohydrates and lipids) varies, depends on species and cultural conditions [6, 12]. The methane yields vary from macromolecule to macromolecule [13, 14]. However, several constraints like high cultivation and harvesting costs, sulphur and ammonia toxicity, inadequate algal biomass degradability, inefficient designs of anaerobic digesters etc. need to be addressed to make AD of algal biomass more workable [15, 16]. But the limited biodegradability of algal cells is one of the crucial constraints demanding more research inputs to make AD of algae economically viable [17]. The composition of the algal cell wall and thus degradability also varies from species to species [18] and thus producing varied methane yields [12]. Spirulina cell wall is composed of protein, peptidoglycans and polysaccharides [19]. The hydrolysis of complex components of cell wall into simpler compounds is carried out by the enzymes produced by hydrolytic bacteria. It is the first stage in the anaerobic digestion process and is imperative for the efficiency of the process [20, 21]. It renders algal organic matter to anaerobic microorganisms. The low hydrolysis rate is generally responsible for the lengthy and ineffective AD process [22]. Therefore, pretreatment approaches were found out as an important step for microalgae cell disruption, solubilization of particulate biomass, improving the anaerobic digestion rate, extent and hence biogas production [23, 24]. The biochemical composition, the structural rigidity of the algal cells determine the efficacy of pretreatment methods on biogas production. Various bacteria such as Bacillus, Proteus, Clostridium, Bacteroides etc. produce enzymes which hydrolyze the proteins as proteins being the main component of Spirulina cell wall [25]. Over the last years, various studies of pretreatment of microalgal biomass with protease showed higher methane production compared to untreated biomass and carbohydrases treated biomass [26]. The effect of pretreatment on algal biomass can be assessed by various techniques like light microscopy, scanning electron microscopy (SEM), transmission electron microscopy (TEM), Fourier transform infrared spectroscopy (FT-IR) [27]. FT-IR is one of the easiest methods with a simple method of sample preparation. It has been suggested as one of the advanced tools for obtaining information about biomass structure and chemical changes taking place during pretreatment [28,29,30].

The aim of the current study was to evaluate the biogas production after giving enzymatic and hydrothermal pretreatments to Spirulina subsalsa BGLR6 biomass, isolated from the waterlogged area of Punjab, India. To this end, biogas production potential was determined through biochemical methane potential (BMP) tests performed with untreated and pretreated biomass. Microscopic images were used to analyze the effect of pretreatment on microalgae cell structure and biodegradability. Furthermore, FTIR was performed to assess the changes in the composition of the structural components. The biogas production kinetics was also studied.

Materials and Methods

Microalgal Biomass Production

Microalgae S. subsalsa BGLR6 previously isolated from the waterlogged area of Punjab, India [31] was used as a substrate for enzymatic, hydrothermal pretreatment and anaerobic digestion for biogas production. S. subsalsa BGLR6 was grown in 1ft3 fabricated algal ponds provided with the artificial illumination system of 81 µmol m−2 s−1 light intensity (provided by compact fluorescent lamps) using the modified algae culture medium [32]. The modified algae culture medium consists of (per litre): 1 g NaNO3, 0.5 g K2HPO4, 0.513 g MgSO4·7H2O, 0.050 g NH4Cl, 0.058 g CaCl2·2H2O, 0.003 g FeCl3, 16.8 g NaHCO3, 4.4 × 10−4 g MnSO4, 4.8 × 10−4 g Na2MoO4·2H2O, 7.2 × 10−5 g CuSO4·5H2O, 8 × 10−3 g disodium EDTA, 2.3 × 10−4 g ZnSO4·7H2O, 3.6 × 10−2 g MgSO4·7H2O. After substantial growth (25 days), the density of S. subsalsa BGLR6 biomass reached 2.5 g dw L−1. The biomass was harvested through filtration and used for further study.

Pretreatment of Algal Biomass

The algal biomass was subjected to enzymatic and hydrothermal pretreatments.

Enzymatic Pretreatment

The pretreatment was carried out with the multi-enzyme mix consisting of commercially available cellulase (specific activity 0.3 U mg−1), hemicellulase (specific activity 0.3 U mg−1) and protease (specific activity ≥ 500 U g−1), all purchased from Sigma-Aldrich, India. The concentration of cellulase, hemicellulase and protease in the enzyme mix was 300 U L−1, 300 U L−1 and 1500 U L−1 respectively. The multi-enzyme solution was prepared in distilled water. Two enzymes doses (10 and 20% w/w) over an exposure time of 12 and 24 h (i.e., 10% 12 h, 10% 24 h, 20% 12 h and 20% 24 h) were compared to evaluate the best pretreatment conditions. The untreated one was run in parallel to these sets. The microalgal biomass was placed in Erlenmeyer flasks (250 mL) where the corresponding dose of the enzyme for corresponding exposure time was added (10 and 20% w/w). Both doses were assayed in triplicate for enzyme mix. Trials were set in a BOD incubator with regulated temperature (37 °C), under continuous mixing. The temperature set for the trials was optimal for enzymatic activity. The liquid phase of the sample was collected for chemical oxygen demand (COD) analysis in order to determine the solubilization of microalgal biomass [33]. COD solubilisation was calculated as per Prajapati et al. [34].

Hydrothermal Pretreatment

Hydrothermal pretreatment was carried out in an autoclave. The pretreatment conditions were 100 °C and 120 °C for 30 min. The exposure time was kept the same for both the temperatures. Pretreatment of biomass was performed in Erlenmeyer flasks with a working volume of 200 mL. The flasks were plugged with cotton and then kept in the autoclave. The temperature of the autoclave was raised to the target value. At this point, algal biomass was retained under the aimed temperature for the decided exposure time. After this, atmospheric conditions were attained by releasing the pressure slowly. Finally, the flasks were cooled in tap water for about half an hour to reach room temperature and stored at 4 °C until use. The biomass solubilization was evaluated by measuring the chemical oxygen demand (COD) for the liquid phase after given treatment [33]. COD solubilisation was determined according to Prajapati et al. [34].

Microscopy of the Untreated and Pretreated Samples

The optical microscopy and SEM were carried out to evaluate the effect of various pretreatments on the algal biomass.

Optical Microscopy

The untreated and treated samples were observed microscopically (Olympus 528293 microscope) to assess the qualitative information on the effect of enzymatic and hydrothermal pretreatments on microalgae cells. The optical microscope used was equipped with the Debro 5.1 Megapixel digital camera and the Toup view software program.

Scanning Electron Microscopic (SEM) Analysis

The surface structure of the S. subsalsa BGLR6 before and after pretreatments (Enzymatic and hydrothermal pretreatment) were also analyzed by scanning electron microscope imaging according to Bozzola and Russell [35]. The sample was processed by dehydrating it with the increasing alcohol series (50%, 70%, 80%, 90%, 95% and 100%) followed by mounting it on the carbon tape. Thereafter, the sputter coating was carried out with the gold particles and then viewed under the Scanning Electron Microscope (Hitachi S-3400N, Germany) at the accelerating voltage of 15000 V.

Fourier Transform Infrared (FT-IR) Spectroscopy

The treated as well as untreated biomass was analyzed for changes in the composition of the structural components by Fourier transform infrared spectrometer (Thermo Scientific Nicolet 6700 spectrometer). One mg algal samples (both untreated and pre-treated) were mixed with 10 mg activated KBr. KBr was activated by heating in an oven at 60 °C for 12 h to get rid of moisture. The mixture of algal sample and KBr was then made a fine intimate powder by crushing in crystal mortar with a crystal pestle. The fine powder was then pressed in a Hydraulic Pellet Press to make a uniform thin pellet. The pellet was then put inside the FT-IR spectrometer. Spectra were collected in the 4000–400 cm−1 range, with a 4 cm−1 interval and 32 scans at room temperature.

Determination of Biogas Production Potential Through BMP Test

After different pretreatments, the biogas production potential of the algal biomass was determined through biochemical methane potential (BMP) test protocol [9]. The experimentation was studied in 300 mL capacity digesters (Borosil). The anaerobic digester set up consists of a digester, a gas collecting chamber and a liquid collecting chamber. The digester with the working volume kept to 150 mL was sealed with a rubber cork and araldite (adhesive). The inoculum (digested biogas slurry) was aseptically transferred to experimental bottles from an actively running cattle dung based biogas plant. The inoculum was first degassified by incubating it at the thermophilic temperature (45–50 °C) for 7–10 days. This incubating the inoculum also increases the microflora responsible for anaerobic digestion in it. The substrate to inoculum ratio of 0.5 was used for the experiments. The volume up to 150 mL was made by distilled water. Digester containing only untreated biomass was used as the control. After inoculation, the installed digesters (in triplicates for each sample) were placed under stationary conditions at 35 ± 2 °C for incubation and the amount of biogas generated was measured after every twenty four hours for a period of 30 days through acidic (HCl) water (pH < 3) displacement method. In parallel to this, the biogas production from the control digester was also studied. The biogas production studies were carried out for the digesters in triplicates.

The volatile solids were determined according to the standard methods of AOAC [36] both before (at the initial stage) and after digestion (i.e., after 30 days). The percentage of volatile solids reduction (VSR%) was calculated as per Eq. (1).

where VSbd and VSad signify volatile solids before and after anaerobic digestion.

Kinetics of Biogas Production

The kinetics of biogas production in all the biogas experiments was studied by using the modified Gompertz equation and also a modified first-order kinetic equation. The biogas produced was measured on daily basis. From this, the daily and cumulative biogas production in terms of mL biogas g−1 VS was calculated. The cumulative biogas data was then fitted with the Gompertz equation for calculating the enhancement in ultimate biogas production potential or yield (P), lag phase (λ) and the maximum rate of biogas production (Rm) in the gas production profile. The used Gompertz equation, adopted from Prajapati et al. [37] is given as

where M is the cumulative biogas yield (mL biogas g−1 VS added) and e = 2.718.

Furthermore, to predict and assess the enhancement in the hydrolysis constant (kh), the cumulative biogas data was evaluated by first order kinetic equation. This kh provides the estimation of the substrate biodegradability. It was supposed that the hydrolysis in the feedstock (algal biomass) digestion follows first-order kinetics and kh was then calculated by fitting the cumulative biogas data to the first order hydrolysis kinetics model adopted from Angelidaki et al. [38].

MS Solver of Excel 2007 was utilized as the platform to fit the experimental data in the models.

Statistical Analysis

All the experiments were done in triplicates. Results are reported as mean. The significant difference in biogas production from pretreated and control (untreated raw biomass) was studied by Duncan’s Multiple Range test.

Results and Discussion

Effect of Enzymatic and Hydrothermal Pretreatments on Algal Biomass

The qualitative information of the pretreatments on S. subsalsa biomass was ascertained from the optical and scanning electron microscopy. It is evident from Figs. 1 and 2 that more damage to the algal cells is caused by higher dose enzymatic and hydrothermal pretreatment. The visual observations of enzymatically and hydrothermally pretreated algal biomass showed a substantial change in colour (from greenish to yellowish). The release of chlorophyll was found in all the pretreatments but the prominent release was noted for 10% 24 h, 20% 24 h and hydrothermal pretreatment (Fig. 1). In the case of enzymatic pretreatment, the depigmentation was found more as both the exposure time and dose were increased. However, overall, the highest depigmentation occurred in hydrothermal pretreatment (Fig. 1e, f). Apart from depigmentation, prominent cell aggregation was noticed in case of hydrothermal treatment than enzymatic pretreatment as is evident from SEM images (Fig. 2d, e). The depigmentation and aggregation are the indications of the damage of the cell wall. The probable reason for the floc and aggregate formation of microalgal cells might be the release of the cellular content through hydrothermal and enzymatic action on the cell wall. Our results are in line to those of the various researchers who too observed the aggregation of algal cells on enzymatic pretreatment [37, 39]. In 10% 24 h pretreatment, the rod and coiled structure were intact, but the rods were clumped together (Fig. 2b). However, in 20% 24 h enzymatic pretreatment, the uncoiling of the filamentous structure of S. subsalsa BGLR6 was noticed (Fig. 2c). After uncoiling, the structure got disintegrated and resulted in the floc formation (Fig. 2c–e). It concludes that both dose percentage and pretreatment time have a considerable effect on the algal cell structure. The hydrothermal pretreatment damaged the cells, the structure of algal cells was lost, as if it appeared that the cell wall was disrupted. These things can be better seen from both the optical microscopy (Fig. 1a–g) and SEM (Fig. 2a–e) images. These images supported well the visual findings. The other researchers too found that hydrothermal pretreatment led to the disruption of the cell wall of algal cells [22, 40].

Although the pretreatment action of enzymatic and hydrothermal treatment can be confirmed by optical microscopy and SEM, however for the comparative evaluation of the pretreatments, quantitative information is provided by COD solubilisation (%). It helps in monitoring the amount of cellular constituents released upon pretreatment of algal biomass [9]. The enzymatic and hydrothermal pretreatment of algal biomass was found to cause the cell degradation and increase in soluble chemical oxygen demand (sCOD) compared to the untreated one and thus the COD solubilisation (%). In case of the enzymatic pretreatment, 23.70–42.22% COD solubilisation was recorded with highest observed in 10% 24 h (42.22%) followed by 20% 12 h (34.81%). This is in harmony with the results of Prajapati et al. [37] who too observed an increase in COD with pretreatment time. However, for hydrothermal pretreatment, the COD solubilisation % at 120 °C for 30 min (32.96%) was found close to 100 °C for 30 min (29.26%). Ometto et al. [20] too have observed similar response that at temperatures < 150 °C, the sCOD concentration is almost the same. The higher amount of sCOD released and thus higher COD solubilisation in enzymatic treatment (10% for 24 h) could be due to the escape of intracellular organic matter from the partially damaged cells of S. subsalsa BGLR6. The floc formation in higher dose enzymatic pretreatment and hydrothermal could have prevented the release of organic cellular constituents and due to which the sCOD measured in these cases was comparatively less. The increase in sCOD indicates the breaking down of complex, insoluble organic cell constituents into simple forms by the pretreatments applied. The soft cell wall of Spirulina made up of complex proteins, sugars, as well as its filamentous nature, makes it more easily degradable [19]. However, the COD solubilisation percentage in our study was found to be comparatively lower than previously reported [9, 41,42,43]. This could be possibly due to the floc formation of algal cells during pretreatment (evident from Fig. 2) which could have prevented the release of organic matter of algal cells.

Characterization of Pretreated Microalgal Biomass by FT-IR

Spirulina consists of complex compounds, its infrared spectrum is complex and contains several bands from the contribution of different functional groups in proteins, saccharides, and others nutrients. The principal components all have their own infrared characteristic peaks. The fingerprint regions of the FT-IR spectra of raw and pretreated S. subsalsa BGLR6 biomass are presented in Fig. 3a–e. This FT-IR analysis of the samples was carried out in order to illustrate the structural and chemical changes taking place during pretreatments in the algal cells [29]. The unique appearances of transmission spectra from untreated and pretreated BGLR6 biomass samples shown in Fig. 3 had 5–7 clear bands over the wavenumber range 4000–500 cm−1. These bands were identified tentatively in accordance with the available literature [44,45,46,47,48,49]. The infrared spectrum is obtained due to the absorption of electromagnetic radiations at certain frequencies that correlate to the vibration of specific chemical bonds in a molecule. The vibrations are of different types but the most simple is bending and stretching to visualize. The vibrations cause a change of dipole moment which results in the absorption of infrared radiation for the molecule or the functional group under study [50]. A functional group was allotted to each peak. Mostly a downshift was observed at all peaks in all the samples except the enzymatically pretreated samples (10% 24 h and 20% 24 h) wherein an upshift was noted approximately at the peak 1408.1 cm−1. The main transmission bands at approximately 3406.0–3426, 2924.2, 1658–1668.6, 1408.1–1453, 1046–1088, 856–871.3 and 534–590 cm−1 were observed in the spectra of pretreated microalgal samples. The band at 3406.0–3426 cm−1 is chiefly due to the stretching vibration of N–H bonds in proteins and O–H stretching vibrations in hydrogen bonds and intermolecular hydrogen bonds [51, 52]. The band at 2924.2 cm−1 mainly represents the asymmetric stretching of CH2 of lipids with the little contribution from carbohydrates, proteins and nucleic acids. Similarly, the 1658–1668.6 cm−1 corresponds to the amide I (C=O stretch) of proteins whereas bands at 1408.1–1453 cm−1 represent the asymmetric stretching (bend) of CH2, CH3 of proteins and asymmetric stretching of CH2 of lipids. The bands at 1046–1088 cm−1 are mainly from the vibrations of C–O or C–C of saccharides, symmetric stretching of C–O–C of polysaccharides. Also a general downshift was observed in all the samples with respect to the untreated one in the region 2850–1700 cm−1 which mainly represents lipids, carbohydrates and proteins [45]. The absorption at 870 cm−1 is assigned to C–H bending on an aromatic ring. With pretreatment, it was found that the intensity of all the bands except at 871 cm−1 decreased significantly. The shifting of bandwidth and broadening of peaks were observed in all the pretreated samples compared to the untreated one. The maximum shifting up to 3426 cm−1 in the band at 3406 cm−1 was found in hydrothermally pretreated (100 °C 30 min) biomass. The band around 1668 cm−1 also shifted maximum by 8 units. The band at 1408 cm−1 shifted slightly by 2 units with the decrease in intensity in enzymatically pretreated samples while as the major shift up to 1453 cm−1 in this band along with an increase in intensity was seen in hydrothermally pretreated ones compared to others. The band at 1056 cm−1 shifted maximum in enzymatic pretreatment. Similarly, the prominent shift in the band at 589 cm−1 was noticed in enzymatically pretreated biomass. Though the transmission peak positions changed, the transmission bands in all the pretreated S. subsalsa BGLR6 biomass were quite similar with those of the untreated (control) sample. The changes in band position and intensity may indicate the decrease in the content of structural components and formation of new types of groups from free radical groups generated during pretreatment [51, 53]. The broadening of the band also represents the weakening of the bond due to pretreatment. As these peaks represent proteins, secondary amines (proteins, lipids), saccharides carbohydrate, the decrease in their intensity corresponds to a decrease in their content. The peak at 2924 cm−1 almost vanished in enzymatic treatment thus depicting the lipid and carbohydrate structures were broken down, however, the same band was found to have retained in hydrothermal pretreatment. The intensity of peaks among pretreated samples was more in 10% 24 h, thus supporting the observation of sCOD which was more in this compared to the others, thus further validating that the cells of S. subsalsa BGLR6 in this case were partially damaged. So, from these spectra it was determined that the treatment affected mostly the protein and carbohydrate structures of the microalgal cells. The decrease of FTIR band heights of proteins, carbohydrates and lipids as observed from FTIR spectra determines the breakdown of carbon storage products [54]. We know the fact that the cell wall of cyanobacteria is composed of peptidoglycan (polymer of sugars and amino acids) [46], thus we can conclude that the cell wall of S. subsalsa BGLR6 was effected by the pretreatments.

Biogas Production Potential of Microalgal Biomass

The biogas production potential of untreated and pretreated S. subsalsa BGLR6 biomass was measured under controlled temperature (35 ± 2 °C) conditions for 30 days. The modified Gompertz equation was utilized to fit the cumulative daily biogas yield and to calculate various kinetic constants. Further, a modified first-order kinetic equation was applied to calculate the hydrolysis constant. The total biogas measured (in L biogas kg−1 substrate) for 30 days ranged from 23.77 to 42.73 for S. subsalsa BGLR6 (Table 1). The biogas production showed an increase from the day first i.e., it started without any lag phase (λ) in all the experimental sets except the untreated one i.e., control as can be seen in Table 1 and Fig. 4. The biogas yield did not differ from 8th to 19th day between the samples pretreated by 10% enzyme dose for 12 h and untreated one and similarly no differences were found in samples pretreated with 20% enzyme dose for 12 h and 20% enzyme dose for 24 h from 5th to 24th day (Fig. 4). The kinetics of biogas production from the untreated and pretreated biomass of S. subsalsa BGLR6, for all the sets of experiments, was studied. While studying the kinetics of biogas production from BGLR6 biomass, it was noticed that the digester containing biomass pretreated with enzyme mix of dose 10% for 24 h produced the highest biogas production potential (P) of 768.92 mL g−1 VS at a maximum biogas production rate (Rm) of 32.16 mL g−1 d−1 with a lag phase (λ) of 0.09 days (Table 1) at the end of 30 days. This suggests that the multi-enzyme mix would have solubilised the microalgal organic matter, increased its availability and thus degradability by anaerobic microflora. Compared to the application of hydrothermal pretreatment, the enzymatic pretreatment (10% 24 h) application in our study increased the release of sCOD by 26.32%–41.18%, thus indicating the higher degree of organic matter solubilisation. Hence, more microalgal organic matter was made available in our study by enzymatic pretreatment which ultimately led to the enhanced biogas production compared to control. However, it is imperative to mention here that although the multi-enzyme mix used in this study contains cellulase and hemicellulase (non-specific enzymes as cell wall of Spirulina does not contain cellulose and hemicellulose) along with protease, the pretreatment proved to be efficient and effective. This could be attributed to the synergistic effect of these non-specific enzymes with that of the specific enzyme as reported in many studies [34, 55,56,57]. The least biogas production potential (P) was noticed in raw biomass (466.99 mL g−1 VS) and biomass pretreated hydrothermally at 120 °C 30 min (421.65 mL g−1 VS). This low biogas production than expected from biomass pretreated with 120 °C for 30 min could be possibly due to the formation of complex molecules on the degradation of sugars and carbohydrates through Maillard and Caramelisation reactions as higher temperature favours these reactions [58]. Similarly, the lower biogas production from biomass pretreated with higher dose enzyme and 100 °C 30 min hydrothermal could be due to the same reason. It appears in these cases that the biomass solubilized was not transformed into biogas efficiently due to some inhibitory product formation. Passos and Ferrer [59] too observed lower than expected methane yields with hydrothermal pretreatment of Oocystis sp. but comparatively higher than observed in our study. It could be due to the different algal species used in both the studies. The effect of pretreatment varies from substrate to substrate and species to species depending on the morphology and biochemical composition [7, 16].

The biomass pretreatments resulted in enhancement of biogas production (P) and biogas production rate (Rm) by 1.11–1.65 and 1.07–1.68 times higher compared to that of untreated biomass. An increase in the volatile solids reduction (VSR) was observed on pretreatment of microalgal biomass. The volatile solid reduction in pretreated biomass increased from 28.11–52.57% to that of untreated biomass. This determines and confirms that pretreatment increases the digestibility of the substrates. The modified Gompertz equation suitably and satisfactorily described biogas production with a goodness of fit (R2) of 0.997, 0.997, 0.998, 0.999, 0.999, 0.998 and 0.997 for digesters A, B, C, D, E, F and G respectively, as can been observed from Fig. 4. The hydrolysis stage is the rate-limiting step in anaerobic digestion of microalgae biomass. To assess the hydrolysis of the substrate, the hydrolysis constant was calculated according to Eq. (3). While the untreated biomass exhibited Kh of 0.047 d−1, the pretreated biomass ranged 0.049–0.086 d−1. These results were in harmony with those of Passos and Ferrer [59] who too registered Kh changes when given hydrothermal pretreatment to microalgal biomass. The maximum hydrolysis constant was observed for biomass pretreated hydrothermally at 100 °C for 30 min, but the ultimate biogas production potential (P) was less than enzymatically pretreated samples. The possible reason for this may be the ammonia toxicity as proteins form the major constituent in S. subsalsa, thus having a low C/N ratio. The hydrothermal pretreatment led to the hydrolysis of proteins (amino acids) as is evident from the qualitative analysis (optical microscopy, SEM and FTIR) of the biomass in this study. The protein hydrolysis results in the production of ammonia and this ammonia causes an increase in both alkalinity and pH in the digester which in turn is responsible for the depletion of available substrate (acetate) to methanogens. This reduces the methanogen growth and ultimately the biogas production [1, 6, 60, 61]. Also, it is the fact that Kh comprises the part of the ultimate biogas yield being converted to the actual biogas yield. These pretreatments especially enzymatic not only provided the highest biogas yield but also the fastest. This will be beneficial as pretreated biomass would demand less retention time compared to untreated biomass and thus low energy input is needed. Further, the cumulative biogas yield curves obtained from the digesters under study were found to be sigmoidal in nature (Fig. 4). These type of curves have been described in anaerobic batch digestion experiments by various researchers [62, 63].

Finally, it is demonstrated that the enzymatic pretreatment is an effective approach for enhancing the microalgae anaerobic digestion process and thus biogas yield. However, more research is required to optimize and enhance the competence of the pretreatment approach.

Conclusion

This study aimed at investigating the effect of enzymatic and hydrothermal pretreatments on S. subsalsa BGLR6 biomass for biogas production. The sCOD release and biogas production were more in enzyme pretreated biomass compared to that of the hydrothermal pretreated biomass. although the prominent cell aggregation, highest depigmentation and also VSR (%) (indicators of cell wall damage) were noticed in hydrothermal pretreatment. A positive equivalence between VSR and biogas production was not observed in hydrothermal pretreatment. The pretreatments enhanced the ultimate biogas production potential and biogas production rate (Rm) by 1.11–1.65 and 1.07–1.68 folds compared to the untreated raw biomass. On the whole, the enzyme mix of dose 10% for 24 h of exposure time produced the best results, which need to be further evaluated for full-scale viability in terms of economics and sustainability at pilot scale.

References

Prajapati, S.K., Kaushik, P., Malik, A., Vijay, V.K.: Phycoremediation coupled production of algal biomass, harvesting and anaerobic digestion: possibilities and challenges. Biotechnol. Adv. 31, 1408–1425 (2013). https://doi.org/10.1016/j.biotechadv.2013.06.005

Li, Y., Horsman, M., Wu, N., Lan, C.Q., Dubois-Calero, N.: Biofuels from microalgae. Biotechnol. Prog. 24, 815–820 (2008). https://doi.org/10.1021/bp070371k

Wiley, P.E., Campbell, J.E., McKuin, B.: Production of biodiesel and biogas from algae: a review of process train options. Water Environ. Res. 83, 326–338 (2011)

Park, J.B.K., Craggs, R.J., Shilton, A.N.: Wastewater treatment high rate algal ponds for biofuel production. Bioresour. Technol. 102, 35–42 (2011). https://doi.org/10.1016/j.biortech.2010.06.158

Vandamme, D., Pontes, S.C.V., Goiris, K., Foubert, I., Pinoy, L.J.J., Muylaert, K.: Evaluation of electro-coagulation-flocculation for harvesting marine and freshwater microalgae. Biotechnol. Bioeng. 108, 2320–2329 (2011). https://doi.org/10.1002/bit.23199

Sialve, B., Bernet, N., Bernard, O.: Anaerobic digestion of microalgae as a necessary step to make microalgal biodiesel sustainable. Biotechnol. Adv. 27, 409–416 (2009). https://doi.org/10.1016/j.biotechadv.2009.03.001

Bohutskyi, P., Kula, T., Kessler, B.A., Hong, Y., Bouwer, E.J., Betenbaugh, M.J., Allnutt, F.C.T.: Mixed trophic state production process for microalgal biomass with high lipid content for generating biodiesel and biogas. BioEnergy Res. 7, 1174–1185 (2014). https://doi.org/10.1007/s12155-014-9453-5

Bohutskyi, P., Chow, S., Ketter, B., Betenbaugh, M.J., Bouwer, E.J.: Prospects for methane production and nutrient recycling from lipid extracted residues and whole nannochloropsis salina using anaerobic digestion. Appl. Energy 154, 718–731 (2015). https://doi.org/10.1016/J.APENERGY.2015.05.069

Alzate, M.E., Muñoz, R., Rogalla, F., Fdz-Polanco, F., Pérez-Elvira, S.I.: Biochemical methane potential of microalgae: influence of substrate to inoculum ratio, biomass concentration and pretreatment. Bioresour. Technol. 123, 488–494 (2012)

González-Fernández, C., Sialve, B., Bernet, N., Steyer, J.P.: Thermal pretreatment to improve methane production of Scenedesmus biomass. Biomass Bioenergy 40, 105–111 (2012). https://doi.org/10.1016/j.biombioe.2012.02.008

González-Fernández, C., Sialve, B., Bernet, N., Steyer, J.P.: Comparison of ultrasound and thermal pretreatment of Scenedesmus biomass on methane production. Bioresour. Technol. 110, 610–616 (2012). https://doi.org/10.1016/j.biortech.2012.01.043

Markou, G., Angelidaki, I., Georgakakis, D.: Carbohydrate-enriched cyanobacterial biomass as feedstock for bio-methane production through anaerobic digestion. Fuel 111, 872–879 (2013). https://doi.org/10.1016/J.FUEL.2013.04.013

Angelidaki, I., Sanders, W.: Assessment of the anaerobic biodegradability of macropollutants. Rev. Environ. Sci. Bio/Technology. 3, 117–129 (2004). https://doi.org/10.1007/s11157-004-2502-3

Magdalena, J., Ballesteros, M., González-Fernandez, C.: Efficient anaerobic digestion of microalgae biomass: proteins as a key macromolecule. Molecules 23, 1098 (2018). https://doi.org/10.3390/molecules23051098

Ward, A.J., Lewis, D.M., Green, F.B.: Anaerobic digestion of algae biomass: a review. Algal Res. 5, 204–214 (2014). https://doi.org/10.1016/J.ALGAL.2014.02.001

Bohutskyi, P., Bouwer, E.: Biogas production from algae and cyanobacteria through anaerobic digestion: a review, analysis, and research needs. In: Lee, J.W. (ed.) Advanced Biofuels and Bioproducts, pp. 873–975. Springer, New York (2013)

Inglesby, A.E., Griffiths, M.J., Harrison, S.T.L., van Hille, R.P.: Anaerobic digestion of Spirulina sp. and Scenedesmus sp.: a comparison and investigation of the impact of mechanical pre-treatment. J. Appl. Phycol. 27, 1891–1900 (2015). https://doi.org/10.1007/s10811-015-0669-3

Mussgnug, J.H., Klassen, V., Schlüter, A., Kruse, O.: Microalgae as substrates for fermentative biogas production in a combined biorefinery concept. J. Biotechnol. 150, 51–56 (2010). https://doi.org/10.1016/j.jbiotec.2010.07.030

Van Eykelenburg, C.: On the morphology and ultrastructure of the cell wall of Spirulina platensis. Antonie Van Leeuwenhoek 43, 89–99 (1977). https://doi.org/10.1007/BF00395664

Ometto, F., Quiroga, G., Pšenička, P., Whitton, R., Jefferson, B., Villa, R.: Impacts of microalgae pre-treatments for improved anaerobic digestion: thermal treatment, thermal hydrolysis, ultrasound and enzymatic hydrolysis. Water Res. 65, 350–361 (2014). https://doi.org/10.1016/J.WATRES.2014.07.040

Miao, H., Lu, M., Zhao, M., Huang, Z., Ren, H., Yan, Q., Ruan, W.: Enhancement of Taihu blue algae anaerobic digestion efficiency by natural storage. Bioresour. Technol. 149, 359–366 (2013). https://doi.org/10.1016/J.BIORTECH.2013.09.071

Passos, F., Ferrer, I.: Microalgae conversion to biogas: thermal pretreatment contribution on net energy production. Environ. Sci. Technol. 48, 7171–7178 (2014). https://doi.org/10.1021/es500982v

Passos, F., Uggetti, E., Carrère, H., Ferrer, I.: Pretreatment of microalgae to improve biogas production: a review. Bioresour. Technol. 172, 403–412 (2014)

Chen, P.H., Oswald, W.J.: Thermochemical treatment for algal fermentation. Environ. Int. 24, 889–897 (1998). https://doi.org/10.1016/S0160-4120(98)00080-4

Gonzalez-Fernandez, C., Sialve, B., Molinuevo-Salces, B.: Anaerobic digestion of microalgal biomass: challenges, opportunities and research needs. Bioresour. Technol. 198, 896–906 (2015). https://doi.org/10.1016/J.BIORTECH.2015.09.095

Mahdy, A., Ballesteros, M., González-Fernández, C.: Enzymatic pretreatment of Chlorella vulgaris for biogas production: influence of urban wastewater as a sole nutrient source on macromolecular profile and biocatalyst efficiency. Bioresour. Technol. 199, 319–325 (2016). https://doi.org/10.1016/J.BIORTECH.2015.08.080

Mishra, V., Dubey, A., Prajapti, S.K.: Algal biomass pretreatment for improved biofuel production. In: Gupta, S.K., Malik, A., Bux, F. (eds.) Algal Biofuels, pp. 259–280. Springer, Cham (2017)

Fan, J., Yan, C., Andre, C., Shanklin, J., Schwender, J., Xu, C.: Oil accumulation is controlled by carbon precursor supply for fatty acid synthesis in Chlamydomonas reinhardtii. Plant Cell Physiol. 53, 1380–1390 (2012). https://doi.org/10.1093/pcp/pcs082

Monlau, F., Barakat, A., Steyer, J.P., Carrere, H.: Comparison of seven types of thermo-chemical pretreatments on the structural features and anaerobic digestion of sunflower stalks. Bioresour. Technol. 120, 241–247 (2012). https://doi.org/10.1016/j.biortech.2012.06.040

Salehian, P., Karimi, K., Zilouei, H., Jeihanipour, A.: Improvement of biogas production from pine wood by alkali pretreatment. Fuel 106, 484–489 (2013). https://doi.org/10.1016/J.FUEL.2012.12.092

Dar, R.A., Arora, M., Phutela, U.G.: Optimization of cultural factors of newly isolated microalga Spirulina subsalsa and its co-digestion with paddy straw for enhanced biogas production. Bioresour. Technol. Reports. 5, 185–198 (2019). https://doi.org/10.1016/J.BITEB.2019.01.009

Lembi, C.A., Waaland, J.R.: Phycological Society of America.: Algae and Human Affairs. Cambridge University Press, New York (1988)

Eaton, A.D., Clesceri, L.S., Greenberg, A.E., Franson, M.A.H., American Public Health Association, American Water Works Association, Water Environment Federation: Standard Methods for the Examination of Water and Wastewater. American Public Health Association, Washington, DC (1998)

Prajapati, S.K., Bhattacharya, A., Malik, A., Vijay, V.K.: Pretreatment of algal biomass using fungal crude enzymes. Algal Res. 8, 8–14 (2015). https://doi.org/10.1016/J.ALGAL.2014.12.011

Bozzola, J.J., Russell, L.D.: Electron Microscopy: Principles and Techniques for Biologists. Jones and Bartlett, Burlington (1999)

AOAC: Official Methods of Analysis. AOAC International, Rockville (2012)

Prajapati, S.K., Malik, A., Vijay, V.K., Sreekrishnan, T.R.: Enhanced methane production from algal biomass through short duration enzymatic pretreatment and codigestion with carbon rich waste. RSC Adv. 5, 67175–67183 (2015). https://doi.org/10.1039/C5RA12670C

Angelidaki, I., Alves, M., Bolzonella, D., Borzacconi, L., Campos, J.L., Guwy, A.J., Kalyuzhnyi, S., Jenicek, P., van Lier, J.B.: Defining the biomethane potential (BMP) of solid organic wastes and energy crops: a proposed protocol for batch assays. Water Sci. Technol. 59, 927–934 (2009). https://doi.org/10.2166/wst.2009.040

Gerken, H.G., Donohoe, B., Knoshaug, E.P.: Enzymatic cell wall degradation of Chlorella vulgaris and other microalgae for biofuels production. Planta 237, 239–253 (2013). https://doi.org/10.1007/s00425-012-1765-0

Schwede, S., Rehman, Z.-U., Gerber, M., Theiss, C., Span, R.: Effects of thermal pretreatment on anaerobic digestion of Nannochloropsis salina biomass. Bioresour. Technol. 143, 505–511 (2013). https://doi.org/10.1016/j.biortech.2013.06.043

Samson, R., Leduy, A.: Influence of mechanical and thermochemical pretreatments on anaerobic digestion of Spirulina maxima algal biomass. Biotechnol. Lett. 5, 671–676 (1983). https://doi.org/10.1007/BF01386360

Ciferri, O.: Spirulina, the edible microorganism. Microbiol. Rev. 47, 551–578 (1983)

Bohutskyi, P., Betenbaugh, M.J., Bouwer, E.J.: The effects of alternative pretreatment strategies on anaerobic digestion and methane production from different algal strains. Bioresour. Technol. 155, 366–372 (2014). https://doi.org/10.1016/J.BIORTECH.2013.12.095

Ramos, Ó.L., Reinas, I., Silva, S.I., Fernandes, J.C., Cerqueira, M.A., Pereira, R.N., Vicente, A.A., Poças, M.F., Pintado, M.E., Malcata, F.X.: Effect of whey protein purity and glycerol content upon physical properties of edible films manufactured therefrom. Food Hydrocoll. 30, 110–122 (2013). https://doi.org/10.1016/j.foodhyd.2012.05.001

Duygu, D.Y.: Fourier transform infrared (FTIR) spectroscopy for identification of Chlorella vulgaris Beijerinck 1890 and Scenedesmus obliquus (Turpin) Kützing 1833. Afr. J. Biotechnol. 11, 3817–3824 (2012). https://doi.org/10.5897/ajb11.1863

Murdock, J.N., Wetzel, D.L.: FT-IR microspectroscopy enhances biological and ecological analysis of algae. Appl. Spectrosc. Rev. 44, 335–361 (2009). https://doi.org/10.1080/05704920902907440

Movasaghi, Z., Rehman, S., ur Rehman, D.I.: Fourier transform infrared (FTIR) spectroscopy of biological tissues. Appl. Spectrosc. Rev. 43, 134–179 (2008). https://doi.org/10.1080/05704920701829043

Benning, L., Phoenix, V., Yee, N., Cosmochimica, M.T.-G., et al.: Undefined: Molecular Characterization of Cyanobacterial Silicification Using Synchrotron Infrared Micro-spectroscopy. Elsevier, Amsterdam (2004)

Sigee, D.C., Dean, A., Levado, E., Tobin, M.J.: Fourier-transform infrared spectroscopy of Pediastrum duplex: characterization of a micro-population isolated from a eutrophic lake. Eur. J. Phycol. 37, S0967026201003444 (2002). https://doi.org/10.1017/S0967026201003444

Coates, J.: Interpretation of infrared spectra, a practical approach. In: Meyers, R.A. (ed.) Encyclopedia of Analytical Chemistry. Wiley, Chichester (2006)

Liu, H.J., Xu, C.H., Zhou, Q., Wang, F., Li, W.M., Ha, Y.M., Sun, S.Q.: Analysis and identification of irradiated Spirulina powder by a three-step infrared macro-fingerprint spectroscopy. Radiat. Phys. Chem. 85, 210–217 (2013). https://doi.org/10.1016/J.RADPHYSCHEM.2012.12.001

Ramirez, F.J., Luque, P., Heredia, A., Bukovac, M.J.: Fourier transform IR study of enzymatically isolated tomato fruit cuticular membrane. Biopolymers 32, 1425–1429 (1992). https://doi.org/10.1002/bip.360321102

Dogan, A., Siyakus, G., Severcan, F.: FTIR spectroscopic characterization of irradiated hazelnut (Corylus avellana L.). Food Chem. 100, 1106–1114 (2007). https://doi.org/10.1016/j.foodchem.2005.11.017

Stehfest, K., Toepel, J., Wilhelm, C.: The application of micro-FTIR spectroscopy to analyze nutrient stress-related changes in biomass composition of phytoplankton algae. Plant Physiol. Biochem. 43, 717–726 (2005). https://doi.org/10.1016/J.PLAPHY.2005.07.001

Ehimen, E.A., Holm-Nielsen, J.-B., Poulsen, M., Boelsmand, J.E.: Influence of different pre-treatment routes on the anaerobic digestion of a filamentous algae. Renew. Energy 50, 476–480 (2013). https://doi.org/10.1016/J.RENENE.2012.06.064

Passos, F., Hom-Diaz, A., Blanquez, P., Vicent, T., Ferrer, I.: Improving biogas production from microalgae by enzymatic pretreatment. Bioresour. Technol. 199, 347–351 (2016). https://doi.org/10.1016/J.BIORTECH.2015.08.084

Hom-Diaz, A., Passos, F., Ferrer, I., Vicent, T., Blánquez, P.: Enzymatic pretreatment of microalgae using fungal broth from Trametes versicolor and commercial laccase for improved biogas production. Algal Res. 19, 184–188 (2016). https://doi.org/10.1016/J.ALGAL.2016.08.006

Mendez, L., Mahdy, A., Demuez, M., Ballesteros, M., González-Fernández, C.: Effect of high pressure thermal pretreatment on Chlorella vulgaris biomass: organic matter solubilisation and biochemical methane potential. Fuel 117, 674–679 (2014). https://doi.org/10.1016/J.FUEL.2013.09.032

Passos, F., Ferrer, I.: Influence of hydrothermal pretreatment on microalgal biomass anaerobic digestion and bioenergy production. Water Res. 68, 364–373 (2015). https://doi.org/10.1016/J.WATRES.2014.10.015

Shanmugam, P., Horan, N.J.: Optimising the biogas production from leather fleshing waste by co-digestion with MSW. Bioresour. Technol. 100, 4117–4120 (2009). https://doi.org/10.1016/j.biortech.2009.03.052

Shanmugam, P., Horan, N.J.: Simple and rapid methods to evaluate methane potential and biomass yield for a range of mixed solid wastes. Bioresour. Technol. 100, 471–474 (2009). https://doi.org/10.1016/j.biortech.2008.06.027

Sung, S., Liu, T.: Ammonia inhibition on thermophilic anaerobic digestion. Chemosphere 53, 43–52 (2003). https://doi.org/10.1016/S0045-6535(03)00434-X

Cuetos, M.J., Fernández, C., Gómez, X., Morán, A.: Anaerobic co-digestion of swine manure with energy crop residues. Biotechnol. Bioprocess Eng. 16, 1044–1052 (2011). https://doi.org/10.1007/s12257-011-0117-4

Acknowledgements

The author RAD greatly acknowledges the Indian Council of Medical Research (ICMR), New Delhi for providing support in the form of Junior Research Fellowship under Grant No. 3/1/3/JRF-2015 (2)/HRD. The authors also thankfully acknowledge the financial support provided by Indian Council of Agricultural Research (ICAR) for pursuing the All India Coordinated Research Project (AICRP) on Renewable Sources of Energy for Agriculture Agro-based Industries.

Author information

Authors and Affiliations

Contributions

RAD, UGP designed the experiments. RAD carried out the experimental work. RAD analyzed the data and wrote the manuscript. UGP thoroughly revised and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors hereby declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dar, R.A., Phutela, U.G. Enzymatic and Hydrothermal Pretreatment of Newly Isolated Spirulina subsalsa BGLR6 Biomass for Enhanced Biogas Production. Waste Biomass Valor 11, 3639–3651 (2020). https://doi.org/10.1007/s12649-019-00712-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-019-00712-y