Abstract

Oil palm industry is the largest contributor of biomass in Malaysia. Oil palm biomass are constantly generated in large quantities annually with a small fraction being converted into value added product while a large percentage are left underutilized. Several researchers have reported the various technologies available for the conversion of oil palm biomass into useful bio-products, including bio-fuel, biogas, bio-fertilizers, bio-composite and briquettes. In general, these technologies are either underutilized or inadequate for full conversion of these abundantly available biomass, hence, there is an urgent need for upgrading of such technologies. This review article highlights the availability of oil palm biomass in Malaysia, the chemical compositions, as well as a brief description of current technologies for converting oil palm biomass into value added products. The review also outlines a summary of the various products obtained from oil palm biomass. Steps to achieve maximum utilization of biomass from oil palm industry are also proposed.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Biomass is organically based waste matter of plant and animal origins [1,2,3] such as sewage and municipal solid wastes [4, 5]. Biomass has been described by several researchers as one of the earliest sources of energy with important and unique properties [6,7,8,9,10,11,12,13,14]. Kwietniewska and Tys [15] described biomass as biodegradable fraction of products, wastes and residues from agriculture (including vegetable and animal substances), forestry and related industries, as well as the biodegradable fractions of industrial and municipal wastes. Biomass is also viewed as organic matters consisting of carbon, hydrogen, oxygen and nitrogen [16].

Biomass is considered as one of the earliest sources of energy especially in rural areas [14, 17] due to its accessibility and affordability. Biomass is known for its potentials to provide a variety of different bioenergy and biomaterial products, and contributes to global greenhouse gas reductions by serving multiple sectors, such as electricity, heating and as transport fuels [18,19,20]. Biomass also plays pivotal role of decarbonizing agricultural sector using biochar, as well as in production of renewable chemicals [21]. As reported by Khan et al. [22], biomass contributes about 9–14% of the total energy supply in the developed countries while in the developing countries, it contributes about one-fifth to one-third of the total energy supply.

Oil palm biomass refers to agricultural by-products generated from the oil palm industries during replanting, pruning and milling activities, which in most cases is left to decompose in the fields [23]. While the bulk of oil palm tree (\(\,\sim\) 90%) is predominantly considered as biomass, palm oil only accounts for 10% of the tree [24]. Oil palm biomass generated at the plantation includes oil palm trunk (OPT) and oil palm fronds (OPF); biomass from empty fruit bunch (EFB), palm kernel shell (PKS), mesocarp fibre (MF) and palm oil mill effluent (POME) is generated at the oil palm processing mills [3, 25, 26]. It is disheartening to note that a large portion of oil palm biomass is either air burnt or left at the plantations, thereby constituting environmental hazards to lives. In order to circumvent the challenges posed by the improper disposal of oil palm biomass, several researches had been carried out to convert this readily available and renewable biomass into value added products with varied applications [27]. It has been reported amongst others, fibres from oil palm biomass possess excellent and outstanding properties. Therefore, they can be used as reinforcing fillers in support matrices for enzyme immobilization and renewable sources of materials to produce value-added products such as pulp and paper, as well as bio-composite and hybrid composites in paper and furniture industries respectively [28, 29].

Brief History of Oil Palm and Its Biomass in Malaysia

Oil palm (Elaeis guineensis), has its origin in West Africa where it was considered as a native plant useful for different purposes, and now its plantation has been spreading widely, particularly in South American and Asian continents [30,31,32]. Nigeria was first regarded as the world’s largest producer of palm oil until mid-1960s [33], when Malaysia’s palm oil production surpassed that of Nigeria as a result of rapid growth in the oil palm industry. Until 2007 when Indonesia took over the lead, Malaysia was the world’s largest producer and exporter of palm oil and its associated products [30, 34, 35]. Oil palm tree grows well in tropical weather with high amount of rainfall [32], accountable for its successful cultivation in Indonesia and Malaysia. Palm oil production from these two countries accounts for about 85% of palm oil produced worldwide, with Indonesia and Malaysia contributing 44 and 41% of yields, respectively [36].

Oil palm tree was first introduced in Malaysia as ornamental plant by the British in 1871 [37]. The commercial scale cultivation of oil palm tree in Malaysia started about a century ago with the establishment of the first oil plant plantation at Tenamaran Estate in Selangor in 1917 [3]. Malaysia experienced a steady increase in cultivation of oil palm trees after her independence in 1957. This success was achieved through the establishment of various programs initiated by the Malaysian government [3] that led to the rapid growth in the oil palm industry, and by 2014 palm oil plantations had occupied more than 16% of the available land in Malaysia [2].

Although its status quo as the world’s largest palm oil producer has been overtaken by Indonesia [34], Malaysia still retains its position as the world’s largest palm oil exporter to date [38]. From 1960s to 2014, the oil palm plantation in Malaysia had been rapidly growing, from just about 54,000 hectares in the 1960s to approximately 5.39 million hectares in 2014 [39,40,41].

Oil Palm Biomass in Malaysia

Palm oil is considered as the most important agricultural crop in Malaysia, with the oil palm industry being the fourth largest contributor to the Malaysian’s Gross National Income (GNI), generating billions of Ringgits [38]. The production of palm oil is associated with large amount of biomass [40] and one of the major challenges is its biomass disposal [42]. As mentioned earlier, there are six major biomass generated from the oil palm industries (Fig. 1) viz. oil palm fronds (OPF), oil palm trunks (OPT), empty fruit bunches (EFB), palm kernel shells (PKS) mesocarp fibres (MF) and palm oil mill effluent (POME) [25, 43]. The oil palm biomass is further categorized into solid and liquid wastes, with a total of 83 million tonnes of solid wastes and 60 million tonnes of liquid waste generated in 2012, respectively [38]. This figure is expected to have increased to a range between 85–110 million and 70–110 million tonnes for dry solid and liquid wastes, correspondingly by year 2020 [38]. This projection is in line with the continuous growth of the planted area of the oil palm in Malaysia. As earlier stated, most of the biomass is left in the plantations, a scenario that demonstrates underutilization of the important lignocellulosic feedstock. About 75% of the solid waste is made up of OPF and OPT that are readily available in the plantations, while EFB, MF and PKS that account for the remaining 25% are usually available at the mills [38]. Available at the mill also is the liquid waste—POME.

The rapid growth in the oil palm plantation has its challenges, one of which being the huge quantity of biomass generated from the plantations. As a matter of fact, 44 million tonnes of dry weight OPF is produced annually during harvesting of oil palm fruits [3] and out of which about 15 ton per hectare of dry OPF were usually cut off and allowed to decompose naturally during the season of replanting. While insignificant percentages of such biomass have been converted to value-added products (adsorbents, fillers and anti-caking) by various conversion processes such as that of mechanical [44] and thermochemical [45], the full economic benefits of this versatile tree remains unexploited.

Availability of Oil Palm Biomass in Malaysia

Oil palm biomass is generated basically from pruning, harvesting, replanting and milling activities. In 2014, a total of 95.38 million tonnes of oil palm fresh fruit bunch (FFB) was harvested [46]. During the harvesting process, approximately 42.06 million tonnes of OPF were pruned. Also, in the same year, the replanted area was estimated as 95,584 hectare [41]. It has been estimated that during replanting activities, 14.47 ton of OPF can be generated per hectare of replanted area [47]. Therefore, in 2014, about 1.3 million tonnes of OPF was generated from replanting activity, bringing the total OPF from both activities to 43.39 million tonnes of which 50% is expected to be left in the plantation, hence the available OPF as at 2014 was approximately 21.7 million tonnes. OPT generated per hectare of land during replanting was estimated at 75 ton [48], hence, a total of 7.3 million tonnes of OPT was generated from replanting activity in 2014. Out of this figure, 50% was expected to be left in the plantation for maintenance of soil nutrient. Therefore, based on the data of 2014, a total of 3.6 million tonnes of OPT was available and needed to be converted into value added products that can generate more revenue for the Malaysian government [3].

Typically, FFB is made up of palm oil, palm kernel, EFB, PKS, MF and POME and their weight percentages on wet basis are shown in Fig. 2 [49]. The biomass generated at the mill from the processing of the 95.38 million tonnes of FFB harvested in 2014 [46], in accordance with the percentage composition as shown in Fig. 2, would have led to the generation of 7.34 million tonnes of EFB, 4.46 million tonnes of PKS, 7.72 million tonnes of MF dry weight basis [46]. The oil palm solid biomass generated in 2014 was approximately 70.21 million tonnes, out of which 44.82 million tonnes was available for conversion into value added products and almost 25.39 million tonnes were left to decompose in the plantations [46]. The above statistics is an indication that oil palm biomass is readily available in Malaysia.

Components of fresh fruit Bunch [49]

Composition of Oil Palm Biomass

The large quantity of oil palm biomass generated in the fields and mills is of great concern. Knowing the chemical composition of such biomass has become necessary to unravel its hidden potentials, which subsequently results in proper utilization.

Energy Content of Oil Palm Biomass

Considering the nonrenewable nature of fossil fuel, shortage of fossil fuel and the continuous rise in oil price, specific interest to develop alternative renewable fuel remains relevant. Also, the over dependence of the chemical industries on petrochemicals raw materials especially organic chemicals produced from petroleum feedstock had placed much demand on fossil fuel. The negative impact of these trends on the environment is enormous, particularly as it leads to increase level of greenhouse gases (GHGs) in the atmosphere, and its associated global warming effect [50, 51]. Fossil fuel combustion accounts for about 90% of CO2 which is the major contributor to greenhouse gases [52].The expected environmental damage due to emissions from combustion of fossil fuel (oil, coal and natural gas) has become a critical issue. This has therefore necessitated a shift from the use of fossil fuel as source of energy to utilizing renewable energy sources such as biomass with less environmental harmful effects [53, 54]. In the light of this, the development of large bioenergy economy as an alternative to the current fossil fuel dependent energy system has become a necessity.

The calorific values of the major biomass from oil palm industry as shown in Fig. 3, records that PKS possesses the highest calorific value; lower calorific values were observed for OPF and OFL [46]. Experimentally, the calorific value of a biomass can be determined using an adiabatic bomb calorimeter [55]. On the other hand, the same purpose can be achieved by utilizing data generated from ultimate and proximate analyses, via elemental analyzers [56]. The percentage weight of the various components—moisture (M), volatile matter (VM), and ash (A) present in the biomass can be determined using thermogravimetric analyzer [57] and the percentage weight of fixed carbon (FC) can be obtained by calculating its difference. In like manner, the percentage weight of the chemical elements (C, H, N and S) in the biomass can be estimated using CHNS analyzer while oxygen is determined by difference [57]. The data generated from these analyses can be used to estimate the calorific value (total energy content) of a fuel, that is, the lowest heating value (LHV) and the highest heating value (HHV) of the biomass [56]. Two empirical correlations (Eqs. 1, 2) for HHV were predicted using data from ultimate and proximate analyses of lignocellulosic biomass [56].

Calorific values for oil palm biomass [46]

Ultimate Analysis

Several researchers have carried out characterization (ultimate and proximate analyses) of oil palm biomass to establish its chemical compositions [26, 46, 57,58,59,60,61, 64, 67]. Ultimate analysis of oil palm biomass (Table 1) has revealed the presence of elements such as carbon (C), hydrogen (H), nitrogen (N), sulfur (S) and oxygen (O) [26, 57,58,59,60,61]. The HHV of oil palm biomass can be estimated from the values of carbon and hydrogen using Eq. 1 [56]. The ratios of H:C and O:C in a biomass determine its energy content, as the energy released during combustion is a measure of the strength of the bonds between the elements that constitute the fuel. Biomass with high proportion of hydrogen and oxygen compared to carbon would possess low calorific value [1]. This is because of the lower energy required to break the bonds that exist between hydrogen–carbon and oxygen–carbon as compared to the energy required to break carbon–carbon bonds. The oil palm biomass has more oxygen content compared to coal [46], hence, its calorific value is lower when compared with that of coal. This deficiency is provided for by the large quantities of oil palm biomass that are readily available and accessible. One of the advantages of oil palm biomass having high proportion of oxygen is that, when used as fuel, less external air is required for complete combustion [62], which makes it an economically viable fuel source. The low values of nitrogen and sulfur (Table 1) in oil palm biomass indicate that it is potentially an environmentally friendly fuel with lower risk of further emissions of greenhouse gases (GHGs) [46, 63].

Proximate Analysis

Proximate analysis of some of the solid oil palm biomass (Table 2) showed that the biomass contained moisture (M), volatile matter (VM), ash (A) and fixed carbon (FC) in various proportions [26, 57,58,59,60,61, 64, 66, 67]. The values of volatile matter and fixed carbon for the various oil palm biomass range from 66 to 83% and 3 to 20% respectively, an indication that some biomass would contain high calorific values. A combination of VM and FC provides information about the extent to which the biomass can be ignited, gasified or oxidized [1]. These data have presented oil palm biomass as a good source of fuel that can be converted into biogas [65, 68] and biofuels using appropriate technology. The low moisture contents of oil palm biomass as shown in Table 2 further proves that it is a good feedstock for thermochemical production of biofuels [1].

Furthermore, analysis of the volatile matter had further confirmed that oil palm biomass is made up of organic substances such as cellulose, hemicellulose and lignin as shown in Table 3 [26, 59, 64, 70]. From Table 3, it can be inferred that the solid oil palm biomass is lignocellulosic in nature, hence, can be converted easily into simple sugars that can be transformed into useful biochemical and biofuels [46]. The relatively high value of lignin in PKS and MF is an indication that oil palm biomass is good fuel for thermal combustion [46]. On the other hand, OPF, OPT and EPB contain relatively high amount of cellulose and hemicellulose, which implies that the oil palm biomass could serve as a good feedstock for bioprocessing [46].

Lignocellulosic Components of Oil Palm Biomass and Their Respective Applications

Lignocellulosic materials are organic compounds that largely comprised of hemicellulose, cellulose and lignin. Hemicellulose is made up of different monosaccharide units, predominantly pentose sugars and it exists as either homo-polymer or hetero-polymer and both are readily soluble in alkalis, making the hydrolysis of hemicellulose relatively easy [71,72,73]. Cellulose is a crystalline natural polymer consisting 6-carbon monomers (pyranose) that are joined to each other by -O-, \(\beta\)-(1,4)-glycosidic linkages [74, 75]. Its crystalline structure makes it resistant to both acid and enzymatic hydrolysis. Lignin, on the other hand, is an aromatic polymer basically made up of randomly substituted phenylpropane monomeric units, such as syringly and guaiacyl p-hydroxylphenyl units [76, 77].

Virtually all oil palm biomass are lignocellulosic in nature, with exception of POME. The chemical composition of solid oil palm biomass are largely made up of hemicellulose, cellulose and lignin in varying proportion, depending on the biomass types [69]. A study by Hashim et al. [69] on the chemical composition of oil palm biomass revealed that hemicellulose is the dominant chemical component of all the solid oil palm biomass followed by cellulose, with lignin having the lowest value, except for PKS.

Like other lignocellulosic biomass, the energy stored in solid oil palm biomass found in the form of polysaccharides can either be utilized directly as fuel or can be broken down into simple sugars that can be subjected to further processing to generate various bio-products valuable in various spheres of life. Biofuel can be produce from oil palm lignocellulosic biomass by subjecting the biomass to extraction and purification to produce bio-oil. Similarly, biodiesel can also be obtained from the lignocellulosic portion of oil palm biomass via esterification and purified processes. On the other hand, fermentation and distillation of oil palm biomass produce bioethanol. Biogases is also produced from lignocellulosic oil palm biomass by employing anaerobic digestion method, with useful applications in cogeneration of electricity [78]. Lignocellulosic oil palm biomass can be transformed into a myriad of technologically advanced materials for industrial applications. A recent study by Elias et al. [79] had demonstrated the utilization of nanocellulose extracted from oil palm frond leaves to reinforce chitosan as support matrix for covalent immobilization of Candida rugosa lipase. Similarly, EFB being relatively rich in cellulose (49–65%), is a potential source for natural fibre [80]. The high cellulose content of EFB qualifies it to be used in plastic industries to reinforce thermosetting and thermoplastic materials [81, 82]. OPT and OPT reinforced with EFB had been successfully used to produce laminated bio-composite and hybrid of laminated bio-composite respectively with excellent features [80].

Current Utilization Level

It has been described that certain parts of the oil palm biomass wastes are useful in their natural forms, while others may require physical, chemical, thermochemical or biological processes to be converted into commercially valuable end products. A brief summary of the various end products obtained directly or indirectly from oil palm biomass is presented in Table 4 [83,84,85,86,87,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109,110,111,112,113,114,115,116,117,118,119,120]. EFB and OPF parts of the oil palm tree undergo chemithermomechanical pulping forming small sized pulps, and crushed oil palm fruit shells are converted into briquettes and used as fuel [86]. While OPF are pelleted for feeding live stocks [87] and also a good source of hydrogen gas [45], the general bulks of OPF are decomposed for soil mulching or decomposed naturally by action of microorganisms in the plantation [39, 88]. Some of the technologies available for converting oil palm biomass as published by earlier researchers are as reviewed below.

Technologies for Converting Oil Palm Biomass to Value Added Products

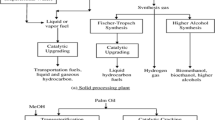

There are numerous benefits embedded in lignocellulosic biomass, but before these benefits can be exploited fully, the biomass must be subjected to certain pretreatments [88]. The use of biomass directly as a source of fuel can generate substantial amount of pollutants to land and the environment [89, 93], hence the need to convert biomass into useful materials with minimal environmental challenges, has become imminent. The various technologies (Fig. 4) available for converting oil palm biomass to value added products such as biofuels and biochemical include chemical, physical, thermochemical and biochemical conversions respectively [16, 45, 95, 103]. Some of these technologies will be briefly discussed in the following sub-sections.

Thermochemical Conversion of Oil Palm Biomass

This involves the conversion of oil palm biomass into a range of important compounds by a combination of thermal decay and chemical reformation. It is achieved by either heating oil palm biomass in the presence of oxygen at different concentrations or heating in the absence of oxygen [6]. One of the advantages of this method is that nearly all the organic components of the oil palm biomass can be converted into useful products such as gaseous and liquid fuels. Thermochemical processes include pyrolysis, combustion, gasification and liquefaction/hydrothermal upgrading [1].

Pyrolysis

Pyrolysis is a thermochemical conversion process that is used to transform lignocellulosic biomass, such as oil palm biomass, directly into gaseous and liquid fuels [97]. This method is accompanied by heating oil palm biomass in total absence of oxygen at a temperature of about 500 °C to produce various organic liquids that can be refined to make liquid fuel [6]. The process proceeds via a slow chemical reaction occurring at low temperatures that converts the biomass into mixtures of hydrocarbon rich gases (OC, CO2, CH4, and H2) and a carbon rich residue [13]. The types of product obtained from pyrolysis largely depend on certain parameters such as temperature, heating rate as well as the particle size of the catalyst used, and therefore, understanding of pyrolysis kinetics is important for optimum conversion of the biomass into the desired products [121]. Pyrolysis can be classified as either slow or fast, depending on the temperature involved, heating rate and the time taken for the process [1, 122, 123]. While the products of slow pyrolysis are mostly char, those of fast pyrolysis are predominantly liquid [123, 124]. EFB, PKS and MF have been subjected to pyrolysis to produce bio-oil [59, 125] that are used as feedstock for industrial processes, as well as porous char, serving as a good precursor for producing adsorbents like activated charcoal [126].

Combustion

This is the oldest technology employed by man to generate energy by directly burning biomass in the presence of oxygen or air to release the stored chemical energy as heat in burners, boilers, internal combustion engines and turbines [16, 127]. Generally, combustion of biomass results in the production of hot gases at a temperature around 800–1000 °C [1]. It leads to release of carbon dioxide which was initially removed from the atmosphere during the process of photosynthesis and thus maintains an equilibrium level of carbon dioxide, unlike combustion of fossil fuels that increases the level of carbon dioxide [128]. The stoichiometric equation (Eq. 3) for the combustion of biomass using the basic empirical formula for cellulose is given below:

Biomass can be burned directly in waste-to-energy plants without any chemical processing to produce steam for making electricity and heat for industries and homes [127]. Bulk of the energy required at the palm oil mills is supplied by direct combustion of oil palm biomass especially PKS and MF [39, 129]. However, the high moisture content of some oil palm biomass, particularly EFB, has limited its direct combustion efficiency, leading to unstable combustion rate [16]. It also has a negative impact on the environment, hence, to protect the environment from air pollution, the Malaysian government has discouraged the direct combustion of oil palm biomass [39].

Gasification

Gasification of biomass is a thermochemical technology that involves the conversion of biomass into various gaseous fuels through partial oxidation of the biomass at high temperatures, usually in the range of 800–900 °C [1]. Products obtained from gasification of biomass include hydrogen, carbon monoxide, methane, carbon dioxide, water vapor and nitrogen [1, 130]. Subjecting oil palm biomass to gasification leads to the production of synthesis gas [131]. The synthesis gas can be processed into several other products such as liquid hydrocarbons through Fischer–Tropsch synthesis [132]. PKS, OPF, OPT EFB and MF of oil palm biomass are good source of hydrogen [45, 133]. One of the major disadvantage of gasifying oil palm biomass is that it leads to the production of substantial quantity of impurities such as acid gases that have negative effect on the environment [134]. Another challenge associated with this technology is the laborious downstream purification process involved in order to obtain the products in their pure forms, hence limiting the efficiency of the technology.

Liquefaction/Hydrothermal Upgrading

Liquefaction is a thermochemical conversion that involves breaking down high molecular weight components (cellulose, hemicellulose and lignin) of lignocellulosic biomass into compounds of low molecular weight that are quite reactive, and can be used as precursors for several industrial processes [135,136,137,138]. Hydrothermal liquefaction of biomass is a technology designed to handle the high moisture content in biomass, leading to high biomass conversion with good purity of products [139]. Hydrothermal upgrading converts biomass in a wet environment at high pressure to partly oxygenated hydrocarbon, whereas liquefaction is the conversion of biomass into stable liquid hydrocarbon that utilizes low temperature and high hydrogen pressure. The interest in this technology is low because the reactors and the fuel-feeding systems are more complicated, and are not cost effective when compared to pyrolysis processes [1].

The liquefaction of oil palm solid biomass such as EFB [139, 140] has been studied using different alkaline catalysts and different solvents. It has been established that using 1 M potassium carbonate (K2CO3) as catalyst and ethylene glycol as solvent in different studies would give the best conversion of EFB to liquid oil. In a separate analysis, Mazaheri et al. [34] carried out the decomposition of oil palm press fibber using 10% of sodium carbonate and sodium hydroxide (NaOH) independently and obtained 90% conversion of the solid biomass to liquid oil. Optimization of the above work was done using subcritical water and NaOH as additive, and the result showed that optimal condition for the conversion of oil palm press fibre to liquid oil could be achieved 278 °C with an incubation period of 40 min [141].

Biochemical Conversion of Biomass

This involves the conversion of biomass to useful products using five major technologies viz. fermentation and anaerobic digestion, photosynthetic organisms, dark fermentation and esterification processes [6]. Among these five alternatives, fermentation, esterification and anaerobic digestion are the most frequently used, while the other two are still in the experimental stage [6].

Fermentation/Enzymatic Hydrolysis

Lignocellulosic biomass is usually converted to biofuels and biochemical via a disruptive pretreatment process followed by enzymatic hydrolysis of the resulting cellulose to simple sugars that are subjected to fermentations to yield the desired products [142]. Fermentation is used commercially on a large scale for production of ethanol from sugar crops (sugarcane, sugar beet) and starch crops (maize, wheat) by action of enzymes [1]. Starch has to be first converted to simpler sugars–maltose, glucose, fructose—before fermentation to ethanol can be accomplished.

Solid oil palm biomass of lignocellulosic in nature, such as OPT can easily be converted to ethanol via fermentation of the sap, the bagasse or the cell wall [143]. The sap of OPT is made up of various types of sugars predominantly glucose, sucrose and fructose [144]. Other chemical compounds present in the sap of OPT are vitamins, amino acids and organic acids. As a result, the sap of OPT could be subjected to direct fermentation to produce biochemical products such as lactic acid and ethanol [145,146,147]. Cellulose, hemicellulose and lignin present in the cell wall of OPT can undergo hydrothermal treatment, followed by enzymatic hydrolysis to yield the desired bio-products [143]. Bioethanol can also be synthesized from a combined process of saccharification and fermentation simultaneously [148]. EFB is another good raw material for bioethanol production using this technology [149,150,151].

Anaerobic Digestion

This is the biochemical conversion of biomass into bio-gas which is majorly made up of methane and carbon dioxide with small quantities of other gasses such as hydrogen sulfide [13]. In this technology, the biomass is converted by bacteria in an anaerobic environment to produce a gas with an energy content of about 20–40% of the lower heating value of the feedstock [1]. It is a widely used technology for the treatment of organic wastes with high moisture content. Anaerobic digestion is the process that involves the decomposition of organic matter by a microbial consortium in an oxygen-free environment [152]. Anaerobic digestion is achieved through a series of metabolic reactions such as hydrolysis, acidification, acetogenesis and methanogenesis that are carried out by various groups of microorganisms [153]. The first group of microorganisms enzymatically hydrolyze complex organic compounds to monomers (e.g. glucose, amino acids), which are subsequently converted to higher volatile fatty acids (VFA), H2 and acetic acid. The second group that is the acetogens convert higher volatile fatty acids such as propionic and butyric acid to H2, CO2, and acetic acid. Finally, methanogenic bacteria convert H2, CO2, and acetate to CH4 and CO2 [15, 154].

Chaikitkaew et al. [78] subjected EFB, palm press fibre (PPF) and decanter cake (DC) to solid state anaerobic digestion to produce methane, with EFB giving the highest yield of 55 m3 CH4/tonne. Their work therefore confirmed that oil palm solid biomass is a good source of methane. POME, a liquid waste from palm oil mills, has been subjected to anaerobic digestion to yield methane [155,156,157]. The adopted method for methane production from POME that has been the practice in Malaysia is anaerobic digestion in pond system [158]. However, the production of methane from POME through this technological route is associated with several drawbacks [155, 157], making recovery of the synthesized methane practically impossible [156]. It has therefore become necessarily to develop biogas plants in the various oil palm mills to enhance proper recovery and utilization of CH4 produced from POME [159]. The presence of some marine macro algae as co-substrate in the biogas plant designed for high CH4 synthesis can reduce the yield of CH4 [160], hence it should be eliminated.

Physical Conversion Technology

Physical method of converting biomass into useful end products include distilling, mechanical extraction and briquetting (Fig. 4). The briquetting technology is briefly discussed below.

Briquetting of Oil Palm Biomass

Briquetting is a mechanical conversion technology employed to compact loose oil palm solid biomass into uniformly packed solid fuel. It leads to improvement in the heating properties of oil palm solid biomass by compacting it into pallets of higher density [49]. Palm press fibres, PKS as well as EFB has been made into briquettes to produce better fuel properties [161]. Briquettes are usually of higher energy with much lower moisture compared to the starting materials. Briquetting of biomass can be achieved through either piston press or screw extrusion technologies [162]. An additional advantage of briquetting technology is that, it makes transportation and storage of the fuel a lot easier.

Technologies Available in Malaysia to Valorize Oil Palm Biomass

At the moment in Malaysia, utilization of technologies such as pyrolysis, gasification, hammering, baling, pelleting, anaerobic digestion, fermentation and esterification to valorize oil palm biomass has reached a relatively advanced stage. Value-added products such as syngas, biodiesel, bio-char, biogas, bioethanol pellets and briquette have been produced from various oil palm biomass using these technologies [163]. In addition to the abovementioned technologies, direct utilization of oil palm biomass as bio-fertilizer is another technology that has been in existence in Malaysia. In this technology, OPT and OPF are shredded and reused in the plantations as mulch to preserve and enhance soil fertility [164]. EFB is also converted into bio-fertilizer i.e. composting [33]. Likewise, untreated PKS and MF have been used in oil palm processing mills as solid fuels to generate electricity [165], enabling several oil palm mills in Malaysia to become energy self-sufficient. Another technology employed to improve the energy capacity of oil palm biomass is torrefaction. Torrefied biomass is preferable as it is more brittle, facilitating grinding, and therefore is less energy intensive. This technology involves heating oil palm biomass at temperatures ranging between 200 and 300 °C under non-oxidizing atmosphere, affording a high energy density bio-products [165]. Essentially, the process converts biomass into a coal-like material, which has better fuel characteristics than the original biomass.

In Malaysia, oil palm biomass has been successfully converted into various wood products, viz. bio-composites, plywood, fibre mats, fibre boards, activated charcoal and several others [27, 29, 44, 166]. Production of plywood from OPT has been reported [167, 168]. EFB can be processed into fiber mats and mulch used to control erosion and preservation, as well as for soil enrichment, respectively. Likewise, both forms of EFB have found applications in landscaping and beautification of residential areas, as well as drainage channel banks and used in construction of embankment in railways/highways [165]. Melt and blending technology is also practiced in Malaysia, where oil palm biomass is converted into oil palm fibre-based hybrid composites with impressive features, such as biodegradability, low density and non-abrasiveness [169, 170]. Production of activated carbon from oil palm biomass is another technology employed in Malaysia to convert EFB into value-added product, and it is used extensively as industrial adsorbent for the removal of a mixture of pollutants [83, 171]. For instance, removal of 2,4,6-trichlorophenol in wastewater using activated carbon produced from EFB has been reported [172].

Steps to Achieve Maximum Utilization of Biomass from Oil Palm Industries in Malaysia

It’s important to mention here that the effective use of lignocellulosic oil palm biomass via transformation into useful bio-products viz. bioethanol, biochemical and other green products at the commercial-scale has not been very encouraging due to the absence of an effective collection and processing systems of such biomass in Malaysia. To boost conversion of oil palm biomass or any other forms of biomass in Malaysia into value-added products, Lahad Datu Biomass JV Cluster Berhad was established in July 2014, following a joint venture agreement signed by five biomass leading companies in Malaysia. This consortium of companies includes; Genting Sdn Bhd, Kelas Wira Sdn Bhd, Bell Corp Sdn Bhd, Teck Guan Industries sdn Bhd and Golden Elate Sdn Bhd [38]. To address the bottleneck of long existing gap in the market between owners of biomass (oil palm farms, mills, processing industries) and the downstream users, the establishment of a cluster (led by the Agensi Inovasi Malaysia (AIM)) by the Malaysian Government in 2014 was indeed relevant and timely. In addition to the present existing cluster, the Malaysian Prime Minister in February 2016, launched the Sabah and Sarawak Biomass Industries Development Plan. In this plan, a total of eight clusters are expected to take off fully in Malaysia to cater for the large volume of oil palm biomass in the country. These clusters include; Lahad Datu, Sandakan and Tawau for Sabah, as well as Bintulu, Miri, Tanjung, Manis and Kuching for Sarawak [38]. The proposed plan to establish these eight biomass clusters would further strengthen the technological advancement in the biomass industries in Malaysia. Asia’s first integrated biomass cluster or bio hub is also proposed to take off at Kuching, Sarawak. If this proposal materializes, Sarawak may finally have the first commercial-scale biomass plantation, multi-feedstock biomass hub, bio-port, 2G ethanol plant and 2G biochemical plant in Asia. This project would open up the market for biomass industries with an estimated RM20 billion additional Gross National Income (GNI) for Malaysian government [38].

Hock Lee group and Beta Renewables were the earlier companies to commence a commercial-scale production of bioethanol in Malaysia, utilizing the facilities available at the first Asia’s Commercial-scale Biomass–to–Ethanol Plant located at Bintulu. Subsequently, a Biomass–to–ethanol plant was established in Tawau, Sabah in 2013 by Tech Guan, Mitsui and Inbicon to handle the conversion of lignocellulose biomass to value-added products. However, all stakeholders, ranging from biomass as well as technology owners, and international off-takers were fully involved [38]. Commercial-scale production of bioethanol from oil palm biomass in Malaysia was first achieved in 2014 and commercial biofuel from cellulosic ethanol became first available in Malaysia. Production of cellulosic ethanol from oil palm biomass started as a pilot-scale project through a joint partnership between Sime Darby Plantation and Mitsui Engineering Shipbuilding of Japan (Biofuel Digest). The facility producing cellulosic ethanol formally co-located within Sime Darby’s facilities in Selangor was later taken over and operated by Tech Guan Group in Malaysia (Biofuel Digest). Correspondingly, Beta Renewable state-of-the-art technology is another foreign technology that specializes in converting oil palm biomass into biofuels and biochemical in Malaysia. While cellulosic ethanol (second generation biofuel) from oil palm biomass may not be as cost-effective as bioethanol from other agricultural products i.e. corns and sugarcane (first generation biofuels), the conversion of cellulosic ethanol from oil palm biomass into a plethora of important industrial chemicals, such as butanol, ethylene, acetic acid polyethylene, butadiene, ethyl acetate, butene and ethylene oxide proves its versatility. Pertinently, the synergistic effect of all the aforementioned initiatives would significantly encourage and facilitate better involvement of the different agricultural and manufacturing players at transforming oil palm biomass into value-added products [165], an integral aspect for the country’s alternative wealth creation objective.

Markets for Oil Palm Biomass Products

Bio-products from oil palm biomass have useful applications in several spheres of life, ranging from residential homes, offices to industries. At the moment, several products are patronized locally while a few being exported to other countries where they are needed to meet the energy requirement for those nations. In Malaysia, most oil palm processing mills are operating on self-generated electricity from oil palm biomass [173], and the magnitude of energy generated is far more than what is required by the mills. With proper agreement between relevant authorities, the excess generated electricity has the potential to be sold to residential and commercial areas within the locality. Biogas produced from oil palm biomass in Malaysia is currently utilized locally for generating power in both National Grid Feed In and in the private sectors. Other potential local markets for biogas in Malaysia include; SEDA FiT Sales, BOO/BOT investors as well as factories processing agricultural and food products [163]. Furthermore, there is a growing demand for biogas locally, especially in the palm oil sector, attributable to a lucrative and robust downstream processes. Another bio-product that have been extensively used in power plants and as secondary raw materials for other industrial processes is pellets obtained from OPT, EFB, MF and PKS. This is due to their excellent burning properties as compared to coal. In Malaysia, not fewer than 25 projects are operating sorely on fuels from oil palm biomass [103].

Several bio-products from oil palm biomass have gained recognition and acceptance in the international markets. Popular among these is EFB pellets that have been fully accepted in South Korea, Japan and China. Other bio-products exported from Malaysia include bio-char, torrefied pellet and activated carbon. A major breakthrough in the international market for pellets occurred in 2013, when the Established Pellets Association of Malaysia successfully convinced the Korean government to amend their laws (December 2013) to allow the importation of EFB pellets. In January 2014, Detik Aturan, a home grown pellets producer has been contracted by the Korean government to export 1.2 million tonnes of pellets/annum, following a Memorandum of Understanding (MoU) signed between Detik Aturan and Korean BC21 in 2013 [38]. In order to keep the South Korean Renewable Portfolio Standard (RPS) mandate running, about 5 million tonnes of EFB pellets have been exported to South Korea yearly. In the same year, another MoU was signed between Global Green Synergy Sdn Bhd and Chinalight for off-take of pellet to China [38]. China in their quest to replace 1% of their national coal consumption with fuel pellets, would require up to 40 million tonnes of pellets per year. Another international market for pellets is Japan to cater for all their new Biomass Power Plants. For this, about 5 million tonnes/annum of pellets is required by Japan to meet its mandate [38].

Utilization of bioethanol as fuel is a better alternative to gasoline obtained from crude oil, principally because of the former’s low emission rate. The technology of blending bioethanol directly with petrol has gradually led to reduction in the over-dependence on ethyl tertiary butyl ether (ETBE) as petrol additive to improve its anti-knock properties. The emergence of ‘Flexible Fuel Vehicles’ (FFVs) in Europe, United States and Brazil, designed to run on both conventional petrol and petrol blended with 20–86% bioethanol [103], is another major advancement for the bioethanol market, an area in which the Malaysian government should consider exploring. Expansion of current infrastructures to boost bioethanol production in Malaysia is required to tap into such markets.

The Way Forward for Oil Palm Biomass in Malaysia

“Zero Waste Initiatives”

Oil palm biomass is the most abundant agricultural biomass in Malaysia that is yet to be fully harnessed. Advancement of green technologies has promoted the conversion of certain percentage of oil palm biomass into useful industrial feedstock as well as solid, liquid and gaseous bio-fuels, bio-composites, bio-fertilizers, green chemicals, industrial sugars and polymers. This achievement is anchored on the policy of the Malaysian government to promoting green technologies, which serves as a source of encouragement to industry players and other stakeholders to participate in the conversion of biomass to value-added products. Other structures that have been put in place by the Malaysian government to enhance full utilization of oil palm biomass is the introduction of new technologies and the relative ease of accessing the market.

Despite all, implementation of these policies in the industry is still at its nascent stage as the rate of oil palm biomass conversion to value-added products remains rather low. The obstacles responsible for low conversion of oil palm biomass to desired end products include;

-

i.

Low participation of Small and Medium-sized Enterprises (SMEs) in the utilization of oil palm biomass to produce value added products.

-

ii.

Low quality of the products (fibres, compost, fuel and fuel products) from oil palm biomass which renders them inferior, and can easily be displaced by other substitute products, hence affecting its market value and patronage.

To effectively develop the Malaysian biomass industry, it has become imperative to take a critical look at the gap in the value chain. The following areas require close monitoring for effective realization of the “zero waste initiative”.

-

a.

Development of newer technologies and technical know-how that will enhance production of high quality end products from oil palm biomass. Having appropriate green technologies in place, oil palm biomass can easily be converted into bio-energy (solid pallets, liquid fuels and biogas), green chemicals (bio-polymers, oxo-alcohols, lactic acids, etc.), bio-fertilizers (compost, soil conditioner, soil stabilizer) and bio-composite (composite wood, engineering lumber, plywood, eco-products, etc).

-

b.

Infrastructures as well as seed funds should be put in place to attract potential investors.

-

c.

Bio-based products should be designed to meet the requirement of the local and international standard; this will place bio-products in the right position to compete favorably with existing substitutes in the market, as well as increasing its global acceptance.

-

d.

Bio-products should be given good publicity, stressing their numerous advantages over products from fossil fuels, especially as bio-products are more environmentally friendly and safer to handle.

Building Value Chain for Consumer Products Based on Oil Palm Biomass

The value chain in the oil palm biomass industry consists of the following components; its availability, transportation and logistics, technology and human capacity, relevant policies and laws, investment and financing, marketing and branding as well as easy access by local and export markets. The major stakeholders include the private sector (biomass owners) and the public administration (the government). The biomass owners are saddled with the responsibility of making the biomass available for downstream utilization. To ensure availability of oil palm biomass, the current practice of returning some oil palm biomass, such as EFB, OPF and MF to the plantations for the purpose of preserving and enriching the soil nutrient can be replaced by utilizing bio-products such as bio-fertilizer, bio-char, compost and boiler ash. Substituting oil palm biomass by the above mentioned bio-products will not only create local markets for the bio-products but will ultimately make available more oil palm biomass for downstream processing [174].

Another important role that the biomass owners have to play in the value chain is the area of transportation and logistics. To effectively handle this, pre-treatment of oil palm biomass with high moisture content prone to easy decomposition, becomes necessary. This should be executed as soon as possible to stabilize and preserve the value of such oil palm biomass before leaving the mills. The recommended upstream pre-treatment include; drying, fiberizing, baling, pelleting and packaging, which can be achieved using the excess energy generated in the mills. The process will also facilitate the transportation of oil palm biomass for further processing into value-added products. It is worth mentioning here that the location of the mills also plays a vital role in determining the cost of the oil palm biomass. Moreover, mode of collection as well as the available transportation facilities are also factors that affect its cost. For instance, the cost of EFB in Johor ranges from RM40 to RM400 per tonne, in line with the factors mentioned above [174]. The variation in the cost of oil palm biomass is further largely due to non-existence of a universally accepted price for the biomass, leaving the cost of selling/buying at the discretion of the parties involved in the deal, a challenge that requires specific attention by the government.

Correspondingly, the government can play a major role in the value chain by ensuring a suitable policy is in place to facilitate smooth utilization of available oil palm biomass, the conversion to value-added products and quality monitoring of the products that reach the end users. While there are existing policies targeted at addressing the issues of demand and pricing of oil palm biomass, new policies should be in place to promote maximum utilization of oil palm biomass for manufacturing activities. The existing policies include: Fifth Fuel Policy 2001, National Biotechnology Policy 2005, National Biofuel Policy 2006, National Green Technology Policy 2009, Energy Act 2011, The National Biomass Strategy 2020 (NBS2020), Bio-economy Transformation Programme and SME Master Plan 2012–2020, to mention a few [38, 163, 174]. Their implementation has resulted in substantial growth of oil palm biomass utilization for electricity and thermal generation. This has been demonstrated by the fact that 76% of the 60.84 MW of electricity by the National Grid in 2013 came from oil palm biomass [174]. Correspondingly, the Malaysian government has put forward several incentives for existing and prospective investors in the oil palm biomass industry that include [38] but not limited to:

-

i.

BioNexus Status Programme—providing 100% income tax exemption for value-added biotechnology activities.

-

ii.

Investment Tax Allowance—allowing 100% income tax exemption for 60% capital expenditure for biomass–to–energy technologies.

-

iii.

Pioneer Status—providing 100% statuary tax exemption policy for 10 years of value-added biomass utilization.

-

iv.

Biotechnology Venture Fund—making available USD 100 million venture fund for biotech companies operating in Malaysia.

-

v.

Green Lane Facility—providing 2% interest rebates for approved loans [38].

The establishment of research institutions such as Malaysian Palm Oil Board (MPOB), Standard and Industrial Research Institute of Malaysia (SIRIM) and Forest Research Institute of Malaysia (FRIM) alongside five other research universities funded by the Malaysian government has been proven useful for advancing oil palm research and development. These institutions are central for churning out new innovations as well as providing the right technologies and skills needed for growth of oil palm biomass industry in Malaysia [174]. Research data pertaining to potentials of oil palm biomass industry by these research and academic institutions should also be made available to stakeholders like banks and decision makers in the financial sector, to demonstrate the relevance of this biomass to produce engineering products, fine chemicals and eco-products [163, 174], in addition to the existing products [38]. Financial support should be made easier for Small and Medium Entrepreneurs (SMEs) to kick-start businesses focusing on conditioning and developing of oil palm biomass products. Essentially, a government backed financial support would be the main driver of innovations for the expansion and advancements of oil palm biomass industry in Malaysia.

Consequently, to further expand the national oil palm biomass industry, it is crucial that the government review current economic structure and industrial policies. Current exports of Malaysia to its top trading partners such as Singapore, the United States, Japan and China have, so far, been highly concentrated on goods such as electrical and electronics, alongside machinery and furniture [175]. Malaysia remains as a manufacturing hub for technologies and products for foreign companies and not producing technologies or products of her own. Moreover, production and exportation of the aforementioned goods require a lot of intermediary inputs, and generates lower profit margins [176, 177] compared to what can be obtained from the oil palm biomass industries. Therefore, the task of reforming certain parts of the labor, commodity and operational structure may prove necessary for the re-direction or setting up new manufacturing activities that focus on expansion and production of bio-products from oil palm biomass, which may potentially be a more lucrative form of industrial activity. It is vital that the trade and industrial policies are synchronous to entice potential investments into commercial production of value-added products from oil palm biomass. Furthermore, an economic reform that encourages production of bio-products from oil palm biomass would be more profitable over a long term, should most of the biomass processes be automated, starting from harvesting the biomass and all the way to upstream and downstream processing activities. Incentives such as tax reductions, interest rebates and take-off-grants, should be offered to both national and foreign companies that invest in high-end technologies capable of converting oil palm biomass into advanced materials viz. biopolymers and biosensors. With such matters in place, a more conducive economic and manufacturing atmosphere that facilitate expansion and production of oil palm biomass-based products and technologies would be created.

Conclusion

Oil palm biomass is constantly generated in large quantities in Malaysia because of the huge oil palm plantations. To a minimal extent, biomass from the oil palm industry has been converted into valued added products using thermochemical, chemical, physical and biochemical conversion routes. However, a large percentage of such biomass as OPF and OPT are still left in the plantations unharnessed. A pragmatic approach to convert them to value added products will not only lead to a cleaner environment but generate substantial revenue to the Malaysian government, especially through export to countries like China, Japan and South Korea where the gradual shift from fossil fuel and chemical based energy to bio-based ones is eminent. An extract from Malaysian Biomass Industry Action Plan 2020 [174] estimated that the bio-fuel demand from the above three nations would rise to as much as 16 million tonnes by the year 2020, which would generate about RM 4.8 billion annually for Malaysian government. To achieve this, it has been suggested that in addition to the existing technologies and government policies, newer technologies and policies could be formulated and enacted to encourage private sector participation. It is also suggested that more attention should be given to the bio-products to present them in attractive form to the end users, hence encouraging good patronage.

References

McKendry, P.: Energy production from biomass (part1): overview of biomass. Bioresour. Technol. 83, 37–46 (2002)

Hosseini, S.E., Wahid, M.A.: Utilization of palm solid residue as a source of renewable and sustainable energy in Malaysia. Renew. Sustain. Energy Rev. 40, 621–632 (2014)

Awalludin, M.F., Othman, S., Rokiah, H., Wan, N.A., Wan, N.: An overview of the oil palm industry in Malaysia and its waste utilization through thermochemical conversion, specifically via liquefaction. Renew. Sustain. Energy Rev. 50, 1469–1484 (2015)

Demirbaş, A.: Effect of lignin content on aqueous liquefaction products of biomass. Energy Convers. Manag. 41, 1601–1607 (2000)

Akhtar, J., Amin, N.A.S.: A review on process conditions for optimum bio-oil yield in hydrothermal liquefaction of biomass. Renew. Sustain. Energy Rev. 15, 1615–1624 (2011)

Abbasi, T., Abbasi, S.A.: Biomass energy and the environmental impact associated with its production and utilization. Renew. Sustain. Energy Rev. 14, 919–937 (2010)

Borjesson, P.I.I.: Energy analysis of biomass production and transportation. Biomass Bioenergy 11, 305–318 (1996)

Evans, A., Strezov, V., Evans, T.J.: Sustainability considerations for electricity generation from biomass. Renew. Sustain. Energy Rev. 14, 1419–1427 (2010)

de Wit M., Junginger, M., Faaij, A.: Learning in dedicated wood production systems: past trends, future outlook and implications for bioenergy. Renew. Sustain. Energy Rev. 19, 417–432 (2013)

Raslavicius, L., Kucinskas, V., Jasinskas, A.: The prospects of energy forestry and agro-residues in the Lithuania’s domestic energy supply. Renew. Sustain. Energy Rev. 22, 419–431 (2013)

Singh, R., Setiawan, A.D.: Biomass energy policies and strategies: harvesting potential in India and Indonesia. Renew. Sustain. Energy Rev. 22, 332–345 (2013)

Laurent, A., Pelzer, E., Loyce, C., Makowski, D.: Ranking yields of energy crops: a meta-analysis using direct and indirect comparisons. Renew. Sustain. Energy Rev. 46, 41–50 (2015)

Saidur, R., Abdelaziz, E.A., Demirbas, A., Hossain, M.S., Mekhilef, S.: A review on biomass as a fuel for boilers. Renew. Sustain. Energy Rev. 15, 2262–2289 (2011)

Larry, D.C.: The history, genotoxicity and carcinogenicity of carbon-based fuels and their emissions: part 4—alternative fuels. Mutat Res 763, 86–102 (2015)

Kwietniewska, E., Tys, J.: Process, characteristics, inhibition factors and methane yields of anaerobic digestion process, with particular focus on micro-algal biomass fermentation. Renew. Sustain. Energy Rev. 34, 491–500 (2014)

Yaman, S.: Pyrolysis of biomass to produce fuels and chemical feedstocks. Energy Convers. Manag. 45, 651–671 (2004)

Demirbas, A.: Combustion characteristics of different biomass fuels. Prog. Energy Combust. 30, 219–230 (2004)

Larsen, S., Bruun, S., Lindedam, J.: Straw yield and saccharification potential for ethanol in cereal species and wheat cultivars. Biomass Bioenergy 45, 239–250 (2012)

Begum, S., Kumaran, P., Jayakumar, M.: Use of oil palm waste as a renewable energy source and its impact on reduction of air pollution in context of Malaysia. Int. Conf. Energy Environ. (2013). https://doi.org/10.1088/1755-1315/16/1/012026

Thornley, P., Paul, G., Simon, S., Jim, H.: Maximizing the greenhouse gas reductions from biomass. The role of life cycle assessment. Biomass Bioenergy 81, 35–43 (2015)

Gilbert, P., Alexander, S., Thornley, P., Brammer, J.: Assessing economically viable carbon reductions for the production of ammonia from biomass gasification. J. Clean. Prod. 64, 581–589 (2014)

Khan, A.A., Jonga, W.D., Jansens, P.J., Spliethoff, H.: Biomass combustion in fluidized bed boilers: potential problems and remedies. Fuel Process Technol. 90, 21–50 (2009)

Abdul Khalil, H.P.S., Jawaid, M., Hassan, A., Paridah, M.T., Zaidon, A.: Oil Palm Biomass Fibres and Recent Advancement in Oil Palm Biomass Fibres Based Hybrid Biocomposites. Intech, Rijeka, (2012)

Kurnia, J.C., Jangam, S.V., Akhtar, S., Sasmito, A.P., Mujumdar, A.S.: Advances in biofuel production from oil palm and palm oil processing wastes: a review. Biofuel Res. J. 3(28), 332–346 (2016)

Uemura, Y., Omar, W.N., Tsutsui, T., Yusup, S.B.: Torrefaction of oil palm wastes. Fuel 90, 2585–2591 (2011)

Samiran, N.A., Jaafar, M.N.M., Chong, C.T., Jo-Han, N.: A review of palm oil biomass as a feedstock for syngas fuel technology. J. Teknologi. Sci. Eng. 72, 13–18 (2015)

Abdul Khalil, H.P.S., Bhat, A.H.: Oil palm biomass: fibre cultivation, production and its varied applications, In Penna, S. A. (ed.) Oil Palm: Cultivation, Production and Dietary Components, Nova Science Publisher, Inc., Hauppauge, pp. 21–34 (2010)

Abdul Khalil, H.P.S., Kang, C.W., Khairul, A., Ridzuan, R., Adawi, T.O.: The effect of different laminations on mechanical and physical properties of hybrid composites. J. Reinf. Plast. Compos. 28(9), 1123–1137 (2009)

Abdul Khalil, H.P.S., Poh, B.T., Issam, A.M., Jawaid, M., Ridzuan, R.: Recycled polypropylene-oil palm biomass: the effect on mechanical and physical properties. J. Reinf. Plast. Compos. 29(8), 1117–1130 (2010)

Paterson, R.R., Moen, S., Lima, N.: The feasibility of producing oil palm with altered lignin content to control Ganoderma disease. J. Phytopathol. 157, 649–656 (2009)

Nigam, P.S., Pandey, A.: Biotechnology for Agro-Industrial Residues Utilisation: Utilisation of Agro-Residues. Springer, New York (2009)

Yaap, B., Struebig, M.J., Paoli, G., Koh, L.P.: Mitigating the biodiversity impacts of oil palm development. CAB Rev. 5, 1–11 (2010)

Oviasogie, P., Aisueni, N., Brown, G.: Oil palm composted biomass a review of the preparation, utilization, handling and storage. Afr. J. Agric. Res. 5, 1553–1571 (2010)

Mazaheri, H., Lee, K.T., Bhatia, S., Mohamed, A.R.: Sub/supercritical liquefaction of oil palm fruit press fiber for the production of bio-oil: effect of solvents. Bioresour. Technol. 101, 7641–7647 (2010)

Rupani, P.F., Singh, R.P., Ibrahim, M.H., Esa, N.: Review of current palm oil mill effluent (POME) treatment methods: vermicomposting as a sustainable practice. World Appl. Sci. J. 11, 70–81 (2010)

Mohammad, N., Alam, M.Z., Kabbashi, N.A., Ahsan, A.: Effective composting of oil palm industrial waste by filamentous fungi: a review. Resour. Conserv. Recycl. 58, 69–78 (2012)

Basiron, Y.: Palm oil production through sustainable plantations. Eur. J. Lipid Sci. Technol. 109, 289–295 (2007)

AIM, National Biomass Strategy 2020.: New wealth creation for Malaysia’s biomass industry: Version 2.0, 2013. Agensi Inovasi Malaysia, Kuala Lumpur (2015). Available at: http://etp.pemandu.gov.my/upload/Biomass_Strategy_2013.pdf

Sulaiman, F., Abdullah, N., Gerhauser, H., Shariff, A.: A perspective of oil palm and its wastes. J. Phys. Sci. 21, 67–77 (2010)

Abdullah, N., Sulaiman, F.: The Oil Palm Wastes in Malaysia, Intech, Rijeka (2013)

MPOB, Economic & Industry Development Division.: Oil palm planted area. (2014). Available at: http://bepi.mpob.gov.my/index.php/statistics/area.html

Abdullah, N., Sulaiman, F., Aliasak, Z.: A case study of pyrolysis of oil palm wastes in Malaysia. In: Proceedings of the 2012 National Physic Conference: (PERFIK 2012): AIP Publishing, Melville, pp. 331–336 (2013)

Vakili, M., Rafatullah, M., Ibrahim, M.H., Salamatinia, B., Gholami, Z., Zwain, H.M.: A review on composting of oil palm biomass. Environ. Dev. Sustain. (2014). https://doi.org/10.1007/s10668-014-9581-2

Abdul Khalil, H.P.S., Nurul-Fazita, M.R., Bhat, A.H., Jawaid, M., Nik-Fuad, N.A.: Development and material properties of new hybrid plywood from oil palm biomass. Mater. Des. 31(1), 417–424 (2010)

Kelly-Yong, T.L., Lee, K.T., Mohamed, A.R., Bhatia, S.: Potential of hydrogen from oil palm biomass as a source of renewable energy worldwide. Energy Pol. 35, 5692–5701 (2007)

Loh, S.K.: The potential of the Malaysian oil palm biomass as a renewable energy source. Energy Convers. Manag. (2016). https://doi.org/10.1016/j.enconman.2016.08.081

Chan, K.W., Watson, I., Lim, K.C.: Use of oil palm waste material for increased production. Planter 57, 14–37 (1981)

Konga, S.H., Loh, S.K., Bachmann, R.T., Rahim, S.A., Salimon, J.: Biochar from oil palm biomass a review of its potential and challenges. Renew. Sustain. Energy Rev. 39, 729–739 (2014)

Hussain, Z., Zainac, Z., Abdullah, Z.: ‘Briquetting of palm fibre and shell from the processing of palm nuts to palm oil. Biomass Bioenergy 22, 505–509 (2002)

Huybrechts, P., Kuhn, M., Lambeck, K., Nhuan, M.T., Qin, D., Woodworth, P.L.: Changes in sea level. In: Douglas, B.C., Ramirez, A. (eds.) Climate Change: The Scientific Basis, pp. 639–693. Cambridge University Press, Cambridge (2001)

Wigley, T.M.L.: The climate change commitment. Science 307, 1766–1769 (2005)

Rahman, A.A., Abdullah, N., Sulaiman, F.: Temperature effect on the characterization of pyrolysis products from oil palm fronds. Adv. Energy Eng. 2, 14–21 (2014)

Koh, M.P., Hoi, W.K.: Sustainable biomass production for energy in Malaysia. Biomass Bioenergy 25, 517–529 (2003)

Sasaki, N., Knorr, W., Foster, D.R., Etoh, H., Ninomiya, H., Chay, S.: Woody biomass and bioenergy potentials in Southeast Asia between 1990 and 2020. Appl. Energy 86, 140–150 (2009)

Sheng, C., Azevedo, J.L.T.: Estimating the higher heating value of biomass fuels from basic analysis data. Biomass Bioenergy 28, 499–507 (2005)

Yin, C.Y.: Prediction of higher heating values of biomass from proximate and ultimate analyses. Fuel 90, 1128–1132 (2011)

Wan Ab Karim Ghani, W.A., Abdullah, M.S., Matori, K.A., Alias, A.B., da-Silva, G.: Physical and thermochemical characterization of Malaysian biomass ashes. J. Inst. Eng. 71, 9–17 (2010)

Hamzah, M.M.: The production of ecofiber from palm oil empty fruit bunch (EFB), Diss. Universiti Malaysia Pahang (2008)

Abnisa, F., Wan-Daud, W.M.A., Husin, W.N.W., Sahu, J.N.: Utilization possibilities of palm shell as a source of biomass energy in Malaysia by producing bio-oil in pyrolysis process. Biomass Bioenergy 35, 1863–1872 (2011)

Idris, S.S., Abd-Rahman, N., Ismail, K.: Combustion characteristics of Malaysian oil palm biomass, sub-bituminous coal and their respective blends via thermogravimetric analysis (TGA). Bioresour. Technol. 123, 581–591 (2012)

Ninduangdee, P., Kuprianov, V.I.: Study on burning oil palm kernel shell in a conical fluidized-bed combustor using alumina as the bed material. J. Taiwan Ins. Chem. Eng. 44, 1045–1053 (2013)

Ho, W.S., Khor, C.S., Hashim, H., Lim, J.S., Ashina, S., Herran, D.S.: Optimal operation of a distributed energy generation system for a sustainable palm oil-based eco-community. Clean Technol. Environ. 17, 1597–1617 (2015)

Herbert, G.M.J., Krishnan, A.U.: Quantifying environmental performance of biomass energy. Renew. Sustain. Energy Rev. 59, 292–308 (2016)

Abnisa, F., Arami-Niya, A., Wan-Daud, W.M.A., Sahu, J.N., Noor, I.M.: Utilization of oil palm tree residues to produce bio-oil and bio-char via pyrolysis. Energy Convers. Manag. 76, 1073–1082 (2013)

Joselin, H.G.M., Unni, K.A.: Quantifying environmental performance of biomass energy. Renew. Sust. Energy Rev. 59, 292–308 (2016)

Sugumaran, P., Seshadri, S.: Evaluation of selected biomass for charcoal production. J. Sci. Ind. Res. 68, 719–723 (2009)

Guangul, F.M., Sulaiman, S.A., Ramli, A.: Gasifier selection, design and gasification of oil palm fronds with preheated and unheated gasifying air. Bioresour. Technol. 126, 224–232 (2012)

Mekbib, S., Anwar, S., Yusup, S.: Syngas production from downdraft gasification of oil palm fronds. Energy 61, 491–501 (2013)

Hashim, R., Nadhari, W.N.A.W., Sulaiman, O., Kawamura, F., Hiziroglu, S., Sato, M., et al.: Characterization of raw materials and manufactured binderless particleboard from oil palm biomass. Mater. Des. 32, 246–254 (2011)

Kristiani, A., Abimanyu, H., Setiawan Sudiyarmanto, A.H., Aulia, F.: Effect of pretreatment process by using diluted acid to characteristic of oil palm’s frond. Energy Procedia 32, 183–189 (2013)

Theander, O.: In: Overand, R.P., Mile, T.A., Mudge, L.K. (eds.) Fundamentals of thermo-chemical biomass conversion, Elsevier Applied Science Publisher, New York (1985)

Unal, H., Alibas, K.: Agricultural residues as biomass energy. Energy Source Part B 2, 123–140 (2007)

Demirbas, A.: Recent progress in biorenewable feedstock. Energy Educ. Sci. Technol. 22, 69–95 (2008)

Balat, M.: Mechanisms of thermochemical biomass conversion processes. Part 1. Reactions of pyrolysis. Energy Source Part A 30, 620–635 (2008)

Harmsen, P.F.H., Huijgen, W., Bermudez, L., Bakker, R.: Literature Review of Physical and Chemical Pretreatment Processes for Lignocellulosic Biomass, Wageningen UR Food & Biobased Research, Wageningen (2010)

Carrier, M., Loppinet-serani, A., Aymonier, C.: Thermogravimetric analysis as a new method to determine the lignocellulosic composition of biomass. Biomass Bioenergy 35, 298–307 (2011)

Mohan, D., Pittman, C.U., Steele, P.H.: Pyrolysis of wood/biomass for bio-oil: a critical review. Energy & Fuels 20, 848–889 (2006)

Chaikitkaew, S., Kongjan, P., Thong, S.O., Biogas production from biomass residues of palm oil mill by solid state anaerobic, digestion. Energy Procedia 79, 838–844 (2015)

Elias, N., Chandren, S., Attan, N., Mahat, N.A., Abdul-Razak, F.I., Jamalis, J., Wahab, R.A.: Structure and properties of oil palm-based nanocellulose reinforced chitosan nanocomposite for efficient synthesis of butyl butyrate. Carbohyd. Polym. 176, 281–292 (2017)

Abdul Khalil, H.P.S., Nurul Fazita, M.R., Jawaid, M., Bhat, A.H., Abdullah, C.K.: Empty fruit bunches as a reinforcement in laminated bio-composites. J. Compos Mater. 45(2), 219–236 (2011). https://doi.org/10.1177/0021998310373520

Sreekala, M.S., Jayamol, G., Sabu, T.: Water-sorption kinetics in oil palm fibers. J. Polym. Sci. Part B 39, 1215–1223 (2001)

Myrtha, K., Holia, O., Abdullah, D.A.H., Anung, S.: Effect of oil palm empty fruit bunch fiber on the physical and mechanical properties of fiber glass reinforced polyester resin. J. Biol. Sci. 8(1), 101–106 (2008)

Firoozian, P., Bhat, I.H., Abdul Khalil, H.P.S., Noor, A.M., Akil, H.M., Bhat, A.H.: High surface area activated carbon prepared from agricultural biomass: empty fruit bunch (EFB), bamboo stem and coconut shells by chemical activation with H3PO4. Mater. Technol. Adv. Perform. Mater. 26(5), 222–228 (2011)

Kormin, S., Rus, A.Z.M., Azahari, M.S.M.: Preparation of polyurethane foams using liquefied oil palm mesocarp fibre (OPMF) and renewable monomer from waste cooking oil, 4th International Conference on the Advancement of Materials and Nanotechnology (ICAMN IV 2016), AIP Conf. Proc. 1877, 060006-1-060006-7; https://doi.org/10.1063/1.4999885

Mayulu, H.: The Nutrient potency of palm oil plantation and Mill’s by-product processed with amofer technology as ruminant feed. Int J. Sci. Eng. 6(2), 112–116 (2014)

Chaiyaomporn, K., Chavalparit, O.: Fuel pellets production from biodiesel waste. Environ. Asia 3, 103–110 (2010)

Daud, W.R.W., Law, K.N.: Oil palm fibers as papermaking material: potentials and challenges. BioResources 6, 901–917 (2010)

Mulakhudair, A.R., Hanotu, J., Zimmerman, W.: Exploiting microbubble-microbe synergy for biomass processing: Application in lignocellulosic biomass pretreatment. Biomass Bioenergy 93, 187–193 (2016)

Pei-dong, Z., Guomei, J., Gang, W.: Contribution to emission reduction of CO2 and SO2 by household biogas construction in rural China. Renew. Sustain. Energy Rev. 11, 1903–1912 (2007)

Sulaiman, O., Hashim, R., Wahab, R., Samsi, H.W., Mohamed, A.H.: Evaluation on some finishing properties of oil palm plywood. Holz Roh Werkst 66, 5–10 (2008)

Nordin, K., Jamaludin, M.A., Ahmad, M., Samsi, H.W., Salleh, A.H., Jallaludin, Z.: Minimizing the environmental burden of oil palm trunk residues trough the development of laminated veneer lumber products. Manag. Environ. Qual. 15, 484–490 (2004)

Hashim, R., Nadhari, W.N.A.W., Sulaiman, O., Sato, M., Hiziroglu, S., Kawamura, F., Sugimoto, T., Seng, T.G., Tanaka, R.: Properties of binderless particleboard panels manufactured from oil palm biomass. BioResources 7, 1352–1365 (2012)

Wanrosli, W.D., Mazlan, I., Law, K.N., Nasrullah, R.: Influences of the operating variables of acetosolv pulping on pulp properties of oil palm frond fibers. Maderas. Ciencia y Tecnología 13(2), 193–202 (2011). https://doi.org/10.4067/S0718-221X2011000200007

Thornley, P., Upham, P., Huang, Y., Rezvani, S., Brammer, J., Rogers, J.: Integrated assessment of bioelectricity technology options. Energy Pol. 37, 890–903 (2009)

Ahmadzadeh, A., Zakaria, S., Rashid, R.: Liquefaction of oil palm empty fruit bunch (EFB) into phenol and characterization of phenolated EFB resin. Ind. Crops Prod. 30, 54–58 (2009)

Ghazali, A., Wanrosli, W.D., Law, K.N.: Alkaline peroxide mechanical pulping (APMP) of oil palm lignocellulosics: part 2 Empty fruit bunch (EFB) responses to pretreatments. Appita J. 59, 65–70 (2006)

John, E., White, W., Catallo, J., Legendre, B.L.: Biomass pyrolysis kinetics: a comparative critical review with relevant agricultural residue case studies. J. Anal. Appl. Pyrol. 91, 1–33 (2011)

Sivasangar, S., Zainal, Z., Salmiaton, A., Taufiq-Yap, Y.: Supercritical water gasification of empty fruit bunches from oil palm for hydrogen production. Fuel 143, 563–569 (2015)

Sumanthi, S., Chai, S.P., Mohamed, A.R.: Utilization of oil palm as a source of renewable energy in Malaysia. Renew. Sustain. Energy Rev. 12, 2404–2421 (2008)

Nasrin, A.B., Ma, A.N., Choo, Y.M., Mohamad, S., Rohaya, M.H., Azali, A., et al.: Oil palm biomass as potential substitution raw materials for commercial biomass briquettes production. Am. J. Appl. Sci. 5, 179–183 (2008)

Bernama. Biochar Malaysia: UPM-NASMECH effect of producing EFB Biochar: world’s first.7 January 2010. http://biocharmalaysia.blogspot.com/2010/01/upm- nasmech-effort-of-producing-efb.html, (Accessed 4 April 2011)

Azali, A., Nasrin, A.B., Choo, Y.M., Adam, N.M., Sapuan, S.M.: Development of gasification system fuelled with oil palm fibres and shells. Am. J. Appl. Sci. 72–75 (2005)

Shuit, S.H., Tan, K.T., Lee, K.T., Kamaruddin, A.H.: Oil palm biomass as a sustainable energy source: Malaysian case study. Energy 34, 1225–1235 (2009)

Salema, A.A., Ani, F.N.: Microwave induced pyrolysis of oil palm biomass. Bioresour. Technol. 102, 3388–3395 (2011)

Nomanbhay, S.M., Palanisamy, K.: Removal of heavy metal from industrial wastewater using chitosan coated oil palm shell charcoal. Electron. J. Biotechnol. 8, 44–53 (2005)

Tan, J., Ani, F.: Carbon molecular sieves produced from oil palm shell for air separation. Sep. Purif. Technol. 35, 47–54 (2004)

Ahmad, M., Wan-Daud, W., Aroua, M.: Synthesis of carbon molecular sieves from palm shell by carbon vapor deposition. J. Porous Matter. 14, 393–399 (2007)

Daud, W., Ahmad, M., Aroua, M.: Carbon molecular sieves from palm shell: effect of the benzene deposition times on gas separation properties. Sep. Purif. Technol. 57, 289–293 (2007)

Ahmad, M., Wan-Daud, W., Aroua, M.: Adsorption kinetics of various gases in carbon molecular sieves (CMS) produced from palm shell. Colloids Surf. A 312, 131–135 (2008)

Kim, S.W., Koo, B.S., Lee, D.H.: Catalytic pyrolysis of palm kernel shell waste in a fluidized bed. Bioresour. Technol. 167, 425–432 (2014)

Esther, O.U.: Anaerobic digestion of palm oil mill effluent and its utilization as fertilizer for environmental protection. Renew. Energy 10, 291–294 (1997)

Fakhru’l-Razi, A., Yassin, A.A.A., Lyuke, S.E., Ngan, M.A., Morimoto, M.: Bio-hydrogen synthesis from wastewater by anaerobic fermentation using microflora. Int. J. Green Energy 2, 387–396 (2005)

Kow, K.W., Mun, L.Y., Yusoff, R.: Silica gel synthesized from oil palm boiler ash. J. Miner. Met. Mater. Eng. 1, 14–18 (2015)

Haron, K., Mohammed, A.T., Halim, R.M., Din, A.K.: Palm-based bio-fertilizer from decanter cake and boiler ash of palm oil mill. Inf. Ser. (MPOB TT No. 412), 1–4 (2008)

Tangchirapat, W., Jaturapitakkul, C., Chindaprasirt, P.: Use of palm oil fuel ash as a supplementary cementitious material for producing high-strength concrete. Constr. Build. Mater. 23, 2641–2646 (2009)

Mohamed, A.R., Lee, K.T., Noor, N.M., Zainudin, N.F.: Oil palm ash/Ca (OH)2/CaSO4 absorbent for flue gas desulfucrization. Chem. Eng. Technol. 28, 939–945 (2005)

Isa, M.H., Lang, L.S., Asaari, F.A.H., Aziz, H.A., Ramli, N.A., Dhas, J.P.A.: Low cost removal of disperse dyes from aqueous solution using palm ash. Dyes Pigm. 74, 446–453 (2007)

Isa, M.H., Ibrahim, N., Aziz, H.A., Adlan, M.N., Sabiani, N.H.M., Zinatizadeh, A.A.L., et al.: Removal of chromium (VI) from aqueous solution using treated oil palm fibre. J. Hazard. Mater. 152, 662–668 (2008)

Bhat, A.H., Khalil, H.A.: Exploring, nano filler based on oil palm ash in polypropylene composites. BioResources 6, 1288–1297 (2011)

Ooi, Z.X., Ismail, H., Abu-Bakar, A.: Optimisation of oil palm ash as reinforcement in natural rubber vulcanisation: a comparison between silica and carbon black fillers. Polym. Test. 32, 625–630 (2013)

Sensoz, S., Can, M.,, Part, A., Recovery: Pyrolysis of pine (Pinus Brutia Ten.) chips: effect of pyrolysis temperatures and heating rate on the product yields. Energy Sources 24, 347–355 (2002)

Idris, S.S., Rahman, N.A., Ismail, K., Alias, A.B., Rashid, Z.A., Aris, M.J.: Investigation on thermochemical behaviour of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour. Technol. 101, 4584–4592 (2010)

Vardon, D.R., Sharma, B.K., Blazina, G.V., Rajagopalan, K., Strathmann, T.J.: Thermo- chemical conversion of raw and defatted algal biomass via hydrothermal liquefaction and slow pyrolysis. Bioresour. Technol. 109, 178–187 (2012)

Bridgwater, A.V.: Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 38, 68–94 (2012)

Sulaiman, F., Abdullah, N.: Optimum conditions for maximising pyrolysis liquids of oil palm empty fruit bunches. Energy 36, 2352–2359 (2011)

Meier, D., Faix, O.: State of the art of applied fast pyrolysis of lignocellulosic materials—a review. Bioresour. Technol. 68, 71–77 (1999)

Demirbas, A.: Potential applications of renewable energy sources, biomass combustion problems in boiler power systems and combustion related environmental issues. Prog. Energy Combust. 31, 171–192 (2005)

Goh, C.S., Tan, K.T., Lee, K.T., Bhatia, S.: Bio-ethanol from lignocellulose: status, perspectives and challenges in Malaysia. Bioresour. Technol. 101, 4834–4841 (2010)

Aljuboori, A.: Oil palm biomass residue in Malaysia: availability and sustainability. Intl. J. Biomass Renew. 2, 13–18 (2013)

Demirbas, A.: Relationships between lignin contents and fixed carbon contents of biomass samples. Energy Convers. Manag. 44, 1481–1486 (2003)