Abstract

A new bioconversion-composting process of golden needle mushroom (Flammulina velutipes) root waste was established using black soldier fly larvae (BSFL) to produce added-value biomass and organic fertilizer. The entire process included two stages: BSFL conversion and conventional composting, which lasted 40 days. After a 26-day bioconversion, a considerable quantity of BSFL was obtained, which could be used to produce the protein feed, chitin, antibacterial peptide, biodiesel and so on. The bioconversion parameters of waste reduction rate and BSFL conversion rate were 54.8 ± 0.4 and 5.06 ± 0.27%, respectively. Following the 14-day conventional composting, the mushroom root waste turned into an organic fertilizer. The moisture, organic matter, total nitrogen, total phosphorus, and total potassium concentrations of the obtained fertilizer were 29.3 ± 0.9, 76.0 ± 1.7, 2.74 ± 0.09, 2.07 ± 0.06, and 1.34 ± 0.15%, respectively. The germination index was 65.7 ± 3.2% for Chinese cabbage and 52.9 ± 1.3% for rapeseed. To accelerate bioconversion, increase output of larvae biomass and shorten the developing time of BSFL, two auxiliary materials, nitrogen source, namely, bran and kitchen wastes, were mixed with mushroom roots. Both were significantly effective, and the recommended percentage was 40%. In that case, the developing time reduced to approximately 15–16 days, and the BSFL conversion rate increased by 31.2–172.7%. Accordingly, one simple process flowchart was drawn, and the output was estimated.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Golden needle mushrooms (Flammulina velutipes) are widely eaten by people worldwide, especially in China and Japan [1]. The mushroom’s high nutritional value and delicious taste rapidly increase its production [2], and it has become one of the fourth most popular edible mushrooms worldwide [3, 4]. According to the statistical data from Zhiyan Consulting Group (http://www.chyxx.com/research/201409/277249.html), 3,180,000 tons of this mushroom were produced in 2014 in China. With the increasing yield of golden needle mushroom (GNM), its production waste, nearly double yield of GNM and including mushroom residue and mushroom root waste (an abandoned part of the fruiting bodies), is becoming a huge burden that increases the treatment cost for edible mushroom companies. Recycling the waste and reducing the treatment cost become part of their important objectives.

The mushroom residue normally acts as the accessory to adjust the status of manure composting and could be consumed by the composting factory with less cost. However, the mushroom root waste could not easily be used in a similar fashion because of its high water content and drying pretreatment. Furthermore, the mushroom root has highly similar nutritional value to fruiting bodies, thereby requiring the former with high value-added recycling. Many research focused on the medicinal properties of fruiting bodies, which contained bioactive polysaccharides with beneficial immunomodulatory, anti-tumor, and biological activities on hepatocytes as well as anti-proliferation and antioxidant activities [1, 5,6,7,8,9]. Mushroom root waste may have a grand prospect of developing medicinal value in the future. Hence, a practical and value-added process is needed.

Black soldier fly larvae (BSFL), Hermetia illucens, could feed in organic wastes, thereby incorporating the nutrients into their bodies and reducing the amount of waste material in the process [10,11,12]. The treatment process with BSFL had been applied to many types of manure and kitchen wastes, which could produce a biomass of protein, fat, and other by-products, such as organic fertilizer, chitin, antibacterial peptide, and biodiesel [13,14,15,16,17,18,19,20]. This developing process may meet the requirement of mushroom root treatment.

This paper investigates the feasibility of a new bioconversion-composting process of mushroom root waste by BSFL. The key parameters of the new process were evaluated. We further provided a schematic of the new process for mushroom root treatment for future application.

Materials and Methods

Source of Black Soldier Fly

The black soldier flies were obtained from a colony maintained year round in a greenhouse in Huazhong Agricultural University, Wuhan. The Wuhan colony was established from eggs collected at a poultry facility in November 2008.

In the colony breeding system, the room temperature was controlled, ranging from 25 to 30 °C and the air humidity above 70%. The larvae were fed on standard colony diet [1:1 bran and wheat shorts (w:w)] [16, 18, 21] for an average of 22–24 days. Then, they went through stages of pupation, eclosion, copulation, and oviposition [22], and the eggs were collected and hatched to the first-day larvae. Part of the first-day larvae would join this life cycle again to keep the system running; others would be fed for approximately 6 days on standard colony diet to be used in waste treatment [18, 21].

Source of Golden Needle Mushroom Root Waste

The fresh mushroom root waste was collected from Wuhan Ruyi Edible Mushrooms Co. Ltd., located in the Hutong Street, East of Xihu District, Wuhan City, Hubei Province, China. Each are cylindrical of diameter 80 mm × height 40 mm approximately, but any pretreatments were not done. The mushroom roots were stored in a cooling room of 4 °C. Before using for experiment, three samples of about 200 g was taken randomly and their nutritional parameters were measured by the Shanghai Supervision and Testing Center for Feed Quality, according to the standard method coded as GB/T 18246-2000, GB/T 6434 - 2006, GB/T 13082-1991, GB/T 13080-2004, and GB/T 18246-2000, Standardization Administration of the People’s Republic of China.

Bioconversion-Composting Process of Mushroom Root Waste

Approximately 2000 6-day-old BSFL were inoculated in an open barrel with humid cotton gauze by triplicates, and the fresh mushroom roots totaling 1000 dry g were placed into each barrel (50 mg larva−1 day−1 for 20 days) [23]. The room temperature was controlled at 25–30 °C in the entire process, and the mushroom was kept to wet but no free water was in the barrel bottom by spraying water until the first prepupa appeared. To evaluate the efficacy of the BSFL feeding the mushroom roots, the BSFL’s growth was monitored during the conversion process. So a total of 200 larvae were weighed randomly every day and returned to the experiment after weighting. When approximately 50% larvae grew to become a prepupa, the bioconversion process was stopped. The larvae separated from the residue were dried at 105 °C for 10 min and 60 °C for 2 days. A control treatment was conducted with standard colony diet.

After the larval conversion, the resulting residue was collected, in which 400 g residue was kept in the homemade insulated containers for composting by triplicates. The container’s main size was 85 mm (diameter) × 300 mm (height), and its shape is similar to an inverted cola bottle, as shown in Fig. S1. The residues were composted and its temperature was detected every day. When its temperature were similar with room temperature and no longer increasing for 3 days, we stopped the experiment. The samples of 20 g were collected at the beginning and the end of the composting and stored in the refrigerator at −20 °C.

Auxiliary Materials for Accelerating the BSFL Conversion

To accelerate mushroom root bioconversion, shorten the bioconversion time, and improve the BSFL conversion rate and yield, two auxiliary materials (bran and kitchen wastes) were added in the mushroom roots in different proportions for improving BSFL conversion. The kitchen wastes were collected from restaurants in Wuhan City, China, by Hubei Tianji Bioengineer Co. Ltd, which was drained and minced. The bran was collected from Wuhan Ruyi Edible Mushrooms Co. Ltd. The water content of these materials was determined by comparing their weight before and after drying at 105 °C for 10 min and 60 °C for 2 days. According to the water content, the different proportions (0, 20, 40, 60%, dry w/total dry w) of the auxiliary material were mixed with mushroom roots by triplicates. 200 6-day-old BSFL were inoculated in 100 dry g mixture materials. The bioconversion process was controlled as described above.

Chemical Analysis

The levels of total nitrogen (TN), total phosphorus (TP), total potassium (TK), and organic matter (OM) of residue samples [24] were assayed according to the standard method coded as NY 525-2011 Standardization Administration of the People’s Republic of China. The concentration assay of crude fat of larvae referenced the standard method coded as GBT 6433-2006.

The parameters of Vermicomposting

The parameters of vermicomposting were measured and calculated for the vermicomposting process as follows [23, 25]:

where WRR, WRI, CR, and RGR represent waste reduction rate (Eq. 1), waste reduction index (Eq. 2), conversion rate (Eq. 3), and relative growth rate (Eq. 4), respectively; S is the total quantity of substrate provided throughout the experiment; R is the residue left after bioconversion (non-digested substrate + excretion products); t is the bioconversion time; Wlf is the larvae weight by the end of the process; Wl0 is the larvae weight at the start of the process. The mass balances were performed on dry base.

Maturity Index of Composting

To evaluate the maturity degree of composting, the germination index (GI) of composting residue was measured [26]. The composting samples were weighed for 5 g and added with a 50 mL distilled water in a centrifuge tube. They were shaken for 30 min and then centrifuged at 3000 rpm for 20 min. About 5 mL of supernatant of extraction solution was added into the culture dish (9 cm diameter), and the two-layer filtration papers were soaked in the solution. Twenty rapeseed or Chinese cabbage seeds were placed evenly on the surface of a filtration paper by triplicates. The germination occurred in the biochemical incubator (SPX-100B-Z, Shanghai Boxun Industry & Commerce Co., Ltd. Medical Equipment Factory, China) with dark and 25 °C condition for 48 h; then, the germination rate and each root length in each dish were measured. The GI was calculated according to Eq. (5) [27]. A control treatment was conducted using distilled water.

Data Analysis

Analyses of variance (ANOVA) or significance were applied for all the data. The predictive analytic software SPSS (version 16) was employed for the analysis.

Results and Discussion

The Nutritional Component of Mushroom Root Waste

Table 1 shows the measurement results of phosphorus, potassium, crude protein and a series of amino acids as the nutritional component of the mushroom root. The 19 components of F. velutipes root waste showed no significant difference with the fruiting body, except potassium and alanine, compared to the references [2, 28,29,30]. This result means that the mushroom root waste had a similar nutritional content to the fruiting body and had significant potential recycling value as feed. The amino acids of the root waste were abundant, and the glutamic acids were the most plentiful, which were backbone precursors for producing other amino acids [30]. The content of six essential amino acids, including threonine, valine, isoleucine, leucine, phenylalanine and lysine, were 2.22 g/100 g (total content). The results presented above show that the mushroom root waste is a good source of phosphorus, potassium, proteins, and amino acids, and it may be fed by the larvae of H. illucens.

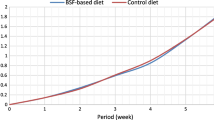

Growth of BSFL in the Bioconversion Process

The larval growth curve was shown in Fig. 1. It showed that the growth curve of BSFL in both substrates was linear in the first 18 days because of continuous feeding. The slopes (representing the growth rate) of these two lines were calculated to be 0.6614 ± 0.0173 (R2 = 0.9885, p < 0.01) and 0.6951 ± 0.0233 (R2 = 0.9812, p < 0.01), respectively, in mushroom root waste and standard colony diet (control) through regression analysis (n = 19), and the frontier was slightly lower than the latter. The BSFL in the mushroom root waste require more time for the prepupa than those in the control group; and their developing time was longer as well. However, they were able to feed the mushroom root waste very well and live to reach the prepupa stage to join their future fly life.

Only a 1-day difference existed between the mushroom root waste group and standard colony diet group when the first prepupa appeared. The weight of fresh larvae in the mushroom root waste group showed no significant difference (t = 0.008, p = 0.995; t = −0.678, p = 0.535) with that in the standard colony diet group in the 21st and 22nd day. Furthermore, the weight was stable in the range from the 21st day to 26th day. The optimal bioconversion time was suggested to be 22 days when the larvae weight reached the maximum and were kept stable.

The Bioconversion Process of Mushroom Root Waste

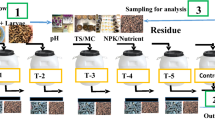

Figure 2 describes the status changes of the mushroom root waste and BSFL in the different stages of the bioconversion process. When the fresh mushroom root waste was added in the bioconversion system, an amount of larvae came to the bottom of the mushroom root waste because of their photopathy. The larvae were actively eating and move themselves into the mushroom root waste strongly. After several hours, the mushroom root waste structure becomes loose and broke up. At the beginning, middle, and end of bioconversion, their form was lumpish, spongy, and in small pieces, respectively, whereas the color changed from white to brick red, then to russet, and finally to taupe.

The larvae were energetic in the entire process. Their movement and respiration could warm the material, thereby possibly accelerating their lives in return and promoting a mutual relationship. In that case, the center temperature of the material could reach maximum of 52 °C at some time when the water volatilized quickly and the bioconversion process was accelerated. But high temperature would cause migration of larvae in which case the substrate should be manually turned for heat dissipation.

The entire bioconversion process lasted 26 days, and the parameters of this bioconversion were determined and calculated in Table 2. Results indicated that the WRR, WRI, CR, RGR, and crude fat values of the mushroom root waste group were significantly lower than those of the control group. But the mushroom root waste groups run healthily and sustainably. The CR and RGR of the mushroom root waste group were 5.06 ± 0.27% and 0.64 ± 0.04 days−1, respectively, which both were approximately 60% that of the control group. Zhou [22] invested the bioconversion of three black soldier fly strains on three livestock manures, which showed CR values of 5.37–6.55, 6.92–7.67, and 2.24–3.13% for swine manure, chicken manure, and dairy manure, respectively. The CR of mushroom root waste group was higher than that of dairy manure, and similar with that of swine manure. BSFL’s crude fat content was 14.9 ± 0.2% in the mushroom root waste bioconversion; whereas, it was approximately 34.3% in the control group. The fat accumulation of BSFL in the mushroom root waste was suggested to be weaker than that in the control group. However, it was potentially possible for their grease to product biodiesel [16].

Biochemical Changes of the Mushroom Roots During Bioconversion-Composting

In the entire bioconversion-composting process, the BSFL conversion requires 26 days, whereas the composting requires 14 days. Some biochemical parameters were monitored during the process, showed in Fig. 3. It showed that the moisture and OM of mushroom root waste reduced significantly in the process, whereas the TN, TP, and TK increased significantly. The final concentrations of moisture, OM, TN, TP, and TK were 29.3 ± 0.9, 76.0 ± 1.7, 2.74 ± 0.09, 2.07 ± 0.06, and 1.34 ± 0.15%, respectively, all of which met the standard of organic fertilizer coded as NY 525-2011. The reduction of moisture and OM resulted from the movement and feeding behavior of BSFL in bioconversion and microorganism activity in composting. The increase in TN, TP, and TK was mainly caused by mass transformation (referencing the “WRR”). The contribution of the bioconversion program may be more than that of conventional composting in terms of the values of each parameter in the bioconversion stage and conventional composting stage, which was consistent with the bioconversion of swine manure via housefly larvae [24].

The GI of the final composting residue was 65.7 ± 3.2% for Chinese cabbage and 52.9 ± 1.3% for rapeseed (shown in Fig. 4), which was assessed as mature compost (the immature compost when below 50%) [27]. Due to the bioconversion, the following traditional compost lasted 14 days, which was very short compared with much research [26, 31, 32]. The results proved that the bioconversion-composting process of F. velutipes root waste by BSFL was feasible and available. The two main products, namely, BSFL and organic fertilizers, would be obtained, which could improve the additional value for mushroom root waste management.

Process of Accelerating the Mushroom Root Waste Bioconversion

Table 3 shows the result of the conversion rate and waste reduction rate. Results showed that the conversion rate and the waste reduction rate increased with the increasing percentage of bran or kitchen wastes in the mushroom roots, whereas the BSFL developing time decreased. This result suggested that both bran and kitchen wastes could accelerate BSFL conversion, which may be because that the bran and kitchen wastes were palatability and brought carbohydrate and grease [21, 33]. The accelerating efficacy of kitchen wastes is better than that of bran because all conversion rate values of kitchen waste group are higher than those of bran group. Both conversion rate and waste reduction rate of 40 and 60% auxiliary material showed no significant difference, but were significantly different from those of the 20% auxiliary material and pure mushroom roots. When adding 40% of bran or kitchen wastes into the mushroom, the BSFL conversion rate respectively increased 31.2 and 172.7% times from those of pure mushroom root waste. Furthermore, the BSFL developing time would be shortened from 26 days to 15–16 days. Therefore, adding the auxiliary material is a good method to accelerate bioconversion. The best percentage result of kitchen wastes or bran obtained under the experimental conditions was 40%.

Design of the New Process for Mushroom Root Waste Bioconversion-Composting

The new process design for mushroom root waste bioconversion-composting was proposed according to the above results and analysis, as shown in Fig. 5.

The BSFL (6th day after hatching) was supplied by the breeding system. The moisture of mushroom root waster and auxiliary materials (bran or kitchen wastes) should be controlled to 70–80% at the beginning of BSFL conversion. The bioconversion system should be under the temperature range of 25–30 °C, where the inoculating ratio of larvae was advised as 2000 larvae per 1 kg dry material. In the process, the bran or kitchen wastes could be mixed with the mushroom root waste to accelerate the bioconversion process, with its recommended percentage suggested as 40% bran or kitchen wastes and 60% mushroom root wastes. According to the parameters of bioconversion-composting, 48–53 kg of aging BSFL and approximately 170 kg organic fertilizer could be obtained from 1 ton of fresh mushroom root waste; 68–72 kg of aging BSFL and approximately 190 kg of organic fertilizers could be obtained from 1 ton of fresh mixture of 60% mushroom root waste and 40% bran; 129–163 kg of aging BSFL and approximately 200 kg of organic fertilizer could be obtained from 1 ton of fresh mixture of 60% mushroom root waste and 40% kitchen wastes.

Conclusions

A new process for mushroom root waste bioconversion-composting by BSFL was designed and proven to be available in this study. This process could shorten the conventional composting time tremendously and return a profit. Two high-value products, namely, the biomass of BSFL and organic fertilizer, were obtained in this process. To accelerate bioconversion, the bran and kitchen wastes were used as auxiliary material. Apart from the speed of bioconversion, it was practical and effective as well. This process proved to be feasible, effective, and profitable, which may produce a new industrial chain and facilitate popularization and application.

References

Xia, Z.: Preparation of the oligosaccharides derived from Flammulina velutipes and their antioxidant activities. Carbohydr. Polym. 118, 41–43 (2015). doi:10.1016/j.carbpol.2014.10.074

Kang, L.-z., Zeng, X.-l., Ye, Z.-w., Lin, J.-f., Guo, L.-q.: Compositional analysis of the fruiting body of transgenic Flammulina velutipes producing resveratrol. Food Chem. 164, 211–218 (2014). doi:10.1016/j.foodchem.2014.05.023

Yang, W., Yu, J., Pei, F., Mariga, A.M., Ma, N., Fang, Y., Hu, Q.: Effect of hot air drying on volatile compounds of Flammulina velutipes detected by HS-SPME–GC–MS and electronic nose. Food Chem. 196, 860–866 (2016). doi:10.1016/j.foodchem.2015.09.097

Donglu, F., Wenjian, Y., Kimatu, B.M., Mariga, A.M., Liyan, Z., Xinxin, A., Qiuhui, H.: Effect of nanocomposite-based packaging on storage stability of mushrooms (Flammulina velutipes). Innov. Food Sci. Emerg. Technol. 33, 489–497 (2016). doi:10.1016/j.ifset.2015.11.016

Sheng, J., Yu, F., Xin, Z., Zhao, L., Zhu, X., Hu, Q.: Preparation, identification and their antitumor activities in vitro of polysaccharides from Chlorella pyrenoidosa. Food Chem. 105(2), 533–539 (2007). doi:10.1016/j.foodchem.2007.04.018

Pang, X., Yao, W., Yang, X., Xie, C., Liu, D., Zhang, J., Gao, X.: Purification, characterization and biological activity on hepatocytes of a polysaccharide from Flammulina velutipes mycelium. Carbohydr. Polym. 70(3), 291–297 (2007). doi:10.1016/j.carbpol.2007.04.010

Shi, M., Yang, Y., Guan, D., Zhang, Y., Zhang, Z.: Bioactivity of the crude polysaccharides from fermented soybean curd residue by Flammulina velutipes. Carbohydr. Polym. 89(4), 1268–1276 (2012). doi:10.1016/j.carbpol.2012.04.047

Yang, W., Pei, F., Shi, Y., Zhao, L., Fang, Y., Hu, Q.: Purification, characterization and anti-proliferation activity of polysaccharides from Flammulina velutipes. Carbohydr. Polym. 88(2), 474–480 (2012). doi:10.1016/j.carbpol.2011.12.018

Zhang, A.-q., Xiao, N.-n., Deng, Y.-l., He, P.-f., Sun, P.-l.: Purification and structural investigation of a water-soluble polysaccharide from Flammulina velutipes. Carbohydr. Polym. 87(3), 2279–2283 (2012). doi:10.1016/j.carbpol.2011.10.061

Čičková, H., Newton, G.L., Lacy, R.C., Kozánek, M.: The use of fly larvae for organic waste treatment. Waste Manag. 35, 68–80 (2015). doi:10.1016/j.wasman.2014.09.026

Diener, S., Studt Solano, N.M., Roa Gutiérrez, F., Zurbrügg, C., Tockner, K.: Biological treatment of municipal organic waste using black soldier fly larvae. Waste Biomass Valorization. 2(4), 357–363 (2011). doi:10.1007/s12649-011-9079-1

Westerman, P.W., Bicudo, J.R.: Management considerations for organic waste use in agriculture. Bioresour. Technol. 96(2), 215–221 (2005). doi:10.1016/j.biortech.2004.05.011

Kroeckel, S., Harjes, A.G.E., Roth, I., Katz, H., Wuertz, S., Susenbeth, A., Schulz, C.: When a turbot catches a fly: evaluation of a pre-pupae meal of the black soldier fly (Hermetia illucens) as fish meal substitute—growth performance and chitin degradation in juvenile turbot (Psetta maxima). Aquaculture. 364–365(0), 345–352 (2012). doi:10.1016/j.aquaculture.2012.08.041

Barroso, F.G., de Haro, C., Sánchez-Muros, M.-J., Venegas, E., Martínez-Sánchez, A., Pérez-Bañón, C.: The potential of various insect species for use as food for fish. Aquaculture 422–423(0), 193–201 (2014). doi:10.1016/j.aquaculture.2013.12.024

Li, W., Li, M., Zheng, L., Liu, Y., Zhang, Y., Yu, Z., Ma, Z., Li, Q.: Simultaneous utilization of glucose and xylose for lipid accumulation in black soldier fly. Biotechnol. Biofuels. 8(1), 1–6 (2015). doi:10.1186/s13068-015-0306-z

Li, Q., Zheng, L., Qiu, N., Cai, H., Tomberlin, J.K., Yu, Z.: Bioconversion of dairy manure by black soldier fly (Diptera: Stratiomyidae) for biodiesel and sugar production. Waste Manag. 31(6), 1316–1320 (2011). doi:10.1016/j.wasman.2011.01.005

Jing, Y., Hao, Y., Qu, H., Shan, Y., Li, D., Du, R.: Studies on the antibacterial activities and mechanisms of chitosan obtained from cuticles of housefly larvae. Acta Biol. Hung. 58(1), 75–86 (2007). doi:10.1556/ABiol.57.2007.1.7 doi

Zheng, L., Li, Q., Zhang, J., Yu, Z.: Double the biodiesel yield: rearing black soldier fly larvae, Hermetia illucens, on solid residual fraction of restaurant waste after grease extraction for biodiesel production. Renew. Energy. 41, 75–79 (2012). doi:10.1016/j.renene.2011.10.004

Li, W., Li, Q., Zheng, L., Wang, Y., Zhang, J., Yu, Z., Zhang, Y.: Potential biodiesel and biogas production from corncob by anaerobic fermentation and black soldier fly. Bioresour. Technol. 194, 276–282 (2015). doi:10.1016/j.biortech.2015.06.112

Park, S.-I., Kim, J.-W., Yoe, S.M.: Purification and characterization of a novel antibacterial peptide from black soldier fly (Hermetia illucens) larvae. Dev. Comp. Immunol. 52(1), 98–106 (2015). doi:10.1016/j.dci.2015.04.018

Sheppard, D.C., Tomberlin, J.K., Joyce, J.A., Kiser, B.C., Sumner, S.M.: Rearing methods for the black soldier fly (Diptera: Stratiomyidae). J. Med. Entomol. 39(4), 695–698 (2002). doi:10.1603/0022-2585-39.4.695

Zhou, F., Tomberlin, J.K., Zheng, L., Yu, Z., Zhang, J.: Developmental and waste reduction plasticity of three black soldier fly strains (Diptera: Stratiomyidae) raised on different livestock manures. J. Med. Entomol. 50(6), 1224–1230 (2013). doi:10.1603/me13021

Diener, S., Zurbrügg, C., Tocknera, K.: Conversion of organic material by black soldier fly larvae—establishing optimal feeding rates. Waste Manag. Res. 27(6), 603–610 (2009). doi:10.1177/0734242X09103838

Zhang, Z., Wang, H., Zhu, J., Suneethi, S., Zheng, J.: Swine manure vermicomposting via housefly larvae (Musca domestica): the dynamics of biochemical and microbial features. Bioresour. Technol. 118(0), 563–571 (2012). doi:10.1016/j.biortech.2012.05.048

Parra Paz, A.S., Carrejo, N.S., Gómez Rodríguez, C.H.: Effects of larval density and feeding rates on the bioconversion of vegetable waste using black soldier fly larvae Hermetia illucens (L.), (Diptera: Stratiomyidae). Waste Biomass Valorization. 6(6), 1059–1065 (2015). doi:10.1007/s12649-015-9418-8

Liu, L., Kong, H., Lu, B., Wang, J., Xie, Y., Fang, P.: The use of concentrated monosodium glutamate wastewater as a conditioning agent for adjusting acidity and minimizing ammonia volatilization in livestock manure composting. J. Environ. Manag. 161, 131–136 (2015). doi:10.1016/j.jenvman.2015.06.029

Zucconi, F., Pera, A., Forte, M., De Bertoldi, M.: Evaluating toxicity of immature compost. Biocycle. 22(2), 54–57 (1981)

Ko, W.-C., Liu, W.-C., Tsang, Y.-T., Hsieh, C.-W.: Kinetics of winter mushrooms (Flammulina velutipes) microstructure and quality changes during thermal processing. J. Food Eng. 81(3), 587–598 (2007). doi:10.1016/j.jfoodeng.2006.12.009

Lee, K.J., Yun, I.J., Kim, K.H., Lim, S.H., Ham, H.J., Eum, W.S., Joo, J.H.: Amino acid and fatty acid compositions of Agrocybe chaxingu, an edible mushroom. J. Food Compos. Anal. 24(2), 175–178 (2011). doi:10.1016/j.jfca.2010.09.011

Smiderle, F.R., Carbonero, E.R., Sassaki, G.L., Gorin, P.A.J., Iacomini, M.: Characterization of a heterogalactan: some nutritional values of the edible mushroom Flammulina velutipes. Food Chem. 108(1), 329–333 (2008). doi:10.1016/j.foodchem.2007.10.029

Wu, X., Wei, Y., Zheng, J., Zhao, X., Zhong, W.: The behavior of tetracyclines and their degradation products during swine manure composting. Bioresour. Technol. 102(10), 5924–5931 (2011). doi:10.1016/j.biortech.2011.03.007

Qian, X., Sun, W., Gu, J., Wang, X.-J., Sun, J.-J., Yin, Y.-N., Duan, M.-L.: Variable effects of oxytetracycline on antibiotic resistance gene abundance and the bacterial community during aerobic composting of cow manure. J. Hazard. Mater. 315, 61–69 (2016). doi:10.1016/j.jhazmat.2016.05.002

Zheng, L., Hou, Y., Li, W., Yang, S., Li, Q., Yu, Z.: Biodiesel production from rice straw and restaurant waste employing black soldier fly assisted by microbes. Energy. 47(1), 225–229 (2012). doi:10.1016/j.energy.2012.09.006

Acknowledgements

This work is supported in part by grants from National Natural Science Foundation of China (41603110), The Special Fund for Agro-scientific Research in the Public Interest from the Ministry of Agriculture, China (201303094), Postdoctoral Science Foundation of China (2015M572165).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Cai, M., Zhang, K., Zhong, W. et al. Bioconversion-Composting of Golden Needle Mushroom (Flammulina velutipes) Root Waste by Black Soldier Fly (Hermetia illucens, Diptera: Stratiomyidae) Larvae, to Obtain Added-Value Biomass and Fertilizer. Waste Biomass Valor 10, 265–273 (2019). https://doi.org/10.1007/s12649-017-0063-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0063-2