Abstract

Green waste (GW) represents a large fraction of municipal solid waste (MSW) and has increased significantly with the rapid development of urban green areas in some countries. Composting is an appropriate method for the treatment and recovery of these wastes. However, the high content of lignocellulosic substances in GW is known to slow down the decomposition process. This research evaluated the effect of introducing processed food waste (PFW) and unprocessed food waste (UPFW) on composting of GW, it monitored the process itself and assessed the end-product quality. A field-scale experiment was developed using three treatments: Treatment A (100%GW), Treatment B (40%UPFW + 60%GW) and Treatment C (50%GW + 30%UPFW + 20%PFW). Treatment C reached thermophilic temperatures in a shorter time than the other treatments and maintained those temperatures for longer periods. In addition, treatment C reached ambient temperatures during curing in a shorter time compared to treatments A and B. An improved product quality was observed in treatment C compared to other treatments. For example, products from treatment C had lower ash content, higher concentrations of TOC and PTotal and lower EC values compared to treatments A and B. The final fertility index of the end-product from treatment C was 4.8–5.0, which indicates that the product can be suitable for agricultural use.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Green waste GW represents a significant fraction of municipal solid waste (MSW). For example, in the United States in 2013, GW represented 13.45% of MSW (34.7 million tons) [1], while in Taiwan, GW accounts for 22–30% of MSW [2]. Municipal green waste (GW) commonly consists of tree wood and bark, pruning from young trees and shrubs, dead and green leaves, grass clippings and soil, and originates from municipal parks, gardens, reserves and domestic dwellings [3, 4]. GW has increased dramatically with the rapid development of urban green spaces in several countries [5]. GW management is often difficult and expensive due to its low bulk density. The principal cost is due to collection and transportation to landfill or treatment facilities [6].

Composting is an alternative for GW management in cities. For example, in the United States, 36 states have reported a total of 3474 GW composting facilities [7]. Other authors reported GW management in composting facilities like Benito et al. [8] in Madrid and Lopez et al. [6] and Cáceres et al. [9] in Catalunya, Spain.

Composting can constitute a suitable method for the recycling of GW, since the compost obtained is a useful organic amendment and/or organic substrate that can be reincorporated into the economic system, can reduce waste to be disposed, and can reduce emissions of greenhouse gases [10]. In addition, compost can sequestrate carbon and result in reduced net CO2 emissions to the atmosphere. However, the composting of lignocellulosic GW is challenging due to its low decomposition rates [3].

Organic matter includes readily available compounds that will be immediately used by the composting microbiota, and polymeric organic compounds that need to be enzymatically processed before they can be used by microorganisms as carbon and nitrogen sources [11]. Among the polymers commonly found in raw materials for composting, the lignocellulosic fraction is the most difficult to degrade and there are few microbial species capable of degrading these materials [12]. In addition, the composition of GW is highly variable and depends on the predominant vegetation in the area, the season of the year, and the local collection policies [6]. This increases the difficulty to degrade these materials.

Even though indigenous microbiota usually carries out composting successfully, the completion time may become too long, as the rate at which the process proceeds is directly related to the microbial population capable of acting upon polymeric materials [11]. According to Zhang and Sun [3], these composting problems can be reduced by using organic or inorganic fermentation additives and by optimizing the composting process conditions.

Several practices have been developed to improve GW composting with promising results in reducing processing times and in improving product quality. Such practices can be: (a) application of earthworm casts (EWCs), which are organic, and zeolite, which is inorganic [3]; (b) recirculation of refuse obtained from GW composting and used at the start of the process to active GW composting [6]; (c) inoculation with microorganisms specifically capable of decomposing polymeric compounds [11]; (d) addition of organic bulking agents (BA) appropriately selected for GW composting, such as sawdust, rice husks, or cotton waste [13].

Since it is not always feasible to identify supporting materials, other easily available wastes could be used for GW composting. For instance, Kumar et al. [2] indicate that food wastes, given their high content of easily-degradable organic matter, could complement GW to initiate and support composting conditions. This alternative could overcome the constraints of composting those materials individually [14].

Considering the high proportion of unprocessed food waste (UPFW) and processed food waste (PFW) in MSW, this research evaluates the influence of adding those materials (UPFW and PFW) on the composting of GW. Therefore, the novelty of the work lies on the fact that although GW are traditionally viewed as amendments or bulking materials during composting [6, 15,16,17], they are, instead, viewed here as the main substrate with food waste being the amendment. In addition, food waste is classified here into unprocessed and processed which were separately studied as two alternative additives during GW composting. This classification, according to the authors’ knowledge, is performed for the first time during the study of organic waste composting. This differentiation is important, since the physicochemical characteristics of UPFW and PFW are not similar (e.g. the microbial population is expected to be different between cooked and uncooked FW), and this feature can influence the composting process and product quality.

Methodology

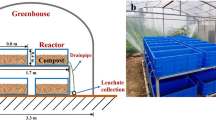

Description of the Experiment

A pilot-scale experiment was developed at the university campus of Universidad Industrial de Santander (Bucaramanga, Colombia). The experimentation area had a roof and a level surface made of concrete. The campus had an average ambient temperature of 24 °C. Three treatments were used with contents of GW, UPFW and PFW, identified as follows: Treatment A: 100% GW (wet weight-w/w) (i.e. which was established as the control); Treatment B: (60% GW and 40% UPFW) (w/w); Treatment C: (50% GW, 30% UPFW and 20% PFW) (w/w). Two criteria were considered to define the mixtures: (i) GW should be the predominant substrate, and (ii) C/N ratio should be higher than 18 (i.e. mixtures were established using mass balances based on theoretical values for the substrates). This study did not assess the mixture of GW and PFW because the high content of fats and oils in those substrates could inhibit the composting process when high proportions are involved. All treatments were run in duplicates (two piles per treatment). Thus, a total of six piles were constructed. GW originated from the pruning of trees, the harvesting of leaves and the cutting of grass within the campus. UPFW and PFW were source-separated and were collected, using composite sampling, from the university restaurant, where approximately 3000 lunches per day are normally prepared.

Each pile weighed around 100 kg (wb) and had a conical shape with an approximate height of 0.8 m. Prior to the experiment startup, substrates were manually crushed to sizes between 5 and 7 cm. In addition, non-biodegradable or inert materials were removed (e.g. stones and plastics). All piles were run simultaneously so that to maintain similar environmental conditions during the experiments.

Substrate Characterization

GW was stored for two weeks in an open space before the initiation of the experiments. Storage periods were one day for PFW and three days for UPFW, trying to simulate real conditions since food waste are not directly composted after disposal. Storage was carried out in a covered space at ambient temperature. Before pile formation, all components were manually mixed (i.e. with shovels) in the proportions defined for each treatment. However, UPFW, PFW and GW are typically non-homogeneous even after extensive natural mixing due to their larger particle size [2].

Among the UPFW, peels from potato, carrots, fruits (banana, orange, papaya), lettuce, peppers, banana (green and ripe), green beans and onion predominate.

A representative sample (2 kg each) was taken from each substrate (i.e. UPFW, PFW, treatment A, treatment B and treatment C). For this, the random quartering technique described by Sakurai [18] was followed. For the UFPW and PFW, prior to the piles’ formation, all stored material (i.e. 180 and 120 kg respectively) was discharged separately. Subsequently, it was mixed and through quartering, a 2 kg sample was obtained for analysis. For treatments A, B and C, the samples were obtained right after the piles were formed (i.e. completely mixed substrates). Subsamples from four different locations of each pile (approximately 10 kg each) were combined (composite sample), and then by successive quartering, 2 kg of samples were obtained per pile. Therefore, the physicochemical characteristics mentioned in Table 3 per starting substrate/mixture per treatment were based on one measurement (one composite sample per treatment).

Samples were taken to the laboratory to perform analysis of: pH, moisture, ashes, Total Potassium (KTotal), Total Phosphorous (PTotal), and Total Organic Carbon (TOC) by methods described in the Colombian Technical Norm (NTC) 5167 [19]. The Total Nitrogen (NTotal) was determined by technical norm NTC 370 [20]. Table 1 summarizes the methods used to analyze the parameters studied.

Process Monitoring

Monitoring started right after the preparation of the piles. Temperature was measured daily on the compost pile centroid, using a 60 cm thermometer. Subsamples taken from four opposite locations in each compost pile were combined to form a 200 g sample that was specifically used for pH and moisture measurements [8, 21].

pH was measured at least three times a week for the first 2 weeks and then at least twice a week, until the end of the monitoring. pH was potentiometrically measured to an aqueous extract obtained from a stirred mixture of the sample and distilled water (1:5 w/w). Measurement was carried out using a desk pH meter ionometer, model S220K. Moisture content was determined using a portable moisture meter Ohaus MB-35 (Ohaus Corporation).

Pile monitoring was performed until one of the piles reached ambient temperature (24 ± 2 °C) (i.e. day 67). Prior to the completion of the experiment, on-site self-heating tests were performed to determine if temperature rises occurred when piles were moisturized [22].

Product Quality

At the end of the composting process, a manual sieving of the products was carried out using a 1.25 cm sieve. Subsequently, a representative sample was received and the same analyzes performed on the substrates were carried out on the products using the same techniques mentioned above. Finally, the characteristics of the products obtained were analyzed and compared with the Colombian technical standard for organic products used as fertilizers and soil amendments or conditioners [19]. A recently introduced compost quality index, namely the fertilizing index (FI) proposed by Saha et al. [23] was adapted and applied. The FI of a compost end-product is computed using the formula of Eq. 1:

where ‘Si’ is score value of analytical data (i.e. 1–5) and ‘Wi’ is weighing factor of the ‘i’th fertility parameter (i.e. 1–5). The parameters included in this study were: TOC, Total N, Total P, Total K, C:N. The criteria for assigning ‘weighing factor’ to fertility parameters and ‘score value’ to analytical data can be seen in Table 2.

Results and Discussion

Substrate Characterization

Table 3 includes the physicochemical characterization of the substrates. It is observed that GW presents typical conditions that limit its composting, such as low moisture and low C/N ratio. These results are partly similar to those reported by Eggerth et al. [24] and Krogmann et al. [25], who had found low C/N ratios and TOC contents for grass clipping and mixed GW. Cáceres et al. [9] suggest that the relatively low organic matter level (OM) in the GW material is probably due to the presence of mineral soil in the mixture.

On the other hand, GW values found in this research were different to those obtained in previous research [27], where higher TOC (36.1% db) and C/N ratios (28.8) had been noticed. This difference could be related to the typical variability on the physical composition and physicochemical characteristics of the collected GW. Bary et al. [28] indicate that the sub-components of GW i.e. grass clippings, woody trimmings, leaves, debris can highly differ in chemical composition, resulting in highly variable composition of the yard trimmings materials. Additionally, variation in the size of the material and the proportion of the different subcomponents in GW (e.g. leaves, grass, branches) also influence the physicochemical characteristics of the whole GW mixture. Benito et al. [8] concluded that the characteristics of GW will vary, depending upon the predominant vegetation in the area and the climatic conditions. In addition, storage conditions could affect parameters such as TOC and NTotal.

Therefore, the differences found in GW are due to the fact that these substrates are a heterogeneous mixture of cutting residues from tree branches, grass, leaves, and in general, plant remains (i.e. different plant species), which influence physicochemical characteristics. In addition, GW can also change depending on their level of degradation (i.e. fresh or partially degraded materials). For instance, Bary et al. [28] indicate that yard waste management can influence the concentrations of organic matter and N, which can vary significantly, even if the materials are stored for 1 week.

The physicochemical characteristics of UPFW and PFW were typical for these substrates namely acidic pH, high moisture, high N content, low C/N ratio, low phosphorus content and high presence of salts [25, 29].

The addition of UPFW and PFW to GW (i.e. treatment B and treatment C) reduced pH, which can affect the initiation of the composting process, as reported by Beck-Friis et al. [30]. Likewise, moisture increased to values higher than those typically recommended by the literature for the start of the process (65%) [2, 31].

In treatments B and C, the C/N ratios were lower than the values required to start a typical composting process (25–30) [25, 32, 33]. This may lead to the volatilization of nitrogen in the form of ammonia, when high temperatures occur and pH is at the alkaline range [12, 34]. The most critical case was treatment C, in which the C/N ratio was 14.3, possibly associated with the presence of PFW in the mixture, since PFW has a low TOC content and high concentration of NTotal. However, Kumar et al. [2] found that even with low C/N ratios (i.e. 13.9 a 19.6), the composting of GW and food waste progressed effectively.

With regards to the PTotal content, a low concentration was obtained, which is typical for these substrates (GW, UPFW, PFW), as found in other studies on food waste [29] and GW [13]. Likewise, typical values were found for KTotal, except for PFW, which had an extremely low content that influenced the KTotal concentration in treatment C. This could be linked to the composition of the food waste in the days in which the characterization, sampling and experimental set up took place.

The EC of PFW was high, which could be linked to the presence of salts during food preparation and cooking. Likewise, GW had conductivity values relatively higher for this kind of substrates compared to results obtained by Zhang and Sun [13]. Treatment B and C had EC values similar to those for GW, possibly because this was the predominant substrate in the mixture.

Experimental Assembly and Monitoring Process

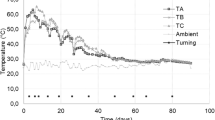

Temperature

Figures 1, 2 and 3 show the temperature profiles for treatments A, B and C, respectively. Table 4 includes a summary of the temperature behavior during the process, namely the time to reach the maximum temperature, the time to reach the initiation of the thermophilic phase (>45 °C), the duration of the thermophilic phase and the time to reach ambient temperatures from the start of the experiment are presented per pile. The total amount of water added during the wetting phases and the initial pH of the treatments are also included in Table 4.

The treatments with food wastes (B and C) reached thermophilic temperatures in a relatively small time (day 2 and 3, respectively) due to the presence of rapidly degradable compounds in the substrates (i.e. carbohydrates and proteins) [12, 31], compared to treatment A (in which 4 days were needed), due to the higher presence of lignocellulosic materials with low rates of degradation [35].

None of the treatments reached 65 °C, which is the temperature required for sanitization and destruction of insect larvae and seeds [12, 36]. However, the requirement by Haug [37] stating that the length of thermophilic temperatures in all piles must be greater than or equal to 4 days was fulfilled. Also, only treatment C had temperatures above 55 °C for more than three days, a criterion that according to Stentiford and de Bertoldi [33] aids in material sanitization.

The highest temperatures (58–59 °C) were reached in the piles that had a mixture of UPFW and PFW (treatment C), although there was a strong temperature oscillation in the first 10 days of the process, possibly due to the lack of turning between days 5 and 13. Treatment B had maximum temperature values of 56 °C, while treatment A (i.e. made only with GW) reached 55 °C. In general, treatment C stayed longer in the thermophilic range of 45–55 °C, which is where the highest rate of degradation typically occurs [33]. This behavior agrees with Pandey et al. [14], who indicated that reaching temperatures higher than 55 °C in the composting of food waste mixed with GW is a challenge that, if achieved, can favor the reduction of pathogens such as salmonella and fecal coliforms.

In relation to the capacity to maintain temperatures in the thermophilic range (>45 °C), in treatments B and C this condition lasted 18–21 and 25 days respectively, compared to treatment A, where the condition lasted 17–21 days. This is associated to the fast decomposition of easily-degradable organic matter present in those substrates (e.g. treatment C), as opposed to GW, in which the predominant lignocellulosic compounds induce low rates of degradation. This makes it difficult for such materials to reach and maintain thermophilic temperatures for long periods of time [12]. Treatment C behaved in accordance to Cáceres et al. [9], who argue that high temperatures for several consecutive days indicate a process efficiency in the composting process. Therefore, high temperatures should be maintained as long as possible.

Figures 1, 2 and 3 also show continuous temperature oscillations during the first 20 days in all treatments, that alternate between the thermophilic and mesophilic range. These temperature oscillations may be related to the presence of slowly degradable compounds, such as lignin (i.e. contained in tree branches and leaves) that are resistant to microbial degradation [38]. However, during wetting and turning of piles, these materials can be exposed to the attack of the microorganisms, that can reactivate their degradation [39]. Likewise, turning activities immediately reduce the temperature. However, the temperature is rapidly recovered according to the specific stage of the process [9].

On the other hand, treatment B reached ambient temperatures in a shorter time (days 47 and 51), compared to treatments C (day 57) and A (day 65). Thus, the cooling phase was smaller in treatments B and C. This shows that the incorporation of UPFW and the mixture with UPFW and PFW decreased GW composting times. The longer cooling time in treatment A, is associated to the higher content of compounds such as cellulose and lignin in GW, which typically slows down the degradation process compared to the substrates in treatment B and C that contain more readily degradable material. According to Chiumenti et al. [31], materials containing cellulose and lignin take longer to decompose. Since easily degradable materials have been metabolized during the mesophilic and thermophilic phase (i.e. generating a lack of food and subsequent death for an important portion of the microbial population), the decomposition process is performed on more complex organic molecules, slowing down the process. Similarly, the low degradability of lignin, which is extremely resistant to chemical and enzymatic degradation, can significantly extend the length of the process [40].

pH

Figures 4, 5 and 6 show pH behavior in treatment A, B and C, respectively. pH started on the acidic range; treatments B and C, those that included PFW and the mix of PFW and UPFW, having the lower values. This is due to the fact that from the storage, at the beginning of the composting process, food wastes generate organic acids as intermediate products from the metabolic process of the bacteria [34].

Subsequently, pH increased to values between 8 and 9 units, as a result of the CO2 release, the complete mineralization of the intermediates metabolites, aeration of biomass, and ammonia production from protein degradation [2, 34]. At the end of the process, values between 7.6 and 8.9 units were reached, B treatment having the highest values. In treatment A and B, the increase in pH was faster than in treatment C, which may be associated with a higher decomposition rate of organic acids due to the increase in the O2 concentration [30], promoted by a higher turning frequency in treatment A and B during the first days of the process (see Figs. 4, 6).

Product Quality

Table 5 shows product quality obtained from the different piles and comparison with the Colombian Technical Standard (NTC) for use of organic products as fertilizers. In addition, results of product quality from GW composting reported by other studies are included [13, 24, 41]. The table indicates that a very good agreement between the replicate piles per treatment exists for almost all parameters.

Regarding pH, products had neutral values, adjusted to the values required by the NTC for soil improvers [19]. A notable influence on the pH of the products due to the addition of UPFW and PFW to GW was not observed. Other studies using GW, reported similar pH values in the product [13, 24].

Although several authors recommend moisture levels lower than 35% at the end of the process, all treatments had higher values, which could be associated with the fact that before the end of the experiment, the piles were moisturized to determine possible self-reheating of the material. Moisture levels as those obtained (approximately 50%) in products that are already stable, are not inconvenient for the maturation process, but they could be for product marketing activities (handling, transport and application).

Regarding the TOC content, the results show that it was above the NTC requirements for use as soil improver [16]. This may be associated with the fact that these materials were not completely stable (i.e. they required more time in the maturation phase). Particularly noteworthy is the high TOC content in treatment C treatment. This higher value is possibly associated to the UPFW organic matter input, as evidenced in Table 3.

In relation to the NTotal concentration, it was observed that in all cases, the values were higher than those required by the NTC. Likewise, a higher value was observed in the products compared to the substrates, possibly due to the NTotal concentration from the mass transformation (CO2, H2O), and/or nitrogen fixation or immobilization, which may occur during composting processes [12, 14, 33]. Products with these characteristics are suitable for use in agriculture [23].

The C/N ratio according to Saha et al. [23] should be below ten, while authors such as Sullivan and Miller [21] suggest it should be between 10 and 15. According to Diaz and Savage [34], if compost has a high C/N ratio and decomposes rapidly in the soil, it can uptake nitrogen from the soil to sustain plant growth. In contrast, a low C/N, releases ammonia that can be phytotoxic to the roots of plants. This study found that in the case of treatment A, values below ten occurred, while in the remaining treatments, the ratio was in a range between 10 and 15. Likewise, it was observed that in all cases lower values of C/N were obtained for the products compared to the substrates, due to the transformation of the TOC during the process [12, 40] (i.e. approximately 60% of the biodegradable organic matter is transformed).

The content of nutrients, such as P, in the product was limited. This is likely associated to the low P concentration in the initial substrates (see Table 3). However, higher concentrations were observed in the product, due to the mineralization of organic matter and mass transformation, which generate an apparent increase in its concentration after composting [42, 43]. None of the products reached the minimum value reported in the NTC so that it is used as a soil improver, although it is worth noting the higher concentration of PTotal found in treatment C. Likewise, the values found are consistent with values from products reported in other studies for GW [13, 24, 41]. From an agronomic point of view, the PTotal content was low for crop production, ratifying the need to supplement crop fertilization where high yields are expected. Strategies such as the incorporation of phosphoric rock into the product or the addition of P-rich amendments could be effective in increasing the agronomic quality of the product.

The KTotal content was in all the treatments greater than the minimum report value suggested by the Colombian NTC to be used as soil improver [19]. The lowest values were those of treatment C, which were characterized by a low KTotal concentration in the substrates (i.e. due to the low KTotal values in PFW).

The ash content in the product, with values below 60% db, fulfills the Colombian NTC. The lower values were found in C treatment, which is related to the low ash content found in the substrates that made these piles (i.e. PFW and UPFW), therefore, resulting in better conditions for this type of products.

The conductivity values in the products obtained from treatments A and B were relatively high compared to those required for a stable and mature product (<4 mS/cm) [44]. In the case of treatments B and C, which had lower conductivity values, it can be attributed to the addition of UPFW and PFW which increased the temperature and improved the breaking of the food waste, which also could accelerate the production of inorganic compounds and the release of soluble salts [13]. Except for the product obtained from C treatment, the use of the products from treatment A and B, with their electrical conductivity values, could affect soils characteristics.

Finally, the adapted fertility index calculated according to Saha et al. [23] obtained values higher than 3.5 in all treatments, which according to the classification proposed by that author reveals a high potential for fertilization of soils by the end-products. The best conditions, however, were for the end-product obtained from treatment C (i.e. score of 4.8–5.0). Full-scale studies should be developed to study physicochemical and microbiologic parameters complementary to product quality (e.g. other nutrients, calcium, sodium, cation-exchange capacity, water holding capacity, total coliforms and total fecal coliforms, heavy metals).

Conclusions

The conclusions obtained from this research are:

-

1.

GW has characteristics that limit their composting alone. These characteristics are variable due to aspects such as the proportion of materials collected each day (e.g. leaves, branches, grass, soil), particle size and degree of degradation. The incorporation of PFW and UPFW contributed to overcome these limitations, allowing adequate composting conditions from the beginning of the process.

-

2.

The incorporation of the UPFW and PFW mixture (treatment C) allowed the GW composting to reach the temperatures of the thermophilic range in less time, also achieving higher temperatures, in comparison to GW composted alone (treatment A). It was also effective to maintain temperatures at the thermophilic range for longer periods (19 days) compared to the treatment with only UPFW (12 days) and only GW (9 days). The cooling phase of the process was also characterized by a shorter duration and the ambient temperature was reached at between 14 days (piles B) and 8 days (piles C) faster than the piles with only GW (piles A). This shows that the addition of UPFW and PFW provides greater effectiveness to the composting process with better conditions to sanitize the final product.

-

3.

An improvement in product quality was observed with the incorporation of the UPFW and PFW mixture (treatment C) compared to GW alone. This was judged by the adequate final C/N ratio (i.e. 10.2 compared to 9.2), a lower proportion of ash (i.e. 25.98% compared to 45.76%), higher concentration of PTotal (i.e. 0.8% compared to 0.55%), lower values of electrical conductivity (i.e. 1.62 mS/cm compared to 7.90 mS/cm) and a higher fertility index (i.e. 4.8–5.0 compared to 4.47). These characteristics make the product suitable for use in agricultural activities.

-

4.

Although the addition of UPFW to GW (treatment B) resulted in improvement in the product quality (compared to GW alone), the best composting conditions were achieved when the UPFW and PFW mixture was added (treatment C).

-

5.

It is important to develop field-scale experiments, instead of solely laboratory and pilot scale ones, to better evaluate the composting of GW with other easily degradable substrates. In addition, it is necessary to include a full set of parameters (e.g. micronutrients, heavy metals, stability, phytotoxicity and/or seed bioassays, microbiological parameters) to monitor the process and to adequately assess both the stability and maturity of the product.

References

EPA—Environmental Protection Agency. Advancing Sustainable Materials Management: 2013 Fact Sheet. https://www.epa.gov/sites/production/files/2015-09/documents/2013_advncng_smm_fs.pdf (2015). Accessed 10 May 2017

Kumar, M., Ou, Y., Lin, J.: Co-composting of green and food waste at low C/N ratio. Waste Manag. 30, 602–609 (2010)

Zhang, L., Sun, X.: Effects of earthworm casts and zeolite on the two-stage composting of green waste. Waste Manag. 39, 119–129 (2015)

Haynes, R.J., Belyaeva, O.N., Zhou, Y.F.: Particle size fractionation as a method for characterizing the nutrient content of municipal green waste used for composting. Waste Manag. 35, 48–54 (2015)

Zhang, L., Sun, X.: Effects of rhamnolipid and initial compost particle size on the two-stage composting of green waste. Bioresour. Technol. 163, 112–122 (2014)

Lopez, M., Soliva, M., Martínez-Farré, F.X., Bonmatí, A., Huerta-Pujol, O.: An assessment of the characteristics of yard trimmings and recirculated yard trimmings used in biowaste composting. Bioresour. Technol. 101, 1399–1405 (2010)

Levis, J., Barlaz, M., Themelis, N., Ulloa, P.: Assessment of the state of food waste treatment in the United States and Canada. Waste Manag. 30, 1486–1494 (2010)

Benito, M., Masaguer, A., Moliner, A., De Antonio, R.: Chemical and physical properties of pruning waste compost and their seasonal variability. Bioresour. Technol. 97(16), 2071–2076 (2006)

Cáceres, R., Coromina, N., Malińska, K., Marfà, O.: Evolution of process control parameters during extended co-composting of green waste and solid fraction of cattle slurry to obtain growing media. Bioresour. Technol. 179, 398–406 (2015)

Morales, A.B., Bustamante, M.A., Marhuenda-Egea, F.C., Moral, R., Ros, M., Pascual, J.A.: Agri-food sludge management using different co-composting strategies: study of the added value of the composts obtained. J. Clean Prod. 121, 186–197 (2016)

Jurado, M.M., Suárez-Estrella, F., López, M.J., Vargas-García, M.C., López-González, J.A., Moreno, J.: Enhanced turnover of organic matter fractions by microbial stimulation during lignocellulosic waste composting. Bioresour. Technol. 186, 15–24 (2015)

Insam, H., de Bertoldi, M. Microbiology of the composting process. Compost science and technology. In: Diaz, L.F., de Bertoldi M., Bidlingmaier, W., Stentiford, E. (eds.) Waste Manage, vol. 8, pp. 25–45 (2007)

Zhang, L., Sun, X.: Influence of bulking agents on physical, chemical, and microbiological properties during the two-stage composting of green waste. Waste Manag. 48, 115–126 (2016)

Pandey, P.K., Cao, W., Biswas, S., Vaddella, V.: A new closed loop heating system for composting of green and food wastes. J. Clean Prod. 133, 1252–1259 (2016)

Dzulkurnain, Z., Hassan, M.A., Zakaria, M.R., Wahab, P.E.M., Hasan, M.Y., Shirai, Y.: Co-composting of municipal sewage sludge and landscaping waste: a pilot scale study. Waste Biomass Valor. 8, 1–11 (2017)

Moretti, S.M.L., Bertoncini, E.I., Abreu-Junior, C.H.: Composting sewage sludge with green waste from tree pruning. Sci. Agricola. 72, 432–439 (2015)

Pandey, P.K., Vaddella, V., Cao, W., Biswas, S., Chiu, C., Hunter, S.: In-vessel composting system for converting food and green wastes into pathogen free soil amendment for sustainable agriculture. J. Clean Prod. 139, 407–415 (2016)

Sakurai, K.: Método sencillo del análisis de residuos sólidos, HDT 17. CEPIS. http://www.cepis.ops-oms.org/eswww/proyecto/repidisc/publica/hdt/hdt017.html. (2001). Accessed 23 October 2016

ICONTEC. Norma Técnica Colombiana. Productos para la industria agrícola. Productos orgánicos usados como abonos o fertilizantes y enmiendas de suelo. Instituto Colombiano de Normas Técnicas y Certificación. Bogotá (2003)

ICONTEC. Norma Técnica Colombiana NTC 370. Abonos o Fertilizantes. Determinación de Nitrógeno Total. Instituto Colombiano de Normas Técnicas y Certificación, Bogotá (1997)

Sullivan, D.M., Miller, R.O.: Compost quality attributes, measurements, and variability. In: Stoffella, P.J., Kahn, B.A. (eds.) Compost Utilization in Horticultural Cropping Systems, pp. 95–120. Lewis Publishers, Boca Raton (2001)

Dulac, N.: The Organic Waste flow in Integrated Sustainable Waste Management.—The Concept. Waste. Tools for Decision-makers: Experiences from the Urban Waste Expertise Programme (1995–2001). Netherlands, p. 49 (2001)

Saha, J.K., Panwar, N., Singh, M.V.: An assessment of municipal solid waste compost quality produced in different cities of India in the perspective of developing quality control indices. Waste Manag. 30, 192–201 (2010)

Eggerth, L.L., Diaz, L.F., Chang, M.T.F., Iseppi, L.: Marketing of composts. Waste Manag. Ser. 8, 325–355 (2007)

Krogmann, U., Körner, I., Diaz, L.F., Composting: technology. In: Solid Waste Technology Management, pp. 533–568. Wiley, Chichester (2010)

Jolanun, B., Towprayoon, S., Chiemchaisri, C.: Aeration improvement in fed batch composting of vegetable and fruit wastes. Environ. Prog. 27, 250–256 (2008)

Hernandez, L., Gaitan, C.: Evaluación de la calidad fisicoquímica de los residuos orgánicos de rápida degradación generados en el campus universitario como potencial materia prima del proceso de compostaje. Proyecto de Grado. Escuela de Ingeniería Civil. Universidad Industrial de Santander (2014)

Bary, A.I., Cogger, C.G., Sullivan, D.M., Myhre, E.A.: Characterization of fresh yard trimmings for agricultural use. Bioresour. Technol. 96, 1499–1504 (2005)

Oviedo-Ocaña, E.R., Torres-Lozada, P., Marmolejo-Rebellon, L.F., Torres-López, W.A., Dominguez, I., Komilis, D.: & Sánchez, A.: A systematic approach to evaluate parameter consistency in the inlet stream of source separated biowaste composting facilities: a case study in Colombia. Waste Manag. 62, 24–32 (2017)

Beck-Friis, B., Smårs, S., Jönsson, H., Eklind, Y., Kirchmann, H.: Composting of source-separated household organics at different oxygen levels: gaining an understanding of the emission dynamics. Compost. Sci. Util. 11(1), 41–50 (2003)

Chiumenti, A., Chiumenti, R., Diaz, L., Savage, G., Eggerth, L., Goldstein, N.: Modern composting technologies, p. 96. The JG Press. Inc., Singapore (2005)

Adhikari, B., Barrington, S., Martinez, J., King, S.: Characterization of food waste and bulking agents for composting. Waste Manag. 28, 795–804 (2008)

Stentiford, E., de Bertoldi, M.: Composting process. In: Christensen, T. (ed.) Solid Waste Technology Management, vol. 1–2. Blackwell, Oxford (2010)

Diaz, L.F., Savage, G.M., Eggerth, L.L., Chiumenti, A. Systems used in composting. Compost Science and Technology. In: Diaz L.F., de Bertoldi, M., Bidlingmaier, W., Stentiford, E., Waste Management Series, vol. 8, 1–364 (2007)

Francou, C., Linéres, M., Derenne, S., Villio-Poitrenaud, M., Houot, S.: Influence of green waste, biowaste and paper–cardboard initial ratios on organic matter transformations during composting. Bioresour. Technol. 99, 8926–8934 (2008)

Böhm, R.: Pathogenic agents. Waste Manag. Ser. 8, 177–200 (2007)

Haug, R.T.: The Practical Handbook of Compost Engineering. Lewis Publishers, Boca Raton (1993)

Tuomela, M., Vikman, M., Hatakka, A., Itävaara, M.: Biodegradation of lignin in a compost environment: a review. Bioresour. Technol. 72, 169–183 (2000)

Getahun, T., Nigusie, A., Entele, T., Gerven, T., Van der Bruggen, B.: Effect of turning frequencies on composting biodegradable municipal solid waste quality. Resour. Conserv. Recyl. 65, 79–84 (2012)

Nolan, T., Troy, S.M., Healy, M.G., Kwapinski, W., Leahy, J.J., Lawlor, P.G.: Characterization of compost produced from separated pig manure and a variety of bulking agents at low initial C/N ratios. Bioresour. Technol. 102, 7131–7138 (2011)

Boldrin, A., Andersen, J.K., Christensen, T.H.: LCA Report: Environmental Assessment of Garden Waste Management in Arhus Kommune. Department of Environmental Engineering, Technical University of Denmark, Copenhagen (2009)

Boldrin, A., Christensen, T.H., Körner, I., Krogmann, U.: Composting: mass balances and product quality. In: Christensen, T. H. (ed.) Solid Waste Technology & Management, vol 1, 2. Wiley, Chichester (2011). doi:10.1002/9780470666883.ch36

Wei, Y., Zhao, Y., Xi, B., Wei, Z., Li, X., Cao, Z.: Changes in phosphorus fractions during organic wastes composting from different sources. Bioresour. Technol. 189, 349–356 (2015)

Jiang, J., Liu, X., Huang, Y., Huang, H.: Inoculation with nitrogen turnover bacterial agent appropriately increasing nitrogen and promoting maturity in pig manure composting. Waste Manag. 39, 78–85 (2015)

Acknowledgements

The authors thank Universidad Industrial de Santander for funding the research projects identified CI 1371 of 2014 and CI 2354 of 2017.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oviedo-Ocaña, E.R., Dominguez, I., Komilis, D. et al. Co-composting of Green Waste Mixed with Unprocessed and Processed Food Waste: Influence on the Composting Process and Product Quality. Waste Biomass Valor 10, 63–74 (2019). https://doi.org/10.1007/s12649-017-0047-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-017-0047-2