Abstract

In the present study, sewage sludge (SS) was applied for the preparation of activated carbons (ACs) by chemical activation with phosphoric acid (H3PO4) and acid (HCl, HF) and base (NaOH) washing as post-treatment steps were employed to eliminate the mineral matter and other impurity composition of sewage-sludge based ACs. The post-treatment methods under study for the AC include: (1) the as-prepared AC by chemical activation with H3PO4 (aAC) was soaked with sodium hydroxide solution (NaOH), (2) the as-carbonized SS (cAC) by chemical activation with H3PO4 was soaked with sodium hydroxide solution (NaOH), (3) the aAC refluxed with hydrochloric acid (HCl), washed with NaOH solution and then soaked with HCl, (4) the aAC refluxed with NaOH, washed with HCl and then soaked with NaOH, and (5) aAC refluxed with HCl and then autoclaved with hydrofluoric acid (HF). The resultants ACs were characterized by scanning electron microscopy (SEM), the standard Brunauer-Emmet-Teller method (BET), FT-IR spectroscopy and X-ray fluorescence (XRF). The results of FT-IR demonstrate that the properties of the post-treated final products are dependent on the method used and that it contains similar functional groups to those present in the untreated AC, but at a higher peak intensity. XRF results indicated that refluxing AC with HF removed the impurities and decreased the percentage composition of silicon dioxide. BET surface area and pore volume of the post-treated AC were about sixty times higher than that of aAC. The BET surface area rose from 5.58 to 511 m2 g−1 and pore volume increased around 13% when compared with that of the untreated AC sample. The five types of AC showed high Cr (VI) adsorption capacities, however, haAC adsorbed more Cr (VI) than AC.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Activated carbons are an effective adsorbent and are extensively used in wastewater treatment due to the relatively high surface area, well-developed porous structure, favorable pore size distribution, specific surface properties, high rate of adsorption and fast kinetics of the binding (a diffusion control binding) [1]. AC can be prepared from different carbonaceous precursors with high carbon and low inorganic content. Some examples of these materials are groundnut husk [2], coconut husk and palm pressed fibers [3], Tamarind wood [4], eucalyptus wood [5–7], acacia mangium wood [8], china fir wood [9], date stones [10], coconut tree sawdust [11], rice husk [12], hazelnut shell [13], cornelian cherry, apricot stone, almond shell, [14], rotten potatoes [15], broiler waste [16], date seed [17] and sawdust [18]. Furthermore, recently waste feedstock with a high amount of inorganic matter such as carbon fly ash from pulverized coal-fired boiler and sewage sludge from wastewater treatment are used for generating cheap AC, which arises from its carbonaceous nature [19–23]. The usage of sewage sludge for AC production has some advantages: it can manage the large volume of waste, save the cost of waste disposal resulting in the occupation of valuable landfill space, and decrease the cost of adsorbent [19, 24]. AC can be produced by two main processes: physical activation and chemical activation [25]. Chemical activation compared to physical activation is more interesting because its process is conducted at a lower temperature and the yield of the obtained AC is greater. Several chemical agents such as potassium hydroxide, zinc chloride, phosphoric acid, sulfuric acid can be used for chemical activation [26–29].

Preparation of ACs from sewage sludge by H3PO4 activation decreases the cost of manufacture as well as solving environmental problems. Recently, many studies have been carried out to find a suitable way to convert sludge of wastewater to AC [30]. Sludge is mainly composed of micro-organisms, proteins, fats (soap, oil, and grease), urea, cellulose, silica, nitrogen, phosphoric acid, iron, calcium oxide, alumina, magnesium oxide and potash, peptidoglycan, teichoic acids, and complex polysaccharides, which are not readily biodegradable and still retain in sludge. Heavy metals and a wide variety of minerals are also present. Therefore, the sewage sludge as a feedstock turned into a carbon material by techniques of carbonization and activation, the carbonization increased the porosity by unblocking many of the pores obscured by volatile matter [31, 32]. The surface area of AC derived from sewage sludge can be improved by acid washing by partially removing the inorganic fractions of the carbonaceous framework [30]. Acid washing can be used as a tool to lower the inorganic content of a carbonaceous material through realizing the partial dissolution of the inorganic fraction and improvement in the accessibility of the carbon fraction. It is reported that the AC derived from sewage sludge has a high ash content that significantly reduced after acid or alkali washing [33]. The main crystalline phases of the ash are reported to be SiO2, Albite (Na(AlSi3O8)) and Anorthite (Ca(Al2Si2O8)) which silicon part of the compound can be removed by acid or alkali washing, because the conjugation reaction between base reagents and Si compounds may occur [34]. Hydrochloric acid leaching can be used as a tool to reduce the inorganic content and ash of a carbonaceous material through realizing the partial dissolution of the inorganic components. Due to the high percentage of silica in the AC-based sewage sludge adsorbents, NaOH washing can also be used as a tool to lower the silica content of a carbonaceous material and improve the carbon fraction of activated materials according to the following reactions [35, 36]:

Hydrofluoric acid leaching can be used for the purpose of the removal of silica of AC-based sewage sludge according to the following equation [35, 36]:

The aim of this work is to prepare the purified-AC with pure carbon, high surface area and pore volume, and abundant surface functional groups, which is expected to have the higher pollutants uptake capacity than that with impurities [37]. The effects of different H3PO4 activating agent amounts and post-treatment purification methods were studied to optimize pore size distribution and the surface area of AC. Furthermore, the difference in physicochemical properties between ACs that washed with acids (HCl and HF) or alkalis (NaOH) was investigated. The effect of impurity removal on the formation of porous structure and surface functional groups of treated ACs was studied.

Materials and Methods

Materials

The dewatered sewage sludge was used as feedstock for the preparation of AC and collected from an industrial wastewater treatment plant in Amol, Iran. The filter press is used to remove water from digested sludge that yielded sludge filter cakes (obtained by thickening and dewatering process) with moisture contents of about 80%. The moisture content was measured by drying the sewage sludge for 24 h at 103 °C. Then, the dewatered raw sewage sludge was first sterilized in an autoclave (H+P Labortechnik Varioklav 500E, Germany) at 120 °C for 20 min in order to destroy pathogens and other microbial population and consequently protect human health and the environment and then dried in a freeze dryer (OPERON, FDU-7012, Korea) for 48 h. The average moisture content of sewage sludge after freezing treatment was about 70%. The dried sewage sludge was crushed and sieved to obtain a particle size smaller than 250 µm (60 meshes).

Preparation of the AC

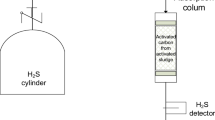

As described below, three different strategies for preparing five types of sewage-sludge based activated carbons by origival H3PO4 activation are demonstrated in Fig. 1.

In the first strategy, the ACs production was based on research performed by Liou [36]. Their results showed that the AC prepared by post-treatment (base-leaching) has a greatly mesoporous structure. The experiments were done as follows: first, the feedstock was impregnated with ortho-phosphoric acid (H3PO4 85%, Merck) in weight ratios of 1:2, 1:2.5 and 1:3 g precursor/g H3PO4 at room temperature for 1 h and then dried in an oven at 110 °C for 48h. After the impregnation step, the sample was carbonized in a horizontal tube furnace (Nabertherm, Germany) at 450 °C under nitrogen atmosphere. The heating rate and the nitrogen flow rate were 5 °C/min and 200 ml/min, respectively. The samples were kept at 450 °C for 2 h. The possible residues of carbonization are removed in accordance with the protocol used by Valizadeh et al. [38]. The AC samples were soaked in 0.1 N NaOH for 3 h, as the pH of the washing water reached to about 5, and then with three liters of hot de-ionized under reflux until the pH of the rinsing water was neutral. The samples were filtered through Whatman filter paper (0.45 µm) to separate the supernatant and the AC particles [39]. The yield and the particle size of the obtained AC were 48% and >250 µm, respectively. The samples were named ACHP2, ACHP2.5 and ACHP3.

In the second strategy, the preparation of AC was based on research carried out by Diao et al. [40]. They found that the two-stage process of carbon production (the carbonization of the feedstock followed by the activation of resulting char) significantly enhanced the porosity. In this study, first, the dried sewage sludge was carbonized at 450 °C under nitrogen atmosphere. The heating rate and the nitrogen flow rate were 15 °C/min and 200 ml/min, respectively, and the sample held at 450 °C for 2h. The carbonized sample was crushed and sieved to obtain a particle size smaller than 150 µm (100 meshes). The resulting particle was then impregnated with H3PO4 in weight ratio of 2.5 g/g at room temperature for 1h and then dried in an oven at 110 °C for 48 h. After the impregnation step, the obtained sample was carbonized at 450 °C under nitrogen atmosphere. The heating rate and the nitrogen flow rate were 10 °C/min and 100 ml/min, respectively. The samples held at 450 °C for 2 h. The carbonized samples were soaked in 0.1 N NaOH and washed with de-ionized water several times until the pH was near neutral in order to eliminate the residual chemical agent or other possible residues of carbonization. The samples were filtered through Whatman filter paper (0.45 µm) to separate the supernatant and the AC particles, as mentioned above. The obtained sample was named base soaked AC (bsAC).

The third strategy was carried out according to the methods reported by Ribas et al. [41] and Sandi et al. [42]. The dried sewage sludge was first impregnated with H3PO4 in weight ratios of 1:2.5 g/g at room temperature for 1h and the solid materials undergone post-treated in three different procedures. The obtained samples were named aAC. In the first method, aAC samples were refluxed in 1 N hydrochloric acid (HCl 37%, Merck) at 90 °C for 1 h, and then washed with 0.1 N sodium hydroxide (NaOH ISO, Merck) for 3 h followed by hot de-ionized water several times until the pH was near neutral in order to eliminate the residual chemical agent or other inorganic formed species. The samples were filtered through Whatman filter paper (0.45 µm) to separate the supernatant and the AC particles. The obtained samples were named acid refluxed AC (arAC). In the second method, the aAC samples were refluxed with 1 N NaOH at 90 °C for 1h in order to dissolve large quantities of certain mineral elements, such as Al, Cr and P. Afterwards, they were washed with 0.1 N HCl at 90 °C for 3h and de-ionized water as mentioned above. The obtained sample was named base refluxed AC (brAC). In the third method, the resultant aAC samples were refluxed with 1 N HCl at 90 °C for 1h followed by 1 N HF in a Teflon-lined stainless steel autoclave in order to eliminate the mineral matter and large quantity of silicon of the precursor, respectively. The autoclave was sealed and maintained at 90 °C for 1h. Afterwards, the solid materials were washed with 0.1 N NaOH for 3h followed by hot de-ionized water several times until the pH was near neutral [35]. The obtained sample was named HF autoclaved AC (haAC). Figure 1 shows an overall flow diagram for sewage sludge-base AC preparation.

Characterization of the Feedstock and ACs

The industrial sewage sludge was analyzed for proximate (moisture, volatile matter, fixed carbon and ash content) and elemental analyses (carbon, nitrogen, hydrogen and oxygen). For the proximate analysis, moisture content was analyzed by drying the sludge samples at 103 °C according to ASTM D2866-94. Fixed carbon content was determined by heating samples in a muffle furnace (Nabertherm, Germany) at 900 °C for 7 min based on ASTM D5832-98. Ash and volatile matter contents were determined by burning the samples at 600 °C based on ASTM D2867-09 [43]. The result of the proximate and ultimate analyses of industrial sewage sludge is given in Table 1. The inorganic fractions of sewage sludge were characterized by X-ray fluorescence (1480, Philips, Netherland). XRD patterns of carbon materials were recorded using Philips X-ray diffractometer (Netherland) operated at a scan range of 1° with CuK radiation and a Ni filter. The diffraction profiles were obtained in the scan range (2θ) of 5–80°. The porosity characterization of the prepared ACs including surface area, pore volume, the extent of the micro- and mesoporosity, and the average pore diameter was determined by the Brunauer-Emmett-Teller (BET) method using the adsorption isotherms obtained at 77 K using ASAP2010 analyzer (Micromeritics Instrument Corp., USA). The total pore volume (Vtotal) was determined by the Barrett-Joyner-Halenda (BJH) method [44]. The micropore volume and average pore width were determined by Dubinin-Radushkevich (DR) equation. The mesopore volume was calculated by subtracting the micropore volume from the total pore volume. The surface morphology of AC sample was observed by scanning electron microscopy (SEM, EM3200, KYKY, China). The surface functional groups of samples were also examined with Fourier transforms infrared spectra (FT-IR-8300, Shimadzu, Japan).

Results and Discussion

Texture Properties

The surface area of a porous material is one of the most useful micro- and meso-structural parameters for defining its properties. The N2 adsorption–desorption isotherms and pore size distributions for the five ACs are shown in Fig. 2. The textural characteristics of ACs prepared from chemical activation of industrial sewage sludge with H3PO4 including the BET surface area (SBET) and the total pore volumes (Vtotal), the mesopore volume (Vmes) and the average pore diameters (Da) are summarized in Table 3. The isotherm of aAC sample (Fig. 2a) shows a type II curve according to the IUPAC classification, exhibiting a characteristic of nonporous or macroporous adsorbents, where unrestricted monolayer–multilayer adsorption can occur (inside Fig. 2b). The huge hysteresis loop in this sample indicated the presence of a small amount of large mesopores in the aAC sample that can be seen in the pore size distribution curves [37]. Improvements in the porosity of char and the surface area are needed to enable their use as adsorbents of contaminants. Such improvements were obtained with a combination of chemical activation and acid and/or base wash treatments. Furthermore, the impregnation of sewage sludge with H3PO4 followed by a thermal treatment under nitrogen gas creates cavities on the surface of the carbons and increase its porosity and specific surface area due to the evaporation of activating agents during carbonization [38, 45]. The SBET results indicated that among all the samples studied, ACHP2, ACHP2.5 and ACHP3 had the lowest specific surface area of less than 10 m2g−1, while the bsAC had the greatest one of 635 m2g−1. This was likely caused by the high SBET associated with the based-washed activated carbon. For the four AC samples, namely aAC, arAC, brAC and haAC, the SBET were proportional to their LOI (Table 3). The greater SBET for bsAC compared to the other aforementioned samples could be a result of the lower LOI in this AC because the obtained AC had greater microporosity than other AC samples. The isotherm of bsAC (inside Fig. 2a) showed the type IV curve behavior with a hysteresis loop, indicating the presence of microporosity and mesoporosity (Fig. 2b). For arAC, brAC and haAC samples (inside Fig. 2a), the N2 adsorption showed the type V curve behavior with a hysteresis loop, indicating the presence of mesoporosity (Fig. 2b). It should be noted that their higher specific surface area and narrow pore volume were characterized for the presence of mesoporous structures in the synthesized samples using acid and base refluxed and HF autoclaved of aAC as a post-treatment method. As shown in Table 3, the total pore volume (Vtotal) of sewage sludge-base AC derived by chemical activation of H3PO4 was in the following order: AC2HP > AC2.5HP > AC3HP. It can be seen from Table 3 that sewage sludge based ACs obtained by soaking with NaOH (samples ACHP2, ACHP2.5 and ACHP3), exhibit SBET ranging from 5 to 10 m2/g, while applying a post-treatment step by refluxing with HCl and NaOH and autoclaved with HF (arAC, brAC and haAC samples) resulted in AC with a SBET up to 472, 432 and 511 m2/g. The two essential steps in the preparation of AC are carbonization and activation. In the activation step, the sewage sludge is impregnated with H3PO4 as a dehydration agent. In the process of activated carbon production, H3PO4 was transformed by the dehydration, depolymerization and decomposition reactions during carbonization and converts to H4P2O7 and Hn+2PnO3n+1 [46]. Phosphoric acid causes oxygen and hydrogen atoms in the sewage sludge to convert water vapors rather than oxygenated compounds or hydrocarbons. During the carbonization step, the removal of volatile matters as well as other complex reactions like the formation of double bonds, polymerization and condensation take place. In the after effect activation step, activated agents are mixed with the carbonized char to assist activation. At the end of the activation step, a large pore volume AC with a high surface area results. We found that the treatment of carbonized sewage sludge with the H3PO4 (2.5) after carbonization increased the specific surface and porous volume significantly compared with sewage sludge based ACs obtained by soaking with NaOH (samples ACHP2, ACHP2.5 and ACHP3). Table 3 also shows that the maximum value of SBET of 635 m2/g for bsAC sample obtained from chemical activation with 2.5 g H3PO4 of and then soaked with 1 N NaOH. The reasons for this are described as follows. From Table 1, the ash content of industrial sewage sludge is high (above 30.48%) and the carbon content of wood biomass [38] was higher than that found for sewage sludge, exhibiting around 43% of dry mass compared to 34.95% for sewage sludge. From Table 2, the XRF measurement also shows that sewage sludge mainly consists of silica, alumina, iron oxides, and alkaline and alkaline earth metals. As can be seen from Table 2, in this study, the aAC samples were refluxed with HCl and NaOH and autoclaved with HF in order to remove the impurity and to reduce the silica from the aAC sample as well as to improve the surface area and texture properties of the final samples. Hydrochloric acid removed much of the inorganic matter and the silica reacted with the NaOH forming sodium silicate (Na2SiO3) solution. Also carbonization before impregnation leads to the development of pore structure. It can be concluded that refluxing the aAC sample with HCl and NaOH and autoclaving with HF are an appropriate procedure to reduce inorganic content of the aAC, resulting in improvement in a BET surface area [47]. A high ash content of the feedstock severely limits the development of porosity over the pyrolysis process [48]. In addition, the induced thermal decomposition of the non-carbon elements, such as the inorganic components that are present in the forms of oxides or salts in sludge, also serves to develop the porous structure through their release as gaseous volatile products [49]. In this study, the sludge pyrolysis was performed before impregnation in order to reduce mineral matter. Ros et al. [50] observed that HCl treatment leads to a significant increase in SBET from 13 to 188 m2/g due to the removal of much of the inorganic materials and enhancement in the availability of the carbon fraction. Lin et al. [51] also determined the SBET of 118 m2/g for the AC based municipal sewage sludge. In their study, sewage sludge was refluxed with 3 M HCl, then activated with H3PO4 and finally carbonized in a tube furnace. However, Zhang et al. [52] and Wang et al. [53] obtained the AC with the SBET about 289, 290 m2/g, respectively, from activated sewage sludge with H3PO4 chemical activation using post-treatment with NaOH for elimination of soluble ash fractions. Generally, the AC is prepared from industrial sewage sludge that has a low SBET compared to commercial AC (400–1000 m2/g). This can be attributed to the properties of the feedstock, including the high ash content and low organic materials, the greatest of which, carbonaceous fraction, contributes to creating the porosity of AC [54]. The textural properties of the AC such as pore volumes are dependent on the ash content of raw material. The total pore volume of bsAC, arAC, brAC and haAC samples are observed above 0.496, 0.573, 0.616 and 0.606 cm3/g, indicating a significant increase in its porosity compared to the other three AC samples (the samples containing high ash). The total pore volume determined by BET was ten times higher compared to three other ACs. It should be noted that the post-treatment of aAC sample by HCl, NaOH and HF corresponded mesopore AC in the range of 3–6 nm. In comparison to other studies, the SBET of the AC derived from different types of sludge was reported to be 359 [55], and 141 [56], 82 [43] and 103 m2/g [57]. However, Zhang et al. [52] and Wang et al. [53] obtained AC with SBET of about 289 and 290 m2/g, respectively, from sewage sludge with H3PO4 as activated agent and post-treatment with sewage sludge-based AC soaked with NaOH (bsAC). Furthermore, SBET of 511 m2/g was obtained from sewage sludge-based AC autoclaved with HF to reduce Si and then refluxing with HCl to reduce metal residues. However, the highest mesoporosity percentage of 86% was obtained for sewage sludge-based AC refluxed with NaOH (brAC). As shown in Table 3, the average pore diameter (Da) of these AC was in the following order: brAC > arAC > haAC > bsAC.

SEM study

Figure 3 shows the surface morphology of AC samples was observed by SEM micrographs. It can be seen from Fig. 3a–c, as impregnation ratio increased from 1:2 to 1:3 g/g, the surface is gradually cleaned and the pore structure becomes more homogeneous. As can be seen from Table 2, based on the XRF analysis, some inorganic species such as Na2O, MgO, Al2O3, SiO2, P2O5, SO3, K2O, CaO, TiO2, and Fe2O3 are present in the sewage sludge and described as impurities. In the carbonization process, the amount of some of these impurities such as SiO2, Fe2O3, P2O5 and CaO was increased. The impurities on the surface of AC resulted in a very large pore structure (inside Fig. 2b), which is due to undesirable side reactions, and thus AC should be acid/base washed before use. In other words, the mesopore distribution, a very low SBET (Table 3) and different shape of ACs obtained (Fig. 3) can likely be attributed to the metal compounds. On the other hand, the leaching of the inorganic fractions by acid and base soaking as well as the refluxing by the specific acid on the surface of the pyrolyzed phase particles is required to clean non-condensable fraction and the porosity on an AC prepared from sewage sludge. However, SEM of Fig. 3a–c indicated that surface morphology and large pore structure may lead to an increase in the adsorption capacity of pollutants from aqueous solution. As is clear from Fig. 3d–g, there are some spherical shapes on the surface of the AC samples. The new small pores are formed, indicating more removal of mineral matters and silica in theses samples. It can be observed that the AC samples obtained using post-treatment with acid and base have smaller particle sizes. According to literatures, the carbons prepared from the smallest particle size generally possess a higher yield and porosity due to high external surface area to contact with the chemical reagents as well as a weaker resistance for intraparticle diffusion of the reagents [36, 58]. However, bsAC, arAC and brAC samples with acid and base refluxing appear to contain particles in the form of spherical in the micrometer range (Fig. 3d–f).

XRF and XRD Analyses

Sludge is the byproduct of industrial wastewater treatment and used as feedstock for activated carbon production. The amounts of chemical composition and loss on ignition [24] test were determined. Major oxide analysis by XRF was carried out on 1.0 g of samples. LOI test is generally used for estimating the unburned carbon content and organic matters of the feedstock and was determined using a gravimetric method for raw sludge and unburned carbon based on the weight loss at 550 °C for samples dried at 103 °C [59 ]. Table 2 shows the chemical compositions of raw sewage sludge (raw SS), carbonized sewage sludge (cAC) and H3PO4 impregnated with cAC and followed by soaking in 0.1 N NaOH (bsAC), as-prepared AC (aAC), refluxed aAC with 1 N HCl (arAC), refluxed aAC with 1 N NaOH (brAC), and refluxed aAC with 1 N HF (hrAC). As can be seen in Table 2, the LOI of sewage sludge and all as-prepared ACs were more than 47%. The results of LOI overestimate the amount of organic matter not only due to the burning of organic carbon, but also due to other possible reactions such as calcination of inorganic carbonates, desorption of physically and chemically bound water, and oxidation of sulfur and iron minerals [60]. Beside the results of XRF analysis is shown in Table 2, the raw sewage sludge has a high content of Al2O3, Fe2O3 and CaO due to the use of alum, ferric salts, and lime in the wastewater treatment and SiO2 which could affect the textual morphology of produced AC [61]. High content of sulfur dioxide (SO2) in raw sewage sludge indicates high sulfur-rich of wastewater sample and high levels of oxides of sodium and potassium (sodium oxide and potassium oxide) alkalis show compounds of sulphates such as potassium sulfate and sodium sulfate (Table 1). XRF results of raw sewage sludge showed that trace amount of Mn, Ni, As, Sr, Zr, Ag, Ba, and Pb was retained in the sewage sludge (data not shown). The cAC char showed reduction in LOI and enhancement in Na2O, Al2O3, SiO2, P2O5, CaO, and Fe2O3 compared to the feedstock, whereas carbonization had significant effects on ash components in the sewage sludge feedstock. Thermal operation resulted in the accumulation of metal oxides in cAC char, which increases considerably compared to the sewage sludge feedstock. Table 2 shows a high amount of SiO2 remained in aAC sample. As shown in Table 2, chemical activation with H3PO4 followed by additional acid and base refluxing (arAC and brAC samples) removed significant amounts of mineral matter. Refluxing with NaOH was effective in removing silica where as refluxing with HCl was effective in the removal of alkali (Na, K), alkaline (Ca, Mg) and metals (Fe) which are inevitable in the aACs from industrial sewage sludge. However, aAC sample refluxed with HCl and followed by autoclaved HF (haAC) showed that the elemental oxides determined gives P2O5 containing the highest percentage (23.07%) followed by Fe2O3 (3.45%) and SiO2 (2.80%) and about 10% of the SiO2 was removed in the final products. However, acid and base refluxing of aAC samples facilitated the elimination of the non-carbon species and enrichment of carbon.

The XRD patterns of carbon materials (char as well as AC materials) are shown in Fig. 4. The use of base and acid treatments to remove impurities was desirable because their presence may reduce the XRD peak intensity. The sharp diffraction peak characteristics of mineral matter become much sharper in those samples refluxed with NaOH and HCl (brAC and arAC samples). The effectiveness of NaOH and HCl refluxing in the removal of mineral matter is also confirmed from the analysis of the XRF of bsAC, brAC and arAC samples (Table 2). XRD patterns of H3PO4 impregnated AC (aAC) and samples of post-treated ACs (bsAC, arAC, brAC, haAC4) are shown in Fig. 4. Sewage sludge contains quartz as the main phase, in addition to anhydrite, albite, and hematite minerals. Figure 4a shows that the broad peak of XRD spectra centered at 2θ = 24.21° indicates the presence of amorphous components. As can be seen from Fig. 4b, the major inorganic crystalline phases detected in the bsAC samples by XRD are quartz (SiO2), mullite (Al6Si2O13), hematite (Fe2O3) and/or magnetite (Fe3O4), anhydrite (CaSO4), calcite (CaCO3), lime (CaO), potassium feldspar (KAlSi3O8), plagioclase ((Ca, Na)(Al-Si)4O8), and illite ((KH3O)Al2Si3AlO10(OH)2). The XRD spectra of post-treated aAC refluxed with HCl (arAC) reflect the presence of silicon oxide species (SiO2 and Si2O3) characteristic peaks at 2θ angle of 31.035°associated in peaks at 2θ values of 27.8, 39.72 and 49.17°, H3PO4 related to peaks at 2θ values of 17.77, 27.98 and 36.18°, pyro-phosphoric acid (H4P2O7) related to peaks at 2θ values of 21.39 and 35.38°, H3PO3f assigned to peak at 2θ values of 26.94, 28.53, 30.41°, as major components (Fig. 4c). Figure 4d shows that XRD peaks were located at 2θ = 32.05, 34.17 and 38.650 detected for mullite, hematite and quartz crystalline phases, respectively, and accompanied by the disappearance of related zeolite phases due to the silicon elimination during reflux with base and other mineral impurities during washing with acid in brAC sample. Figure 4e shows that Zeolite X and Y was detected at 2θ = 30.61°, followed by faujasite observation at 2θ = 26.93°. XRD conducted on haAC sample also showed related phases such as sodalite, analcime and sodium silicates relocated at 2θ = 43.58, 47.97 and 49.21°. In the treated sample of haAC, the remaining silicon oxide (SiO2) crystals in aAC sample have removed other crystalline components because most probably the acid concentration used was sufficient [62]. In addition to diffraction peaks mentioned earlier, the authors have also observed that small diffraction peaks at 2θ values of 10 and 22° was characteristic of the presence of the amorphous nature of the lignin in the AC samples.

FT-IR Analysis of the Surface Functional Groups

Infrared spectroscopy is an important technique and it is an easy way to identify the presence of certain functional groups in a sludge-based AC. The FT-IR spectra can provide valuable information about the surface chemistry of the adsorbent. Figure 5 illustrates the FT-IR spectra of surface functional groups on the ACs prepared with different impregnation ratios of H3PO4 and also samples treated with acid and base. As shown in Fig. 5, the FT-IR spectra show that approximately all AC samples activated with H3PO4 contained similar bands and also all post-treated AC samples contained similar bands, indicating that there were similar functional groups among them. By comparing the untreated and post-treated samples, the FT-IR spectra exhibit visible changes after purification which is related to the surface structural changes in the solid matrix. For instance, chemical activation by phosphoric acid, the acid reacts with the precursor to thermally decompose and form activated carbon products. This leads to bond weakening and formation of cross-linked structure. It reduces the release of volatile materials, restricts tar formation and loss of porosity. In addition, the effect of the added chemicals leads to lower activation temperature and higher carbon yields. FT-IR peaks showed an obvious increase in the peak intensity of AC samples, indicating how the experimental conditions affect the surface chemistry of the AC samples. The absorption bands at 1087, 1103, 1126 cm− 1 in ACHP2, ACHP2.5, ACHP3 samples corresponded to the existence of a C–O single bond in carboxylic acids, alcohols, phenols, and esters, or the P = O bond in phosphate esters, O–C bond in P–O–C linkage, and P = OOH bond the P–O–P or C–O stretching vibration [63]. Figure 5(a–d) shows a transmittance band around 520 cm− 1. This band can be associated with oxidized metal species (oxygen interstitial), which disappears after post-treatment with acid and base Fig. 5(e–h), which is indicative of the removal of metal oxide in AC samples. The sharp peaks appearing at 1026 cm− 1 of cAC sample can be attributed to Si–O–Si structuring vibration, representing the existence of silicate functional groups [49]. Although this vibration band at 972 cm− 1 ACHP2, ACHP2.5 and ACHP3 samples appeared different from the AC sample without impregnation (cAC). With an increasing impregnation ratio, the band at 1126 cm−1 becomes obvious, whereas the intensity of the other bands mentioned above decreased gradually. The decrease could be due to the higher degree of carbonization for the samples with a higher impregnation ratio as it can be valued by the lower intensity of C = O at 1670 cm− 1. The band appeared at 2291, 2306, 2314, and 2368 cm− 1 of ACHP2, ACHP2.5, ACHP3 and all post-treated samples associated to O = C–H stretches in aldehydes. In addition, the vibration bands located at 1042, 1080, 1088 and 1080 cm− 1 in bsAC, arAC, brAC and haAC samples can be ascribed to stretching modes of Si–O–Si [37]. In our samples, these spectra also show the transmittance bands associated with bending (around 800 cm− 1) and rocking (around 450 cm− 1) vibration modes of the Si–O–Si bonds in SiO2. Furthermore, the peaks at 680–700 cm− 1 are an indication of Si–Si bonds. It should be mentioned that changes in their intensity and position were related to structural vibration in the silicon oxide particles when the impregnation ratio and silicon amount in the samples were varied. In these spectra, the band at 3734 cm− 1 is due to the –OH stretching mode of the isolated silanols. The peak at 1620 cm− 1 in the spectra of all AC samples was assigned to the C = O stretching vibration of carbonyl groups [64]. In addition, all of the spectra of AC samples show the band at about 3400 cm− 1, which corresponded to the O–H stretching vibration of the hydroxyl functional groups [65]. For post-treated samples, the band at 3448 cm− 1 indicated the presence of O–H at alcohols or phenols [65]. As illustrated in Fig. 5, peaks at 563 and 771 cm− 1 assigned to the asymmetric Si–O–Si and symmetric Si–O–Si stretching, respectively, weaken in treating sample at 1026 cm− 1. A stronger band was further detected at 1050 cm− 1, which is attributed to the structure of either Si–O–C functional group. The peak at 3400 cm− 1 corresponds to stretching vibration of the hydroxyl groups. But despite stages of washing and refluxing, groups of silanol (Si–OH) at peak 3600 cm− 1 remains.

Comparison with other AC

The comparison of the AC prepared in this study with other carbons reported in the literatures was shown in Table 4. As shown in this table, the maximum of BET surface area in this study from sample bsAC reached 635 m2/g, while the AC exhibited a BET surface area of only 5–10 m2/g without the acid or base leaching steps. The greatest improvement in the BET surface area was achieved in comparison to AC-based fertilizer derived from municipal sludge (41 m2/g) after HCl washing step [66], AC-based dewatered aerobically digested municipal wastewater treatment plant (188 m2/g) [50]. A study has reported that the BET surface area can reach 289 m2/g for AC-based municipal sludge after washing with NaOH [52]. In another study, the sewage sludge AC had higher BET than that obtained by Bagreev et al. [67] whilst in the three stage washing with HCl (193 m2/g). To explain, the AC was then mixed with a further acid-wash step which is evidently attainable in order to improve the efficiency of removing the inorganic fraction. Until now, no studies were performed on HF washing of sewage sludge-derived AC, which leads to a high BET surface area of 511 m2/g. In this work, the raw sewage sludge was found to be a potential source of producing sewage-sludge based AC as an adsorbent, haAC sample, for Cr (VI) uptake was performed. The result achieved the maximum uptake capacity of 94.54 mg/g for an initial Cr (VI) concentration of 100 g/l at 0.4 g/l adsorbent dosage, 120 min contact time and pH 3. The results of this study showed that a thermo-chemical conversion process of sewage sludge to carbon, significantly reduce the sludge volume produced in the industrial wastewater treatment plant, eliminate the need for further treatment of sludge, reduce hauling and disposal costs and land filling and incinerating the sludge, and reduce transportation costs. Therefore, a comparative analysis of performance and cost of the AC adsorbents should be carried out to understand the process efficiency and mechanism.

Conclusions

ACs were prepared from the industrial sewage sludge by chemical activation with H3PO4 followed by post-treatment with acid and base. The inorganic fractions had an additional negative effect on the porosity, surface, textural and morphological properties of producing AC. The XRF, XRD, BET and FT-IR techniques confirmed successful elimination of the mineral fraction on AC samples. The post-treated samples have remarkably higher BET surface area, and total pore volume compared to the untreated AC samples. The pore size distributions of the untreated AC samples were mainly in the mesopore range of 19.59–37.05 nm, however the average pore diameter of post-treated was mainly distributed in the mesopore range of 3.13–5.70 nm due to the elimination of the mineral matter and other impurity composition of precursor. From the results, it could be noticed that the preparation conditions of acid and base post-treated AC from industrial wastewater sewage sludge by H3PO4 activation affected well textual properties, surface chemistry and metal oxide content of sludge-based AC and its efficiencies in the adsorptive purification of Cr (VI). Therefore, there may be a possible alternative method to dispose sewage sludge by producing AC and experimental results showed that the textural properties of sewage sludge-based AC can be improved by acid and base post-treatment method and can be applied in wastewater treatment.

References

Crini, G.: Recent developments in polysaccharide-based materials used as adsorbents in wastewater treatment. Prog. Polym. Sci. 30, 38–70 (2005)

Periasamy, K., Srinivasan, K., Murugan, P.: Studies on chromium (VI) removal by activated groundnut husk carbon. Indian J. Environ. Health. 33, 433–439 (1991)

Tan, W., Ooi, S., Lee, C.: Removal of chromium (VI) from solution by coconut husk and palm pressed fibres. Environ. Technol. 14, 277–282 (1993)

Singh, C.K., Sahu, J.N., Mahalik, K.K., Mohanty, C.R., Mohan, B.R., Meikap, B.C.: Studies on the removal of Pb(II) from wastewater by activated carbon developed from Tamarind wood activated with sulphuric acid. J. Hazard. Mater. 153, 221–228 (2008)

Heidari, A., Stahl, R., Younesi, H., Rashidi, A., Troeger, N., Ghoreyshi, A.A.: Effect of process conditions on product yield and composition of fast pyrolysis of Eucalyptus grandis in fluidized bed reactor. J. Ind. Eng. Chem. 20, 2594–2602 (2014)

Heidari, A., Younesi, H., Rashidi, A., Ghoreyshi, A.: Adsorptive removal of CO2 on highly microporous activated carbons prepared from Eucalyptus camaldulensis wood: Effect of chemical activation. J. Taiwan Inst. Chem. Eng. 45, 579–588 (2014)

Heidari, A., Younesi, H., Rashidi, A., Ghoreyshi, A.A.: Evaluation of CO2 adsorption with eucalyptus wood based activated carbon modified by ammonia solution through heat treatment. Chem. Eng. J. 254, 503–513 (2014)

Danish, M., Hashim, R., Ibrahim, M.M., Rafatullah, M., Ahmad, T., Sulaiman, O.: Characterization of acacia mangium wood based activated carbons prepared in the presence of basic activating agents. BioResources. 6, 3019–3033 (2011)

Wu, F.-C., Tseng, R.-L.: Preparation of highly porous carbon from fir wood by KOH etching and CO2 gasification for adsorption of dyes and phenols from water. J. Colloid Interface Sci. 294, 21–30 (2006)

Hazourli, S., Ziati, M., Hazourli, A.: Characterization of activated carbon prepared from lignocellulosic natural residue:-Example of date stones. Physics Procedia. 2, 1039–1043 (2009)

Selvi, K., Pattabhi, S., Kadirvelu, K.: Removal of Cr(VI) from aqueous solution by adsorption onto activated carbon. Bioresour. Technol. 80, 87–89 (2001)

Sahu, J.N., Agarwal, S., Meikap, B.C., Biswas, M.N.: Performance of a modified multi-stage bubble column reactor for lead(II) and biological oxygen demand removal from wastewater using activated rice husk. J. Hazard. Mater. 161, 317–324 (2009)

Kobya, M.: Removal of Cr(VI) from aqueous solutions by adsorption onto hazelnut shell activated carbon: kinetic and equilibrium studies. Bioresour. Technol. 91, 317–321 (2004)

Chen, X., Wu, K., Gao, B., Xiao, Q., Kong, J., Xiong, Q., Peng, X., Zhang, X., Fu, J.: Three-dimensional activated carbon recycled from rotten potatoes for high-performance supercapacitors. Waste Biomass Valoriz. 7, 551–557 (2016)

Demirbas, E., Kobya, M., Senturk, E., Ozkan, T.: Adsorption kinetics for the removal of chromium(VI) from aqueous solutions on the activated carbons prepared from agricultural wastes. Water S. A. 30, 533–540 (2004)

Brisolara, K. F., Lima, I. M., Marshall, W. E.: Cation and anion release from broiler litter and cake activated carbons and the role of released anions in copper ion uptake. Waste Biomass Valoriz. 5, 689–697 (2014)

Mahdi, Z., Hanandeh, A.E., Yu, Q.: Influence of pyrolysis conditions on surface characteristics and methylene blue adsorption of biochar derived from date seed biomass. Waste and Biomass Valoriz. 1–13 (2016). doi:10.1007/s12649-016-9714-y

Huang, Y., Liu, Y., Zhao, G., Chen, J.Y.: Sustainable activated carbon fiber from sawdust by reactivation for high-performance supercapacitors. J. Mater. Sci. 52, 478–488 (2017)

Khalili, N. R., Campbell, M., Sandi, G., and Golaś, J. Production of micro- and mesoporous activated carbon from paper mill sludge: I. Effect of zinc chloride activation, Carbon 38, 1905–1915 (2000)

Yang, X., Xu, G., Yu, H., Zhang, Z.: Preparation of ferric-activated sludge-based adsorbent from biological sludge for tetracycline removal. Bioresour. Technol. 211, 566–573 (2016)

Chen, T., Zhou, Z., Han, R., Meng, R., Wang, H., Lu, W.: Adsorption of cadmium by biochar derived from municipal sewage sludge: Impact factors and adsorption mechanism. Chemosphere. 134, 286–293 (2015)

Sun, D., Guo, S., Ma, N., Wang, G., Ma, C., Hao, J., Xue, M., Zhang, X.: Sewage sludge pretreatment by microwave irradiation combined with activated carbon fibre at alkaline pH for anaerobic digestion, Water Sci. Technol. wst2016149 (2016).

Maroto-Valer, M.M., Zhang, Y., Granite, E. J., Tang, Z., Pennline, H. W.: Effect of porous structure and surface functionality on the mercury capacity of a fly ash carbon and its activated sample. Fuel. 84, 105–108 (2005)

Loizidou, M.: Waste valorization and management. Waste Biomass Valoriz. 7, 645–648 (2016)

Girgis, B.S., El-Hendawy, A.N.A.: Porosity development in activated carbons obtained from date pits under chemical activation with phosphoric acid. Microporous Mesoporous Mater. 52, 105–117 (2002)

Kula, I., Uğurlu, M., Karaoğlu, H., Çelik, A.: Adsorption of Cd(II) ions from aqueous solutions using activated carbon prepared from olive stone by ZnCl2 activation. Bioresour. Technol. 99, 492–501 (2008)

Demiral, H., Güngör, C.: Adsorption of copper (II) from aqueous solutions on activated carbon prepared from grape bagasse. J. Cleaner Prod. 124, 103–113 (2016)

Mendes, F.M.T., Marques, A.C.C., Mendonça, D.L., Oliveira, M.S., Moutta, R.O., Ferreira-Leitão, V.S.: High surface area activated carbon from sugar cane straw. Waste Biomass Valoriz. 6, 433–440 (2015)

Ma, Y.: Comparison of activated carbons prepared from wheat Straw via ZnCl2 and KOH Activation. Waste Biomass Valoriz. 1–11 (2016)

Ding, R., Zhang, P., Seredych, M., Bandosz, T.J.: Removal of antibiotics from water using sewage sludge-and waste oil sludge-derived adsorbents. Water Res. 46, 4081–4090 (2012)

Shehu, M.S., Abdul Manan, Z., Wan Alwi, S.R.: Optimization of thermo-alkaline disintegration of sewage sludge for enhanced biogas yield. Bioresour. Technol. 114, 69–74 (2012)

Bernardino, C.A.R., Mahler, C.F., Veloso, M.C C., Romeiro, G.A.: Preparation of biochar from sugarcane by-product filter mud by slow pyrolysis and its use like adsorbent. Waste Biomass Valoriz. 1–11 (2016)

Ros, A., Lillo-Ródenas, M.A., Canals-Batlle, C., Fuente, E., Montes-Morán, M.A., Martin, M.J., Linares-Solano, A.: A new generation of sludge-based adsorbents for H2S abatement at room temperature. Environ. Sci. Technol. 41, 4375–4381 (2007)

Pan, Z.-h., Tian, J.-y., Xu, G.-r., Li, J.-j., Li, G.-b: Characteristics of adsorbents made from biological, chemical and hybrid sludges and their effect on organics removal in wastewater treatment. Water Res. 45, 819–827 (2011)

Smith, K., Fowler, G., Pullket, S., Graham, N.J.D.: Sewage sludge-based adsorbents: a review of their production, properties and use in water treatment applications. Water Res. 43, 2569–2594 (2009)

Liou, T.-H.: Development of mesoporous structure and high adsorption capacity of biomass-based activated carbon by phosphoric acid and zinc chloride activation. Chem. Eng. J. 158, 129–142 (2010)

Zou, J., Dai, Y., Wang, X., Ren, Z., Tian, C., Pan, K., Li, S., Abuobeidah, M., Fu, H.: Structure and adsorption properties of sewage sludge-derived carbon with removal of inorganic impurities and high porosity. Bioresour. Technol. 142, 209–217 (2013)

Valizadeh, S., Younesi, H., Bahramifar, N.: Highly mesoporous K2CO3 and KOH/activated carbon for SDBS removal from water samples: Batch and fixed-bed column adsorption process. Environ. Nanotechnol. Monitor. Manage. 6, 1–13 (2016)

Lin, Q., Cheng, H., Chen, G.: Preparation and characterization of carbonaceous adsorbents from sewage sludge using a pilot-scale microwave heating equipment. J. Anal. Appl. Pyrolysis. 93, 113–119 (2012)

Diao, Y., Walawender, W.P., Fan, L.T.: Activated carbons prepared from phosphoric acid activation of grain sorghum. Bioresour. Technol. 81, 45–52 (2002)

Ribas, M.C., Adebayo, M.A., Prola, L.D.T., Lima, E.C., Cataluña, R., Feris, L.A., Puchana-Rosero, M.J., Machado, F.M., Pavan, F.A., Calvete, T.: Comparison of a homemade cocoa shell activated carbon with commercial activated carbon for the removal of reactive violet 5 dye from aqueous solutions. Chem. Eng. J. 248, 315–326 (2014)

Sandí, G., Khalili, N. R., Lu, W., Prakash, J. Electrochemical performance of carbon materials derived from paper mill sludge, J. Power Sources 119–121: 34–38 (2003).

Inguanzo, M., Menendez, J., Fuente, E., Pis, J.: Reactivity of pyrolyzed sewage sludge in air and CO2. J. Anal. Appl. Pyrolysis. 58, 943–954 (2001)

Barrett, E.P., Joyner, L.G., Halenda, P.P.: The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 73, 373–380 (1951)

Alimohammadi, Z., Younesi, H., Bahramifar, N.: Batch and Column Adsorption of reactive Red 198 from textile industry effluent by microporous activated carbon developed from walnut shells. Waste Biomass Valoriz. 7, 1255–1270 (2016)

Liu, H., Zhang, J., Bao, N., Cheng, C., Ren, L., Zhang, C.: Textural properties and surface chemistry of lotus stalk-derived activated carbons prepared using different phosphorus oxyacids: Adsorption of trimethoprim. J. Hazard. Mater. 235–236, 367–375 (2012)

Smith, K.M., Fowler, G.D., Pullket, S., Graham, N.J.D.: Sewage sludge-based adsorbents: A review of their production, properties and use in water treatment applications. Water Res. 43, 2569–2594 (2009)

Monsalvo, V.M., Mohedano, A.F., Rodriguez, J.J.: Activated carbons from sewage sludge: application to aqueous-phase adsorption of 4-chlorophenol. Desalination. 277, 377–382 (2011)

Velghe, I., Carleer, R., Yperman, J., Schreurs, S., D’Haen, J.: Characterisation of adsorbents prepared by pyrolysis of sludge and sludge/disposal filter cake mix. Water Res. 46, 2783–2794 (2012)

Ros, A., Lillo-Ródenas, M.A., Fuente, E., Montes-Morán, M.A., Martín, M.J., Linares-Solano, A.: High surface area materials prepared from sewage sludge-based precursors. Chemosphere. 65, 132–140 (2006)

Lin, Q.H., Cheng, H., Chen, G.Y.: Preparation and characterization of carbonaceous adsorbents from sewage sludge using a pilot-scale microwave heating equipment. J. Anal. Appl. Pyrolysis. 93, 113–119 (2012)

Zhang, F.-S., Nriagu, J. O., Itoh, H.: Mercury removal from water using activated carbons derived from organic sewage sludge. Water Res. 39, 389–395 (2005)

Wang, X., Liang, X., Wang, Y., Wang, X., Liu, M., Yin, D., Xia, S., Zhao, J., Zhang, Y.: Adsorption of Copper(II) onto activated carbons from sewage sludge by microwave-induced phosphoric acid and zinc chloride activation. Desalination. 278, 231–237 (2011)

Gu, L., Wang, Y., Zhu, N., Zhang, D., Huang, S., Yuan, H., Lou, Z., Wang, M.: Preparation of sewage sludge based activated carbon by using Fenton’s reagent and their use in 2-Naphthol adsorption. Bioresour. Technol. 146, 779–784 (2013)

Zhai, Y.-b., Wei, X.-x., Zeng, G.-m: Effect of pyrolysis temperature and hold time on the characteristic parameters of adsorbent derived from sewage sludge. J. Environ. Sci. 16, 683–686 (2004)

Bandosz, T. J., Block, K.: Municipal sludge-industrial sludge composite desulfurization adsorbents: synergy enhancing the catalytic properties. Environ. Sci. Technol. 40, 3378–3383 (2006)

Seredych, M., Bandosz, T. J.: Removal of copper on composite sewage sludge/industrial sludge-based adsorbents: the role of surface chemistry. J. Colloid Interface Sci. 302, 379–388 (2006)

Hsu, L.-Y., Teng, H.: Influence of different chemical reagents on the preparation of activated carbons from bituminous coal. Fuel Process. Technol. 64, 155–166 (2000)

Mohebbi, M., Rajabipour, F., Scheetz, B.E.: Reliability of loss on ignition (LOI) test for determining the unburned carbon content in fly ash. Nasvhille (2015)

Brown, R.C., Dykstra, J.: Systematic errors in the use of loss-on-ignition to measure unburned carbon in fly ash. Fuel. 74, 570–574 (1995)

Turovskiy, I.S., Mathai, P. Wastewater sludge processing, Wiley, New Jersy (2006)

Srivastava, V.C., Mall, I.D., Mishra, I.M.: Adsorption of toxic metal ions onto activated carbon: STUDY of sorption behaviour through characterization and kinetics. Chem. Eng. Process Process Intensif. 47, 1269–1280 (2008)

Guo, Y., Rockstraw, D.A.: Physicochemical properties of carbons prepared from pecan shell by phosphoric acid activation. Bioresour. Technol. 98, 1513–1521 (2007)

Chen, X., Jeyaseelan, S., Graham, N.: Physical and chemical properties study of the activated carbon made from sewage sludge. Waste Manage. 22, 755–760 (2002)

Mahapatra, K., Ramteke, D.S., Paliwal, L.J.: Production of activated carbon from sludge of food processing industry under controlled pyrolysis and its application for methylene blue removal. J. Anal. Appl. Pyrolysis. 95, 79–86 (2012)

Bagreev, A., Bandosz, T.J., Locke, D.C.: Pore structure and surface chemistry of adsorbents obtained by pyrolysis of sewage sludge-derived fertilizer, Carbon. 39, 1971–1979 (2001).

Bagreev, A., Bashkova, S., Locke, D.C., Bandosz, T.J.: Sewage sludge-derived materials as efficient adsorbents for removal of hydrogen sulfide. Environ. Sci. Technol. 35, 1537–1543 (2001)

Li, Y., Li, Y., Li, L., Shi, X., Wang, Z.: Preparation and analysis of activated carbon from sewage sludge and corn stalk. Adv. Powder Technol. 27, 684–691 (2016)

Kacan, E.: Optimum BET surface areas for activated carbon produced from textile sewage sludges and its application as dye removal. J. Environ. Manage. 166, 116–123 (2016)

Martin, M.J., Artola, A., Balaguer, M.D., Rigola, M.: Towards waste minimisation in WWTP: activated carbon from biological sludge and its application in liquid phase adsorption. J. Chem. Technol. Biotechnol. 77, 825–833 (2002)

Dos Reisa, G.S., Adebayo, M.A., Lima E.C., Sampaioa, C.H., Prola L.D.: Activated carbon from sewage sludge for preconcentration of copper. Anal. Lett. 49, 541–555 (2015)

Qiu, M., Xiong, S., Xin, H.: Removal of copper ion in aqueous solution by activated carbon from sewage sludge. Int. J. Environ. Technol. Manage. 18, 83–94 (2015)

Yu, L., Zhong, Q.: Preparation of adsorbents made from sewage sludges for adsorption of organic materials from wastewater. J. Hazard. Mater. 137, 359–366 (2006)

Acknowledgements

The authors wish to thank the Ministry of Science and the Faculty of Natural Resources and Marine Sciences of the Tarbiat Modares University (TMU) for their financial support. Their funding and research grant made this study possible.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aliakbari, Z., Younesi, H., Ghoreyshi, A.A. et al. Production and Characterization of Sewage-Sludge Based Activated Carbons Under Different Post-Activation Conditions. Waste Biomass Valor 9, 451–463 (2018). https://doi.org/10.1007/s12649-016-9823-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9823-7