Abstract

The present study deals with the performance and emissions of conventional diesel fuel and biodiesel produced from waste cooking oil and their blends (B10, B15). The waste cooking oil methyl esters synthesis has been (WCOME) carried out by a single step alkali catalysed transesterification reaction. Significant physico-chemical properties have been measured and compared against the ASTM D6751 standards. The tests have been performed on a single cylinder, direct injection diesel engine at a constant speed 1500 ± 50 rpm. During the tests, brake thermal efficiency, specific fuel consumption, exhaust gas temperature, exhaust emissions are measured. The experimental results revealed that, relative to diesel, WCOME fuel blends show 1.7–4.14 % decrease in the brake thermal efficiency and 2.18–5.57 % increase in the brake specific fuel consumption due to higher density and kinematic viscosity of WCOME, which reduces the fuel atomization rate. Moreover, most of the constituents of exhaust gas such as CO (13.67–16.89 %) and HC (4.35–11.84 %) along with greenhouse gas such as CO2 (8.34–17.39 %) are reduced in case of all the blends. However, an increase in the NOx emissions (0.3–4.2 %) is mainly due to the higher cetane number of fuel blends, which decreases the ignition delay. The results of this study revealed that WCOME blends show fewer exhaust emissions with a little compromise in the performance of the engine.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Fuels are essential input for economic development, social growth, human benefit and quality life of every country. Currently, most of the world’s energy demands are rendered by fossil based resources, such as gasoline, kerosene, diesel and natural gas etc. Since 1970, need for energy is increasing with the development of technology, with an increasing trend of modernization, rapid population growth and industrialization; consequently, the world’s energy need is also growing at a faster rate [1, 2]. Furthermore, fossil derived fuels are producing negative effects on the environment and burning of these fuels contributes discharge of pollutant gases like NOx, CO2, SOx, HC [3]. However, currently human beings are caught between two major crises due to rapid depletion of fossil fuels and degradation of the eco-system. Internal Combustion (IC) engines (both diesel and petrol engines) have fallen victim to these crises. Due to the aforementioned and following understandings, like uncertainties in the petroleum supply, a result of greenhouse gases from industries, increased environmental concern and their high prices have accelerated an intensive exploration of substitute sources for fossil-based fuels, including diesel fuel [4]. Nabi et al. [5] reported that within 40 years, the present stock of fossil fuels will exhausts at an increased consumption rate approximated to be 3 % per annum. Therefore, it is essential that low emission alternative fuels must be developed to use in diesel engines in order to meet the current energy demands. In addition to that, for arising economy, it is understood that the energy uptake must be much more than the level at present.

Currently, various potential substitutes of fuels are available such as plant seed oils, alcohols (methanol, ethanol and butanol), producer gas and liquefied petroleum gas (LPG), gases such as compressed natural gas (CNG) etc. Among these available resources, plant seed oils provide a promising substitute to conventional diesel engines since they don’t contain sulphur, aromatic hydrocarbons, metals, oil residues. Similarly, they also can maintain carbon neutrality, provides good physico-chemical properties and vegetable oils can be transformed easily into the modern forms of energy. Many researchers have concluded that vegetable oils hold promise as an alternative to diesel fuel, since their properties are close to the diesel fuel [6, 7]. Recently, the use of biodiesel has grown dramatically around the globe. However, utilizing raw vegetable oils for diesel engines can cause numerous engine-related problems such as engine deposits, injector chocking and piston ring sticking due to the increased viscosity and low volatility of vegetable oils [8–10]. Nevertheless, these negative consequences can be reduced via transesterification of vegetable oil to form fatty acid esters [11–14]. Transesterification reduces the viscosity of vegetable oil and supplies a fuel having viscosity near to that of No. 2 conventional diesel fuel. Transesterification is a process in which triglyceride reacts with short-chain alcohol in the presence of a catalyst to produce fatty acid esters and glycerol. Transesterification technique also used to minimise the product cost, and it improves the physico-chemical properties of fatty acid esters in order to use in diesel engines.

Currently, raw materials for more than 95 % of biodiesel production come from edible oils (i.e. rapeseed, palm, canola, mustard, peanut and soybean). The consumption of these raw materials is due to their abundance around the globe in many regions. In addition to that, the properties of biodiesel produced from plant seed oils are worthy to be used as a conventional diesel fuel substitute. However, utilisation of plant seed oils to synthesise biodiesel is not viable in view of a large gap in demand and supply of such oils for food, and they are high-priced to be utilized at present. Therefore, the use of non-edible plant seed oils compared to edible seed oils is very significant in order to reduce the raw material cost and proper utilization of non-edible, edible waste oils, which are abundantly available in the commercial way. Since the cost of feed stock accounts for 60–80 % of the total price of methyl esters production, properties of fatty acid esters produced from various feed stocks are quite different, hence selecting a proper feed stock plays a major role in the entire synthesis process [15, 16]. In order to overcome the aforementioned difficulties many technocrats, industrialists as well as scientists are attracted towards edible waste, non-edible oil sources, which are unfit for the edible purpose due to the presence of few toxic constituents. Further, in-edible plant seed oil crops can be cultivated in barren lands that are unfit for food crops and the cost of cultivation is much lower, because these crops can still maintain higher oil yields without intensive care. Indeed, most of the non-edible oils hold high free fatty acids (FFA) content, thus these non-edible oils need multiple chemical steps to synthesise biodiesel, which increases the production cost and lower the ester yield. Therefore, in the current study methyl esters is synthesised from waste cooking oil (WCO) having very low FFA content.

During the past decade biodiesel has been broadly investigated in testing different types of engines. Many studies on engine test reported a reduction in particulate matter (PM), carbon monoxide (CO), and total hydrocarbon (THC) emissions with either neat or blended biodiesel compared to diesel fuel [17]. Wide range of studies has been conducted on combustion characteristics and regular emissions of a diesel engine fueled with biodiesel obtained from WCO [18–20]. Previous investigation results revealed that, biodiesel has higher viscosity compared to conventional diesel fuel; therefore in order to use the prepared biodiesel in DI engine it should be blended with conventional diesel. Hence, the effect of blending ratio on the mixture should be determined to reduce the emissions and safe operation of the engine. However, vast literature is available about the influence of using biodiesel in pure form or biodiesel blends with conventional diesel fuels, but there is no similarity in many engine aspects. For this reason, there is a necessity to perform a set of experiment before using any biodiesel from any resource in DI engine that has not been documented. In this direction, present work aims to study the influence of biodiesel blending ratio on engine performance (brake thermal efficiency, specific fuel consumption, exhaust gas temperature, exhaust emissions) and emission characteristics (CO, HC, CO2 and NOx) at a wide range of engine operating conditions. All the experiments are performed without any engine modification and this data will be important in formulation of optimal biodiesel blends and their use in DI engines from waste/used cooking oils.

Materials

The WCO used in this study (fish fried soybean oil) has been collected from the institute hostel mess, IIT Guwahati, Guwahati, India. Methanol, phenolphthalein Indicator, sodium hydroxide (NaOH) pellets, ethyl alcohol, carbon tetrachloride (CCl4), potassium Iodide (KI), sodium thiosulphate (Na2S2O3), Wij’s reagent, hydrogen peroxide, potassium hydroxide are supplied by Merck India Pvt. Ltd. All the other reagents used for analysis are analytical grade and are used as received without any further purification.

Experimental Methodology

Synthesis of WCO Biodiesel, Blending with Diesel and Physico-Chemical Characterization

WCO biodiesel is prepared by a single step alkali catalysed transesterification. Experimental details, synthesis procedure and product confirmation is followed as per earlier communication on the synthesis of jatropha biodiesel [21]. The formation of methyl ester has been confirmed by Hydrogen-1 Nuclear Magnetic Resonance (1H NMR) spectroscopy on a 500 MHz NMR spectrometer (Oxford, AS400, China). The fatty acid composition of the sample estimated using a gas chromatography technique (GC, CP-3800, Varian, Netherland) is reported elsewhere [22]. The prepared WCO biodiesel have been blended at two different ratios such as 10 and 15 % of diesel on a volume basis and labelled as B10 (10 % WCO biodiesel + 90 % high speed diesel) and B15 (15 % WCO biodiesel + 85 % high speed diesel). The blending is carried out using a mechanical stirrer for 40 min continuously to prepare a homogeneous mixture of fuel and biodiesel to achieve the best performance of the engine. After stirring the fuel mixture is injected to fuel tank without any time lag. Prepared biodiesel and their blends are used to analyse the physico-chemical properties in order to carry out the further study on engine performance and emission characteristics. The physico-chemical properties of WCO methyl esters and their blends are examined according to ASTM and AOCS standard methods as reported in our earlier communication [21].

Engine Test Setup

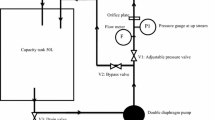

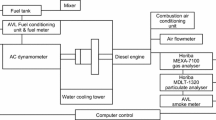

The experimental set-up considered for testing of various blends is as shown in Fig. 1. This set up mainly consists of a single cylinder-4-stroke engine which is water cooled and runs at a constant speeds. This engine is naturally aspirated and has provision of direct injection (DI) of diesel in the hemispherical combustion chamber. The injection nozzle has three holes of 0.3 mm diameter with a spray angle of 120°. It is coupled with an eddy current dynamometer (SAJ Make, Model AG10) for measurement of torque at various loading conditions. The engine specification and associated measuring devices are listed in Table 1 [23].

Schematic of DI diesel engine test bench. 1 Diesel engine test bench; 2 Eddy current dynamometer with load cell; 3 Fuel tank with fuel meter; 4 Air box and orifice meter attached with U-tube manometer; 5 Piezo power unit; Digital temperature indicator; 7 Potentoimeter with load indicator; 8 Exhaust gas calorimeter; 9 Exhaust gas analyzer and probe inserted in exhaust gas environment; T1, T2—T6 are the thermocouples for temperature measurement

Engine Instrumentation

The engine test rig is equipped with various measurement systems. These systems are mainly related to load application on the engine, temperature measurement, air flow rate measurement, fuel consumption measurement and exhaust analysis. This section deals with the specification of these sub-systems of the present experimental set-up. During the experimental study performance of the fuel has been analyzed at various engines loading conditions keeping the engine speed constant. In these experiments, the amount of loads on the engine has been varied by changing the input current of the eddy-current dynamometer. Thus the varied load is measured using the load cell of strain gauge type (0–50 kg). A burette glass is connected to the flow path of the fuel from a fuel tank to the fuel pump. This method enables the measurement of a volumetric fuel flow rate from a tank to the engine. In case of experiments with 100 % diesel, the tank is filled with diesel while for the experiments with biodiesel-diesel blend the tank is filled with the blend of interest. The air flow rate received by the present engine has been estimated from the pressure drop across the orifice meter mounted in the air path. A U-tube water manometer is attached for this measurement.

Coefficient of discharge of the orifice meter is 0.6. An exhaust gas analyzer ‘Testo-350S/M/XL” is used for the quantitative assessment of the engine exhaust. This flue gas analyzer is helpful to quantify the presence of five gases viz. O2, CO, CO2, NOX and HC generated as the products after combustion of diesel or diesel blends with WCOME. The manufactures specifications of the exhaust gas analyzer are as given in Table 2. A ‘K’ type thermocouple has also been used for measurement of exhaust gas temperature.

Results and Discussion

Product Confirmation by 1H NMR spectroscopy

NMR spectroscopy has been recorded to observe the structural change and to monitor the transesterification reaction. In case of WCO 1H NMR spectra multiplet, peaks are noticed in the region δ 4.12- 4.16 ppm and δ 4.27- 4.31 ppm indicate the presence of methylene proton of –CH2-CH-CH2– glycerol group (Fig. 2). The completion of transesterificationreaction is confirmed by the presence of a characteristic peak of methoxy protons (–CH3) as a singlet at δ 3.6 ppm. The change in 1H NMR spectrums with WCO along with its methyl esters are shown in Fig. 2. The singlet at δ 3.6 ppm is indicative of WCO to methyl esters conversion. Therefore, from the 1H NMR spectra of WCO and its methyl esters, it can be confirmed that WCO conversion into methyl esters is accomplished, and the conversion is reported to be 96 % as per formula reported by Sharma et al. [24]

Physico-Chemical Characterization of WCOME and Their Blends

Physico-chemical properties of WCO, WCOME and their blend are evaluated as per ASTM standard methods and reported in Table 3. During the study kinematic viscosity and densities are found to be increased with an increase biodiesel ratio in the blends. These are highly significant properties, which influence the fuel atomization of the blends [25] and these properties are reduced significantly after transesterification.

The obtained values of biodiesel blends are in the satisfactory range of ASTM measures, along with WCO biodiesel density value. As reported earlier, considering the viscosity which is the serious problem in the utilization of plant seed oils for engine functioning is reduced considerably after transesterification. Similarly, flash point values decrease after transesterification and found to be in the range of diesel and WCO biodiesel. The higher flash point of blends and WCO biodiesel makes it safer for handling, storage and transportation [16]. Flash point temperature depends on viscosity; hence, reduced viscosity after transesterification may be one of the causes for a lower flash point of prepared methyl esters. However, boiling point of individual fatty acids also considered for a lower flash point. The reduced viscosity leads to improved atomization, fuel vaporization and combustion. Cold flow properties such as the cloud point found to be improved after transesterification, but there is no significant change in pour point value before and after transesterification. However, cold flow properties of prepared blends are in the permissible limit of ASTM standards. Higher heating value (HHV) is one of the crucial properties for evaluation of biodiesel, which allows the suitability of fuels as the substitute to conventional diesel fuels. HHV for WCO methyl esters found to be 39.19 MJ/Kg. The result shows that HHV of methyl esters is higher than the raw WCO (Table 3). From Table 3, it could be observed that, as blend percentage in diesel increases the calorific value decreases, due to the low calorific value of WCO biodiesel. Nevertheless, all the estimated blends properties are in the range of reported ASTM standards. Finally, it could be concluded that WCOME and their blend can act as potential candidates to use in a diesel engine.

Engine Performance Characteristics

Initial experiments are conducted for base line studies of the engine using diesel as the fuel, these experiments are followed by testing of different fuel blends. The fuels prepared for the testing purpose are B10 and B15. The same fuel injection pressure of 190 bars and crank position of 23° before the top dead centre (bTDC) has been considered for all blends. Tests are conducted at a rated speed of 1500 rpm while the load has been varied from 0 to 100 % in steps of 20 %. The engine jacket outlet water temperature at no-load condition is considered as the steady-state engine condition for all the blended fuels that are tested as one blends in a day basis, followed by flush off the blend fuel by running the engine on pure diesel for some time. Then the engine performance has been analyzed for a given fuel in terms of brake power (BP), brake thermal efficiency (BTE), brake specific fuel consumption (BSFC), exhaust gas temperature and emissions. Uncertainty involved during these estimations is given in Table 4.

Performance Characteristics

The variation of engine brake power with load for various blends is shown in Fig. 3. This Fig. 3 is necessarily portrays the self-validation of the experiments since the engine runs at a constant speed which in turn produces constant specific brake power at given load.

Thus the power being same for all the blends and diesel, the methodology of experimentation and associated measurements get validated. In present experimentation, governor attached on the camshaft of the engine regulates the flow of fuel to the engine as per load and maintains constant speed. As a result of this, the fuel flow rate supplied to the engine changes. This fact can be observed from Fig. 4, for the same load and power, more fuel is required in case of blends and this requirement also increases with an increase in the percentage of WCOME in diesel. During low load condition, it can be noticed that the brake specific fuel consumption (BSFC) for WCOME is 11 % higher whereas during the high load side, it is 8 % higher with respect to diesel fuel (B0) [26].

Overall increment of 10 % in BSFC with use of WCO biodiesel blends in comparison with base diesel tests [27]. Hence the brake specific fuel consumption is found to be more for the same power in case of the blend. This indicates the higher fuel requirement for a given power, while considering WCOME as the blend with diesel. The major reason of this increment is the lower heating value of WCOME than that of diesel, which in turn reduces the heating value of the mixture. It is worth mentioning that the density and kinematic viscosity of WCOME are higher than those of diesel owing to which higher amount of blended fuel gets passed through the fuel injector [28].

Brake thermal efficiency (BTE) variation with load for pure diesel and WCO biodiesel blendedfuel is plotted in Fig. 5. The BTE is found to be increasing with an increase in load on the engine till a critical vlaue (~80 %) beyond which BTE decreases for all fuels with the further increase in load [29].

This critical load value is found to be independent of the WCOME percentage in the diesel. Moreover, for a given load, BTE decreases with an increase in the blend percentage. The higher fuel economy at lower blended rates, as noticed in Fig. 4 justify the decrement in BTE with an increase in the amount of blend in fuel. Thus the lower heating value along with higher specific gravity and viscosity of WCOME affects air–fuel ratio and lowers the brake thermal efficiency with respect to diesel [30].

The exhaust gas temperature (EGT) is the form of loss of heat produced by combustion of fuel and air mixture in a cylinder. The EGT isan important factor for thermodynamic analysis of the engine used with different fuels. The variation of EGT obtained from the present set of experiments is plotted in Fig. 6. Although less variation in EGT is seen for different blends at low and high load sides, experiements with pure diesel show higher EGT at intermediate loading conditions. The lower EGT of biodiesels for the same brake power and at the cost of higher BSFC is probably due to the poor atomization rate of fuel blends in the combustion chamber due to higher viscosity, specific gravity and poor volatility [31, 32]. Apart from this, the longer ignition delay of diesel results in higher exhaust gas temperature [33].

Emission Characteristics

The emissions of carbon monoxide (CO) with a varying load is described in the Fig. 7. The CO emission is increases with an increase in load on the engine for all fuels. Initial increment in CO emission up to 40 % load is negligible. However, it increases at a higher rate with a further increase in the load. The CO emission is found always higher for diesel fuel, which is around 11.4 % at lower load and 31.67 % at high load conditions in comparison with B15 [32].

The WCO biodiesel–diesels blend and conventional diesel fuel show increase in NOx emission due to increase in load as shown in Fig. 8.This NOx emission is found to be 22.69 and 27.68 % lower in B15 blend on lower and higher load respectively in comparison with base diesel tests. The NOx formation in the diesel engine is strongly dependent on the fuel distribution and its evolution with time [34]. Thus the altered fuel distribution for blended fuels, due to change in physical properties of the fuel alters the percentage of NOx in the exhaust [35].

Apart from this, expected a higher value of the peak cylinder pressure and peak combustion temperature in case of diesel fuel are responsible for higher NOx in exhaust for diesel fuel [36, 37]. They also reported that fuel cetane number and aromatic taste increase NOx in the exhaust.

The effect of B0, B10, B15 fuel blends on CO2 emission is summarized in Fig. 9. CO2 emission increases with an increase in load for any fuel under consideration. Along withthis, it is seen to be lower in WCOME biodiesel-diesel blend with respect to the diesel. In particular, it is 15.77 and 17.6 % lower for B15 at 20 and 80 % loads with respect to diesel emission. These results are in good agreement with the observations of Behcet [38]. Thus the oxygenated biofuel substantially reduces the CO2 emission, mainly at low load conditions [39]. Therefore, this Fig. 9 reconforms the fact that the reduced carbon content in blends is responsible for lower CO2 emission [40].

The hydrocarbon (HC) emission which is mainly the left unburnt fuel varies with the engine loading as shown in Fig. 10. The HC emission initially decreaes with an increase in the load, attains a minimum and then increases with the further increase in engine load for all the fuels under consideration. Consistently it has been observed the HC emission is higher in case of diesel than any blends considered herein. In particular, it is 8.5 and 20 % lower for B15 WCO biodiesel-diesel blend for 40 and 80 % loads with respect to the diesel. Two major reasons can be given for the lowered HC emission in case of blended fuels. Among which one is the expected lower ignition delay of blended fuels than the diesel improcess cetane number, which in turn avoids the accumulation of fuel in the combustion chamber [41–43]. Secondly, biodiesel blends to have higher oxygen availability in the fuel itself so even if the mixture is reached, the HC produced is comparatively less than diesel fuel. As a result of these, exhaust for blends found with lesser HC percentage [44, 45].

Conclusions

An experimental investigation of WCOME blends with conventional diesel is carried out to explore the diesel engine performance and emissions. Results of the study show 2.70 % overall decrease in maximum efficiency and 9.1 % increase in the brake specific fuel consumption for blended fuel B15 compared to diesel fuel. The reduce exhaust gas emission (i.e. CO, HC and CO2) as well as a decrease exhausts gas temperature attributes to the reduce ignition delay during combustion. Prepared blends are found more effective in lowering all the constituents of emission except NOx emission. The increase in the NOx emissions is 0.7 % especially at higher load. Thus the blending of bio-diesel with the conventional diesel is noted to be slightly less economical in terms of fuel consumption, but it is highly desirable to provide cleaner exhaust. Further, techniques such as exhaust gas recirculation can be considered to reduce the NOx emissions.

Abbreviations

- B0, B5:

-

Blend 0 %, blend 5 %

- BP:

-

Brake power

- BSFC:

-

Brake specific fuel consumption

- bTDC:

-

Before top dead centre

- BTE:

-

Brake thermal efficiency

- CNG:

-

Compressed natural gas

- CO:

-

Carbon monoxide

- CO2 :

-

Carbon dioxide

- CR:

-

Compression ratio

- EGT:

-

Exhaust gas temperature

- FFA:

-

Free fatty acids

- HC:

-

Unburnt hydrocarbon

- IC:

-

Internal combustion

- LPG:

-

Liquefied petroleum gas

- NMR:

-

Nuclear magnetic resonance

- NOx:

-

Oxides of nitrogen

- WCO:

-

Waste cooking oil

- WCOME:

-

Waste cooking oil methyl esters

- 1H NMR:

-

Hydrogen 1 nuclear magnetic resonance

References

Borugadda, V.B., Goud, V.V.: Biodiesel production from renewable feedstocks: status and opportunities. Renew. Sustain. Energy Rev. 16(7), 4763–4784 (2012)

Sahoo, P., Das, L., Babu, M., Naik, S.: Biodiesel development from high acid value polanga seed oil and performance evaluation in a CI engine. Fuel 86(3), 448–454 (2007)

Shahid, E.M., Jamal, Y.: A review of biodiesel as vehicular fuel. Renew. Sustain. Energy Rev. 12(9), 2484–2494 (2008)

Balat, M., Balat, H.: A critical review of bio-diesel as a vehicular fuel. Energy Convers. Manag. 49(10), 2727–2741 (2008)

Nabi, M.N., Akhter, M.S., Shahadat, M.M.Z.: Improvement of engine emissions with conventional diesel fuel and diesel–biodiesel blends. Bioresour. Technol. 97(3), 372–378 (2006)

Goering, C.E., Schwab, A.W., Daugherty, M.J., Pryde, E.H., Heakin, A.J.: Fuel properties of eleven vegetable oils. Trans. ASAE 25, 1472–1477 (1982)

Bagby, M.O., Freedman, B., Schwab, A.W.: Seed oils for diesel fuels sources and properties. ASAE Paper, 87-1583 (1987)

Korus, R.A., Moursetis, T.L., Lloyd, L.: Polymerization of vegetable oils. Vegetable Oil Fuel. In: International Conference on Plant and Vegetable Oils as Fuels, St. Joseph, USA (1982)

Vanderwalt, A.N., Hugo, F.J.C.: Attempts to prevent injection coking with sunflower oil by engine modification and fuel additives. Vegetable Oils Fuel. In: International Conference on Plant and Vegetable Oils as Fuels, St. Joseph, USA, pp. 230–238. (1982)

Velgutth, G.: Performance of vegetable oil and their monsters as fuels for diesel engines. SAE Paper, 8313–8358 (1983)

Clark, S., Wagner, L., Schrock, M., Piennaar, P.: Methyl and ethyl soybean esters as renewable fuels for diesel engines. J. Am. Oil Chem. Soc. 61(10), 1632–1638 (1984)

Perkins, L., Peterson, C., Auld, D.: Durability testing of transesterified winter rape oil (Brassica napus L.) as fuel in small bore, multi-cylinder, DI, CI engines. In: SAE Technical Paper (1991)

Pestes, M., Stanislao, J.: Piston ring deposits when using vegetable oil as a fuel. J. Test. Eval. 12(2), 61–68 (1984)

Felderman, Q.M.Z., Peterson, C.L.: Diesel engine durability when fuelled with methyl ester of winter rapeseed oil. ASAE Paper, 881562 (1988)

Leung, D.Y., Wu, X., Leung, M.: A review on biodiesel production using catalyzed transesterification. Appl. Energy 87(4), 1083–1095 (2010)

Silitonga, A., Masjuki, H., Mahlia, T., Ong, H.C., Chong, W.: Experimental study on performance and exhaust emissions of a diesel engine fuelled with Ceiba pentandra biodiesel blends. Energy Convers. Manag. 76, 828–836 (2013)

Jadhav, S.D., Tandale, M.S.: Multi-objective performance optimization of compression ignition engine operated on mangifera indica biodiesel by applying Taguchi grey relational analysis. Waste Biomass Valoriz. 7, 1309–1325 (2016)

An, H., Yang, W.M., Maghbouli, A., Li, J., Chou, S.K., Chua, K.J.: Performance, combustion and emission characteristics of biodiesel derived from waste cooking oils. Appl. Energy 112, 493–499 (2013)

Can, O.: Combustion characteristics, performance and exhaust emissions of a diesel engine fueled with a waste cooking oil biodiesel mixture. Energy Convers. Manag. 87, 676–686 (2014)

Hwang, J., Qi, D., Jung, Y., Bae, C.: Effect of injection parameters on the combustion and emission characteristics in a common-rail direct injection diesel engine fueled with waste cooking oil biodiesel. Renew. Energy 63, 9–17 (2014)

Mazumdar, P., Borugadda, V.B., Goud, V.V., Sahoo, L.: Physico-chemical characteristics of Jatropha curcas L. of North East India for exploration of biodiesel. Biomass Bioenergy 46, 546–554 (2012)

Borugadda, V.B., Goud, V.V.: Thermal, oxidative and low temperature properties of methyl esters prepared from oils of different fatty acids composition: a comparative study. Thermochim. Acta 577, 33–40 (2014)

Chaudhari, A.J., Kulkarni, V., Sahoo, N.: Performance assessment of octane fuels on a variable compression ratio spark ignition In: Paper presented at the International conference on theoretical, applied, computational and experimental mechanics, IIT Kharagpur

Sharma, Y.C., Singh, B., Korstad, J.: High yield and conversion of biodiesel from a nonedible feedstock (Pongamia pinnata). J. Agric. Food Chem. 58(1), 242–247 (2009)

Kaya, C., Hamamci, C., Baysal, A., Akba, O., Erdogan, S., Saydut, A.: Methyl ester of peanut (Arachis hypogea L.) seed oil as a potential feedstock for biodiesel production. Renew. Energy 34(5), 1257–1260 (2009)

Sahoo, B., Sahoo, N., Saha, U.: Effect of engine parameters and type of gaseous fuel on the performance of dual-fuel gas diesel engines—a critical review. Renew. Sustain. Energy Rev. 13(6), 1151–1184 (2009)

Chokri, B., Ridha, E., Rachid, S., Jamel, B.: Experimental study of a diesel engine performance running on waste vegetable oil biodiesel blend. J. Energy Res. Technol. 134(3), 032202 (2012)

Nabi, M.N., Hoque, S.N., Akhter, M.S.: Karanja (Pongamia Pinnata) biodiesel production in Bangladesh, characterization of karanja biodiesel and its effect on diesel emissions. Fuel Process. Technol. 90(9), 1080–1086 (2009)

Bousbaa, H., Sary, A., Tazerout, M., Liazid, A.: Investigations on a compression ignition engine using animal fats and vegetable oil as fuels. J. Energy Res. Technol. 134(2), 022202 (2012)

Chattopadhyay, S., Sen, R.: Fuel properties, engine performance and environmental benefits of biodiesel produced by a green process. Appl. Energy 105, 319–326 (2013)

Enweremadu, C., Mbarawa, M.: Technical aspects of production and analysis of biodiesel from used cooking oil—a review. Renew. Sustain. Energy Rev. 13(9), 2205–2224 (2009)

Hirkude, J.B., Padalkar, A.S.: Performance and emission analysis of a compression ignition: engine operated on waste fried oil methyl esters. Appl. Energy 90(1), 68–72 (2012)

Usta, N., Ozturk, E., Can, O., Conkur, E., Nas, S., Con, A., Can, A., Topcu, M.: Combustion of biodiesel fuel produced from hazelnut soapstock/waste sunflower oil mixture in a diesel engine. Energy Convers. Manag. 46(5), 741–755 (2005)

Heywood, J.B.: Internal Combustion Engine Fundamentals. McGraw Hill International Editions, New York (1988)

Rakopoulos, C., Antonopoulos, K., Rakopoulos, D., Hountalas, D., Giakoumis, E.: Comparative performance and emissions study of a direct injection diesel engine using blends of diesel fuel with vegetable oils or bio-diesels of various origins. Energy Convers. Manag. 47(18), 3272–3287 (2006)

Huang, J., Wang, Y., Qin, J.B., Roskilly, A.P.: Comparative study of performance and emissions of a diesel engine using Chinese pistache and jatropha biodiesel. Fuel Process. Technol. 91(11), 1761–1767 (2010)

Abu-Jrai, A., Yamin, J.A., Ala’a, H., Hararah, M.A.: Combustion characteristics and engine emissions of a diesel engine fueled with diesel and treated waste cooking oil blends. Chem. Eng. J. 172(1), 129–136 (2011)

Behçet, R.: Performance and emission study of waste anchovy fish biodiesel in a diesel engine. Fuel Process. Technol. 92(6), 1187–1194 (2011)

Guo, Z., Li, T., Dong, J., Chen, R., Xue, P., Wei, X.: Combustion and emission characteristics of blends of diesel fuel and methanol-to-diesel. Fuel 90(3), 1305–1308 (2011)

Muralidharan, K., Vasudevan, D., Sheeba, K.: Performance, emission and combustion characteristics of biodiesel fuelled variable compression ratio engine. Energy 36(8), 5385–5393 (2011)

Karavalakis, G., Tzirakis, E., Stournas, S., Zannikos, F., Karonis, D.: Biodiesel emissions from a diesel vehicle operated on a non-legislative driving cycle. Energy Sour. Part A: Recovery Utilization Environ. Effects 32(4), 376–383 (2009)

Wu, F., Wang, J., Chen, W., Shuai, S.: A study on emission performance of a diesel engine fueled with five typical methyl ester biodiesels. Atmos. Environ. 43(7), 1481–1485 (2009)

Lue, Y.F., Yeh, Y.Y., Wu, C.H.: The emission characteristics of a small DI diesel engine using biodiesel blended fuels. J. Environ. Sci. Health Part A 36(5), 845–859 (2001)

Xue, J., Grift, T.E., Hansen, A.C.: Effect of biodiesel on engine performances and emissions. Renew. Sustain. Energy Rev. 15(2), 1098–1116 (2011)

Cubio, G.M., Capareda, S.C., Alagao, F.B.: Real-time analysis of engine power, thermal efficiency, and emission characteristics using refined and transesterified waste vegetable oil. J. Energy Res. Technol. 136(3), 032201 (2014)

Acknowledgments

Authors VBB and AKP thank CIF, IIT Guwahati for furnishing NMR facility and FIST, DST, SR/FST/ETII-028/2010 for interfacial rheometer and Center of Excellence for Sustainable Polymers (CoE, SusPol) at IIT Guwahati for providing analytical facilities to perform this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Borugadda, V.B., Paul, A.K., Chaudhari, A.J. et al. Influence of Waste Cooking Oil Methyl Ester Biodiesel Blends on the Performance and Emissions of a Diesel Engine. Waste Biomass Valor 9, 283–292 (2018). https://doi.org/10.1007/s12649-016-9749-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9749-0