Abstract

The purpose was to investigate the treatability of a wastewater from a biodiesel production industry under (1) aerobic conditions, using domestic activated sludge as inoculum; (2) anaerobic conditions, using sludge from an anaerobic domestic wastewater treatment digester; (3) utilization of wastewater for biogas production. The aerobic biodegradation batch tests were conducted in reactors with a working volume of 1.0 L, according to Zahn Wellens’s methodology proposed by the Organization for Economic Co-operation and Development. The anaerobic treatability was determined by the methodology proposed by Field et al. (4º Seminario de Depuración anaerobia de aguas residuales, Valladolid Universidad, Secretariado de Publicaciones, Valladolid, 1988). Based on the results of anaerobic biodegradation, four new reactors with a working volume of 1.0 L were inoculated to evaluate the biogas production potential. The experiments showed that wastewater can be degraded under aerobic conditions with no lag-phase. COD maximum concentration of 780 mg L−1 could be metabolized aerobically. The anaerobic biodegradation only started after the adaptation phase (3 days). After 28 days, it was possible to achieve removal efficiencies above 90 % for the conditions applied in anaerobic tests. It was possible to obtain 114 mL of biogas for the highest influent COD concentration of 800 mg L−1 and F/M ratio = 0.25.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

The world energy matrix is mainly composed of non-renewable resources, especially fossil fuels. Due to the escalating costs associated with the increase of crude oil prices and also to the concern with problems related to the emission of greenhouse gases, alternative energy sources are sought in an attempt to gradually overcome dependency on fossil fuels on a global scale.

In 2004, the Brazilian government launched the National Program for Biodiesel Production (NPBP) and stated that this biofuel could replace, partially or completely, mineral diesel. The addition of biodiesel in Brazil was legally established in 2008. Initially, the mandatory blend was 2 % and it was increased, year by year, to 5 % in 2010, which currently corresponds to a production of 2.4 billion L per year. The NPBP gives special value to the participation of small producers of castor and palm oil from the poorest regions of the country. This means that social inclusion and consideration of ecological reality are found, although the program also requires quality assurance and the ability to compete. Nowadays, Brazil is the second largest producer and consumer of biodiesel in the world.

The process of biodiesel production is usually carried out by catalysed transesterification with alcohol, most likely methanol. Alkalis (sodium hydroxide, potassium hydroxide, carbonates, and corresponding sodium and potassium alkoxides), acids (sulphuric acid, sulphonic acid or hydrochloric acid), or enzymes can be used to catalyse the reaction. Transesterification using alkali catalysis is a useful method that enables a high conversion of triglycerides (oils) to fatty acid methyl esters (BDF) by a simple chemical reaction in a short time, and thus is most often used commercially [1, 2]. In the reaction of transesterification, triglycerides are converted into glycerol and methyl esters (biodiesel), which are separated from the heavier glycerol phase (crude glycerine) by settling. Crude biodiesel is subsequently washed to remove the impurities, soaps, short chain fatty acids and excess methanol, generating the washing water as another pollutant by-product [2].

The amount of effluent generated in biodiesel production plants is strongly influenced by the production method used to obtain the biofuel. According to Suehara et al. [1], when using the transesterification process, for each 100 L of biodiesel, 20 L of effluent is generated. Kolesárová et al. [2] state that, depending on the washing method utilised, up to 300 L of effluent can be generated for each 100 L of biodiesel produced. Considering the qualitative aspects, wastewater from biodiesel production has a high organic load and pH value (when alkaline catalysis is used), a considerable concentration of oils, fats and suspended solids, and low nitrogen and phosphorus concentrations [3, 4].

Part of the success of wastewater treatment processes is determined by the physicochemical characterisation of the effluent. Generally, characterisation studies are limited to the examination of non-specific organic material in the form of biochemical oxygen demand (BOD) or chemical oxygen demand (COD), total or suspended solids, nitrogen compounds, phosphorus and chloride, among others. Although COD is the most appropriate parameter for characterising and quantifying the organic matter present in wastewater, this statement is only of practical manner, since the concentration of COD provides no information about the biodegradability or the identity of the pollutants present in a specific wastewater sample. In this case, one can apply sophisticated analytical techniques such as gas or liquid chromatography and mass spectrometry, or even perform biodegradability tests.

There are a variety of methods for assessing the biodegradability of wastewater. Typically, aerobic biodegradability may be determined from the Zahn-Wellens method, which consists of operating batch reactors with constant aeration and monitoring the decrease of the sample substrate concentration of the initial reactors fed with sample, nutrient solution and sludge as inoculum [5]. On the other hand, anaerobic biodegradation may be evaluated by monitoring methane gas production using the specific methanogenic activity test, or by monitoring the depletion of substrate concentration during degradation of organic matter by microorganisms in batch reactors under controlled temperature [5–7].

Because of the potential energy of biogas utilisation, anaerobic digestion is a possible way to revalorise industrial wastewater. Besides this, anaerobic digestion shows other advantages that include low levels of biological sludge, low nutrient requirements and high efficiency. Applying anaerobic methanogenic digestion for the treatment of wastewater generated in the production of biodiesel can contribute to the energy sustainability of the industrial process as a whole, in that the biogas may serve as a substitute for natural gas or liquefied natural gas, since it can be further upgraded to become clean vehicle fuel, or it can be directly utilised in combined heat and power units (CHP) [8].

Therefore, the purpose of this study was to evaluate aerobic and anaerobic treatability and potential biogas production from wastewater generated in a biodiesel production industry, located in the city of Candeias, Bahia, Brazil.

Methods

Substrate and Inoculum

The industrial effluent samples were collected downstream of the flotation unit in the Biodiesel Wastewater Treatment Plant of Candeias. In general, this substrate was rich in biodiesel, traces of oil, glycerol, water, methanol, salts and free fatty acids. Following collection, samples were stored at 4 °C until their utilisation. The aerobic sludge used as inoculum in the biodegradability batch tests was collected from an activated sludge reactor of Vog Ville, Lauro de Freitas wastewater treatment plant (WWTP). This is a small WWTP (12°53′41′′ S and 38°19′03′′ O) that treats the domestic wastewater produced by a community of approximately 1000 inhabitants. The sludge age was equal to 10 days and the main characteristics of the aerobic sludge were: pH value of 7.6, TSS of 2.1 g L−1 and VSS of 1.1 g L−1. The anaerobic sludge came from an Upflow Anaerobic Sludge Blanket (UASB) reactor installed at the same location since 2009. The hydraulic residence time of this reactor is between 6.5 and 8 h and the sludge age is equal to 28 days. The main characteristics of the anaerobic sludge were: pH value of 7.1, TSS of 3.4 g L−1 and VSS of 1.7 g L−1. After obtaining the sludge samples in 20 L plastic drums, the fresh aerobic sludge sample was washed with tap water and centrifuged for 10 min at 400 rpm; the fresh anaerobic sludge was washed and separated from liquid by settlement for 24 h.

Initially, the samples of effluent were characterised for pH, total alkalinity, COD, dissolved COD, chloride, total nitrogen and total suspended solids. All analyses were performed according to the recommendations of the Standard Methods for the Examination of Water and Wastewater [9]. Table 1 shows the characteristics of the samples.

Specifically during biodiesel production, the raw material used in the transesterification considerably affects the characteristics of the waste generated. Physicochemical characterisation (Table 1) indicated that the industrial effluent had high concentrations of COD, total organic carbon (TOC), solids and chlorides, which are likely to seriously compromise the efficiency of the biological treatment.

Aerobic and Anaerobic Biodegradability Tests

The experiment was conducted in two phases, based on a 2k full factorial design. The conditions applied in each experiment were modified using different combinations of the two selected levels. The first one involved the study of the effects of two factors (substrate, F, and microorganism, M, concentration) at two levels in order to obtain high COD removal (response variable) for aerobic and anaerobic biodegradability at the end of the experiments. Then, after characterising the organic matter content of the wastewater (COD concentration) and determining the VSS content of the sludge, the proportion of effluent and sludge was calculated in order to establish a ratio between 0.25 and 4.0. Table 2 shows the conditions applied during biodegradability tests.

In the second phase, biogas production was evaluated based on levels of the factors which provided the best COD removal in the anaerobic biodegradability tests. Therefore, two other levels were chosen to compare. Minitab® 16 Statistical Software was used to design graphs of the statistical analysis. Analysis of variance (ANOVA) was used for estimating the effects of COD removal. Normality was investigated by a normal probability plot of the residuals. Main and interaction effects were evaluated by the probability (P value) with a 95 % confidence level.

Aerobic and anaerobic biodegradability were monitored by COD soluble analyses performed throughout the study. The samples were collected from each reactor using a syringe and filtered in membrane filters of cellulose nitrate (porosity 0.45 µm). The volume removed for analysis did not exceed 10 % of the working volume of the reactors in any of the tests.

The degradation at a given time was calculated using Eq. 1:

CA = COD concentration after (3 h ± 30 min) incubation; Ct = COD concentration at time t; CBA = COD concentration of the control experiment after (3 h ± 30 min) incubation; CB = COD concentration of the blank control experiment at time t

The aerobic biodegradation batch tests were performed in reactors with a working volume of 1.0 L according to the Zahn-Wellens methodology proposed by the Organisation for Economic Co-operation and Development (OECD). Eight reactors were filled with sludge, previously centrifuged, and substrate, respecting the F/M ratios described in Table 2, and a mineral nutrient solution prepared according to the Zahn-Wellens methodology (Table 3). The mineral medium was prepared from those solutions by mixing 10 mL of solution with 1.1 mL of solutions 2, 3 and 4 and distilled water to complete to 1.0 L [5]. Blank controls containing only sludge and mineral nutrients were monitored in parallel with the tests. The reactors were covered with dark plastic to prevent direct incidence of light. A ceramic air stone diffuser connected to a small air pump was placed within each reactor in an attempt to spread the air and ensure mixing of the solution. The pH value was checked on each day of sampling and maintained between 6.5 and 8.0 with solutions of NaOH and H2SO4. The process was monitored until the end of the depletion of the substrate concentration through periodic analysis of COD.

Anaerobic biodegradability was determined by monitoring consumption of the substrate using the methodology proposed by Field et al. [10]. The reactors only filled with the sludge were thoroughly washed and 100 mL of nutrient solution were kept at rest for 7 days at room temperature, in order to eliminate the production of biogas originating from endogenous respiration. After the incubation period, the produced gas was purged, and then a solution comprising distilled water and industrial wastewater was added in order to meet the set F/M ratio described in Table 2. All flasks were stanched with rubber septa, sealed and stored at rest in a container with a mercury bulb thermometer to monitor the temperature (28 ± 1 °C) in the dark. The literature reports that anaerobic biodegradability testing should be performed within the range 30–35 °C to allow methanogenic microorganisms to have the best growing conditions. However, anaerobic reactors in full scale wastewater treatment plants are submitted to different environmental conditions and rarely operate in the ideal temperature range for methanogenic activity. Therefore, to make the process as close as possible to the reality found in a biodiesel industry wastewater treatment plant, the tests were performed at room temperature. Immediately after collection of samples for quantification of COD, manual agitation of the reactors was performed. COD removal was monitored for 28 days.

Two stock solutions (Table 4) were prepared to ensure the presence of essential nutrients for the biodegradation process The nutrient solution added to the anaerobic reactors was made by addition of 2 mL of the micronutrient solution, 200 mL of the macronutrient solution and distilled water to complete to 1 L.

The tests conducted to determine the biogas production potential were performed only after obtaining the results for anaerobic biodegradability. F/M ratio equal to 0.25 (800 mg L−1 of COD, 12 mL substrate amount, and 3200 mg L−1 of VSS, 40 g inoculums amount) and two other ratios, that were chosen to compare the performance of the process, equal to 0.1 (320 mg L−1 of COD, 5 mL substrate amount, and 3200 mg L−1 of SSV) and 0.05 (160 mg L−1 of COD, 2 mL substrate amount, and 3200 mg L−1 of VSS). Therefore, three new reactors with a working volume of 1.0 L were inoculated to evaluate the biogas production potential, under the same conditions of the first anaerobic biodegradability tests. A blank experiment was performed that allowed evaluation of the production of biogas derived from the degradation and cell lysis of microorganisms (endogenous respiration). The volume of accumulated biogas over time (28 days) was obtained by monitoring the pressure in the headspace of the reactors using a digital pressure transducer coupled to a metallic needle. The total pressure value of the reactors containing the wastewater was subtracted from the pressure value of the blank control at the end of the tests. The determination of the biogas volume generated in the reactor was calculated taking as a starting point the ideal gas equation, which allows relating the five parameters involved in the experiment, pressure (P), volume (V), number of substance (n), universal gas constant (R) and temperature (T).

Starting from Eq. 2, a hypothetical volume change (ΔV) in the reactor, i.e. the volume of biogas produced in the reactor under the experimental conditions, that results in the Eq. 3.

P is the pressure in the headspace of each reactor (mbar), Patm is the absolute pressure (1013.25 mbar) and V0 is volume of the headspace (mL). The gas composition was obtained at the end of experiment using a portable gas monitor (CH4, CO2, O2), model GEM™ 2000, with an accuracy of 0.5 ± 0.1 mbar.

Results and Discussion

Aerobic Biodegradation Batch Tests

The experiments showed that wastewater from biodiesel production can be degraded under aerobic conditions using activated sludge from a domestic wastewater treatment plant as inoculum. Figure 1 shows the COD concentration of filtered aliquots during the aerobic biodegradability tests.

The results show that the COD decreases until reaching the minimum point of degradation. After 40 h of tests, there was an increase of COD, probably due to the production of microbial soluble compounds that are associated with the decay mechanism and cell lysis. This phenomenon begins when there is a low F/M ratio and substrate limitation, in association with an increase in active biomass degradation.

It is noteworthy that over 70 % of the organic matter present in the biodiesel wastewater was degraded in the first 15 h of tests with no lag phase. In fact, in almost all tests, it was possible to obtain greater than 90 % removal of COD concentration after 15 h of aeration (Fig. 2) with a maximum substrate removal rate of 39 mg L−1 h−1. An aqueous solution can already be considered to be biodegradable, as a COD fraction greater than 70 % was removed [5]. After 40 h, all the tests presented COD removal values above 97 %. The results confirmed that, under the experimental conditions applied with a maximum COD concentration of 780 mg L−1, wastewater from biodiesel production can be degraded under aerobic conditions using activated sludge from a domestic wastewater treatment plant as inoculum with no lag phase. Suehara et al. [1] observed efficiencies of organic matter removal superior to 98 % after 48 h of aeration using biodiesel wastewater diluted with the same volume of water. However, these authors did not observe degradation when they provided wastewater without dilution to the microorganisms, probably because of growth inhibition caused by soap present in the waste oil. Siles et al. [11] also observed an inhibitory effect on aerobic biodegradation of glycerol caused by long-chain fatty acids. Therefore, our results suggest that the physicochemical pre-treatment to remove oil and fats improved the efficiency of the biological treatment and, considering the results obtained by Suehara et al. [1], should be a required step of the wastewater treatment process.

Our results also showed that the higher the F/M ratio, the smaller the percentage of COD removal in a short period of time. Aerobic biodegradation of wastewater coming from biodiesel production applying an aeration time of less than 41 h requires F/M ratios smaller than 0.32 to increase the efficiency of the process (Fig. 1). On the other hand, the results of ANOVA showed that the main effects of substrate (Food, F) and microorganism (M) concentrations, and the effect of interaction between them, were not significant for COD removal. However, although these factors are not significant, observing the main effects plot (data means) (Fig. 3), the slope of the plot indicates a positive effect on the response variable, decreasing the concentration of factors (F and M).

The F/M ratio is a widely adopted parameter, but it is also often set by experience during operation. The procedure for controlling the F/M ratio is based on the adjustment of the influent load of the substrate as a function of the concentration of biomass (VSS) present in the reactor. In this case, the monitoring process is essential for its appropriate performance. Nonetheless, the results permit us to conclude that the choice of an aerobic route can provide stability to the wastewater treatment process. This is particularly important in the production of biodiesel, since the raw material used in transesterification can be altered by environmental or economic reasons and that decision affects the production process and consequently the qualitative and quantitative characteristics of the wastewater generated.

Anaerobic Biodegradability Tests

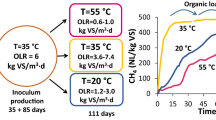

Figure 4 shows COD concentrations during the anaerobic biodegradation tests of the wastewater from biodiesel production. In contrast to the aerobic tests, the results indicate that within the first 72 h, the removal of organic matter is limited in the majority of the anaerobic tests (Fig. 5). At longer test times, COD concentrations started to decrease, suggesting slow adaptation of the biomass. Such inhibition of anaerobic degradation may be caused by methanol; however, that was not expected. In fact, previous studies indicate that methanol has been added as a co-substrate to improve the anaerobic biodegradation of various different complex substrates, such as phenolic wastewater [12, 13]. Wang et al. [14] stated that the presence of methanol can reduce the toxicity of wastewater from coke production. Confirming this statement, after the adaptation period (10 days), the soluble COD concentration began to reduce and it was possible to observe the production of biogas in the reactors.

Inhibitory substances are often found to be the leading cause of anaerobic reactor upset and failure since they are present in substantial concentrations in wastewater and sludge. It is important to state that chlorides are formed during the acid neutralisation step with hydrochloric acid (HCl) since alkaline compounds are used as reaction catalysts and must be neutralised to prevent the formation of soaps. The chloride ion (Cl−) binds to the cation of the catalyst providing saline in the wash water [2]. The characterisation tests of wastewater from biodiesel production have shown chloride concentrations between 750 and 1916 mg L−1. Some researchers have shown that the chloride concentrations required to cause inhibition of methanogenesis can range from 5 to 9 g L−1 [15–17]. Although the chloride concentrations found in the wastewater used in this study were smaller, they may have been responsible for the lag phase observed in the tests. Our experimental observations correspond to the explanation from Riffat and Krongthamchat [17] that observed a long period of anaerobic biomass acclimation in highly saline wastewater at 25 °C. Therefore, the process of biodiesel manufacture and biological treatment of biodiesel wastewater should be undertaken under optimum operating conditions for its suitable performance.

From the 22nd day of tests, it was observed that the concentration of COD reduced significantly. At the same time, the reactors had become less and less pressurised. Only after 27 days, near the end of the tests, did the COD values remain almost constant. Siles et al. [11] reported 100 % anaerobic biodegradability of a mixture of glycerol-containing waste and wastewater derived from the manufacture of biodiesel with a mean value of 0.378 g COD, between 18 and 45 h. In their study, a step of biomass acclimatisation was carried out before the batch experiments. Therefore, the acclimatisation is an important step for active anaerobic biomass prior to exposure to the substrate present in wastewater originating from biodiesel production.

According to Fig. 5, all F/M ratios applied resulted in COD removal above 90 %. The F/M ratio equal to 0.25 resulted in maximum efficiency of COD removal, above 96 %. ANOVA showed that the main effect of substrate concentration (Food) (P value = 0.507) and the effect of interaction between Food and Microorganism concentrations (VSS) (P value = 0.292) were not significant for COD removal. Observing the main effects plot (data means) (Fig. 6), increasing factor M and decreasing factor F results in an increase of COD removal efficiency, which confirms the results of the tests.

During the second phase of experiments, the biogas production was evaluated for an F/M ratio equal to 0.25, 0.1 and 0.05. It is emphasised that we carried out a new series of tests to detect biogas production, i.e. the sludge used had not yet been exposed to wastewater from biodiesel production. As shown in Fig. 7, the slope of the curves for COD removal demonstrates similar behaviour to the results from the anaerobic tests. After 23 days, there was an increase in COD concentrations.

Figure 8 shows the net production of biogas in the second phase. The cultures exerted more than 90 % of the total biogas production during the first 21 days. The results seem to confirm a certain inhibition of the process in the first 3 days. It was possible to obtain 114 mL of biogas in the 165 mL headspace for the highest influent COD concentration of 800 mg L−1 and a F/M ratio of 0.25. The results for gas composition obtained at the end of the experiment for this F/M ratio indicated that the CH4 content of the biogas produced from wastewater of a biodiesel industry was 84 ± 4 %, i.e. 96 NmL of CH4. Considering the biomass growth and cell maintance null, 354 NmL of CH4 are theoretically produced per gram of CODremoved [18]. In experimental terms, the methane yield coefficient was found to be 161 NmL of CH4 per gram of CODremoved. The effectiveness of the process was 60 % meaning that most of the CODremoved is employed for methane production and the microbial metabolism is primarily oriented towards generating gas. The operating records of the Candeias WWTP since 2009 report that the influent flow rate is equal to 49 ± 8 cubic meters per day, the concentration of COD is equal to 11,830 ± 1220 mg L−1 and COD removal efficiency in the UASB reactor is equal to 60 ± 12 % (mean value and standard deviation). Therefore, considering such information, theoretically, it can be expected a minimum production of methane gas equal to 33,617 NL per day, which may represent a minimum level of energy production equal to 1204 MJ per day or 334.6 kWh daily.

In Brazil, the full scale recovery of biogas and/or methane gas as an electric source is still incipient. Unfortunately, the few systems deployed using internal combustion engines or generating microturbines for conversion. These equipments present low conversion efficiency (approximately 35 % for internal combustion engines and 26 % for microturbines). On the other hand, since 2012, the Brazilian legislation guarantees consumers the right to generate their own electricity from renewable sources and provide the excess to the local electrical grid. Some requirements must be observed—i.e. generation sources need to be renewable or energy efficient that is based on hydro, solar, wind or biomass.

A Brazilian ethanol industry has reported a successful experiment using cogeneration from sugarcane bagasse and states that the energy has been marketed for U$29.00 per MW (unpublished data). Taking into account this information and our results, the attractiveness of the commercialization of electric energy generated from anaerobic digestion of wastewater from Candeias biodiesel production industry is very low. For example, if the biodiesel industry chooses to use internal combustion engines for the conversion of methane into electrical energy, only 117.1 kWh would be generated daily or 42.7 MW per year. This value results in a gross income equal to U$1239.00 per year that certainly does not cover operating expenses arising from the capture, purification and use of the biogas.

On the other hand, under environmental perspective, it is not acceptable the release of 8.8 tons per year of methane generated by the anaerobic digestion of the biodiesel industry effluent. This is equal to 184 tCO2equ. Concerned about such aspects, the Candeias biodiesel industry is developing actions to reduce its global CO2 emissions. One of the alternatives under consideration, it is trading Emission Reduction Certificates in the international Carbon Credit Market. The Kyoto Protocol provides for three flexible mechanisms to assist Annex-I countries into achieve their reduction targets set. Clean Development Mechanisms (CDM) projects are the only ones applicable to Brazil and this country ranks third in the world among the countries participating in this market, with about 5 % of the world total and 268 projects Therefore, the results of our tests encourages the implementation of a full-scale research protocol to assess the quantity and quality of biogas generated in the Candeias WWTP and evaluate the implementation costs of a process of purification and use of these biogas for electricity generation considering a cost-benefit analysis.

Figure 9 shows the volume of methane accumulated (G) as a function of time for different concentrations of substrates added to the reactors. In order to characterise each set of experiments kinetically, the methane production first order kinetic model described by Borja et al. [19] was used to fit the experimental data. According to this model, the volume of methane accumulated (G) (mL at 1 atm, 25 °C) at a given time t (h) fits the following equation:

where Gm is the maximum methane volume accumulated at an infinite digestion time, G is zero at t = 0 and the rate of gas production becomes zero at t = infinity. \( {\text{K}}_{\text{G}}^{\prime} \) is an apparent kinetic constant for methane production (h−1) which includes the biomass concentration:

where KG is the specific methane production kinetic constant (L g VSS−1 h−1) and X is the biomass concentration (g VSS L−1).

Equation 4 shows a good fit with the experimental data. Thus, it is correct to apply the proposed kinetic model to all the loads studied. The values of \( {\text{K}}_{\text{G}}^{\prime} \) and Gm for each reactor were calculated numerically from the experimental data obtained by non-linear regression using Excel® and Minitab®. Once the biomass concentration values were determined, the values of KG were calculated using Eq. 5. Table 5 shows the Gm, \( {\text{K}}_{\text{G}}^{\prime} \) and KG values obtained in the experiments.

Moreover, the theoretical values of Gm were plotted against their corresponding experimental values (Fig. 10). In almost all cases, deviations obtained were lower than 5 %, confirming that the model can be used to accurately predict the behaviour of the process and that the kinetic parameters satisfactorily represented the anaerobic digestion of the effluent.

Comparison between the experimental maximum methane production (Gt) values and the theoretical values (Gm) predicted by Eq. (4): a Reactor 1; b reactor 2; c reactor 3

Conclusions

Considering the results of the anaerobic and aerobic biodegradation tests using the industrial effluent generated in a biodiesel production plant located in Candeias, Bahia, Brazil, it can be concluded that:

-

The effluent has high biodegradability in both aerobic and anaerobic environments, indicating that organic material present in industrial wastewater is subject to degradation in biological treatment processes.

-

In most aerobic tests, it was possible to obtain removal of COD concentration greater than 90 % after 15 min of aeration. After 40 h, all the tests presented COD removal values above 97 %. The substrate utilisation rate (SUR) tests ranged between 0.11 and 0.19 mg COD (g VSS day−1) with no lag phase.

-

Degradation of the substrate by anaerobic sludge from a UASB reactor which treats domestic wastewater was only possible after a faster adaptation period of 3 days. After 28 days, it was possible to achieve removal efficiencies above 90 % for the conditions applied in anaerobic tests.

-

It can be stated that anaerobic treatment presents a viable alternative for the treatment of wastewater from biodiesel production, yielding significant energy recovery in the form of methane gas.

References

Suehara, K., Kawamoto, Y., Fuji, E., Khoda, J., Nakano, Y., Yano, T.: Biological treatment of wastewater discharged from biodiesel fuel production plant with alkali-catalyzed transesterification. J. Biosci. Bioeng. 100, 437–442 (2005)

Kolesárová, N., Hutňan, M., Bodík, I., Špalková, V.: Utilization of biodiesel by-products for biogas production. J. Biomed. Biotechnol. 2011, 1–15 (2011)

Jaruwat, P., Kongjao, S., Hunsom, M.: Management of biodiesel wastewater by the combined processes of chemical recovery and electrochemical treatment. Energy Convers. Manag. 53, 531–537 (2010)

Rattanapan, C., Sawain, A., Suksaroj, C.: Enhanced efficiency of dissolved air flotation for biodiesel wastewater treatment by acidification and coagulation processes. Desalination 280, 370–377 (2011)

Organization for Economic Co-operation and Development (OECD): Guideline for Testing of Chemicals, 302 B. Zahn-Wellens/EMPA Test (1992)

Guwy, A.J.: Equipment used for testing anaerobic biodegradability and activity. Rev. Environ. Sci. Biotechnol. 3, 131–139 (2004)

Massardier-Nageotte, V., Pestre, C., Cruard-Pradet, T., Bayard, R.: Aerobic and anaerobic biodegradability of polymer films and physico-chemical characterization. Polym. Degrad. Stab. 91, 620–627 (2006)

Antonopoulou, G., Alexandropoulou, M., Lytras, C., Lyberatos, G.: Modeling of anaerobic digestion of food industry wastes in different bioreactor types. Waste Biomass Valoriz. 6, 335–341 (2015)

American Public Health Association (APHA), American Water Works Association (AWWA), Water Environment Federation (WEF): Standard Methods for the Examination of Water and Wastewater, 22nd edn., Washington (2012)

Field, J., Sierra-Alvárez, R., Lettinga, G.: Ensayos anaerobios. In: University of Valladolid (ed.) 4º Seminario de Depuración anaerobia de aguas residuales, pp. 52–80. Valladolid Universidad, Secretariado de Publicaciones, Valladolid (1988)

Siles, J.A., Martin, M.A., Chica, A.F., Martin, A.: Anaerobic co-digestion of glycerol and wastewater derived from biodiesel manufacturing. Bioresour. Technol. 101, 6315–6321 (2010)

Field, J.A., Alfons, J.M.S., Kato, M., Schraa, G.: Enhanced biodegradation of aromatic pollutants in cocultures of anaerobic and aerobic bacterial consortia. A. Van Leeuw. J. Microb. 67, 47–77 (1995)

Razo-Flores, E., Iniestra-González, M., Field, J.A., Olguín-Lora, P., Puig-Grajales, L.: Biodegradation of mixtures of phenolic compounds in an upward-flow anaerobic sludge blanket reactor. J. Environ. Eng. 129, 999–1006 (2003)

Wang, W., Han, H., Yuan, M., Li, H.: Enhanced anaerobic biodegradability of real coal gasification wastewater with methanol addition. J. Environ. Sci. 22, 1868–1874 (2010)

Vijayaraghavan, K., Ramanujam, T.K.: Effect of chloride and condensable tannin in anaerobic degradation of tannery wastewaters. Bioprocess Eng. 20, 499–503 (1999)

Ito, T., Nakashimada, Y., Senba, K., Matsui, T., Nishio, N.: Hydrogen and ethanol production from glycerol-containing wastes discharges after biodiesel manufacturing process. J. Biosci. Bioeng. 100, 260–265 (2005)

Riffat, R., Krongthamchat, K.: Specific methanogenic activity of halophilic and mixed cultures in saline wastewater. Int. J. Environ. Sci. Technol. 2, 291–299 (2006)

Tchobanoglous, G., Burton, F.L., Stensel, H.D.: Wastewater Engineering: Treatment and Reuse, 4th edn. Metcalf & Eddy Inc., McGraw-Hill Book Company, New York (2003)

Borja, R., Martín, A., Alonso, V., García, I., Banks, C.J.: Influence of different pretreatments on the kinetics of anaerobic digestion of olive mill wastewater. Water Res. 29, 489–495 (1995)

Acknowledgments

The authors would like to thank the Foundation for Research Support of the Bahia State and The Center for Research and Development Leopoldo Américo Miguez de Mello (PETROBRAS®) for financial and material support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Queiroz, L.M., Nascimento, I.O.C., de Melo, S.A.B.V. et al. Aerobic, Anaerobic Treatability and Biogas Production Potential of a Wastewater from a Biodiesel Industry. Waste Biomass Valor 7, 691–702 (2016). https://doi.org/10.1007/s12649-016-9536-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-016-9536-y