Abstract

The new definition of the kilogram was implemented on May 20, 2019. The kilogram is presently defined by a fixed value of the Planck constant. On the basis of the new definition, the kilogram will be realized at the National Metrology Institute of Japan by the X-ray crystal density method using 28Si-enriched spheres. For the realization, the volume of 28Si-enriched spheres is measured by optical interferometry. The sphere surface characterization by X-ray photoelectron spectroscopy and ellipsometry is also performed. The relative standard uncertainty of the realization is estimated to be 2.4 × 10−8. Details of the realization and future dissemination of mass standards in Japan based on the 28Si-enriched spheres are described.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

On May 20, 2019, the International System of Units (SI) was essentially revised. Presently, all SI units are defined in terms of the seven defining constants [1]. In the new SI, the kilogram, the unit of mass, is defined by fixing the value of the Planck constant. Under the new definition, it is in principle possible for each national metrology institute to realize the kilogram independently. To ensure the consistency among the realizations by national metrology institutes, an international comparison of the realizations based on the new definition, CCM.M-K8.2019, is presently organized by the Consultative Committee for Mass and Related Quantities. This comparison is an essential step to the dissemination of the kilogram based on the individual realization by each national metrology institute [2].

There are currently two independent methods that are capable of realizing the definition of the kilogram with relative uncertainties within a few parts in 108 [3]. The first of these relies on determining the unknown mass using an electromechanical balance specially designed for the purpose. The second method compares the unknown mass to the mass of a single atom of a specified isotope by counting the number of atoms in a crystal, where the mass of the atom is well-known in terms of the Planck constant. The second method is referred to as the X-ray crystal density (XRCD) method. After the confirmation of the international consistency of the realizations, the National Metrology Institute of Japan (NMIJ) will realize the kilogram on the basis of the new definition by the XRCD method. This method realizes the kilogram at a nominal mass of 1 kg using 28Si-enriched spheres [4, 5]. Details of the realization at NMIJ and future dissemination of mass standards in Japan based on the 28Si-enriched spheres are described in this paper.

2 X-ray Crystal Density (XRCD) Method

In the XRCD method, the number N of Si atoms in a Si sphere is counted by measuring its volume VS and lattice constant a [4, 5]. The number N is given by

where 8 is the number of atoms per unit cell of crystalline silicon. The mass of the sphere mS is therefore expressed by

where m(Si) is the mass of a single Si atom. The new definition of the kilogram is based on the Planck constant h. The relationship between the Planck constant h and the mass of a single electron m(e) is given by

where c is the speed of light in vacuum, α is the fine-structure constant and R∞ is the Rydberg constant [6]. The mass of a single Si atom m(Si) is related to m(e) by

where Ar(e) and Ar(Si) are the relative atomic masses of electron and Si, respectively. Silicon has three stable isotopes, 28Si, 29Si and 30Si. The value of Ar(Si) can therefore be determined by measuring the isotopic amount-of-substance fraction of each isotope. The relationship between m(Si) and h is given by

By combining Eqs. (1), (2) and (5), we can express the sphere mass ms in terms of h using

Equation (6) is established when the Si sphere consists of only Si crystal. However, the surface of Si spheres is covered by a surface layer mainly consisting of amorphous SiO2 [7]. Figure 1 shows the surface model of 1 kg 28Si-enriched spheres manufactured from a silicon crystal highly enriched with the 28Si isotope produced by the International Avogadro Coordination (IAC) project [8]. This surface model under vacuum was derived on the basis of surface characterization using various analysis techniques developed by the IAC project [7, 8]. In addition to the oxide layer (OL), a chemisorbed water layer (CWL) and a carbonaceous layer (CL) are also present. The CWL is a chemically absorbed water layer that remains under high vacuum conditions. The CL is a carbonaceous contamination layer formed by different adsorbed gases and contaminants, stemming from the environment during the measurement, handling, storage and cleaning of the sphere. These layers are hereinafter referred to as the surface layer (SL). Equation (6) should therefore be modified to

where mcore and Vcore are the mass and volume of the “Si core” part, which excludes the surface layer, respectively, and mdeficit is the effect of point defects (i.e., impurities and self-point defects in the crystal) on the core mass [9]. The mass of the sphere msphere including the mass of the surface layer mSL is given by

The relative uncertainty of R∞/(α2Ar(e)) is estimated to be 4.0 × 10−10 [10] and the values of h and c are exactly defined in the new SI [1]. The values of a, Ar(Si) and mdeficit of the two 1 kg 28Si-enriched spheres, AVO28-S5c and AVO28-S8c, were already measured by the IAC project with relative undercities at the level of 10−9 [9, 11], and it is confidently believed that these parameters are constant over the years. There is no known mechanism that changes those parameters when the Si crystal is kept close to room temperature. The kilogram can therefore be realized by measuring Vcore and mSL of the 28Si-enriched spheres at NMIJ [4, 5]. Details of the measurements for the realization are described in the following sections.

3 Procedure of Realization of the Kilogram at NMIJ

The two 28Si-enriched spheres, AVO28-S5c and AVO28-S8c, used for the realization of the kilogram at NMIJ were manufactured by the IAC project. The masses of the spheres are almost 1 kg, and details of the spheres are described in [8, 9].

To measure the sphere core volume Vcore in Eq. (7), an optical interferometer for measuring the sphere diameter is used. However, the diameter measured by the optical interferometer is slightly different from the core diameter owing to the surface layer shown in Fig. 1. To calculate the core diameter from the measured diameter, the thickness of the surface layer is required. For the thickness measurement, an X-ray photoelectron spectroscopy (XPS) system and a spectroscopic ellipsometer are used. The surface mass, mSL in Eq. (8), is derived from the surface characterization. Details of each measurement apparatus are presented in the following sections.

3.1 Sphere Volume Measurement by Optical Interferometry

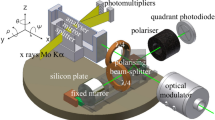

Figure 2 shows a schematic drawing of the optical interferometer used to determine the volume of the 28Si-enriched sphere by optical frequency tuning [12, 13]. A 28Si-enriched sphere is placed in a fused-quartz Fabry–Perot etalon. The sphere and etalon are installed in a vacuum chamber equipped with an active radiation shield to control the sphere temperature. The pressure in the chamber is reduced to 10−2 Pa. Two beams (Beam 1 and Beam 2) from an external cavity diode laser are irradiated onto the sphere from opposite sides of the etalon. The light beams reflected from the inner surface of the etalon plate and the adjacent surface of the sphere interfere to produce concentric circular fringes. These are projected onto CCD cameras. The fractional fringe order of interference for the gaps between the sphere and the etalon, d1 and d2, are measured by phase-shifting interferometry [14, 15]. The sphere diameter D is calculated as D = L − (d1 + d2), where L is the etalon spacing. To determine L, the sphere is removed from the light path by a lifting device installed underneath the sphere, and Beam 1 is interrupted by a shutter. Beam 2 passes through a hole in the lifting device, and the beams reflected from the two etalon plates produce fringes on a CCD camera. The fringes are also analyzed by phase-shifting interferometry. The sphere volume is determined from the mean diameter calculated on the basis of the diameter measurement from many different directions. The phase shifts required for phase-shifting interferometry are produced by changing the optical frequency of the diode laser. The optical frequency is controlled on the basis of the optical frequency comb, which is used as the national length standard of Japan [16, 17]. Details on the volume measurement are given in [12,13,14].

Reused with the permission from IEEE [12]

Schematic drawing of the optical interferometer used to measure the volume of the 28Si sphere. The 28Si sphere and etalon are installed in a vacuum chamber equipped with an active radiation shield to control the sphere temperature. The uncertainty of the sphere temperature measurement is estimated to be 0.62 mK.

The temperature of the sphere is measured using small platinum resistance thermometers (PRTs) inserted into copper blocks that come in contact with the sphere. The copper blocks are coated with polyether ether ketone (PEEK) to prevent damage of the silicon sphere. The PRTs are calibrated using temperature fixed points in ITS-90 [18]. The measured diameters are converted to those at 20.000 °C using the thermal expansion coefficient of the enriched 28Si-enriched crystal [19].

A sphere rotation mechanism installed under the sphere is used to measure the diameter from many different directions. In a set of diameter measurements, the diameter is measured from 145 directions distributed near-uniformly on the sphere surface [4]. Ten sets diameter measurement are performed, and between each set, the sphere is rotated to distribute the starting point of each set of measurements to the vertices of a regular dodecahedron. Because the ten directions defined by the vertices of a regular dodecahedron are uniformly distributed, the procedure therefore distributes all of the measurement points as uniformly as possible. The total number of the measurement directions is therefore 1450. The sphere volume is calculated from the mean diameter.

As an example of the results of the diameter measurement, the Mollweide map projection of the distribution of the diameter based on the 145 directions for AVO28-S5c is shown in Fig. 3 [4]. The three-dimensional plot of the diameter is displayed in Fig. 4, where the deviation from the mean diameter is enhanced.

Reused with the permission from IEEE [4]

Mollweide map projection of the distribution of the diameter based on 145 directions for AVO28-S5c.

Reused with the permission from IEEE [12]

Three-dimensional plot of the distribution of the diameter of AVO28-S5c. The peak-to-valley value of the diameter is 69 nm.

A different type optical interferometer for the volume measurement of 28Si-enriched spheres has been developed at the Physikalisch-Technische Bundesanstalt (PTB, Germany) [20]. Figure 5 shows a comparison of the mean diameters of a 28Si-enriched sphere measured at PTB and NMIJ. In the interferometer developed at PTB, an etalon with spherical reference surfaces is used. The mean diameters obtained using the two interferometers with different optical configurations and phase-shifting algorithms show excellent agreement within their uncertainties [12]. This shows the high reliability of the diameter and volume measurements at the two national metrology institutes.

Reused with the permission from IEEE [12]

Comparison of the mean diameters of a 28Si-enriched sphere measured at PTB and NMIJ. The difference from the weighted mean diameter Dwm calculated from the diameters measured at the two national metrology institutes is plotted. The horizontal error bars indicate the standard uncertainty of each value.

3.2 Sphere Surface Characterization by XPS and Ellipsometry

X-ray photoelectron spectroscopy (XPS) and ellipsometry are used for the sphere surface characterization at NMIJ. The main component of the XPS system is ULVAC-Phi 1600C equipped with a monochromatic Al Kα X-ray source. The pressure in the XPS chamber is reduced to 5.0 × 10−7 Pa. A manipulator with a five-axis freedom is installed in the XPS chamber to realize the rotation of the sphere around the horizontal and vertical axes for the mapping of the entire surface. The sphere is placed on two rollers of the manipulator during the measurement. The rollers are made of polyimide for protecting the sphere surface from damage during the rotation. Details of the XPS system are given in [21].

The main component of the spectroscopic ellipsometer is Semilab GES5E. Its spectral bandwidth ranges from 250 to 990 nm. The ellipsometer and an automatic sphere rotation system are integrated to a vacuum chamber to characterize the surface layer in vacuum, where the pressure is reduced to 1 × 10−3 Pa. The ellipsometric measurement can be carried out over the entire sphere surface using the automatic sphere rotation system. Details of the ellipsometer are provided in [22].

The thickness of the CL and OL at 52 points on the sphere surface is measured using the XPS system. The 52 points are distributed near-uniformly on the sphere surface [4]. The ellipsometer is used to examine the uniformity of the thickness of the OL at 812 points on the sphere surface [4].

Table 1 shows an example of the results of the surface characterization, where the thicknesses of all sublayers of AVO28-S5c measured in 2017 are tabulated. The thickness of the CWL estimated from the water adsorption coefficient to silicon surface reported in our previous work [23] is also listed in this table. The total thickness of the surface layer is about 3 nm.

3.3 Mass of Surface Layer

The mass of the surface layer mSL is given by

where mOL, mCL and mCWL are the masses of the OL, CL and CWL, respectively. The masses are calculated from the thickness and density of each sublayer. The masses of all sublayers of AVO28-S5c measured in 2017 [4] are summarized in Table 1 with the density and thickness of each sublayer. The mass of the surface layer was determined to be about 120 μg with an uncertainty of 8.9 μg.

3.4 Volume of Si Core

The volume measured by the optical interferometer is slightly different from the core volume owing to the surface layer shown in Fig. 1. To determine the Si core volume, the total phase retardation on reflection at the sphere surface δ is calculated from the thickness and optical constants of each sublayer on the basis of the procedure in [14]. The value of δ is slightly smaller than π, and the effect of this phase shift on the gap measurement Δd is calculated using Δd = λ (δ − π)/(4π). This means that the actual diameter Dactual including the surface layer is larger than the apparent diameter measured by optical interferometry Dapp by − 2Δd. The phase shift correction to obtain the Si core diameter from the apparent diameter, Δd0, was determined using Δd0 = − (2Δd + dtotal), where dtotal is the sum of the thicknesses of all sublayers. The Si core diameter Dcore is determined using Dcore = Dapp + Δd0.

3.5 Mass Deficit

Owing to point defects and impurities, there is a mass difference between a sphere having Si atoms occupying all regular sites and the real sphere [9]. The mass difference, mdeficit in Eq. (7), is given by

where m28 and mi are the mass of a 28Si atom and that of the point defect named i, respectively. For a vacancy, mi = mv = 0. For interstitial point defects, mi is the sum of the masses of the defect and a 28Si atom. Ni is the concentration of the point defect i. For example, mdeficit of AVO28-S5c was estimated to be 3.6(3.6) μg [9].

3.6 Mass of Si Sphere

The sphere mass msphere is derived by using Eqs. (7) and (8) from the Planck constant, realizing the new definition of the kilogram. As an example, the uncertainty budget of the determination of msphere using AVO28-S5c in 2017 is shown in Table 2 [4]. This determination was performed for a pilot study to compare the realizations of the kilogram by several national metrology institutes on the basis of the Planck constant in CODATA 2014 [24]. The values of a and Ar(Si) of AVO28-S5c were measured with relative uncertainties of 1.8 × 10−9 and 5.4 × 10−9, respectively, by the IAC project [9, 11]. The relative uncertainty of msphere was 2.4 × 10−8. From this result, the relative uncertainty of the realization of the new kilogram is therefore estimated to be 2.4 × 10−8, corresponding to 24 µg for 1 kg.

The largest uncertainty source for the realization is the sphere volume determination by optical interferometry, as shown in Table 2. For the more accurate realization at NMIJ, the optical interferometer is being improved [12]. This improvement will reduce the relative uncertainty of the realization of the kilogram will be reduced to 1.7 × 10−8, corresponding to 17 µg for 1 kg.

4 Dissemination of the Mass Unit Based on the 28Si-Enriched Spheres

Figure 6 shows the traceability chain of mass standards planned at NMIJ after the consistency of individual realizations of the kilogram by national metrology institutes is confirmed. The masses of the 28Si-enriched spheres are determined by the XRCD method on the basis of the Planck constant as described in the previous sections. On the basis of the masses of the 28Si-enriched spheres, the masses of 1 kg platinum–iridium weights and 1 kg stainless steel weights in air and vacuum are determined. These 1 kg weights will form an ensemble of reference mass standards and maintain the value of the realized kilogram at NMIJ.

The mass differences between the 28Si-enriched spheres and the 1 kg weights are measured by using a mass comparator installed in a vacuum chamber, which enables mass comparisons at a constant atmospheric pressure or under vacuum [25]. Owing to density differences among silicon, stainless steel and platinum–iridium, the 28Si-enriched spheres and the 1 kg weights have different volumes. This requires air buoyancy corrections in the mass difference measurement. For the precise air buoyancy correction, artifacts are used to accurately determine the air density [26]. The artifacts are a pair of weights that are equal in mass and surface area but different in volume. Furthermore, the masses of the 28Si-enriched spheres and the 1 kg weights in air and those under vacuum are different owing to the difference in the amount of adsorbed water onto their surfaces. For the precise estimation of this sorption effect, a pair of weights that are equal in mass and volume but different in surface area are used [27].

5 Small Mass Measurement Based on the Planck Constant

Under the previous definition of the kilogram, the metrological traceability of mass measurements was secured by using standard weights whose masses were measured on the basis of the international prototype of the kilogram. However, obtaining a standard weight with a mass less than 1 kg usually requires submultiples of a primary 1 kg standard. Each time a mass is subdivided, the relative uncertainty of the mass of the weights calibrated by the subdivision process accrues progressively.

On the other hand, the new definition enables us to realize the kilogram using any measurement technique that relates the Planck constant to the kilogram [3]. Mass in any range can therefore be directly measured on the basis on the definition of the kilogram without using the standard weights. An example of such measurement techniques is the use of an electrostatic force balance for mass measurements in mg range [28]. In this technique, electrostatic force is generated and is balanced with the gravity force acting on a sample, where the electrostatic force is measured on the basis of the Planck constant and the elementary charge. The electrostatic force balance can therefore realize the kilogram in the new SI [1] without using the standard weights. Recently, Shaw et al., have extended the measurement range by this technique to μg range [29]. At NMIJ, Yamamoto et al. have developed an electrostatic force balance for mass measurements in sub-mg range [30]. This balance will be also used for the realization of the kilogram at NMIJ in the future.

6 Conclusion

Under the new definition of the kilogram based on the Planck constant, it is in principle possible for each national metrology institute to realize the kilogram independently. After the confirmation of the international consistency of the individual realizations by national metrology institutes, NMIJ will realize the new kilogram by the XRCD method, where two 28Si-enriched spheres manufactured by the International Avogadro Coordination project are used. The masses of the two spheres are almost 1 kg, and the relative standard uncertainty of the realization is estimated to be 2.4 × 10−8, corresponding to 24 μg for 1 kg. On the basis of the spheres, the masses of weights consisting of the NMIJ ensemble of reference mass standards are measured. The ensemble will be used for dissemination of mass standards to scientific and industrial fields in Japan.

References

The International System of Units (SI), 9th edition, Bureau International des Poids et Mesures (2019) https://www.bipm.org/utils/common/pdf/si-brochure/SI-Brochure-9-EN.pdf.

CCM detailed note on the dissemination process after the redefinition of the kilogram, https://www.bipm.org/utils/common/pdf/CC/CCM/CCM_Note-on-dissemination-after-redefinition.pdf.

Mise en pratique for the definition of the kilogram in the SI, https://www.bipm.org/utils/en/pdf/si-mep/SI-App2-kilogram.pdf.

N. Kuramoto, L. Zhang, S. Mizushima, K. Fujita, Y. Azuma, A. Kurokawa and K. Fujii, Realization of the kilogram based on the Planck constant at NMIJ, IEEE Trans. Instrum. Meas., 66 (2017) 1267–1274.

K. Fujii, H. Bettin, P. Becker, E. Massa, O. Rienitz, A. Pramann, A. Nicolaus, N. Kuramoto, I. Busch and M. Borys, Realization of the kilogram by the XRCD method, Metrologia, 53 (2016) A19–A45.

P. Cladé, F. Biraben, L. Julien, F. Nez and S. Guellati-Khelifa, Precise determination of the ratio h/mu: a way to link microscopic mass to the new kilogram, Metrologia, 53 (2016) A75–A82.

I. Busch, Y. Azuma, H. Bettin, L. Cibik, P. Fuchs, K. Fujii, M. Krumrey, U. Kuetgens, N. Kuramoto and S. Mizushima, Surface layer determination for the Si spheres of the Avogadro project, Metrologia, 48 (2011) S62–S82.

B. Andreas, Y. Azuma, G. Bartl, P. Becker, H. Bettin, M. Borys, I. Busch, P. Fuchs, K. Fujii, H. Fujimoto, E. Kessler, M. Krumrey, U. Kuetgens, N. Kuramoto, G. Mana, E. Massa, S. Mizushima, A. Nicolaus, A. Picard, A. Pramann, O. Rienitz, D. Schiel, S. Valkiers, A. Waseda and S. Zakel, Counting the atoms in a 28Si crystal for a new kilogram definition, Metrologia, 48 (2011) S1–S13.

Y. Azuma, P. Barat, G. Bartl, H. Bettin, M. Borys, I. Busch, L. Cibik, G. D’Agostino, K. Fujii, H. Fujimoto, A. Hioki, M. Krumrey, U. Kuetgens, N. Kuramoto, G. Mana, E. Massa, R. Meeß, S. Mizushima, T. Narukawa, A. Nicolaus, A. Pramann, S. A. Rabb, O. Rienitz, C. Sasso, M. Stock, R. D. Vocke Jr, A. Waseda, S. Wundrack and S. Zakel, Improved measurement results for the Avogadro constant using a 28Si-enriched crystal, Metrologia, 52 (2018) 360–375.

CODATA International recommended 2018 values of the Fundamental Physical Constants, https://physics.nist.gov/cuu/Constants/index.html.

G. Bartl, P. Becker, B. Beckhoff, H. Bettin, E. Beyer, M. Borys, I. Busch, L. Cibik, G. D’Agostino, E. Darlatt, M. Di Luzio, K. Fujii, H. Fujimoto, K. Fujita, M. Kolbe, M. Krumrey, N. Kuramoto, E. Massa, M. Mecke, S. Mizushima, M. Müller, T. Narukawa, A. Nicolaus, A. Pramann, D. Rauch, O. Rienitz, C. P. Sasso, A. Stopic, R. Stosch, A. Waseda, S. Wundrack, L. Zhang and X. W. Zhang, A new 28Si single crystal: counting the atoms for new kilogram definition, Metrologia, 54 (2017) 693–715.

N. Kuramoto, L. Zhang, K. Fujita, S. Okubo, H. Inaba and K. Fujii, Volume measurement of a 28Si-enriched sphere for a determination of the Avogadro constant at NMIJ, IEEE Trans. Instrum. Meas., 68 (2019) 1913–1920.

N. Kuramoto, S. Mizushima, L. Zhang, K. Fujita, Y. Azuma, A. Kurokawa, S. Okubo, H. Inaba and K. Fujii, Determination of the Avogadro constant by the XRCD method using a 28Si-enriched sphere, Metrologia, 54 (2017) 716–729.

N. Kuramoto, K. Fujii and K. Yamazawa, Volume measurements of 28Si spheres using an interferometer with a flat etalon to determine the Avogadro constant, Metrologia, 48 (2011) S83–S95.

B. Andreas, L. Ferroglio, K. Fujii, N. Kuramoto and G. Mana, Phase corrections in the optical interferometer for Si sphere volume measurements at NMIJ, Metrologia, 48 (2011) S104–S111.

H. Inaba, Y. Daimon, F. L. Hong, A. Onae, K. Minoshima, T. R. Schibli, H. Matsumoto, M. Hirano, T. Okuno, M. Onishi and M. Nakazawa, Long-term measurement of optical frequencies using a simple, robust and low-noise fiber based frequency comb, Opt. Express 14 (2006) 5223–5231.

H. Inaba, Y. Nakajima, F. L. Hong, K. Minoshima, J. Ishikawa, A. Onae, H. Matsumoto, M. Wouters, B. Warrington and N. Brown, Frequency measurement capability of a fiber-based frequency comb at 633 nm, IEEE Trans. Instrum. Meas., 58 (2009) 1234–1240.

H. Preston-Thomas, The international temperature scale of 1990 (ITS-90), Metroloiga, 27 (1990) 3–10.

G. Bartl, A. Nicolaus, E. Kessler, R. Shödel and P. Becker, The coefficient of thermal expansion of highly enriched 28Si, Metrologia, 48 (2011) S104–S111.

A. Nicolaus, G. Bartl, A. Peter, E. Kuhn and T. Mai, Volume determination of two spheres of the new 28Si-crystal of PTB, Metrologia, 54 (2017) 512–515.

L. Zhang, N. Kuramoto, Y. Azuma, A. Kurokawa and K. Fujii, Thickness measurements of oxide and carbonaceous layer on a 28Si sphere by using XPS, IEEE Trans. Instrum. Meas., 66 (2017) 1297–1303.

K. Fujita, N. Kuramoto, Y. Azuma, S. Mizushima and K. Fujii, Surface layer analysis of a 28Si-enriched sphere both in vacuum and in air by ellipsometry, IEEE Trans. Instrum. Meas., 66 (2017) 1283–1288.

S. Mizushima, Determination of the amount of gas adsorption on SiO2/Si(100) surfaces to realize precise mass measurement, Metrologia, 41 (2004) 137–144.

M. Stock, P. Barat, P. Pinot, F. Beaudoux, P. Espel, F. Piquemal, M. Thomas, D. Ziane, P. Abbott, D. Haddad, Z. Kubarych, J. R. Pratt, S. Schlamminger, K. Fujii, K. Fujita, N. Kuramoto, S. Mizushima, L. Zhang, S. Davidson, R. G. Green, J. Liard, C. Sanchez, B. Wood, H. Bettin, M. Borys, I. Busch, M Hämpke, M. Krumrey and A. Nicolaus, A comparison of future realizations of the kilogram, Metroloiga, 55 (2018) T4–T7.

S. Mizushima, N. Kuramoto, L. Zhang and K. Fujii, Mass measurement of 28Si-enriched spheres at NMIJ for the determination of the Avogadro constant, IEEE Trans. Instrum. Meas., 66 (2017) 1275–1282.

S. Mizushima, M. Ueiki and K. Fujii, Mass measurement of 1 kg silicon spheres to establish a density standard, Metrologia, 41 (2004) S68–S74.

S. Mizushima, K. Ueda, A. Ooiwa and K. Fujii, Determination of the amount of physical adsorption of water vapour on platinum-iridium surfaces, Metrologia, 52 (2015) 522–527.

G. Shaw, J. Stirling, J. A. Kramar, A. Moses, P. Abbot, R. Steiner, A. Koffman, J. R. Pratt and Z. Kubarych, Milligram mass metrology using an electrostatic force balance, Metrologia, 53 (2016) A86–A94.

G. A. Shaw, J. Stirling, J. Kramar, P. Williams, M. Spidell and R. Mirin, Comparison of electrostatic force and photon pressure force references at the nanonewton level, Metrologia, 56 (2019) 025002.

Y. Yamamoto, K. Fujita and K. Fujii, Development of a new apparatus for SI traceable small mass measurements using the voltage balance method at NMIJ, IEEE Trans. Instrum. Meas. (2020). https://doi.org/10.1109/tim.2020.3001408.

Acknowledgements

This research work was partly supported by JSPS KAKENHI Grant Numbers 24360037, 16H03901 and 20H02630.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Kuramoto, N., Mizushima, S., Zhang, L. et al. Realization of the New Kilogram Using 28Si-Enriched Spheres and Dissemination of Mass Standards at NMIJ. MAPAN 35, 491–498 (2020). https://doi.org/10.1007/s12647-020-00393-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12647-020-00393-2