Abstract

Hydrogen is a promising candidate for clean and sustainable energy resources to substitute fossil fuels to mitigate global environmental issues. Electrochemical hydrogen production has been regarded as a viable and promising strategy. The overall water splitting is currently the predominant electrochemical hydrogen production method, which could be driven by renewable energy to achieve sustainable production. However, the current challenges are the intrinsically sluggish and energy-intensive oxygen evolution reduction (OER) at the anode and the expensive noble metal-based catalysts for overall water splitting, which limit the practical applications. Extensive efforts have been made to develop bifunctional non-noble metal-based electrocatalysts to boost hydrogen production efficiency and lower the cost. Meanwhile, alternative oxidation reactions with faster kinetics and less energy requirement than OER are being explored as the anodic reaction to couple with the hydrogen evolution reaction for energy-saving hydrogen production. In this review, the non-noble metal-based bifunctional electrocatalysts for overall water splitting, as well as other novel energy-saving hydrogen productions have been introduced and summarized. Current challenges and outlooks are commented on at the end of the article.

Graphical abstract

摘要

氢气是清洁和可持续能源, 也是替代化石燃料从而缓解全球环境问题的最佳候选。电化学制氢被认为是一种可行且具备应用前景的重要策略。目前, 电化学催化水分解是目前最主要的电化学制氢方法, 该方法可以由可再生能源驱动从而实现可持续产氢过程。然而, 当前水分解催化制氢面临的挑战是阳极的析氧还原不仅动力学缓慢而且需要较高的过电势来驱动反应进行, 一般需要昂贵稀少的贵金属基催化剂来实现水分解制氢, 从而限制了大规模的工业应用前景。目前, 科学界已经进行了广泛的研究来开发双功能非贵金属基电催化剂用于水分解, 从而提高制氢效率并降低成本。与此同时, 作为与析氢反应耦合以实现高效节能制氢的阳极反应, 探索具有比析氧还原反应具有更快动力学和更少能量需求的替代氧化反应也成为了新的研究重点。在该综述中, 我们对于可用于整体水分解的非贵金属基双功能电催化剂进行了分类与总结, 并对其他新型可用于高效水分解制氢的替代氧化过程进行了介绍, 并在最后对当前的电化学制氢催化剂所面临的挑战和未来发展方向进行了全面的展望。

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

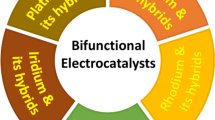

Under the global warming crisis, tremendous efforts have been devoted to the development of clean and sustainable energy resources to substitute fossil fuels. Electrochemical storage devices and energy conversion systems are regarded as promising alternatives to mitigate fossil fuels-related problems. Renewable energy can be produced from wind, thermal, or solar sources and stored in devices such as metal-air batteries, fuel cells, and electrolytic cells [1,2,3]. Hydrogen is considered as a promising candidate for energy storage and conversion to replace fossil fuels, due to its zero CO2 emission in production and application and high energy density [4, 5]. Electrochemical overall water splitting has been considered as a suitable technique to produce H2. It is noteworthy that efficient electrocatalysts are demanded since the sluggish kinetics and high thermodynamic barriers of oxygen evolution reduction (OER) are the bottlenecks of the as-mentioned energy devices. Currently, Pt-group metals are the most effective catalysts for hydrogen evolution reaction (HER) while the benchmark catalysts for OER are Ir/Ru-based compounds [1, 6]. However, the scarcity and high cost of these metals and their stability issues in reaction conditions severely limit their widespread use. Therefore, earth-abundant metal electrocatalysts have been extensively researched in recent years to address the limits of noble metals [7]. Recently, bifunctional electrocatalysts have also raised much research interest (Fig. 1a [8]). Bifunctional electrocatalysts can simplify the reaction system design and lower the cost of catalyst synthesis [9, 10]. For instance, it is difficult to pair two electrocatalysts together in an integrated electrolyzer for practical use, because of the mismatch of working pH ranges of the two electrocatalysts. In other words, the maximum catalytic activities and durabilities of the electrocatalysts are not fully exploited. In comparison, developing bifunctional electrocatalysts, especially the non-noble metal-based ones, is critical to the practical implementation of electrochemical energy devices.

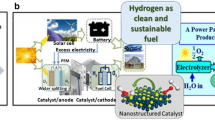

Reproduced with permission from Ref. [8]. Copyright 2019, Elsevier B.V. b Schematic illustration of integrated HER and biomass valorization. Reproduced with permission from Ref. [11]. Copyright 2016, American Chemical Society

a Schematic illustration of an electrolytic cell and possible bifunctional electrocatalysts containing elements.

Although non-noble metal-based bifunctional catalysts for overall water splitting have been extensively studied, the intrinsic sluggish kinetics and high energy barriers in OER severely hinder the efficiency of H2 production from the water splitting process. In recent years, alternative oxidation reactions with faster kinetics and lower thermodynamic barriers than OER are proposed to couple with HER for more effective hydrogen production (Fig. 1b [11]), which also requires the corresponding bifunctional catalysts. In this article, bifunctional electrocatalysts for water splitting and novel hydrogen production process replacing OER will be briefly reviewed to summarize the recent advances in this topic, which will be helpful for the potentially interested researchers. Based on the results discussed, the current challenges will be pointed out briefly, and the future outlooks of non-noble metal bifunctional electrocatalysts for H2 production will also be presented.

2 Bifunctional metal-based electrocatalysts for water splitting

Hydrogen production by electrochemical water splitting is regarded as a promising strategy for sustainable energy storage and substitute of fossil fuels [12]. Developing highly efficient and low-cost electrocatalysts to replace the noble-metal-based ones is vital to the large-scale implementation of hydrogen energy devices. Bifunctional electrocatalysts for both HER and OER are favorable for the overall water splitting systems, which not only promote the performance of systems but also simplify the system design. In recent years, earth-abundant transition metal-based compounds have been extensively explored and employed as the bifunctional electrocatalysts for overall water splitting, such as transition metal sulfides, phosphides, oxides or hydroxides, nitrides, carbides, and their mix.

2.1 Transition metal oxide-based electrocatalysts

Transition metal oxides (TMO) with the spinel structure (AB2O4) have been demonstrated to have high electrocatalytic activity due to the various oxidation states, high conductivity, and excellent structural durability [10, 13].

Wang et al. [14] reported the improvement of catalytic activity when transition metal oxide (Fe, Co, Ni oxides and their mixed oxides) nanoparticles (~ 20 nm) are electrochemically transformed into ultra-small diameter (2–5 nm) nanoparticles, which can serve as an efficient and durable bifunctional water splitting catalyst in alkaline conditions. The nanoparticle size reduction was conducted through lithium-induced conversion reactions (Fig. 2a–f). This method maintains excellent electrical interconnection among nanoparticles and results in large surface areas and numerous catalytically active sites, which is different from most traditional chemical synthesis. The lithium-induced ultra-small NiFeOx nanoparticles achieved 10 mA·cm−2 water splitting current at only 1.51 V for over 200 h without degradation in a two-electrode configuration and 1 mol·L−1 KOH, demonstrating the excellent bifunctional catalytic activity and stability for overall water splitting in base. This work also first demonstrated that a single transition metal oxide could be an efficient bifunctional catalyst for both HER and OER [14,15,16,17]. Morphology control is another important and effective strategy for developing transition metal oxides-based water splitting bifunctional catalysts. For instance, Elakkiya et al. [18] fabricated a flower-like hierarchical nanoporous nickel–cobalt oxide (NP-NiCo2O4) for electrochemical water splitting reactions under alkaline solution. The NP-NiCo2O4 displayed a high mass activity (83.3 A·g−1) with low overpotentials (360 mV@10 mA·cm−2 and 370 mV@10 mA·cm−2 for OER and HER, respectively) and small Tafel slopes. The Ni-substitution in Co3O4 spinel system modifies the surface and electronic band structures, leading to high porosity, abundant active sites, and rapid electron transfer kinetics, resulting in the substantial enhancement of electrocatalytic activities for both OER and HER. Tahir et al. [19] reported a novel hybrid of Co3O4 embedded in tubular nanostructures of graphitic carbon nitride (GCN) and synthesized through a facile, large-scale chemical method at low temperature. Owing to the high surface area, unique tubular nanostructure and composition of the hybrid, all redox sites are easily available for catalysis and provide faster ionic and electronic conduction. The Co3O4@GCN tubular nanostructured (TNS) hybrid exhibited the lowest overpotential (0.12 V) and excellent current density (147 mA·cm−2) in alkaline OER, better than the benchmarks IrO2 and RuO2. The hybrid also demonstrated remarkable performance in HER, with a much lower onset and overpotential and a stable current density. Zhang et al. [20] reported that regulating crystal structure and atomic arrangement in single-component metal oxides significantly enhanced the electrocatalytic activity toward the overall water splitting (Fig. 2g–i). Single-component transition metal oxide (TMO: FeOx, NiOx, or CoOx) nanosheets grown on nickel foam (NF) were electrochemically optimized with Li ion (Na ion)-induced conversion reactions for bifunctional electrocatalyst. Among all the candidates, FeOx/NF-Li exhibited the optimum performance for both HER (239 mV overpotential at 100 mA·cm−2) and OER (276 mV overpotential at 100 mA·cm−2). By using FeOx/NF-Li as both the anode and cathode, the two-electrode water splitting cell achieved a current density of 10 mA·cm−2 with only a cell voltage of 1.60 V. The remarkable water splitting performance is attributed to the Li-induced electrochemical conversion, which alters the crystal structure and introduces O vacancies, creating more active sites and increasing the electron density and conductivity. Moreover, the coordination of Fe is regulated from tetrahedral to octahedral, which reduces Gibbs free energy for the rate-determining steps. Li et al. [21] fabricated a bifunctional water splitting catalyst by growing amorphous Co and Fe oxide on two-dimensional (2D) black phosphorus (BP) (CoFeO@BP), which could form an adaptive surface structure under the reduction and oxidation conditions (Fig. 2j). The amorphous CoFe oxide is in a metastable state. During HER, the CoFe oxide reacts with BP to in situ form CoFe phosphide, which acts as the real active center for HER. While in OER, the CoFe oxide with abundant oxygen vacancies drives OER via the lattice oxygen oxidation mechanism (LOM), which can effectively bypass the energy unfavorable adsorbate evolution mechanism (AEM) at higher pH. These intriguing properties of CoFeO@BP and novel mechanisms result in the remarkable catalytic activity for overall water splitting, which requires a cell voltage of only 1.58 V to reach 10 mA·cm−2 in 1.0 mol·L−1 KOH. The performance comparison is shown in Table 1 [14, 16, 18, 19, 21].

Reproduced with permission from Ref. [14]. Copyright 2015, the Author(s). g LSV curve of two-electrode setup with bifunctional catalysts for overall water splitting in 1 mol·L−1 NaOH and (inset) optical image of O2 and H2 bubble generated at FeOx/NF-Li anode and cathode, respectively; h chronoamperometry of water electrolysis at a cell voltage of 1.63 V for FeOx/NF-Li; i mechanism schematic illustration for OER and HER on FeOx/NF-Li. Reproduced with permission from Ref. [20]. Copyright 2020, American Chemical Society. j proposed mechanism of adaptive bifunctional amorphous CoFeO@BP electrocatalyst for overall water splitting. Reproduced with permission from Ref. [21]. Copyright 2020, Wiley–VCH GmbH

Schematic illustration of TMO morphology evolution under galvanostatic cycles: a–e TMO particles gradually change from single-crystalline to ultra-small interconnected crystalline NPs; f galvanostatic cycling profile of CoO/CNF galvanostatic cycling.

Briefly, the limited exposed active sites and low electric conductivity of transition metal oxides are the barriers to be overcome for the development of transition metal oxide-based bifunctional water splitting catalysts. Besides the strategies reviewed above, combined with conductive materials to form heterostructure electrocatalyst is another promising solution.

2.2 Transition metal sulfide-based electrocatalysts

The outstanding physical and chemical properties of transition metal sulfides (TMSs) have raised tremendous research interest, and TMS-based compounds have been extensively applied as bifunctional catalysts in overall water splitting. TMS-based compounds generally possess better electrical conductivity compared to transition metal oxides, which guarantees faster electron transfer kinetics intrinsically [22].

The bifunctional TMS-based electrocatalysts can be generally categorized into layered TMS (MS2: M = Mo, W, Ta, etc.) and non-layered TMS (MxSy: M = Fe, Co, Ni, etc.). The layered TMS have been extensively studied as robust alternatives for noble metals as the HER electrocatalysts [23,24,25,26,27,28,29]. However, their intrinsic OER activities are not satisfying. Therefore, numerous efforts have been made to enhance the OER activity of layered TMS to enable the bifunctional catalytic ability for overall water splitting. Wei et al. [30] reported a spontaneous phase transformation strategy of MoS2 to prepare the stabilized 1T phase from the 2H phase. The phase transformation was triggered by the adsorption of Ir on the surface of 2H-MoS2, which induced a strong metal-support interaction. The water splitting cell assembled with the Ir/MoS2 catalyst achieved the current density of 10 mA·cm−2 at a cell voltage of 1.57 V. The synergistic effect of the adsorbed Ir species and 1T-MoS2 is the origin of the superior catalytic activity. Zhang et al. [31] applied the composite design strategy, fabricating a novel MoS2/Ni3S2 heterostructures with superior OER activity and overall water splitting performance (Fig. 3a). The alkaline water splitting electrolyzer assembled with such MoS2/Ni3S2 heterostructure as catalyst delivers a current density of 10 mA·cm−2 at a very low cell voltage of ca. 1.56 V. Density functional theory (DFT) calculations suggest that the synchronous chemisorption of hydrogen and oxygen species is promoted by the established interfaces between the components and the in situ generated interfaces under OER condition. In consequence, the overall electrochemical water splitting activity is promoted significantly. Heteroatom doping is another effective strategy to modulate the fundamental properties of layered TMS via the increased active sites as well as the modulation of surface electronic structures [32, 33]. Xue et al. [34] prepared the bifunctional Fe-doped MoS2 nanocanopies on Ni foam (Fe-MoS2/NF) via an in situ solvothermal reaction. It can achieve a water splitting current density of 10 mA·cm−2 with a low potential of 1.52 V in 1.0 mol·L−1 KOH electrolyte. The activity of Fe-MoS2/NF was maintained for more than 140 h under the reaction conditions. The remarkable catalytic performance and durability were attributed to the strong coupling interactions between Fe and MoS2. Non-layered TMS-based catalysts generally have comparable HER and OER activities to the noble-metal-based electrocatalysts. Further optimizations of activities are also under research. Gong et al. [35] fabricated a Mo/Mn-NixSy/NF non-layered TMS-based catalyst with only a cell voltage of 1.49 V to deliver a current density of 10 mA·cm−2 for the water splitting. It can also stand for more than 24 h while affording a current density of 18 mA·cm−2.

Reproduced with permission from Ref. [31]. Copyright 2016, WILEY–VCH Verlag GmbH & Co. KGaA, Weinheim. b Schematic illustration of a general approach for metal phosphide@C for highly efficient overall water splitting. Reproduced with permission from Ref. [42]. Copyright 2020, American Chemical Society. c Schematic illustration of synthesis of CoNx@GDY NS/NF via an in-site growth strategy. Reproduced with permission from Ref. [44]. Copyright 2019, Elsevier Ltd

a Proposed-mechanisms of dissociation of H2O, OH, and OOH intermediates on MoS2/Ni3S2 heterostructures (yellow = S, green = Ni, blue = Mo, white = H, red = O).

In summary, the catalytic activity of TMS-based compounds for HER and OER can be optimized by introducing heteroatoms, phase engineering, and construction of heterostructures. The goal is to increase the active sites on the surface or/and regulate the electronic structure to enhance the bifunctional electrocatalytic performance for water splitting. A detailed comparison table has been supplied in Table 2 [30, 31, 34, 35].

2.3 Transition metal phosphide-based electrocatalysts

Transition metal phosphides (TMPs) feature the suitable d-electron configuration, rich chemical states, and similar zero-valent metallic characteristics [36, 37]. Although phosphate atoms are active for OER, the poor conductivity and shortage of active sites limit the catalytic activity of TMPs. TMP-based electrocatalysts are also prone to corrosion in strong alkaline and high overpotential condition [38, 39]. In order to solve these issues, electronic structures and surface properties of TMP-based electrocatalysts need to be adjusted. Cao’s group demonstrated an ultrathin 2D Ni2P structure as a bifunctional overall water splitting catalysts [40]. With the resulting large pore size, decent electronic conductivity, and a distinctive structure, Ni2P shows outstanding catalytic performances for both HER and OER, and drives the water splitting cell at the voltage of merely 1.47 V to attain a current density of 10 mA·cm−2. Introducing a secondary transition metal is a general approach. Yu et al. [41] reported a hybrid catalyst constructed by iron and dinickel phosphides on nickel foams (FeP/Ni2P/NF) substantially expedites alkaline overall water splitting at 10 mA·cm−2 with only a cell voltage of 1.42 V, which outperforms the IrO2/Pt couple (1.57 V) and most of the state-of-the-art bifunctional water splitting catalysts. More importantly, it demands only a voltage of 1.72 V to reach the commercially practical current density of 500 mA·cm−2, which is lower than those for any reported bifunctional catalysts. The catalytic activity of FeP/Ni2P/NF maintains for more than 40 h at 500 mA·cm−2, showing remarkable durability and great potential for large-scale implementation for hydrogen generation. Combining TMPs with porous carbon materials and conductive materials can effectively improve the electrical conductivity, active sites, and corrosion resistance for water splitting. Kang et al. [42] proposed a universal strategy for carbon-supported TMPs as high-performance bifunctional electrocatalysts towards efficient overall water splitting (Fig. 3b). The sol–gel method and a carbonization-assisted route are combined to facilely fabricate a series of TMP nanoparticles, including CoP, MoP, FeP, Cu2P, Ni2P, PtP2, FeNiP, CoNiP, and FeCoNiP, coupled in an amorphous carbon matrix with one-step carbon composite formation. Among these prepared catalysts, the NiFeP@C exhibits excellent activities for both OER and HER with overpotentials of 260 and 160 mV, respectively, at 10 mA·cm−2 in 1 mol·L−1 KOH solution. The integrated electrolyzer with NiFeP@C as both electrodes delivers a water splitting current density of 47.0 mA·cm−2 at 1.60 V, which is superior to that of the Pt/C and IrO2 assembled counterpart. The encapsulation of the carbon matrix effectively inhibits the corrosion of NiFeP nanoparticles and results in excellent stability. The superior electrocatalytic activity is ascribed to the accelerated charge transfer induced by the synergistic effects from Ni, Fe, P, and C.

2.4 Transition metal nitride-based electrocatalysts

Transition metal nitrides (TMNs) are also regarded as promising candidates for bifunctional electrocatalysts for overall water splitting. The electronic structure of TMNs is similar to those of Pd and Pt noble metals up to the Fermi level due to the electron transfer with nitrogen atoms [43]. Nonetheless, the intrinsic conductivity, activity, and stability of TMNs need further improvement to gain better catalytic performance as the bifunctional catalysts for overall water splitting. Fang et al. [44] developed an in-situ growth strategy to prepare graphdiyne-encapsulated cobalt nitride nanosheets (CoNx@GDY NS), demonstrating high activity and stability in alkaline water splitting (Fig. 3c). The catalyst achieved a current density of 10 mA·cm−2 for HER and OER with low overpotentials of 70 and 260 mV, respectively, which was obviously superior to that of the commercial Pt/C and RuO2. When it was applied as both the cathode and anode in a two-electrode alkaline electrolyzer, 10 mA·cm−2 can be attained at an ultralow cell voltage of 1.48 V, which is significantly smaller than that of Pt/C–RuO2 couple. The unique chemical and electronic structures and associated interactions between GDY and CoNx lead to greatly enhanced conductivity, promoted charge transfer kinetics as well as an increased number of active sites. Combining an OER active component to the TMN is another effective strategy to promote the bifunctional catalytic activity for overall water splitting. Xie et al. [9] reported an ultrathin Ni-borate (Ni-Bi) layer on a metallic Ni3N nanosheet array supported on a Ti mesh (Ni3N@Ni-Bi NS/Ti) as a durable three-dimensional (3D) core/shell structured nanoarray electrocatalyst for neutral pH water splitting. The OER activity of Ni-Bi at near-neutral pH has been reported by Nocera et al., however, the inferior electrical conductivity hampers the overall OER efficiency [45]. With the combination of the conductive Ni3N nanoarray, the synergistic effect promotes both the HER and OER catalytic activities of the Ni3N@Ni-Bi NS/Ti catalyst, which are superior to most reported non-noble metal catalysts [45]. The nanoarray structures of Ni3N expose more active sites with facilitated diffusion of electrolyte and gas evolved in the reaction. The two-electrode electrolyzer with Ni3N@Ni-Bi nanoarray only needs 1.95 V for 10 mA·cm−2 water splitting current at 25 °C in 0.5 mol·L−1 K-Bi solution. This cell voltage is much lower than that for Ni3N NS/Ti (2.45 V), Ni-Bi/Ti (2.44 V), and CoO2/CoSe2 (2.18 V) [46] for the same current density.

2.5 Other transition metal-based compounds

Transition metal carbides (TMCs) have raised great attention for overall water splitting due to the excellent corrosion resistance and stability, high mechanical strength, high electrical conductivity, and low cost [10]. Han et al. [47] successfully coupled the defect-rich FeN0.023 and Mo2C onto N-doped carbon nanosheets to synthesize FeN0.023/Mo2C/C heterostructure nanoparticles, which exhibited outstanding catalytic activity and stability for HER, OER and overall water splitting. The current density of FeN0.023/Mo2C/C can reach 10 mA·cm−2 at low overpotentials of 227 mV for OER and 76 mV for HER with good stability, and it needs only 1.55 V to reach water splitting current density of 10 mA·cm−2 in 1 mol·L−1 KOH. The outstanding electrocatalytic performance is attributed to the enriched active sites on the formed interfaces, adjusted binding energy through the coupling of the FeN0.023 and Mo2C, and finally the protection by the encapsulating carbon nanosheets. Kou et al. [48] presented a surface engineering strategy of assembling 2D Mo2C into 3D microflower structures, which demonstrates efficient alkaline water splitting performance (Fig. 4a). They developed a pyrolysis route to prepare 2D molybdenum carbide nanomeshes and their assembled 3D microflowers (Mo2CTx NMs and MFs, respectively). The atomic-level surface engineering endows the Mo2CTx NMs with the highest OER activity reported so far, which achieves 10 mA·cm−2 at an ultralow overpotential of 180 mV. By using the Mo2CTx MFs as both electrodes for overall water splitting, a current density of 10 mA·cm−2 is achieved at 1.7 V. This work revealed the significance of multiscale structural controls and surface engineering to boost electrocatalytic performance and long-term stability. Xing et al. [49] proposed a highly efficient bifunctional-phase molybdenum carbide (–Mo2C) electrocatalyst embedded into carbon nanosheets, with cornstalks as the green carbon source. The high intrinsic activity, high porosity of the resultant, and synergistic effect between Mo2C and carbon matrix promote the HER and OER catalytic activities of the as-prepared catalyst. Low overpotentials of 130 and 274 mV are needed to deliver a current density of 10 mA·cm−2 for HER and OER, respectively. In the water splitting electrolyzer, a cell voltage of 1.65 V is required for 10 mA·cm−2 in alkaline water, as well as long-term stability of 30 h. This strategy is intriguing with its reproducible starting materials, simple and easily scalable synthetic procedure, which is inspiring for the sustainable energy industry.

Reproduced with permission from Ref. [48]. Copyright 2018, Elsevier B.V. b Current density of NixB/f-MWCNT and NixB as a function of scan rate, where surface-specific double-layer capacitance (Cdl) is shown in annotation; c EIS spectra of NixB/f-MWCNT and NixB recorded under the constant potential of 1.55 V (vs. RHE); d comparison of required voltage for overall water splitting at current density of 10 mA·cm−2 for NixB/f-MWCNT and other recently reported noble metal-free bifunctional catalysts. Reproduced with permission from Ref. [51]. Copyright 2019, Royal Society of Chemistry

a Schematic illustration of synthetic process for 2D molybdenum carbide nanomeshes (Mo2CTx NMs) and assembled 3D microflowers (Mo2CTx MFs).

Transition metal borides (TMBs) are the emerging bifunctional catalyst candidates for overall water splitting. Similar to other aforementioned transition metal-based compounds, TMBs have intrinsically high catalytic properties and long stability, yet are also limited by poor electrical conductivity and low specific surface area. Therefore, growing TMBs on conductive substrates, such as carbon materials, is an effective strategy to further boost the catalytic performance for overall water splitting. Xu et al. [50] deposited Co-Ni-B nanoparticles on Ni foam by a facile electroless plating method (Co-Ni-B@NF), and the resultant catalyst demonstrated promising catalytic activity as bifunctional catalyst for overall water splitting. The Co-Ni-B@NF catalyst requires a cell voltage of 1.72 V to reach water splitting current density of 10 mA·cm−2. Chen et al. [51] designed a generalizable approach to overcome the limitations of TMBs by anchoring ultrathin nickel boride (NixB) sheets on the surfaces of functionalized small-diameter multi-walled carbon nanotubes (f-MWCNTs). As a result, the electrochemically active surface area and charge transfer resistance of the NixB/f-MWCNT is 3.40 and 0.24 times that of NixB nanosheets, respectively (Fig. 4b, c). For the overall water splitting, it requires only 1.60 V to reach the current density of 10 mA·cm−2, outperforming existing metal boride catalysts as well as a commercial IrO2/Pt/C catalysts (Fig. 4d). The outstanding electrocatalytic performance is ascribed to the strong chemical coupling between NixB and f-MWCNTs and the in situ formation of highly active NiOOH/NixB and Ni(OH)2/NixB heterojunctions. The detailed comparison table of water splitting performances among TMPs, TMNs, TMCs, and TMBs is supplied in Table 3 [41,42,43, 45,46,47,48,49,50,51].

3 Bifunctional transition metal-based catalysts for other H2 production processes

Efficient and sustainable approaches for H2 production are critical to the development of the H2 energy industry. Although water splitting has been deemed as the suitable technique for green H2 production, the anode reaction OER becomes the bottleneck of the process, which typically demands a much higher overpotential to match the rate of HER on the cathode [52]. This complex four-electron-transfer process has intrinsically sluggish kinetics and high thermodynamic barriers to overcome [53]. Moreover, the product of OER, O2, is not of significant value, and the potential mixing of H2 and O2 in the headspace of an electrolyzer poses safety concerns, requiring costly gas separation steps. Therefore, strategies that replace the formidable OER with more readily oxidized molecules for energy-saving H2 production and more additional chemical values, have been proposed recently. Several molecules, such as methanol [54], ethanol [55], benzyl alcohol [56], hydrazine [57,58,59,60], and 5-hydroxymethylfurfural [52], etc. have been tested as replacements for OER due to their more thermodynamically favorable electrochemical oxidations. The corresponding bifunctional catalysts for these reactions coupled with HER will be briefly overviewed in the following sections.

3.1 Benzyl alcohol oxidations

Selective oxidation of benzyl alcohols is one of the most significant issues in the modern chemical industries and synthetic chemistry because the product benzaldehydes is of central value in pharmaceuticals and fine chemicals synthesis [56]. The electrochemical oxidation (ECO) of benzyl alcohol is intrinsically advantageous to traditional approaches, in which harsh conditions are not required [61]. Zheng et al. [56] fabricated a self-supported, hierarchical, porous, nitrogen-doped carbon (NC)@CuCo2Nx/carbon fiber (CF), which demonstrated excellent catalytic activity and stability for overall water splitting and H2 production coupled with selective ECO of benzyl alcohol. When 15 × 10–3 mol·L−1 benzyl alcohol was added into the 1 mol·L−1 KOH solution, the cell voltage required for 10 mA·cm−2 was lowered by 0.07 to 1.55 V, which is smaller than those of the IrO2/Pt/C couple (1.56 V at 10 mA·cm−2). This outstanding electrocatalytic performance is attributed to several advantages of the NC@CuCo2Nx/CF. First, the uniform hierarchical architecture with abundant porous structure endows it with highly exposed surface area, which is beneficial for mass transfer. Second, the synergistic effects between Cu3N and Co5.47N nanoparticles modulate the adsorption strengths of key intermediates and optimize the reaction pathway. Finally, the N-doped carbon shell not only improves the conductivity and electron transfer rate, but also substantially enhances the mechanical stability of CuCo2Nx/CF.

3.2 Hydrazine oxidation (HzOR)

Hydrazine (N2H4) is one of the significant industrial raw materials, which has been widely used in fuel cells, rocket fuels, corrosion inhibitors, and synthesis chemistry [57]. Compared with other oxidizable species for coupling with HER, hydrazine oxidation (HzOR, N2H4 + 4OH−→N2 + 4H2O + 4e−) has several advantages. First, its products are nitrogen and water without greenhouse gas, and the risk of mixing H2 and O2 in OER is thereby avoided. Second, it has no carbon atoms, thereby avoiding the generation of catalyst-poisoning species. Third, the oxidation potential is significantly lowered by its stronger reducing power, which is only − 0.33 V (vs. RHE) compared to that of OER (1.23 V vs. RHE) [62, 63].

Tang et al. [57] first explored the H2 production with hydrazine oxidation (HzOR) in alkaline conditions by preparing Ni2P nanoarrays in situ grown on nickel foam (Ni2P/NF). In 1.0 mol·L−1 KOH solution with 0.5 mol·L−1 hydrazine, the Ni2P/NF-based two-electrode outputs a current density of 500 mA·cm−2 at a cell voltage of only 1.0 V, with strong durability and nearly 100% Faradaic efficiency (FE) for HER. The system can constantly deliver 100 mA·cm−2 for 10 h with the potential increases only by 15 mV. In comparison, without the presence of hydrazine, the system only produces a current density of 20 mA·cm−2 at 1.6 V, which is much larger than 1.0 V with hydrazine presented. This substantially demonstrates that replacing OER with HzOR in the anode is an effective strategy for energy-saving electrolytic hydrogen generation. Liu et al. [60] further developed this strategy by constructing a self-powered H2 production with bifunctional hydrazine as sole consumable. Fe-doped CoS2 nanosheets (Fe-CoS2) are fabricated as a bifunctional electrocatalyst for HER and HzOR, by which direct hydrazine fuel cells (DHzFCs) and overall hydrazine splitting (OHzS) units are realized and integrated to form a self-powered H2 production system. In the OHzS unit assembled with Fe-CoS2 as both electrodes, an extremely low cell voltage of 0.95 V is needed to deliver a large current density output of 500 mA·cm−2, which is among the best reported OHzS works. The DHzFCs with Fe-CoS2 as anode and H2O2 or O2 as oxidizing agents also reached the best performance among published works for DHzFCs with Co-based electrocatalyst, which produces the maximum power density values of 246 mW·cm−2 (H2O2) and 125 mW·cm−2 (O2). The integrated system, where Fe-CoS2 nanosheets are applied in DHzFCs anode and the two electrodes in OHzS unit, exhibits good stability at 0.7 V for 20 h and a hydrogen evolution rate of 9.95 mmol·h−1, comparable to the best reported for self-powered H2 production system based on water splitting (Fig. 5a, b). Theoretical calculations interpreted these outstanding performances as the effect of Fe doping, which decreases the free-energy changes of H adsorption as well as the dehydrogenation of adsorbed NH2NH2 on CoS2 [64,65,66,67,68]. Similarly, Zhang et al. utilized a bifunctional P, W co-doped Co3N nanowire array catalyst to construct a self-powered H2 production system where a DHzFC and a OHzS unit are integrated together [58]. The production rate of H2 achieves a decent rate of 1.25 mmol·h−1 at room temperature. DFT calculations decipher that the P, W codoping optimized H* adsorption/desorption and dehydrogenation kinetics could be the underlying mechanism. These examples substantially demonstrate the remarkable advantages of replacing OER with the highly energetically favorable HzOR, while the development of the bifunctional catalyst for HER and HzOR has been thriving at the current stage.

Reproduced with permission from Ref. [60]. Copyright 2018, the Authors. c LSV curves for UOR (0.33 M being 0.33 mol·L−1); d Tafel slopes for UOR; e LSV curves for HER; f Tafel slopes for HER. Urea splitting performance of NO and NFO in 1 mol·L−1 KOH solution with 0.33 mol·L−1 urea: g LSV curves; h chronopotentiometry curves at the current density of 10 mA·cm−2. Reproduced with permission from Ref. [72]. Copyright 2019, Royal Society of Chemistry

a Schematic illustration of a self-powered H2 production system integrating a DHzFC and an OHzS unit, in which hydrazine is sole consumable serving bifunctionally as DHzFC fuel and splitting target; b OHzS polarization curves of 20 wt% Pt/C, pure CoS2 nanosheets, and Fe-CoS2 ones, which all worked bifunctionally as anodes and cathodes with same electrocatalyst loading of 0.5 mg·cm−2.

3.3 Urea oxidation (UOR)

Urea electrolysis is an intriguing energy-saving electrolysis technique developed recently since it can simultaneously produce H2 and purify urea-rich waste water (CO(NH2)2 + H2O → 3H2 + N2 + CO2) [69]. The thermodynamic potential of urea electrolysis is merely 0.37 V, which is significantly lower than that of 1.23 V for OER [69]. Nonetheless, the urea oxidation reaction is a complex 6e− transfer process with sluggish kinetics, which needs highly active catalysts to promote the reaction rate. Non-noble metal-based bifunctional catalysts for HER and UOR are highly favorable since they can reduce not only the cost of the catalyst but also the design complexity of the electrolysis system. Ni-Mo-based catalysts have attracted much attention and exhibited promising UOR activity [70]. Zhang et al. [71] reported a bifunctional Ni-Mo alloy nanotube for efficient hydrogen production coupled with UOR as anode reaction in a hybrid water electrolysis system. The hybrid cell constantly affords a current density of 10 mA·cm−2 at a low cell voltage of 1.43 V, which is 40 mV lower than that of the traditional water splitting with commercial Pt||IrO2 couple. More importantly, the output current gap between Ni-Mo nanotube and Pt||IrO2 couple drastically increases when the driving potential increases. DFT calculations reveal that Mo centers are the active centers for chemisorption and O–H bond cleavage of H2O, while Ni centers are responsible for hydrogen-evolving. Wu et al. [72] prepared lantern-like porous and hollow microspheres composed of nickel oxide-based nanosheets for overall urea splitting. The Ni0.9Fe0.1Ox (NFO) and NiO (NO) microspheres exhibit excellent electrocatalytic properties (Fig. 5c–f). NFO achieved outstanding overall urea splitting activity with a potential of 1.455 V at a current density of 10 mA·cm−2, and also demonstrated excellent stability after 25-h continuous electrolysis (Fig. 5g, h). Recently, Pang et al. have also reported the synthesis of porous rod-like Ni2P/Ni assemblies for the urea oxidation reaction, which display improved electroactivity and conductivity [73]. The constructed electrolytic cell based on Ni2P/Ni exhibits the cell voltage of 1.47 V at a current density of 10 mA·cm−2.

3.4 5-hydroxymethylfurfural (HMF) oxidation

The 5-hydroxymethylfurfural (HMF) is one of the most widely studied biomass-derived platform molecules, which is in great abundance and can be upgraded to a series of chemicals. In particular, the 2,5-furandicarboxylic acid (FDCA) can serve as a monomer to produce polyamides, polyesters, and polyurethanes, being a replacement of terephthalic acid [74]. Compared to traditional methods of HMF to FDCA oxidation, the electrocatalytic method does not require harsh conditions and expensive noble metal-based catalysts [75]. You et al. [52] fabricated a bifunctional catalyst of 3D Ni2P nanoparticle arrays on nickel foam (Ni2P NPA/NF) to catalyze the oxidation of HMF to FDCA and HER. The two-electrode electrolyzer employing Ni2P NPA/NF required a voltage at least 200 mV smaller than pure water splitting to achieve the same current density. The Faradaic efficiencies for H2 production and oxidation of HMF to FDCA are 100% and 98%, respectively. Deng et al. [76] reported the facile preparation of copper sulfide nanowire@NiCo-layered double hydroxide nanosheet core–shell (CuxS@NiCo-LDH) nanoarrays as efficient bifunctional electrocatalyst towards HMF oxidation and simultaneous H2 production. The CuxS core/NiCo-LDH shell structure facilitates the charge/mass transfer and tunes the electronic structure of Ni with Co, which shifts the onset potential of HMF oxidation negatively by 150–200 mV. The Faradaic efficiency for HMF oxidation product, FDCA, reaches nearly 100%. The CuxS@NiCo-LDH nanoarrays also show outstanding HER activity and durability. As a result, the electrolyzer with this catalyst only demands a voltage of 1.34 V to achieve the current density of 10 mA·cm−2. These representative works illustrate the superior bifunctionality in transition metal-catalyzed biomass upgrading coupled with energy-saving H2 production. The performances of these electrocatalysts in other electrochemical reactions for hydrogen production have been supplied in Table 4 [52, 56,57,58,59, 69,70,71,72,73, 76].

4 Summary and outlook

Being a promising candidate to replace fossil fuels, H2 has received extensive research interest in the field of the clean energy industry. Large-scale and sustainable approaches to produce H2 are the cornerstone of the H2 industry. Electrocatalytic water splitting is currently deemed as a reliable strategy. However, challenging issues such as the sluggish kinetics of anodic OER, unaffordable cost of the commercial noble metal-based catalysts, and overall efficiency have to be addressed to make it practical in large-scale applications. Utilization of bifunctional electrocatalysts in water splitting can significantly lower the cost of catalyst production and simplify the electrolyzer design. In particular, bifunctional electrocatalysts with non-noble metals are highly desired for their promising intrinsic catalytic activity and abundance on the earth. Therefore, in this review article, the various types of water splitting non-noble metal-based bifunctional catalysts are briefly reviewed. All these researches aimed to obtain highly active, earth-abundant, and low-price bifunctional electrocatalysts, and promote the current density efficiency to a commercially available level. The efforts have been made in the design and the fabrication of these non-noble metal compound-based electrocatalysts can be summarized as follows: (1) nanostructure design and optimization of the transition metal-based compounds to endow them the bifunctional catalytic activity for HER and OER, and also the long-term stability; (2) combination with conductive materials such as nickel foams and carbon materials to facilitate the intrinsic electrical conductivity, and protect the active sites/components from the corrosive reaction conditions; (3) exploration and utilization of the synergistic effect of the various metal or non-metal species in the electrocatalysts, which maximizes the electrocatalytic performance to be comparable to or even surpass the benchmark commercial noble metal-based electrocatalysts.

The further study of bifunctional catalysts for overall water splitting should focus on the following key points. First, the HER and OER mechanisms over the bifunctional catalysts should be understood at the molecular scale, especially based on the crystal morphologies and electronic structure modifications. Meanwhile, to improve the long-term stability, degradation mechanisms under reaction conditions should also be paid attention to. Second, morphologies and composition designs should be conducted to increase the exposure of active sites and facilitate the electron/mass transfer over the electrocatalysts. Third, state-of-the-art characterization techniques, especially the in-situ techniques, should be applied to study the complex synergistic effects to understand the real catalytic active sites and reaction mechanisms. Finally, integration of these bifunctional catalysts into solar cells should be an interesting and environmentally friendly way to produce H2.

While tremendous efforts have been made to the bifunctional electrocatalysts for overall water splitting, some researchers innovatively proposed that the energy-intensive and sluggish OER could be replaced by other more thermodynamically favorable oxidation reactions. In this way, the efficiency of H2 evolution will be substantially increased with less energy input. More importantly, the reactions to replace OER can produce other valuable chemicals, which provides the energy-efficient strategies for their large-scale production with simultaneous H2 production. For instance, the electrooxidation of 5-hydroxymethylfurfural (HMF) is an ambient way to produce the important monomer and precursor 2,5-furandicarboxylic (FDCA). Therefore, we also provide an overview of these novel hydrogen productions with oxidation reactions other than OER. In particular, the extremely low thermodynamic potential of hydrazine oxidation reaction endows the electrolyzer with remarkably high efficiency and ultra-small operation potentials at large current density, and it even meets the commercial standard (500 mA·cm−2). More importantly, the significantly lowered energy requirements enable the self-powered H2 production devices to be practical [60]. Therefore, replacing OER with other more readily oxidized reactions is a promising strategy for the large-scale production of H2 evolution with valuable oxidation products, which is beneficial to the renewable energy industries and sustainable chemical production. The future development of such energy-saving H2 production should address the key problems as follows. First, exploration of readily oxidized molecules with high added value in chemical industries or pharmacies should be continued to enlarge the scope of candidates for energy-saving H2 production. Second, more in-depth insights into the reaction mechanisms for these oxidations should be investigated. Thirdly, advanced morphologies and compositions techniques should be applied to further enhance the catalytic activity performance. Finally, the commercial standard current density should be the primary goal to reach in the future development of energy-saving H2 productions.

References

Ibrahim KB, Tsai MC, Chala SA, Berihun MK, Kahsay AW, Berhe TA, Su WN, Hwang BJ. A review of transition metal-based bifunctional oxygen electrocatalysts. J Chin Chem Soc. 2019;66(8):829.

Li X, Yang X, Xue H, Pang H, Xu Q. Metal–organic frameworks as a platform for clean energy applications. EnergyChem. 2020;2(2):100027.

Liu W, Lustig WP, Li J. Luminescent inorganic-organic hybrid semiconductor materials for energy-saving lighting applications. EnergyChem. 2019;1(2):100008.

Lin L, Zhou W, Gao R, Yao S, Zhang X, Xu W, Zheng S, Jiang Z, Yu Q, Li YW, Shi C, Wen XD, Ma D. Low-temperature hydrogen production from water and methanol using Pt/α-MoC catalysts. Nature. 2017;544:80.

Liu G, Sheng Y, Ager JW, Kraft M, Xu R. Researc advances towards large-scale solar hydrogen production from water. EnergyChem. 2019;1(2):100014.

Yan Y, Xia BY, Zhao B, Wang X. A review on noble-metal-free bifunctional heterogeneous catalysts for overall electrochemical water splitting. J Mater Chem A. 2016;4(45):17587.

Li XX, Zhu PY, Li Q, Xu YX, Zhao Y, Pang H. Nitrogen-, phosphorus-doped carbon–carbon nanotube CoP dodecahedra by controlling zinc content for high-performance electrocatalytic oxygen evolution. Rare Met. 2020;39(6):680.

Wang J, Yue X, Yang Y, Sirisomboonchai S, Wang P, Ma X, Abudula A, Guan G. Earth-abundant transition-metal-based bifunctional catalysts for overall electrochemical water splitting: a review. J Alloys Compd. 2020;819:153346.

Xie L, Qu F, Liu Z, Ren X, Hao S, Ge R, Du G, Asiri AM, Sun X, Chen L. In situ formation of a 3D core/shell structured Ni3N@Ni–Bi nanosheet array: an efficient non-noble-metal bifunctional electrocatalyst toward full water splitting under near-neutral conditions. J Mater Chem A. 2017;5(17):7806.

Guo X, Zheng S, Luo Y, Pang H. Synthesis of confining cobalt nanoparticles within SiOx/nitrogen-doped carbon framework derived from sustainable bamboo leaves as oxygen electrocatalysts for rechargeable Zn-air batteries. Chem Eng Sci. 2020;401:126005.

You B, Liu X, Jiang N, Sun Y. A general strategy for decoupled hydrogen production from water splitting by integrating oxidative biomass valorization. J Am Chem Soc. 2016;138(41):13639.

Walter MG, Warren EL, McKone JR, Boettcher SW, Mi Q, Santori EA, Lewis NS. Solar water splitting cells. Chem Rev. 2010;110(11):6446.

Moni P, Hyun S, Vignesh A, Shanmugam S. Chrysanthemum flower-like NiCo2O4–nitrogen doped graphene oxide composite: an efficient electrocatalyst for lithium–oxygen and zinc–air batteries. Chem Commun. 2017;53(55):7836.

Wang H, Lee HW, Deng Y, Lu Z, Hsu PC, Liu Y, Lin D, Cui Y. Bifunctional non-noble metal oxide nanoparticle electrocatalysts through lithium-induced conversion for overall water splitting. Nat Commun. 2015;6:7261.

Liao L, Zhang Q, Su Z, Zhao Z, Wang Y, Li Y, Lu X, Wei D, F. G, Yu Q, Cai X, Zhao J, Ren Z, Fang H, Robles-Hernandez F, Baldelli S, Bao J. Efficient solar water-splitting using a nanocrystalline CoO photocatalyst. Nat Nanotechnol. 2014;9:69.

Gong M, Zhou W, Tsai MC, Zhou J, Guan M, Lin MC, Zhang B, Hu Y, Wang DY, Yang J, Pennycook SJ, Hwang BJ, Dai H. Nanoscale nickel oxide/nickel heterostructures for active hydrogen evolution electrocatalysis. Nat Commun. 2014;5:4695.

Smith RDL, Prévot MS, Fagan RD, Zhang Z, Sedach PA, Siu MKJ, Trudel S, Berlinguette CP. Photochemical route for accessing amorphous metal oxide materials for water oxidation catalysis. Science. 2013;340(6128):60.

Elakkiya R, Ramkumar R, Maduraiveeran G. Flower-like nickel-cobalt oxide nanomaterials as bi-functional catalyst for electrochemical water splitting. Mater Res Bull. 2019;116:98.

Tahir M, Mahmood N, Zhang X, Mahmood T, Butt FK, Aslam I, Tanveer M, Idrees F, Khalid S, Shakir I, Yan Y, Zou J, Cao C, Hou Y. Bifunctional catalysts of Co3O4@GCN tubular nanostructured (TNS) hybrids for oxygen and hydrogen evolution reactions. Nano Res. 2015;8:3725.

Zhang X, Dong CL, Wang Y, Chen J, Arul KT, Diao Z, Fu Y, Li M, Shen S. Regulating crystal structure and atomic arrangement in single-component metal oxides through electrochemical conversion for efficient overall water splitting. ACS Appl Mater Interfaces. 2020;12(51):57038.

Li X, Xiao L, Zhou L, Xu Q, Weng J, Xu J, Liu B. Adaptive bifunctional electrocatalyst of amorphous CoFe oxide@2D black phosphorus for overall water splitting. Angew Chem Int Ed. 2020;59(47):21106.

Guo Y, Park T, Yi JW, Henzie J, Kim J, Wang Z, Jiang B, Bando Y, Sugahara Y, Tang J, Yamauchi Y. Nanoarchitectonics for transition-metal-sulfide-based electrocatalysts for water splitting. Adv Mater. 2019;31(17):1807134.

Li H, Tan Y, Liu P, Guo C, Luo M, Han J, Lin T, Huang F, Chen M. Atomic-sized pores enhanced electrocatalysis of TaS2 nanosheets for hydrogen evolution. Adv Mater. 2016;28(40):8945.

Lin J, Peng Z, Wang G, Zakhidov D, Larios E, Yacaman MJ, Tour JM. Enhanced electrocatalysis for hydrogen evolution reactions from WS2 nanoribbons. Adv Energy Mater. 2014;4(10):1301875.

Lukowski MA, Daniel AS, Meng F, Forticaux A, Li L, Jin S. Enhanced hydrogen evolution catalysis from chemically exfoliated metallic MoS2 nanosheets. J Am Chem Soc. 2013;135(28):10274.

Tang Q, Jiang D. Mechanism of hydrogen evolution reaction on 1T-MoS2 from first principles. ACS Catal. 2016;6(8):4953.

Najafi L, Bellani S, Oropesa-Nuñez R, Martín-García B, Prato M, Mazánek V, Debellis D, Lauciello S, Brescia R, Sofer Z, Bonaccorso F. Niobium disulphide (NbS2)-based (heterogeneous) electrocatalysts for an efficient hydrogen evolution reaction. J Mater Chem A. 2019;7(44):25593.

Wang M, Zhang L, Huang M, Zhang Q, Zhao X, He Y, Lin S, Pan J, Zhu H. One-step synthesis of a hierarchical self-supported WS2 film for efficient electrocatalytic hydrogen evolution. J Mater Chem A. 2019;7(39):22405.

Geng X, Sun W, Wu W, Chen B, Al-Hilo A, Benamara M, Zhu H, Watanabe F, Cui J, Chen TP. Pure and stable metallic phase molybdenum disulfide nanosheets for hydrogen evolution reaction. Nat Commun. 2016;7:10672.

Wei S, Cui X, Xu Y, Shang B, Zhang Q, Gu L, Fan X, Zheng L, Hou C, Huang H, Wen S, Zheng W. Iridium-triggered phase transition of MoS2 nanosheets boosts overall water splitting in alkaline media. ACS Energy Lett. 2019;4(1):368.

Zhang J, Wang T, Pohl D, Rellinghaus B, Dong R, Liu S, Zhuang X, Feng X. Interface engineering of MoS2/Ni3S2 heterostructures for highly enhanced electrochemical overall-water-splitting activity. Angew Chem Int Ed. 2016;55(23):6702.

Xie C, Yan D, Chen W, Zou Y, Chen R, Zang S, Wang Y, Yao X, Wang S. Insight into the design of defect electrocatalysts: from electronic structure to adsorption energy. Mater Today. 2019;31:47.

Deng J, Li H, Xiao J, Tu Y, Deng D, Yang H, Tian H, Li J, Ren P, Bao X. Triggering the electrocatalytic hydrogen evolution activity of the inert two-dimensional MoS2 surface via single-atom metal doping. Energy Environ Sci. 2015;8(5):1594.

Xue JY, Li FL, Zhao ZY, Li C, Ni CY, Gu HW, Young DV, Lang JP. In situ generation of bifunctional Fe-doped MoS2 nanocanopies for efficient electrocatalytic water splitting. Inorg Chem. 2019;58(16):11202.

Gong Y, Zhi Y, Lin Y, Zhou T, Li J, Jiao F, Wang W. Controlled synthesis of bifunctional particle-like Mo/Mn-NixSy/NF electrocatalyst for highly efficient overall water splitting. Dalton Trans. 2019;48(20):6718.

Stern LA, Feng L, Song F, Hu X. Ni2P as a Janus catalyst for water splitting: the oxygen evolution activity of Ni2P nanoparticles. Energy Environ Sci. 2015;8(8):2347.

Huang Y, Song X, Deng J, Zha C, Huang W, Wu Y, Li Y. Ultra-dispersed molybdenum phosphide and phosphosulfide nanoparticles on hierarchical carbonaceous scaffolds for hydrogen evolution electrocatalysis. Appl Catal B. 2019;245:656.

Kaneti YV, Tang J, Salunkhe RR, Jiang X, Yu A, Wu KCW, Yamauchi Y. Nanoarchitectured design of porous materials and nanocomposites from metal-organic frameworks. Adv Mater. 2017;29(12):1604898.

Read CG, Callejas JF, Holder CF, Schaak RE. General strategy for the synthesis of transition metal phosphide films for electrocatalytic hydrogen and oxygen evolution. ACS Appl Mater Interfaces. 2016;8(20):12798.

Mushtaq N, Qiao C, Tabassum H, Naveed M, Tahir M, Zhu Y, Naeem M, Younasa W, Cao C. Preparation of a bifunctional ultrathin nickel phosphide nanosheet electrocatalyst for full water splitting. Sustain Energy Fuels. 2020;4(10):5294.

Yu F, Zhou H, Huang Y, Sun J, Qin F, Bao J, Goddard WA, Chen S, Ren Z. High-performance bifunctional porous non-noble metal phosphide catalyst for overall water splitting. Nat Commun. 2018;9:2551.

Kang Q, Li M, Shi J, Lu Q, Gao F. A universal strategy for carbon-supported transition metal phosphides as high-performance bifunctional electrocatalysts towards efficient overall water splitting. ACS Appl Mater Interfaces. 2020;12(17):19447.

Ham DJ, Lee JS. Transition metal carbides and nitrides as electrode materials for low temperature fuel cells. Energy Environ Sci. 2009;2(4):873.

Fang Y, Xue Y, Hui L, Yu H, Liu Y, Xing C, Lu F, He F, Liu H, Li Y. In situ growth of graphdiyne based heterostructure: toward efficient overall water splitting. Nano Energy. 2019;59:591.

Dincă M, Surendranath Y, Nocera DG. Nickel-borate oxygen-evolving catalyst that functions under benign conditions. Proc Natl Acad Sci USA. 2010;107(23):10337.

Li K, Zhang J, Wu R, Yu Y, Zhang B. Anchoring CoO domains on CoSe2 nanobelts as bifunctional electrocatalysts for overall water splitting in neutral media. Adv Sci. 2016;3(6):1500426.

Han N, Luo S, Deng C, Zhu S, Xu Q, Min Y. Defect-rich FeN0.023/Mo2C heterostructure as a highly efficient bifunctional catalyst for overall water-splitting. ACS Appl Mater Interfaces. 2021;13(7):8306.

Kou Z, Zhang L, Ma Y, Liu X, Zang W, Zhang J, Huang S, Du Y, Cheetham AK, Wang J. 2D carbide nanomeshes and their assembling into 3D microflowers for efficient water splitting. Appl Catal B. 2019;243:678.

Xing J, Li Y, Guo S, Jin T, Li H, Wang Y, Jiao L. Molybdenum carbide in-situ embedded into carbon nanosheets as efficient bifunctional electrocatalysts for overall water splitting. Electrochim Acta. 2019;298:305.

Xu N, Cao G, Chen Z, Kang Q, Dai H, Wang P. Cobalt nickel boride as an active electrocatalyst for water splitting. J Mater Chem A. 2017;5(24):12379.

Chen X, Yu Z, Wei L, Zhou Z, Zhai S, Chen J, Wang Y, Huang Q, Karahan HE, Liao X, Chen Y. Ultrathin nickel boride nanosheets anchored on functionalized carbon nanotubes as bifunctional electrocatalysts for overall water splitting. J Mater Chem A. 2019;7(2):764.

You B, Jiang N, Liu X, Sun Y. Simultaneous H2 generation and biomass upgrading in water by an efficient noble-metal-free bifunctional electrocatalyst. Angew Chem Int Ed. 2016;55(34):9913.

Roger I, Shipman MA, Symes MD. Earth-abundant catalysts for electrochemical and photoelectrochemical water splitting. Nat Rev Chem. 2017;1:0003.

Take T, Tsurutani K, Umeda M. Hydrogen production by methanol–water solution electrolysis. J Power Sources. 2007;164(1):9.

Chen YX, Lavacchi A, Miller HA, Bevilacqua M, Filippi J, Innocenti M, Marchionni A, Oberhauser W, Wang L, Vizza F. Nanotechnology makes biomass electrolysis more energy efficient than water electrolysis. Nat Commun. 2014;5:4036.

Zheng J, Chen X, Zhong X, Li S, Liu T, Zhuang G, Li X, Deng S, Mei D, Wang GJ. Hierarchical porous NC@CuCo nitride nanosheet networks: highly efficient bifunctional electrocatalyst for overall water splitting and selective electrooxidation of benzyl alcohol. Adv Funct Mater. 2017;27(46):1704169.

Tang C, Zhang R, Lu W, Wang Z, Liu D, Hao S, Du G, Asiri AM, Sun X. Energy-saving electrolytic hydrogen generation: Ni2P nanoarray as a high-performance non-noble-metal electrocatalyst. Angew Chem Int Ed. 2017;56(3):842.

Liu Y, Zhang J, Li Y, Qian Q, Li Z, Zhu Y, Zhang G. Manipulating dehydrogenation kinetics through dual-doping Co3N electrode enables highly efficient hydrazine oxidation assisting self-powered H2 production. Nat Commun. 2020;11:1853.

Wen H, Gan LY, Dai HB, Wen XP, Wu LS, Wu H, Wang P. In situ grown Ni phosphide nanowire array on Ni foam as a high-performance catalyst for hydrazine electrooxidation. Appl Catal B. 2019;241:292.

Liu X, He J, Zhao S, Liu Y, Zhao Z, Luo J, Hu G, Sun X, Ding Y. Self-powered H2 production with bifunctional hydrazine as sole consumable. Nat Commun. 2018;9:4365.

Cheung KC, Wong WL, Ma DL, Lai TS, Wong KY. Transition metal complexes as electrocatalysts—development and applications in electro-oxidation reactions. Coord Chem Rev. 2007;251(17–20):2367.

Lu Z, Sun M, Xu T, Li Y, Xu W, Chang Z, Ding Y, Sun X, Jiang L. Superaerophobic electrodes for direct hydrazine fuel cells. Adv Mater. 2015;27(14):2361.

Wu LS, Wen XP, Wen H, Dai HB, Wang P. Palladium decorated porous nickel having enhanced electrocatalytic performance for hydrazine oxidation. J Power Sources. 2019;412:71.

Yang J, Wang X, Li B, Ma L, Shi L, Xiong Y, Xu H. Novel iron/cobalt-containing polypyrrole hydrogel-derived trifunctional electrocatalyst for self-powered overall water splitting. Adv Funct Mater. 2017;27(17):1606497.

Zhang J, Dai L. Nitrogen, phosphorus, and fluorine tri-doped graphene as a multifunctional catalyst for self-powered electrochemical water splitting. Angew Chem Int Ed. 2016;55(42):13296.

Yin J, Li Y, Lv F, Lu M, Sun K, Wang W, Wang L, Cheng F, Li Y, Xi P, Guo S. Oxygen vacancies dominated NiS2/CoS2 interface porous nanowires for portable Zn–air batteries driven water splitting devices. Adv Mat. 2017;29(47):1704681.

Yang Y, Zhang H, Lin Z-H, Liu Y, Chen J, Lin Z, Zhou YS, Wong CP, Wang ZL. A hybrid energy cell for self-powered water splitting. Energy Environ Sci. 2013;6(8):2429.

Tang W, Han Y, Han CB, Gao CZ, Cao X, Wang ZL. Self-powered water splitting using flowing kinetic energy. Adv Mat. 2015;27(2):272.

Boggs BK, King RL, Botte GG. Urea electrolysis: direct hydrogen production from urine. Commun Chem. 2009;32:4859.

Liang Y, Liu Q, Asiri AM, Sun X. Enhanced electrooxidation of urea using NiMoO4·xH2O nanosheet arrays on Ni foam as anode. Electrochim Acta. 2015;153:456.

Zhang JY, He T, Wang M, Qi R, Yan Y, Dong Z, Liu H, Wang H, Xia BY. Energy-saving hydrogen production coupling urea oxidation over a bifunctional nickel-molybdenum nanotube array. Nano Energy. 2019;60:894.

Wu F, Ou G, Yang J, Li H, Gao Y, Chen F, Wang Y, Shi Y. Bifunctional nickel oxide-based nanosheets for highly efficient overall urea splitting. Commun Chem. 2019;55(46):6555.

Li Q, Li X, Gu J, Li Y, Tian Z, Pang H. Porous rod-like Ni2P/Ni assemblies for enhanced urea electrooxidation. Nano Res. 2021;14:1405.

Zakrzewska ME, Bogel-Łukasik E, Bogel-Łukasik R. Ionic liquid-mediated formation of 5-hydroxymethylfurfural—a promising biomass-derived building block. Chem Rev. 2011;111(2):397.

Zhang Z, Deng K. Recent advances in the catalytic synthesis of 2,5-furandicarboxylic acid and its derivatives. ACS Catal. 2015;5(11):6529.

Deng X, Kang X, Li M, Xiang K, Wang C, Guo Z, Zhang J, Fu XZ, Luo JL. Coupling efficient biomass upgrading with H2 production via bifunctional CuxS@NiCo-LDH core–shell nanoarray electrocatalysts. J Mater Chem A. 2020;8(3):1138.

Acknowledgments

This work was financially supported by the National Key R&D Program of China (No. 2021YFA1501101), the National Natural Science Foundation of China (No. NSFC 21771156) and the NSFC/RGC Joint Research Scheme Project (N_PolyU502/21).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wu, T., Sun, MZ. & Huang, BL. Non-noble metal-based bifunctional electrocatalysts for hydrogen production. Rare Met. 41, 2169–2183 (2022). https://doi.org/10.1007/s12598-021-01914-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-021-01914-x