Abstract

Artificial photosynthesis is deemed as an efficient protocol for transforming abundant solar energy into valuable fuel. In this paper, the well-defined one-dimensional (1D) core–shell MnO2@CdS hybrids were constructed by employing MnO2 nanotubes and CdS nanoparticles as nano-building blocks via a chemical co-precipitation route. The rationally designed core–shell structure provided an intimate heterojunction interface between the CdS shell and MnO2 core. All the MnO2@CdS core–shell nanocomposites possess higher H2 evolution rate through visible light irradiation contrary to pristine CdS, and the optimal MnO2@CdS hybrid exhibits the utmost H2 evolution rate of 3.94 mmol·g−1·h−1, which is 2.8-fold higher compared with that of CdS. Appertaining to XPS and Mott-Schottky (M-S) analysis, such enhanced photocatalytic H2 generation of MnO2@CdS heterojunction was ascribed to an S-scheme mechanism, which suppressed the charge recombination along with a fast detachment of electron–hole pairs (e−–h+) and significantly improved the severance of carriers, thus improved H2 evolution performance. These findings envision a new insight into the development of S-scheme heterostructure for photocatalytic H2 generation.

Graphic abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The prompt consumption of fossil fuels not only triggers serious environmental pollution but also brings about shortage in near future provoked the attention of the scientific community to the green and clean fuel. Photo-induced water splitting for H2 generation over photocatalysts is profiled as renewable energy resources to vanquish the energy and environmental issues [1,2,3]. Recently, semiconductors are considered the most pledging photocatalysts for water splitting in the S-scheme heterojunction [4], as it keeps reduction and oxidation reaction at two distinct positions and hence promotes the spatial separation of photogenerated charges. The water-splitting system is segregated into two constituents, for H2 evolution, the photogenerated electrons are kept in the higher conduction band (CB); while for O2 evolution, holes are confined in the lower valence band (VB). Recently, various S-scheme photocatalytic systems have been designed and stated for the application of photocatalytic water splitting [5,6,7].

Among those reported photocatalytic systems, a typical semiconductor, CdS, has become the center of attention due to its excellent solar (visible) light conversion performance with suitable bandgap, CB potential, earth abundance, non-toxicity, low price and ease of preparation [8]. However, sole CdS endures the fast recombination rates of light-induced electron–hole (e−–h+) pairs and photo-corrosion, thus substantially impeding its photocatalytic H2 efficacy [9]. Similarly, numerous tactics, comprising doping elements, entrenching heterostructure with semiconductors and conjugating with co-catalysts have been explored to ameliorate the light absorption and accelerate the charge segregation of CdS [10, 11]. These problems can be overcome up to an appreciable extent by the construction of a core–shell hybrid consisting of CdS and another photocatalyst [12]. Construction of core–shell heterojunction is a significant approach, which not only expedites the charge severance and transfer but extends the photo-responsive range [13]. To enhance the photocatalytic efficiency, numerous CdS based core–shell heterojunctions are built by coupling with other semiconductors [14] showing significant improvement in photocatalytic efficiency (water purification, H2 generation, and CO2 reduction). Among all the reported approaches, the formation of a direct S-scheme core–shell heterostructure could figure out the shortcomings of hasty charge carriers recombination and as a result, more carriers join the reaction, being a promising process to boost the photocatalytic activity [15]. To construct the S-scheme core–shell heterojunction, the selection of semiconductors with proper level structure is of vital importance. Among various semiconductors, manganese dioxide (MnO2) with strong oxidation capacity is the highly investigated functional material [13, 16] and it is suitable to establish the S-scheme structure with CdS. The composites including MnO2 have been employed mostly for capacitance applications [17]; however, the narrow bandgap of MnO2 (0.26–2.70 eV) only permits the absorption of visible even near-infrared (NIR) light [18]. Very few reports have been focused on the applications of MnO2 in photocatalysis. Cheng et al. [19] consolidated MnO2/TiO2 nanocomposite for degradation of methylene blue (MB) in the visible radiation-driven extent. The efficiency of the improved photocatalytic response is accredited to the effective severance of photogenerated electrons and holes (e−–h+). Furthermore, the large range of light response of MnO2 caused by defect structure with abundant oxygen vacancies and active sites also promotes the enhancing of photocatalytic performance [20].

In this paper, core–shell MnO2@CdS (MC) nanocomposites via a simple chemical precipitation route was synthesized, resulting in uniformly coated core–shell nanostructures with a shell of CdS nanoparticles (NPs) and a core of MnO2 nanotubes (NTs). The well-shaped one-dimensional (1D) core–shell structure offers substantial and inner interfacial connection within CdS shell and 1D MnO2 core, therefore, fostering the shifting of photo-induced electrons from semiconductor MnO2 to CdS to form S-scheme charge transport scheme. Accordingly, the MC-10 hybrid exhibited enhanced photocatalytic activity (up to 15.80 mmol·g−1 within 4 h) and excellent stability (within 16 h), which is 2.8-fold higher as compared with that of pure CdS NPs. It is foreseeable in the future that the present work will contribute a contemporary highlight to the development of efficient photocatalytic H2 production catalysts.

2 Experimental

2.1 Synthesis of 1D MnO2 nanotubes

Typically, 0.039 mol·L−1 KMnO4 (Aladdin, ≥ 99%) and 3 ml HCl (Aladdin, ≥ 99.9%) were added to 30 ml deionized water (DIW) and stirred for 30 min. The whole suspension was shifted to autoclave and raised its temperature to 140 °C for a duration of 12 h in an oven. The obtained sludge was then isolated via centrifugation several times with a mixture of DIW and ethanol and dried in an oven at 70 °C overnight to obtain MnO2 NTs.

2.2 Synthesis of core–shell MnO2@CdS (MC) hybrids

The core–shell MnO2@CdS composites were fabricated via the coprecipitation route. Initially, 1 g cadmium nitrate Cd(NO3)2·xH2O (Sinopharm Chemical Reagent Co., Ltd. ≥ 99%) and a specific amount of MnO2 NTs was dissolved in 100 ml DIW under vigorous stirring, which was then ultrasonicated for 30 min and labeled as Solution A. 0.25 g thiourea (CH4N2S, Sinopharm Chemical Reagent Co., Ltd. ≥ 99%) was added to 100 ml DIW which was labeled as Solution B. Solution B was gradually added to Solution A and the mixture was heated at 80 °C for 1 h under stirring. To raise the pH to 10, 10 ml 1 mol·L−1 NaOH (Sinopharm Chemical Reagent Co., Ltd. ≥ 99%) solution was added to the above solution and maintained at 80 °C for a further 15 min. Resulting precipitates were washed with DIW thrice by centrifugation and dried in an oven at 70 °C to obtain core–shell MnO2@CdS (MC) nanocomposites. The core–shell MC composites with various MnO2 mass proportions were marked as CdS (0 wt%), MC-5 (5 wt%), MC-10 (10 wt%), MC-20 (20 wt%), and MC-30 (30 wt%), respectively. The schematic diagram of the synthesis process is shown in Scheme 1.

2.3 Characterizations

X-ray diffractometer (XRD, Bruker-AXS), X-ray photoelectron spectra (XPS, Thermo ESCALAB 250XI system), and ultraviolet–visible (UV–Vis) diffuse reflection spectrum (Shimadzu UV2600) were applied to characterize crystalline phase, chemical composition, and light adsorption, respectively. Scanning electron microscopy (SEM, FEL NovaNano450), transmission electron microscopy (TEM, JEOL JEM-2100HR), and time-resolved transient photoluminescence (PL) spectrum (JASCO FP-6500) were used to observe the morphology and fluorescence intensity. The test of photoelectrochemical properties, photocurrent response, electrochemical impedance spectroscopy (EIS), and Mott-Schottky (MS) was carried out via an electrochemical analyzer (CHI660B) under visible light irradiation (100 W Xe lamp with a 420 nm cut-off filter). Three-electrode quartz cell system with 0.5 mol·L−1 Na2SO4 solution as an electrolyte was employed, Pt foil electrode and Ag/AgCl electrode were used as counter electrode and the reference electrode, respectively. The working electrode was prepared as follows, 5 mg as-prepared samples were dispersed into a mix-solution of ethanol, ethylene glycol (250 μl) and 5% nafion solution (40 μl). Then 80 μl above solution was spread on a fluorine tin oxide (FTO) glass and then dried at 80 °C for 2 h to form a thin film. The cathodic polarization curves were obtained using the linear sweep voltammetry (LSV) technique with a scan rate of 1 mV·s −1.

2.4 Photocatalytic hydrogen generation measurements

Photocatalytic H2 generation was tested by a gas chromatograph (GC-2014, Shimadzu Co, Japan). Firstly, 50 mg catalysts were suspended in 80 ml aqueous solution including 0.25 mol·L−1 Na2SO3 and 0.35 mol·L−1 Na2S as hole scavenger, and 3 wt% Pt was dispelled in the mixture, the system was purged with nitrogen for 20 min to remove the residual air, and then irradiated with a Xe illuminant (light source) with 420 nm cut-off filter. The reaction lasted for 4 h. The apparent quantum efficiency (AQE) was measured under the identical condition of the photocatalytic reaction while the light irradiation was cut off through a bandpass filter (420, 450, 550 or 650 nm).

3 Results and discussion

The crystallographic structural identification of the prepared samples was explored via XRD. Figure 1a reveals that all the diffraction peaks of pure CdS NPs and MnO2 NTs are well-matched to the crystal planes of hexagonal structure (PDF No. 41–1049) [21] and tetragonal structure of α-MnO2 (PDF No. 44–0141), respectively. In case of MnO2@CdS core–shell composites, the CdS peaks demonstrate a slight shift to larger angles, indicating a decrease of CdS lattice parameters. The reason is supposed that interaction between CdS and MnO2 would lead to internal stresses in the CdS NPs [22,23,24]. Furthermore, MnO2 peaks are less intense due to small content and the peaks starting to appear with increasing MnO2 concentration as shown in Fig. 1b.

XPS measurements were performed to unveil the chemical state of the synthesized samples MnO2, CdS, and MC-10 core–shell nanocomposite. The full survey scans of MnO2, CdS, and MC-10 (Fig. 2a) evidenced the existence of these elements Cd, S, Mn, and O. The high-resolution XPS spectra of MC-10 nanocomposite and pure CdS clearly show the Cd 3d3/2 and Cd 3d5/2 observed at 411.8 and 404.8 eV sequentially, as illustrated in Fig. 2b, revealing the presence of Cd2+ [25]. The high-resolution S 2p spectra of both CdS NPs and MC-10 nanocomposite [26] are shown in Fig. 2c. The difference of 1.20 eV represents the S2− in the CdS NPs and the 1.19 eV shift in the case of MC-10 to lower binding energy (B.E.) is the characteristic of well-deposited CdS NPs on MnO2 NTs. The S 2p peaks centered at 161.4 and 162.6 eV are labeled as S 2p1/2, and S 2p3/2 respectively. The high-resolution Mn 2p XPS spectra of MnO2 NTs and MC-10 are shown in Fig. 2d. The Mn 2p has two Gaussian peaks having peak values at 641.7 and 653.5 eV, denoted as Mn 2p3/2 and Mn 2p1/2, respectively [27]. In the case of MC-10, the Mn 2p are shifted to lower binding energies (negative shift) as compared to MnO2 NTs, which is the indication of well-deposited CdS NPs on MnO2 NTs. The high-resolution O 1s spectra of MnO2 NTs and MC-10 are shown in Fig. 2e. The O 1s spectrum is composed of two Gaussian peaks with their maxima at 529.6 and 531.2 eV and attributed as lattice oxygen (Mn–O) and surface adsorbed oxygen (O–H). In the case of MC-10, the O 1s spectrum is shifted to lower binding energy (negative shift, 529.2 eV) [28]. These findings may indicate the formation of the heterojunction between the CdS NPs attached to the surface of MnO2 NTs with electron transfer from CdS NPs to MnO2 NTs until the establishment of thermodynamic equilibrium.

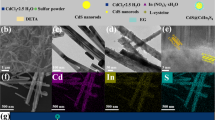

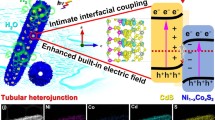

The morphological features of the synthesized samples (MnO2, CdS, and MC-10) are revealed by SEM and TEM images, as depicted in Fig. 3. Figure 3a, d reveals the tubular morphology of MnO2. Figure 3b, e represents the spherical-shaped CdS NPs, and the small spherical-shaped CdS NPs have a size distribution of 7–15 nm with an average particle size of 10 nm. Figure 3c shows SEM image of MC-10, it can be observed that spherical-shaped CdS NPs are deposited on the surface of MnO2 NTs in such way that all MnO2 NTs are uniformly covered by the small spherical CdS NPs validating the formation of MC-10 nanocomposite with a core–shell structure. The corresponding EDS result of MC-10 sample confirms the presence of Cd, S, Mn, and O. The low and high magnifications of TEM images of MC-10 hybrid are shown in Fig. 3f, g, the CdS NPs with an average particle size of 10 nm are covered over the MnO2 NTs. HRTEM image of MC-10 composite is displayed in Fig. 3h, an intimate interfacial contact is observed and the CdS NPs are firmly attached to MnO2 NTs, and the calculated lattice fringes of 0.31 and 0.50 nm are assigned to (101) and (200) planes of CdS and MnO2 NTs, respectively. Figure 3i–l exhibits the elemental mappings of the MC-10 sample and indicates the deposition of CdS NPs on the MnO2 NTs in MC-10 nanocomposite.

To investigate the light-harvesting properties, UV–Vis spectra of all samples are shown in Fig. 4. The MnO2 NTs demonstrate absorption in the visible, as well as the NIR region with an absorption edge of ~ 1150 nm, and an extended absorption tail from 700 to 1400 nm. The calculated bandgap using Tauc’s plot is 1.02 eV. The CdS NPs show visible light absorption with an absorption edge of ~ 650 nm and the calculated bandgap using Tauc’s equation is 1.89 eV, as indicated in Fig. 4b. After loading CdS NPs on MnO2 NTs (MC core–shell nanocomposites), all the MC core–shell nanocomposites exhibit improved absorption extending from visible to NIR light. The predicated flat band potentials (Efb, vs. Ag/AgCl) on the Mott-Schottky (M-S) plots of the MnO2 and CdS are − 0.08 and − 0.86 V, as depicted in Fig. 4c, and the conduction band (ECB) positions of the CdS and MnO2 are reckoned to be − 0.56 and 0.37 V (vs. NHE, pH = 0), sequentially, by utilizing the equation Efb = EAg/AgCl + 0.059 × pH + EAg/AgCl (pH = 6.8 and EAg/AgCl = 0.197 V) [1]. Eventually, the bandgap design and corresponding band positioning of the CdS and MnO2 are evinced in Fig. 4d.

The light-induced H2 production activities of all synthesized samples were carried out under visible light radiations (λ > 420 nm). Figure 5a represents that the hydrogen production over pure MnO2 NTs is negligibly small (0.29 mmol·g−1) while over CdS NP is 5.6 mmol·g−1 in an activity of 4 h. All the MC hybrids display enhanced photocatalytic H2 generation performance in comparison with pure CdS and MnO2, which can be ascribed to the formation of heterojunction between CdS NPs and MnO2 NTs. Among all hybrid nanocomposites, MC-10 displayed the utmost photocatalytic hydrogen generation rate of 3.94 mmol·g−1·h−1, which is as large as 2.8 times in comparison with pure CdS, as depicted in Fig. 5b. When CdS coupled with excessive MnO2, H2 efficiency was gradually inhibited due to that excessive MnO2 NTs would lead to a re-combination center. As shown in Table 1 [29,30,31,32,33,34,35], the as-prepared MnO2@CdS hybrid in this work surpasses most of its counterparts, indicating that S-scheme heterojunction exhibits an outstanding photocatalytic hydrogen evolution reaction (HER) activity. The cycling experiments were executed due to the importance of photostability in the photocatalytic application, as shown in Fig. 5c. Four cycling H2 photocatalytic production tests were performed over MC-10, and continuous H2 generation without obvious deviation can be observed, suggesting that MC-10 hybrid owns fine longevity for photocatalytic H2 production. Figure 5d shows that the highest quantum efficiency (QE) of MC-10 is 16.9% at 450 nm, and the calculated apparent quantum yield (AQY) for 420 and 550 nm is up to 4.90% and 3.62%, respectively.

After cycling test, the sample was collected and characterized by XRD, XPS, SEM and TEM. It can be found that no obvious peak change in XRD patterns of MC-10 hybrid pre and post photocatalytic reaction was observed (Fig. 6a), and no distinct peak shifts happened before and after the recycle test (Fig. 6b–d). Besides, there is no obvious difference in the morphology of MC-10 hybrid after HER reaction as manifested in SEM and TEM images (Fig. 7), signifying that no structural and morphology change occurs in the MC-10 nanocomposite pre and post photocatalytic reaction and the MC-10 hybrid possesses high stability [36, 37].

In order to get an insight into the light-induced charge transfer dynamics, the transient photocurrent (TPC) and electrochemical impedance spectroscopy (EIS) measurements were conducted. The TPC measurements were undergone by frequently turning on and off the illuminant. Figure 8a depicts a higher photocurrent density of MC-10 hybrid as compared to that of CdS NPs and MnO2 NTs, validating the improved separation efficiency of e−-h+ pairs. The Nyquist plots of all synthesized samples are shown in Fig. 8b in which the smallest arc of MC-10 affirms the reduced charge transfer resistance and swifter transfer rate. The TPC and EIS results suggest that the recombination of light-induced carriers substantially is suppressed due to the construction of MnO2@CdS (MC-10) heterojunction, resulting in the enhancement in photocatalytic activity. In the presence of visible light, the electrode current density of MC-10 is significantly enhanced compared to that of MnO2 and CdS. For the potential sweep (Fig. 8c), the enhancement in photocurrent density of MC-10 is due to the fact of efficient charge detachment. At a given potential, interestingly, the electrode photocurrent becomes larger in the order MC-10 > CdS > MnO2. The PL spectra of CdS NPs, MnO2 NTs, and MC-10 samples (using an excitation wavelength of 300 nm) are shown in Fig. 8d. The substantially reduced PL intensity of MC-10 nanocomposite with respect to MnO2 NTs and CdS NPs shows enhanced charge transfer between constituent semiconductors when exposed to visible light.

To further determine the charge transfer in the CdS@MnO2 heterojunction, the work functions of CdS and MnO2 were calculated using density functional theory (DFT) calculations. As shown in Fig. 9, the electrostatic potentials of CdS (101) facet and MnO2 (200) facet are estimated to be 5.12 and 7.61 eV, respectively. Taking into account of band alignments of the CdS and MnO2, an S-scheme is supposed for the MC-10 core–shell nanocomposite, as shown in Fig. 10. Underneath the irradiation of the visible light, both MnO2 and CdS can produce the e−-h+ couples for photocatalytic reaction. In case that the light-induced electrons (e−) follow the type II course, the e− will shift from the CB of the CdS to the CB of the MnO2. Nevertheless, the CB of the MnO2 is positioned at 0.37 V (vs. normal hydrogen electrode, NHE), which is not enough for the oxidoreduction of water, since the oxidoreduction potentials of water (O2/O2− and H+/H2) are 0 and − 0.33 V (vs. NHE), respectively. Therefore, the MC-10 composite pursues the S-scheme charge transport scheme. Under the visible light irradiation, the e− accumulated on the CB of MnO2 merge with the holes (h+) of the CdS, leaving the e− with stronger reduction capacity on the CB of the CdS to participate in the photocatalytic water reduction reaction to ensure the efficient H2 production performance.

4 Conclusion

The core–shell-structured MnO2@CdS heterojunctions were fabricated via a coprecipitation route. The morphology of the core–shell-structured MnO2@CdS composite was observed by microscopy. The MnO2@CdS hybrids exhibit improved photocatalytic H2 production performance upon exposure to visible light irradiation (> 420 nm), and the optimal MC-10 demonstrates 2.8-fold greater photocatalytic H2 generation (3.94 mmol·g−1·h−1) in comparison to pristine CdS nanoparticles. The MnO2@CdS core–shell hybrid with intimate interfacial contact is favorable for transferring photoexcited holes in CdS shell to combine with MnO2 core, forming an S-scheme charge transport scheme. The core–shell MnO2@CdS hybrid can not only reserve the strong redox ability of CdS but also expedite the charge detachment for high photocatalytic H2 generation activity. These findings may exploit new strategies into broad-range driven photocatalysts employing S-scheme water splitting.

References

Liu QQ, Shen JY, Yang XF, Zhang TR, Tang H. 3D reduced graphene oxide aerogel-mediated Z-scheme photocatalytic system for highly efficient solar-driven water oxidation and removal of antibiotics. Appl Catal B. 2018;232:562.

Xu QL, Zhang LY, Cheng B, Fan JJ, Yu JG. S-scheme Heterojunction Photocatal Chem. 2020;6(7):1543.

Zhong W, Wu XH, Wang P, Fan JJ, Yu HG. Homojunction CdS photocatalysts with a massive S2–-adsorbed surface phase: one-step facile synthesis and high H2 evolution performance. ACS Sustain Chem Eng. 2020;8(1):543.

Tang H, Wang R, Zhao CX, Chen ZP, Yang XF, Bukhvalov D, Lin ZX, Liu QQ. Oxamide-modified g-C3N4 nanostructures: tailoring surface topography for high-performance visible light photocatalysis. Chem Eng J. 2019;374:1064.

Wang Z, Li C, Domen K. Recent developments in heterogeneous photocatalysts for solar-driven overall water splitting. Chem Soc Rev. 2019;48(7):2109.

Cheng L, Xiang QJ, Liao YL, Zhang HW. CdS-based photocatalysts. Energy. Environ Sci. 2018;11(6):1362.

Xia PF, Cao SW, Zhu BC, Liu MJ, Shi MS, Yu JG, Zhang YF. Designing a 0D/2D S-scheme heterojunction over polymeric carbon nitride for visible-light photocatalytic inactivation of bacteria. Angew Chem-Int Edit. 2020;59(13):5218.

Chen YB, Li JF, Liao PY, Zeng YS, Wang Z, Liu ZQ. Cascaded electron transition in CuWO4/CdS/CDs heterostructure accelerating charge separation towards enhanced photocatalytic activity. Chin Chem Lett. 2019;31(6):1516.

Panahi PN, Rasoulifard MH, Babaei S. Photocatalytic activity of cation (Mn) and anion (N) substitution in LaCoO3 nanoperovskite under visible light. Rare Met. 2020;39(2):139.

Ferraz NP, Nogueira AE, Marcos FCF, Machado VA, Rocca RR, Assaf EM, Asencios YJO. CeO2-Nb2O5 photocatalysts for degradation of organic pollutants in water. Rare Met. 2020;39(3):230.

Hisatomi T, Domen K. Reaction systems for solar hydrogen production via water splitting with particulate semiconductor photocatalysts. Nat Catal. 2019;2(5):387.

Fu JW, Xu QL, Low JX, Jiang CJ, Yu JG. Ultrathin 2D/2D WO3/g-C3N4 step-scheme H2-production photocatalyst. Appl Catal B. 2019;243:556.

Zhong W, Huang Y, Wang XF, Fan JJ, Yu HG. Colloidal CdS and CdZnS nanocrystal photocatalysts with massive S2 adsorption: one-step facile synthesis and highly efficient H2 evolution performance. Chem Commun. 2020;56(65):9316.

Peng JJ, Shen J, Yu XX, Tang H, Zulfiqar LQQ. Construction of LSPR-enhanced 0D/2D CdS/MoO3-x S-scheme heterojunctions for visible-light-driven photocatalytic H2 evolution. Chin J Catal. 2021;42(1):87.

Liu X, Zhao YX, Yang XF, Liu QQ, Yu XH, Li YY, Tang H, Zhang TR. Porous Ni5P4 as a promising cocatalyst for boosting the photocatalytic hydrogen evolution reaction performance. Appl Catal B. 2020;275:119144.

Cao SW. Two-dimensional gersiloxenes with tunable band gap as new photocatalysts. Rare Met. 2020;39(6):610.

Liu QQ, Huang JX, Tang H, Yu XH, Shen J. Construction 0D TiO2 nanoparticles/2D CoP nanosheets heterojunctions for enhanced photocatalytic H2 evolution activity. J Mater Sci Technol. 2020;56(1):196.

Mo Z, Xu H, Chen ZG, She XJ, Song YH, Lian JB, Zhu XW, Yan PC, Lei YZ, Yuan SQ, Li HM. Construction of MnO2/monolayer g-C3N4 with Mn vacancies for Z-scheme overall water splitting. Appl Catal B. 2019;241:452.

Cheng X, Dong GJ, Zhang YJ, Feng CC, Bi YP. Dual-bonding interactions between MnO2 cocatalyst and TiO2 photoanodes for efficient solar water splitting. Appl Catal B. 2020;267:118723.

Ye JW, Zhou MH, Le Y, Cheng B, Yu JG. Three-dimensional carbon foam supported MnO2/Pt for rapid capture and catalytic oxidation of formaldehyde at room temperature. Appl Catal B. 2020;267:118689.

Wu Y, Wang H, Tu W, Wu S, Liu Y, Tan YZ, Luo H, Yuan X, Chew JW. Petal-like CdS nanostructures coated with exfoliated sulfur-doped carbon nitride via chemically activated chain termination for enhanced visible-light-driven photocatalytic water purification and H2 generation. Appl Catal B. 2018;229:181.

Chen R, Yan ZH, Kong XJ, Long LS, Zheng LS. Integration of lanthanide-transition-metal clusters onto CdS surfaces for photocatalytic hydrogen evolution. Angew Chem Int Ed. 2018;57(51):16796.

Gao DD, Yuan RR, Fan JJ, Hong XK, Yu HG. Highly efficient S2− adsorbed MoSx-modified TiO2 photocatalysts: a general grafting strategy and boosted interfacial charge transfer. J Mater Sci Technol. 2020;56:122.

Saravanan L, Pandurangan A, Jayavel R. Synthesis and luminescence enhancement of cerium doped CdS nanoparticles. Mater Lett. 2012;66(1):343.

Li DS, Wang HC, Tang H, Yang XF, Liu QQ. Remarkable enhancement in solar oxygen evolution from MoSe2/Ag3PO4 heterojunction photocatalyst via in situ constructing interfacial contact. ACS Sustain Chem Eng. 2019;7(9):8466.

Xiang XL, Zhu BC, Cheng B, Yu JG, Lv HJ. Enhanced photocatalytic H2 production activity of CdS quantum dots using Sn2+ as cocatalyst under visible light irradiation. Small. 2020;16(26):2001024.

Fan CD, Tang X, Wang L, Wang HF, Zhan WC, Guo Y. Performance of AgIr/MCM-41 catalysts for CO oxidation. Chin J Rare Metals. 2019;43(07):686.

Sun KH, Shen J, Liu QQ, Tang H, Zhang MY, Zulfiqar S, Lei CS. Synergistic effect of Co(II)-hole and Pt-electron cocatalysts for enhanced photocatalytic hydrogen evolution performance of P-doped g-C3N4. Chin J Catal. 2020;41(1):72.

Kai SS, Xi BJ, Li HB, Xiong SL. Z-scheme CdS/Co9S8-RGO for photocatalytic hydrogen production. Inorg Chem Front. 2020;7(14):2692.

Yu HG, Huang Y, Gao DD, Wang P, Tang H. Improved H2 generation performance of Pt/CdS photocatalyst by a dual-function TiO2 mediator for effective electron transfer and hole blocking. Ceram Int. 2019;45(8):9807.

Lin Y, Zhang Q, Li YH, Liu YP, Xu KJ, Huang JG, Zhou XS, Peng F. The evolution from a typical type-I CdS/ZnS to type-II and Z-scheme hybrid structure for efficient and stable hydrogen production under visible light. ACS Sustain Chem Eng. 2020;8(11):4537.

Liu H, Yu JY, Chen YK, Zhou ZG, Xiong GW, Zeng LL, Li HD, Liu Z, Zhao LL, Wang JG, Chu BL, Liu H, Zhou WJ. One-step sublimation and epitaxial growth of CdS-Cd heterogeneous nanoparticles on S-doped MoO2 nanosheets for efficient visible light-driven photocatalytic H2 generation. ACS Appl Mater Interfaces. 2020;12(2):2362.

Zheng NC, Ouyang T, Chen YB, Wang Z, Chen DY, Liu ZQ. Ultrathin CdS shell sensitized hollow S-doped CeO2 spheres for efficient visible-light photocatalysis. Catal Sci Technol. 2019;9(6):1357.

Chen L, Xu YM, Chen B. In situ photochemical fabrication of CdS/g-C3N4 nanocomposites with high performance for hydrogen evolution under visible light. Appl Catal B. 2019;256:117848.

Wu XH, Gao DD, Yu HG, Yu JG. High-yield lactic acid-mediated route for a g-C3N4 nanosheet photocatalyst with enhanced H2 evolution performance. Nanoscale. 2019;11(19):9608.

Huang YM, Yu Y, Yu YF, Zhang B. Oxygen vacancy engineering in photocatalysis. Sol RRL. 2020;4(8):2000037.

Wang YT, Yu YF, Jia RR, Zhang C, Zhang B. Electrochemical synthesis of nitric acid from air and ammonia through waste utilization. Natl Sci Rev. 2019;6(4):730.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 51672113, 21975110 and 21972058).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zulfiqar, S., Liu, S., Rahman, N. et al. Construction of S-scheme MnO2@CdS heterojunction with core–shell structure as H2-production photocatalyst. Rare Met. 40, 2381–2391 (2021). https://doi.org/10.1007/s12598-020-01616-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-020-01616-w