Abstract

Self-organized titanium dioxide (TiO2) nanotubes, which are prepared by electrochemical anodizing, have been widely researched as promising anodes for Li-ion batteries. Both nanotubular morphology and bulk structure of TiO2 nanotubes can be easily changed by adjusting the anodizing and annealing parameters. This is provided to investigate different phenomena by selectively adjusting a specific parameter of the Li+ insertion mechanism. In this paper, we reviewed how the morphology and crystallography of TiO2 nanotubes influence the electrochemical performance of Li+ batteries. In particular, electrochemical performances of amorphous and anatase titanium dioxide nanotube anodes were compared in detail. As we all know, TiO2 nanotube anodes have the advantages of nontoxicity, good stability, high safety and large specific surface area, in lithium-ion batteries. However, they suffer from poor electronic conductivity, inferior ion diffusivity and low theoretical capacity (335 mAh·g−1), which limit their practical application. Generally, there are two ways to overcome the shortcomings of titanium dioxide nanotube anodes, including doping and synthesis composites. The achievements and existing problems associated with doped TiO2 nanotube anodes and composite material anodes are summarized in the present review. Based on the analysis of lithium insertion mechanism of titanium dioxide nanotube electrodes, the prospects and possible research directions of TiO2 anodes in lithium-ion batteries are discussed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Li-ion batteries (LIBs) are becoming the best energy supply option for various electronic devices, especially electric vehicles (EVs). This is because LIBs possess the advantages of high safety, high power density, large capacity, long charge/discharge life and low self-discharge rate [1, 2]. Traditional gasoline-powered transportation causes atmospheric pollution due to the generation of combustion gas. Thus, using electric vehicles can significantly alleviate air pollution and slow down the consumption of fossil fuel. On the other hand, the low energy efficiency of solar, tidal, wind and other renewable energy has become an important issue restricting the formation of an energy-sustainable economy. Therefore, high energy efficiency of LIBs has the prospect of being applied to these new clean sources, thereby improving the energy efficiency of various large electric grid applications and promoting the establishment of an energy-sustainable economy [1, 3,4,5]. With the discovery of graphite as anode material, rechargeable LIBs became commercialized [4]. However, there are still hidden safety risks in the use of graphite anodes in LIBs in various electronic product applications, due to the growth of dendritic lithium [6, 7] and exothermic reaction [8, 9] in the lithium insertion and extraction process. In the past few years, various transition metal oxides have been known as suitable candidates for high-performance anodes in LIBs [10]. Among these transition metal oxides, titanium dioxide is considered to be one of the most suitable anodes for lithium-ion batteries on account of their low cost, high discharge voltage plateau (1.2–2.0 V versus Li+/Li), very good structural stability and environmentally friendly properties [11, 12]. However, TiO2 anodes also have some limitations, including low theoretical specific capacity (335 mAh·g−1), inferior electronic conductivity and poor lithium diffusivity [13]. Fortunately, nanostructured metal oxides with large specific surface areas and short electron/ion diffusion paths can alleviate these issues. Thus, existing numerous studies on synthesizing different TiO2 nanostructures, including nanotubes, nanoparticles, nanowires, nanosheets and even nanocables, then use them as anodes for lithium batteries [1, 2, 13, 14].

As a one-dimensional (1D) nanomaterial, TiO2 nanotube (TiO2 NT) is an excellent candidate material for anode in LIB because of its large surface area and short lithium diffusion path [15]. Through a convenient electrochemical anodizing process, vertically oriented self-organized TiO2 NTs can be directly prepared [16,17,18]. After anodizing, the generated TiO2 nanotubes are tightly connected to Ti foil. Moreover, this Ti substrate can act as an ideal collector for electron and lithium ion, without the need for an additional conductive agent and binder in LIB. Zwilling et al. [19] firstly observed orderly tubular anodized oxide layers on Ti after anodizing Ti foil in a HF electrolyte containing chromic acid. In the following few years, the geometry and performances of these NTs have attracted extensive attention, and the huge improvements in them are mainly achieved by Macak et al. [20, 21]. Maca´k revealed that the pH of the electrolyte is of great importance for preparing long nanotubes during the anodizing process. Meanwhile, in organic electrolytes without water addition, smooth and long nanotubes can grow [22]. And subsequent studies found that in general, the formation of well-defined nanotubular structures depends on a number of factors, including the applied potential/current, the concentration of fluoride in electrolyte, the temperature of the electrolyte, etc. [23,24,25,26]. Anodized TiO2 nanotubes treated by electrochemical anodization are typically amorphous and can be easily transformed into a crystalline structure by using proper annealing [27, 28]. In addition, doping and composite materials have been adopted to enhance the overall electrochemical properties of anodized TiO2 NT electrodes.

In this article, we review the latest advances in the electrochemical performance of highly ordered TiO2 NTs prepared via electrochemical anodization. Morphology (wall thickness, tube length, etc.) and crystallography (amorphous, anatase and rutile) of TiO2 nanotubes are carefully analyzed, and how they affect the electrochemical performances of lithium-ion batteries is summarized. Since most research on as-anodized nanotubes has focused on amorphous and anatase titanium dioxide nanotubes, the electrochemical performances of amorphous and anatase titanium dioxide tube anodes are compared in detail. In order to overcome the shortcomings (poor electrical conductivity and poor lithium diffusivity) of TiO2 electrodes, various methods of solving these problems have been investigated, such as doping Ti3+ or other foreign ions, coating or combining TiO2 NTs with high specific capacity or high-conductivity materials. Indeed, these methods are beneficial to increasing the lithium battery capacity, rate performance and cyclical stability of titanium dioxide nanotube electrodes. And built on the analysis of the TiO2 NT anodes ion implantation mechanism, the prospects and possible research directions of titanium dioxide nanotube as electrodes for LIBs are also discussed in this review.

2 Lithiation in amorphous and crystalline TiO2 nanotube (TiO2 NT) anodes

TiO2 has four common polymorphs, namely anatase, rutile, brookite and TiO2(B), and each polymorphic has attractive lithium storage behavior, especially in nanostructures [13, 14]. As for electrochemically anodized TiO2 nanotubes (TiO2 NTs), they are typically amorphous when they are just prepared by anodization. And through proper annealing treatment, amorphous TiO2 NTs can be easily transformed into a crystal structure (anatase or rutile) [27, 28]. In detail, the anatase phase starts to appear when annealing temperature is upon 280 °C, and the percentage of anatase to amorphous increases with increasing temperature [29]. In most cases, a temperature of about 450 °C can be utilized to obtain the dominant phase of anatase. At a temperature above 500 °C, the composition of rutile phase begins to appear. Meanwhile, a mixed anatase and rutile phase is formed. Then, at 900 °C, the rutile phase is mainly obtained [28]. Actually, the thermal annealing process can not only change the crystalline structure of the TiO2 nanotubes, but also drastically alter the morphology of individual tubes and the entire nanotube ensemble [28]. When the annealing temperature is higher than 700 °C, the decline of the nanotube structure (sintering and collapse) is observed, so until now, without ruining the tubular structure, TiO2 NTs still cannot achieve a complete rutile phase transition [30]. Furthermore, the charge carrier mobility [30] and electrochemical activity [14] of rutile are lower than those of anatase TiO2. Therefore, most of the studies on electrochemical anodized TiO2 NTs have concentrated on amorphous and anatase TiO2 NTs, which is thanks to their excellent properties in lithium battery applications. Thence, the main focus of Sect. 2 lies in these two categories.

2.1 Electrochemical performances of amorphous and anatase TiO2 NTs

As we all know, TiO2 has the advantages of rich reserves, nontoxicity, harmlessness and small volume change (less than 3%) in the lithium insertion and extraction process [31]. The Li insertion potential of titanium dioxide (1.2–2.0 V vs Li+/Li) is in the stable voltage window of general organic lithium battery electrolytes, thus highly enhancing the safety of LIBs [4]. For the self-organized TiO2 nanotubes prepared via electrochemical anodization, the Ti substrate is an excellent host for electrons and Li ions in LIBs [31]. The lithiation and delithiation of TiO2 NT anodes can be described as Eq. (1):

Here, x is the lithium insertion coefficient, and its value can reach 1 in the anatase and amorphous structure, which corresponds to the theoretical lithium capacity of 335 mAh·g−1 and associates with the full reduction of Ti4+–Ti3+ [14, 32,33,34,35]. Actually, the amount of lithium insertion of TiO2 depends on its polymorph, particle size and morphology [1, 36]. Originally, it was believed that about 0.55 mol Li could be inserted per mole TiO2 at ~ 1.7 V versus Li/Li+ [34, 37]. And until now, per mole of bulk TiO2 actually can only contain 0.55 mol of lithium [32]. However, nanostructured TiO2 has an increased surface area and a short Li diffusion length, which makes it possible to insert 1 mol of lithium into per mole of TiO2 and form LiTiO2 [38]. In nanostructured anatase, complete lithiation can only be realized in materials with a size of less than 7 nm [39]. However, extending the value of x to 1 or even higher may result in more electrolyte and solid electrolyte interface (SEI) films and low coulombic efficiency, which may reduce the stability of the TiO2 anode [40, 41]. Therefore, overcoming the contradiction between the high capacity and good stability of TiO2 anode is still a challenge.

Generally, as for the anatase TiO2, it undergoes two phase transformation processes during lithium intercalation: in the first process, Li0.55TiO2 is formed; in the following process, the complete lithiation and formation of LiTiO2 can be realized to some extent [4, 13]. Although the concentration of lithium as high as x = 0.6 has ever been observed, a vast amount of studies still reported the composition of Li0.55TiO2 as the maximum lithiation grade of bulk anatase titanium dioxide [42]. For amorphous TiO2, a very large initial lithium capacity of 810 mAh·g−1 has ever been reported, which corresponds to x = 2.42 (Li2.42TiO2) [43]. However, this capacity decreased to 200 mAh·g−1 after 50 cycles. This high irreversible capacity is normally attributed to the fact that a large part of the total lithium consumed is caused by the reaction of H2O/OH species adsorbed on the surface of NTs and form Li2O.

2.1.1 Amorphous versus anatase TiO2 NT anodes

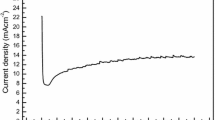

In this section, we will carefully compare the electrochemical performances of amorphous and anatase titanium dioxide nanotubes, as detailed below. Figure 1 depicts the lithiation and delithiation curves of amorphous and anatase titanium dioxide electrodes. There is a smooth curve without voltage platform on amorphous TiO2 nanotube anode during the process of lithiation/delithiation. However, for the anatase TiO2 NT anode, the lithiation/delithiation curves appear stable at 1.73 V and 1.9 V. Initial lithiation capacities of these amorphous- and anatase-phase TiO2 NT anodes are 0.207 mAh·cm−2 and 0.110 mAh·cm−2, respectively. It is obvious that the storage capacity of lithium ions in amorphous titanium dioxide nanotubes is significantly superior to that of anatase-phase nanotubes. This indicates that the amorphous TiO2 NT anodes can be available to accommodate more Li per titanium dioxide molecule than the anatase anode [42]. The higher capacity of amorphous TiO2 NT anode [35, 44,45,46,47,48] can be ascribed to several reasons, including partly reversible surface lithiation [49], pseudocapacitive lithiation/delithiation behavior of surface lithiation [35] or structural self-improvement during cycling [44]. It can also be seen from Fig. 1 that the irreversible capacity of amorphous TiO2 NTs (35% of initial discharge capacity) is higher than that of anatase ones (5% of initial discharge lithium capacity). The different irreversibility indicates that the irreversible capacity of amorphous TiO2 NT is greater, which is caused by the structural and chemical defects making as Li+ traps [42]. In addition, such high irreversibility can be attributed to the physical and chemical absorption of H2O and OH on the surfaces of amorphous TiO2 nanotube arrays. And through the literature investigation, it is found that the content of absorbed H2O and OH is ~ 8.3 wt% and ~ 6.4 wt% [43, 50, 51], respectively, in amorphous TiO2. Therefore, especially in the first cycle, it can be expected that Li ions will react with these adsorbed substances to produce almost irreversible Li2O (H2O + Li+ + e− → LiOH + \(\frac{1}{2}\)H2, then LiOH + Li+ + e− → Li2O + \(\frac{1}{2}\)H2) [43, 52, 53]. Recently, on the basis of maintaining high capacity, reducing irreversible capacity and improving the cycling stability of amorphous TiO2 already become the focus of research.

a Lithium insertion and extraction curves of amorphous TiO2 NT. b lithiation/delithiation curves of anatase TiO2 NTs (Cells charged and discharged at a constant current of 100 μA·cm−2, a voltage range of 3.0 V and 1.0 V). Reproduced with permission [42]. Copyright 2020 Elsevier

Later, Jiang et al. [46] reported on the amorphous TiO2 NT anodes formed by anodizing 3D porous Ti foams. Interestingly, this sample possesses higher areal capacity and cyclic stability compared to previously informed TiO2 nanotube anodes fabricated by anodizing planar Ti foil [54, 55]. This provided a new direction for the research of enhanced-performance lithium battery. Figure 2a, b and c describes the rate performance of amorphous titanium dioxide nanotubes and anatase ones. As shown in Fig. 2b, not only the main plateaus appeared at around 1.75 and 1.9 V in the lithium insertion/extraction curves of anatase-phase TiO2 anode, but also another pair of platforms arose at around 1.46 V and 1.73 V. The primary plateau corresponds to the phase transition between the Li-poor LixTiO2 (0.01 < x ≤ 0.21) with a tetragonal anatase structure (I41/amd) and the orthorhombic Li-titanate (Li~0.55TiO2) phase (Imma) [56]. And the additional pair of plateaus shows a transition to the second phase of fully lithiated Li1TiO2 (I41/amd). And the fully intercalated lithium typically occurs when the size of the titanium dioxide crystal is less than 7 nm [39, 56], as described above. These main [57, 58] and additional plateaus [39] are consistent with that reported in the literature for anatase TiO2 electrodes [4, 56]. The amorphous TiO2 NT anode exhibited higher rate capability than the anatase TiO2 NT anode, which is apparent in Fig. 2c. This amorphous TiO2 NT anode grown by way of electrochemical anodizing 3D porous Ti foam has a large area capacity, improved rate performance and great cycle stability. This is owing to its high defects, loose structure and disorder, which not only promote a significant acceleration of the Li+ diffusion process, but also boost the improvement in interface charge transfer kinetics.

Galvanostatic lithiation and delithiation curves of a amorphous and b anatase titanium oxide anodes measured at different C-rates with a range of 0.125–12.5 C; c rate performance, and d cycling stability and coulombic efficiencies of amorphous and anatase titanium dioxide anodes. Reproduced with permission Ref. [46]. Copyright 2018 American Chemical Society

Figure 3 reveals a typical cyclic voltammograms (CVs) and the corresponding galvanostatic lithiation curves of amorphous TiO2 and anatase TiO2−x (x < 2, oxygen-deficient) NTs [35]. As we can see, there is a broad symmetrical wave around 1.8 V in the CV of amorphous NTs, indicating high reversibility [34]. This shape of CV for amorphous NTs has been widely reported. By conducting CV analysis at different scan rates [34, 35, 59, 60], it has been confirmed that the high symmetry or quasi-superposition of the cathode and anode waves corresponds to the pseudocapacitive faradaic behavior. Moreover, the kinetics of lithiation/delithiation of such pseudocapacitive faradaic behavior are not limited by the solid-state diffusion of lithium ions [60]. And compared with anatase TiO2 NTs in LIBs, amorphous TiO2 NTs have a higher diffusion coefficient, which helps to obtain higher coulombic efficiency and higher rate capability. This higher diffusion coefficient is caused by the high degree of disorder and a large number of defects in amorphous titanium dioxide nanotubes [61]. In addition, there is a peak at around 1.1 V in the CV of amorphous titanium dioxide nanotubes, which indicates part of the titanium dioxide undergoes a phase transformation to form cubic phase Li2Ti2O4 [34, 44]. Correspondingly, a plateau in the constant current discharge curve can be observed, and it is only visible in the first cycle and seems to be irreversible. [35]. As for the anatase TiO2−x NTs, a pair of sharp peaks appears at 1.72 V and 2.03 V in CV, respectively. This peak pair represents the transition from the Li-poor phase LixTiO2 [62] to the orthorhombic Li titanate (Li∼0.55TiO2) [62, 63]. Additionally, for the cyclic voltammogram of anatase nanotubes, another pair of smaller peaks is observed around 1.46/1.74 V, corresponding to the subsequent phase transition from Li∼0.55TiO2 to completely lithiated LiTiO2 [34, 63]. These phase transitions of anatase TiO2 appear as potential plateaus in the constant current discharge curve, which is in agreement with the conclusion of Fig. 2.

Cyclic voltammograms of a amorphous TiO2 nanotubes and b anatase TiO2−x nanotubes; c initial constant current lithium insertion curves of amorphous TiO2 nanotubes, d of anatase TiO2−x nanotubes, cells discharge to 1.1 V and at a rate of 0.05C. Reproduced with permission Ref. [35]. Copyright 2018 American Chemical Society

Kinetic properties of TiO2 NT anodes during the lithiation/delithiation process are usually analyzed by electrochemical impedance spectra (EIS). Representative Nyquist plots of the amorphous TiO2 (a-TiOx) and anatase TiO2 (c-TiOx) anodes are shown in Fig. 4, which also display the measured data and equivalent circuit in the inset. According to the equivalent circuit model, the best fitting curve is obtained and represented by a solid line in Fig. 4 [46]. In the equivalent circuit model, RΩ and Rct correspond to electrolyte resistance and interfacial charge transfer resistance, respectively. And the CPE is a constant phase element, Zw is the finite-length Warburg element and Cint is the differential intercalation capacitance. The fitting results in the chemical diffusion coefficients D value of the amorphous TiO2 being 2 × 10−14, while that of the anatase TiO2 electrode is 3 × 10−16 cm2·s−1. The Rct values of amorphous and anatase TiO2 are 29 Ω and 78 Ω, respectively. The higher chemical diffusion coefficient and lower interfacial charge transfer resistance of the amorphous TiO2 anode indicate that the diffusion speed of Li + and the speed of interface charge transfer of the amorphous TiO2 material are both faster than those of the anatase material. Thus, lithium storage capacity and rate performance of amorphous titanium dioxide are superior to the anatase titanium dioxide electrode. This good performance of the amorphous titanium dioxide anode may be attributed to that the Li+ exposed to the entire surface of the electrolyte can “enter” the amorphous TiO2, but in the anatase NTs, Li+ needs to diffuse side across the whole crystal surface to interact with crystal channels where ions can diffuse and coincide. And previous researches showed that the implant and transfer of Li+ are more easy in the [001] direction [58]. However, the surface of anatase titanium oxide is normally anisotropic, as it has a highly polycrystalline structure and many different grain orientations, which means that nonpreferred orientations may be exposed on the surface of NT [46], further leading to poor kinetic performance of the anatase TiO2 electrode.

Nyquist plots of amorphous TiO2 (a-TiOx) and anatase TiO2 (c-TiOx) anodes; insets showing equivalent circuit and measured data; solid lines being best fitted curves. Reproduced with permission Ref. [46]. Copyright 2018 American Chemical Society

From the above comparison, compared with anatase TiO2, amorphous TiO2 NT has more advanced performances, such as larger initial capacity, superior rate performance, higher electronic conductivity and better diffusion coefficients. These are mainly due to the high disorder, larger number of defects and OH in amorphous titanium oxide. Unfortunately, poor cyclic stability of amorphous TiO2 NT severely limits its practical application to LIBs. Therefore, maintaining the complete crystal form of the body and introducing the amorphous shell layer of TiO2 tube, which combines the advantages of crystalline and amorphous TiO2, maybe can produce an excellent anode for lithium batteries.

2.1.2 Influences of nanotube morphology on lithiation performances

The electrochemical performances of TiO2, such as specific capacity and Li+ insertion/extraction kinetics, are strongly related to their morphology. And because of the larger surface area and shortened lithium diffusion path, the nanostructured TiO2 has a significantly higher specific capacity and enhanced kinetics performances compared to bulk or macroscopic TiO2. As we all know, the bulk anatase TiO2 typically has a lithium-ion insertion coefficient of 0.55 (Li0.55TiO2) [64]. However, when the size of nanostructured TiO2 is less than 7 nm, they can be fully lithiated and form LiTiO2 [65]. Among various nanostructured TiO2, the highly ordered TiO2 nanotubes fabricated by electrochemical anodizing have aroused widespread interest. As a 1D nanomaterial, TiO2 NTs not only possess large surface areas and short ion diffusion paths, but are also directly electrically connected to the metal substrate, making nanotubes possible electrode materials for LIBs. At the same time, it is well known that the morphology of as-anodized TiO2 nanotubes is also affected by many factors, and the difference in nanotube morphology also affects their electrochemical performance. Therefore, some studies have researched the effect of the nanotube array morphology on the resulting property in LIBs. And it has been found that the overall capacity of the anatase-phase titanium dioxide nanotubes is determined by the surface pseudocapacitor lithium storage and bulk lithium storage [57, 66]. Zhu et al. [57] found firstly that the thickness of the TiO2 NT film, that is, the length of the nanotube, had no influence on the rate character of the NT electrode. In contrast, the subsequent study has shown that the electrochemical performances of nanotubes have a clear correlation with their morphology [66]. Generally, nominal Li-ion capacity can be improved via growing the length and reducing the diameter of NT, and TiO2 nanotubes with the thinnest wall thickness possess the best rate performance [66,67,68].

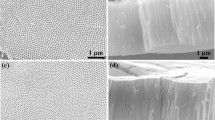

In order to further understand influences of nanotube morphology on lithiation performances, the key factors in terms of nanotube morphology which affect the electrochemical properties of anodized self-organized nanotube arrays have been systematically investigated by Kirchgeorg et al. [38]. It has been found that in addition to the length, wall thickness and diameter of the NTs; top morphology, the appearance of initiation/nanograss layers and double-walled morphology also affect the lithium storage performance of the TiO2 NTs.

As expected, nanotube arrays with the longest tube length hold the largest areal specific capacity. However, if the area capacity is normalized by the length of the tube, the shorter NTs demonstrate a better rate capacity than longer ones. The reason why the electrochemical performance decreases with the increase in tube length is generally divided into two aspects: on the one hand, the surface morphology can change with the rise in tube length and the long tube is usually covered with a layer of nanograss [24, 26]. On the other hand, when NTs are grown in an organic electrolyte, an inner carbon-rich layer is formed in NT which will reduce the efficiency of lithium insertion [28, 69].

When nanotubes are experiencing prolonged anodization, their tops are exposed to the corrosive medium longer than the bottoms. Thus, the tops of the tubes are excessively etched and needle-like structures appear on the top of tubes. And these needles eventually collapse, forming bundles on the nanotube surface called “nanograss” [24, 26]. The nanograss has been found that has a nonnegligible influence on the lithium storage of NTs. First, the appearance of nanograss can be related to surface charge, and they contribute to Li storage of NTs like an electrochemical double layer. However, the observed efficiency decrease is not caused by this factor. Furthermore, because the inner carbon-rich layer more tends to be etched, the composition and dimension of the nanograss are considered more like single-walled nanotubes; thus, the nanograss is constituted of tapered, collapsed tube tops and has impacts on the performance of nanotubes.

When NTs with high aspect ratio are anodized in various organic electrolytes, a carbon-rich oxide layer can be formed at the interior tube wall [28]. Through the work of Paul et al., we can see that grazing incidence scattering technology can be used to characterize the compositions of the nanotube wall [69]. In order to reduce the negative influences of the internal carbon-rich layer on the TiO2 NT lithium storage performance, there are generally two different and effective approaches for double-walled NTs. First, for the double-walled character of traditional TiO2 nanotubes, the carbon in the carbon-rich layer can be dissolved by cathodic polarization in aqueous Na2SO4 electrolyte [70]. When the resulting NTs are used as the anodes of lithium batteries, the capacity of these anodes is increased by about 17% compared with the same-length double-walled nanotube anodes. Furthermore, Mirabolghasemi et al. [71] and Kirchgeorg et al. [38] prepared single-walled nanotubes by the same experimental method. And compared to double-walled nanotubes of similar size, the lithium capacity can even be increased by 33%. It is also found that the normalized areal capacity of such single-walled TiO2 nanotubes is 40 μAh·cm−2·μm−1, and it is equivalent to that of the water-based nanotubes [24]. Because the length of such single-walled TiO2 NTs is much longer than that grows in water-based electrolyte, they can achieve a higher total capacity in LIBs.

2.1.3 Influence of texture on lithiation properties

According to previous studies, TiO2 NTs with [001] preferred orientation exhibit improved lithium-ion transfer kinetics compared to randomly oriented nanotubes, because the [001] preferred orientation provides more effective lithium-ion diffusion pathways along the c-axis in anatase NTs [72, 73]. And it has been reported that the c-oriented TiO2 NT crystalline structure can be manufactured by anodizing the polished Ti foil in an ethylene glycol electrolyte containing 2% w/w water. As a comparison, when anodizing unpolished Ti foil, a randomly formed NT crystal structure can be generated or anodized with other ingredients in the water in the electrolyte [74, 75]. Furthermore, annealed amorphous TiO2 nanotubes in an oxygen-deficient environment can also obtain highly c-oriented NTs. In this way, TNs with a long tube and high c-oriented crystalline structure are formed. When they are used as anodes for LIBs, high rate capacity can be obtained [72]. However, compared with the fully oxidized TiO2 nanotubes with random orientation, the nanotubes produced by this annealing process not only have a preferential crystal orientation, but also have a higher oxygen vacancies (V–O) concentration [72]. Thus, the high rate capacity cannot be attributed solely to the preferential orientation, since it is well known that V–O can also enhance the Li-ion insertion/extraction performance of TiO2 anodes [33, 63, 76].

Recently, the TiO2 NTs are mostly free of V–O, and the preferential crystallographic orientation in the [001] direction was produced by Auer et al. [58]. They prepared self-organized anodized TiO2 NTs in an electrolyte containing 2 wt% water and then annealed these grown NTs at 450 °C in air. As a result, the nanotubes are not only accompanied by the desired preferential crystal orientation along the [001] direction, but are also almost completely free of oxygen vacancies. As a comparison, randomly oriented TiO2 NTs are prepared by the anodizing Ti substrate in an electrolyte containing 10 wt% H2O. In order to ensure accuracy, this reference (randomly oriented) NTs have similar morphology and the same annealing conditions with the preferential crystal orientation TiO2 NTs. Preferentially oriented TiO2 NTs have enhanced kinetics during the lithium insertion and extraction compared with randomly oriented TiO2 NT anodes. However, for preferentially oriented and randomly oriented nanotubes, the thermodynamic properties are almost identical. By separating the kinetic and thermodynamic characteristics of TiO2 NTs during lithium insertion and extraction process, it can be found that the preferential orientation in the [001] direction increases (without oxygen vacancies) the charge storage capacity and rate capability of the TiO2 NT electrode [58].

At almost the same time, Kashani et al. [50] investigated the synthesis method of anodizing TiO2 nanotube arrays in an electrolyte containing 3% (w/w) water by using different counter electrodes. Their research reveals that the crystal orientation of the NTs strongly relies on the counter electrode materials used in the anodizing process. As shown in Fig. 5, the XRD patterns indicate that the annealed (500 °C, 3 h) TiO2 NTs are pure anatase structure. And in each case, facets (101), (004) and (200) appear in the X-ray diffraction (XRD) patterns, while the peak intensity ratios of 2.5, 2.1, 1.7, 1.5, 1.0 and 0.9 correspond to the counter electrodes of Pt, graphite, Ni, Ti, Cu and Al, respectively. Therefore, it is evident that the anatase TiO2 NTs prepared with the Pt counter electrode exhibit the best [001] preferred orientation. As we all know, the weight loss during heating in the temperature range of 250–500 °C is due to the dehydroxylation of the main body of TiO2 NTs. And these removed OH groups are actually injected during the anodizing process. As a result, based on thermogravimetric analysis data, the preferred orientation can be attributed to rare defects of anatase NTs [77,78,79,80]. In addition, it was found that the counter electrode also affects the crystalline orientation of nanotube arrays with dissimilar percentages of water content (2% w/w) in the electrolyte. It also confirms that the water content of the electrolyte will have an effect on the crystalline orientation of the nanotube, which is consistent with the aforementioned research ref 46.

XRD patterns of all these anatase TiO2 nanotube samples (peaks of TiO2 anatase phase marked as the miller index). Reproduced with permission Ref. [50]. Copyright 2020 Royal Society of Chemistry

Synthesized TiO2 NTs using a Pt counter electrode with [001] preferred orientation showed good rate performance, high reversible areal capacity and stable cyclability. And the preferred orientation also contributes to good kinetics of the lithiation and delithiation process. Because of the bulk anatase TiO2 with an anisotropic tetragonal structure and thus the preferentially oriented TiO2 NTs, Li+ diffuses faster into the anatase lattice along the c-axis direction. Figure 6 shows a schematic diagram of the lithium intercalation process of nanotubes. As we can see, Li+ is directly transferred into the TiO2 NT array crystal channel at a high density of (004) plane along the [001] direction, while in disorderly orientation TiO2, Li+ should traverse a longer winding path, thereby reducing the diffusion speed. In summary, when TiO2 NTs have a preferred [001] orientation, they possess appropriate electrochemical properties, such as good rate performance, high reversibility, stable cyclability, low charge transfer resistance and high exchange current.

Schematic diagrams of a Li+ insertion in the preferred orientation TiO2 nanotube crystals along [001] direction and the disorderly orientation TiO2 nanotube crystals.; b (101) and (004) plane positions in the TiO2 crystals. Reproduced with permission Ref. [50]. Copyright 2020 Royal Society of Chemistry

2.2 Electrochemical properties of mixed-phase TiO2 NT anodes

When TiO2 nanotubes are produced by electrochemical anodization, they are amorphous, and then through an annealing at 450 °C, the anatase structure can be easily obtained. At an annealing temperature above 500 °C, a rutile fraction can be detected; meanwhile, mixed anatase and rutile phases are formed, and at 900 °C, the major rutile phase is acquired [28, 48]. However, it is found that the collapse of nanotube is strongly linked to the conversion rate of rutile [28]. Morphology of the complete nanotube layers can be retained at an annealing temperature below 700 °C [28, 81]. Thus, for electrochemically anodized TiO2 NTs with a complete tube structure, only the mixed phase (anatase and rutile phase) rather than the pure rutile phase can as anodes for LIBs.

The electrochemical property of amorphous, anatase and mixed anatase/rutile phases TiO2 NTs has been compared by Guan et al. [48]. Among these three types, amorphous TiO2 nanotubes process the highest lithium capacity. This is because the Li-ion diffusion coefficient of amorphous titanium dioxide is larger than that of crystalline one. Additionally, capacity of mixed-phase titanium dioxide nanotubes is larger than that of pure anatase nanotubes, because the formation of rutile phase in anatase nanotubes facilitates the Li-ion transportation [48]. Subsequently, the work of Wei et al. [82] also indicates that the mixed-phase TiO2 NTs possess a higher specific capacity compared to the anatase NTs. And the mixed-phase sample shows better cyclic performance and rate performance than the anatase sample. The electrochemical properties of mixed-phase TiO2 NTs are enhanced, because the influence of the rutile effect and the increased grain boundaries can facilitate Li-ions transportation [82].

3 Lithiation process in doped TiO2 NT anodes

As a semiconductor material, the band gap of TiO2 (e.g., 3.0/3.2 eV for rutile/anatase) is wide, and the semiconductor nature results in inherently inferior conductivity of TiO2, which limits its application in high-performance lithium batteries [70, 76, 83, 84]. The inferior conductivity of TiO2 indicates that both electrons and ions have poor transmission problems and lead to disappointing rate performance of TiO2 anodes in LIBs [1, 13, 85]. Therefore, intensive investigations have been devoted to solving the problem of poor transport of the lithium ion and electron in TiO2 electrodes. Researchers have found that nanostructured metal oxides can curtail the diffusion path of electrons and lithium ions, which can alleviate these issues [42, 86, 87]. Furthermore, incorporating some elements such as Ti3+ [85], C [88], N [89], Ni2+ [90], V3+ [91], Sn4+ [84] into TiO2 lattice can solve these problems.

3.1 Self-doped (Ti3+-doped) TiO2 NT anodes

3.1.1 Reduced TiO2 NTs produced by annealing

Introducing defects into TiO2 and other metal oxides can improve their performance in some applications. For TiO2 NTs, it is very important to develop effective reduction strategies to raise their ion and electron conductivity by introducing quite a few electron-donating defects such like oxygen vacancies (Ti3+ sites) into the structure. To this end, masses of researches have concentrated on producing reduced TiO2 NTs by performing high-temperature annealing under oxygen-deficient atmospheres including reductive (H2 [92, 93], CO [94] and vacuum [72]) and inert (Ar [95] and N2 [96]) atmosphere.

Lu et al. [33] have produced TiO2 nanotubes with improved rate capability for Li+ batteries by treating TiO2 NTs in a reducing environment (5% H2 and 95% Ar). Their method is simple and effective and can heighten the electrochemical performance of electrochemical anodizing TiO2 nanotubes intended for anode material in LIBs. This hydrogenation treatment (annealing process) introduces a large quantity of oxygen vacancies into the TiO2 crystal lattices, and the resulting TiO2 NTs are beneficial to the bulk n-type conductor. Therefore, improved rate performance is mainly due to the enhancement of the electrical conductivity of the entire titanium dioxide tubes rather than the conductive conductivity of the surface coating. Subsequently, Brumbarov et al. [63] reported the lithium insertion and extraction characteristics of TiO2 NTs grown by anodization and then annealed in Ar and Ar/C2H2. After this annealing process, Brumbarov et al. not only produced oxygen-deficient TiO2 nanotubes (TiO2-x NTs), but also obtained anoxic and carbon coated TiO2 nanotubes (TiO2−x-CNTs). Their work reveals that the lithium storage capacity of the TiO2−x-C NTs reaches (320 ± 68) mAh·g−1 (Li0.96TiO2), while that of TiO2−x NTs is just (180 ± 38) mAh·g−1 (Li0.54TiO2). In addition, TiO2−x-C NTs demonstrate a higher rate capability than TiO2−x NTs, which indicates that TiO2−x-C NTs are promising anodes for high-energy and large-power LIBs. As we all know, double-layer capacity can be estimated by cyclic voltammetry measurements. Here, the double-layer capacitance of TiO2−x and TiO2−x-C NT is 85 μF·cm−2 and 20 μF·cm−2, respectively. As depicted by the electrochemical impedance spectroscopy, the charge transfer resistance of TiO2−x-C NT is small at the electrode/electrolyte interface, which facilitates the shift of Li+ from the electrolyte to the electrode.

Actually, in addition to oxygen vacancies, cationic vacancies can also be generated during TiO2 annealing. To further research the formation and effects of point defects in TiO2 (oxygen and cation vacancies) created through annealing in different atmospheres, anatase TiO2 NT array after annealing in various different atmospheres including O2, Ar, N2 [32] as the anode in the LIBs was systematically studied.

If TiO2 is annealed in an oxygen-poor atmosphere, oxygen vacancies and free electrons can be produced, meanwhile reducing Ti (Eqs. (2), (3)) [32, 92, 97,98,99,100], which can be depicted by the classical Kröger–Vink formula as follows:

Where \({\text{V}}_{\text{O}}^{ \cdot \cdot }\) is the oxygen vacancy, \({\text{Ti}}_{\text{Ti}}^{x} \, \text{and} \, {\text{Ti}}_{\text{Ti}}^{\prime }\) is the reducing Ti. Here, the formation of oxygen vacancies may arouse higher electrical conductivity, larger capacity and better rate performance [97, 99, 101, 102]. As shown in Eq. (4), when oxygen is present during the heat treatment, any existing oxygen vacancies will be eliminated, resulting in a higher stoichiometric amount of TiO2, and the \({\text{O}}_{\text{O}}^{x}\) corresponds to the reduced O2:

Then, if water vapor (WV) is added to the oxygen-enriched annealing condition, the cation vacancies can be stabilized [103]. In detail, the WV can protonate the oxygen sites already present in the sample and yield a positive charge, which would subsequently stabilize the existing cation vacancies (Eq. (5)). It has been found that the cation vacancies in TiO2 and other metal oxides can provide more lithium insertion sites to increase lithium battery capacity [103,104,105,106]. Furthermore, as described in Eq. (6), Li ions can be exchanged with protons without affecting the charge balance in the process of intercalation lithium, which would provide additional locations to store Li, thus also increasing capacity [103] of TiO2:

Where, \({\text{V}}_{\text{Ti}}^{\prime \prime \prime \prime } \, \text{and}\, {\text{V}}_{\text{O}}^{ \cdot \cdot }\) are the cation vacancy and oxygen vacancy, respectively. \({\text{OH}}_{\text{O}}^{ \cdot }\) is the protonated oxygen vacancy, and when proton (H+) in \({\text{OH}}_{\text{O}}^{ \cdot }\) are replaced by lithium, \(({\text{OLi}})_{\text{O}}^{ \cdot }\) is formed. Savva et al. [32] found that the generation of oxygen vacancies increases the electrical conductivity of the sample; conversely, Ti vacancies may lead to a slight decrease in conductivity. These effects of point defects (oxygen and cation vacancies) have been predicted by density functional theory calculations. And the Raman spectroscopy also proves the formation of oxygen and cation vacancies. As expected, both oxygen vacancies and Ti vacancies help to improve specific capacity of the TiO2 nanotube anodes in the lithium-ion battery. Capacity of TiO2 nanotube annealed in Ar and N2 atmosphere increased by 10% and 25%, respectively, while the capacity of WV-treated TiO2 NTs increased by 24% (Fig. 7). The increased capacity of TiO2 NTs treated with Ar and N2 can be attributed to the growing electrical conductivity caused by oxygen vacancies. Furthermore, the boosting electrochemical performances in TiO2 NT treated with water vapor can be explained by the accelerating Li+ diffusion owing to Ti vacancies. The improvement in capacity caused by the formation of Ti vacancies implies that the electronic conductivity may not be the only indicator of whether lithium battery property can be enhanced. In understanding the lithium storage and transfer characteristics of intercalated oxide electrodes, both electronic and ionic conductivities in the material should be considered [32].

Cycle performances of anatase TiO2 nanotube electrodes annealed in different atmospheres (cells lithiated and delithiated between 0.9 to 2.5 V, at 0.05C). Reproduced with permission Ref. [32]. Copyright 2020 Royal Society of Chemistry

3.1.2 Reduced TiO2 NTs produced by electrochemistry

Generally speaking, current technology for doping pristine TiO2 largely focuses on thermal annealing in a reducing environment. However, this method for preparing highly conductive TiO2 NTs involves very harsh reducing conditions such as high temperature, pressure, vacuum and dangerous H2 gas. Fortunately, a mild, safe and fast cathodic electrochemical reduction route has recently been exploited to prepare reduced TiO2 NTs [31, 70, 85, 107,108,109,110,111]. The cathodic reduction experiment is normally carried out in a three-electrode or two-electrode system at room temperature, using the original TiO2 NTs as working/cathodic electrodes and Pt grids as counter/anode electrodes. And it was found that cathode-reduced TiO2 delivers higher photocatalytic efficiency and charge storage capability. This is because the field-driven interaction between small ions (such as H+ and Li+) modifies the electronic structures of TiO2 and enhances its performance [112,113,114,115]. However, in many cases, the effect of the cathodic reduction treatment fades away quickly after removing the bias voltage (around few minutes or hours), which leads to the low stability of the reduced TiO2 [113, 114]. This low stability may be due to the fact that most cathodic treatments reported to date are performed in the low-viscosity aqueous electrolytes. This is consistent with that the dynamic performances of ion insertion or release from titanium dioxide are very dependent on the electrolyte viscosity which is reported by Song et al. [116].

Subsequently, Li et al. [109] reported the electrochemical cathode doping of anatase TiO2 embedded in a glycol electrolyte by protons. The self-doped black TiO2 with high stability and beneficial effects of reduction treatment can last over one year. In addition, compared to primitive anatase TiO2, the self-doped titanium dioxide possesses an obviously lower band gap value and better electrical conductivity. As a conclusion, the doped TiO2 films largely improved the light conversion, photocatalytic efficiency and capacitance of the supercapacitor. In particular, it is worth noting that the specific capacitance of this treated TiO2 has increased by around 42 times, which is remarkably higher than previous studies of TiO2 doped in an aqueous electrolyte (around 13-fold improvement) [117].

These room-temperature cathodic reduction methods have been proven to be used to prepare reduced TiO2 NTs and their composite materials to be applied for field emission [108], photocatalysis [107, 109] and supercapacitors [70, 109, 111], but they are seldomly used in Li-ion batteries. Recently, a 3D ordered TiO2 NT doped in situ with Ti3+ for lithium-ion battery anode was designed and implemented via one-step facile mild electrochemical method by Duan et al. [85]. As expected, the resulting cathode self-doped TiO2 NTs with increased electrochemical property can be attributed to the modified electronic structures of TiO2. This changed electronic structure is thought to be caused by the field-driving interaction of H+. It has been found that these cathode-doped TiO2 nanotubes are accompanied by oxygen vacancies (V–O), Ti3+ ions and OH groups. When NTs are used as anodes in LIBs, these defects and groups can lower the resistivity, promote lithium-ion diffusion and increase lithium battery capacity [85]. However, in most cases, reported cathodic-treated TiO2 NTs for anodes of LIBs are fabricated by doping the pristine TiO2 with low-viscosity aqueous electrolyte at small (around several volts) and direct voltage. Such doping condition leads the doped TiO2 anodes to possess limited enhancement of specific capacity and cyclic stability in LIBs [85, 110].

Actually, it was observed that bubbles were generated on the electrode during the doping process. If the bubbles are too large, they will cause the TiO2 NT film to rupture and the nanotubes to collapse. It has been observed that the generation of bubbles is related to the value of the cathode doping voltage. A large voltage will create the formation of large bubbles; in other words, an excessive voltage will destroy the nanotube structure [107]. However, as we all know, the larger voltage will more powerfully force the H+ from the surface into the interior of the active TiO2. And at the same time, the H elements reduce the tetravalent Ti to trivalent and form stable oxygen vacancy [107]. Therefore, it is a challenge to achieve high-voltage cathode doping while controlling the generation of bubbles. The viscosity of the electrolyte is another important factor affecting the generation of bubbles during the cathode doping process. And a suitable electrolyte viscosity can provide a suitable kinetic process for inserting ions into active materials [116]. A recent study reveals that doping TiO2 NTs in ethylene glycol solution under a large pulse voltage can produce self-doped nanotube anodes with significantly improved electrochemical performance [31]. The applied pulse voltage is up to tens of volts, and the period is 4 min (− 40 V, 2 min and − 20 V, 2 min). After this doping process, the nanotubes preserve their tubular structure well and possess a stable black appearance [31]. As observed, the resulting self-doped titanium dioxide nanotubes are rich in V–O/Ti3+ and OH. It is worth noting that when TiO2 NTs are used as anode in LIBs, the initial discharge capacity of the cathode-doped black TiO2 NT electrode is more than four times that of the undoped TiO2 NT. In addition, compared with undoped nanotubes, self-doped nanotubes have higher electronic conductivity and ion diffusion rate.

To reveal the reasons for the improved electrochemical performance of self-doped nanotubes, the surface characteristics and chemical environment of the prepared as-anodized and cathode-doped titanium dioxide nanotubes were investigated by X-ray photoelectron spectroscopy (XPS), electron paramagnetic resonance (EPR) and X-ray absorption near-edge spectroscopy (XANES) (see Fig. 8). Depending on Fig. 8a, b, it has been found that doped TiO2 NTs had higher concentration of Ti3+/oxygen vacancies and OH than undoped TiO2. Moreover, these extra defects of self-doped NTs are caused by the transfer of H species from the counter electrode to the TiO2 NTs electrode, which occurs during the cathodic pulse doping process. These H species reduce a part of Ti4+ to Ti3+ to leave some oxygen vacancies and form more OH in the self-doped nanotubes. Thus, the possible mechanism of self-doped TiO2 NTs has been proposed as Eq. (7),

Where Ti4+O2 means the TiO2 and the Ti is tetravalent in Ti4+O2. The Ti3+O(O-H) corresponds to reduced TiO2, in which Ti has a valence of 3 and there are oxygen vacancies and hydroxyl groups (O-H) in Ti3+(O-H). And this resulting Ti3+ ions act as donor centers, and the electrical conductivity increases with the density of the donor centers within TiO2 structure [31].

a Ti 2p XPS, b O 1s XPS, c EPR, d Ti L2,3-edge XANES and e O K-edge XANES spectrum of self-doped and as-anodized titanium dioxide nanotubes. Reproduced with permission Ref. [31]. Copyright 2020 Elsevier

As shown in Fig. 8c–e, the measurements of EPR and XANES are in good agreement with the measurements of XPS. The conclusion is that doped titanium dioxide nanotube surface has richer hydroxyl and oxygen vacancy, which are the main reasons for the significant increase in the capacity of the self-doped TiO2 nanotube anodes in LIBs [109]. According to previous reports, it can be known that when H+ and Li+ ions are in the suitable electrolyte, they can be reversibly inserted into and extracted from the TiO2 NT anodes [118, 119]. Therefore, those Ti3+O(O–H) groups formed in Eq. (7) can also store Li+. And the corresponding mechanism can be depicted as Eq. (8):

Where Ti3+O(O-H) is the reduced TiO2 formed in Eq. (7); and during the lithium insertion process Li+ reversibly replaces the H+ in Ti3+O(O-H) to form Ti3+O(O-Li), thus increasing lithium capacity of TiO2 NT anode. In summary, a schematic diagram of the lithiation process of undoped and doped TiO2 nanotubes is shown in Fig. 9. We can see that for the anodized amorphous TiO2 nanotubes, the lithium capacity comes from the intrinsic TiO2, and few hydroxyl and V–O groups originate from electrochemical anodization.

Schematic representation of cathode doping and lithiation of TiO2 nanotubes. a, b macroscopic schematics of as-anodized and self-doped TiO2 NTs, c, d corresponding microscopic atomic structure; e, f microscopic structures after lithiation. Reproduced with permission Ref. [31], Copyright 2020 Elsevier

For the self-doped titanium dioxide nanotubes, the additional V–O and OH groups caused by electrochemical cathode doping not only directly lead to the enhancement of the lithium storage capacity [31], but also improve the electric conductivity and Li+ diffusivity. Therefore, the cathode self-doped TiO2 nanotubes possess large specific capacity and good rate capability.

3.2 Foreign ion-doped NT anodes

It is well known that the disadvantages of TiO2 nanotube anodes are poor electronic conductivity and low ion diffusion rate, which lead to poor rate performance and rapid capacity decay during cycling in LIBs. In order to address these shortcomings, the self-doping (Ti3+-doping) of nanotubes concentrated by researchers has been summarized above. In addition, the incorporation of foreign species into TiO2 NTs is another effective method to enhance the electrochemical property of NTs, which has been proved, and the recent relevant investigations are summarized as follows.

Carbon is a wonderful conductive agent, and carbon-doped (C-doped) TiO2 has increased electronic conductivity, which leads to higher electrochemical performance of LIBs [88]. Kim et al. [88] annealed TiO2 NT in a 20% C2H2/N2 gas mixture at the temperature of 500 °C, resulting in the C-doped TiO2 NT. It has been found that the C-doped TiO2 NTs exhibited superior cycling performance and better electrochemical kinetics than the undoped TiO2 NT arrays. The enhanced electrochemical performance of C-doped TiO2 NT is considered because the improvement in electronic conductivities of intrinsic TiO2 NT materials.

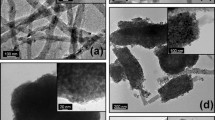

Nitrogen doping (N-doping) is also an effective way to increase the electrochemical property of titanium dioxide nanotube [120, 121]. Zhang et al. [89] have fabricated TiO2 nanotube by electrochemical anodization and then annealed the anatase TiO2 in flowing ammonia gas. The resulting samples had a high nitrogen doping concentration. Similar to carbon doping, here the nitrogen doping can also effectively improve the electrical conductivity of anatase TiO2 NTs, thereby substantially improving the rate capability of the TiO2 NT anodes. As for this designed N-doped anatase TiO2 NT, when the lithiation/delithiation rate increases from 0.1 to 10 C, the lithium capacity only decreased from 200 to 100 mAh·g−1, which confirms the enhancement of rate capability. And it was proved via in situ transmission electron microscopy (TEM) that although the structure and chemical evolution of N-doped nanotubes are similar to those of undoped ones during lithiation, nitrogen doping obviously promotes the lithium insertion into nanotubes and improves the overall electrochemical performance.

In addition to annealing, TiO2 nanotubes are doped with foreign alloy ions by anodization, which is another common doping strategy [84, 122, 123]. For example, anodizing co-sputtered Ti–Sn thin films in a viscous glycerol electrolyte containing 1.3 wt% NH4F and 10 wt% H2O can fabricate highly ordered Sn-doped titanium dioxide nanotubes [84]. During the electrochemical anodizing process, nanotubes were formed, accompanied by Sn4+ instead of Ti4+; as a result, Ti1-xSnxO2-type (x = ~ 0.5) nanotubes were obtained. The fact is that Sn4+ substitution of Ti4+ in titanium dioxide normally has a phase transformation from anatase to rutile apart from the very low Sn content (x ≤ 0.05) [124, 125]. When the doping coefficient x is around 0.5, the usual anatase TiO2 NT is transformed to rutile phase. The lithium capacity of Sn-doped titanium dioxide tubes is obviously larger than that of simple TiO2 NTs, when NTs are used as anodes for LIBs. Sn doping contributes to the formation of rutile structure and the enhanced lithium-ion diffusion of TiO2 NTs, which is the main reason for the outstanding performance of doped nanotubes.

Since Wang et al. [126] doped niobium into mesoporous TiO2 and increased the electronic conductivity of TiO2 by two orders of magnitude, niobium-doped (Nb-doped) titanium dioxide has attracted widespread attention. Recently, a self-supporting TiO2 nanotube containing a high concentration of niobium has been prepared through anodizing Nb/Ti alloys, and the Nb-doped NTs have been used as anodes in LIBs [122]. The Nb not only enriches the upper surface of NTs, but also the phenomenon that Nb5+ cation replaces Ti4+ occurs in TiO2 NTs, which can be supported by the analyses of structure and chemistry. As for the electrochemical performance, the discharge lithium capacity of the Nb-doped titanium dioxide nanotubes with the Nb concentration of 10 wt% is almost twice that of the pristine nanotubes. In addition, the doped NTs have high cycling performance under multiple C-rates, and the LIBs maintain 86.7% of initial capacity after 100 cycles. These enhanced electrochemical properties of Nb-doped TiO2 nanotubes are also owing to the improved electrical conductivity [122].

Besides binary alloys, ternary titanium alloys (such as Ti–6Al–4V, with 6 wt% aluminum and 4 wt% vanadium) have also been used to fabricate highly ordered titanium dioxide nanotubes. And these doped NTs have been widely used, especially as bone substitutes in the field of plastic surgery and dental implants. This is because such TiO2 NTs possess excellent compatibility, mechanical resistance, superthermal stability and good corrosion resistance [127, 128]. And Fraoucene et al. [123] reported firstly anodizing Ti-6Al-4 V (TA6V) alloy as anode in lithium-ion micro-batteries. They anodized Ti–6Al–4V alloy under 60 V for 3 h in a fluorinated ethylene glycol electrolyte containing 20 wt% H2O; as a result, the self-organized TiO2 nanotubes are successfully prepared. The anodized TiO2 NTs were annealed at 500 °C for 3 h, thereby obtaining the anatase TiO2 NTs. The appearance of vanadium oxide in the TiO2 NT led to a narrow band gap of anatase TiO2 NTs. Thanks to the doping of Al and V, the doped anatase TiO2 NTs showed excellent electrochemical performance. And the constant current charge–discharge tests showed that there was a large Li capacity up to 82 mAh·g−1 (34 µAh·cm−2·µm−1) at 1C rate over 50 cycles.

4 Lithiation process in composite TiO2 NT anodes

At present, TiO2 NTs as the anode material of LIBs have low specific capacity and conductivity. To settle these problems, researchers tried to modify TiO2 NTs by combining NTs with high specific capacity materials or good conductivity materials to get anode materials with excellent specific capacity, good conductivity, large specific surface area and anti-agglomeration.

4.1 Composite with high specific capacity materials

4.1.1 Composite with Si

Lower specific capacity (335 mAh·g−1) of titanium dioxide limits its application. However, some materials such as Si have ideal theoretical specific capacity (4200 mAh·g−1), but the SEI film will cyclically thicken, detach and rebuild during lithium intercalation and deintercalation, causing a dramatic change in the volume of Si (> ≈ 300%), leading to the loss of the active materials and electrolytes and the rapid decline in battery capacity [129]. Therefore, many researchers choose to load such high specific capacity materials on the surface of TiO2 NTs, which not only can improve the specific capacity of the composite material, but also effectively curb the volume expansion of Si anode because TiO2 NTs have good cycle stability. Paul et al. [69] ever compared the electrochemical properties of structure, surface and volume morphology of self-organizing conductive titanium dioxide nanotube arrays with (anodizing of the Si substrate) and without (anodizing of the Ti disk substrate) silicon coating in detail. Their results fully demonstrated that the conductive TiO2 NTs composites loaded with thin silicon films show greater potential and additional advantages when it comes to specific capacity, circulating stability as well as rate performance.

The above method directly prepares the TiO2 NT composite material during the anodizing process. As for preparing pure TiO2 NTs by anodization in advance, and then TiO2 NT composite materials can de prepared by methods other than anodization. Brumbarov et al. [130] firstly prepared TiO2 NTs by anodic oxidation method and then established a composite electrode model of self-organizing conductive titanium dioxide (TiO2−x-C) nanotubes with silicon (Si) coating by plasma-enhanced chemical vapor deposition (PECVD) method. In this model the nanotube array is tightly connected to the Ti foil (current collector), and electron can be transferred directly to the collector and doing not require additional adhesives or conductive agents. Since both the two ingredients in the composite material can be lithiated, for the first cycle of the experiment, the lithium capacity of the Si/TiO2−x-C with silicon coating decreased from 120 mAh·cm−2 to 110 mAh·cm−2. But after 30 and 88 cycles, its capacity retention was 93% and 86%, which is 2.4 times higher than the capacity of TiO2-x-C without silicon coating measured under the same conditions. However, this method should strictly control the thickness of the Si coating, so it still poses a challenge to the large-scale and widespread application.

Unlike coating TiO2 NTs with silicon (Si) by PECVD method, Nemaga et al. [131] used a two-step electrochemical method to synthesize a compound structure consisting of TiO2 NTs which have amorphous Si films coating. TiO2 NTs were synthesized through anodized titanium foil, and then Si was electrodeposited in an ionic liquid at room temperature to produce nanostructured Si/TiO2 NTs composite electrodes. In this composite material, the TiO2 NTs frame not only serves as a stable mechanical support for the Si layer, but also increases the exterior acreage of the Si activated mass. Meanwhile, the straightforward contact between the silicon and titanium collection fluid also facilitates one-dimensional electron transport, thereby removing the demand for additional inactive adhesives or conductive additives. The investigation of this composite material showed that stable lithiation and delithiation can be obtained for the optimized TiO2 NTs loaded with amorphous Si. When the total surface charge capacity of the composite electrode material was approximately 0.32 mAh·cm−2, the capacitance retention rate of the composite electrode material increased to around 84% after 50 cycles. Obviously, the material of electrodeposited amorphous Si on amorphous TiO2 NTs is one of the excellent candidates for LIB anode materials. In addition, not only anodized TiO2 NTs can be combined with Si, but other morphological silicon–titanium dioxide composites made by different methods are also common. For example, Lee et al. [132] used plasma electrolytic oxidation (PEO) method to prepare silica/titanium dioxide nanocomposite films, where silica yields large lithium capacity and titanium dioxide brings outstanding cycle stability. The prepared silicon dioxide/titanium dioxide composite anode shows a lithium storage capacity of 240 µAh·cm−2 under the relatively high current density of 500 µA·cm−2. It reveals at least twice the capacity of other types of binderless silica and titanium dioxide composite materials and has significantly stable cycle stability after more than 250 cycles, but this composite material has severe mechanical stress.

4.1.2 Composite with metal oxides and sulfides

In addition to silicon materials, various metal oxides and sulfides also have high specific capacities and are often used for composite TiO2 NTs. Wu et al. [133] believed that when using ultra-long titanium dioxide nanotubes as a template to deposit guest nanotubes, the advantages of solvothermal method are obvious because electrochemical approach cannot ensure complete coating over the entire range. So, they successfully synthesized a new type of SnO2@TiO2 coaxial nanotube array (SnO2@TiO2 NTs) through two simple assembly strategies, i.e., electrochemical and solvothermal methods. The schematic diagram of the SnO2@TiO2 coaxial nanotube hybrids is presented in Fig. 10. The initial capacity of the material was 469.8 mAh·cm−2, and its average coulomb efficiency reached above 94% in the subsequent cycle. After cycling 50 times, the reversible capacity is 113 mAh·cm−2, which is much larger than that of the primitive TiO2 NTs (51.6 mAh·cm−2). It is shown that the Li-ion storage performance of the prepared nanohybrid materials with good and definite tubular structures has been significantly enhanced. Due to the synergistic effect of the increased electrical conductivity and double lithium storage mechanisms, their potential as a new alternative material for electrochemical energy storage is further highlighted.

Schematic diagram of the SnO2@TiO2 coaxial nanotube hybrids (SnO2@TiO2 NTs) and the advantages of using the nano-architecture electrodes for lithium-ion battery. Reproduced with permission Ref. [133]. Copyright 2020 Royal Society of Chemistry

In addition to the simple solvothermal method, photochemical deposition, an innovative synthesis method, has also received widespread attention for its energy-saving, convenient and low-cost characteristics. Zhang et al. [134] reported a creative and low-consumption light deposition method to produce SnO2/TiO2 hybrid NTs. They firstly prepared TiO2 nanotubes by anodization, and then during the light deposition process, Sn2+ can be oxidized to form SnO2 through photogenerated holes, so that SnO2 nanoparticles can be deposited on the inner and outer walls of TiO2 NTs to constitute the SnO2/TiO2 composite nanomaterials possessing graded porous structure. The initial lithiation and delithiation capacities of the SnO2/TiO2 hybrid membrane anode prepared by this method are 216 µAh·cm−2 and 147 µAh·cm−2, and the coulomb efficiency is 68%. This composite nanotube anode in the second cycle showed a lithiation capacity of 168 µAh·cm−2 as well as a coulomb efficiency of 98%. Through cycling 100 times, the anode also has a reversible capacitance of 130 µAh·cm−2, which proves its outstanding lithium storage performance and shows the much larger capacity than the corresponding reference electrode. The simple and energy-saving light deposition method thus constructed can be applied as an effective way to fabricate composite materials with controlled morphology and size.

Tang et al. [135] prepared Li4Ti5O12-coated titanium dioxide nanotube array (Li4Ti5O12/TiO2 NTs), a three-dimensional electrode material for LIBs, by anodic oxidation and sol–gel method. Li4Ti5O12/TiO2 NTs have higher thermal stability of anatase phase than TiO2 NTs. The latest phase Li4Ti5O12 extends to the inner side of TiO2 NTs, separating anatase phase and rutile phase. Due to space effects, the phase transition from anatase to rutile is seriously hindered. In addition, the nanocrystalline Li4Ti5O12 coating is firmly bonded to TiO2 NTs, thereby improving the stability of the porous tubular structure. The area capacity of Li4Ti5O12/TiO2 NTs anode at 10 µA·cm−2 is 401 µAh·cm−2. After cycling 50 times under different current densities, its capacity remains at 176 µAh·cm−2, almost three times than that of TiO2 NTs (64 µAh·cm−2). In addition, Li4Ti5O12/TiO2 NTs anode has good cycle stability. It has a beginning capacity of 147.7 µAh·cm−2 and a current density of 30 µA·cm−2, which is almost twice that of TiO2 NTs anode (72.3 µAh·cm−2). The results show that the new 3D nanotube Li4Ti5O12/TiO2 NTs composite material is a promising anode for lithium micro-battery. And this strategy can be applied to prepare other 3D functional materials.

Except for smaller tin dioxide particles, additional metal oxides are commonly used in combination with titanium dioxide. Guan et al. [136] prepared titanium dioxide nanotube arrays with good orientation by using a constant potential anodic oxidation method and then conducted heat treatment to convert the prepared nanotubes into anatase for deposition of molybdenum trioxide. By modifying the number of deposition cycles to optimize the amount of MoO3, the nanotube composite anode with the best Li+ insertion property was obtained. The maximum capacity of the TiO2 NTs material compounded with MoO3 after 48 cycles at 50 µA·cm−2 can reach 277.6–227.9 µAh·cm−2, which is almost twice that of the TiO2 NTs electrode under the same conditions. Increasing not only the capacity of the material, but also the capacity retention efficiency of the last 48 battery cycles, it can be noted that the capacity retention efficiency of the deposited sample is 75.3%–82.1%, while that of the bare electrode is only 73.4%, which indicates that MoO3 can also improve the cycling ability of the TNTs.

Not only can compound with metal oxides increase the capacity of titanium dioxide nanotubes, but compound with metal sulfides can also be used to enhance the electrochemical performance of titanium dioxide. Zheng et al. [137] achieved the coupling of titanium dioxide nanotubes and molybdenum disulfide nanosheets through a simple combination of anodizing and hydrothermal methods. This strategy provides a flexible and direct way to design and prepare nanocomposites based on functional semiconductor nanostructures. The nanocomposites have 1D self-ordered nano-titanium dioxide. The composite material has higher electrical conductivity and theoretical specific capacity, which provide ideas and possible methods for preparing negative electrode materials for LIBs.

4.2 Composite with high-conductivity materials

4.2.1 Composite with carbon nanomaterial and graphene

In recent years, emerging carbon nanomaterials have attracted widespread attention. Researchers have studied the mixed materials of TiO2 and carbon nanomaterials and made some progress [40, 41, 138]. Menéndez et al. [139] studied a heterostructure composed of reduced graphene oxide and anodized TiO2 NTs as a new electrode material for LIBs. They deposited graphene films on self-organized nanotubes, combining the advantages of self-organized TiO2 NT and graphene composites. The capacity shown in the battery test can still exceed 300 mA·h·g−1 after cycling 100 times, thus being superior to the mixed nanostructure of bare TiO2 NT and rutile TiO2–graphene. Moreover, in the range of 1.0–2.6 V, the capacity of these electrodes is as large as 200 mAh·g−1, which is much higher than any other previously reported electrodes based on titanium dioxide. The excellent rated performance of these electrodes can ensure a very fast charging and discharging capability, which is of great significance in the future for high power density full batteries.

However, graphene has an amorphous structure and is mostly prepared by Hummers' method. In order to perfectly combine graphene with titanium dioxide, the composite materials prepared by graphene and titanium dioxide nanotubes by anodic oxidation method are far less than those prepared by other methods and morphologies.

Huang et al. [140] synthesized a novel TiO2 nanotube/graphene hybrid nanostructure using a simple two-step hydrothermal process. The obtained TiO2 nanotube/graphene sample consists of TiO2 NTs uniformly distributed on the graphene matrix. In the one-dimensional TiO2 hollow tubes structure, the graphene matrix supplies numerous interconnected “conductive bridges” among TiO2 NTs, thus greatly improving the electron transport of TiO2 nanotube/graphene. And since the electrolyte can pass through the hollow tubular structure of TiO2 nanotube/graphene, the ionic conductivity of the material is further increased. Therefore, this prepared sample (TiO2 nanotube/graphene) showed a larger average lithium storage capacity of 410 mAh·g−1 under 0.1 A·g−1 and showed outstanding cycling stability with insignificant capacitance attenuation after cycling 300 times. The improved electrochemical capabilities of TiO2 nanotube/graphene samples could be thanks to their special compound structure.

Different from their 1D TiO2 hollow tubes structure, Shen et al. [141] grew nanocrystalline titanium dioxide on conductive graphene nanosheets and multiwalled carbon nanotubes to fabricate a 3D hierarchic structure for rapid Li+ storage on the basis of the solution method. The specific hybrid structure of carbon nanotubes not only prevents the graphene from piling up again to add the basic distance among graphene pieces, but also offers extra electronic transmission path enlarging the touch area of the electrolyte and electrode and promotes the electrolyte ions and electrons transfer to the internal electrode area. This 3D TiO2–graphene–carbon nanotube (TiO2–GNS–CNT) has an extremely wide specific surface area of 291.2 m2·g−1 and shows ultra-high rate property up on superb circulation characteristic. The starting discharge capacity of TiO2–GNS–CNT nanocomposites at 10C was 121.8 mAh·g−1, and the capacitance retention rate was 92.3% after cycling 100 times. However, for TiO2–GNS, the preliminary discharge capacitance and capacitance reservation rate after the 100th cycle were 103.4 mAh·g−1 and 88.5%, and furthermore, those for raw TiO2 were 72.3 mAh·g−1 and 85.3%, respectively. The results show that TiO2–GNS–CNT nanocomposites with 3D hierarchy are extremely stabilizing, showing wonderful rate property and high cycling performance at high rates.

TiO2 can be combined with graphene not only in the form of nanotubes, but also in other forms [138, 142]. Sun et al. [143] put forward an uncomplicated and valid method for synthesizing anatase-type TiO2 nanocomposites by depositing them on reduced graphene oxide (TiO2-RGO) sheets as electrode materials for LIBs. In this structure, anatase TiO2 nanoparticles are distributed on the reduced nanosheets in the form of chemical bonds. Electrochemical test results showed that the coulomb efficiency of TiO2-RGO nanocomposites was about 100% at the multiplier of 1C even after 50th cycle, and the cycle stability was very good. Even after the 50th charge–discharge cycle, the capacitance retention rate is still as high as 99%, with almost no capacity attenuation. The performance of lithium storage is improved, and the cycle stability is nice. These improvements in electrochemical properties are mainly owing to the effective dispersion of nanocrystallized TiO2 on the appearance of the conductive RGO films, which make these TiO2-RGO nanocomposites suitable for high-speed lithium-ion batteries.

4.2.2 Composite with metal materials

It is well known that the electrical conductivity of metal materials is even as good as that of graphite materials. Therefore, they are often used in combination with TiO2 NTs. Kim et al. [144] firstly prepared titanium dioxide nanotubes by electrochemical anodic oxidation, then sputtered and calcined them to successfully prepare Sn/TiO2 NT arrays. The electrochemical properties of Sn/TiO2 NTs indicate that due to the conductive path from Sn to TiO2 NTs, the nanophase and uniform Sn coating along the entire surface of the TiO2 NTs significantly improve their capacity retention and multiplier capacity. When the material was used as a positive electrode material for LIBs, the Sn/TiO2 NTs anode showed a large reversible Li+ storage capacitance of 15.5 µAh·cm−2 and a coulombic efficiency of 84.9% in the initial cycle, while those of the uncoated TiO2 NT film were 12.7 µAh·cm−2 and 71.9%, respectively. At high current rates, the property of Sn/TiO2 NTs electrodes is superior to uncoated TiO2 NTs electrodes in terms of reversible Li-ion capacity, cycle stability and rate performance. The improvement in electrochemical property is due to the beneficial effect of a uniform tin coating inside the titanium dioxide nanotubes in providing a conductive path.

Metals such as copper and silver have also been the focus of long-term attention; Meng et al. [145] designed and implemented a combination of a nonadhesive high-conductivity copper bridge and the amorphous TiO2 NT array for the anode of a LIB through one-step simple electrodeposition method. Amorphous TiO2 NTs are received by simple anodizing in a double-electrode battery. After electrodeposition, the surface of the amorphous titanium dioxide nanotube array is covered with copper particles, some of which grow into rod-shaped or dendritic crystals and are located on the surface of the titanium dioxide nanotube array. It was found that even after the 50th cycle, the discharge capacity and retention rate of the composite anode remained at 215 mAh·g−1 and 103%, respectively, which were much larger than those of the bare electrode at 121 mAh·g−1 and 92%. Obviously, this binderless combination of copper bridges and titanium dioxide nanotube arrays significantly improves the reversible capacity and cycle stability, which not only improves the conductivity, but also maintains a large surface area in favor of improving the electrochemical performance. Fang et al. [146] grew the self-organizing TiO2 NTs on titanium films via anodizing and then prepared silver/titanium dioxide nanotube arrays by thermal decomposition. They analyzed from the Nyquist diagram analysis that the charge transfer resistance (Rct) of Ag/TiO2 nanotubes (27.32 Ω) is less than that of pure TiO2 nanotubes (184.30 Ω). The results showed that the lithium-ion transfer rate of Ag/TiO2 nanotubes was larger than that of TiO2 nanotubes, and the surface electrical conductivity of titanium dioxide nanotubes was enhanced by adding Ag. The reduced resistance of Ag/TiO2 nanotubes also resulted in the decreased polarization of the battery.

5 Summary and outlook

In summary, this article showed various research efforts on the development and improvement of TiO2 NT-based anodes for lithium-ion batteries. TiO2 NTs prepared via electrochemical anodization with enormous surface area and short lithium-ion diffusion paths are excellent candidate anodes for LIBs. As-grown amorphous TiO2 NT can be easily converted into anatase, mixed or rutile phase by using an adequate annealing treatment. Meanwhile, the morphology of the individual tube and the entire collection of nanotubes can be drastically changed through the annealing process. Amorphous TiO2 nanotube has larger Li-ion intercalation capacity because lithium-ion transfers faster in amorphous state than crystalline titanium dioxide. For anatase TiO2 NT, the [001] preferred orientation offers a more efficient lithium diffusion pathway in the c-axis, so the [001] preferentially oriented TiO2 NT has improved Li-ion transition kinetics and enhanced electrochemical performance compared to the randomly oriented nanotube. It has been found that the overall capacity of the TiO2 NT electrode is determined by the pseudocapacitive charge storage at the TiO2 nanotube surface and bulk charge storage. The nominal charge storage capacity can be improved by growing the length and reducing the diameter of NT, but if the area capacity is normalized by the length of the tube, the shorter organic anodized NTs demonstrate a better rate capacity than longer ones. “Nanograss”, which covers the surface of long nanotube, and double-tube wall have nonnegligible influences on the lithium capacity of the NT in LIB.