Abstract

MoS2, MoSe2 and WSe2 thin flakes were fabricated by the standard micromechanical cleavage procedures. The thickness and the optical contrast of the atomic thin dichalcogenide flakes on SiO2/Si substrates were measured by atomic force microscopy (AFM) and spectroscopic ellipsometer. A rapid and nondestructive method by using reflection spectra was proposed to identify the layer number of 2D layered transition metal dichalcogenides on SiO2 (275 nm)/Si substrates. The contrast spectra of 2D nanosheets with different layer numbers are in agreement with theoretical calculations based on Fresnel’s law, indicating that this method provides an unambiguous and nondestructive contrast spectra fingerprint for identifying single- and few-layered transition metal dichalcogenides. The results will greatly help in fundamental research and application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The success of obtaining graphene with mechanical exfoliation method has opened a door for two-dimensional (2D) layered materials [1, 2]. Many 2D layered materials exist in bulk form with weak interlayer attraction. This feature makes the exfoliation of these 2D layered materials, such as h-BN [3,4,5,6], transition metal dichalcogenides [7,8,9,10,11] and black phosphorus [12,13,14] into individual, atomically thin layers possible. Recently, transition metal dichalcogenides have attracted a great deal of attention due to their novel layer-dependent electrical, optical, mechanical and magnetic properties which differ greatly from the properties of the bulk materials, and the potential to be the candidates for next-generation nanoelectronic devices [9, 15, 16]. For instance, MoS2, MoSe2 and WSe2 are chalcogenide semiconductors showing semiconducting (n-type semiconducting for MoS2 and MoSe2, p-type semiconducting for WSe2) with a comparable band gap, charge mobility and higher on/off ratio [9, 15, 17].

Several methods have been reported to obtain 2D transition metal dichalcogenides including chemical vapor deposition [18], epitaxial growth [19], liquid exfoliation [20] and mechanical exfoliation [2, 7,8,9, 21, 22]. Among these methods, mechanical exfoliation is one of the most efficient ways to obtain high-quality nanosheets of 2D transition metal dichalcogenides. However, the layer number of 2D transition metal dichalcogenide flakes produced by mechanical exfoliation is uncontrollable. Thus, locating and identifying a single- or few-layered transition metal dichalcogenide flake among the exfoliated flakes become a time-consuming work. Atomic force microscopy (AFM) is a common way to measure the thickness of the 2D materials but with low efficiency. Transmission electron microscope (TEM) [23, 24] could be used to determine the thickness of 2D materials. Unfortunately, it is usually very difficult to transfer the samples onto a TEM grid. Raman spectroscopy shows potential for rapid and nondestructive inspection of the thickness of the 2D materials [3, 25, 26]. However, the difference between double-layered and few-layered transition metal dichalcogenide nanosheets is not obvious and unambiguous in Raman spectra, making it inconvenient for the accurate identification of the layer number. Optical imaging has shown the advantages of simplicity and accessibility for rapid and nondestructive thickness identification of single- and few-layered 2D materials [3, 7, 27,28,29,30,31], such as grapheme, BN and black phosphorus [32]. Reflection spectroscopy also works very well in graphene layer number counting [28] and may play a role in other 2D materials layer number counting.

In this paper, it is demonstrated a rapid and nondestructive reflection spectroscopy method for identifying the layer number of atomic thin transition metal dichalcogenides (MoS2, MoSe2 and WSe2). White light reflection spectra from sample surface and substrate were collected in a few seconds, and contrast spectra of the samples are obtained. The contrasting spectra from atomic thin sheets with various thicknesses can be obviously observed and be used to identify layer number. The calculated results based on Fresnel’s equation show excellent agreement with the experimental data, and the reflection spectra in combination with calculated results could be a more universal method to identify the layer number of 2D transition metal dichalcogenides.

2 Experimental

The MoS2, MoSe2 and WSe2 thin flakes were prepared by the standard micromechanical cleavage procedure [1] similar to the graphene preparation and then transferred to a Si wafer with a 275-nm SiO2 capping layer. The thickness of the silicon dioxide and its real (n) and imaginary (k) part of the refractive indices were measured by spectroscopic ellipsometer (Horiba Uvisel FUV). A Nikon MM-400 optical microscope (OM) was used to locate those thin flakes and to obtain the optical images of the samples. The thickness of samples was measured by using a BRUKER Dimension Icon AFM. In the reflection experiments, the reflection spectra of both substrate and samples were measured by Raman spectrometer (Jobin Yvon HR800). The optical contrast spectra of the samples were carried out by comparing the samples’ reflection spectra with the substrate’s reflection spectra.

3 Results and discussion

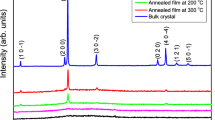

Figure 1a1, b1, c1 shows OM images of single- and multilayered MoS2, MoSe2 and WSe2 flakes on SiO2/Si substrate. One can see that these flakes have different contrast regions. AFM was used to measure the thickness of these nanolayers. Figure 1a2, b2, c2 shows the corresponding 2D AFM images of the areas marked by white rectangles in OM images. The height values measured from the white solid lines in Fig. 1a3, b3, c3 are 7.75 nm for MoS2, 2.88 nm for MoSe2 and 5.82 nm for WSe2. Other areas which have different contrast were also measured by AFM. By considering the thickness of single-layered MoS2, MoSe2 and WSe2 flakes, the layer number is obtained for different contrast regions. The corresponding layer numbers for MoS2, MoSe2 and WSe2 are marked by white digital in Fig. 1a1, b1, c1, respectively.

The optical contrasts of MoS2, MoSe2 and WSe2 flakes transferred on top of SiO2/Si substrates with 275 nm SiO2 were measured as a function of their thickness at different illumination wavelengths. By measuring the reflection spectra of each layer and substrate, respectively, these contrast spectra are obtained by the formulation C = 1−I/I 0, where I is the reflection light intensity of each layer and I 0 is the reflection light intensity of substrate. Figure 2 shows the visible range contrast spectra for MoS2, MoSe2 and WSe2 samples. It is clear that the optical contrast strongly depends on flake thickness. These contrast features in visible range make contrast spectroscopy become a quantitative and accurate method in identifying the layer number of semiconductor dichalcogenide thin flakes.

To interpret the measured contrast spectroscopy, it was calculated the contrast between light reflected from the sample with and without the semiconductor dichalcogenide thin flakes based on the Fresnel law similar to the one developed by Jung et al. [33]. Figure 3a is a schematic diagram of reflection light and transmission light for the layered film system. For a SiO2 film on a Si substrate, there are two interfaces. One is the interface between SiO2 and air, and the other one is the interface between SiO2 and Si wafer. If the semiconductor dichalcogenide thin flakes are added, a third interface is introduced. When a beam of light goes through the layered film system, a part of incident light is reflected from each interface and the reflected light will interfere. The amplitude of the reflected light is determined by the incident wavelength (λ), the incident angle (θ), the thicknesses (d) of the layers, the refractive indices (n) and the absorption coefficients (k). In this model, 1.004 was used as the refractive indices of air and the dichalcogenide flakes were treated as a thin homogeneous film of thickness (d 1) with complex refractive indices (n 1(λ)) and absorption coefficients (k 1(λ)). Both n 1(λ) and k 1(λ) are dependent on λ. The silicon dioxide layer of thickness (d 2) was optically characterized by wavelength-dependent refractive indices (n 2(λ)) with only a real part. As the thickness of Si layer is several orders of magnitude larger than that of SiO2 layer, the Si layer can be considered as a semi-infinite film. The reflected light intensity from SiO2/Si substrate thus can be written as:

where \(\delta^{\prime}_{2} = (2\uppi/\lambda )d_{2} n_{2} \cos \theta^{\prime}_{2}\) is the phase shift which is determined by the path difference of two neighboring interfering light beams when the light passes through the silicon dioxide layer; \(\theta^{\prime}_{2}\) is the incident angle; and \(r^{\prime}_{1}\) and \(r^{\prime}_{2}\) are the reflection coefficients for the interface between air and silicon dioxide, and the interface between silicon dioxide and Si substrate, respectively. When the light incidents from air into a dichalcogenide thin flake, SiO2 and Si substrate, the reflected light intensity from the trilayer system can be written as:

where \(\delta_{2} = (2\uppi/\lambda )d_{1} (n_{1} - ik_{1} )\cos \theta_{2}\) and \(\delta_{3} = (2\uppi/\lambda )d_{2} n_{2} \cos \theta_{3}\) are the phase shift when the light passes through the dichalcogenide thin flakes and SiO2 layer, respectively; θ 2 and θ 3 are the incident angles for different layers; r 1, r 2 and r 3 are the relative reflection coefficients for different interfaces. It is assumed that the intensity profiles of reflected light follow a Gaussian distribution, and the total reflected light intensity can be obtained by integrating each component throughout the angle of incidence. In this paper, the total reflected light intensity from SiO2/Si substrate is:

where θ max is the maximum incident angle which is related to the numerical aperture (NA) of the optical lens and defined as \(\theta_{\hbox{max} } = \arcsin ({\text{NA}})\). In this experiment, the value of the 100 × objective lens is 0.9. R 0(θ) represents the reflected light intensity for the incident angle (θ), and \({\text{d}}N(\theta ,0,\theta_{\hbox{max} } /3)\) represents the Gaussian distribution with the mean of 0 and standard deviation of θ max/3 at an angle interval of \({\text{d}}\theta\). The contrast is defined as the relative intensity of reflected light in the presence and absence of the 2D dichalcogenide materials and can be written as:

Schematic of light reflection in a three-layered model a; experimental (Exp.) and theoretically calculated (Cal.) optical contrast of 1–4 layered MoSe2 flakes as a function of incident light wavelength on SiO2 (275 nm)/Si substrates using b bulk MoSe2 absorption coefficients and c fitted MoSe2 absorption coefficients

The calculated light contrast spectra of exfoliated MoS2, MoSe2 and WSe2 samples could be obtained by changing the thickness of the samples. At the very start, the contrast was calculated using the refractive indices and absorption coefficients of bulk materials. The results show a large deviation when sample’s layer number is small. Figure 3b gives the experimental and the theoretically calculated optical contrast of 1–4 layered MoSe2 flakes as a function of incident light wavelength. This deviation may be caused by the variation of the refractive indices and absorption coefficients of ultrathin nanosheet from that of bulk material and may be ascribed to the decrease in interlayer interaction when the sample is ultrathin. Here, the refractive indices and absorption coefficients of those materials were treated as fitting parameters from the fit to Eq. (4) and found that the refractive indices values of MoS2, MoSe2 and WSe2 are in concert with its bulk materials. However, the absorption coefficient values of single-layered MoS2 and MoSe2 are 20% smaller than those of its bulk material. For single-layered WSe2, the absorption coefficients values are 60% larger than those of its bulk material. By using the fitted absorption coefficients, the optical contrasts of 1–4 layered MoSe2 flakes were recalculated as a function of incident light wavelength on SiO2 (275 nm)/Si substrates (Fig. 3c), and the calculated results show good agreement with the experimental results.

Figure 4 gives the theoretical calculated contrast spectra of 1–13 layered MoS2, MoSe2 and WSe2 by using fitted absorption coefficient values. For the Si substrate with a 275-nm SiO2 capping layer, the peak at the wavelength of 500 nm gives the largest distinction among 1–13 layered MoS2 thin flakes. This means that 500-nm monochromatic light is the optimal light to distinguish the layer number of MoS2. For MoSe2 and WSe2, it is only when the layer number is greater than 5 that the 500-nm monochromatic light makes the layers most visible and distinguishable. When the layer number is less than 5570-nm monochromatic light would be the best choice. Here, it would be like to emphasize that the result applies for using the Si substrate with a 275-nm SiO2 capping layer. If other substrate or light source was used, the peak and the contrast curve would shift [31, 32]. In the experiment, the light contrast spectra of the MoS2, MoSe2 and WSe2 thin flakes in Fig. 4 are in perfect agreement with the experimental results of responding layer numbers, indicating that light contrast spectra could be a useful technique for identification of 2D dichalcogenide thin flakes. One can identify the layer number of layered semiconductor dichalcogenides rapidly and nondestructively by comparing the experimental contrast spectra with its corresponding theoretical contrast spectra.

4 Conclusion

In conclusion, the thickness and the optical contrast of MoS2, MoSe2 and WSe2 thin flakes on SiO2/Si substrates were measured and compared to the theoretical calculated optical contrast using Fresnel’s equation. The results show that the contrast spectra could be an effective, unambiguous and rapid way to identify the layer number of the atomic thin dichalcogenide flakes. It is also demonstrated that the refractive indices and the absorption coefficients of single-layered like MoS2, MoSe2 and WSe2 are quite different from those of their bulk materials. When the layer number is small, the corresponding experimental contrast spectra could be well simulated by refractive indices and absorption coefficients of single layer. We hope our finding will help further research and application of atomic thin dichalcogenides.

References

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA. Electric field effect in atomically thin carbon films. Science. 2004;306(5696):666.

Novoselov KS, Jiang D, Schedin F, Booth TJ, Khotkevich VV, Morozov SV, Geim AK. Two-dimensional atomic crystals. Proc Natl Acad Sci USA. 2005;102(30):10451.

Gorbachev RV, Riaz I, Nair RR, Jalil R, Britnell L, Belle BD, Hill EW, Novoselov KS, Watanabe K, Taniguchi T, Geim AK, Blake P. Hunting for monolayer boron nitride: optical and Raman signatures. Small. 2011;7(4):465.

Castellanos-Gomez A, Wojtaszek M, Tombros N, Agraït N, van Wees BJ, Rubio-Bollinger G. Atomically thin mica flakes and their application as ultrathin insulating substrates for graphene. Small. 2011;7(17):2491.

Pacile D, Meyer JC, Girit CO, Zettl A. The two-dimensional phase of boron nitride: few-atomic-layer sheets and suspended membranes. Appl Phys Lett. 2008;92(13):133107.

Dean CR, Young AF, Meric I, Lee C, Wang L, Sorgenfrei S, Watanabe K, Taniguchi T, Kim P, Shepard KL, Hone J. Boron nitride substrates for high-quality graphene electronics. Nat Nanotechnol. 2010;5(10):722.

Castellanos-Gomez A, Agraït N, Rubio-Bollinger G. Optical identification of atomically thin dichalcogenide crystals. Appl Phys Lett. 2010;96(21):213116.

Late DJ, Liu B, Matte HSSR, Rao CNR, Dravid VP. Rapid characterization of ultrathin layers of chalcogenides on SiO2/Si substrates. Adv Funct Mater. 2012;22(9):1894.

Radisavljevic B, Radenovic A, Brivio J, Giacometti V, Kis A. Single-layer MoS2 transistors. Nat Nanotechnol. 2011;6(3):147.

Splendiani A, Sun L, Zhang Y, Li T, Kim J, Chim CY, Galli G, Wang F. Emerging photoluminescence in monolayer MoS2. Nano Lett. 2010;10(4):1271.

Benameur MM, Radisavljevic B, Héron JS, Sahoo S, Berger H, Kis A. Visibility of dichalcogenide nanolayers. Nanotechnology. 2011;22(12):125706.

Li L, Yu Y, Ye GJ, Ge Q, Ou X, Wu H, Feng D, Chen XH, Zhang Y. Black phosphorus field-effect transistors. Nat Nanotechnol. 2014;9(5):372.

Koenig SP, Doganov RA, Schmidt H, Castro Neto AH, Ozyilmaz B. Electric field effect in ultrathin black phosphorus. Appl Phys Lett. 2014;104(10):103106.

Fei R, Yang L. Strain-engineering the anisotropic electrical conductance of few-layer black phosphorus. Nano Lett. 2014;14(5):2884.

Podzorov V, Gershenson ME, Kloc C, Zeis R, Bucher E. Novel high-mobility field-effect transistors based on transition metal dichalcogenides. Appl Phys Lett. 2004;84(17):3301.

Akinwande D, Petrone N, Hone J. Two-dimensional flexible nanoelectronics. Nat Commun. 2014;5:5678.

Larentis S, Fallahazad B, Tutuc E. Field-effect transistors and intrinsic mobility in ultra-thin MoSe2 layers. Appl Phys Lett. 2012;101(22):223104.

Lee YH, Zhang XQ, Zhang W, Chang MT, Lin CT, Chang KD, Yu YC, Wang JTW, Chang CS, Li LJ, Lin TW. Synthesis of large-area mos2 atomic layers with chemical vapor deposition. Adv Mater. 2012;24(17):2320.

Shi Y, Zhou W, Lu AY, Fang W, Lee YH, Hsu AL, Kim SM, Kim KK, Yang HY, Li LJ, Idrobo JC, Kong J. van der Waals epitaxy of MoS2 layers using graphene as growth templates. Nano Lett. 2012;12(6):2784.

Nicolosi V, Chhowalla M, Kanatzidis MG, Strano MS, Coleman JN. Liquid exfoliation of layered materials. Science. 2013;340(6139):1226419.

Li H, Lu G, Wang Y, Yin Z, Cong C, He Q, Wang L, Ding F, Yu T, Zhang H. Mechanical exfoliation and characterization of single- and few-layer nanosheets of WSe2, TaS2, and TaSe2. Small. 2013;9(11):1974.

Li H, Wu J, Huang X, Lu G, Yang J, Lu X, Xiong Q, Zhang H. Rapid and reliable thickness identification of two-dimensional nanosheets using optical microscopy. ACS Nano. 2013;7(11):10344.

Childres I, Jauregui LA, Foxe M, Tian J, Jalilian R, Jovanovic I, Chen YP. Effect of electron-beam irradiation on graphene field effect devices. Appl Phys Lett. 2010;97(17):173109.

Wu RJ, Odlyzko ML, Mkhoyan KA. Determining the thickness of atomically thin MoS2 and WS2 in the TEM. Ultramicroscopy. 2014;147:8.

Lee C, Yan H, Brus LE, Heinz TF, Hone J, Ryu S. Anomalous lattice vibrations of single- and few-layer MoS2. ACS Nano. 2010;4(5):2695.

Ferrari AC, Meyer JC, Scardaci V, Casiraghi C, Lazzeri M, Mauri F, Piscanec S, Jiang D, Novoselov KS, Roth S, Geim AK. Raman spectrum of graphene and graphene layers. Phys Rev Lett. 2006;97(18):187401.

Blake P, Hill EW, Castro Neto AH, Novoselov KS, Jiang D, Yang R, Booth TJ, Geim AK. Making graphene visible. Appl Phys Lett. 2007;91(6):063124.

Ni ZH, Wang HM, Kasim J, Fan HM, Yu T, Wu YH, Feng YP, Shen ZX. Graphene thickness determination using reflection and contrast spectroscopy. Nano Lett. 2007;7(9):2758.

Jung I, Pelton M, Piner R, Dikin DA, Stankovich S, Watcharotone S, Hausner M, Ruoff RS. Simple approach for high-contrast optical imaging and characterization of graphene-based sheets. Nano Lett. 2007;7(12):3569.

Wang YP, Zhou HJ, Zhao GH, Xia TL, Wang L, Wang L, Zhang LY. Rapidly counting atomic planes of ultra-thin MoSe2 nanosheets (1 ≤ n≤4) on SiO2/Si substrate. Rare Met. 2016;35(8):632.

Ouyang WG, Liu XZ, Li QY, Zhang YY, Yang JR, Zheng QS. Optical methods for determining thickness of few-layer graphene flakes. Nanotechnology. 2013;24(50):505701.

Chen H, Fei W, Zhou J, Miao C, Guo W. Layer identification of colorful black phosphorus. Small. 2017;13(5):1602336.

Jung I, Rhyee JS, Son JY, Ruoff RS, Rhee KY. Colors of graphene and graphene-oxide multilayers on various substrates. Nanotechnology. 2012;23(2):25708.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (Nos. 11304381 and 11174366).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, JP., Wang, L. & Zhang, LY. Rapid and nondestructive layer number identification of two-dimensional layered transition metal dichalcogenides. Rare Met. 36, 698–703 (2017). https://doi.org/10.1007/s12598-017-0927-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-017-0927-4