Abstract

The effects of Gd content on crystalline orientation, microstructure and superconductivity of Gd x Y1−x Ba2Cu3O7−δ (GdYBCO) films were systematically investigated. By varying the Gd content in the liquid precursor without changing the total amount of rare earth elements, series of GdYBCO films with x values of 0, 0.1, 0.3, 0.5, 0.7, 0.9 and 1.0 were fabricated by metal organic chemical vapor deposition (MOCVD). X-ray diffraction (XRD) and scanning electron microscope (SEM) analysis revealed that Gd introducing could restrain the formation of CuYO2 phase, but induce a-axis growth of GdYBCO film. The increase of x from 0 to 0.5 leads to enhancing critical current density at self-field and 77 K (J csf) from 1.8 to 2.8 MA·cm−2, which benefits from the decrease in CuYO2 impurities and improvement of in-plane texture from 5.0° to 4.3°. However, raising x from 0.5 to 1.0 gives rise to abundant a-axis growth of film and degradation of in-plane texture from 4.3° to 5.4°, consequently resulting in the decrease of J csf from 2.8 to 0.8 MA·cm−2. Even though J csf has not varied monotonically, the critical transition temperature of GdYBCO films linearly increases from 90.75 to 92.25 K and the in-field performance at magnetic field (B) of 0–1.1 T and 77 K as well as B parallel to film normal is also superior with Gd content increasing.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Critical current density (J c) of YBa2Cu3O7−δ (YBCO) superconducting film decays severely with applied magnetic field due to the motion of vortices [1]. How to immobilize the vortices to improve the in-field performance of YBCO film has captured the researchers’ attention. Although naturally grown defects [1], such as boundaries, in-plane or out-of-plane misorientation, dislocations and voids, can somewhat pin flux vortices, yet reports [2–6] have revealed that the density or effectiveness of these naturally grown defects was not high enough to retain high-field J c at a necessary level.

Substantial efforts on introducing artificial pinning centers (APCs) have been made to improve the flux pinning effects. For instance, nano-sized Y2O3 particles resulted from the excess of yttrium in YBCO films could form point, line and/or plane defects, thus enhanced the flux pinning effects [7–10]. Alternatively, perovskites such as BaZrO3 [10–15], BaSnO3 [16], BaHfO3 [17] and BaIrO3 [18] could also form randomly oriented particles or c-axis oriented columnar defects in YBCO matrix to improve the flux pinning effects. Additionally, inclusion of nanoparticles of Gd3TaO7 [19], Ba2GdTaO6 [20], Ba2YNbO6 [21], YBa2CuO5 [22] or Y2BaCuO5 [23] has also been demonstrated to be an effective way to raise the in-field performance of YBCO films. In addition to introduction of the above-mentioned extra particulates, the partial or complete substitution of lanthanides for yttrium to form REBCO (RE = rare earth) has also manifested the enhanced flux pinning effects. As an example, GdBa2Cu3O7−δ (GdBCO) was reported being of superior in-field performance to YBCO [24]. However, systematic research about the effects of Gd content on the properties of Gd x Y1−x Ba2Cu3O7−δ (GdYBCO) superconducting films has been barely reported [25].

Hence, the authors have applied metal organic chemical vapor deposition (MOCVD) to fabricate GdYBCO films with various Gd contents on the metallic substrates and systematically investigated the effects of Gd content on the crystalline orientation, in-plane and out-of-plane textures, surface morphology, self-field and in-field superconductivity at 77 K.

2 Experimental

The MOCVD system applying single mixed liquid precursor of metal organics was used to deposit GdYBCO films. And the home-made buffer stack of LaMnO3/homo-epi MgO/ion beam-assisted deposition (IBAD)-MgO/Y2O3/Al2O3/Hastelloy tape [26, 27], collectively termed as IBAD template, was used as substrate, which was preheated to 810 °C during the deposition of GdYBCO film. The precursor was prepared by dissolving solid-state metal organics of Y(tmhd)3, Gd(tmhd)3, Ba(tmhd)2 and Cu(tmhd)2 into tetrahydrofuran. To fabricate GdYBCO films with various Gd contents, the mole ratio of Gd to the constant total amount of Gd and Y in precursor was set as 0%, 10%, 30%, 50%, 70%, 90% and 100%, corresponding to x values of 0, 0.1, 0.3, 0.5, 0.7, 0.9 and 1.0 in GdYBCO film, respectively. More experimental details could be found elsewhere [28].

The crystalline orientation and texture of as-deposited GdYBCO films were examined by X-ray diffractometer (XRD, Bede D1). The microstructure was observed by scanning electron microscope (SEM, JEOL JSM-7001F). The critical transition temperature (T c) was measured by four-probe method using the current of 1 mA, and the GdYBCO samples were cooled by cold head of Sumitomo (RDK-101D). The J c at 77 K and 0 T (J csf) was obtained by induction method using Leipzig J c-scan system. The critical current in the magnetic field (B) from 0 to 1.1 T was measured on the sample bridge of 1 mm × 5 mm (width × length) with magnetic field direction parallel to the film normal, and the criteria to determine the critical current was 1 μV·cm−1. Additionally, the film thickness was tested by step profiler (Veeco, Dektak 150).

3 Results and discussion

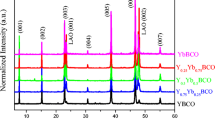

500-nm-thick GdYBCO films with x values of 0, 0.1, 0.3, 0.5, 0.7, 0.9 and 1.0 were fabricated on IBAD-MgO templates. Figure 1 shows the detailed θ–2θ patterns, which exhibit clear and sharp peaks of (00l) GdYBCO and a few unexpected peaks of CuYO2 phases and (h00) GdYBCO. As x < 0.5, only (00l) GdYBCO peaks can be clearly observed, indicating that the corresponding films crystallize well and align their c-axis perpendicular to the substrate surface. However, the films mix with a few CuYO2 particles, demonstrated by the presence of CuYO2 peaks in Fig. 1. As x ≥ 0.5, the peaks of CuYO2 disappear, revealing that the increase in Gd content prevents the formation of CuYO2 precipitates and the composition ratio of the film body is closer to the stoichiometric value. However, the presence of (h00) GdYBCO peaks suggests that the film transfers from purely c-axis orientation to mixed orientation of c-axis and a-axis. It should also be noted that the intensity of (002) peak of the film becomes weaken with Gd content increasing. To give quantitative understanding, I (002) and I (003) are used to represent the intensities of (002) peak and (003) peak of the film, respectively, and the I (003)/I (002) values are summarized in Fig. 2. It is obvious that I (003)/I (002) value is enlarged as Gd content increases. As reported in Ref. [29], it is the intrinsic character of GdBCO that the (002) peak is much weaker than (003) peak. Hence, it is easy to understand that such increase in I (003)/I (002) ratio is ascribed to the change of film body from YBCO to GdBCO with Gd content increasing from 0 to 1. Conversely, the curve in Fig. 2 can also be used to semi-quantitatively determine the Gd content of GdYBCO film when the Gd content is uncertain.

Figure 3 shows χ-scans [30] on (102) planes of all GdYBCO films. As x < 0.5, there is only one peak around 57° corresponding to (102) plane of c-axis oriented GdYBCO grains, whereas there arises one more peak around 33° corresponding to (102) planes of a-axis oriented GdYBCO grains when x further increases to 1.0. The above-obtained results are in agreement with those yielded from 2θ scans, further demonstrating that the orientation of GdYBCO films transfer from c-axis orientation to a-axis orientation. Such conversion of orientation suggests that the MOCVD conditions optimized for YBCO film deposition are not appropriate any more, since the film body has transferred from YBCO to GdBCO as x > 0.5. For example, with experiments it has been found that the deposition temperature of GdBCO film was about 15 °C higher than that of YBCO film.

To determine the out-of-plane and in-plane textures of the films, the ω-scans and Φ-scans were performed, respectively, on (005) GdYBCO and (103) GdYBCO, and the corresponding full width at half maximum (FWHM) values (Δω, ΔΦ) are summarized in Fig. 4. As Gd content rises up to 0.5, Δω hardly changes, while ΔΦ decreases from 5.0° to 4.3°, indicating that Gd substitution for Y deeply improves the in-plane texture rather than out-of-plane texture. Such improvement on in-plane texture would be owed to the disappearance of CuYO2 impurities. However, ΔΦ is enlarged as Gd content further increases, suggesting that the in-plane texture deteriorates. And this deterioration is attributed to the appearance of a-axis oriented growth, which results from the above-mentioned improper deposition conditions of GdYBCO films.

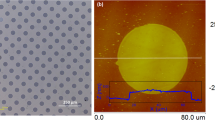

SEM images of GdYBCO films are shown in Fig. 5, exhibiting dense and crack-free microstructure as well as some surface particles. As x = 0, there is a large number of particles identified as Y–Cu–O phases by energy dispersive spectroscopy (EDS) analysis (not shown here), which is consistent with the XRD examinations in Fig. 1. As x is enlarged, the number of Y–Cu–O particle decreases, which is in agreement with the weakening of diffraction peak of CuYO2 phase in Fig. 1. However, the a-axis oriented GdYBCO grains (rectangular shape particles in Fig. 5) also arise with Gd content increasing, especially for x > 0.5. When x > 0.5, the size and density of a-axis grains increase with Gd content increasing, consistent with the higher (h00) GdYBCO peaks at larger x in Fig. 1. Such microstructure with large number of a-axis grains for x > 0.5 further demonstrates that the deposition conditions are not appropriate anymore and the substrate temperature is somewhat low, especially for those of higher Gd content.

The superconductivity of GdYBCO film is characterized by the measurements of critical transition temperature (T c) and J csf, of which the results are depicted in Fig. 6. In Fig. 6a, the T c almost linearly increases from 90.75 to 92.25 K, whereas the transition width (ΔT) firstly increases and then decreases with the increase in Gd content. And ΔT is 0.65 and 0.93 K for YBCO and GdBCO, respectively, and reaches its maximum of ~2 K at x = 0.5. Owing to the higher T c of GdBCO than YBCO, such variation of ΔT results from the co-existence of YBCO phase and GdBCO phase at 0 < x < 1.0. In Fig. 6b, J csf increases from 1.8 to 2.8 MA·cm−2 as 0 ≤ x ≤ 0.5, which benefits from the rising of T c and the above-mentioned improvement of in-plane texture yielded from the decrease in CuYO2 impurities. When Gd content is above 0.5, the film body transfers to GdBCO and the improper deposition conditions leads to the degradation of in-plane and out-of-plane textures as well as the presence of misoriented grains including (103) GdYBCO and (h00) GdYBCO. The texture degradation and grain misorientation are harmful to the transmission of superconducting current, consequently resulting in the drop of J csf from 2.8 to 0.8 MA·cm−2.

The dependence of critical current (I c) on B was measured on the samples with Gd content of 0, 0.3, 0.5, 0.7 and 1.0 at 77 K and plotted in Fig. 7a, which shows that I c of all samples declines with B. To intuitively exhibit the effects of Gd content, the curves in Fig. 7a are normalized by I c(B = 0) and replotted in Fig. 7b. It is clearly illustrated that the increase in Gd content slows down the declining rate of normalized I c/I c(B = 0) with B increasing, which benefits from the flux pinning effects induced by substituting Gd for Y [24, 25]. At B = 1 T and 77 K, the normalized I c/I c(B = 0) corresponding to Gd content of 1.0 retains about 27%, twice more than that of Gd content of 0, demonstrating that GdBCO film has in-field performance quite superior to that of YBCO film at 77 K. As reported, I c(B) is proportional to B −α in the field range of 0.1–1.0 T (α value is calculated from the I c–B curve in Fig. 7) and the smaller α value means the better in-field performance [1]. By fitting the data points (shown in inset of Fig. 7b), the α values corresponding to Gd content of 0, 0.3, 0.5, 0.7 and 1.0 are 0.400, 0.397, 0.394, 0.375 and 0.332, respectively, among which the smallest value of 0.332 is comparable to those reported α values [12, 13, 15, 31]. Figure 8 shows the magnetic field dependence of flux pinning force (F p), where F p = J c(B) × B [31]. And J c(B) is deduced from the data in Fig. 7a through the following equation:

where w and t represent the width and thickness of the micro-bridge of GdYBCO films used in I c measurements, being 1 and 500 nm, respectively.

In view of the various J csf shown in Fig. 6b, the comparative analysis of Gd content of 0 and 1.0 as well as 0.3 and 0.7 is more illustrative. With regard to Gd content of 0 and 1.0, F p of the former is higher than that of the latter as B < 0.2 T, which is attributed to the much higher J csf of 1.8 MA·cm−2 of the former than 0.8 MA·cm−2 of the latter. As 0.2 T < B < 1.0 T, F p of Gd content of 1.0 is almost same with that of Gd content of 0, indicating that the flux pinning effect of GdBCO is stronger than that of YBCO at this moment. As for Gd content of 0.3 and 0.7, they have the same J csf and their F p is same too as B < 10 mT, whereas F p of the latter is increasingly higher than that of the former as B increases to 1.0 T, suggesting that the latter is of superior flux pinning effect. All the above discussion suggests that substitution of Gd for Y is beneficial to enhance the flux pinning effect of the film.

4 Conclusion

Gd content deeply affects the in-plane texture, morphology and superconducting performance of GdYBCO films. The increase in Gd content from 0 to 0.5 could suppress the formation of CuYO2, thus improves the in-plane texture and microstructure of the films and finally enlarges J csf from 1.8 to 2.8 MA·cm−2. As Gd content further increases from 0.5 to 1.0, the growth of a-axis GdYBCO grains arises abundantly and becomes much severer at Gd content of 1.0, which consequently deteriorates the texture and thus drops J csf from 2.8 to 0.8 MA·cm−2. However, the increasing Gd content brings the linear increase of T c from 90.75 to 92.25 K and the slower decay of normalized I c/I c(B = 0) as well as the stronger flux pinning effect. Even though the flux pinning force of GdBCO is smallest due to the lowest J c, the authors believe that further modification on MOCVD process would raise J c and then enhance the flux pinning force.

References

Foltyn SR, Civale L, MacManus-Driscoll JL, Jia QX, Maiorov B, Wang H, Maley M. Materials science challenges for high-temperature superconducting wire. Nat Mater. 2007;6(9):631.

Hylton TL, Beasley MR. Flux-pinning mechanisms in thin films of YBa2Cu3O7−δ . Phys Rev B. 1990;41(16):11669.

Blatter G, Feigelman MV, Geshkenbein VB, Larkin AI, Vinokur VM. Vortices in high temperature superconductors. Rev Mod Phys. 1994;66(4):1125.

Brandt EH. The flux line lattice in superconductors. Rep Prog Phys. 1995;58(11):1465.

Dam B, Huijbregtse JM, Klaassen FC, Van der Geest RCF, Doornbos G, Rector JH, Testa AM, Freisem S, Martinez JC, Stäuble-Pümpin B, Griessen R. Origin of high critical currents in YBa2Cu3O7−δ superconducting thin films. Nature. 1999;399(6735):439.

Huijbregtse JM, Klaassen FC, Szepielow A, Rector JH, Dam B, Griessen R, Kooi BJ, de Th M, Hosson J. Vortex pinning by natural defects in thin films of YBa2Cu3O7−δ . Supercond Sci Technol. 2002;15(3):395.

Lu P, Li YQ, Zhao J, Chern CS, Gallois B, Norris P, Kear B, Cosandey F. High density, ultrafine precipitates in YBa2Cu3O7−x thin films prepared by plasma-enhanced metalorganic chemical vapordeposition. Appl Phys Lett. 1992;60(10):1265.

Wang H, Serquis A, Maiorov B, Civale L, Jia QX, Arendt PN, Foltyn SR, MacManus-Driscoll JL, Zhang X. Microstructureand transport properties of Y-rich YBa2Cu3O7−x thin films. J Appl Phys. 2006;100(5):053904.

Holesinger TG, Maiorov B, Ugurlu O, Civale L, Chen Y, Xiong X, Xie Y, Selvamanickam V. Microstructural and superconducting properties of high current metal–organic chemical vapor deposition YBa2Cu3O7−δ coated conductor wires. Supercond Sci Technol. 2009;22(4):045025.

Chen YM, Selvamanickam V, Zhang YF, Zuev Y, Cantoni C, Specht E, Paranthaman MP, Aytug T, Goyal A, Lee D. Enhanced flux pinning by BaZrO3 and (Gd, Y)2O3 nano-structures in metal organic chemical vapor deposited GdYBCO high temperature superconductor tapes. Appl Phys Lett. 2009;94(6):062513.

Macmanus-Driscoll JL, Foltyn SR, Jia QX, Wang H, Serquis A, Civale L, Maiorov B, Hawley ME, Maley MP, Peterson DE. Strongly enhanced current densities in superconducting coated conductors of YBa2Cu3O7−x +BaZrO3. Nat Mater. 2004;3(7):439.

Aytug T, Paranthaman M, Specht ED, Zhang Y, Kim K, Zuev YL, Cantoni C, Goyal A, Christem DK, Maroni VA. Enhanced flux pinning in MOCVD-YBCO films through Zr additions: systematic feasibility studies. Supercond Sci Technol. 2010;23(1):014005.

Jha AK, Khare N, Pinto R. Comparison of flux pinning mechanism in laser ablated YBCO and YBCO:BaZrO3 nanocomposite thin films. J Supercond Nov Magn. 2012;25(2):377.

Selvamanickam V, Chen Y, Shi T, Liu Y, Khatri ND, Liu J, Yao Y, Xiong X, Lei C, Soloveichilk S. Enhanced critical currents in (Gd, Y)Ba2Cu3O x superconducting tapes with high levels of Zr addition. Supercond Sci Technol. 2013;26(3):035006.

Xu AX, Khatri N, Liu YH, Majkic G, Galstyan E, Selvamanickam V, Chen YM, Lei CH, Abraimov D, Hu XB, Jaroszynski J, Larbalestier D. Broad temperature pinning study of 15 mol.% Zr-added (Gd, Y)–Ba–Cu–O MOCVD coated conductors. IEEE Trans Appl Supercond. 2015;25(3):6603105.

Varanasi CV, Burke J, Wang H, Lee JH, Barnes PN. Thick YBa2Cu3O7−x +BaSnO3 films with enhanced critical current density at high magnetic fields. Appl Phys Lett. 2008;93(9):092501.

Tobita H, Notoh K, Higashikawa K, Inoue M, Kiss T, Kato T, Hirayama T, Yoshizumi M, Izumi T, Shiohara Y. Fabrication of BaHfO3 doped GdBa2Cu3O7−δ coated conductors with the high I c of 85 A/cm-w under 3 T at liquid nitrogen temperature (77 K). Supercond Sci Technol. 2012;25(6):062002.

Hanisch J, Cai C, Huhne R, Schultz L, Holzapfel B. Formation of nanosized BaIrO3 precipitates and their contribution to flux pinning in Ir-doped YBa2Cu3O7−δ quasi-multilayers. Appl Phys Lett. 2005;86(12):122508.

Harrington SA, Durrell JH, Maiorov B, Wang H, Wimbush SC, Kursumovic A, Lee JH, MacManus-Driscoll JK. Self-assembled, rare earth tantalate pyrochlore nanoparticles for superior flux pinning in YBa2Cu3O7−δ films. Supercond Sci Technol. 2009;22(2):022001.

Wee SH, Goyal A, Specht ED, Cantoni C, Zuev YL, Selvamanickam V, Cook S. Enhanced flux pinning and critical current density via incorporation of self-assembled rare-earth barium tantalate nanocolumns within YBa2Cu3O7−δ films. Phys Rev B. 2010;81(14):140503.

Feldmann DM, Holesinger TG, Maiorov B, Foltyn SR, Coulter JY, Apodaca I. Improved flux pinning in YBa2Cu3O7 with nanorods of the double perovskite Ba2YNbO6. Supercond Sci Technol. 2010;23(9):095004.

Emergo RLS, Wu JZ, Haugan TJ, Barnes PN. Tuning porosity of vicinal films by insertion of nanoparticles. Appl Phys Lett. 2005;87(23):232503.

Haugan T, Barnes PN, Wheeler R, Meisenkothen F, Sumption M. Addition of nanoparticle dispersions to enhance flux pinning of the YBa2Cu3O7−x superconductor. Nature. 2004;430(7002):867.

Takahashi K, Yamada Y, Konishi M, Watanabe T, Ibi A, Muroga T, Miyata S, Shiohara Y, Kato T, Hirayama T. Magnetic field dependence of J c for Gd-123 coated conductor on PLD-CeO2 capped IBAD-GZO substrate tapes. Supercond Sci Technol. 2005;18(8):1118.

Selvamanickam V, Chen Y, Zhang Y, Guevara A, Shi T, Yao Y, Majkic G, Lei C, Galtsyan E, Miller DJ. Effect of rare-earth composition on microstructure and pinning properties of Zr-doped (Gd, Y)Ba2Cu3O x superconducting tapes. Supercond Sci Technol. 2012;25(4):045012.

Xiong J, Xue Y, Xia YD, Zhang F, Zhang YX, Li LH, Zhao XH, Tao BW. Fabrication of long-length ion beam-assisted deposited MgO templates for YBCO-coated conductors. Rare Met. 2013;32(6):574.

Yang C, He YY, Chu JW, Xue Y, Zhang F, Wang H, Tao BW, Xiong J. Tailoring surface roughness of LaMnO3 buffer layers for YBCO-coated conductors. Rare Met. 2015;34(12):859.

Zhang F, Xiong J, Zhao RP, Xue Y, Wang H, Wang QL, He YY, Zhang P, Tao BW. Temperature-modulated growth of MOCVD-derived YBa2Cu3O7−x Films on IBAD-MgO templates. J Supercond Nov Magn. 2015;28(9):2697.

Prado F, Caneiro A, Serquis A. High temperature thermodynamic properties, orthorhombic/tetragonal transition and phase stability of GdBa2Cu3Oy and related R123 compounds. Phys C. 1998;295(3–4):235.

Shi DQ, Ko RK, Song KJ, Chung JK, Choi SJ, Park YM, Shin KC, Yoo SI, Park C. Effects of deposition rate and thickness on the properties of YBCO films deposited by pulsed laser deposition. Supercond Sci Technol. 2004;17(2):S42.

Augieri A, Galluzzi V, Celentano G, Angrisani AA, Mancini A, Rufoloni A, Vannozzi A, Silva E, Pompeo N, Petrisor T, Ciontea L, Gambardella U, Rubanov S. Transport property improvement by means of BZO inclusions in PLD grown YBCO thin films. IEEE Trans Appl Supercond. 2009;19(3):3399.

Acknowledgements

This study was financially supported by the National Science Foundation of China (No. 91421110), the National High Technology Research and Development Program of China (No. 2014AA032702), the National Basic Research Program of China (No. 2015CB358600), the Sichuan Youth Science and Technology Innovation Research Team Funding (No. 2011JTD0006) and the Sichuan Provincial Fund for Distinguished Young Academic and Technology Leaders (No. 2014JQ0011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, YX., Zhang, F., Zhao, RP. et al. Microstructure and properties of MOCVD-derived Gd x Y1−x Ba2Cu3O7−δ films with composition fluctuations. Rare Met. 37, 675–681 (2018). https://doi.org/10.1007/s12598-016-0837-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0837-x