Abstract

The cube texture evolution of Ni-5 at%W alloy deformed up to a very high strain was thoroughly investigated by X-ray diffraction (XRD) and electron back-scattered diffraction (EBSD) during the process of deformation, recrystallization and grain growth. A typical copper-type rolling texture, mainly consisting of components of S, copper and brass orientations, is obtained after heavy cold rolling. The fraction of rolling texture is slightly strengthened during recovery and then strongly reduced during recrystallization process. The cube texture is formed by consuming the rolling texture components during the discontinuous recrystallization process. The cube grains have a size advantage with respect to the non-cube grains. A strong cube-textured Ni5W alloy substrate with cube texture area fraction of 98.2 % (<10°) is obtained after annealing at 1050 °C for 1 h. The full width half maximum (FWHM) values for the X-ray (111) φ-scan and the (002) ω-scan of this substrate are 5.84° and 4.76°, respectively. Furthermore, the area fraction of {001} 〈110〉 orientation of the epitaxially grown La2Zr2O7 buffer layer is 97.1 % (<10°), and the FWHM values of (111) φ-scan and (002) ω-scan are 5.22° and 5.00°, respectively.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The rolling-assisted biaxially textured substrates (RABiTS) process based on Ni and Ni-based alloys is a promising approach for the economical production of high Curie temperature (Tc) superconducting tapes of YBa2Cu3O7−δ (YBCO) [1]. With this method, the desired substrate alloys with strong biaxial texture is produced through the epitaxial growth of a buffer layer and YBCO film on the strong cube-textured substrates [2–7]. In order to avoid a significant reduction in the critical current density for the epitaxially grown superconductor layers [8, 9], the main requirements for the substrates are a strong cube texture and few high-angle boundaries (HABs).

The previous experiments on Ni5W and Ni–Cu alloys have confirmed that a copper-type rolling texture can be obtained after heavy deformation and that the copper-type rolling texture is beneficial for the cube texture formation during recrystallization [5, 10]. At present, Ni5W alloy is widely preferred as substrate material for YBCO-coated conductors due to that strong cube texturing and low HAB area fraction can be achieved by heavy cold rolling and subsequent annealing. Previous studies of RABiTS-processed Ni5W alloy substrates focused mostly on microstructures and textures produced by the high-temperature annealing [8]. Only a few reports focus on the recrystallization nucleation of Ni5W, and little effort has been directed toward investigating the evolution of the cube texture in heavily deformed Ni5W alloys during deformation and recrystallization [10].

In the present work, the evolution of texture during cold rolling and recrystallization annealing was characterized using four-circle X-ray diffraction (XRD). In addition, the microstructure and texture development during recrystallization and grain growth of the Ni5W alloy substrates were investigated by electron back-scattered diffraction (EBSD). The systematic analysis of the cube texture evolution in the Ni5W alloy not only is of scientific value, but is useful in optimizing the microstructure and texture of the substrates after the final annealing. Another important aspect has to be considered is the substrates quality after coating with a buffer layer [11, 12]. Therefore, the epitaxially grown La2Zr2O7 (LZO) buffer layer was investigated in the present study.

2 Experimental

The Ni5W alloy was prepared by high-frequency vacuum induction melting of Ni and W metals with the high purity of 99.95 %. The ingot was deformed at 1150 °C to produce a bulk with dimensions of 22 mm × 12 mm × 15 mm, and a heat treatment at 1200 °C for 24 h was applied to homogenize the alloy. Subsequently, cold rolling from 15 to 3 mm in thickness and a recrystallization annealing at 850 °C for 1 h were performed to prepare the ingot for final deformation. Cold rolling was applied with a 5 % reduction per pass to obtain a final thickness of 80 µm. The total reduction in thickness reduction in the tapes by cold rolling was 97.3 % yielding a von Mises strain (ε VM) of 4.17. To analyze rolling texture formation of the Ni5W alloy, the deformation reductions of 70.0 %, 80.0 %, 90.0 %, 95.0 % and 97.3 % were performed, and the corresponding strains were 1.39, 1.86, 2.66, 3.46 and 4.17, respectively. The final cold-rolled tapes with strain of 4.17 were annealed at 400, 600, 650, 675, 700, 800, 900, 1000 and 1050 °C for 1 h, respectively, under flowing Ar–4 vol% H2. In these annealing experiments, the quartz tube containing the specimens was inserted into a preheated furnace and was retracted from the furnace after annealing. A La2Zr2O7 (LZO) buffer layer was produced using the propionic acid-based metal organic deposition route on the textured Ni5W alloy substrate annealed at 1050 °C for 1 h. The total cation concentration of the LZO precursor solution was 0.8 mol·L−1, and the spinning rate was 4000 r·min−1 for 60 s. For the crystallization of the buffer layer, the sample was held at 1150 °C for 1 h in a tube furnace, also containing Ar–4 vol% H2.

The rolling texture and the textures after recovery and recrystallization were investigated by XRD (Bruker D8) equipped with an Eulerian cradle. For each measurement, the {111}, {200} and {220} pole figures were detected and transformed to orientation distribution functions (ODFs) to calculate the contents of the texture components in volume fraction, S {123} 〈634〉, brass {110} 〈112〉, copper {112} 〈111〉 and cube {001} 〈100〉 orientations (with a maximum deviation angular of 15°). EBSD characterization was conducted with a field emission gun scanning electron microscope (QUANTA FEG 650, FEI, Oregon, USA) equipped with a Channel 5 system. The microstructures and textures of the partially recrystallized samples were measured at step interval of 0.5 µm in the rolling plane. A large step size of 2 µm was applied to obtain EBSD maps from areas of 400 µm × 400 µm for the samples annealed at high temperature. Low-angle boundaries (LABs) and HABs were defined as boundaries with misorientations of 2°–10° and >10°, respectively. The Σ3 boundaries were defined in the present experiment by applying a maximum deviation of 3° from the exact 60° 〈111〉 orientations. Area fractions (f) of the cube texture were calculated from the EBSD data lying within 10° of the corresponding ideal cube orientations. The in-plane and out-of-plane textures of the strong cube-textured Ni5W substrates and the epitaxially grown LZO buffer layer were detected using X-ray (111) φ-scan and (002) ω-scan.

3 Results and discussion

3.1 Deformation texture

Figure 1 shows the {111} pole figures for the rolling direction (RD) and transverse direction (TD) section of the deformed Ni5W alloy affected by the strains. The strength of the texture is marked with contour and different colors represent different texture concentrations. A copper-type rolling texture with main rolling components of S, copper and brass orientations is found in the cold-rolled Ni5W alloy after being deformed to an intermediate strain. With strains increasing, the rolling texture is subsequently enhanced. The fractions of rolling components calculated from the ODFs are presented in Fig. 2. The content of the rolling texture obtained by the summation of the contents of S, copper and brass orientations is enhanced from 65 vol% to 85 vol% with deformation strain increasing from intermediate (ε VM = 1.39) to a high strain (ε VM = 4.17). The content of other orientations (except the main rolling components and cube orientation) is reduced for enhanced rolling texture (Fig. 2a). The content of cube orientation is very small in the deformed state and decreases slightly when the strain increases due to the appearance of instability in the cube orientation during deformation [13, 14]. The content of each of the main rolling components increases with strain increasing. The S orientation with the highest content in each deformation strain dominates the rolling texture in the deformed Ni5W alloy (Fig. 2b).

3.2 Recrystallization

The texture transition of the cold-rolled Ni5W alloy samples during annealing was investigated by means of XRD. The {111} pole figures of the Ni5W alloy samples annealed at 600–800 °C are presented in Fig. 3. During recovery at annealing temperatures ≤600 °C, the texture still remains a copper-type rolling texture. The texture transforms from the copper-type rolling texture after annealing at 650 °C for 1 h to a recrystallized cube texture after annealing at 800 °C for 1 h (Fig. 3b–f). The recrystallization takes place at 650 °C with little increase in cube orientation content, whereas after annealing at 675 °C for 1 h, the strength of cube orientation increases significantly, whereas the strength of rolling texture decreases (Fig. 3c). The recrystallization cube texture is formed with little rolling texture after further annealing at high temperature (≥700 °C).

The contents of each main rolling component, cube orientation and other orientation of the deformed and annealed Ni5W alloy samples were calculated, as presented in Fig. 4. The rolling texture content increases from 85 vol% after heavy cold rolling to 91 vol% after annealing at 600 °C for 1 h. The copper-type rolling texture and the cube orientation are both enhanced during recovery, agreeing with the previous results for Cu–45 %Ni alloy [3, 14]. Recrystallization of the Ni5W alloy is accompanied by a high reduction in the rolling texture, while the content of cube orientation increases significantly. The content of cube orientation increases strongly from 1 vol% after annealing at 650 °C for 1 h to 80 vol% after annealing at 800 °C for 1 h (Fig. 4a).

The evolution of the content of each main rolling component during annealing is presented in Fig. 4b. The increased content of rolling texture during recovery is mainly due to the increase in the content of the brass orientation for the annealed Ni5W alloy samples. It can be considered that the brass orientation is believed to coarsen significantly more than the S and copper orientations, especially toward the end of the recovery and hence increasing process which may increase the opportunity of nucleation for the brass orientation. During recrystallization, three main rolling texture components diminish simultaneously. There is no evidence showing that the different rolling components have different effects on the formation of the recrystallization cube texture in the Ni5W alloy. The content of rolling texture drops around 80 vol% during recrystallization and most of them are consumed by recrystallized cube grains. Hence, this leads to the formation of a recrystallization cube texture with a content of 80 vol% after primary recrystallization (annealed at 800 °C for 1 h).

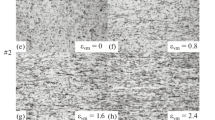

The microstructures and textures of the partial recrystallized Ni5W alloy samples were analyzed by EBSD (Fig. 5). It shows that recrystallized grains develop from the deformed matrix, while the recrystallized grains contain cube grains, grains with rolling components and grains with other orientations. A cube texture forms with annealing temperature increasing followed by nucleation and discontinuous recrystallization. The nucleus is detected on the rolling plane after annealing at 650 °C for 1 h, which is consistent with the results obtained by XRD. The cube orientation tends to have the advantage of nucleation due to the larger average grain size with respect to the rolling components and the other orientations (Fig. 5a). Subsequently, a discontinuous recrystallization takes place rapidly, accompanied by the formation of the recrystallization cube texture (Fig. 5b–d). During recrystallization, the cube grains consume both the deformation matrix and recrystallized non-cube grains. The area fraction of the recrystallized cube texture strongly increases to 80 % after the completion of the primary recrystallization of the Ni5W alloy, due to the cube grain growth via HABs migration during recrystallization [10, 15].

The average grain size of the recrystallized cube grains (d cube) increases from 3.28 µm after annealing at 650 °C for 1 h to 12.18 µm after 750 °C for 1 h (Table 1). The average grain size of the non-cube grains (d non-cube) is markedly smaller than that of the cube grains in the same state, thus indicating a discontinuous recrystallization. This leads to the formation of cube texture during recrystallization for the Ni5W alloy samples. This result is consistent with the previous findings, indicating that during recrystallization, the cube grains grow faster compared to non-cube grains in Cu and Ni metals [15, 16]. Following the results from the classical Beck experiment [17], it is often assumed that such preferential growth is related to the migration of the boundaries with the misorientation close to 40° 〈111〉 relationship. In fact, cube orientation is found to have such misorientation relationship with S orientation, which suggests that S orientation could be consumed by cube grains first and be beneficial for the development of recrystallization cube texture [18]. At present, EBSD orientation maps of recrystallized samples were investigated in view of this possibility by marking all 40° 〈111〉 misorientation, and the area fraction of 40° 〈111〉 boundaries was confirmed to be extremely low (<2 %) [10, 15, 19].

The temperature dependence of the parameters associated with microstructure and texture for the partially recrystallized Ni5W alloy samples are presented in Table 1. The cube texture area fraction (f cube) increases, whereas the rolling components are consumed significantly during cube grains growth via HABs migration. The HABs area fraction (f HABs) increases and reaches ~64 % in the Ni5W alloy samples annealed at 750 °C for 1 h. In addition, the area fraction of Σ3 boundaries (f Σ3) increases from ~4 % after annealing at 650 °C for 1 h to ~15 % after 750 °C for 1 h, which is mainly due to the formation of annealing twin during recrystallization of the Ni5W alloy.

3.3 Grain growth

Even though a high area fraction of cube texture has already developed after primary recrystallization, its value is insufficient to enable Ni5W to be used as alloy substrates for YBCO-coated conductors. Grain growth is therefore required to further strengthen the area fraction of cube texture to the required value of >95 % [20, 21]. Figure 6 shows EBSD maps of Ni5W alloy substrates annealed at 800, 900, 1000 and 1050 °C. The grain size, as well as the area fraction of cube texture and the grain boundaries, is strongly dependent on the annealing temperature. It is apparent that the high-temperature annealing enhances the average grain size and the cube texture formation. The area fraction of HABs decreases as the growing cube grains encounter one another, forming new LABs (Fig. 6). The microstructure and texture parameters of high-temperature annealed Ni5W alloy substrates annealed at different high temperatures are listed in Table 2. After annealing at 1050 °C for 1 h, the area fraction of cube texture (f cube) is 98.2 % (<10°) and the area fraction of LABs (f LABs) is 86.8 %. The annealing twins formed during recrystallization are reduced after high-temperature annealing, while the area fraction of Σ3 boundaries is very little, ~1 %, after annealing at 1050 °C for 1 h. The in-plane and out-of-plane textures of this substrate were detected by XRD. The full width half maximum (FWHM) values of the X-ray (111) φ-scan and (002) ω-scan of this substrate are 5.84° and 4.76°, respectively.

3.4 LZO buffer layer

The LZO buffer layer was successfully deposited on strongly cube-textured Ni5W alloy substrates annealed at 1050 °C for 1 h. EBSD map of an epitaxially grown LZO buffer layer on the textured Ni5W substrates (Fig. 7) indicates that the buffer layer is smooth, continuous and crack-free, and contains a strong {001} 〈110〉 texture. The area fraction of {001} 〈110〉 orientation is 97.1 % (<10°). The FWHM values of (111) φ-scan and (002) ω-scan are 5.22° and 5.00°, respectively. Compared with the texture values of the Ni5W alloy substrate, it implies only a small degradation is seen in the texture transferred to the LZO buffer layer by epitaxial grain to grain.

4 Conclusion

The evolution in the cube texture of heavy cold-rolled Ni5W alloy was investigated by XRD and EBSD. Moreover, a LZO buffer layer was successfully deposited on the strong cube-textured Ni5W alloy substrate. After heavy cold rolling, a copper-type rolling texture is formed for the Ni5W alloy with a rolling texture content of 80 vol% when the strain reaches 4.17. The copper-type rolling texture strengthens during recovery (annealed at low temperature <600 °C) and is subsequently reduced during the discontinuous recrystallization (650–800 °C). The cube grains have the size advantage and consume non-cube grains and deformation matrix by HABs migration during recrystallization, thus leading to the cube texture formed in the Ni5W alloy. Cube grain growth takes place at high annealing temperature and develops into a strong cube texture with low area fraction of HABs. The strong cube texture with the high area fraction of 98.2 % (<10°) is obtained after annealing at 1050 °C for 1 h for the Ni5W alloy substrates. The FWHM values for the XRD (111) φ-scan and (002) ω-scan of this substrate are 5.84° and 4.76°, respectively. Furthermore, the area fraction of {001} 〈110〉 orientation of the epitaxially grown high-quality LZO buffer layer is 97.1 % (<10°), and the FWHM values of φ-scan and ω-scan of the buffer layer are 5.22° and 5.00°, respectively.

References

Goyal A, Norton DP, Budai JD, Paranthaman M, Specht ED, Kroeger DM, Christen DK, He Q, Saffian B, List FA, Lee DF, Martin PM, Klabunde CE, Hatfield E, Sikka VK. High critical current density superconducting tapes by epitaxial deposition of YBa2Cu3Ox thick films on biaxially textured metals. Appl Phys Lett. 1996;69(12):1795.

Tian H, Suo HL, Qiu HQ, Ma L, Liu M, Wang LM, Wang DM, Wang YX. Investigation of cold rolling texture and recrystallization texture in NiW substrates. Rare Met Mater Eng. 2011;40(S3):329.

Tian H, Suo HL, Mishin OV, Zhang YB, Jensen DJ, Grivel JC. Annealing behaviour of a nanostructured Cu–45 at% Ni alloy. J Mater Sci. 2013;48(12):4183.

Wulff AC, Mishin OV, Grivel J-C. Evolution of microstructure, texture and topography during additional annealing of cube-textured Ni–5 at%W substrate for coated conductors. J Alloys Compd. 2012;539(15):161.

Tian H, Suo HL, Wulff AC, Grivel C, Mishin OV, Jensen DJ. Comparative characterization of Cu–Ni substrates for coated conductors. J Alloys Compd. 2014;601:9.

Boer BD, Eickemeyer J, Reger N, Fernandez L, Richter J, Holzapfel B, Schultz L, Prusseit W, Berberich P. Cube textured-nickel alloy tapes as substrates for YBa2Cu3O7−δ coated conductors. Acta Mater. 2001;49(8):1421.

Chen JY, Feng Q, Cao LM, Sun ZQ. Influence of Ru addition on microstructure and stress-rupture property of Ni-based single crystal superalloys. Prog Nat Sci. 2010;20(1):61.

Goyal A, Nortoa DP, Kroeger DM, Christen DK, Paranthaman M, Specht ED, Budai JD, He Q, Saffian B, List FA, Lee DF, Hatfield E, Martin PM, Klabunde CE, Mathis J, Parka C. Conductors with controlled grain boundaries: an approach to the next generation, high temperature superconducting wire. J Mater Res. 1997;12(11):2924.

Goyal A, Ren SX, Specht ED, Kroeger DM, Feenstra R, Norton D. Texture formation and grain boundary networks in rolling assisted biaxially textured substrates and in epitaxial YBCO films on such substrates. USA Micron. 1999;30(5):463.

Bhattacharjee PP, Ray RK, Tsuji N. Cold rolling and recrystallization textures of a Ni-5 at%W alloy. Acta Mater. 2009;57(7):2166.

Xiong J, Wang XB, Guo P, Xia YD, Zhao XH, Tao BW, Li YR. Tailoring the crystallographic orientation of MOD-derived La2ZrO7 buffer layers for coated conductors. Phys C. 2013;492(25):103.

Xiong J, Wang XB, Guo P, Zhang F, Xia YD, Zhu C, Xu PJ, Zhao XH, Tao BW. Microstructure modification of La2Zr2O7 buffer films for coated conductors by metal organic decomposition. J Mater Sci Mater Electron. 2013;24(5):1546.

Leffers T, Rey RK. The brass-type texture and its deviation from the copper-type texture. Prog Mater Sci. 2009;54(3):351.

Tian H, Suo HL, Liang YR, Ma L, Meng YM, Peng FX, Wang P. Cube texture formation of Cu–45 at% Ni alloy substrates for YBCO coated conductors. Chin Sci Pap. 2014;9(2):230.

Li XL, Liu W, Godfrey A. Development of the cube texture at low annealing temperatures in highly rolled pure nickel. Acta Mater. 2007;55(10):3531.

Li JW, Yang ST, Wei SZ, Zhang GS, Xu LJ. Microstructure and texture of pure molybdenum sheet at different rolling methods and deformation. Chin J Rare Met. 2014;38(3):348.

Beck PA, Sperry PR. Strain induced grain boundary migration in high purity aluminum. J Appl Phys. 1950;21(2):150.

Doherty RD. Nucleation and growth kinetics of different recrystallization texture components. Scr Metall. 1985;19(8):927.

Zhang YB, Godfrey A, Liu Q, Liu W, Jensen DJ. Analysis of the growth of individual grains during recrystallization in pure nickel. Acta Mater. 2009;57(9):2631.

Zhao Y, Suo HL, Liu M, Liu DM, Zhang YX, Zhou ML. Development of cube textured Ni-5 at%W alloy substrates for coated conductor application using a melting process. Phys C. 2006;440(1):10.

Zhang YB, Godfrey A, Miodoenik AM, Liu W, Liu Q. Modeling of cube-texture evolution during grain growth in Ni thick-films based on experimental observations. Mater Sci Forum Trans Tech Publ. 2007;558(1):1043.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51171002), Beijing Municipal Natural Science Foundations (Nos. 2132011 and KZ201310005003), the Project of Construction of Innovative Teams and Teacher Career Development for Universities and Colleges under Beijing Municipality (No. IDHT20130510), China Postdoctoral Science Foundation funded project (No. 2014M560030) and Beijing Postdoctoral Research Foundation (No. 2014ZZ-38).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, P., Tian, H., Suo, HL. et al. Cube texture evolution of Ni5W alloy substrates and La–Zr–O buffer layer of YBCO-coated conductors. Rare Met. 41, 3887–3894 (2022). https://doi.org/10.1007/s12598-016-0790-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-016-0790-8