Abstract

Photonic Crystal Fiber Fabry–Perot Interferometers (FPI) based on Surface Plasmon Resonance (SPR) was investigated in this paper in order to detect changes in photonic crystal fiber sensitivity with increasing temperature. FPI is composed of a PCF (ESM-12) solid core spliced with a single-mode fiber (SMF) on one side and a 40nm thick gold Nano film on the other. In order to obtain the SPR curve, the end of PCF can be spliced with the side of SMF before covering the gold film on the PCF. SPR results are included in the suggested sensor, based on the conclusions of the investigations. Resolution (R) is 0.0871, Signal-to-Noise Ratio (SNR) is 0.1867, a figure of merit (FOM) is 0.0069, and sensitivity (S) is 1.1481 \((\frac{{\varvec{n}}{\varvec{m}}}{^\circ {\varvec{C}}})\). This sensor proposed is strong mechanically, it costs less, and uncomplicated to fabricate, permitting it to supply larger quantity field and activity zone to measure surrounding environment's temperature without requiring a longer sensor. The reflection-based plasmonic sensing is compact, low-cost, and suitable for biomedical uses, observing environmental contaminants, and water analysis.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In many areas of science, including biomedicine, biology, chemistry, biochemistry and physics, sensing has been developed. As a result of these developments, sensors have been able to solve a variety of problems. Sensors may encounter difficulties due to their cost, sample size, signal to noise ratio, sensitivity, and resolution, as well as their performance parameters [1,2,3]. Air holes extend endlessly the fiber axis in the cladding part of the PCF, and it is flexible and contains many excellent properties, including an endless single mode, great nonlinearity, high birefringence, enormous mode fields, simple satisfying material, and small transmission loss [4,5,6]. Due to its microstructure, PCFs differ from standard optical fibers in that they contain air holes along their length. It is possible to propagate light in air through air holes or to inject gases/liquids into them [7]. By controlling the interaction between light and matter, it allows for unique sensing applications that are not achievable with standard optical fibers [8]. A photonic crystal fiber SPR sensor features a flexible structure design in addition to high mechanical strength and reliability [9]. A sensor's sensitivity is an important performance parameter that influences its accuracy and resolution. A practical material or specific material can be applied to the metal film to increase the sensitivity of SPR sensor. By the metallic film producing SPR, the sensor is approaching its maximum sensitivity, so improving its performance is more difficult [10]. Between the fastest-developing fields of study, plasmonics carries together researchers from chemistry, physics, and medicine [11]. Plasmonics is the study of how photons (light) interact on a Nano scale with surface electrons. Surface plasmons (SPs) oscillate collectively due to photons emitted from a light source. As a result of SP excitation, surface waves can propagate at the crossing between dielectric and metallic Nano films or electrons can oscillate strongly in or Nano configurations (localized surface Plasmon resonance [12,13,14]. A thin reflecting metal layer (such as silver or gold) and a sample are coupled through a substrate with a high refractive index to produce surface Plasmon waves (SPWs) [15, 16]. It occurs when light makes a charge density oscillation at a metal–dielectric interface below the phase corresponding condition between polarized light and Surface Plasmon Resonance (SPR) [17,18,19]. As a result of their elasticity, developed light limitation, compressed size, and controlled birefringence structures, photonic crystal fibers are widely investigated for SPR detecting [20]. The resonance state be influenced by the instance angle, the metal, and the dielectric constants [21].With their distinctive microstructures and dispersive properties, photonic crystal fibers have become increasingly popular in recent years [22]. Evanescent fields are used in PCF-SPR's sensing system. A specific wavelength of light passes through the cladding and onto the fiber's core, producing some fields [23]. An optical sensor based on SPR can be utilized for applications such as chemical and biomedical diagnostics, environmental safety, electrochemistry sciences, and life sciences [24]. Using SPR in fiber-based refractive index sensing, it is widely used in environmental monitoring, bio sensing, medical development, and food safety [25]. This work aimed at sensing and measuring the temperature of an environment using a SMF-PCF sensor established on SPR.In SPR, incident light is absorbed by plasma on a metal surface, and the reflected light is affectedly decreased in energy [26]. Plasma oscillations at the surface or interface are denoted to as surface Plasmons. The term "plasmon" refers to a quasiparticle representation of plasma frequency. Plasma oscillation describes the phenomenon that free electrons of the metal oscillate cooperatively from their equilibrium position [27]. SPR technique was first applied to sensing in 1983 [28]. The technique works by interacting light with free electrons in a semitransparent noble metallic layer. A resonance condition occurs when incident light's frequency coincides with the electron oscillation frequency of the metal. Metals such as gold and silver are favored for SPR triggers because they are chemically unchanging silver still given that sensible sensitivity to changes in \({(\mathrm{ n}}_{{\text{a}}})\) [29,30,31,32,33]. In recent decades, SPR sensors have gained much attention due to their high sensitivity and versatile use in sensing, as shown in Fig. 1 [34].

Applications of surface Plasmon resonance sensors [34]

Performance parameter for surface plasmon resonance

Performance characteristics to be studied include sensitivity, signal to noise ratio, figure of merit, and resolution. In the case of spectral interrogation, sensitivity can be defined as the change in resonance wavelength per unit change in refractive index of the sensing medium, and it can be written as [35]:

where \({\Delta \lambda }_{res}\) and \(\Delta T\) are the change of the resonance wavelength and the change of temperture, respectively. From this equation, the unit of the sensitivity is nanometers per refractive index unit (nm/C°).

Signal to noise ratio (SNR) and figure of merit (FOM) are inversely proportional to the width of SPR spectral curve and can be written as [35]:

where \({\Delta \lambda }_{0.5}\) is the width of the spectral curve?

The resolution of the sensor can be defined as the minimum of change in refractive index that is detectable by the sensor, and is given as [36]:

where ( \({\Delta\uplambda }_{{\text{DR}}}\)) is the spectral resolution of the spectrometer.

The devices and experimental work

The Set-up of The effect of increasing temperature on the sensitivity of Photonic Crystal fiber consists of the following:

Fabry–Perot interferometer structure fabrication

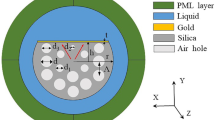

The Scanning Electron Microscope (SEM) of the (PCF) is used to determine the morphology of the PCF; Fig. 2 shows a cross section of the investigation's PCF. It consists of six coats of hexagonal air holes encircling a core of silica. The fiber contains a core diameter of 10.2μm, an outside diameter of 125μm holes with diameters of 2.46m, and a pitch of 7.8μm. These are the dimensions of the PCF alignment and splicing with Single Mode Fiber (SMF) from another side utilizing a splicing machine as shown in Fig. 3. First, mechanical stripping was used to remove the coating from a PCF and SMF. The SMF and PCF were then cut utilizing a fiber cleaver in the next step. The PCF (10 mm) was then combination linked with (SMF) from one side utilizing a splicing instrument. Finally, a gold coating with 40 nm thickness is coated on the ending face of PCF by utilizing the Sputter Coater which operated with an Au target bombarded utilizing ions of argon gas.

Experimental work

The practical design for calculating the temperature of the surrounding environment is shown in Fig. 4, which consists of a Thermostat Water Bath HH_1 of KW-1000DC, TRUE RMS MULTIMETER from FLUKE 179, optical fiber coupler, has three connections. The first terminal is connected to a diode laser with a wavelength of 653nm and 0.05mW power, the second terminal connects to (SMF-PCF), and the third terminal connects to an optical spectrum analyzer (OSA). The light from the diode laser source is first transmitted to the SMF-PCF sensor through a coupler. Finally, the modulated optical signal is processed through a USB port on the computer.

Results and discussion

SMF-PCF sensors were immersed in a Thermostat water bath to determine their SPR curves. The spectra are obtained by registering the transmission curves T of the transferred light via the SMF-PCF sensor. The spectra are created by calculating the transition curves T for light using an optical cable. As illustrated in Fig. 5, the transmission (T) is computed by dividing intensity (I) recorded when there is sample intensity to the intensity without sample (I0). T, estimated as a ratio, is schemed in Fig. 6 as a function of the wavelength described in nm. This figure called SPR curve.

Figure 6 shows Plasmon resonance curves at different temperatures of (sensing medium). These figures are in expressions of the normalized transmitted power. This normalized transmitted is schemed as a function of the wavelength of the incident wave. In these figures, the responses are simulated for an arranged sensor illuminated in Fig. 4. The resonance appears as a dip in the SPR curves. The dip happens at a resonance wavelength during the transfer of energy from the transferred power of light directed via the fiber to the surface plasmons. Increases the temperature of a sensing medium increases the resonance wavelength to a longer wavelength, which may be described through the resonance condition of surface Plasmon waves. Figure 7 displays a linear association between resonant wavelength and temperature. Table 1 displays the performance parameters values for the sensor with the Au cover. Where sensitivity, resolution, signals to noise ratio and figure of merit was calculated. Table 2 explains the values of resonance wavelength, and the temperatures.

Conclusion

In this paper, a Reflection-Type Photonic Crystal Fiber sensor (PCF) based on Surface Plasmon Resonance Technology is presented and used to detect and calculate environmental temperatures. A dip in the resonance position was observed when SPR response curves were recorded for different temperatures. With each temperature change, the resonance wavelength change. This SMF-PCF-based SPR sensor with an Au metal film 40 nm thick measured 1.1481 \((\frac{{\varvec{n}}{\varvec{m}}}{^\circ {\varvec{C}}})\) sensitivity and 0.1867 signal-to-noise ratio. The reflection-based plasmonic sensing is compact, low-cost, and suitable for biomedical uses, observing environmental contaminants, and water analysis.

References

N.S. Rahim, S.S, Ahmed, M.F. Sultan, Optical fiber biomedical sensor based on surface Plasmon resonance. Iraqi J Sci 1650–1656 (2020). https://doi.org/10.24996/ijs.2020.61.7.13

M.F. Sultan, A.A. Al-Zuky, S.A. Kadhim, Performance parameters evaluation of surface plasmon resonance based fiber optic sensor with different bilayer metals: Theoretical study. Al-Mustansiriyah J. Sci. 29(1), 195–203 (2018)

A.S. Alattar, S.A. Kadhim, F.S. Mohammed, A.I. Mahmood, Performance simulation and design comparison of optical heterodyne temperature sensor based on Fiber Bragg Grating. IOP Conf. Ser.: Mater. Sci. Eng. 871(1), 012069 (2020)

J. Yang, L. Zhou, X. Che, J. Huang, X. Li, W. Chen, Photonic Crystal Fiber Methane Sensor Based on Modal Interference with an Ultraviolet Curable Fluoro-Siloxane Nano-Film Incorporating Cryptophane A. Sens. Actuators B Chem. 235, 717–722 (2016)

T. Cheng, Z. Duan, M. Liao, W. Gao, D. Deng, T. Suzuki, Y. Ohishi, A Simple All-Solid Tellurite Microstructured Optical Fiber. Opt. Express 21, 3318–3323 (2013)

W.C. Wong, C.C. Chan, L.H. Chen, T. Li, K.X. Lee, K.C. Leong, Polyvinyl Alcohol Coated Photonic Crystal Optical Fiber Sensor for Humidity Measurement. Sens. Actuators B Chem. 174, 563–569 (2012)

G.M. Jassam, S.S. Ahmed, High sensitivity for toxic metal ion sensor based on tapered PCF Mach–Zehnder interferometer. J Opt. 1–7 (2023). https://doi.org/10.1007/s12596-023-01197-8

J. Mathew, Y. Semenova, G. Farrell, Photonic crystal fbre interferometer for humidity sensing. InTech. (2012)

X. Yan, B. Li, T. Cheng, S. Li, Analysis of high sensitivity photonic crystal fiber sensor based on surface plasmon resonance of refractive indexes of liquids. Sensors. 18, 2922 (2018)

M.S. Islam, C.M.B. Cordeiro, J. Sultana, R.A. Aoni, S. Feng, R. Ahmed, M. Dorraki, A. Dinovitser, B.W. Ng, D. Abbott, A Hi-Bi Ultra-Sensitive Surface Plasmon Resonance Fiber Sensor. IEEE Access. 7, 79085–79094 (2019)

M.I. Stockman, Nanoplasmonics: past, present, and glimpse into future. Opt. Express 19, 22029–22106 (2011)

C. Liu, L. Yang, P.K. Chu et al., Mid-infrared surface plasmon resonance sensor based on photonic crystal fbers. Opt. Express 25, 14227–14237 (2017)

M.F.S. Al-Saady, A.K. Albarazanchi, F.S. Mohammed, Design and simulation of localized surface plasmon resonance-based fiber optic chemical sensor. IOP Conf. Ser.: Mater. Sci. Eng. 871(1), 012074 (2020)

F.J. Kadhum, S.H. Kafi, A.A. Saeed, A.A. Al-Zuky, A.H. Al-Saleh, Simulation of Surface Plasmon Resonance (SPR) of Silver with Titanium Oxide as a Bi-Layer Biosensor. Sci. J. King Faisal Univ. Basic Appl. Sci. 22(2), 76–80 (2021)

Q. Wang, et al., Research advances on surface plasmon resonance biosensors. Nanoscale. 14(3), 564–591 (2022). https://doi.org/10.1039/D1NR05400G

H.J. Mohamad, S.H. Kafi, D.A. Taban, Ag/CdS surface plasmon simulation systems for gas sensor. Kuwait J Sci. 50(3), 216–222 (2023). https://doi.org/10.1016/j.kjs.2023.05.007

K. Emad, S.S. Bassam, Surface plasmon plastic optical fber resonance with multi-layer as chemical sensor. Iraqi J. Phys. (IJP) 19(50), 51–59 (2021)

M.F. Sultan, A.A. Al-Zuky, S.A. Kadhim, Surface plasmon resonance based fber optic sensor: theoretical simulation and experimental realization. ANJS 21(1), 65–70 (2018)

S.S. Al-Bassam, Tapered coated coreless optical fber pollution sensor. J. Phys. Conf. Ser. 2114(1), 012054 (2021)

G. Mohammed Jassam, S.S. Ahmed, The effect of tapered photonic crystal fiber structure on the performance of Mach-Zehnder interferometer to detection of toxic metal ion (Zinc). J. Opt. 52(2), 683–690 (2023)

M.H. Nida, S.S. Al-Bassam, Coreless optical fiber for hemoglobin (HB) sensing with bilayer based on surface plasmon resonance. J. Opt. 52(4), 1724–1729 (2022)

H.J. Taher, Low loss in gas flled hollow core photonic crystal fber. Baghdad Sci. J. 7(1), 129–138 (2010)

M.T. Rahman, S. Datto, M.N. Sakib, Highly sensitive circular slotted gold-coated micro channel photonic crystal fber based plasmonic biosensor. OSA Continuum 4, 1808–1826 (2021)

G.M. Jassam, Acetic acid concentration estimation using plastic optical fiber sensor based surface plasmon resonance. Iraqi J. Phys. 17(43), 11–17 (2019)

A.A. Rifat, M.R. Hasan, R. Ahmed, H. Butt, Photonic crystal fiber-based plasmonic biosensor with external sensing approach. J. Nanophotonics 12(1), 012503–012503 (2018)

X. Yan, Y. Wang, T. Cheng, S. Li, Photonic crystal fiber SPR liquid sensor based on elliptical detective channel. Micromachines 12(4), 408 (2021)

M.B. Hossain, M.S. Hossain, M. Moznuzzaman, M.A. Hossain, M. Tariquzzaman, M.T. Hasan, M.M. Rana, Numerical analysis and design of photonic crystal fiber based surface plasmon resonance biosensor. J. Sens. Technol. 9(2), 27–34 (2019)

B.D. Gupta, R.K. Verma, Surface Plasmon resonance-based fiber optic sensors: principle, probe designs, and some applications. J Sens. (2009). https://doi.org/10.1155/2009/979761

P. Lecaruyer, M. Canva, J. Rolland, Metallic film optimization in a Surface Plasmon Resonance biosensor by the extended Rouard method. Appl. Opt. 46, 2361–2369 (2007)

S.A. Zynio, A.V. Samoylov, E.R. Surovtseva, V.M. Mirsky, Y.M. Shirshov, Bimetallic layers increase sensitivity of affinity sensors based on Surface Plasmon Resonance. Sensors 2(2), 62–70 (2002)

C. Perrotton, N. Javahiraly, M. Slaman, B. Dam, P. Meyrueis, Fiber optic Surface Plasmon Resonance sensor based on wavelength modulation for hydrogen sensing. Opt. Express 19(106), A1175–A1183 (2011)

D.V. Nesterenko, Z. Sekkat, Resolution estimation of the Au, Ag, Cu, and Al single- and double-layer surface plasmon sensors in the ultraviolet, visible, and infrared regions. Plasmonics 8(4), 1585–1595 (2013)

J. Hottin, E. Wijaya, L. Hay, S. Maricot, M. Bouazaoui, J.P. Vilcot, Comparison of gold and silver/gold bimetallic surface for highly sensitive near-infrared SPR sensor at 1550 nm. Plasmonics 8, 619–624 (2013)

A.A. Rifat, R. Ahmed, A.K. Yetisen, H. Butt, A. Sabouri, G.A. Mahdiraji, F.A. Adikan, Photonic crystal fiber based plasmonic sensors. Sens. Actuators, B Chem. 243, 311–325 (2017)

N. Cennamo, D. Massarotti, L. Conte, L. Zeni, Low cost sensors based on SPR in a plastic optical fiber for biosensor implementation. Sensors 11(12), 11752–11760 (2011)

S.K. Srivastava, B.D. Gupta, Influence of ions on the surface plasmon resonance spectrum of a fiber optic refractive index sensor. Sens Actuators B: Chem. 156(2), 559–562 (2011)

Author information

Authors and Affiliations

Contributions

Namaa Salem Rahim: Preparation samples, conceptualization, writing-original draft, while, Soudad S.Ahmed: supervision, investigation, Ghufran Mohammed Jassam writing-reviewing and editing analysis.

Corresponding author

Ethics declarations

Declarations

The present research did not receive any grant from funding agencies in the public, Commercial or not-for profit sectors. So its personal work and the statement of declaration of interests are only mine and support has been subjective during the research work for the past year.

Competing interests

Authors would like to declare that they do not have any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Rahim, N.S., Jassam, G.M., Ahmed, S.S. et al. The effect of increasing temperature on the sensitivity of photonic crystal fiber. J Opt (2024). https://doi.org/10.1007/s12596-024-01826-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12596-024-01826-w