Abstract

Cadmium selenide (CdSe) quantum dots (QDs), being a well established highly luminescent semiconducting optical material, has diverse applications in the recent fields of optoelectronics, light emitting diodes and photo voltaic solar cell, attributed to its tunable band gap as a consequence of their tunable size and shape. Besides having tremendous utility, most of the synthesis routes of CdSe QDs reported, seems to be hazardous. Therefore, in the present study, we are reporting a considerably, greener method to synthesize CdSe QDs by using sodium borohydride, as the reducing agent. The highly stabilized QDs, over a period of one year, were characterized using high resolution transmission electron microscope and powder X-ray diffraction technique. Nanocrystallites with hexagonal and cubic polycrystallinity, exhibiting 3–12 nm size were successfully observed, without using any capping reagent. The UV–visible absorption is also revealing good agreement by showing a blue shift at the range of 450–470 nm. The QDs are further subjected to the fabrication of homogeneous thin films upon a glass template using spin coater. The thin films were further characterized using atomic force microscopy, which showed an average area (root mean square) roughness of 5.7898 nm at 2.53 µm area.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The nanoparticles of semiconducting materials have been of a great interest to the researchers, as these materials provide a unique, broad platform to work in the field of optoelectronics, photo voltaic solar cell [1], light emitting diodes [2, 3], laser [4] etc., by helping in the fabrication of the devices, which may be based on energy storage or interconversions, thereby, leading to the ultimate solution to the energy crisis in the present day world. Although, nanocrystals synthesized by chemical routes e.g., from organometallic precursors, microwave irradiation, solvothermal, single molecule precursor, sonochemistry etc., do allow us to manipulate their distribution of size and shape, but, since there is an increasing demand for high crystallinity, narrow emission spectrum and high quantum yield of quantum dots (QDs) in a greener way, it has become very important to develop environmentally less hazardous, low cost and mass producible methods for the synthesis of QDs. The QDs of cadmium selenide (CdSe), being an II-VI semiconducting optical material, have a very characteristics peculiarity, due to possible accession of whole visible spectrum with its tunable size [5]. Research reveals that the thin films of CdSe QDs have a promising utility in the photo conducting devices as an active element in photo voltaic cell [6]. Since the colloidal semiconducting QDs of CdSe of size, ranging between 2 and 12 nm, have gained enormous interest, in both, optical and electrical applications, the quest of synthesis route without using hazardous organometallic and chemically unstable reagents have become a challenging necessity [7,8,9,10]. In the present work, a greener pathway for the synthesis of CdSe quantum dots is attempted in low temperature ranges as well as without using any capping reagent, which is atom economic, less energy consuming, easier, faster and environment friendly too.

Methods

Cadmium nitrate tetra hydrate [Cd (NO3)2·4H2O], selenium powder (Se), sodium borohydride (NaBH4) (all 99.0% purity, Sigma Aldrich) and methanol (99.8% purity, Qualigens) were used without further purification. The synthesized material was purified with de-ionized water and acetone (99.5%, SDFCL) several times.

The CdSe QDs were synthesized through a simple two step procedure. In the first step, 0.05 mM (0.0039 g) of Se powder was dispersed in 10 ml of methanol in a 25 ml round bottom flask and the system was placed in an ice bath so as to allow the reaction medium to attain a temperature of 0 °C under vigorous stirring. Then, 2.5 mM (0.200 g) of NaBH4 was added slowly in order to control the brisk effervescence of H2 gas evolved during the reaction. The reaction was further stirred for 20 min, till the entire Se powder got fully dissolved with no effervescence of H2 gas. At this time, the colour of the solution transformed from black to a clear light brown coloured solution. Simultaneously, 0.2 mM (0.0617 g) [Cd(NO3)2·4H2O], was dissolved in 5 ml of methanol in a 25 ml round bottom flask. The reaction was subjected to vigorous stirring at ice-cooled condition till the material got fully dissolved and a clear solution was obtained. At this junction, freshly prepared Se solution was added drop by drop to the cadmium precursor and eloquent was collected after each interval of 5 s since the first drop of Se was added to the solution. The collected colloidal samples of CdSe were centrifuged at 14,000 rpm for 4 min. The precipitate collected was washed by de-ionized water (3–4 times) in order to remove unwanted borax from the solution. It was further subjected to several acetone washings to get fine, pure product of CdSe nanoparticles. The product was dried at 100 °C and redispersed in ethanol for further characterization. The thin films of the CdSe nanoparticles were fabricated by photo resist spin coating method at an rpm of 900 and the topology of the dried film was analyzed with atomic force microscopy technique.

The optical absorption spectra of the prepared samples of CdSe nanoparticles were obtained at room temperature by using UV–visible spectrophotometer (Hitachi, U-3900). The morphology was analyzed with high resolution transmission electron microscope (HR-TEM) (JEOL JEM 2100 at 200 kV). The structural characterization was done by Bruker D8 advance X-ray powder diffractometer (powder XRD), Bruker AXS Inc (X-ray wavelength, λ = 1.5405 Å). The analysis of photoluminescence spectra was recorded by fluorescence spectrophotometer (Hitachi, F-4500).Thin films were prepared using photo resist spin coater (Ducom, PR-6-M2) and their topology was studied with the help of atomic force microscopy, AFM (Nanosurf, Easyscan 2).

Results and discussion

The powerful X-ray diffraction technique revealed different crystalline planes for CdSe nanoparticles, attributed to both Wurtzite (Hexagonal) and Zinc Blende (Cubic) structures (Fig. 1.). We observe the predominant peaks for the Hexagonal planes 100 [11] and 110 for the 2θ values 23.54 and 42.09 [from JCPDS (Joint Committee on Powder Diffraction Standards) CAS no. 77-2307] respectively. Cubic planes 220 [12] and 111, 200, 311 [from JCPDS CAS no. 65-2891] for the 2θ values 20.19, 25.89, 30.44 and 50.00 are also observed. The usual observation for the hexagonal CdSe planes is the splitting of peaks as reported in literature [12], which is fully merged in this case. The plausible reason behind the formation of both kinds of planes is the low temperature reaction and the sample was dried at 100 °C, hence some of the cubic crystalline structure may have got transformed into hexagonal ones. The average grain size is calculated 12 nm by using Scherrer equation as follows:

where τ, mean size of the particle; κ, shape factor; λ, X-ray wavelength; β, Line broadening at the half of the intensity (FWHM—full width half maximum); θ, Bragg angle (in degree).

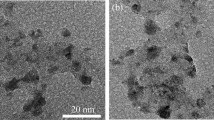

The structural properties of the nanoparticles were studied with HR-TEM. Morphological observations revealed the characteristic spherical shape of the CdSe QDs (Fig. 2a). The size of these highly crystalline nanoparticles is found to be in varying range of 3–8 nm (Fig. 2c inset), which shows a good agreement with the XRD data (Fig. 1). The overall scenario shows that most of the particles are individual and not agglomerated, whereas some of them are aggregating together forming nano clusters of variable shapes and sizes. The selected area electron diffraction (SAED) pattern clearly speaks about the polycrystallinity of the developed CdSe nanomaterial, (Fig. 2b inset), with the d-spacing of 2.2 Å (Fig. 3).

The optical absorption spectral maxima for the CdSe QD samples are found to be in the range of 450–470 nm (Fig. 4.).The blunt and hump type pattern of the curves perhaps indicate the synthesis of unannealed Zinc Blende (cubic) crystals, recorded immediately after the synthesis. Steady increase in spectral absorption peak values with elapsed time duration, often referred as red shift is indicative of the growth of QDs. Here, we can observe that the optical absorption spectrum is showing a blue shift (higher energy), which indicates the decrease of the size of the bulk CdSe. As the size decreases, the electron is confined to the particle leading to the increase in the band gap energy and therefore the band levels get quantized. The trap states lying in the band gaps become of great importance as they create changes in the optical properties of the nanomaterial. The emission spectra of the CdSe quantum dots show high luminescence intensity at 560 nm. The lower FWHM (13 nm) gives the information of narrow size distribution of the quantum dots. Most importantly, here stokes shift is found to be as large as 100 nm (Fig. 5), which leads to the higher optical efficiency [13].

The developed CdSe nanoparticles are subjected upon thoroughly cleaned glass template and thin films are made with the help of photo resist spin coater. The morphological study of the thin films of samples using atomic force spectroscope (AFM) showed (Figs. 6, 7) the overall homogeneity with an area roughness (root mean square) of 5.7898 nm at the specified area of 6.451(pm)2 with 2.53 µm scan area dimension (Table 1).

Conclusion

We have successfully designed the synthesis procedure of highly luminescent CdSe quantum dots with incorporation of benign greener route and fabricated thin films, which can be further utilized as efficient components of photo voltaic solar cells. The efficiency of the device is expected to be promising as the material has enhanced optical efficiency, which has been found to be ideal for luminescent solar concentrator (LSC).

References

J. Nanda, K.S. Narayan, B.A. Kuruvilla, G.L. Murthy, D.D. Sarma, Sizable photocurrent and emission from solid state devices based on CdS nanoparticles. Appl. Phys. Lett. 72(11), 1335–1337 (1998)

D.S. Koktysh, N. Gaponik, M. Reufer, J. Crewett, U. Scherf, A. Eychmuller, J.M. Lupton, A.L. Rogach, J. Feldmann, Near-infrared electroluminescence from HgTe nanocrystals. ChemPhysChem 5(9), 1435–1438 (2004)

M.Y. Gao, C. Lesser, S. Kirstein, H. Mohwald, A.L. Rogach, H. Weller, Electroluminescence of different colors from polycation/CdTe nanocrystal selfassembledfilms. J. Appl. Phys. 87(5), 2297–2302 (2000)

V.I. Klimov, A.A. Mikhailovsky, S. Xu, A. Malko, J.A. Hollingsworth, C.A. Leatherdale, H.J. Eisler, M.G. Bawendi, Optical gain and stimulated emission in nanocrystal quantum dots. Science 290(5490), 314–317 (2000)

P.K. Khanna, R.M. Gorte, R. Gokhale, Synthesis of CdSe from cyclohepteno-1,2,3-selenadiazole and cadmium salts in ethylene glycol. Mater. Lett. 58(6), 966–969 (2004)

D.J. Miller, D. Hanemann, Preparation of stable efficient CdSe films for solar PEC cells. Sol. Energy Mater. 4(2), 223–231 (1981)

J.E. Bowen Katari, V.L. Colvin, A.P. Alivisatos, X-ray photoelectron spectroscopy of CdSe nanocrystals with applications to studies of the nanocrystal surface. J. Phys. Chem. 98(15), 4109–4117 (1994)

B.O. Dabbousi, J. Rodriguez-Viejo, F.V. Mikulec, J.R. Heine, H. Mattoussi, R. Ober, K.F. Jensen, M.G. Bawendi, (CdSe)ZnS core-shell quantum dots: synthesis and characterization of a size series of highly luminescent nanocrystallites. J. Phys. Chem. B 101(46), 9463–9475 (1997)

M.A. Hines, P. Guyot-Sionnest, Bright UV-blue luminescent colloidal ZnSe nanocrystals. J. Phys. Chem. B 102(19), 3655–3657 (1998)

D.V. Talapin, A.L. Rogach, A. Kornowski, M. Haase, H. Weller, Highly luminescent monodisperse CdSe and CdSe/ZnS nanocrystals synthesized in a hexadecylamine–trioctylphosphine oxide–trioctylphospine mixture. Nano Lett. 1(4), 207–211 (2001)

R. Jain, V.K. Verma, Synthesis and characterization of CdSe nanoparticles from novel cadmium complex of selenolate precursor. Phosphorus, Sulfur Silicon Relat. Elem. 190(11), 1749–1754 (2015)

M.G. Bawendi, A.R. Kortan, M.L. Steigerwald, L.E. Brus, X-ray structural characterization of larger CdSe semiconductor clusters. J. Chem. Phys. 91(11), 7282–7290 (1989)

C. Li, W. Chen, D. Wu, D. Quan, Z. Zhou, J. Hao, J. Qin, Y. Li, Z. He, K. Wang, Sci. Rep. (2015). doi:10.1038/srep17777

Acknowledgements

The authors are grateful to the Department of Chemistry, Centre for Advanced Studies, North Eastern Hill University, Shillong, for providing the facility of Fluorescence Spectrophotometer and Institute of Advanced Study in Science & Technology, Guwahati for providing the facility of Powder XRD respectively. The authors are extending their gratitude to University Grants Commission, India for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baruah, J.M., Narayan, J. Development of greener methodology for the synthesis of CdSe quantum dots and characterization of their thin films. J Opt 47, 202–207 (2018). https://doi.org/10.1007/s12596-017-0417-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12596-017-0417-y