Abstract

Aflatoxins are one of the major factors that affect the quality and safety of feeds. They can be transferred into livestock through contaminated feed and then onto humans via animal sources of food such as milk, meat, and eggs. The objective of this study was to detect and quantify the level of aflatoxins (B1, B2, G1, G2, and total aflatoxin) in dairy feeds, poultry (layer and broiler) feeds, and feed ingredients produced in Addis Ababa. A total of 42 feeds and feed ingredients consisting of dairy feeds (n = 5), poultry broiler feeds (n = 6), layer feeds (n = 6), and feed ingredients (n = 25) were collected from feed factories in the city and analyzed in fresh weigh basis. The aflatoxins were analyzed using high-performance liquid chromatography after clean-up with immunoaffinity columns. Aflatoxin B1 levels in feeds ranged from 51.66 to 370.51 µg/kg in dairy cattle feed, from 1.45 to 139.51 µg/kg in poultry layer feed, and from 16.49 to 148.86 µg/kg in broiler feed. Aflatoxin B1 levels in maize ranged from 2.64 to 46.74 µg/kg and in Niger seed cake from 110.93 to 438.86 µg/kg. Aflatoxin B1 levels in wheat bran, wheat middling, and soybean were below 5 µg/kg. 100% of dairy feeds, 67% of poultry layer, 67% of broiler feeds, and 24% of ingredients contained aflatoxin in levels higher than the maximum tolerable limit set by the US Food and Drug Administration and Ethiopian Standard Agency. This shows the need for strong regulatory monitoring and better feed management practices to prevent consumers of animal-source foods from significant health impacts associated with aflatoxins.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Animal feeds have an important role in enabling the economic production of animal-source foods. Feeds may be produced in industrial feed mills, simple on-farm mixers, or by hand mixing (Afsah-Hejri et al. 2013). Feed safety and supply are closely associated because the origin, processing, handling, and storage of feedstuffs, as well as other market-related factors, can influence both the quality and safety of feed at different levels (Pinotti 2011).

Poor nutrition is a major barrier to market-oriented livestock production. It leads to a slow growth rate in growing animals and low production and reproduction performance. Poorly fed animals give a low output of meat and milk. Nutritional problems also lead to delayed age of onset of puberty, long parturition intervals, low conception rates, and low overall lifetime reproductive performance. Under poor feeding conditions, animals take too long to reach optimum slaughter weight, and the meat produced by such animals may not satisfy the desired quality attributes to fulfill the demand of the consumers (Adugna 2008).

Aflatoxins are one type of mycotoxins, which are fungal metabolites produced by some strains of Aspergillus flavus and Aspergillus parasiticus. Eighteen different aflatoxins have been identified, but the major aflatoxins found in animal feedstuffs are aflatoxin B1 (AFB1), B2, G1, and G2. Lactating mammals that ingest AFB1 deposit the 4-hydroxylated metabolite, aflatoxin M1 (AFM1), in their milk (Creppy 2002). Aflatoxin is produced at a temperature ranging between 12 and 40 °C, and it also requires 3 to 18% moisture (Duncan and Hagler 2008). Animals are exposed to aflatoxins through their feed (Gallo et al. 2015). Aflatoxins are produced in cereal grains as well as forages before, during, and after harvest in various environmental conditions (Yiannikouris and Jouany 2002).

Several studies reported levels of aflatoxin levels in dairy cattle feeds, poultry layer feeds, broiler feeds, and feed ingredients that were above the recommended FDA action level (Gizachew et al. 2016; Rehrahie 2018; Kotinagu et al. 2015; Greco et al. 2014). The presence of aflatoxins in feeds may decrease feed intake and affect animal performance. Besides, the possible presence of toxic residues in an edible animal product such as milk, meat, and eggs has detrimental effects on human health. Fungal contamination affects both the organoleptic characteristics and the alimentary value of feeds and entails a risk of toxicities (Akande et al. 2006; Gizachew et al. 2016).

Aflatoxins can cause acute or chronic toxic effects that can be characterized by mutagenic, teratogenic, carcinogenic, hepatotoxic, and immunotoxic nature (Chu 2006). Several regulatory limits have been set for aflatoxins in feeds and feed ingredients. The levels vary depending on the feed type, ingredient type, or the age and type of animal that consumes the feed. Several countries use the guidelines established by the European Union (EU 2002) or by the United States Food and Drug Administration (FDA 2019) as a base for establishing regulatory limits. Although guidelines differ from each other, the maximum levels for aflatoxins are lower in the guidelines given by the EU than those drafted by the FDA (Khanafari et al. 2007). The Ethiopian Standard Agency (ESA) has also set a regulatory limit of 20 μg/kg for both dairy and poultry feeds (ESA 2019).

The presence of aflatoxin-contaminated milk in the market is becoming an alarming problem. A recent study conducted on dairy and feed samples collected from the greater Addis Ababa milk shed indicated that all collected milk and feed samples had detectable levels of aflatoxins. Most of the milk was contaminated with aflatoxin M1, and it was presumed that aflatoxin M1 contamination in milk must have originated from aflatoxin B1-contaminated cattle feed of lactating cows (Gizachew et al. 2016; Rehrahie 2018).

Considering the serious health-related issues associated with aflatoxins, it is important to study the contamination level of animal feeds thoroughly. Possible factors for the contamination of animal sources of food should be looked at to reduce the health risks of consumers and major economic setbacks. This study will investigate the occurrence and contamination level of aflatoxins in animal feeds and ingredients produced in Addis Ababa, Ethiopia.

Materials and methods

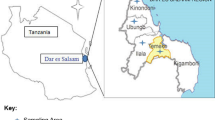

Description of the study area

The study was conducted in Addis Ababa, Ethiopia. The city of Addis Ababa is a major trade center for animal feeds. In the city, there are 10 animal feed producers registered by the Veterinary Drug, Feed Administration and Control Authority (VDFACA), but three of them were out of business during the time the study was conducted. Thus, animal feed and feed ingredient samples were collected from seven dairy and poultry feed factories in Addis Ababa, Ethiopia. These factories use five common ingredients, maize, wheat bran, wheat middling, soybean cake, and Niger seed cake, for producing dairy cattle, poultry layer, and broiler feed in different rations.

Sampling and sample collection

A total of 42 samples of dairy and poultry feed and feed ingredients were collected from 7 dairy and poultry feed factories in Addis Ababa, following the protocol outlined in ISO 6497:2002–Animal feeding stuffs–Sampling (ISO 6497:2002). The samples included 25 feed ingredients (maize (n = 5), wheat middling (n = 5), wheat bran (n = 5), soybean meal (n = 5), and niger seed cake (n = 5)) and 17 feeds (dairy cattle (n = 5), poultry layer (n = 6), and broiler feed (n = 6)). To obtain reasonably representative samples, primary large samples of approximately 10 kg were collected from different parts of the store, sack, or unit of feed according to the sampling points calculated using the square-root relationship between lot size and number of increments as specified in ISO 6497:2002. The samples were then homogenized and quartered to obtain a 1 kg laboratory sample. The samples were transported to the laboratory for analysis in sealed plastic sample bags. The samples were stored at 4 ℃ prior to analysis and analyzed within 3 days after the collection.

Sample preparation

The samples were prepared following the protocols outlined in ISO 6498:2012–Animal feeding stuffs–Guidelines for sample preparation (ISO 6498:2012) in their fresh weight basis. As the distribution of aflatoxin is extremely non-homogeneous, laboratory samples were homogenized by grinding the entire laboratory sample. The sampled 1 kg portions were ground using a high-speed multifunction laboratory grinder (RRH-500A, Ririhong, China) and passed through a 1000 μm sieve. The ground samples were thoroughly homogenized using a laboratory mixer (B15, Brice, Australia) for 10 min each. Before and after grinding, the grinder was cleaned using a laboratory detergent and thoroughly dried to prevent cross-contamination.

Study design for knowledge, attitude, and practice (KAP) survey

A structured questionnaire was designed to collect information from feed producers (seven production managers and seven owners/general managers), dairy farmers who use the feed formulated by the feed producers (n = 9), and poultry farmers who use the feed formulated by the feed producers (n = 7) to capture their knowledge, attitude, and practice on aflatoxin contamination. The questionnaire was focused on their storage practices, awareness of mold growth, and the formation of aflatoxin on animal feed. A total of 30 participants were engaged in the survey.

Nutritional analysis with near-infrared spectrometer (NIR)

The moisture, fat, protein, ash, and fiber content of the feed samples were determined using a NIR spectrometer (DS2500, FOSS, Denmark) (Balehegn et al. 2022; Harris et al. 2018). The NIR instrument was calibrated using grain, vegetal-protein, by-product so that infrared light can be detected number of organic compounds present in the samples will be interpreted.

Aflatoxin analysis

Materials and chemicals

Pure Reference Standards: obtained from Sigma-Aldrich and included aflatoxin B1 (Ref A6636–Batch No. 118K4094), aflatoxin B2 (Ref A9887–Batch No. 029K4062), aflatoxin G1 (Ref A0138–Batch No. 069K4001), and aflatoxin G2 (Ref A0263–Batch No. 018K4019). The pure reference standards were stored in the dark at 4 °C. Standard solutions of all four aflatoxins were prepared in methanol and stored in the dark at 4 °C. Acetonitrile, n-hexane, water, methanol, sodium chloride, sodium phosphate dibasic, and sodium dihydrogen phosphate (HPLC grade, ≥ 99.9% assay, Merck KGaA, Germany) were used. Immunoaffinity columns were purchased from LC-Tech GmbH (AflaCLEAN™, LC-Tech GmbH, Germany). Standard Reference Material: peanut butter SRM ® 2387 from NIST and Proficiency Testing Materials: maize proficiency testing material from FAPAS (FAPAS 04166) was also used to validate the method.

Extraction and clean-up

Aflatoxins were analyzed using the method provided in AOAC 2003.02 (Horwitz and Latimer 2005). 20 g of feed sample and 2 g of salt (NaCl) were weighed and transferred into a jar. A 100 mL portion of a mixture of methanol and water (80:20, v/v) and 50 mL of n-hexane were added to the jar. The mix was placed on an orbital shaker (Ika KS 130 basic, Ika-Werke GmbH & Co. KG, Germany) for 45 min, and the blended contents were filtered through Whatman No. 4 filter paper into a 500 mL filtration flask. The filtrate was transferred to a separatory funnel, and in the case of phase separation, the lower phase was used for the next steps. A 7 mL portion of the extract was taken and diluted with 43 mL of phosphate buffer solution (pH 7.2). The diluted filtrate (equivalent to 1.4 g of the sample) was passed through an immunoaffinity column at a flow rate of 2 mL/min. The column was washed by passing 10 mL of water, and the toxin was eluted by 1 mL of 100% pure methanol two times and collected with a vial for HPLC injection.

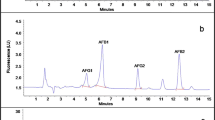

Instrumentation and chromatographic conditions

The quantification of aflatoxins was performed using an Agilent 1260 Infinity HPLC with a fluorescence detector (excitation at 365 nm and emission at 440 nm). Column oven temperature was set at 39 °C. The HPLC had a quaternary pump set to a flow rate of 1.2 mL/min, delivering the mobile phase consisting of acetonitrile, water, and methanol (15:60:25, v/v). The injection volume was set at 20 μL, and the data was processed using Agilent Open Lab CDS software.

Post-column derivatization was achieved by hydroxylation from the water of the mobile phase under UV light at 265 nm wavelength so that aflatoxins B2 and G2 would be formed and flourish well for easy detection, unlike the parent B1 and G1. A reversed-phase C-18 HPLC column with a 5 µm particle size, 10 cm length, and 4.6 mm internal diameter was used for the separation of analytes.

Aflatoxins were identified using their retention time by first injecting a blank sample, followed by the injection of a 20 μg/L pure aflatoxin analytical standard containing all four aflatoxins. The order of retention was in the order AFG2, AFG1, AFB2, and AFB1, with retention times of 5.36, 6.25, 6.96, and 8.48 min, respectively.

Calibration curve preparation

Calibration curves were prepared for all four aflatoxins by using the standard solutions covering the concentration ranges from 0.5 to 10 μg/L for aflatoxin G2, 2 to 40 μg/L for aflatoxin G1, 0.5 to 10 μg/L for aflatoxin B2, and 2 to 40 μg/L for aflatoxin B1. Peak areas of the different aflatoxins were plotted against the concentrations, and linear regression analysis was used to calculate the equation and the correlation coefficient of the standard curves. The correlation coefficients (r2) for all four 8-point calibration curves were greater than 0.9985, demonstrating the linearity of the curves.

Validation of the method

The validation of the aflatoxin analytical method was performed by Bless Agri Food Laboratory Services PLC (an ISO 17025 accredited laboratory) using replicate analyses of Standard Reference Material and Proficiency Testing materials. Their validation procedure comprised limit of detection, limit of quantification, linearity, accuracy and precision, reproducibility, specificity and selectivity, recovery, sensitivity, ruggedness, robustness, stability study, and working range and all are within the acceptable level for this study. The analytical method had a limit of detection of 0.3, 0.9, 0.2, and 0.6 μg/kg for aflatoxins G2, G1, B2, and B1, respectively. The limit of quantitation was 0.7, 2.8, 0.7, and 2.9 μg/kg for aflatoxins G2, G1, B2, and B1, respectively. The recovery for the different aflatoxins ranged from 94.2 to 111.4%. The NIST SRM® 2387 Standard Reference Material and the FAPAS 04166 Proficiency Testing Sample were also analyzed with each sample batch to monitor the accuracy of the method. The analyzed batch was only accepted if the recovery was between 80 and 120% (Horwitz 2002).

Quality assurance

To ensure the quality of the data, the accuracy and the precision of the method were also evaluated for all feed and feed ingredients analyzed in this study by spiking each sample with known concentrations of aflatoxins and analyzing aflatoxin contents. The accuracy and precision evaluation result of all sample types in fresh weigh basis is shown in Table 1. The recoveries obtained ranged between 78.75 and 112.0% for all four aflatoxins. This demonstrates the accuracy of the method as the recoveries obtained were within the range of 70 to 125% as specified in the AOAC guideline (Horwitz 2002) for this concentration level. The %RSD obtained was within the range of 0.1% and 3.84%, showing the method’s precision as the values were below 15%. The LOD and LOQ were calculated using a signal-to-noise (S/N) ratio of 3 and 10, respectively.

Calculation

The aflatoxin content of the feed samples was calculated using the following formula:

where n is ng of aflatoxin as eluate injected, Ve is final volume collected after elution from immunoaffinity column (µL), VI is volume eluate injected into HPLC (µL), We is weight of matrix represented by final extract (g), and DF is a dilution factor.

Statistical data analysis

For the purpose of data analysis, Microsoft Excel 2013 and IBM SPSS Statistics Version 20 software were used. One-way analysis of variance (ANOVA) followed by Tukey’s honest significant difference test was performed to evaluate the difference in the level of aflatoxins between the feed samples collected from the different study sites. All data results are presented in fresh weight basis. A p value of less than 0.05 was considered to show statistical significance.

Results and discussion

Aflatoxin in feed ingredients

The total aflatoxin content of the maize samples ranged between 2.64 and 106.72 µg/kg with a mean value of 26.92 µg/kg, while the content of aflatoxin B1 was between 2.64 and 46.74 µg/kg with a mean aflatoxin B1 content of 12.71 µg/kg. Aflatoxins were not detected (ND) in some wheat bran samples, and concentrations ranged from ND to 5.82 µg/kg with a mean value of 3.7 µg/kg. The aflatoxin B1 content of wheat bran ranged between ND and 3.66 µg/kg with a mean value of 2.29 µg/kg. The total aflatoxin content of wheat middling ranged between ND and 4.75 µg/kg with a mean value of 2.2 µg/kg, while the aflatoxin B1 content ranged from ND to 12.77 µg/kg with a mean aflatoxin B1 concentration of 1.35 µg/kg. Total aflatoxin in soybean cake was between ND and 7.39 µg/kg with a mean value of 3.36 µg/kg, and the aflatoxin B1 content ranged between ND and 3.43 µg/kg with a mean value of 1.67 µg/kg. The total aflatoxin content of Niger seed cake ranged between 251.94 and 491.66 µg/kg, with a mean value of 385.45 µg/kg. Niger seed cake contained aflatoxin B1 ranging from 110.93 to 438.86 µg/kg with a mean value of 288.34 µg/kg (Table 2).

Many studies have been conducted on aflatoxin levels of feed ingredients in different parts of the world. In a study conducted in Iran, the mean aflatoxin contents of maize, wheat grain, wheat bran, and soybean meal were 2.35, 1.54, 3.05, and 6.0 μg/kg, respectively (Nemati et al. 2014), which are similar to the findings of this study. A study by Gizachew et al. (2016) conducted on wheat bran and Niger seed cake samples in Ethiopia showed AFB1 levels ranging between 9 and 31 µg/kg in wheat bran and between 290 and 397 µg/kg in Niger seed cake, respectively. These findings were similar to the reports of this study.

The high aflatoxin content in Niger seed cake samples could be the result of improper storage management and moisture content, which can increase the risk of mycotoxin formation and aflatoxin contamination. The traditional way Niger oil is extracted in Ethiopia involves heating, grinding, mixing with hot water, and centrifugation in a clay container by hand. The involvement of heat and high moisture content promotes mold growth. According to Schmidt-Heydt et al. (2010), water activity and temperature interactions have a significant effect on aflatoxin production. The high nutrient content and moisture content in Niger seed cake might have supported mold growth and formation of aflatoxin.

Among the dairy and poultry feed ingredients in this study, the aflatoxin content of Niger seed cake showed a significant difference when compared to the rest of the ingredients (maize, wheat bran, wheat middling, and soya bean cake), with a p value of less than 0.05 for both aflatoxin B1 and total aflatoxin.

Aflatoxin in feeds

Aflatoxin levels in dairy feeds

The total aflatoxin content of dairy cattle feed collected from the feed factories ranged between 114.23 and 557.12 µg/kg, with a mean value of 313.03 µg/kg (Table 3). The aflatoxin B1 content of the dairy feed was between 51.66 and 370.51 µg/kg, with a mean aflatoxin B1 content of 192.80 µg/kg.

Gizachew et al. (2016) reported aflatoxin B1 content ranging between 7 and 419 µg/kg in dairy feed samples collected from the greater Addis Ababa milk shed and analyzed using commercial enzyme-linked immunosorbent assay (ELISA). These values are similar to the reports of this study, and it is probably associated with the use of the same ingredient involving Niger seed cake. In a study conducted in Kenya, 74 dairy feed samples showed aflatoxin contamination ranging between ND and 147.86 μg/kg (Makau et al. 2016). These values are lower than the values reported in this study. A total of 112 dairy feed samples analyzed in Costa Rica showed a mean aflatoxin concentration of 290.04 µg/kg (Granados-Chinchilla et al. 2017). The reasons for differences in aflatoxin B1 content of feeds among Ethiopia and other countries could be associated with the differences in feed types commonly utilized.

Aflatoxin levels in poultry layer feeds

The total aflatoxin content of poultry layer feeds collected from feed factories in Addis Ababa ranged between 3.5 and 260.60 µg/kg, with a mean value of 143.04 µg/kg, while the aflatoxin B1 content was between 1.45 and 139.51 µg/kg, with a mean aflatoxin B1 content of 74.80 µg/kg (Table 4).

Different studies on aflatoxin levels in poultry layer feeds were conducted in different parts of the world. In Jordan, 52 poultry feed samples showed a maximum aflatoxin B1 concentration level of 12.7 µg/kg (Alshawabkeh et al. 2015), which is significantly lower than what is observed in this study. Similarly, significantly lower total aflatoxin levels ranging from 5.3 to 29.9 µg/kg (Nsiah et al. 2023) and from 1.0 to 13.6 µg/kg (Alahlah et al. 2021) have been reported in poultry feeds in Ghana and Morocco, respectively. In North Asia, 622 poultry feed samples showed aflatoxin B1 levels ranging between 8.7 and 225 μg/kg (Rodrigues and Naehrer 2012), which is similar to the findings of this study. The significant variations in aflatoxin levels between the samples may be associated with storage conditions, including factors such as warm temperature and humid environmental conditions.

Aflatoxin B1 can have a strong influence on egg quality. It can lower the thickness of the shell, egg weight, egg production, and quality of eggs and increase the mortality of challenged hens. In addition, aflatoxin in the feed of laying hens can result in aflatoxin residue in the eggs; it is, therefore, very important to control aflatoxin levels in the feeds for laying hens (Oliveira et al. 2000).

Aflatoxin levels in poultry broiler feeds

The total aflatoxin content of poultry broiler feeds collected from feed factories in Addis Ababa ranged between 36.51 and 287.44 µg/kg, with a mean value of 151.07 μg/kg (Table 5). The aflatoxin B1 content of the poultry broiler feeds was between 16.49 and 148.86 µg/kg with a mean aflatoxin B1 content of 71.22 μg/kg.

In a study on broiler feeds (starter, grower, and finisher) conducted in Iran, aflatoxin B1 content ranged between 1.28 and 40 µg/kg (Nemati et al. 2014). In Pakistan, a mean aflatoxin B1 content of 23.75 µg/kg and a maximum contamination level of 78 µg/kg were reported in poultry feed samples (Anjum et al. 2012). The values reported by both studies were significantly lower than the findings of this study. The significant variation in aflatoxin level for broiler feed samples could be the utilization of different feed ingredients. If a feed ingredient is contaminated, it can contaminate the full batch of feed produced (Gallo et al. 2015). A recent study reported mean AFB1, AFB2, AFG1, AFG2, and AFT concentrations of 70.11 µg/kg, 13.50 µg/kg, 88.55 µg/kg, 18.00 µg/kg, and 190.18 µg/kg, respectively, in poultry feed samples collected from Bishoftu, Ethiopia (Kassaw et al. 2022), which are comparable to the findings of the present study.

Comparison of aflatoxin levels among the feeds

There was no significant difference (p > 0.05) in aflatoxin levels between poultry layer and poultry broiler feeds. However, there was a significant variation in levels of aflatoxin B1 and total aflatoxin in dairy feeds (Table 6). The reason for the higher level of aflatoxin contamination in dairy feeds could be associated with the high amount of Niger seed cake used in the preparation of dairy feed. The high aflatoxin contamination of dairy feed shows a higher risk of aflatoxin contamination, which leads to contaminated milk unless diluted with or replaced by other feeds.

Comparison of aflatoxin levels among the feeds and feed ingredients with the limit and nutritional quality

Out of a total of 25 dairy and poultry feed ingredient samples collected from the seven feed factories in Addis Ababa, 24% (6 of 25) showed contamination of aflatoxin B1 and total aflatoxin level higher than the recommended 20 μg/kg limit set by the US Food and Drug Administration (Table 7). Ethiopia has a similar limit of 20 μg/kg for aflatoxin B1 and 40 μg/kg for total aflatoxin. 20% (1 of 5) of maize grain and 100% (5 of 5) of Niger seed cake samples contained aflatoxin B1 and total aflatoxin higher than the action levels set by the US FDA and the regulatory limit set by ESA. Wheat bran, wheat middling, and soybean cake samples all contained aflatoxin in levels lower than the limit.

All five dairy feed samples in this study contained aflatoxin B1 higher than the 20 μg/kg action levels set by the FDA and the regulatory limit set by ESA (Table 7). Aflatoxin B1 levels in dairy feed and feedstuff are important to human health since approximately 1–2% of the aflatoxin B1 in animal feed is transformed to aflatoxin M1 in milk. Therefore, aflatoxin B1 concentration in feed above standard limits may result in milk containing higher levels of aflatoxin M1 (Oruc et al. 2007).

Aflatoxin B1 and total aflatoxin levels of the poultry feeds collected from four factories were higher than the action levels set by the FDA and the regulatory limit set by ESA. The remaining two poultry feed samples (F004 and F006) showed aflatoxin contamination levels of 4.05 µg/kg and 1.45 µg/kg. The low amount of aflatoxin contamination in poultry layer feed in F004 could be associated with low Niger seed cake content since the nutritional quality of the feed, as observed from the NIR analysis, was low (Table 8). Poultry feed F006 showed good nutritional quality, and its low aflatoxin contamination may have been a result of using protein sources such as soybean cake instead of Niger seed cake.

The action level for aflatoxin in poultry broiler feed set by the FDA is 20 μg/kg. Among the six poultry broiler feed samples collected from the feed factories in Addis Ababa, four samples (67%) contained aflatoxin B1 levels higher than the ESA regulatory limit (Table 7).

Two of the poultry broiler feeds (F004 and F006) contained aflatoxins at levels lower than the ESA regulatory limit set. In Ethiopia, the regulatory limit set for poultry broiler feed is 20 µg/kg for aflatoxin B1 and 40 µg/kg for total aflatoxin, which is similar to the action levels set by the FDA. The high contamination of broiler feeds with aflatoxins could be the result of poor storage conditions or the use of ingredients that were stored in bulk for a long time under conditions that favor the development of fungi.

In summary, among all the feed and feed ingredients investigated, 20% maize (1/5), 100% Niger seed cake (5/5), 100% dairy feeds (5/5), 67% (4/6) poultry layer feeds, and 67% (4/6) poultry broiler feeds contained aflatoxin B1 higher than the 20 µg/kg action levels set by FDA and the regulatory limit set by ESA. Aflatoxin levels in wheat bran, wheat middling, and soybean cake were all below the tolerable limit.

Aflatoxin knowledge assessment of feed producers and farmers

A total of 30 participants, including 7 dairy and poultry feed producers and 23 dairy and poultry farmers, were interviewed for their knowledge, attitude, and practice (KAP) regarding aflatoxin contamination in dairy and poultry feed.

The outcomes of the survey indicated that awareness of mold growth formation and mycotoxin is very low in dairy and poultry farmers. Knowledge about aflatoxins and their associated health impacts was very low. The farmers believe eating moldy food to be harmful, but they considered milk, egg, and meat from animals fed moldy feeds to be safe. This was supported by previous findings that showed lower levels of awareness about aflatoxins: 25% in Ethiopia (Gizachew et al. 2016), 6% in Vietnam (Lee et al. 2017), 12% in Zimbabwe (Bankole and Adebanjo 2003), and 20% in Tanzania (Magembe et al. 2016).

From the seven feed factories, 86% of the respondents reported that they were aware of mold growth and the formation of mycotoxin. And, among the 23 dairy and poultry farmers, 79% of respondents were not familiar with mold growth and aflatoxin formation. On the other hand, more than 50% of the respondents do not know about the transfer of aflatoxin from feed to animal sources of food.

Out of the 30 dairy and poultry feed producers and farmers interviewed, 25 (80%) were not aware of cleaning, drying, ventilation, pest control, and visual inspection before and after storage of the feed. This practice is critical in feed handling as fungi can grow easily in the storage and result in the formation of aflatoxin. According to the survey result, over 50% of the dairy and poultry feed producers and 40% of farmers did not know that milk, egg, and meat could be contaminated with aflatoxin as a result of contaminated dairy and poultry feed. Feed processors were more aware of aflatoxin than dairy and poultry farmers, yet they did not control the quality of the raw materials and finished products for fear of risking their business.

Conclusions

Aflatoxins were detected in all dairy feeds, poultry feeds, and feed ingredients investigated in this study. According to the result of this study, 100% of the dairy feed, 67% of poultry layer and broiler feeds, 20% of maize, and 100% of Niger seed cake contained aflatoxin B1 higher than the levels set by FDA and ESA. The KAP assessment outcome about mycotoxin, specifically aflatoxin, in the feed factories and farmers was not satisfactory, and there is a huge knowledge gap. The findings revealed that feedstuffs and complete feeds in Addis Ababa serve as neglected, underestimated, and unmonitored sources of aflatoxins, which are transferred through animal-derived food items such as milk, eggs, and meat. Consequently, the need for surveillance and constant monitoring programs could be crucial. It is essential to implement the monitoring of regulatory limits appropriately, incorporating regular analyses of both animal feed and its constituent ingredients. This study revealed a high prevalence of aflatoxins in dairy and poultry feeds in Ethiopia, suggesting the need for comprehensive data and surveillance concerning aflatoxin contamination. This necessity extends beyond animal-derived foods to include crops intended for direct human consumption as well. Emphasis should be placed on the development of effective strategies for aflatoxin decontamination and deactivation, aiming to mitigate both animal and human exposure to aflatoxins.

Data availability statement

The raw data of the feed and feed ingredients HPLC raw results and chromatogram presented in this study are openly available in Mendeley Data at https://doi.org/10.17632/ppwdt849m9.1.

References

Adugna T (2008) Feed resources and feeding management: a manual for feedlot operators and development workers. Ethiopian Sanitary &Phyto-sanitary Standards and Livestock & Meat marketing Program (SPS-LMM) Texa Agricultural Experiment Station (TAES)/Texas A&M University System, Addis Ababa.

Afsah-Hejri L, Jinap S, Hajeb P, Radu S, Shakibazadeh S (2013) A review on mycotoxins in food and feed: Malaysia case study. Compr Rev Food Sci Food Saf 12(6):629–651

Akande KE, Abubakar MM, Adegbola TA, Bogoro SE (2006) Nutritional and health implications of mycotoxins in animal feeds: a review. Pak J Nutr 5(5):398–403

Alahlah N, Maadoudi ME, Bouchriti N, Triqui R, Stitou M, Hafid NH, Ouahabi OE (2021) Occurrence of aflatoxin B1 in animal feed collected from the northeastern area of Morocco. World’s Vet J 11(4):587–593

Alshawabkeh K, Alkhalaileh NI, Abdelqader A, Al-Fataftah ARA, Herzallah SM (2015) Occurrence of aflatoxin B1 in poultry feed and feed ingredients in Jordan using ELISA and HPLC. Am-Eurasian J Toxicol Sci 7(4):316–320

Anjum MA, Khan SH, Sahota AW, Sardar R (2012) Assessment of aflatoxin B1 in commercial poultry feed and feed ingredients. J Anim Plant Sci 22(2):268–272

Balehegn M, Varijakshapanicker P, Zampaligre N, Blummel M, Ayantunde A, Jones C, ... Adesogan AT (2022) Near‐infrared reflectance spectroscopy for forage nutritive value analysis in sub‐Saharan African countries. Agron J 114(1):100–114

Bankole SA, Adebanjo A (2003) Mycotoxins in food in West Africa: current situation and possibilities of controlling it. Afr J Biotech 2(9):254–263

Chu FS (2006) Mycotoxins and alimentary mycotoxicoses. HP Rieman, and DO Cliver, eds, 583–661

Creppy EE (2002) Update of survey, regulation and toxic effects of mycotoxins in Europe. Toxicol Lett 127(1–3):19–28

Duncan HE, Hagler M (2008) Aflatoxins and other mycotoxins. Oklahoma Cooperative Extension. Fact Sheet (CR-2105-1203), Oklahoma, USA

ESA (Ethiopian Standard Agency) (2019) Limits of contaminants in compound feed for lactating dairy cows and poultry feeds

EU (2002) European Commission. Directive 2002/32/EC of the European Parliament and of the Council of 7 May 2002 on undesirable substances in animal feed. Official J Eur Com 140:10–21

FDA (2019) Food and Drug Administration. CPG Sec. 683.100 Action Levels for Aflatoxins in Animal Feeds

Gallo A, Giuberti G, Frisvad JC, Bertuzzi T, Nielsen KF (2015) Review on mycotoxin issues in ruminants: occurrence in forages, effects of mycotoxin ingestion on health status and animal performance and practical strategies to counteract their negative effects. Toxins 7(8):3057–3111

Gizachew D, Szonyi B, Tegegne A, Hanson J, Grace D (2016) Aflatoxin contamination of milk and dairy feeds in the Greater Addis Ababa milk shed, Ethiopia. Food Control 59:773–779

Granados-Chinchilla F, Molina A, Chavarría G, Alfaro-Cascante M, Bogantes-Ledezma D, Murillo-Williams A (2017) Aflatoxins occurrence through the food chain in Costa Rica: applying the One Health approach to mycotoxin surveillance. Food Control 82:217–226

Greco M, Capretti G, Beretta L, Gemma M, Pecorelli N, Braga M (2014) Enhanced recovery program in colorectal surgery: a meta-analysis of randomized controlled trials. World J Surg 38(6):1531–1541

Harris PA, Nelson S, Carslake HB, Argo CM, Wolf R, Fabri FB, ... Ellis AD (2018) Comparison of NIRS and wet chemistry methods for the nutritional analysis of haylages for horses. J Equine Vet Sci 71:13–20

Horwitz W (2002) AOAC guidelines for single laboratory validation of chemical methods for dietary supplements and botanicals. Gaithersburg, MD, USA: AOAC International 12–9

Horwitz W, Latimer GW (2005) Official methods of analysis of AOAC International. Gaithersburg, Md: AOAC International

ISO 6497:2002 Animal feeding stuffs – sampling. International Organization for Standardization (ISO)

ISO 6498:2012 Animal feeding stuffs – guidelines for sample preparation. International Organization for Standardization (ISO)

Kassaw TS, Megerssa YC, Woldemariyam FT (2022) Occurrence of aflatoxins in poultry feed in selected chicken rearing villages of Bishoftu Ethiopia. Vet Med: Res Reports 277–286

Khanafari A, Soudi H, Miraboulfathi M (2007) Biocontrol of Aspergillus flavus and aflatoxin B1 production in corn. J Environ Health Sci Eng 4(3):163–168

Kotinagu K, Mohanamba T, Kumari LR (2015) Assessment of aflatoxin B1 in livestock feed and feed ingredients by high-performance thin layer chromatography. Veterinary World 8(12):1396

Lee HS, Nguyen-Viet H, Lindahl J, Thanh HM, Khanh TN, Hien LTT, Grace D (2017) A survey of aflatoxin B1 in maize and awareness of aflatoxins in Vietnam. World Mycotoxin J 10(2):195–202

Magembe KS, Mwatawala MW, Mamiro DP, Chingonikaya EE (2016) Assessment of awareness of mycotoxins infections in stored maize (Zea mays L.) and groundnut (arachis hypogea L.) in Kilosa District, Tanzania. Int J Food Contam 3(1):12

Makau CM, Matofari JW, Muliro PS, Bebe BO (2016) Aflatoxin B 1 and deoxynivalenol contamination of dairy feeds and presence of aflatoxin M 1 contamination in milk from smallholder dairy systems in Nakuru. Kenya Int J Food Contam 3(1):6

Nemati Z, Janmohammadi H, Taghizadeh A, Maleki Nejad H, Mogaddam G, Arzanlou M (2014) Occurrence of aflatoxins in poultry feed and feed ingredients from northwestern Iran. Eur J Zoological Res 3(3):56–60

Nsiah B, Ofori H, Oduro-Yeboah C, Kyereh E, Johnson PNT (2023) Incidences of aflatoxin contaminations in ingredients, feed and products of poultry from two regions in Ghana. Heliyon, 9(12)

Oliveira CAF IV, Kobashigawa E, Reis TA, Mestieri L, Albuquerque R, Correa LMB (2000) Aflatoxin B1 residues in eggs of laying hens fed a diet containing different levels of the mycotoxin. Food Addit Contam 17(6):459–462

Oruc HH, Cengiz M, Uzunoglu İ (2007) Occurrence of aflatoxin B1 and T-2 toxin in FEED and raw ingredients used for animal feeding stuffs (Bazı Yem ve Yem Hammaddelerinde Aflatoksin B1 veT-2 Toksin Düzeyleri). Uludağ Üniversitesi Veteriner Fakültesi Dergisi 26(1–2):1–5

Pinotti L, Dell’Orto V (2011) Feed safety in the feed supply chain. BASE.

Rehrahie MG (2018) Aflatoxins, heavy metals, and safety issues in dairy feeds, milk and water in some selected areas of Ethiopia (doctoral dissertation, Addis Ababa University).

Rodrigues I, Naehrer K (2012) A three-year survey on the worldwide occurrence of mycotoxins in feedstuffs and feed. Toxins 4(9):663–675

Schmidt-Heydt M, Rüfer CE, Abdel-Hadi A, Magan N, Geisen R (2010) The production of aflatoxin B 1 or G 1 by Aspergillus parasiticus at various combinations of temperature and water activity is related to the ratio of aflS to aflR expression. Mycotoxin Res 26(4):241–246

Yiannikouris A, Jouany JP (2002) Mycotoxins in feeds and their fate in animals: a review. Anim Res 51(2):81–99

Acknowledgements

The authors would like to thank Kunifira Agro-processing PLC for their financial contribution. The authors would like to acknowledge the feed factories and farmers who provided samples and all required information. Bless Agri Food Laboratory Services PLC provided all research supplies and laboratory space for the research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mengesha, G., Bekele, T., Ashagrie, H. et al. Level of aflatoxins in dairy feeds, poultry feeds, and feed ingredients produced by feed factories in Addis Ababa, Ethiopia. Mycotoxin Res 40, 309–318 (2024). https://doi.org/10.1007/s12550-024-00531-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12550-024-00531-8