Abstract

Herein, the gilt-bronze Gaigongmao (chariot parasol components) were excavated in the Dafenbao cemetery, Pengshan county, Sichuan province, China. This paper illustrates the parasols virtual restoration pictures and infers its usage. The samples were characterized by combining ultra-depth three-dimensional microscope (Ultra-depth 3D microscope), attenuated total internal reflectance fourier transform infrared spectroscopy (ATR-FTIR), scanning electron microscope (SEM), scanning electron microscope (EDS), element mapping, and wood species identification. The fibers around the Gaigongmao were detected as cotton threads, and the woods inside was bamboo, thus, the type of the parasol was indicated to be the San type. The gilding technology of the gilt-bronze was resulted of traditional mercury amalgam technology, and the traditional “Yaguang” technique can be observed in the SEM images. By comparing with the other data, the lead isotope date of the Gaigongmao was determined to be within the range of the Yangtze River basin.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Dafenbao cemetery is located at Pengshan county, Sichuan province, China (Fig. 1). The period of the cemetery was continually in use from the Warring States Period to Qing Dynasty (ca. 476 BC-AD 1911). The Dafenbao Cemetery was excavated from March 2020 to December 2021, and the gilded bronze chariot parasols were excavated from grave M327 in the January of 2021. This is the first study of excavated gilded bronze chariot parasols in China. Furthermore, the artefactual and the compositional change of the graves attest to a significant development in the Dafenbao cemetery, which has great academic value in the process of civilization unification from Ba-shu culture to Chinese culture during the Chinese history.

Gaigongmao is a component of the Chariot Parasol placed on the ends of the ribs, used for fastening the canopy (called the Gai), shown in Fig. 2a. The earliest archaeological evidence of the chariot in China is the single-shaft chariot from the Shang Dynasty (ca. 1600 − 1046 BC) but without the Gai (Zheng and Yang 1984), the earliest evidence of the Gai was found in the Western Zhou Dynasty (ca. 367 − 256 BC) (Wang and Huang 1984). In the archaeological report, there are two types of Gais were sorted out, which are called the San type and the Peng type. In the Han Dynasty (202 BC-AD 220), the San type and Peng type have obviously different outline structures. The most representative differences were the overall shape, which was round for the San type but tortoise-shell shape for the Peng type, with different outlines, components, load-bearing force, and the different martials made up for the Gaigong. The San type was notably composed of the canopy (Gai), the ribs (Gaigong), the ends (Gaigongmao) and amongst others, the practical use was for the emperor or leader of the guard of honor. Thus, the San type needed to have a wide field of view and allow for faster speeds. The Peng type was composed of the Ping (“walls/curtains” of sorts) and other components, the Ping was directly connected with the Gai and formed a four-sided shield carriage (Huang 2023). Therefore, the Peng type hade a lower height and a lower field of view, in order to keep out wind and shield the occupants from view. In ancient Chinese craft, the Gai was supported by a different number of ribs (called the Gaigong), holes were cut in the middle and bottom of the Gaigong, then the threads were fitted into the holes to tie and fix on the Gaigong for convenience (Wang and Li 1997).

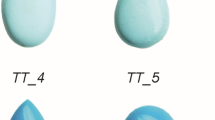

a The components of the chariot parasol reproduced from Huang (Huang 2023), Gaigongmao in different periods: b the Spring and Autumn Period (Wu and Zhang 1978), c the Warring States Period (Luo 1982), d the Warring States to the Qin and Han dynasties (Liu 2011), e the Warring States Period (Gao and Feng 1982), f the Eastern Han Dynasty (Tang 2017), g the Eastern Han Dynasty (Li et al. 2019), h the Western Han Dynasty (Zhu and Hu 2008)

Gaigongmao (Sun 1985) was functionally like the ends we still use on the umbrella today, it was placed on the top end of the Gaigong in order to hooking up the Gai. In addition, ancient Chinese people also make a claw in the middle of the Gaigongmao to assist in tying threads and stretching the Gai round. The ancient Chinese chariot Gai system directly expresses the strict hierarchy. The textures, the shapes and the numbers of the Gaigongmao corresponds to the status of their owner, therefore, the gilding technology of these Gaigongmao may correspond to the high social status of the users. Besides, since the concept of gold was gradually associated with the immortality in the Qin Dynasty (221 BC-AD 207) and Han Dynasty (202 BC-AD 220), the gilding of Gaigongmao may also have been in pursuit of the ritual or religious meaning of “living forever” (Li 2007).

Furthermore, as a component of the chariot parasol, Gaigongmao already expresses a high social stratum. The Gai was a kind of Chinese ritual symbol of social status, and also a general utility tool for the peerages to flaunt nobility to the public, which was accompanied by convenient use and flexible disassembly. In the Spring and Autumn Period (ca. 770 − 476 BC), the shape of the Gaigongmao was like a curved tube (Sun 1985), the Zao was produced in the middle part set with a double annulus connected, one annulus was hung on the Zao and the other fixed on the edge of Gai (Zhu and Zhang 1981), shown in Fig. 2b. In the Warring States (ca. 476 − 221 BC), the shape of the Gaigongmao became straight, the top part of the it was usually produced as globosity or cylinder shapes (Wang and Li 2016), shown in Fig. 2c, d, e. In the Qin and Han dynasties (221 BC-AD 220), along with the rapid development of the technology for the chariot, Gaigongmao become more and more elegant in styles, colors and patterns, with many kinds of flower-shaped and petaloid Gaigongmao starting to emerge. As shown in Fig. 2f, Gaigongmao was called “Jinhuazao” in the later Han Dynasty (ca. 25–220 AD), which means “beautiful golden ends”.

The aim of the paper is to understand the function and gilding technology of the gilt-bronze Gaigongmao through the scientific analysis of the samples excavated from the Dafenbao cemetery, this paper may be of great value in providing new information for the research of Eastern Han Dynasty (25–220 AD) chariots.

Materials and methods

The samples in this paper were excavated from the M327, Dafenbao cemetery, Pengshan county, Sichuan Province, China (Fig. 3). There are eight kinds of artefacts excavated from the M327, including 11 pieces of bronze Gaigongmao, Gaidou, Tongpao and bronze money tree (yaoqianshu) and so on. It is preliminarily concluded that the period of M327 is the Eastern Han Dynasty judging by the characteristics of burial objects and the stratigraphy relationships. Due to the high humidity of the environment, the gilt-bronze samples were significantly corroded, thus, there isn’t any copper extant in the gilt-bronze samples, and the gilding layer falls off by touch. The sample list and analysis details of the Dafenbao cemetery are in Table 1.

The lead isotope composition testing was performed using the Neptune Plus multicollection inductively coupled plasma mass spectrometer (MC-ICP-MS) from Thermos Fisher Scientific. Prior to the sample analysis, the instrument parameters of the Neptune Plus were optimized using a standard solution of NIST 981 at a concentration of 200 µg/L. This optimization included parameters related to the plasma source (such as skimmer cone position and carrier gas flow rate) and ion lens settings to achieve maximum sensitivity.

To explore the function of the gilt-bronze Gaigongmao, analyses the information and the trace from the gilt-bronze scrupulously, the morphologies of the gilded layers and the microscopic traces were observed by Ultra-depth 3D microscope, KEYENCE VHX-7000, the usage and the manufacturing questions of Gaigongmao have been discussed.

To analysis the composition of the fibers around the Gaigongmao (G-5, G-6, G-8), ATR-FTIR spectroscopy is particularly efficient. For ATR spectroscopy, 16 scans were accumulated with a spectral resolution of 4 cm−1.

Woods species identification is an important method in the scientific approach of archaeology of the wooden cultural heritage, wood samples were obtained from the inside of the Gaigongmao (G-5) and prepared by microtomy, surveyed by using microscopy (PHENOM proX SEM).

The characterization of the gilded layers and cross-section were surveyed by using SEM, EDS and element mapping, without any gold or carbon coating. SEM images were observed by Zeiss Evo18, EDS and element mapping were carried out with Oxford Ultim Max, the acceleration voltage was set to 15 keV.

Results and discussion

Lead isotope analysis

The Plots of lead isotope ratios contains 8 samples from G-1, G-2, G-3, G-4, G-5, G-6, G-8 and G-10. The lead isotope ratios characterized by 206Pb/204Pb ratios ranging from 18.125 to 18.533, 207Pb/204Pb ratios ranging from 15.652 to 15.699, and 208Pb/204Pb ratios ranging from 38.491 to 38.854 (shown in Fig. 4). By comparing the lead isotope data of Eastern Han Dynasty and the distribution patterning of the Pb isotopes in China, it is found that the lead isotope data of the Gaigongmao fall within the range of the Yangtze River basin (Hsu and Sabatini 2019).

Ultra-depth 3D microscope analysis

The Ultra-depth 3D microscope images were prepared for the scratches on the surface and the casting jointed places of the samples, as shown in Fig. 5. Many scratches were observed with different depth and directions, Fig. 5a, especially on the spherical top surface of the Gaigongmao. It was inferred that, the scratches were left by the “Yaguang” technique in the process of gilding. In ancient China, the gilded layer was applied by hand-made, to make the gilded layer firm and the color uniform, the “Yazi” which was made up by jade was invented and used to press the gilded layer, aiming to make the layer tight during the gilding process (Cao 2010). The “Yaguang” technique used the “Yazi” press the gilded layer after the heating process and made the gilded layer tighter and uniform on the bronze.

Meanwhile, many deeper scratches were observed in Fig. 5, they were hard to see by eyes but have the same direction with small and dense features. As shown in Fig. 5b, the scratches on G-2 were upright with the same direction. The scratches on G-4 were uniform and highlighted by slanting lines, in Fig. 5c. On the top part and the casting joint of the samples, many deep polish lines appear with the same direction, we infer that the gilt-bronze was polished before the gilding process, and many kinds of handcraft were used to ensure the shape of the samples.

Furthermore, grooves beside many rasping can be seen in the casting joints, the rasping have the same direction and deep depth, and on the bottom of the grooves many gilded layers can be seen, showing that the grooves were produced before the gilded process, shown as Fig. 5d, e, f, g, h, i. The details of the grooves in the samples of G-1, G-2, G-5, G-6, G-7, G-10, G-11 are shown in Fig. 6. The hand-made grooves observed above the Zao, as well as those below the Zao in samples G3 and G8, combined with the surrounding fibers, we can infer that the grooves may have had the functional purpose of securing a rope.

ATR-FTIR analysis of the fibers

ATR-FTIR has been widely tested for the investigation of fibers, we sampled the fibers around G-5, G-6, G-8. Comparison of the spectra of mineralized excavated cellulosic fibers with spectra of modern fibers, has enabled fiber identification and observation of certain peak differences attributed to mineralization.

In Fig. 7a, for the peak at 2900 cm−1 ν(C-H) stretching vibration, indicative of polysaccharides. 1635 cm−1 corresponding to vibration of water molecules absorbed in cellulose (Margariti 2019), 1365 cm−1 for δ(C-H) bond in cellulose, 1155 cm−1 is the ν(C–C) ring breathing of the indicative of polysaccharides in cellulose, 1105 cm−1 ν(C–O–C) glycosidic ether band which indicative of polysaccharides in cellulose (Geminiani and Campione 2022).

Guided by the ATR-FTIR analysis results of hemp (Alessia 2022), 1735 cm−1 ν(C = O) ester will appear within the fibers, but there aren’t any peak in 1735 cm−1 appear in the ATR-FTIR spectra of the fibers from G-5, G-6 and G-8, therefore, hemp can be preliminarily ruled out. Jute is a kind of bast fiber, and jute contains much more lignin than the others (Jakes 2007), and thus shows clearer lignin peaks at 1595 cm−1, so the fibers around the Gaigongmao should not be jute, either.

In the detail image of the fibers of ultra-depth 3D microscope, Fig. 7b, many micro-fibers can be observed in G-8, with mid-cavity and natural curling in the longitudinal fiber bundle, only little crazing shown in longitudinal of the fiber, moreover, there aren’t irregularly bamboo-like transverse segments arranged, the average diameter is 19.33 μm (Table 2), which consistent with the average diameter and the characteristics of cotton fibers.

As stated above, compared with the ATR-FTIR analysis results of other natural fibers (Tanil and Sevim 2017), the fibers sampled from G-5, G-6 and G-8 should be identified as cotton by preliminary.

Wood species identification

The wood in G-5 should be identified as bamboo, Fig. 8. According to the historical sources, bamboo began to be used as the material of Gaigong in the Han Dynasty. Usually, bamboo Gaigong were used for the San type, this type of chariot parasol was ride by males with strict riding manners due to the open-air (Ban and Sun 2020; Jia and Yan 2000). On the other hand, the Peng type was ridden by females and peerage, this type was composed of hard and thick woods, with an enclosed space (Huang 2023).

The identified of bamboo Gaigong and the tiny size of the Gaigongmao are the strong indicators of the San type.

Virtual restoration of the winding patterns

The function of the Gaigongmao was to fastening the Gai and keep it open, the threads around them play a role in tying the Gaigong and stretching the Gai round. Base on the location of the grooves and the traces fibers around it, as shown in Fig. 9a, we can infer that the purpose of the groove was to lock the fibers in position.

Combined with the positions of the grooves and the fibers, we diagrammed the virtual restoration pictures of the winding patterns, Fig. 9b. The usage of the Gaigongmao may have been, at first, making a cotton thread winding though the groove below the Zao, winding then though the joint place, and then, making the cotton thread wind though the groove above, to tie a knot with the line on the opposite side, finally, tying the ends through the Gaigong and fixing them together.

The literature indicate that there are holes in the bottom of Gaigong in order to secure the ropes (Sun 1985), but there isn’t any evidence about the holes in this paper, thus, it doesn’t bare any additional discussion here.

Scientific analysis and the gilding technology of the gilt-bronze

Based on the excavation reports, gold and silver have been utilized by Chinese people during the late Neolithic period, a golden earring has been excavated in the Yumengou site (Wenwubianji 1979), Gansu province, China. The earliest gilded artefact was reported from the Spring and Autumn Period (Mou 1984), at the Shizishan cemetery, Shaoxing city, China. Thus, it is considered that, the gilding technology was invented in the late Spring and Autumn Period, starting to developed in the Warring States Period, and becoming popular in the Qin and Han dynasties (Qi 1998).

The technology of mercury gold gilding is well known as fire gilding (Ma and Scott 2004), the ancient method of fire gilding can be summarized in three steps. Firstly, polish the surface of the bronze, dip a little diluted acid and spread it evenly (Wang 1984), then, wipe the surface with a new cotton cloth or a clean fur until it is smooth enough, the smoothness of the bronze surface was directly related to the gilding result. Secondly, forge the gold and formed it into a thin gold paper, cut the gold paper into pieces, and put them into a crucible filled with mercury, the proportion was gold: mercury = 1: 7 (Jiang 2010), cover the crucible tightly, the gold will dissolve in the mercury when the temperature reaches 400 ℃, after that, the Hg-Au amalgam can be produced (Chen 2007). Finally, apply the Hg-Au amalgam on the surface of the bronze artefacts and spread evenly. In this step, some craftsmen would choose to brush some mercury on the surface at first, spread the amalgam evenly by a bristle brush, then, heating the object, a thin gold layer remains when the Hg evaporated by high temperature. Repeat the last step 3 ~ 4 times, completing the gilding process.

It is reported that, the thickness of the gilded layers can reach 2–10 μm (Jin and Ruan 2016) through mercury gilding technology. In this paper, the bottom of G-5 was sampled (Fig. 10), and surveyed by element mapping and EDS.

The element mapping images of the gilded layer from G-5 are shown in Fig. 10, the elements Au, Ag, Hg, Cu, Sn and O were detected. The EDS results of the gilded layer (G-2, G-5, G-6, G-8), the cross-section of G-5 and the place gilded layer peeled off sampled from G-3 are reported in Table 3. Among them, Hg was commonly found in the gilded layer, which is characteristic feature of the gilding. Shown as the images of Au, Ag and Hg in Fig. 9, the shape of the peeled off gilded layer can be clearly profiled, proving the Au and Hg was only extant in the gilded layer. It’s worth noting that Ag, which was detected in the gilded layers, may be due to the underdeveloped gold purification technology of ancient China, or intended to adjust the color of the layer by added the silver into the gilding mercury amalgam (Cai 2019). With the time goes by, the bronze and its’ gilded layers were severely corroded in the wet environmental conditions, the gilded layers fell off and honeycomb corrosion holes appear in the layers (Fig. 11b. On the other hand, this phenomenon of honeycomb corrosion holes signifies the corrosion process and also explains the amount of O attested on the surface in element mapping images. In another case, Sn and O abundant in the cross-section and the place the gilded layers fell off, detected relatively less in the gilded layer, in Table 3, which consider that Sn and O come from the oxidative corrosion of bronze alloy. Much research about bronze mechanism of corrosion has reported that, the sequence of corrosion is Pb> Cu> Sn (Wang and Xu 2004), thus, the inexistence of Pb in the surface and cross-section of the samples and the irregular distribution of Cu (in Fig. 10; Table 3) were related to the corrosion of the bronze alloy, which led to the Pb loss first.

The thickness of the gilded layer was about 1.143 μm in the measurement of the gilded layer peeled off from G-11, in Fig. 11c and d. The SEM observation shows long and narrow indentations on the gilded layer of G-6, and the places with the indentations were more stable and attach to the surface of the bronze, shown in Fig. 11a and b, which shows the scientific and reliability of the “Yaguang” technique in the gilding process.

Conclusions

In summary, this paper studied the gilt-bronze Gaigongmao excavated from the M327 of the Dafenbao cemetery, and provides the direct evidence of the function, usage and the gilding technology of the Gaigongmao in the Eastern Han Dynasty.

For the first time, virtual pictures about one of the winding methods of Gaigongmao were inferred, and the material of the thread was cotton. The wood placed into the Gaigongmao was identified as bamboo, which serve as Gaigong. The usage of the Gaigongmao was to make a cotton thread winding though the groove below the Zao and the joint place, then, make the cotton thread winding though the groove above, to tie a knot on the opposite side, finally, tie the ends of the line through the Gaigong and fixing them together. In addition, by comparing the lead isotope data of the Eastern Han Dynasty and the distribution patterning of the Pb isotopes in China, it is found that the lead isotope date of the Gaigongmao falls within the range of the Yangtze River basin.

The gilding technology of the Gaigongmao in the Dafenbao cemetery was resulted for traditional mercury amalgam technology, and the indentations on the gilded layers observed in the SEM images have proven that the traditional “Yaguang” technic was scientific and reliable.

Data availability

No datasets were generated or analysed during the current study.

References

Alessia M (2022) Evolution of the ultrastructure and polysaccharide composition of flax fibres over time: when history meets science. Carbohydr Polym 291:119584

Ban B, Sun W (2020) Hanshu 汉书. China Social Sciences, Beijing

Cai Y (2019) The decorative technology of gold and silver bronze chariot pit wares in Haihunhou 海昏侯外藏椁鎏金银青铜车马器装饰工艺研究. Cult Relics South China (06):153–164

Cao J (2010) The traditional gilding technology 传统的鎏金工艺. Technology of cultural relics protection (1981–1991), pp. 242–248

Chen Z (2007) Manufacture technology of gold ware before the Qin Dynasty 先秦金器生产制作工艺的初步形成. Res Chin Econ Hist 01:83–90

Gao Y, Feng Y (1982) Two Warring States Chu tombs in Jinjiashan, Dangyang County, Hubei Provinc 湖北当阳县金家山两座战国楚墓. Cult Relics (04):46–48

Geminiani L, Campione F (2022) Differentiating between Natural and Modified Cellulosic fibres using ATR-FTIR spectroscopy. Heritage 5(4):4114–4139

Hsu YK, Sabatini BJ (2019) A geochemical characterization of lead ores in China: an isotope database for provenancing archaeological materials. PLoS ONE 14(4):e0215973

Huang X (2023) Study of the design of the umbrella cover of a Han Dynasty carriage 汉代與用伞盖设计研究. Master Degree Thesis, Jingdezhen Ceramic University, Jingdezhen

Jakes KA (2007) Infrared examination of Fiber and particulate residues from Archaeological Textiles. ACS Symp Ser 968:44–77

Jia Y, Yan Z (2000) Xinshu Jiaozhu 新书校注. Chung hwa book Co. ltd, Beijing

Jiang H (2010) The gilding technology of Xizang 西藏的鎏金技术. Technology of cultural relics protection (1981–1991), pp 453–454

Jin PJ, Ruan FH (2016) Microstructural and Componential characterization of the Plating Technology on Chinese Han Dynasty bronze fragments. Archaeometry 59(2):274–286

Li N (2007) Gold and Eternity: Gilt-Bronze and the Idea of Immortality in China through the Han Periods 金与不朽. Master Degree Thesis, Shandong University, Jinan

Li Z, Kang Q, Wang J (2019) The report on the excavation of Eastern Han cemetery in Balaizi Caochang, Jingzhou, Hubei Province 湖北荆州八癞子草场东汉墓发掘简报. Cult Relics South China (04):89–96

Liu X (2011) The Guijing cemetery in period from the Warring States to the Qin and Han dynasty, Fengjie county, Chongqing city 重庆市奉节县桂井战国秦汉墓地. Archaeology (11):51–66

Luo P (1982) Zhao Wang Mausoleum, Handan, Hebei 河北邯郸赵王陵. Archaeology (06):597–605

Ma Q, Scott DA (2004) Metal compounds in the plating of gilt and silver bronze ware in the Western Han Dynasty 西汉时期鎏金与鎏银青铜器镀层中的金属化合物. Sciences of Conservation and Archaeology 16(2):21–26+65

Margariti C (2019) The application of FTIR microspectroscopy in a non-invasive and non-destructive way to the study and conservation of mineralised excavated textiles. Herit Sci 7(1):1–14

Mou Y (1984) The report on excavation of Shaoxing 306 Warring States tomb 绍兴306号战国墓地发掘简报. Cult Relics (01):10–26

Qi D (1998) Early Chinese gold and silver technology 中国早期金银工艺初论. J Chin Antiq (02):66–72

Sun J (1985) The structure of the ancient Chinese independent Shaft carriage 中国古独辀马车的结构. Cult Relics (08):25–40

Tang B (2017) Liu Dongrui talks about several cultural relics excavated from the tomb of Haihunhou 刘东瑞谈海昏侯墓出土的几件文物. Identif Apprec Cult Relics (01):38–43

Tanil A, Sevim A (2017) Investigations of historical textiles from the Imperial Pavilion (Hunkar Kasri) of the new mosque Eminonu-Istanbul (Turkey) by multiple analytical techniques. J Cult Herit 25:180–184

Wang H (1984) Textual research about gilding technology 鎏金工艺考. Palace Museum J (02):50–58

Wang W, Huang X (1984) The report on excavation of Western Zhou Yan cemetery in Liulihe in 1981–1983 1981–1983年琉璃河西周燕国墓地发掘简报. Archaeology (05):405–416

Wang Z, Li Q (1997) Research and restoration of the Chariot in the Eastern Han Dynasty 东汉车制复原研究. Science Press, Beijing

Wang J, Xu C (2004) Chemical behavior of mass transfer at the bronze/environment interface 三元青铜/环境界面上物质转移的化学行为. Chin J Mater Res (03):244–250

Wang H, Li M (2016) The Warring-States Tombs at the Fanjia Mudi in Linzi District, Zibo City, Shandong 山东淄博市临淄区范家墓地战国墓. Archaeology (02):25–63

Wenwubianji W (1979) Thirty years of archaeological work 文物考古工作三十年. Cultural Relics Press, Beijing

Wu W, Zhang Q (1978) Two Chu state (Spring and Autumn Period) tombs with human sacrifices at Dadian in Junan County, Shandong Province 莒南大店春秋时期莒国殉人墓. Acta Archaeol Sin (03):317–336

Zheng R, Yang B (1984) A chariot pit was found in the west of Yinxu 殷墟西区发现一座车马坑. Archaeology (06):505–509

Zhu L, Zhang J (1981) Spring and Autumn Tomb in Luoyang, Henan Province 河南洛阳春秋墓. Archaeology (01):24–26

Zhu L, Hu R (2008) The excavation report of the Han Dynasty cemetery (C9M2441) in Jili District, Luoyang 洛阳吉利区汉墓(C9M2441)发掘简报. Cult Relics (04):33–41

Acknowledgements

Thanks to Wang Hui from the Analytical & Testing Center of Sichuan University for her help with SEM /EDS characterization, Yan Xue from the Archaeology of Chengdu for her help with the wood species identification, and Jake Glover for his help with the proofreading.

Funding

This work was funded by the National Natural Science Foundation of China (T2350410495), and Sichuan University (SKSYL2023-05 & 2035xd-02).

Author information

Authors and Affiliations

Contributions

Chenxi Liang wrote the main manuscript text, did the data analyses and prepared the figures, Yuniu Li supervision, review and edited the paper, Wantao Li provide the information of the cemetery and the samples, Xiaohong Yu review and edited the paper. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liang, C., Li, W., Yu, X. et al. Scientific analysis of the gilt-bronze chariot parasol component of the Eastern Han Dynasty excavated from the Dafenbao cemetery, Pengshan, Sichuan, China. Archaeol Anthropol Sci 16, 158 (2024). https://doi.org/10.1007/s12520-024-02063-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-024-02063-9