Abstract

During the Eastern Zhou Dynasty (770–222 BC), a large number of bronze arrowheads were unearthed from the Chu tombs, which is of great significance to the study of bronze weapons in the Chu state. However, little is known about the production technology, mode, and provenance of the raw materials for bronze weapons in the Chu state. Therefore, we conducted archaeometallurgical analyses of 16 bronze arrowheads excavated from the Yuwan cemetery using metallographic microscopy, inductively coupled plasma atomic emission spectroscopy, and multi-collector inductively coupled plasma mass spectrometry. The results indicate that the arrowheads are all copper-tin–lead ternary alloys with a high tin content and adequate mechanical properties. The differences in the production process, lead–tin content, and copper groups indicate that bronze arrowheads were produced at a high rate and in multiple batches. Furthermore, comparative lead isotope studies of galena from different regions revealed that during the Warring States period, the Chu state possessed a strong supply network of metal resources, and after occupying regions with abundant metal resources, it was transported to the Chu state for bronze production.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The Eastern Zhou was an important period in which the state form of ancient China shifted from the stage of kingdom to that of empire. In the historical environment of this major transformation, ancient China not only ushered in a great wave of spatial integration, but also set off a new upsurge of cultural intermingling. Whether it was the great vassal states of Qin, Chu, Qi, Yan, Zhao, Wei, and Han, or the small borderland states of Ba, Shu, and Yiqu, all were inevitably caught up in the historical flood of multicultural spatial integration (Xiang 2017). The first half of the Eastern Zhou, in which the vassals competed for hegemony, is called the Spring and Autumn Period (770–477 BC; the second half of the Eastern Zhou is called the Warring States Period (476–222 BC). Although the Eastern Zhou period had already entered the Iron Age, and the ritual role of bronze was greatly reduced, it was still an important period for the development of bronze technology, especially because of the frequent wars, and the bronze weapon technology of the vassal states was greatly developed.

Bronze arrowheads, as important military equipment, gradually developed in artisanship and design and were indispensable weapons in warfare at that time. An arrowhead is a weapon that is used to attack an enemy at a distance. Before the invention of firearms, this type of weapon was an extremely important long-distance weapon in combat. In addition to being used as weapons, arrowheads play an important role in daily activities such as hunting, Yishe (bird shooting), and Touhu (an ancient throwing game) (Liao 2017).

The Chu state was one of the strongest military powers during the Eastern Zhou period. Archaeological excavations reveal a diverse array of projectile armaments, encompassing bows, crossbows, and arrowheads, with bronze arrowheads being the most commonly unearthed in the Chu state. Recently, researchers have expressed increased interest in the function, typology, development, and evolution of the shape of the bronze arrowheads of the Chu state (Zhao 2019; Yuan 2008). He and Chen (1999) conducted a thorough archaeometallurgy analysis of the mechanical characteristics and surface refinement processes employed on the bronze arrowheads excavated from Yutaishan cemetery during the Warring States period. Lin et al. (2022) studied the manufacturing techniques and alloy compositions of arrowheads unearthed from the Gaodian cemetery. Additionally, Chen et al. conducted a lead isotope ratio analysis on arrowheads recovered from Xiquan cemetery; however, they did not investigate the lead source (Chen et al. 2021a). Thus far, there has been limited discussion on the production process, batches, and mineral sources of bronze arrowheads in the Chu state. This gap in research hinders a comprehensive understanding of weapon production in the region.

This study attempts to address the issue of bronze weapon production in the Chu state through systematic archaeometallurgical analyses. In 2016, 16 bronze arrowheads were unearthed at the Yuwan cemetery, and used for this study. Employing metallographic microscopy, inductively coupled plasma atomic emission spectroscopy (ICP-AES), and multi-collector inductively coupled plasma mass spectrometry (MC-ICP-MS), we discuss the production mode and sources of minerals in bronze arrowheads. These findings should make an important contribution to the field of bronze weapon production in the Chu state.

Materials and methods

Archaeological contexts and samples

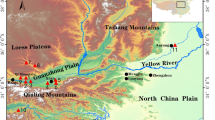

Yuwan cemetery is located on a slope in Leidu Village, Zengji Town, Shayang County, Jingmen City, Hubei Province, and covers an area of approximately 40,000 m2 (Fig. 1). From November 2016 to March 2017, the Department of Archaeology at Sichuan University excavated 57 tombs in a cemetery (Bai et al. 2020), and unearthed 16 arrowheads from four of the tombs (M18, M19, M25, and M42). Among the arrowheads, 11 pieces of M25 were buried, most in Yuwan cemetery. Three pieces of M42 and one piece each of M19 and M18 were buried. According to pottery, such as Ding, Dui, and Fou (ritual vessels) from M18, M19, and M42 which resemble those found in the early Warring States Chu tombs, these three tombs also date to the early Warring States period (Bai et al. 2020). As no pottery was unearthed from M25, it was difficult to determine its chronology. However, M25 had four arrowheads with long tangs, each exceeding 30 cm in length (Fig. 2). Arrowheads with long tangs found in the Chu tombs generally date to the later Warring States period (Liao 2017). Therefore, it is reasonable to infer that the burial of M25 dates back to the later Warring States period.

a. Photos of bronze arrowheads unearthed from Yuwan cemetery; b. The major components of the typical arrowhead (The image modified from Shi 2006) and the remnants of an iron tang in the socket

This study sampled 16 bronze arrowheads from four different tombs in Yuwan cemetery and collected 17 samples (Table 1). Regarding the sampling location and considering the precision of these artefacts, we carefully selected parts that would not seriously damage the bronze arrowheads, thus ensuring that destructive sampling was performed primarily on the Tang or Socket of the arrowhead, not the Head or Blade. (Table 1, Fig. 2a). Therefore, only one arrowhead sample was taken from the blade (YW1), and seven arrowhead samples were taken from the socket. Moreover, nine samples were obtained from the tang of the arrowheads. We noticed that some arrowheads had broken tangs in their sockets. To further determine the material of the tangs, we conducted a scanning electron microscopy and energy spectrum analysis (SEM–EDS) on one of them (YW6). Except for YW6, metallographic analysis and ICP-AES analyses were performed on the remaining 16 samples. Seven samples were simultaneously selected for the MC-ICP-MS analysis.

The 16 arrowheads excavated from Yuwan cemetery can be classified into four different types based on differences in the head (Fig. 2b). Type A has hollow blades and wide heads. The blade features a longer, straight blade with no tang and a hollow edge that extends to the tip of the blade (Fig. 2, YW1). Type B has 3 pieces. The shapes are all the same, double-bladed, with a larger flattened head and a rhombus-shaped cross section. The socket hollowed out and was shorter, with remnants of iron tangs in the socket (Fig. 2, YW6, YW8, and YW9). Type C is a triangular arrowhead with the smallest body and can be divided into three different subtypes. In type C1, the three blades are slightly curved at the top to form a front, and the rear blade is curved inward. The front tang was short, thick, and triangular in shape, and the rear part was slender and rounded (Fig. 2, YW14-YW17). In Type C2, the three curved blades converged into a front edge, and the back blade curved inward. The socket was long and hollow up to the front edge, and broken iron tangs were present (Fig. 2, YW10-YW13). In Type C3, the triangular arrowhead had a longer head. They had long spines, three longer blades, and a broken tang (Fig. 2, YW3-YW5). In Type D, there was one piece that had a well-made triangular arrowhead (blunt). The tang was not broken; the front section was long and thick, with a rounded triangular shape; and the back section was shorter, with a thin triangular shape (Fig. 2, YW2).

Analytical methods

Elemental compositions were measured using ICP-AES. The lead isotope ratios were determined using an MC-ICP-MS system. The mounted samples were subjected to cold mounting in an epoxy resin. A Struers Tegramin-20 polishing machine was used to grind and polish the samples. A Nikon LV-100 polarising/metallographic microscope was used to observe the samples before and after etching with alcoholic ferric chloride (FeCl3).

Before the samples could be dissolved, their corrosion and contamination were removed. The sample was completely dissolved in aqua regia and diluted to 100 ml with deionised water. The elements were analysed using a Prodigy inductively coupled plasma atomic emission spectrometer (Leeman Labs). The working conditions were as follows: RF power of 1.1 kW, Ar gas flow rate of 20 L/min, and plasma and nebuliser gases at 20 MPa. Eight elements were measured in this study: Sn, Pb, Fe, Ni, As, Sb, Ag, and Au. Before the experiment, the instrument was calibrated using standard solutions to ensure that the relative standard deviation of each element was less than 0.1% and that the limit of quantitation value of the ICP-AES was maintained throughout the sample determination (Yang et al. 2024).

The lead isotope ratios were measured using a VG Elemental multi-collector inductively coupled plasma mass spectrometer (VG Elemental Axiom, Thermo Fisher Scientific Inc., USA). The relative errors in the 207Pb/206Pb, 208Pb/206Pb, and 206Pb/204Pb ratios were < 0.01%, 0.01%, and 0.1%, respectively. The SRM981 international lead isotope standard was used as a standard reference to calibrate the spectrometer. Calibration was checked after every set of six to eight measurements.

Results and discussion

Alloy ratio and manufacturing techniques

Different metals have different thresholds when defining them as alloying elements. For example, tin (Sn) needs to exceed only 1 wt% to qualify as an alloy, lead (Pb) must be present with at least 3 wt% to be counted as intentional (Lehner 2017). However, for Chinese Eastern Zhou bronzes, it has been found through extensive research that the bronzes of this period are generally copper-tin–lead ternary alloys (Zhang et al. 2019). Therefore, it is generally accepted that an element can be considered an alloying element if its content exceeds 2%; otherwise, it is considered an impurity introduced from the ore (Sun et al. 2011). Therefore, the ICP-AES results indicate that the arrowheads in this study are all copper-tin–lead ternary alloys. Barring YW1, which had a lower tin content, the other arrowhead samples had a higher tin content, with a ratio ranging from 16 to 24% (Table 2, Fig. 3) and an average value of 19%. Most Eastern Zhou bronzes use 17% as the threshold and those with higher than 17% are high-tin alloys (Zhang et al. 2019). Therefore, 65% of the arrowheads in this study were high-tin alloy. High-tin weapons have higher hardness, strength, and stronger lethality, but their ductility and tensile strength are relatively poor. Most arrowheads contain less than 10% lead, which helps improve their overall strength and durability. However, in a copper-based alloy containing 12% to 18% tin, the addition of approximately 6% lead can further enhance its mechanical properties. The addition of a small amount of lead to tin bronze can significantly enhance its fluidity and increase its overall flow rate (Chen et al. 2022). Moreover, the low melting point of lead allows it to fill the interdendritic pores in the final stage of solidification, effectively improving the quality of the final products (Sun et al. 2011). Additionally, the SEM–EDS results indicated that YW6 was pure iron, indicating that the broken tangs in the sockets of some arrowheads were made of iron (Table S1, Fig. S1, 2).

The Rites of Zhou· The Artificers’ Record (Zhou Li 周礼·Kaogong ji) also mentions the alloy ratio of bronze arrowheads. For more than 100 years, the precise interpretation of the alloy ratios documented in The Rites of Zhou· The Artificers’ Record has eluded any explanation (Pollard and Liu 2022; Yang 2015). However, the consensus is that arrowheads require higher hardness and tin content. The high tin content provides high strength and is suitable for improving the penetrating power and lethality. Furthermore, the addition of a moderate amount of lead can increase the weight of an arrowhead, improve flight stability, and enhance lethality (Nan 2018). Therefore, most of the arrowheads tested in this study exhibited sound mechanical properties.

Existing archaeological material indicates that from the late Spring and Autumn period to the Warring States period, the shape of the arrowheads unearthed in the Chu tombs changed. The shape of the arrowheads ranges from a double blade to a triangular blade, from long and narrow to short, and the tang changes from short to long. Furthermore, the number of bronze arrowheads with iron tang began to increase (Liao 2017). The arrowheads in this study are consistent with this change. Double-blade and triangular arrowheads are the most common. There are six arrowheads with iron tangs remaining in the sockets; however, the iron tangs are shorter with severe corrosion. Additionally, there were four arrowheads with long tangs, with the longest tang reaching 39.4 cm. Related studies have highlighted that the overall pattern of high tin and low lead was seen in bronze weapons from the Chu state during the Warring States period. In this study, the average tin and lead contents of the arrowheads were 19% and 8.7%, respectively.

What factors drive the changes in the arrowhead shape and alloy ratios?

During the Warring States period, with the development of protective devices, such as shields and body armour, the lethality of the double-blade arrowhead declined. In this context, a triangular arrowhead characterised by three blades emerged. This type of arrowhead is designed specifically to penetrate protective equipment, making it suitable for both infantry and vehicle combat (Yin 2023). Bronze arrowheads are combat weapons, and the requirements for lethality are the primary factors that determine their shape. Some scholars have used experimental archaeology to analyse the reasons for the changes in the shape of arrowheads during the Warring States period (Wang 2007; Shi 2006). This research revealed that the implementation of a long tang on arrowheads increased their weight and overall strength, allowing them to remain stable during flight, and ultimately improving their effectiveness in warfare. The high-tin content provides high strength and is suitable for improving the penetrating power and lethality. Furthermore, the addition of a moderate amount of lead can increase the weight of an arrowhead, improve flight stability, and enhance lethality (Nan 2018). Therefore, the shape of bronze arrowheads from a double blade to a triangular blade, the constant lengthening of tang, the invention of the iron tang, and the characteristics of high-tin and low-lead are the embodiments of further enhancement of the lethal performance of bronze arrowheads.

The results of the metallographic analysis are depicted in Fig. 4. The samples exhibited dendritic crystalline structures with dispersed lead and sulphide inclusions, indicating that all samples were cast. As the α + δ eutectoid in tin bronze is relatively fragile, from a practical point of view, it is essential for craftsmen to carefully heat treatment or cold-work the bronze in order to enhance its mechanical strength and durability (Lin et al. 2022). Notably, no clear traces of heat treatment or cold-working were observed in the metallographic analysis. This could be because the samples taken in this study were mostly from the sockets and tangs, rather than from the blades.

All the arrowheads in this study were cast; however, specific casting techniques can be divided into two types: single-casting and separate-casting. Single-casting involves the simultaneous pouring of molten metal into the mould to cast an entire object, whereas separate-casting utilises different accessories that are cast individually and eventually joined (Zhao et al. 2024). YW1-YW5 were single castings. The remaining samples were separated via casting using different methods.

According to relevant research, there are two techniques for producing bronze arrowheads with tangs. The first involves producing an arrowhead with a socket (Fig. 2b) and subsequently, mechanically inserting a bronze or iron tang into the socket after casting the arrowhead (Marcos et al. 2014). YW3-YW5 and YW10-YW13 both have sockets, and remnants of iron tangs are found in the sockets. However, no traces of soldering or casting were observed in the combination of the heads and tangs, which suggests that the heads were cast first and subsequently, the tangs were mechanically inserted into the sockets. The other technique involves first casting the tang and subsequently placing it into the arrowhead mould before pouring it into the molten metal to cast the arrowhead, ensuring a good bond between the tang and head (Shi 2006). The YW14-YW17 have a long tang, divided into two sections: the front section is short and triangular, and the rear section is long and circular. Figure 5 presents the traces of liquid metal overflow at the root of the rear section of the tang. Additionally, a layer of unevenly thick and irregularly shaped metal liquid was formed on the tang at the joint between the front and rear tangs. This indicates that the rear section of the tang was cast first and subsequently placed in the mould and cast together. This method is more efficient than the first method and facilitates large-scale mass production; whereas the first method has an additional process that may have been used in the early period and later improved into the latter (Zhang 2012).

YW14-YW17 are arrowheads with a long tang, and the sampling position is the rear section of the tang. These four arrowheads represent separate casts; therefore, their alloy compositions are representative of the rear sections of the tang. The sampling position of YW2-YW5 is also tang; however, as it is a single cast, the alloy composition should be the same as that of the blade. The same was true for YW1 and YW7-YW13. Overall, the tin-content of the blade was significantly higher than that of the tang blade (Fig. 3). This result implies careful selection and optimisation of the alloy ratios of the different parts of the arrow by the artisan: the good hardness and strength of the high-tin bronze improves the penetration of the head but at the cost of increased brittleness. Contrarily, tangs are made of low-tin content to ensure better toughness and reduce the risk of breaking when inserted into bamboo shafts (Marcos et al. 2014).

Multiple production batches and lead sources reveal the weapon production mode in the Chu state

To further discuss the issue of production batches of arrowheads, we analysed data based on the copper groups (CG) method in the Oxford system (Pollard et al. 2018). Briefly, the CG method uses the presence or absence of four elements (arsenic, antimony, silver, and nickel) in bronze (0.1% cut-off) to define 16 different CGs. Applications of the CG method to ancient bronzes in China have been described in detail in the literature and are not repeated here (Li et al. 2020a, b, c, d).

In general, bronze samples of an identical type, decoration, size, and casting features are most likely to originate from the same batch, and the same production batch should have the same CG and lead isotope ratios (Li et al. 2020c; Chen et al. 2021b). Based on the typological, CGs, and lead isotope analyses of the Yuwan arrowheads, it is possible to discuss the production of these bronze weapons. Types A and D were excluded from the discussion because only one sample was available and no lead isotope ratio analyses were conducted.

First, we examined the case of M25, in which 11 arrowheads were excavated and divided into Types B, C2, and C3 according to their shapes. Three of the Type-B samples have different levels of detail and sizes. The results of the CGs indicated that YW6 and YW8 were both in CG 2, and YW9 was in CG 11. The four Type-C1 samples were broken at the rear of the tang; however, by observing the arrowheads and front of the tang, it was established that the front of the tang of YW14 was longer than that of the other three samples, but the sizes of the heads were equal. YW14, YW15, and YW17 are CG 1, while YW16 is CG 2, and there is no obvious difference in the size of the four Type-C2 samples. YW12 was CG 11, and the remaining three samples were CG 2. Figure 6 depicts a comparison of the lead isotope ratios of the different types of arrowheads. It can be seen that the four Type-C1 samples are discrete, with no overlap, which indicates that the arrowheads of the same shape were made from different sources of lead. The Pb isotope ratios of the two Type-C2 samples are closer, suggesting that the same source of lead ore may have been used; however, the differences in CG still indicate that they were made in different batches.

The lengths of the three M42 arrowheads were different. YW4 and YW5 are CG 11, while YW3 is CG 2. The lead isotope ratios of YW5 overlap with those of one sample from Type C1, suggesting that the same lead source should have been used. The difference in the M42 and M25 dates may indicate that from the early to late Warring States period, the Chu state continued to use this type of lead ore.

Arrowheads of the same type indicate different CGs and lead isotope ratios. Furthermore, the lead and tin contents of arrowheads of the same type also varied greatly (Fig. 3), further indicating that these arrowheads were not produced in a single batch. This implies that the bronze arrowheads of the Chu state were produced more frequently and in multiple batches during the Warring States period.

Evidence can also be obtained from archaeological materials. Compared to other contemporary cultures, the proportion of weapons buried in the Chu tombs is much higher. The burial of arrowheads was a very common practice in the Chu tombs during the Warring States period. Not only were tomb owners of a higher social status, but bronze arrowheads were also found in many lower-class tombs (Liao 2017). Among the tomb owners of higher social status, as many as 4,507 arrowheads were unearthed in the tomb of Marquis Yi of Zeng (The Museum of Hubei Province 1989). The number of arrowheads buried in tombs of other classes ranged from dozens to hundreds (Liao 2017). The practice of using many bronze arrowheads as funerary objects undoubtedly demands a higher level of efficiency in the production of bronze weapons. Moreover, the Warring States period witnessed an increase in the frequency and scale of warfare, which inevitably led to a sharp increase in the demand for bronze weapons. Therefore, a high frequency, multi-batch production mode fulfils this requirement. This is also in line with the spirit of the Chu people in martial arts as recorded in historical documents.

Provenance study

Lead isotope analysis results indicate that the lead isotope ratios of the samples are within the range of common lead, with 206Pb/204Pb ratios ranging from 17.4222 to 18.4189, 207Pb/204Pb ratios ranging from 15.4708 to 15.7031, and 208Pb/204Pb ratios ranging from 37.9645 to 39.0000 (Table 3). Concerning the significance of lead isotopes, if the lead content in bronze is higher than 2%, it is considered to be artificially added lead. In this case, the lead isotope indicated the source of the lead ore; otherwise, it indicated the source of the copper ore. Therefore, the lead isotope data of the arrowheads tested in this study mainly indicate the provenance of the lead ore.

As depicted in Fig. 6a, the distribution of arrowheads excavated from the Yuwan cemetery was relatively scattered, suggesting that the sources of the lead ores used were complex, with at least three groups. Numerous lead isotopes have been published for bronzes from the Warring States period of the Chu state, so we chose lead isotope data from the Shouxian, Lu’an, Bayi Road, Xujialing, Shaoyang, Xiquan, and Chutai cemeteries (Chen et al. 2021a; Luo et al. 2023a, b; Wen et al. 2013; Mu et al. 2019; Luo et al. 2022) (Table S2). The results of the comparison indicate that the distribution pattern of the Yuwan arrowheads is the same as that of the Chu bronze data (Fig. 6b), implying that multiple lead sources were used in the Chu bronzes during the Warring States period.

Ancient documents such as the Yugong section of the Esteemed Documents (Shangshu尚书, the Spring and Autumn period) and the Rites of Zhou· The Artificers’ Record (Zhou Li ·Kaogong ji) indicate that the Chu state was rich in metal resources. Archaeological material also indicates that a large number of ancient mining sites from the Shang Dynasty to the Warring States periods were distributed within the Chu state (Wen et al. 2013). Furthermore, scientific analysis of Chu’s bronzes can provide some clues. Luo et al. analysed Warring States bronze mirrors unearthed from Chu tombs in Hunan and concluded that Changsha was the bronze mirror casting centre during the Warring States period. Artisans mainly used ores from the Nanling Mountains, northern Jiangxi, and western Henan regions to manufacture different types of Chu bronze mirrors (Luo et al. 2022). The rich resources of tin and lead ores in the Nanling region could have been one of the motivations for the southward advancement of the Chu state (Fig. 1). Therefore, to further determine the source of the lead ore for the arrowheads excavated from the Yuwan cemetery, we selected galena from the Nanling, Jiangxi, and western Henan regions (Fig. 1) for a comparative study (Hsu and Benjamin 2019).

As depicted in Fig. 7, the lead isotope ratio data for the Yuwan arrowheads can be divided into three groups. The first group of data (YW5, YW15, and YW17) overlaps with the main range of lead ore from the Nanling Mountains, indicating that the lead ore used in these arrowheads originated from the Nanling area. It is worth noting that although YW5, YW17, and YW15 correspond to galena from the Nanling Mountains, YW5 and YW17 correspond to lead mines in southern Hunan, whereas YW15 corresponds to lead mines in northern Guangdong, suggesting that lead ores from different deposits in the Nanling area were used. From the mid-Spring and Autumn periods, lead ores from the Nanling Mountains were widely used in bronzes from the middle reaches of the Yangtze River (Ma et al. 2023). During the Warring States period, the Nanling Mountains were included in the dominion of the Chu state, and the lead isotope ratios of the first set of arrowheads indicate that the Chu state further developed and utilised the metal resources of the Nanling Mountains during the Warring States period.

YW16 in the second dataset corresponds to the Galena data from the northern Jiangxi area, suggesting that the lead ore used came from northern Jiangxi. In the late Warring States period, northern Jiangxi was incorporated into the sphere of the Chu state (Zhao 2013). Additionally, the similar distribution ranges of YW12-14 and lead ore data from western Henan indicate that the lead material used in these arrowheads likely originated from the western Henan region. Chen et al. conducted lead isotope analyses of lead and tin vessels from the Warring States period excavated in Nanyang, and the results revealed that western Henan not only produced large quantities of copper and iron but was also an important area for lead production (Chen et al. 2021c).

Therefore, the analyses of lead isotopes in the Yuwan arrowheads demonstrate that the Chu state possessed a strong supply network of metal resources during the Warring States period. In addition to using the metal resources within the territory of the Chu state, it occupies areas with abundant metal resources such as the Nanling Mountains, western Henan, and northern Jiangxi. The Chu state can continuously transport local metals for bronze production. One of the important motivations for Chu’s outwards expansion was to obtain large quantities of raw metal materials; the dramatic increase in the demand for metal resources would inevitably lead to an expansion in the scale of mining and smelting, which would also lead to the search for new sources of minerals and the mining of more minerals.

Conclusion

This study presents an archaeometallurgical analysis of 16 bronze arrowheads excavated from Yuwan cemetery. An analysis of the alloy ratios reveals that the arrowheads all contain a high-tin content, 65% of which belongs to copper-tin–lead ternary alloys, which ensures that the arrowheads have high hardness, strength, and good mechanical properties. The difference in tin-content between the tang and blade reveals that the artisans carefully selected and optimised the alloy ratios for the different parts of the arrowheads. Metallographic observations indicated that the arrowheads were all casts, and no signs of secondary processing were established. This may be because the sampling parts are mostly the tang and socket rather than the blade. The production process can be divided into two kinds, single-casting and separate-casting. The separate casting arrowheads can be divided into two different operation methods.

We discuss the production mode of arrowheads using the CG method. According to the CG and typological analysis of Yuwan arrowheads, there are different CGs of arrowheads of the same type, and the lead–tin content of arrowheads of the same type varies greatly. This further suggests that arrowheads of the same type are not a single batch, which implies that the frequency of production of arrowheads from the Chu state during the Warring States period is higher. This provides important clues in understanding the production mode of the Chu state. Moreover, lead isotope analyses indicated that the lead ores used in arrowhead production are complex, mainly using lead materials from the Nanling Mountains and western Henan, with a small portion of lead ores from northern Jiangxi. This also reflects the fact that the demand for metal raw materials in the Chu state greatly increased during the Warring States period, prompting the search for new sources and the exploitation of more metal resources, which was also an important motive for the outwards expansion of the Chu state.

Due to the small number of samples analysed in this study, research on the performance of bronze arrowheads has not yet been conducted. In the future, with the continuous accumulation of scientific data and the unfolding of experimental archaeology, we believe that we can better answer the questions of weapon production in the Chu state.

Data availability

Data supporting the findings of this study are available in the article.

References

Bai B, Wang Z, Tang J et al (2020) Excavation Report on the Chu Tombs at Yuwan in Shayang County of jingmen City, Hubei Province. Jianghan Archaeol 03:33–48

Chen D, Han Y, Wang Z et al (2021a) The prestigious tin-lead horse fittings in the Warring States Period: Evidence from funerary artifacts of a Warring States Tomb at Shouxian, Anhui. Archaeometry 63:1290–1305. https://doi.org/10.1111/arcm.12673

Chen D, Yang Y, Wang T et al (2021b) Imitation or importation: archaeometallurgical research on bronze dagger-axes from Shuangyuan Village Cemetery of the Shu State in the Eastern Zhou Dynasty. J Archaeol Sci-Rep 40:103218. https://doi.org/10.1016/j.jasrep.2021.103218

Chen D, Qiao B, Luo W (2021c) Archaeometallurgical research on the manufacture of lead mingqi from Nanyang in Chu state during the Warring States period. Archaeometry 63:810–825. https://doi.org/10.1111/arcm.12645

Chen D, Yang Y, Wang T et al (2022) Improvement and integration: scientific analyses of willow-leaf shaped bronze swords excavated from the Shuangyuan Village Cemetery, Chengdu. China Herit Sci 10:92. https://doi.org/10.1186/s40494-022-00725-2

He T, Chen Y (1999) Scientific Analysis of Jiangling Warring States Bronzes. Stud History of Natural Sci 02:63–72+99.

Hsu YK, Benjamin JS (2019) A geochemical characterization of lead ores in China: an isotope database for provenancing archaeological material. PLoS ONE 14(4):e0215973. https://doi.org/10.1371/journal.pone.0215973

Lehner J (2017) Compositional analysis of copper alloys from the middle plateau excavations at Boğazköy. Walter De Gruyter Press, Berlin.

Li H, Zhou Z, Liu Y (2020b) Fighting and burial: the production of bronze weapons in the Shu state based on a case study of Xinghelu cemetery, Chengdu. China Herit Sci 8:36. https://doi.org/10.1186/s40494-020-00379-y

Li H, Zuo Z, Cui J et al (2020c) Copper alloy production in the Warring States period (475–221 BCE) of the Shu state: a metallurgical study on copper alloy objects of the Baishoulu cemetery in Chengdu, China. Herit Sci 8:1–16. https://doi.org/10.1186/s40494-020-00412-0

Li H, Zuo Z, Cui J et al (2020d) Bronze production in the Ancient Chengdu Plains: a diachronic metallurgical perspective on a separate cultural region. J Cult Herit 43:26–36. https://doi.org/10.1016/j.culher.2019.11.005

Li H, Cui J, Chen J et al (2020a) Verification and Application of 'Copper Groups' Method. Jianghan Archaeol. 02: 103–109+102.

Liao D (2017) The bows and arows unearthed from Chu Tombs of the Warring States and their related problems. Master’s Thesis, Nanjing University, Jiangsu.

Lin Y, Luo S, Xiao L et al (2022) Techniques and Traditions of Warring States Bronzes from the Southern Edge of the Chu Territory. Cultural Relics 05:188–197

Luo Z, Fan A, Jin Z et al (2022) Scientific analysis and research on the Warring States bronze mirrors unearthed from Changsha Chu cemetery, Hunan province. China Archaeometry 64(5):1187–1201. https://doi.org/10.1111/arcm.12776

Luo Z, Jin Z, Hu G et al (2023a) Lead isotopes of Eastern Zhou Bronzes Unearthed from Shaoyang of Hunan. Jianghan Archaeol 03:125–133

Luo Z, Yang M, Liu J et al (2023b) Diversified manufacturing processes and multiple mineral sources: Features of Warring States bronze vessels excavated from Chutai Cemetery M1. Anhui Province Sci China Technol Sci 66:2297–2307. https://doi.org/10.1007/s11431-022-2363-y

Ma J, Wu X, Yan X (2023) Metal Trade and National Integration: bronze technology and metal resources of Yue Style Bronzes from Hunan (8–5 C. BCE). Herit Sci 11:128. https://doi.org/10.1186/s40494-023-00973-w

Marcos MT, Li XJ, Bevan A et al (2014) Forty thousand arms for a single emperor: from chemical data to the labor organization behind the bronze arrows of the terracotta army. J Archaeol Method Theory 21:534–562. https://doi.org/10.1007/s10816-012-9158-z

Mu D, Luo W, Song G et al (2019) The features as a county of Chu state: Chemical and metallurgical characteristics of the bronze artifacts from the Bayilu site. Archaeol Anthropol Sci 3:1123–1129. https://doi.org/10.1007/s12520-018-0596-8

Nan P (2018) Research on bronze technology of Jin Kingdom in spring and autumn period. PhD Thesis, University of Science and Technology Beijing, Beijing.

Pollard AM, Bray P, Cuénod A, Hommel P, Hsu YK, Liu R, Perucchetti L, Pouncett J, Saunders M (2018) Beyond provenance new approaches to interpreting the chemistry of archaeological copper alloys. Leuven University Press, Leuven. https://doi.org/10.11116/9789461662668

Pollard AM, Liu R (2022) The six recipes of Zhou – a new perspective on Jin (金) and Xi (锡). Antiquity 96:1200–1213. https://doi.org/10.15184/aqy.2022.81

Shi Y (2006) Researches on bronze arrows before Qin Dynasty in northern China. PhD Thesis, Jilin University, Jilin.

Sun S, Han R, Li X (2011) Microstructure Atlas of Ancient Chinese Metallic Materials-Nonferrous Metal Volume. Science Press, Beijing

The Museum of Hubei Province (1989) Tomb of Marquis Yi of Zeng State. Cultural Relics Press, Beijing

Wang Y (2007) An experimental study of the simulation of a long tang of bronze arrowheads. Cultural Relics 11:91–94+96.

Wen J, Ling X, Zhao CC et al (2013) Primary analysis on lead isotope characteristics in Chu State bronzes in Eastern Zhou Period unearthed from Luan District, Anhui Province. J Northwest Univ (nat Sci Ed) 43:1016–1020

Xiang M (2017) Archaeological perspective on Ba's and Shu's ancient histories-focusing on the graves of Ba-Shu culture from East Zhou to West Han periods. PhD Thesis, Jilin University, Jilin.

Yang Z, Jiang Z, Thonglith L et al (2024) New evidence of metal exchange in Southeast Asia during the Iron Age: scientific analysis of excavated bronze in Vilabouly. Laos Archaeol Anthropol Sci 16:26. https://doi.org/10.1007/s12520-023-01933-y

Yang H (2015) A New Opinion on the "ji" of the "Liuji" (Six Formulae of Bronze Alloys). Relics Museol. 01: 35–38+70.

Yin X (2023) Archaeological findings and new evidence of musical instruments and weapons in Chuci. Master’s Thesis, Shandong Normal University, Shandong.

Yuan Y (2008) A Preliminary Study of Chu Arrowheads with a Flat-Tip. Jianghan Archaeol. 03:48–52+54+53.

Zhang H (2012) The production process of iron tang and bronze arrowheads in the Warring States period and its evolution. J Chifeng Univ (philosophy Soc Sci Chinese Edition) 33(05):21–23

Zhang J, Liang C, Wang Z et al (2019) Metallographic and Component Analysis of the Bronze Vessels xcavated from Yugang Cemetery at Xiangyang City. Jianghan Archaeol. 03:126–134+102.

Zhao F, Sun M, Li P et al (2024) Revealing the manufacturing and corrosion characteristics of Chinese archaeological metal arrows by non-destructive neutron techniques. Archaeol Anthropol Sci 16:50. https://doi.org/10.1007/s12520-024-01957-y

Zhao B (2013) A study of the changes in the boundary of the State of Chu: geopolitics as a research perspective. PhD Thesis, Fudan University, Shanghai.

Zhao M (2019) Study on the function of arrowheads unearthed from the Tombs of the Nobles in the Eastern Zhou Dynasty. Master’s Thesis, Xiamen University, Fujian.

Acknowledgements

We would like to thank Xiaoyu Liu, Anhui University, for assistance with Figure 1.

Funding

This research was supported by the National Social Science Fund of China (Grant No. 21AKG008).

Author information

Authors and Affiliations

Contributions

K. Zhang: conceptualisation, methodology, formal analysis and investigation, and the writing of the original draft preparation.

Q. Li: conceptualisation, methodology, formal analysis and investigation, and the writing of the original draft preparation.

J. He: resources, writing—review, and editing.

B. Bai: Methodology, formal analysis, writing the original draft, and project administration.

H.C. Li: Methodology, formal analysis, writing the original draft, and project administration.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Qiang Li is Co-first author.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, K., Li, Q., Bai, B. et al. The production of bronze weapons in the Chu state: a case study of bronze arrowheads excavated from the Yuwan cemetery in Hubei, China. Archaeol Anthropol Sci 16, 152 (2024). https://doi.org/10.1007/s12520-024-02061-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-024-02061-x