Abstract

The article discusses the various options for reconstructing pottery-forming techniques and for making reliable interpretations of forming practices based on archaeological evidence. It begins with a consideration of a classification of forming techniques that provides a framework with a suitable resolution within which observed phenomena can be understood. Such a classification should reflect meaningful distinctions among the forming practices: (a) in terms of the potter’s behaviour and also (b) in terms of the visibility of the effects in the archaeological record. The description of the forming practice reflects the fact that the forming method is a complex series of actions and often comprises more than one technique. The individual techniques are combined in two ways: (a) sequential, to create a single part, and (b) segmental, to create different parts. The relevant diagnostic attributes of pottery-forming practices are related to the structure and shape/size of the ceramics. They can be divided into five categories: (a) surface morphology and topography, (b) variation in the wall thickness, (c) remnants of segmental joints, (d) specific fractures, and (e) alignment and orientation of the components of the ceramic body. Two sources of misinterpretation of the diagnostic features define two types of ambiguous diagnostic features: (a) features that are correlated with a particular technique but are not necessarily a consequence of this technique and (b) features that are a necessary consequence of a particular technique but could also be a consequence of another technique. The analysis is intended to sufficiently narrow the range of possible alternatives by excluding those alternatives that cannot be the cause of the observed phenomena. Many features are randomly preserved on a small proportion of the pottery fragments, and thus, it is difficult to draw statistical inferences based on the evidence of these features. One diagnostic feature is prominent in this respect—the orientation of the components of the ceramic body. This can be observed and measured for every ceramic fragment. The analytical methods comprise direct visual observation and various imaging methods. Direct visual observation is carried out at three scales: macro, meso, and micro. Different scales of observation bring different types of information. Their use in combination is optimum for a reliable analysis. Various imaging methods can display what is difficult or even impossible to observe directly or what is observable at the cost of a destructive impact on the studied object. The image data can represent either the surfaces of the investigated objects or their internal structure, and 2D or 3D techniques are used in both cases. The observations related to pottery forming are most commonly classified or described in a given set of qualitative categories. The advantage of the qualitative approach is that the complex phenomena can be captured using appropriately defined categories. The quantitative approach relies on a measurable parameter or set of parameters to characterize the diagnostic features. The exact measurements have the potential to refine the analysis based on descriptive categories and create a stronger basis for scientific argumentation. However, in many cases, quantification reduces the complexity of the diagnostic features to just several aspects that can be measured. Therefore, it is important to combine the strengths of both of these approaches.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Premise

This paper contributes to the Topical Collection (TC) “Ceramics: Research questions and answers” aimed at guiding researchers in the study of archaeological ceramics from excavation to study and preservation in museum collections.

Each contribution has a tutorial approach covering one of the main issues pertaining to the study of ceramics: research questions and sampling criteria (Gliozzo 2020a); the chemical (Hein and Kilikoglou 2020) and mineralogical-petrographic (Montana 2020) investigation of raw materials; the technological character and suitability of raw materials (Gualtieri 2020); the processing (Eramo 2020) and modelling (this paper) of clays; surface finishing (Ionescu and Hoeck 2020) and ceramic firing (Gliozzo 2020b); the investigation of different coatings such as black glass-ceramic (Aloupi-Siotis 2020), terra sigillata (Sciau et al. 2020), and glazes (Pradell and Molera 2020); the isotopic study of particular types of products such as Chinese ceramics (Henderson et al. 2020); the identification of post-burial transformations (Maritan 2020); the dating of ceramics (Galli et al. 2020); and the restoration and musealization of ceramics (de Lapérouse 2020). This Topical Collection concludes with a tutorial on statistical data processing (Papageorgiou 2020).

Forming techniques in the context of pottery manufacture

Forming is one of the three principal steps in pottery manufacture. Movement of the hands and other tools causes plastic deformation of the clay, leading to the desired shape of the manufactured object. The way the clay is (de)formed causes the development of specific phenomena related to the structure of the clay body and morphology of the formed object. Some of these phenomena are visible or more generally perceivable, but the cause of their appearance is not evident for those observing the product who are unfamiliar with the forming process. In other words, it is hard to imitate the forming process only on the basis of inspection of the products of this process. This lends special importance to pottery-forming techniques in archaeological investigations. While the stylistic and morphological features of pottery can be imitated without direct assistance from the manufacturer, forming processes are transmitted by direct learning. The transmission of these ideas and related skills requires personal contact with a tutor. Individuals learn the required skills from a tutor through the observation of a model that usually represents an expression consistent with the specific technological tradition (Reed and Bril 1996; Bril 2002; Roux 2019). The dissemination of these practices has a different dynamical basis and reflects other mechanisms of cultural transmission. Only part of the human actions are based on discursive consciousness; most of them are at the level of practical consciousness—individuals know how to act in particular situations without knowing how to, or needing to, verbally express this ability. Practical consciousness represents complex and deeply rooted bonds between mind, body, and environment. It is learned without becoming an object of cognisance and thus not an object of choice (Bourdieu 1977; Giddens 1984). That is why learned moves and gestures are considered to be one of the most conservative aspects of human behaviour. Especially technological stages, which do not leave apparent traces on the finished product and that rely principally on specialized gestures, rather than tools and shared information about clay sources and recipes, are resistant to change (e.g., Nicklin 1971; Arnold 1985; Gosselain 2000).

This is why forming practices represent a suitable medium for addressing questions crossing borders of pure technological analysis. Pottery is one of the most abundant archaeological finds, and we witness high variability in the applied sequences of forming methods, which reflect individual links in the social networks in which the potters were embedded (Lemonnier 1992, 1993; Dobres 2000). Consequently, the analysis of variability and changes in pottery forming can complement the stylistic and morphological analysis in mapping a specific dimension of relations within society (Roux 2017, 2019). However, the fundamental question is whether we can reliably identify the forming practices in sufficient detail when we rely only on the archaeological evidence. The aim of this article is to explore this question.

The beginning of archaeologists’ interest in the reconstruction of pottery-forming practices goes back to the second half of the nineteenth century, when the first attempts to describe pottery forming (based on archaeological pottery) appeared (e.g., Greenwell 1877). The value of ethnographic data for the interpretation of archaeologically observed phenomena related to pottery forming was soon acknowledged (Franchet 1911; Guthe 1925; Gifford 1928). The limitations of macroscopic observations have led to attempts to supplement the research with microscopic observation, recognizing the association between forming techniques and the orientation of the components of the ceramic body (Linné 1925; Gifford 1928; Balfet 1953), and the use of radiography (Digby 1948; Balfet 1953). The foundation work laying down the framework for an analysis of forming techniques based on archaeological evidence appeared from the late 1960s (Balfet 1966; Franken and Kalsbeek 1969; Franken 1971; van der Leeuw 1976; Rye 1977, 1981; Balfet et al. 1983) and reflected the increased interest of archaeologists in technology as an important dimension of social and economic relations within society. In this endeavour, contemporary craftwork was used as an analogy for archaeological interpretation (Franken and Kalsbeek 1969; Franken 1971), or the specifics of the forming techniques was considered theoretically on the basis of their constraints (van der Leeuw 1976). The most systematic work mapping the relations between features observed on archaeological pottery and pottery-forming techniques using ethnographic examples was O. Rye’s book Pottery technology (Rye 1981). Since then, two lines of development for pottery-forming analysis can be traced: (a) the development of methods of identification of diagnostic features and (b) the development of a framework for the interpretation of the observed phenomena.

Advances in radiography techniques, coupled with increasing interest in studying internal structure to gain evidence for pottery manufacture, resulted in the extensive employment of this technique in studying pottery forming (e.g., Carmichael 1986; Vandiver 1987; Carr 1990; Carr and Riddick Jr. 1990; Henrickson 1991; Nenk and Walker 1991; Vandiver et al. 1991; Blackman et al. 1993; Vandiver and Tumosa 1995; Levi 1999; Middleton 2005; Berg 2008, 2009; Laneri 2009; Berg and Ambers 2011). Recent developments in the acquisition and computation of radiographic data have brought new possibilities for observing and analysing the internal structure of ceramic objects at different scales (Gibbs 2008; Kahl and Ramminger 2012; Machado et al. 2013; Sanger et al. 2013; Karl et al. 2014; Sanger 2016; Gomart et al. 2017; Kozatsas et al. 2018). Another technique employed in studying microstructure has been thin-section microscopy (e.g., Wirska-Parachoniak 1980; Woods 1985; Whitbread 1989, 1996; Philpotts and Wilson 1994; Capel et al. 1995; Reedy 2008; Quinn 2013) and, exceptionally, scanning electron microscopy (Courty and Roux 1995). However, pottery forming has been rather on the fringes of interest in ceramic petrography, because only a few of the phenomena observable in thin sections are related to the deformation of clay during forming and these phenomena can only be studied locally.

So far, most of the research on pottery forming has been based on qualitative classifications of the observed features. The first attempts to quantify structural phenomena related to pottery forming appeared in the 1990s (Philpotts and Wilson 1994; Pierret and Moran 1996) but were not further developed. Recently, there have been new attempts to employ a quantitative analysis of the orientation of the components of the ceramic body (Gregor and Čambal 2009; Thér and Toms 2016; Thér 2016) and to quantify radiographic data (Greene et al. 2017).

The second fundamental line of development in the field of pottery-forming analysis during the last three decades has been the construction of references using ethnoarchaeological and experimental research. In addition to the ethnographic documentation of technological variability and its relation to society, this research has been aimed at building collections of the diagnostic features associated with forming techniques, to which archaeological data could be compared (e.g., Gelbert 1994, 2003, 2005; Huysecom 1994; Pierret 1994; Roux 1994; Courty and Roux 1995; Roux and Courty 1998; Martineau 2001, 2002, 2003, 2005; López Varela et al. 2002; Hamon et al. 2005; García Rosselló 2007; Livingstone Smith 2007; van Doosselaere 2010; Dupont-Delaleuf 2011; Jeffra 2011, 2013; Gallay 2012; Rosselló and Trias 2013; Doherty 2015; Rückl and Jacobs 2016; Sanger 2016; Thér and Toms 2016; Thér 2016; Todaro 2017; Gomart et al. 2017). In connection with this new frame of reference, there is a renewed interest in the study of surface features—macrotraces (e.g., Arnold 1993; Gelbert 1994; Huysecom 1994; Roux 1994, 2019; Roux and Courty 1998; Knappett 1999; Martineau 2002; van Doosselaere 2010; Dupont-Delaleuf 2011; Gomart 2011, 2014; Choleva 2012; Méry et al. 2012; Rosselló and Trias 2013; Jeffra 2013; Doherty 2015; Rückl and Jacobs 2016; Kudelić 2020). The recent book by V. Roux Ceramics and society (2019) is the outcome of the past three decades of developments in the field of studying ceramic assemblages from a technological perspective, providing a theoretical and methodological framework for the study of pottery forming practices (and many others besides).

Classification of forming techniques and forming sequence

An appropriate classification is crucial for the analysis and interpretation of its results. It provides a framework with an adequate resolution within which the observed phenomena can be grasped. It should reflect the meaningful distinctions among the forming practices: (a) in terms of the potter’s behaviour and also (b) in terms of the visibility of its effects in the archaeological record. From the point of view of the potter’s behaviour, it is important to estimate the behavioural significance (the term is used in accordance with Schiffer and Skibo 1987) of the individual variants of forming methods. From the “visibility” point of view, it is important to consider what variants can or cannot be theoretically identified based on the archaeological evidence. Consequently, we can consider two approaches to the classification: (a) a classification reflecting the behavioural significance of the techniques and (b) a classification reflecting the effects of the forming on the products. Both these approaches are important for the meaningful study of pottery forming in archaeology. The first one is crucial for interpretation of the technological variability. It can reflect similarity or dissimilarity in the concepts of the forming and motor skills required for mastering a technique (Roux and Corbetta 1989; Roux 2019). It is a basic prerequisite for studying the diversity of the forming methods and their evolution. The second is crucial for identification of the forming techniques, as it allows the classification of the techniques according to the diagnostic features observed on archaeological pottery. The greater the correspondence between the two classifications, the better the potential for a meaningful analysis.

The entire series of actions/operations carried out to transform a clay mass into the final shape of a ceramic object is called a forming method. The basic elements from which the forming methods are composed are forming techniques. A forming technique is generally defined by the physical modalities used to transform the raw material (Roux 2019). Most of the pottery-forming classifications primarily define individual forming techniques (e.g., Shepard 1956; Arnold 1993; Orton et al. 1993; Huysecom 1994; Gosselain 1995; Livingstone Smith 2007; Santacreu 2014; Rice 2015; Cuomo di Caprio 2017; Roux 2019). However, the nomenclature of forming techniques is not uniform, which is natural given the diversity of contexts in which the individual nomenclatures were born. Even so, it is not a problem to use different names, as long as it is clear on which criteria the techniques are defined.

Complex criteria for a classification of forming techniques have been proposed and recently comprehensively published by V. Roux (2017, 2019). Her classification arises from five dichotomic variables: (a) the source of the energy used (techniques without rotational energy (abbreviated RKE) or techniques with RKE, (b) the elementary volume on which the forces act (formed from one lump of clay or formed from assembled elements), (c) the forces used in shaping (pressure or percussion), (d) the type of pressure (discontinuous or continuous), and (e) the hydric state of the clay paste (wet or leather-hard state).

The ultimate source of energy in traditional potting where only non-motorised tools are used is the human body. Work done by the human body puts the tools (hands, paddles, potter’s wheel) in motion, thus generating kinetic energy. One form of energy is specific—the RKE generated by the rotating potter’s wheel. The utilization of RKE represents the exploitation of two sources of kinetic energy: the one generated by the potter’s direct action on the material and the second generated by indirect action via the wheel (Pierret 1995). It creates forming conditions with specific deformation regimes.

Pressure and percussion are the basic physical forces causing deformation in plastic clay. The deformation varies according to the direction and intensity of the forces. Three basic types of deformations can be distinguished: simple compression; compression with a revolving movement of the deformed mass; and shear deformation (Pierret 1995; Roux 2019). These three theoretical types of deformation are combined in all the techniques based on the deformation of clay in a plastic state. Compressive deformation prevails in techniques using pressure or percussion perpendicular to the vessel wall or surface of the shaped segment, such as in pinching, slab building, beating, or moulding (Fig. 1a). Compression with a revolving movement of the deformed mass is characteristic of the initial forming of coils in the coiling technique (Fig. 1b); although, in the subsequent stage, when the coils are assembled, the other two types of deformation dominate. Shear deformation prevails when the pressure is exerted in a direction parallel to the surface of the shaped object. It is characteristic of drawing and wheel throwing. In drawing, a simple vertical movement of the hands draws the clay upwards (Fig. 1c). Wheel throwing combines two independent movements: movements of the hands and rotation of the wheel (Fig. 1d). The potter exerts continuous pressure to the clay causing a decrease in the angular speed of the wheel. Consequently, rotational energy is transformed into deformation of the clay (Pierret 1995). When the walls of the vessel are formed, the potter’s fingers at the same time resist the rotational movement and lift the clay upwards.

Actions used to model a basic object, considered as a set of physical forces acting on plastic clay during forming. a Techniques using pressure or percussion perpendicular to the vessel wall or surface of the shaped segment causing predominantly compressive deformation. b Techniques using pressure with a revolving movement of the deformed mass. c Techniques using pressure parallel to the wall margins causing a combination of shear and compression deformation. d Techniques using pressure parallel to the wall margins in combination with rotation of the formed object causing compressive and shear deformation

There are also techniques utilizing pressure to apply stress (both compression and shearing) to overcome the ultimate tensile strength of the object, resulting in separation of the object into two or more pieces (trimming, scraping, shaving). Finally, there is a forming technique that uses clay in a liquid state—for casting into a mould. The main force acting in this forming technique is gravity.

The forces employed in pottery forming are exerted by tools that can be considered to be another source of the variability of forming techniques. The same forces exerted by different tools have different physical effects on the clay being formed. The differences depend mainly on the shape and hardness of the working part of the tool.

An important source of the variability of forming techniques is segmentality (Roux’s elementary volume). This parameter refers to the number, size, shape, and structure of the segments from which the object is assembled. There is a basic dichotomy between forming from one piece of clay and forming from segments (Fewkes 1940). This distinction is important, both from the conceptual perspective of the forming process and from the perspective of the properties of the product. A segment can be characterized by its size and shape: coil, strip/band, ring, slabs of different shapes, layer, etc. A number of techniques are associated primarily with modelling from one piece of clay: pinching, drawing, moulding, and wheel throwing. It does not mean that the use of such techniques implies the building of a vessel from one piece. Separated parts of the vessel can be pinched, moulded, or wheel-thrown and then assembled (e.g., Rye and Evans 1976; van der Leeuw 1993; Cuomo di Caprio 2017; Roux 2019). The difference from segmental techniques lies in the fact that the whole part of the container is shaped from one piece of clay in the basic form in which it is incorporated into the whole vessel. Segmentally describes a whole-forming method and not the technique in this case (see below).

The actions used to assemble and finish the vessel shape represent an important constituent of forming methods and can have a significant effect on the final properties of the formed object. These actions can be characterized as the way in which the segments are joined and transformed to achieve the final shape. The simplest way to join segments is to connect the edge surfaces perpendicular to each other, which creates the shortest joints running perpendicular to the wall of the vessel (Fig. 2). Larger contact areas between segments, which are not oriented perpendicularly to the wall surface, increase the mechanical strength of the vessel. This is why, in many forming traditions, segments are joined on inclined surfaces, overlaps, or the joint shape is irregular (Fig. 2; e.g., Stevenson 1953; Vandiver 1987; Martineau 2002; Livingstone Smith 2007; van Doosselaere 2010; Gomart 2011, 2014; Todaro 2017; Neumannová et al. 2017; Gomart et al. 2017; Roux 2019). The degree of transformation of a segment depends on the differences between its initial and final shapes. A thick coil has to be transformed more than a thin one, a coil more than a slab (Fig. 3). The greater the transformation, the more probable is the destruction of the features of the initial forming of the segments. The most striking differences can probably be observed for the coiling technique. In simple coiling, coils slightly thicker than the final thickness of the wall are prepared and the shape of the vessel is created by horizontally placed coils. The wall is then completed by compression of the coils. Visible remnants of the coil joints are obliterated by displacing the clay (Fig. 4a). At the other end of the coiling spectrum is a technique in which a coil significantly thicker than the target wall thickness is placed perpendicular to the modelled wall and the clay from the coil is displaced by turning the coil while compressing it to form the next part of the wall (Fig. 4b; e.g., Gelbert 2003). The two techniques are different in all the required actions except one—shaping the initial segment, and these two variants also have significantly different effects on the microstructure of the final product.

Diversity of coiling demonstrated by two of its variants. a Coils slightly thicker than the final thickness of the wall are prepared. The shape of the vessel is coiled by horizontally placed coils. The wall is then completed by compression of the coils. Visible remnants of the coil joints are obliterated by displacing the clay. b Coils significantly thicker than the target wall thickness are placed perpendicular to the formed wall and the clay from the coil is displaced by turning the coil while compressing it to form the next part of the wall

There are other phenomena affecting the execution of techniques and their effects besides the actions and tools defining the technique itself. Above all, it is the physical properties of the formed material. Most of the techniques require more-or-less specific properties for their application. For example, it is not possible to throw a vessel if the clay is not in a certain hydric state. Many of the techniques have different effects when applied to materials with different properties. For example, scraping causes a different surface topography when applied to clay paste with a different granulometry or hygrometry. The effect of the physical properties of the formed clay should be carefully considered in the interpretation of forming techniques and their variability.

A forming method is an ordered sequence of functional operations carried out by a set of elementary gestures for which different techniques can be used (Roux 2019). The individual techniques are highly separable within the forming sequence. The individual techniques, or combinations thereof, can be viewed as structural modules whose arrangement is not dependent on other parts of the structure and can be replaced by different techniques, or might not be present in the sequence at all. Many techniques can be employed at different stages of the process. Some require a particular shape of the object on which they can be employed, but do not require a specific technique by which this shape has to be achieved. As a result, we can observe a great variability of forming methods in the ethnographic record (e.g., Drost 1967; Rye and Evans 1976; Reina and Hill 1978; Krause 1985; van der Leeuw 1993; May and Tuckson 2000; Livingstone Smith 2007).

The elementary techniques are combined in two basic ways: (a) sequentially to create a single part and (b) segmentally to create different parts.

O. Rye (1981), from the perspective of the sequence, divided the techniques into primary and secondary forming techniques and surface modifications. Primary forming techniques are actions in which the basic form of the vessel is modelled (throwing, coiling, slab building, pinching, moulding). In secondary forming techniques, the shape of the vessel is finalized, the wall is thinned, and the shape symmetry and wall uniformity are improved. The action of secondary forming also strengthens the bonds within the clay body and between segments (turning, scraping, beating, trimming, etc.). Finally, surface modifications change the texture, enhance the aesthetic character of the vessel, and improve its functional performance (smoothing, polishing, texturing …) (see also Ionescu and Hoeck 2020, in this issue). Others followed this distinction (e.g., Sinopoli 1991; Velde and Druc 1999; Berg 2008; Rice 2015; Cuomo di Caprio 2017). V. Roux (2019) distinguished between roughing-out techniques and preforming techniques, representing them as two basic stages of forming followed by finishing techniques and surface treatments. A roughout is the result of an application of roughing-out techniques—a hollow object that does not present the final geometric characteristics of the vessel. A preform is a hollow object with the final geometric characteristics. It is the result of an application of preforming techniques before undergoing the finishing operations.

The boundary between the actions used to complete the vessel shape, that inherently belong to the primary forming/roughing-out technique, and the actions classified as secondary forming/preforming, can be questionable, because in reality these two operations are often closely combined (Gosselain 1995; Livingstone Smith 2007). Completing the vessel by compressing and displacing the clay from coils with the fingers is not considered to be a separate secondary forming technique but is based on specific actions different from the initial forming of coils and has the same purpose as, for example, the use of a potter’s wheel to complete the coiled vessel. They should both be considered to play the same role in the forming sequence. Distinguishing the actions of the potter according to their relationship to the basic stages of forming, such as (a) forming the basic shape of the vessel from one bulk of clay or forming segments, (b) assembling the vessel (if it is built from individual segments), and (c) finishing the shape is important for analysis of the forming techniques and reconstruction of the forming methods.

The techniques utilizing RKE have a special position among composite techniques. Many variants of the application of rotational movement in the pottery-forming sequence can be distinguished, most of them combining several forming techniques. These methods are usually classified as combinations of two techniques applied at different stages of the forming. They are referred to as wheel coiling or wheel moulding (Berg 2009; Rückl and Jacobs 2016; Thér and Toms 2016; Roux 2017, 2019). An alternative approach is to separately define the variants of use of rotational movement and define them independently of the other techniques (Henrickson 1991; Courty and Roux 1995; Roux and Courty 1998; Roux 2003; Berg 2007, 2008; Choleva 2012; Thér and Toms 2016; Thér 2016; Thér et al. 2017). The differences in the contribution of rotational movement to the whole forming sequence are the main criterion in this classification:

-

(a).

Wheel finishing. The vessel is formed by some hand-building technique and subsequently the rotational movement is used for surface modifications and minor shape corrections, i.e., only in the finishing stage.

-

(b).

Wheel shaping. A roughout of the vessel is formed by some hand-building technique, and subsequently, RKE is used to shape and thin the vessel walls. This technique can be used in assembling and finishing the vessel.

-

(c).

Wheel throwing. The entire forming sequence is performed using RKE.

The most variable group is wheel shaping. Roux and Courty (1998) distinguished four variants of wheel coiling based on the stage of forming in which RKE is used for shaping. The first variant corresponds to wheel finishing and the other three variants to wheel shaping.

The second dimension of the structure of forming methods is the forming of different parts of the vessel (phases in Roux’s terminology (2019)). The base, body, and neck or orifice are the essential parts whose shape differences and location often lead to the choice of a different technique for their modelling. Such a procedure is usual, but not necessarily, successive.

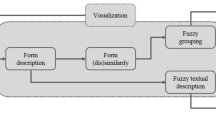

The discussions opened in this chapter result in the proposition of a modular definition of forming methods encompassing all the significant variability in the sequential and segmental dimension (Fig. 5). Forming techniques are perceived as modules, i.e., sets of mutually dependent actions independent of other modules in the forming method.

Potential archaeological evidence for pottery-forming practices

When studying pottery forming in archaeology, we must rely primarily on the products of the forming process or, more exactly, the diagnostic features observable or detectable on these products. The potential to use archaeological evidence of manufacturing tools and devices for studying pottery forming is very limited. In many forming practices, only the bare hands are used. Even if tools are employed, they are often very simple without any specific design, multifunctional, and/or made from perishable materials. One exception is the potter’s wheel. However, even for this very specific device, unequivocal archaeological finds of such devices are absent in many archaeological contexts. For example, for the whole of central Europe, there are only two examples of possible remnants of a potter’s wheel dated to the Iron Age, a period when widespread manufacture of wheel-made pottery occurred in this area. Moreover, both of the finds are problematic. The first one is a sandstone slab with numerous bowl-shaped pits on both the upper and lower surface found in Dürrnberg-Moserstein, interpreted as a foot used for anchoring the axis of a potter’s wheel to the ground (Moosleitner 1974). The second one consists of fragments of a ceramic plate found at Sopron-Krautacker. These fragments have been interpreted as remnants of a disc-like extension temporarily attached to the upper surface of the wheel head (Zeiler 2009). In both of cases, the interpretation is more speculative than that grounded on conclusive evidence. Most of the wheel components were probably manufactured from perishable materials and a meaningful study of the introduction of the potter’s wheel in central Europe cannot rely on such evidence.

Considering the products of forming, the relevant diagnostic attributes are related to the product’s structure and shape/size. All the other resulting properties by which ceramics can be characterized (Garrigós and Fernández 2017) are unaffected during forming. The aim of this chapter is not to give a complete overview of the features typical for each technique, which was recently published by V. Roux (2019). The relation between forming techniques and their effects will only be generally discussed in order to highlight their potential and limitations for the analysis of pottery forming in five basic categories: (a) surface morphology and topography, (b) variation in the wall thickness, (c) remnants of segmental joints, (d) specific fractures, and (e) alignment and orientation of the components of the ceramic body.

Surface morphology and topography

Surface shape is created by the forces applied to the clay paste during shaping. The surface features can be described and analysed using two concepts: morphology and topography. Morphology perceives hollows and protrusion on the surface as separate objects and studies their shape and distribution. Morphological features on the surface arising during the course of shaping are specific to individual techniques, but most of them represent unwanted irregularities and are obliterated during the finishing stage of forming, if not sooner. Topography perceives the surface as a continuum and, in principle, focuses mainly on the quantitative dimensional measurement of its relief (O’Connor et al. 2003; Sahoo 2011), but, in the context of the analysis of pottery forming, it is usually classified in categories related to the surface regularity and discontinuity (Roux 2019).

The principle of topographical analysis is based on the idea that surfaces, irrespective of their method of formation, contain irregularities or deviations from the intended geometrical form (Whitehouse 2002). These might be local or global. These deviations reflect the forming history of the object (if the shape was not altered during subsequent stages of the manufacture, use, or post-depositional transformations). The deviations from the ideal geometry can be intentional (for some functional or aesthetic reasons) or unintentional (caused by negligence, lack of skills or lack of motivation to achieve the intended geometry). The unintentional deviations are the most important from the perspective of the analysis of forming, because they manifest forming techniques and their mastering. In the roughing-out stage of the forming, most of the forming techniques produce a characteristic surface morphology and topography, reflecting the shape of the segments and movements of the formed clay. It could occur that the intention of the potter is to leave these features untransformed as decorative or functional elements or that the potter is satisfied with the actual shape and does not make any effort to continue the modelling (for instance, to achieve visual performance of a hand-made product in the context of current ceramic production). However, in most cases, this form of the vessel is considered insufficient in terms of function (for instance, joints between segments are not sufficiently strengthened in the given forming stage), or the aesthetical appearance and shaping continue towards the intended form. The potter stops shaping when she/he perceives that the actual form is close enough to the intended one or the potter reaches the limits of her/his skills (Budden 2008). The remaining deviation reflects the forming history. Consequently, we have three forms we can work with to distinguish what is inherently related to the employed forming techniques. The materialized form is the final form with all the deviations. The ideal form is a geometrical abstraction removing both intentional and unintentional deviations, whereas the intended form removes only unintentional deviations and is close to the potter’s mental concept of the form (Fig. 6). It is not difficult to measure the materialized form and to abstract the ideal form, but it might be a problem to distinguish the intention of the potter, i.e., to approximate the intended form. The intentional deviations from the ideal form are usually related to surface modifications (see Ionescu and Hoeck 2020, in this issue). Nevertheless, the intentional deviations could have originated from earlier stages of forming (e.g., Hegmon et al. 2000; Pierce 2005). The accentuation of such deviations is the basic indicator of their intentionality.

Three forms of a manufactured object. Materialized form is the final form with all the shape deviations. Ideal form is a geometrical abstraction eliminating both intentional and unintentional deviations. Intended form removes only unintentional deviations and is close to the potter’s mental concept of the form. In this case, it is represented by a combination of the ideal form and intentional texturing of the surface

Variation in wall thickness

There are two kinds of variations in wall thickness: local and global. Local variation is closely related to the surface morphology and topography. Surface shapes and features are manifested by variability in the wall thickness, and consequently, the study of local thickness variability is topographical analysis based on 2D-shape representation in radial sections. The study of the local wall thickness variation can be viewed as a contextual topographical analysis of both surfaces: the exterior and interior, which increases the information value of the topographical analysis.

The global variation refers to the difference in wall thickness within the entire vessel. There are correlations between patterns in global thickness variability and some of the forming techniques. For instance, gradual thinning of the walls from bottom to top should be characteristic for pinching or wheel throwing (Rye 1981), but this does not mean that it is not possible to form a vessel with even thickness with these techniques. These features depend on the skills and style of the potter.

Remnants of segmental joints

Joints between segments may appear as a structural discontinuity on the sherd edges or sections, topographic discontinuities on the surface of the vessel wall (then they are classified as part of the surface morphology), or by a specific morphology on the connecting areas of the separated segments (Fig. 7). They represent strong evidence for specific segmental-forming techniques. The preservation depends on the forming practice, especially on how and in what stage of forming the segments are connected, on the degree and manner of the transformation of the segments during the building of the vessel, and on practices of surface modification. Consequently, the random preservation, usually with small frequencies, limits their use for assessment of technological variability.

Basic manifestation of segmental joints. a Structural discontinuity on the sherd edges (Bylany, Czech Republic, Early Neolithic). b Topographic discontinuity on the surface of the vessel (Tuněchody, Czech Republic, Early Iron Age). c Specific morphology on the connection areas of the separated segments (Turnov, Czech Republic, Late Bronze Age)

Specific fractures

Vessels tend to break along the joints due to the structural weaknesses in the areas where the segments are connected. They represent less conclusive but more frequent evidence of segmental forming techniques than remnants of segmental joints. The specificity of the fracture derives from its position, orientation, and geometry (straight and horizontally or vertically oriented). It can be easily mistaken for a random fracture because the morphology of the fracture itself is not specific. If fractures are to be used as markers of some forming technique, there has to be a statistically non-random repetition of the phenomenon within the assemblage, or the geometry of the fractures has to preclude their random occurrence (Fig. 8).

Alignment and orientation of components of a ceramic body

Alignment and orientation are principal structural characteristics resulting from forming. The relationship between forming techniques and the orientation of inclusions and voids has long been recognized (Linné 1925; Gifford 1928; Felts 1942; Balfet 1953; Shepard 1956; Bordet and Courtois 1967; Rye 1981; Woods 1985; Whitbread 1996). The application of physical force to the plastic clay during forming is the main factor affecting the alignment of the components of ceramic materials. The forming force induces compression and/or shear stress in the material. The compression rotates elongated particles towards the normal perpendicular to the major stress axis and deforms the shape of voids so that their dimension parallel to the major stress axis decreases relative to the dimension perpendicular to this axis. Thus, the deformation by compression stress results in objects being aligned perpendicular to the major axis of the stress, whereas shear stress results in alignment along the direction of shear (Vyalov 1986; Pierret 1995). The resulting alignment of inclusions and voids is characteristic of each forming technique, although some orientation patterns might result from more than one technique (for an overview of the assumptions for particular techniques, see Rye 1981; Carr 1990; Courty and Roux 1995; Whitbread 1996; Middleton 2005; Livingstone Smith 2007; Berg 2008).

These effects are usually documented in two sections cutting the vessel wall. The first section is perpendicular to the wall surface in the plane parallel to the height of the vessel (radial section in relation to the vessel) and the second section is tangential to the vessel wall (tangential section) (Fig. 9; Rye 1981; Woods 1985). In addition, horizontal sections were used to characterize typical orientation patterns (Woods 1985; Vandiver 1987; Whitbread 1996). The horizontal sections are the least informative. The orientation pattern would depend strongly on the position of the section: a section cut in the area of a joint would theoretically exhibit different orientation than a section cut through the body of a coil or slab. Moreover, less specific orientation for individual techniques can be expected in this section (Whitbread 1996).

Typical orientation patterns for individual forming techniques on radial and tangential sections. a Pinching leads to orientation typical for techniques using predominantly pressure or percussion perpendicular to the vessel wall (hereinafter referred to as compressive techniques) with one specific feature. They are typified by strong alignment parallel to the vessel wall in radial sections. Weak but statistically significant vertical orientation can be observed in tangential sections. This corresponds with the movements of the hands supplementing the basic compression. If a particular vessel shape is to be formed, the compression is not sufficient to form and maintain the shape. To control the development of the shape, the potter uses counter compression acting in the horizontal axis of the vessel wall. This wall contraction prevents unintended expansion of the vessel diameter and causes the preferred vertical orientation. The use of contraction movements is more extensive when the potter forms the part that restricts the opening of the vessel. This part should display greater vertical orientation than the lower parts (Fig. 1a; Thér 2016). b Slab building should exhibit orientation typical for compressive techniques. The differences from ideal orientation patterns depend on the shape of the slab and degree of transformation of the slabs during the building of the vessel. For example, to form uniformly thick slabs with a regular shape, the pressure perpendicular to the longitudinal faces of the slab needs to be combined with pressure perpendicular to the slab edges, causing alignment parallel to the edges at the margins of the slab. The effect of this slab shaping results in a tendency towards horizontal alignment in the tangential section and distortion of the parallel alignment in the radial section (Thér et al. 2019). c Beating is usually not used for the initial forming. Thus, it transforms the orientation induced by the initial forming towards the orientation characteristic of compressive techniques. d Moulding is the last representative of the compressive techniques. Theoretically, it should exhibit the most ideal orientation pattern of this group, because there is no need to combine the perpendicular pressure with other forces during pressing the clay into the mould. The development of the shape is controlled by the shape of the mould and thus no shape-correcting movements are needed. e Coiling differs from compression techniques in both the sections. Non-aligned objects in perpendicular- and horizontally aligned objects in tangential sections reflect the orientation of inclusions and voids in coils if the coils are placed horizontally during the vessel building. The problem is that coils are usually highly transformed by compression and shear deformation during building the vessel, which causes transformation towards the orientation pattern of compression techniques (Thér et al. 2019). f Wheel throwing combines compressive and shear deformation in a direction resulting from the combination of rotational movement of the wheel with the lifting movement of the fingers, which causes a diagonal orientation of inclusions and voids in tangential sections. For a radial section, the upper ends of the objects in the marginal zones of wheel-thrown pottery incline inwards towards the core of the wall. This phenomenon has been termed an “imbricate pattern” (Thér and Toms 2016; Thér 2016). It is caused by shear stress induced by upward movements of the fingers during wheel throwing. The clay mass at the margins moves more rapidly during lifting than the mass in the core of the wall. Therefore, marginal zones can be seen as shear zones with a predominance of shear stress. Shear stress can cause a turbulent shear mode. Particles are forced to undergo rotational movement under the influence of shear-generated torques (Lupini et al. 1981; Hiemstra and Rijsdijk 2003). g Vertically oriented shear deformation predominates in drawing. Upward movement of the hands causes vertical alignment in tangential sections. In a radial section, a similar alignment pattern to that in wheel throwing can be expected. This theoretical assumption is not yet based on experimental data

The orientation patterns shown in Fig. 9 are theoretical, based on the force acting in forming the basic object, its parts, or segments. The resulting structure of the vessel wall is affected by other factors associated with the forming method related to (a) preparation of the clay paste prior to forming, (b) shaping the vessel or segments, and (c) assembling the vessel from segments (in the case of segmental techniques).

-

(a)

Preparation of the clay paste prior to forming. The alignment is introduced into the clay paste during its preparation when the raw materials are mixed and the lump of clay is kneaded. This initial alignment more or less affects the final structure of the formed object. Its effect depends on the degree of subsequent deformation of the clay object (see below). Usually, the initial alignment affects the resulting alignment randomly because the piece of clay to be formed is taken from the lump randomly; thus, it has no potential to cause a specific trend in the orientation, confusing the interpretation of the data. Moreover, it is likely that this effect is not sufficiently significant to prevent discernibility of the orientation resulting from the shaping of the segment and subsequently the vessel. One exception of purposeful pre-orienting of the clay components prior to forming is wheel throwing. Skilled potters prebuild the structure of the clay components during kneading and centring the clay on the wheel head (e.g., Cardew 2002; Hamer and Hamer 2004; Carter 2016). By ram’s head or spiral kneading, the components of the clay are aligned in a spiral that winds around the axis of rotation of the lump during the kneading. After kneading, the lump is positioned on the wheel head so that the axis of the wheel rotation corresponds to the axis of rotation of the lump during kneading and the particles are preferentially oriented in the direction of the wheel rotation, leading to a decrease in the resistance force in the formed clay during throwing. In theory, the products of potters who employ this prebuilding will show higher alignment compared with those who do not employ it, but experimental research has not yet confirmed this (Thér and Toms 2016).

-

(b)

Shaping the vessel or segments. Development of the characteristic particle orientation depends on the amount of work needed to transform the bulk of the clay into the final shape of the object/part/segment. The degree of transformation of the original clay mass is reflected in the ratio of the amount of clay to be formed and the wall thickness. The ratio roughly represents the theoretical amount of work required to transform the clay mass into the final object. The higher the ratio, the greater is the degree of transformation. Shaping a small amount of clay into a thick segment causes a less developed characteristic microstructure than shaping a larger amount of clay into a thin segment.

-

(c)

Type and degree of transformation of the segments during building the vessel. When coils, slabs, or any other segments are assembled, deformation is applied to obliterate the joints between them and to attain the desired shape and wall thickness. If the force involved in this deformation acts in different directions or has different effects than the force involved in the primary forming of the segments, it might obscure the orientation and alignment created in the previous stages (Thér et al. 2019).

Description and interpretation of pottery-forming practices

Many of the above-mentioned diagnostic features are ambiguous and randomly preserved. Their detection and interpretation is complicated by the common practise of combining several techniques during the forming and finishing of ceramic objects. This aspect has to be reflected in designing the research. The first step in the analysis is answering three basic questions: (a) what are we looking for, (b) what is the evidence needed to find it, and (c) what is the possibility of finding this evidence in the given archaeological context.

Two basic aims of the analysis can be distinguished: (a) a reconstruction of forming methods or (b) differentiation among technological styles. These two aims may look similar, but they indicate a significant difference in the way the diagnostic features are used. When looking for a specific forming technique, the informative value of the features diagnostic for the individual techniques has to be carefully considered. Whether the feature allows alternative explanations to the explanation we plan to use is crucial for reliable interpretation. It is necessary to explore the interpretative limits of the features. For example, if the prime interest of the research is to estimate the proportion of wheel-thrown pottery, the global variation in wall thickness would not be a useful feature to look for, because such a variation can be caused by other techniques and, moreover, is not a necessary consequence of wheel throwing. On the other hand, such a variation in thickness could be a possible marker of the variability that is worth examining if the research is aimed at differentiating forming styles within wheel-made pottery. Some features mark a potter’s style irrespective of whether they can be clearly associated with a particular forming technique.

There are two sources of misinterpretation defining two classes of ambiguous diagnostic features:

-

(a)

Features that are correlated with a particular technique but are not necessarily a consequence of this technique. The shape of the vessel and global variation in thickness are typical features of this kind. Correspondence between vessel shapes and forming methods has been observed (Rye 1981; Balfet 1984; van der Leeuw 1993). However, the fact that, for example, globular shapes naturally arise from pinching does not mean that other shapes cannot be modelled using this technique and that these shapes cannot be formed using other techniques. The same is true for the global thickness variation. It is impossible to use this attribute to identify a specific forming technique, while it can be used as a marker of a technological style.

-

(b)

Features that are a necessary consequence of a particular technique but are also a consequence of another technique (Fig. 10). For example, poor alignment of components of the ceramic body in tangential sections is the consequence of forces applied when the vessel is modelled by pinching, but also by moulding, beating, or slab building. If the aim is to decide among these alternatives, then another feature is needed that allows for their distinction, for instance, the remnants of joints.

The observability of features is another complicated aspect of the analysis. Features like segmental joints or tool imprints on the surface are usually randomly preserved on a small proportion of pottery fragments. The absence of these features does not mean that the respective forming technique was not employed. It could simply mean that the segments were so carefully connected and surface modified that these features are not usable manifestations of this technique. Consequently, it is difficult to draw statistical inferences based on the evidence of these features. One diagnostic feature is prominent in this respect—the orientation of the components of the ceramic body. This can be observed and measured on every ceramic fragment, but we must not succumb to the belief that what can be measured can also be clearly interpreted (Thér et al. 2019).

Analysis of pottery forming relies on a palimpsest of diagnostic features often with limited informative value bringing a number of interpretive problems. It draws attention to the need for careful selection of a suitable set of diagnostic features and its critical assessment allowing for a sufficient narrowing of interpretive possibilities in relation to the objective(s) of the analysis.

Experimental replication and observations made in recent technological contexts are crucial for the critical evaluation of the information value of the diagnostic features and for their reliable interpretation. Many researches engaged in the study of pottery-forming techniques implement experimental or ethnoarchaeological research as a way of validating their interpretations or even more basically of finding a key for interpretation. The experiments or ethnoarchaeological research are usually designed to test technological hypotheses arising from the analysis of the archaeological evidence (Roux and Courty 1998; Martineau 2001, 2002, 2003; López Varela et al. 2002; Hamon et al. 2005; van Doosselaere 2010; Dupont-Delaleuf 2011; Jeffra 2011, 2013; Doherty 2015; Rückl and Jacobs 2016; Sanger 2016; Todaro 2017; Neumannová et al. 2017; Gomart et al. 2017; Thér et al. 2019). The testing of a hypothesis is not a mere verification that the hypothetical technological process causes the observed phenomena. The experiments should also be designed to reflect both of the above-mentioned sources of ambiguity in interpretation, i.e., (a) to explore the correspondence between techniques and observable features and (b) to investigate alternative explanations for features. The experiments can also be designed irrespective of the archaeological evidence to study the effects of the forming techniques on the products of manufacture in general (Gelbert 1994, 2003, 2005; Pierret 1994; Roux 1994; Courty and Roux 1995; Martineau 2005; García Rosselló 2007; Livingstone Smith 2007; Gallay 2012; Rosselló and Trias 2013; Thér and Toms 2016; Thér 2016). Such research makes it possible to map possible diagnostic features and to assess their informative value. The result is a reference collection of these features with known relationships to factors affecting their development or a quantification of the effects of the forming techniques.

Capturing morphology, topography, and structure

All the methods used for analysis of pottery forming are oriented towards the detection and imaging of morphological, topographical, and structural phenomena.

Direct visual observation

The most common technique is visual inspection and description of the observed phenomena (e.g., Knappett 1999; Martineau 2002; van Doosselaere 2010; Dupont-Delaleuf 2011; Gomart 2011, 2014; Choleva 2012; Méry et al. 2012; Rosselló and Trias 2013; Jeffra 2013; Doherty 2015; Rückl and Jacobs 2016; Roux 2019; Kudelić 2020). Direct visual observation is carried out at three scales: macro, meso, and micro (Roux 2019).

The macroscopic scale includes observation with the naked eye combined with low-angle light to reveal surface features. The observed diagnostic features are related mainly to the surface relief and other morphologic phenomena, specific fractures, remnants of segmental joints, and variations in the wall thickness. Macroscopic observation is a non-destructive, quick, and cheap analytical technique. Thousands of sherds can be inspected, and thus, this practice is crucial for understanding the technological variability. This application depends on the visibility of the diagnostic features. It has limited use in those manufacturing traditions where surface modification carefully obliterates all the readily visible features left by preceding forming techniques. The low cost, speed, and sensitivity are a powerful combination and, in this task, visual inspection is insuperable, but it needs to be complemented by other methods that can validate the results and yield more reproducible and interpretable results.

The microscopic scale of observation is focused on the study of the internal structure of the ceramic body—the organization of the components of the clay paste acquired during forming. It is necessary to obtain oriented sections through ceramic objects to directly observe the structure. The most common technique is the preparation of petrographic thin sections and their observation using optical microscopy (e.g., Bordet and Courtois 1967; Wirska-Parachoniak 1980; Woods 1985; Philpotts and Wilson 1994; Capel et al. 1995; Whitbread 1996; Reedy 2008; Quinn 2013). The structural features (called texture in the context of thin section analysis) are usually observed under low magnification (up to × 40). Indeed, the destructiveness of this technique imposes a practical limit on this approach. Moreover, phenomena can be studied only locally due to the limited size of the sections.

Observation on a mesoscale is focused on structural and micro-topographical phenomena. Observation on this scale is carried out at low magnification (up to × 20) and is usually focused on fresh radial sections to observe microstructural phenomena such as the alignment and orientation of elongated voids and larger grains, networks of larger voids and grains, and relationships of structurally different areas (Roux 2019). Mesoscopic observation is a non-destructive technique; although, when there are no suitable breaks on sherds to observe the ceramic fabric, a fresh break can be created using pliers, a chisel, or a small hammer (Whitbread 2017), or plain sections can be prepared (Ross et al. 2018). Mesoscopic observation can also overcome some of the limitations of observations at the two other scales: (a) poor observability of structural phenomena on a macroscopic scale, on the one hand, and (b) the cost, destructiveness, and time demands of microscopic observation, on the other.

The three different scales of observation are complementary. Each of them brings different types of information. Therefore, their use in combination is optimal for reliable analysis.

Imaging methods

Images, usually captured in visible light, are commonly used to document what is directly observed at each of the previously mentioned scales of observation, but imaging methods offer far broader possibilities for the analysis than mere documentation. Various imaging methods can display what is difficult or even impossible to observe directly or what is observable at the cost of destructive impact on the studied objects. If the images are adequately taken and processed, they can be used for quantification of the diagnostic features and their arrangement. The image data can represent either the surfaces of the investigated objects or their internal structure, and 2D or 3D techniques can be used in both cases.

A variety of metrology systems are available for non-contact acquisition of 2D and 3D data representing the surface at various scales. All of them are non-destructive techniques, unless the size of the investigated object needs to be reduced due to the size of the working area of the device or chamber. The choice of one of these systems depends on the scale of the observation and the purpose of the analysis. Several systems yield 3D representation on a nanometre-level resolution (confocal microscopy, low coherence interferometry, scanning electron microscopy, scanning probe microscopy, etc.), but most applications related to the study of pottery-forming techniques do not require such large resolution and it is preferable to study a wide area of a larger sample, or even the whole object (both sides of the vessel wall or the entire shape). The required resolution usually ranges between 0.1 μm and 0.1 mm according to the type of features to be captured and analysed. Photogrammetry (Barreau et al. 2014) or various optical profilometers and scanners based on laser triangulation or structured-light can be used in this resolution range. The choice of a suitable device depends on the aims of the analysis. Optical profilometers are an optimal tool for acquiring a representation of the surface with greater accuracy to investigate local topography (Fig. 11; Montani et al. 2012; Artal-Isbrand and Klausmeyer 2013, although so far has not been employed directly for pottery-forming analysis). On the other hand, stationary or handheld 3D scanners might be an appropriate choice, despite the lower accuracy when the flexible acquisition of a 3D representation of an entire solid is required to investigate the topography at the macro and mesoscopic scale, or the variability in wall thickness (Karasik and Smilansky 2008; Lami et al. 2016; Fragkos et al. 2018; Wilczek et al. 2018).

A very simple and efficient way to investigate the structure of a ceramic object is imaging using ordinary desktop scanners (Velde and Druc 1999; Ross et al. 2018). In order to acquire measurable images, plain-oriented sections perpendicular to the wall surfaces need to be prepared (radial sections). Ross et al. (2018) prepared a thick-section for this imaging, which facilitates the scanning of multiple samples at once to speed up the process. Moistening the surface of the thick section can improve the visibility of features in the scanned image.

Non-destructive imaging of the internal structure is provided by X-ray imaging (e.g., Rye 1977; Carmichael 1986; Vandiver 1987; Carr 1990; Carr and Riddick Jr. 1990; Henrickson 1991; Nenk and Walker 1991; Vandiver et al. 1991; Blackman et al. 1993; Vandiver and Tumosa 1995; Levi 1999; Middleton 2005; Berg 2008, 2009; Laneri 2009; Berg and Ambers 2011, 2017; Greene et al. 2017). This technique is used to obtain a complex picture, as the entire object can be X-ray imaged, although with limited resolution. The method is well suited to an investigation of porous structures within sherds, because of the high density contrast between solids and voids. On the other hand, the density contrast between a majority of non-plastic mineral particles and the clay matrix is often low and it is difficult to visualize them clearly. Another problem is that in standard X-ray images, overlapping features are projected together and interfere. Some of these problems can be overcome by using X-ray computed tomography (CT) scanning (Gibbs 2008; Kahl and Ramminger 2012; Machado et al. 2013; Sanger et al. 2013; Karl et al. 2014; Kulkova and Kulkov 2016; Sanger 2016; Gomart et al. 2017; Kozatsas et al. 2018; Bernardini et al. 2019). CT scanning combines many X-ray measurements taken from different angles to compute a 3D model. Gaining 3D representation of the microstructure provides the opportunity to work with 3D models of particles and voids and, once the scan is completed and the model constructed, it is possible to virtually cut a cross-section through the samples in any direction to produce the required sections. The disadvantage of this technique is similar to those of X-ray imaging, related to the similarities in material densities, although sections extracted from CT 3D models yield a clearer distinction between the particles and the matrix than single X-ray image projections (Fig. 12c, d). For analysis of the material microstructure, devices equipped with X-ray sources with small diameter focal spots that achieve object resolutions down to the submillimetre range (X-ray microtomography or μ-CT) are particularly useful. Resolution up to 100 μm per pixel is suitable for surveys of coarse and highly porous ceramic materials (Kahl and Ramminger 2012; Sanger et al. 2013; Neumannová et al. 2017; Kozatsas et al. 2018). Application to fine-grained ceramic materials has also been demonstrated (Karl et al. 2014), but quantification of the textural phenomena is more complicated as small voids and particles require higher resolution. Because the scanned sample needs to be rotated close to the roentgen source to achieve high resolution, usually, the size of the ceramic sherds has to be reduced to meet the required parameters and thus the analysis becomes destructive. CT can also be used to investigate the shape and topography of the ceramic object surfaces, especially where some parts of the object are inaccessible to other methods (Karl et al. 2014).

Examples of the results of various imaging techniques capturing the internal structure of a ceramic body. a Optical microscopy of a thin section showing diagonal alignment of elongated particles and voids typical of wheel-throwing (experimental sample made of fine-grained clay); b scanning electron microscopy of thin section depicting a fragment of the Neolithic pottery from Bylany (Czech Republic); c X-ray image and d micro-CT scan of the same sample showing an “imbricate pattern” typical for wheel-thrown pottery (experimental sample made of clay tempered with horse dung)

A few attempts have been made to also use scanning electron microscopy to identify the orientation of the clay matrix and inclusions (Courty and Roux 1995; Felicissimo et al. 2010) or to measure the velocity of ultrasonic wave propagation in clay bodies to detect changes in the density of the material (Dobrzańska and Piekarczyk 2005).

Qualitative and quantitative approach to analysis

The observations related to pottery forming are most commonly classified or described in the given set of qualitative categories. The advantage of the qualitative approach is that complex phenomena can be captured using appropriately defined categories. The ability of human beings to perceive similarities and differences is very sensitive. In many cases, we sense differences that are hard to detect or measure even using sophisticated analytical techniques. On the other hand, classification depends on the abilities and experience of the researcher and there is a risk of subjectivity and the low reproducibility of results.

To avoid subjectivity, it is crucial to carefully distinguish between description and interpretation. These two stages must not interfere with one another. Clear rules for objective formal description of the observed phenomena must be defined. In a formal description, complex phenomena should be decomposed into basic elements or their parameters and described separately.

The quantitative approach relies on a measurable parameter, or set of parameters, to characterize the diagnostic features. This approach places greater demands on the quality of the data obtained by the imaging methods. Exact measurements have the potential to refine the analysis based on descriptive categories and create a stronger basis for scientific argumentation. However, quantification in many cases reduces the complexity of the diagnostic features to only a few aspects that can be measured. Therefore, it is important to combine the strengths of both approaches. So far, the quantitative approach has not been widely employed and its potential is far from being exploited. Significant development of the methodology in this area can be expected.

Computational procedures used to characterize surfaces in material sciences can be useful for quantitative characterization of surface morphology and topography. Among them, measurement of the surface roughness is a basic way to quantify the topography (Bhushan 2001; Sahoo 2011). So far, it has been employed to investigate the surface finish, not the effects of transformation in the earlier stages of forming (Ionescu et al. 2019). Wavelet (Chen et al. 1995; Lee et al. 1998; Bruzzone et al. 2004) or fractal analysis (Majumdar and Tien 1990; Zhou et al. 1995; Podsiadlo and Stachowiak 2002; Borodich and Evans 2013) has also the potential to quantify topographic phenomena related to pottery forming. Methods employed in computational geography—positive/negative openness, sky view factor, etc.—could also be useful for visualizing morphological features on the surface (Zakšek et al. 2011; Doneus 2013). So far, these techniques have been used for analysis of the shape of artefacts (e.g., Wilczek et al. 2014; Wilczek 2017) or in landscape archaeology (e.g., Monna et al. 2018). The first attempts to use the computational methods for the visualization of the pottery forming diagnostic features based on X-ray images have been made (Greene et al. 2017), but their potential for the pottery-forming analysis has not yet been explored to its full extent.

One of the most important features for the analysis of forming techniques is the alignment and orientation of the components of the ceramic material. Suggestions have been made for quantification of the orientation in ceramic petrography (Philpotts and Wilson 1994; Whitbread 1996; Gregor and Čambal 2009). Pierret and Moran (1996) proposed a method for measuring the orientation of the individual pores based on X-ray images, but the method was not further developed and applied. Recently, quantification based on the analysis of thin section images has been developed (Thér and Toms 2016; Thér 2016; Thér et al. 2019).

The captured images resulting from either thin section or CT imaging can be subjected to automatic processes separating the components of the ceramic material based on their specific brightness and colour qualities. Thresholding is a basic method for this extraction. It converts a greyscale or colour image into a binary image based on threshold values. The separated objects can be characterized by a set of descriptors relevant to the analysis. For the analysis of forming techniques, the most important feature is the orientation of the object, complemented by its size and elongation. The appropriate statistical measures of the orientation pattern are (a) the mean direction – the average orientation of objects and (b) the circular standard deviation (CSD)—the dispersion of the values around the average value (Fig. 13; Fisher 1993; Mardia and Jupp 2000).

Polar diagram showing the results of orientation analysis. Each point in the diagram is determined by the angle from a reference direction, which represents the mean direction of the objects of the given sample, and the distance from the centre of the circle which represents the CSD values. The points more distant from the centre of the circle have less aligned microstructures. The axial data consist of an undirected line; therefore, the data are represented by both possible directions, i.e., each sample is plotted by a pair of points. This diagram shows a comparison of the orientation of inclusions and voids for selected forming techniques in tangential sections from the lower parts of experimental vessels. WF wheel finishing, WS wheel shaping

Mean direction and CSD reflect only linear alignment. For example, if the objects are arranged in arcs, the sample will show a similar CSD to that of randomly aligned structures and the mean direction is a meaningless parameter in this case. The specific shape of the alignment can be discovered using interpolation methods (Morphet 2009). The orientation of the captured particles is used as known values to estimate the alignment trends in each area of the section (Fig. 14).

Alignment in a radial section of the sample of wheel-thrown pottery interpolated using circular kriging based on extracted objects used for calculation of the orientation. a Image used for analysis. b Result of interpolation calculated using the “SpatialCircular” R package (Morphet 2009)

Conclusions

Pottery-forming practices represent a suitable medium for addressing questions related to understanding past societies. Analysis of the variability and changes in pottery forming can complement a stylistic and morphological analysis in mapping a specific dimension of relationships within a society. To fulfil this aim, we must depend on a reliable methodology of identification of forming practices based on archaeological evidence. This is not an easy task because, although many theoretical diagnostic features are observable on archaeological pottery, many problems are also associated with their interpretation.

An important part of the analytical process is an appropriate classification of forming techniques and a description of forming methods. The methods can be decomposed into basic modules. The modules can be either individual techniques, or combinations thereof, whose arrangement is not dependent on other parts of the forming method, and can be replaced by different techniques, or might not be present in the sequence at all. Such an approach is based on the fact that there is a high separability of the techniques within the pottery-forming sequence. This provides a flexible tool to describe the complex reality of forming practices, thus fully reflecting the associated effects observable on archaeological pottery.

The link between the technique and the resulting features is frequently ambiguous. Analysis of pottery forming relies on a complicated palimpsest of diagnostic features bringing a number of interpretive problems. Careful selection of a suitable set of diagnostic features and its critical assessment, one that allows a sufficient narrowing of interpretive possibilities in relation to the objective(s) of the analysis, is crucial. Experimental and ethnoarchaeological research will play a key role in this pursuit.

The combination of a qualitative approach, which allows the capture of complex phenomena, with a quantitative approach that has the potential to refine the analysis based on descriptive categories, creates a stronger basis for scientific argumentation. The recent development of computing procedures and technology, as well as the corresponding developments in imaging technologies, offers the means of obtaining fast, accurate, and quantifiable data. Many of the phenomena that have previously been classified qualitatively can now be quantified.

Data availability

Data sharing is not applicable to this review article as no new data were created or analysed in this study.

References

Aloupi-Siotis, E. (2020). Ceramic technology. How to characterise black Fe-based glass-ceramic coatings. Archaeol Anthropol Sci [this topical collection]. https://doi.org/10.1007/s12520-020-01134-x

Arnold DE (1985) Ceramic theory and cultural process. Cambridge University Press, Cambridge

Arnold D (1993) Techniques and traditions of manufacture in the pottery of ancient Egypt. In: Arnold D, Bourriau J (eds) An introduction to Ancient Egyptian pottery. Von Zabern, Mainz am Rhein, pp 11–102

Artal-Isbrand P, Klausmeyer P (2013) Evaluation of the relief line and the contour line on Greek red-figure vases using reflectance transformation imaging and three-dimensional laser scanning confocal microscopy. Stud Conserv 58:338–359. https://doi.org/10.1179/2047058412Y.0000000077

Balfet H (1953) Note sur le façonnage des poteries préhistoriques. Bull Société Préhistorique Fr 50:211–217. https://doi.org/10.3406/bspf.1953.3031

Balfet H (1966) La céramique comme document archéologique. Bull Société Préhistorique Fr Études Trav 63:279–310

Balfet H (1984) Methods of formation and shape of pottery. In: van der Leeuw SE, Pritchard AC (eds) The many dimensions of pottery: ceramics in archaeology and anthropology. Institute for Pre- and Proto-history, University of Amsterdam, Amsterdam, pp 171–197

Balfet H, Fauvet-Berthelot M-F, Monzon S (1983) Pour la normalisation de la description des poteries. Editions du Centre national de la recherche scientifique, Paris

Barreau J-B, Nicolas T, Bruniaux G et al (2014) Ceramics fragments digitization by photogrammetry, Reconstructions and applications. In: In: International Conference on Culturage Heritage, 2014th edn. EuroMed, Lemessos

Berg I (2007) Meaning in the making: the potter’s wheel at Phylakopi, Melos (Greece). J Anthropol Archaeol 26:234–252. https://doi.org/10.1016/j.jaa.2006.10.001

Berg I (2008) Looking through pots: recent advances in ceramics X-radiography. J Archaeol Sci 35:1177–1188. https://doi.org/10.1016/j.jas.2007.08.006

Berg I (2009) X-radiography of Knossian Bronze Age vessels: assessing our knowledge of primary forming techniques. Annu Br Sch Athens 104:137–173