Abstract

A bronze assemblage consisting of weapons, tools, ornaments, and horse furnishings from many Early Iron Age (EIA) sites of Central Kazakhstan was examined for microstructure and chemical compositions. All of the objects under investigation were made of copper alloys with the addition of either tin or arsenic or both, but no lead. Tin served as the preferred alloying element for making key functional and prestige items as opposed to arsenic primarily in service to meet a large demand for various horse trappings. Strong evidence has been found of a new method implemented for the mass production of copper alloys containing up to approximately 10% arsenic based on mass. This high arsenic technology was apparently introduced in keeping with the increased demand for bronze, particularly in horse-related objects, as a means to spare costly tin for use in making more important objects in functional and social perspectives. The use of arsenic in this case is indicative of significant technological and social transformations occurring in Central Asian EIA communities. We will present a detailed account of the analytical results to propose that these changes signified the establishment of mature mobility-based societies in the steppes that encompassed more people and larger territories within a setting of enhanced conflicts and social stratification.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

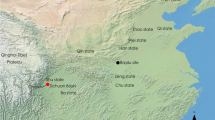

The most conspicuous episode of the Early Iron Age in Central Kazakhstan (Fig. 1) may have been the appearance of the steppe nomads early in the first millennium BC. This event has long since defined the cultural and sociopolitical environment of the region until today. At this critical moment, corresponding to the Saka period (eighth–third century BC), Central Kazakhstan saw the rise and establishment of nomadic communities with a unique lifestyle based on horse riding and animal husbandry. This way of life called Tasmola culture (Kadyrbaev 1996) is well known for its unique long-lasting burial architecture (Fig. 2) that endured few changes throughout its entire existence. The Tasmola cemeteries consist of up to around 3–15 barrows, each of which was built in the form of a rounded hill with a varying scale of 10–60 m in diameter and 0.5–6 m in height (Beisenov 2014, 2015; Chang 2018; Yablonsky 1995). Comprehensive excavation of these burials began only recently (Beisenov 2013, 2015) along with numerous ancient settlements of this culture (Beisenov et al. 2017). The analyses of materials from more than 200 such excavations have produced strong evidence of a connection between the Tasmola population and the previous Bronze Age communities (Beisenov et al. 2015). Now, on the basis of archeological materials and a large collection of radiocarbon data (Beisenov 2018; Beisenov et al. 2016b), the Tasmola culture is dated to the eighth–fifth century BC. Tasmola elite burials often have a peculiar subsurface entrance passage, called dromos, leading to the main burial space. This structure, which in most cases is approximately 15 m long and oriented toward the East or South-East, is unique to the general Saka cultures established in the territory of Kazakhstan. It demonstrates their connections with the cult of the Sun and the cult of the East (Beisenov et al. 2016a). The variability apparent in the scale of the burial mounds and certain exotic objects concentrated in some select graves point to the emergence of complex societies based on enhanced social stratification. Signs of inequality in social status, ranking, and wealth were already evident in the scale of the burial architecture and the quality of the burial goods from the preceding Late Bronze Age (LBA) Begazy-Dandybai culture (fifteenth–tenth century BC), which in Central Kazakhstan constituted a bridge between the Andronovo culture and the Tasmola culture. Burials in the later Korgantas phase (fourth–second century BC) of the region are distinguishable from Tasmola burials by their smaller scale and modified structure (Beisenov 2017).

Map showing the locations of the thirteen Tasmola and one Korgantas archeological sites mentioned in the text, with the particular region in central Kazakhstan indicated on the general Kazakhstan map presented in the inset. On the map, Myrzhyk is located at 1, Nazar at 2, Kosoba at 3, Akbeyt at 4, Bakybulak at 5, Sarybuirat at 6, Taisogan at 7, Edirei at 8, Karashoky at 9, Birlik at 10, Maykuben at 11, Zhamantas at 12, and Sati at 13. The only Korgantas site at Bidaik is located at 14

One of the outstanding features clearly visible in artifact assemblages from Tasmola burials and settlements is the abundance of bronze objects with varying purposes, which can be classified into weapons, tools, decorations, mirrors, and horse-related artifacts. Central Kazakhstan is famed for its huge copper ore deposit, which has a long history of exploitation from the Bronze Age onward. For instance, an ancient open pit copper mine in the region at Kenkazgan had a quarry 500 m long and 80–100 m wide with a depth in ancient times estimated at around 30 m, corresponding approximately to 800,000 tons of ore production (Berdenov 2008). Given the key role of copper and bronze production in the establishment of material culture in the Bronze Age and afterwards, which is particularly true in Central Kazakhstan, Tasmola bronze assemblages may hold critical information on Tasmola communities in terms of their material culture, technology, lifestyle, and sociopolitical environments. For this reason, we carried out microstructural and compositional analyses focusing on a number of bronze objects recently excavated from burials, settlements, and ritual sites dating mostly to the Tasmola period, along with some from a few burials dating to the later Korgantas period (Beisenov 2017).

Microscopic investigation of finished bronze objects as intended in this study produces data primarily on microstructure and alloy compositions. The data may then be used to assess the raw materials employed for the production of a given object and the specific conditions of thermal and mechanical treatments applied during its fabrication. This point is important since alloy composition and thermo-mechanical treatments constitute two major aspects defining a particular bronze tradition unique to a region or community during a specific time period. In keeping with the accumulation of such data with varying regional and chronological contexts, one may trace the flow of technological ideas and practices across the spatiotemporal boundaries as well as the occurrence of technological transitions, innovations, and inventions. In historical bronze metallurgy, tin (Sn) and arsenic (As) served as the key alloying elements added intentionally to control material properties such as strength in the solid state and flow properties of molten metals. It should be noted that bronze is a terminology designating the copper-based alloys containing tin as the primary alloying element while its use is often extended to cases involving copper-arsenic alloys. Preparation of a desired bronze alloy using either tin or arsenic was then followed by the manufacture of a finished product in a series of engineering processes consisting of casting and varying thermo-mechanical treatments. In many cases, bronze objects were made exclusively through casting with no notable treatments applied subsequently.

Similar analytical and interpretive research as described above can be found in the work on the ancient bronze tradition in Mongolia (Park et al. 2011, 2017), the results of which have a particular relevance to the bronze assemblage under consideration. The most significant outcome of their analysis was found in the modification of alloy recipes from tin-based to tin, arsenic, or both tin and arsenic-based, which accompanied the LBA to Early Iron Age (EIA) transition. Another important transition was also observed in the frequent use of lead in bronze alloys, reflecting increased influence from China with the rise of the Xiongnu state. Another significant example can be seen in the analytical investigation of copper and bronze objects excavated from the late Andronovo metallurgical sites at Bozshakol (BSK), Sangyru (SAN), and Myrzhyk (MRZ) in Central Kazakhstan (Park et al. 2020). These LBA bronze assemblages revealed notable diachronic changes that occurred in local bronze technology before the dawn of the Early Iron Age. Tin was found to have played an increasingly important role as an alloying element in keeping with the growing dependence on casting for fabrication. This transition was apparently enforced by the rising demand for weapons and ornamental items requiring strict material properties in fabrication and service, which cannot be achieved without the proper alloying practice. The above LBA assemblages, however, provide no evidence of arsenic alloying. The results to be obtained from investigating Tasmola bronze artifacts are therefore expected to provide an invaluable data set for the characterization of the local bronze tradition at that specific time compared with the tradition established earlier at the nearby LBA sites along with that of the roughly contemporary site in Mongolia (Park et al. 2011).

Comments on artifacts and sites

The external appearance of the bronze objects under investigation is illustrated in Fig. 3 where object nos. 1–28 and nos. 29–38 are shown respectively to scale. The objects in the photo were all recovered from burials, with the exception of object no. 13 from a settlement and object nos. 20–24 from architectures constructed for sacrificial purposes. Classification based on external appearance allows the objects in Fig. 3 to be broadly grouped into weapons, specifically a dagger (no. 1) and arrowheads, whether tanged (nos. 2–8) or socketed (nos. 9–12); tools consisting of knives (nos. 13–16) and awls (nos. 17 and 18); horse trappings including bits (nos. 19–21), a cheek piece (no. 22), strap guides (nos. 23 and 24), and a quiver hook (no. 25); human accessories comprising belt holders (nos. 26 and 27) and an ornament (no. 28); and mirrors (nos. 29–38). The artifacts may also be classified as being functional (nos. 1–18), decorative (nos. 26–38), or horse-related (nos. 19–25).

General appearance of the copper-based metal objects under consideration. The numbers identifying the objects are consistent with those in Table 1. Object no. 1 is a dagger, nos. 2–8 tanged arrowheads, nos. 9–12 socketed arrowheads, nos. 13–16 knives, nos. 17 and 18 awls, nos. 19–21 horse bits, no. 22 a cheek piece for a horse, nos. 23 and 24 strap guides for a horse, no. 25 a quiver hook, nos. 26 and 27 human belt holders, no. 28 a human ornament, and nos. 29–38 mirrors. Object nos. 1–28 and nos. 29–38 are shown, respectively, to scale and were excavated from Tasmola and Korgantas sites distributed over fourteen different areas as illustrated in Table 1 and Fig. 1

The bronze assemblage above was the outcome of recent surveys and excavations at one or more Tasmola sites located within each of the thirteen areas at (1) Myrzhyk, (2) Nazar, (3) Kosoba, (4) Akbeyt, (5) Bakybulak, (6) Sarybuirat, (7) Taisogan, (8) Edirei, (9) Karashoky, (10) Birlik, (11) Maykuben, (12) Zhamantas, and (13) Sati, as well as a Korgantas site within the Bidaik area. All sites are located in Central Kazakhstan (Beisenov 2015, 2018). The fourteen areas from which the objects presented in Fig. 3 were excavated are located in Fig. 1, a map showing the distribution of the Tasmola and Korgantas archeological sites, with the inset specifying the region of interest within the territory of Kazakhstan. Most of the sites were burials while the site at Sarybuirat and some at Bakybulak were used as a settlement and a sacrificial construction, respectively. The summary information on the object number, identification, function, and recovery site is provided in the first four columns of Table 1 where the object numbers are given consistently with those in Fig. 3. It should be noted that two or more sites were excavated in the areas at Akbeit, Bakybulak, and Birlik. Of the four different sites in Bakybulak, two were for burials while the other two were for sacrificial architectures. The multiple sites at Akbeit and Birlik were all used as burials. Figure 2 presents a photo showing the overall view of burial mound no. 2 at Kosoba after the removal of the upper vegetable layer. Object nos. 5 and 16 came from this burial. A recent radiocarbon study (Beisenov 2018; Beisenov et al. 2016b) placed the chronology of the Tasmola culture in Central Kazakhstan between the eighth and fifth century BC while the Korgantas phase was dated to the fourth–second century BC.

Microstructure and chemical composition

Metallographic investigation was performed on one or more specimens taken from each of the bronze objects illustrated in Fig. 3. These specimens were mounted and polished following standard metallographic procedures and then etched, where needed, using a solution of 100 ml methyl alcohol, 30 ml hydrochloric acid, and 10 g ferric chloride. The microstructures were examined using an optical microscope and a scanning electron microscope (SEM). The chemical composition was measured using the energy-dispersive X-ray spectrometer (EDS) included with the SEM instrument and specified in weight fraction to within 0.1%. The average composition was inferred from the EDS spectrum taken in a raster mode from an area of approximately 0.65 mm × 0.45 mm, except in cases where restrictions on the specimen size necessitated a smaller area.

Microstructure examination

Figure 4a–f, optical micrographs taken in specimens from object nos. 9, 19, 30, 21, 38, and 31, respectively, illustrate typical structures that may represent those observed in the artifacts examined. Characterization of microstructures usually begins with identification of phases present, followed by the description of each phase in terms of its size, shape, and fraction. In all the micrographs of Fig. 4a–f, the α phase covers most of the area, forming the background where other phases are scattered. The α phase in Fig. 4a takes the form of tree-like dendrites while the bright space between them is filled with a mixture of two different phases, α and δ, though not clearly resolved in the micrograph. In this micrograph, the presence of dendrites, a unique sign of the beginning of a solidification reaction, informs that the specimen was formed through casting. In addition, the presence of the mixed structure between them, named α-δ eutectoid, indicates that the pertinent object was made of copper-tin alloys containing tin by 10% or more. The fraction of eutectoid, which is significant in Fig. 4a, demonstrates that the overall tin level is well above 10%. This estimation based on structure was confirmed by EDS analyses showing the alloy’s tin and arsenic levels to be approximately 18.2% and 0.9%, respectively, on average. It is evident therefore that object no. 9, a socketed arrowhead, was fabricated by casting from the specific copper alloy, with no notable thermo-mechanical treatments applied subsequently.

Optical micrographs. (a)–(f) Micrographs showing the structure of object nos. 9, 19, 30, 21, 38, and 31 presented in Fig. 3, respectively

Figure 4b also illustrates dendrite structures indicative of a solidification reaction, which occurred during the manufacture of object no. 19, a horse bit, by casting. In this micrograph, the dark dendrite areas as well as the bright space between them are filled with the α phase. This contrast noted in the α areas reflects the difference in the amount of alloying elements incorporated during the solidification process where the dendrites first to form contained less alloying elements than the bright areas, which solidified later with solute enrichment. The micrograph shows no indication of other phases present in a notable amount, suggesting that the level of alloying elements added was well below the solubility limit in the α phase. Composition analyses with the EDS confirmed this prediction by showing that on average, the given specimen included 2.0% tin and 2.0% arsenic as alloying elements.

In contrast to the cases of Fig. 4a and b, no dendrites are clearly visible in Fig. 4c. Instead, the entire micrograph is covered with large α grains, which is a sure sign of a prolonged thermal treatment given at relatively high temperatures, causing the initial dendrite structures determined during solidification to disappear. The numerous particles scattered over the α grains, one of which is marked by the arrow, correspond to copper sulfide derived from sulfur contamination during the smelting of copper. EDS analyses showed that the average tin and arsenic contents of the specimen from object no. 30, a mirror, were 6.2% and 0.9%, respectively, while its overall sulfur content was 0.2%. No evidence of mechanical working is visible in Fig. 4c.

The dendritic structures clearly visible in Fig. 4d indicate that object no. 21, another horse bit, was also cast to shape. In contrast to the α-δ eutectoid observed between dendrites in Fig. 4a, however, the inter-dendritic space, as marked by the arrow in Fig. 4d, is filled with a single phase, which is the γ phase of the copper-arsenic system whose arsenic content is in the vicinity of 30% (see Lechtman 1996). The presence of this second phase in such a notable amount in the structure reveals that the overall arsenic concentration of the specimen in question is well above the level the α phase can dissolve. The EDS determined the average tin and arsenic content to be 0.8% and 9.1%, respectively. As in Fig. 4a, b, and c, no sign of any mechanical treatment is visible in Fig. 4d either. Evidently, the pertinent objects were all made similarly, drawing exclusively on casting.

The structure illustrated in Fig. 4e also consists of dark dendrites and the bright space between them. A feature that makes this structure distinguished from those presented above is the waviness clearly visible throughout the entire micrograph. Such a wavy structure emerges in metals and alloys when they are subjected to a significant plastic deformation. A similar mechanical treatment, most probably at relatively low temperatures, must have been given to object no. 38, a mirror, during its fabrication, apparently subsequent to the initial casting to shape where the dendritic structure emerged. In Fig. 4e, both the dendrites and the space between them consist of the α phase for a similar reason mentioned in reference to the structure of Fig. 4b. One exception is found in a number of tiny irregular gray particles imbedded in the inter-dendritic areas, as seen in spots marked by the arrows. These particles are made of the arsenic-rich γ phase similar to those observed in Fig. 4d. The fraction of this γ phase is significantly reduced in Fig. 4e, indicative of a lower arsenic content. The average composition of the specimen in question was determined using the EDS to be 0.6% tin, 4.0% arsenic, 0.7% sulfur, and 0.4% Fe with the remaining balance being copper. It is significant to note that the object in question, a mirror, was subjected to substantial mechanical working applied at low temperatures subsequent to the casting for preliminary shaping.

Figure 4f presents a structure composed of numerous particles of copper sulfide elongated horizontally, taking the form of ribbons against the background consisting of α grains. The background is seen to consist of twinned α grains with numerous fine parallel lines, called slip lines, crossing the α grains. Such twinned α grains constitute a distinctive indication of recrystallization transformation occurring in many metals and alloys, particularly in copper-based alloys. In order for recrystallization to occur, the specimen must be plastically deformed and then given a prolonged heat treatment at relatively high temperatures. The unique structure in Fig. 4f therefore makes it clear that object no. 31, another mirror with an unusually long handle, was given a severe mechanical treatment, most likely at elevated temperatures, upon completion of the initial casting to shape. The elongated ribbon-like sulfide, together with the numerous slip lines, is another indication of the degree of forging as well as the direction of the resulting plastic flow. In addition, the slip lines, still remaining, reveal that the thermal treatment was not sufficient for the recrystallization transformation to be completed. Nevertheless, the combined application of deformation and recrystallization is seen to have led to the complete loss of the structure previously determined during casting. EDS analyses showed that the specimen contained tin by approximately 9.0% without arsenic.

An important observation was made in the investigation of object no. 20, another horse bit. The specimen was found to contain 7.5% arsenic. Its tin content, however, was below the detection limit of the EDS instrument. Figure 5a, an optical micrograph, taken on the as-polished surface of the specimen, shows several minor phases scattered over the entire background of the α phase. For better contrast between the phases present, the micrograph was taken without etching. Arrows A, B, and C indicate some of those representative of three different precipitates. Figure 5b, an EDS spectrum taken from one of the spots marked by arrow A, corresponds to the γ phase of the copper-arsenic system while Fig. 5c, a spectrum from one of those marked by arrow B, represents a phase termed speiss. Speiss, a name referring to the iron arsenide phase, is often precipitated in copper-arsenic alloys with its copper content significantly enhanced. Another group of particles at arrow C of Fig. 5a is made of copper sulfide similar in chemistry to those found in Fig. 4c and f.

Optical micrograph and EDS spectra. (a) Optical micrograph showing the structure of object no. 20 in Fig. 3; (b), (c) EDS spectra taken at arrows A and B, respectively

Alloy composition

The last two columns of Table 1 summarize the compositional and microstructural data obtained following the method described above for the investigation of all the objects under consideration. Most specimens examined were found to include some other minor elements, particularly sulfur, in addition to copper and the two major alloying elements, tin and arsenic. Given the effect of such minor elements being negligible either on structural development or material properties, we will focus mostly on tin and arsenic in the presentation of the composition data. In Table 1, the data entries set in italics were obtained from specimens that were severely corroded, providing no intact areas large enough to produce valid average values from analyses using the EDS. These samples were all found in tin-based copper alloys, frequently containing trace amounts of arsenic. The tin content of such corroded specimens was in general significantly exaggerated, and EDS data could be used only as a reference for estimating the upper limit. In these cases, information from microstructures could be employed as an alternative means for inferring approximate tin concentrations. The tin level thus determined was 10% or above in all the oxidized specimens.

One of the outstanding features in the composition data of Table 1 is that the objects concerned were all made of copper-based alloys containing either tin or arsenic or both. In contrast, no evidence of the use of either lead or unalloyed copper is noted in the data. In most cases, tin served as the major alloying element while arsenic played a key role primarily in the horse-related items (nos. 19–25), with only three objects (nos. 13, 17, and 38) departing from this grouping. Of the 28 tin-based items, 16 contain tin by more than 10.0%. These higher tin objects are mostly found in weapons such as the dagger (no. 1) and arrowheads (nos. 4–6, 8–12) as well as in personal and cosmetic objects such as belt holders (nos. 26 and 27), ornament (no. 28), and some mirrors (nos. 29, 34, and 37). It is significant to note that, of all the domestic tools including the four knives (nos. 13–16) and two awls (nos. 17 and 18), only one (no. 16) was made of alloys containing more than 10% tin. This is in strong contrast to the socketed arrowheads (nos. 9–12) whose tin levels were all above 10.0%. The tin alloying in copper was apparently applied primarily to the fabrication of weapons, not domestic tools. It should also be noted that the profuse use of tin was practiced in making items for human decorations. The mirrors are of special significance in this respect. The relative size, as illustrated in Fig. 3, signifies that even with the tin level determined well below 10%, much more tin was consumed in the fabrication of one such mirror than was used for making a number of arrowheads. Therefore, mirrors must have been highly valued items deserving of having much tin spent in their manufacture.

Another outstanding feature of the composition data is found in the preferential use of arsenic as the major alloying element in all the horse-related metal objects. Arsenic also played a key role in a knife (no. 13), an awl (no. 17), and a mirror (no. 38). In all these arsenic-dominated specimens, the tin concentration is negligible or kept below 3.0%. It is seen that object nos. 20–24, whose arsenic level was set at a particularly high value of 7.5% or above, contain little or no tin. Another fact of interest is noted in objects of relatively higher arsenic content of 1.2% or above. Some of them were made of alloys with a limited amount of tin set well below 10.0%, while some were made of alloys containing tin by more than 10.0%. The addition of arsenic in objects of low tin content may be understood as a means taken to supplement a lack of tin. In the other case where no such arsenic addition was necessary, however, the presence of arsenic must have been the result of contamination that was not intended. Such contamination was most likely introduced inadvertently during the alloying process where arsenic-bearing copper was employed as a raw material to be mixed with tin.

The arsenic level set at 2.5% in object nos. 26 and 37 containing more than 10.0% tin may then be considered the approximate upper limit resulting from such an unintentional arsenic addition. Figure 6, a graphical representation of the combined tin and arsenic concentration versus the tin concentration of the objects listed in Table 1, uses this limit to define the upper boundary of the composition space representing inadvertent arsenic addition. The data points outside this space then correspond to the addition of arsenic that was intended. It is evident that the points clustered near the vertical axis denote objects made of arsenic-based copper alloys with little tin. The points labeled with the pertinent object numbers, however, are included neither in this arsenic-based group nor in the tin-based group. The deviation from either group is particularly significant in point nos. 25 and 35, both of which contain tin and arsenic in amounts that may not have been attained by inadvertent addition. The addition of both alloying elements may have been necessary to compensate for their relatively low tin or arsenic levels, providing another technological choice for the EIA metalworkers.

Graphical illustration of the combined tin and arsenic concentration versus the tin concentration of the objects listed in Table 1. The numbers labeling some of the data points are consistent with those used in Fig. 3 and Table 1. The straight lines define the composition space between tin + 0% arsenic and tin + 2.5% arsenic

Discussion

The bronze tradition described above may be characterized by the use of both casting and mechanical working as a method for fabrication and the implementation of an alloy recipe based on either the copper-tin or copper-arsenic or copper-tin-arsenic system. As implied in the frequent use of significant cold and hot forging, no addition of lead as an alloying element was observed. This particular bronze recipe based on both tin and arsenic without lead is a significant departure from that established in contemporary China based primarily on tin and lead and could serve as a potential indicator measuring the degree of diachronic interaction with China (Park et al. 2011). The lack of use of unalloyed copper is another feature to be noted.

The most conspicuous aspect of the data presented in Table 1 may be found in the discriminated use of tin and arsenic in preparing copper alloys. This observation, when interpreted with appropriate understanding of the effect of tin and arsenic in copper-based alloys, may provide another line of evidence characterizing the lifestyles of EIA Tasmola communities in Central Kazakhstan in terms of their sociopolitical environments and transitions.

Alloying in copper is generally intended to improve mechanical properties, which can be optimized by creating balance between strength and ductility. The decrease in melting temperatures and improved flow properties, necessary to facilitate casting operations, constitute another important benefit achieved through alloying. Furthermore, control of the color characteristics was often a major motivation driving the addition of tin in copper (Lee and Park 2014; Park and Joo 2017). Tin and arsenic in copper have similar effects on alloy strength and melting temperatures. In as-cast conditions, however, tin, when added by approximately 10% or above, is much more effective than arsenic at enhancing the strength of copper-based alloys (Lechtman 1996). Moreover, tin addition in copper induces change of the alloy’s color progressively from red to yellow, producing a visible effect similar to that of gold. Arsenic in as-cast states, however, has only a marginal effect on mechanical properties and produces no significant effect on color characteristics. As such, tin must have been a far more preferred alloying element than arsenic in any and every aspect expected from alloying. The only area in which arsenic can compare with tin is in its effect on lowering the liquidus temperature. For instance, the addition of 6.0% arsenic reduces the temperature by approximately 85 °C.

Therefore, the use of more tin in weapons, mostly above 10.0% but below 15.0% as observed in the composition data of Table 1, should be understood as an effort to improve their functional properties by relying on the superior effect of tin on hardening. Much tin employed in making personal and cosmetic items such as belt holders and mirrors then signifies the value assigned to the effect tin has on color characteristics as well as on properties for improved casting. The profuse use of tin limited to certain critical items, as observed above, suggests that tin was available but not to such an extent as to meet the full demand for bronze. Evidently, weapons, and ornaments were perceived as being highly valuable in Tasmola communities. The stress placed on such items likely reflects the importance of warfare and material symbols for displaying social status. If warfare, as reflected in the value placed on such weapons, points to frequent conflicts between tribes, groups, or communities, the need for status items may then hint at the presence of an influential ruling class dominating a society hierarchically stratified.

Limited access to tin is also demonstrated clearly in object nos. 13–16 (knives). The tin concentration in all except no. 16 was determined to be well below 10.0%, which is optimal for high strength without being brittle. The increased level of arsenic observed in no. 13 may not have been fortuitous but resulted from an intentional addition to make up for the negligible tin content. The perception of tools for domestic use as being less important than ornamental items, as reflected in their low tin content, may constitute another indication of the crucial role played by status items. This suggests a distinguished lifestyle enjoyed by elite groups holding a privileged social status.

The exclusive utilization of arsenic-based copper alloys in the manufacture of horse-related metal articles, clearly visible in the data of Table 1, is significant in many respects. A substantial fraction (slightly over 25%) of the objects in Table 1 were made of arsenic-based alloys, to be used on horses for their exploitation as domesticated animals. This fact underlines the importance and scale of activities involving horses, in perfect agreement with theories (Christian 1998: 124; Honeychurch 2015: 157–183) viewing Central Kazakhstan and South Siberia as the focal points for the beginning of increased steppe mobility around the turn of the first millennium BC and its subsequent diffusion away from these centers. The application of the specific arsenic-based alloy recipe to the fabrication of such specific articles must have been the result of an educated choice, based on the demand for bronze created by increased social mobility and the availability of technological and material resources. The microstructural data in Table 1 demonstrate that the horse-related items were all made exclusively through casting, which is the best method for mass production of such objects with a complex shape. In the process of casting, low melting temperatures and good flow characteristics of alloys employed are critical. In copper-based alloys, the addition of either tin or arsenic can fulfill this requirement. The discussion above, however, confirmed limited access to tin, precluding the possibility of using tin to meet such a large demand. The data in Table 1 show that arsenic was chosen as a viable alternative, satisfying the demand triggered by the transition in steppe lifeways toward intensified dependence on horses.

The context in which arsenic was employed in EIA Tasmola communities is unique in two respects. First, the addition of arsenic as the major alloying element in copper constituted a new era, which began with the coming of the Iron Age in Central Kazakhstan. This fact is confirmed in analytical studies on bronze objects from certain LBA sites such as at Bozshakol, Sangyru, and Myrzhyk (Park et al. 2020), all within the territorial boundary of Central Kazakhstan (Fig. 1). Another fact of significance is the unusually high level of arsenic added to copper, up to around 10.0%, which allows γ particles to be precipitated as a second phase in their microstructures, often accompanied by the formation of speiss particles. The presence of speiss particles is seen to enable detection of iron primarily in objects made of arsenic-based copper alloys (see Table 1), which was also observed in an assemblage from the royal Xiongnu burial at Golmod 2 in Mongolia (Park et al. 2017). Little is known of the exact method employed for the production of such high arsenic alloys, though a few plausible processes were proposed (Lechtman and Klein 1999; Rehren et al. 2012). At the moment, it is unclear whether the particular method, as yet to be uncovered, represented a newly introduced practice or one already in existence that was revived to meet an increased demand. In any case, there is little doubt that arsenic as a source material and pertinent technologies for its alloying in copper were readily available to such an extent as to satisfy the full demand created in association with increased activities involving horses. A lack of objects made of unalloyed copper, evident in Table 1, is another indication of the ample availability of alternative alloying materials apparently made possible by the use of arsenic.

It is intriguing to note in Table 1 the intimate connection between social and technological transitions reflected in the artifact composition and the microstructure and chemical composition of the various metal objects examined. In the technological environment under consideration where a tin-based bronze tradition was fully established to meet most small-scale production, an insignificant and occasional demand would have provided little incentive to the pursuit of new methods that could supplement or replace one already in practice. The implementation of a new arsenic-based alloy recipe evident in Table 1, therefore, signifies the rise of a substantial demand for certain items. In the course of adopting this new alloy method, the effectiveness of arsenic, especially at facilitating casting, must have been taken into account along with the necessity of casting to be employed as an exclusive technique for making the desired items. The rise of such a large-scale demand for the particular type of objects suggests that with the coming of the EIA, the role of horseback activities became increasingly more important in the everyday life of steppe inhabitants. Given the significance of mobility in the steppe, increased activities on horseback must have signified a social and political transformation, one so significant as to entail a technological transition involving the introduction of a new arsenic-based alloy method.

Conclusion

An artifact assemblage comprised of various bronze objects recovered from many EIA sites of the Tasmola and Korgantas phases of Central Kazakhstan, dating in recent radiocarbon measurements (Beisenov 2018; Beisenov et al. 2016b) to the eighth–fifth and fourth–second century BC, respectively, was investigated for microstructure and alloy composition. Results showed that tin and arsenic played a key role as the major alloying elements, with their application being clearly discriminated between weapons, personal and cosmetic items, domestic tools, and horse trappings. The profuse use of tin was applied only to the making of weapons, especially arrowheads, and prestige items such as mirrors and buckles. The superior effect of tin on the hardening of bronze alloys, particularly in as-cast conditions, and its beneficial effect on alloy color characteristics must have been critical determining the amount of tin to be utilized for such articles. Despite their importance as functional items, most knives for domestic use were made of low tin alloys. Such a distinction found in tin concentrations is a clear indication of limited access to tin and, at the same time, underscores the importance of prestige items as a status symbol or gift.

In strong contrast, all the horse-related articles examined were made of arsenic-based copper alloys of high arsenic concentration. This arsenic-based alloy recipe, rarely observed in local Bronze Age objects, may be regarded as a transition accompanying the rise of iron technology in Central Asia. This suggests a probable connection between the technological and social changes. Limited access to tin, as discussed above, must have necessitated this technological transition. On the other hand, the scale of demand for such products should be large enough to justify the investment in technology and materials required for the implementation and dissemination of such a new technique. Incidentally, arsenic is particularly effective at facilitating casting, which constitutes the most appropriate method for the fabrication of horse accessories. In retrospect, the transition was made possible by the large-scale demand for horse-related items, as inferred from the artifact makeup in Table 1, and the necessity of casting to be employed for their mass production, which was greatly facilitated by the addition of arsenic.

The key findings in this study include the special emphasis put on arrowheads, the importance of status items, and the implementation of a new alloy recipe to meet the need for large-scale production of horse-related objects. These facts, when integrated, provide a coherent and self-sufficient illustration of certain aspects of the social and political settings surrounding EIA communities in Central Kazakhstan. Warfare, as reflected in the mass recovery of quality arrowheads, is indicative of frequent conflicts between steppe tribes or groups. In addition to the coming of a mature nomadic lifestyle, signs of increased mobility as inferred from the large-scale demand for horse trappings may then be understood as pointing to the intensified degree of conflict in terms of the number of people mobilized and the territorial extent they covered. Fighting on horseback, equipped with small but powerful composite re-curved bows able to shoot bronze arrowheads (Christian 1998:126; Park et al. 2011), may have played a crucial role in combat. Moreover, mobilization of large-scale combat forces likely involved significant tribal as well as intertribal politics and social structures with a distinction between leaders and followers. This led to the establishment of socially stratified communities as implied in the importance of status items evident in Table 1. While serving as a sign of greatly expanding interactive networks owing to increased mobility, long-distance articles recovered together with some of the objects under investigation (Beisenov 2015) highlight the need for exotic items in strengthening such a leadership position and solidarity between alliances.

References

Beisenov A (2013) Die nekropole Taldy-2 in beziehung zu den kulturen der fruhsakishen zeit osteurasiens. In: Unbekanntes Kasachstan. Archaolgie im Herzen Asiens. II. Bochum, pp 595–608 (in German)

Beisenov A (2014) Results of new researches of the Sak time in Central Kazakhstan. In: International academic conference on cultural exchange between Korea and Altai regions. Bundang, Korea, pp 147–167

Beisenov A (2015) Settlements and burial grounds of Central Kazakhstan. In: Saka culture of Saryarka in the context of the study of ethno-sociocultural processes of Steppe Eurasia. Collection of scientific articles dedicated to the memory of archaeologist K. Akishev. Research center of history and archeology “Begazy-Tasmola,” Almaty, pp 11–38 (in Russian)

Beisenov A (2017) Korgantas burials in Central Kazakhstan. In: Actual problems of archeology and ethnology of Central Asia: materials of the II International Scientific Conference dedicated to the 80th anniversary of Professor P.B. Konovalov (Ulan-Ude, December 4–6, 2017). Publishing House of the BNTS SB RAS, Ulan-Ude, pp 103–108 (in Russian)

Beisenov AZ (2018) Tasmola culture of Central Kazakhstan in studies of the beginning of the XXI century. Archeology Anc Hist Ukraine 2(27):386–396 (in Russian)

Beisenov A, Ismagulova AO, Kitov EP, Kitova AO (2015) The population of Central Kazakhstan in 1 thousand BC. Institute of Archeology. A.H. Margulan; Research Center of history and archeology “Begazy-Tasmola,” Almaty (in Russian)

Beisenov A, Duisenbai D, Akhiyarov I, Sargizova G (2016a) Dromos burials of Tasmola culture in Central Kazakhstan. Anthropologist 26(1–2):25–33

Beisenov A, Svyatko SV, Kassenalin AE, Zhambulatov KA, Duisenbai D, Reimer PJ (2016b) First radiocarbon chronology for the Early Iron Age sites of Central Kazakhstan (Tasmola culture and Korgantas period). Radiocarbon 58(1):179–191

Beisenov A, Shulga PI, LomanVG (2017) Settlements of Saka era. Research center of history and archeology “Begazy-Tasmola.” Almaty (in Russian)

Berdenov SA (2008) Kazakhstan deposits of copper and tin and their development in the Bronze Age). In: News of the National Academy of Sciences of the Republic of Kazakhstan. Series of social sciences. 1: pp 42–55 (in Russian)

Chang C (2018) Rethinking prehistoric Central Asia: shepherds, farmers, and nomads (Asian states and empires), 1st edn. Routledge, New York

Christian D (1998) A history of Russia, Central Asia and Mongolia, volume I, inner Eurasia from prehistory to the Mongol empire. Blackwell Publishing, Oxford

Honeychurch W (2015) Inner Asia and the spatial politics of empire: archaeology, mobility, and culture contact. Springer Publications, New York

Kadyrbaev MK (1996) Monuments of Tasmola culture. In: Margulan AK, Akishev KA, Kadyrbaev MK, Orazbayev AM (eds) Ancient culture of Central Kazakhstan. Nauka, Alma-Ata, pp 303–433 (in Russian)

Lechtman H (1996) Arsenic bronze: dirty copper or chosen alloy? A view from the Americas. J Field Archaeol 23:477–514

Lechtman H, Klein S (1999) The production of copper-arsenic alloys (arsenic bronze) by cosmelting: modern experiment, ancient practice. J Archaeol Sci 26:497–526

Lee JS, Park JS (2014) Effect of changes on color characteristics by microstructural transformations of Cu-Sn bronzes. J Conserv Sci 30(4):417–425

Park JS, Joo JO (2017) The social implications of technological variability as observed in high tin bronze objects of the Unified Silla. Korean J Met Mater 55(10):745–751

Park JS, Honeychurch W, Chunag A (2011) Ancient bronze technology and nomadic communities of the middle Gobi desert, Mongolia. J Archaeol Sci 38:805–817

Park JS, Diimaajav E, Gelegdorj E (2017) Evolution of Mongolian bronze technology with the rise of the Xiongnu state. Archaeol Anthropol Sci 9:789–798

Park JS, Voyakin D, Beisenov A (2020) The implication of diachronic changes reflected in LBA bronze assemblages of Central Kazakhstan. Archaeol Anthropol Sci. https://doi.org/10.1007/s12520-019-00989-z

Rehren T, Boscher L, Pernicka E (2012) Large scale smelting of speiss and arsenical copper at Early Bronze Age Arisman, Iran. J Archaeol Sci 39:1717–1727

Yablonsky LT (1995) The material culture of the Saka and historical reconstruction. In: Davis-Kimball JD, Bashilov VA, Yablonsky LT (eds) Nomads in Eurasian steppes in the Early Iron Age. Zinat Press, Berkley, pp 202–238

Acknowledgments

This work would not have been possible without the generous support of the scholars in the Margulan Institute of Archaeology in Almaty, Kazakhstan. We express our special gratitude to Mr. Islam Akhiyarov for his kind support throughout the work. The preparation of this manuscript was done while one of the authors (JSP) was a visiting scholar at the School of Anthropology, University of Arizona. Mr. Jason Buschman is acknowledged for his linguistic assistance with this manuscript.

Funding

The analysis and research presented were financially supported by the National Research Foundation of Korea (NRF-2017R1A2B4002082).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Park, JS., Beisenov, A. & Voyakin, D. The technological and social implication of the discriminated use of tin and arsenic noted in EIA copper-based objects of Central Kazakhstan. Archaeol Anthropol Sci 12, 81 (2020). https://doi.org/10.1007/s12520-020-01036-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12520-020-01036-y